Analysis of Particle Size Distribution of Coke on Blast Furnace Belt Using Object Detection

Abstract

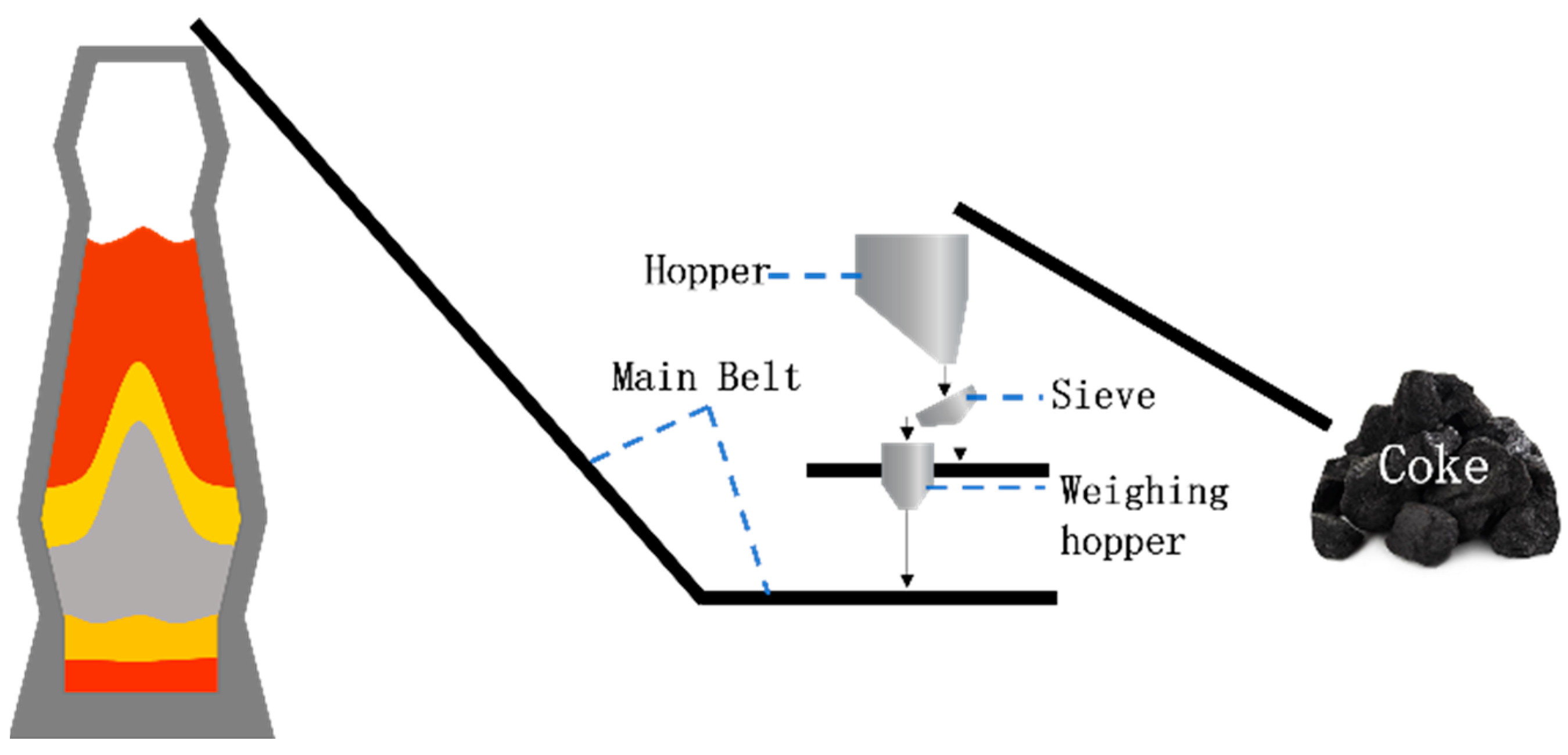

:1. Introduction

2. Materials and Methods

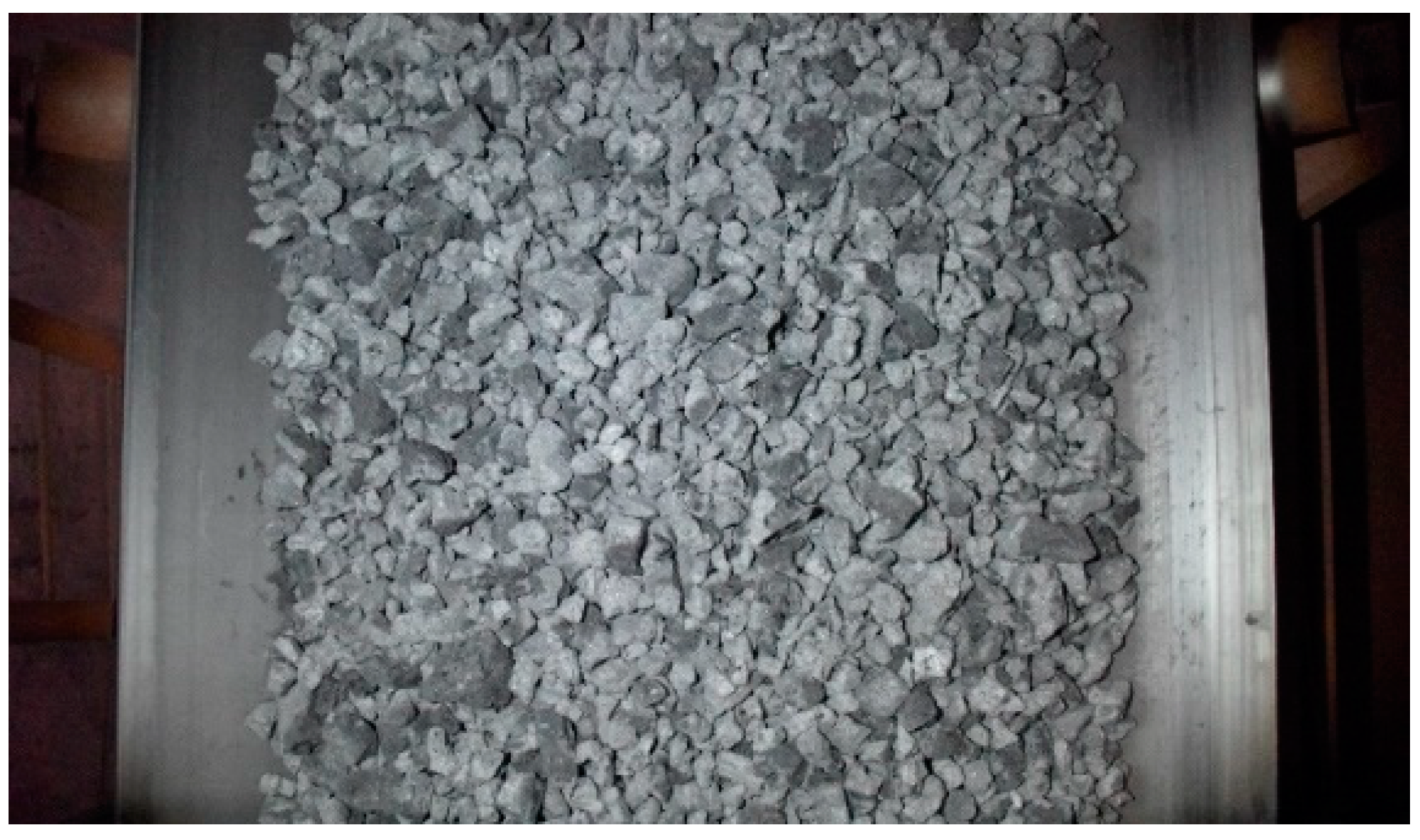

2.1. Data Acquisition

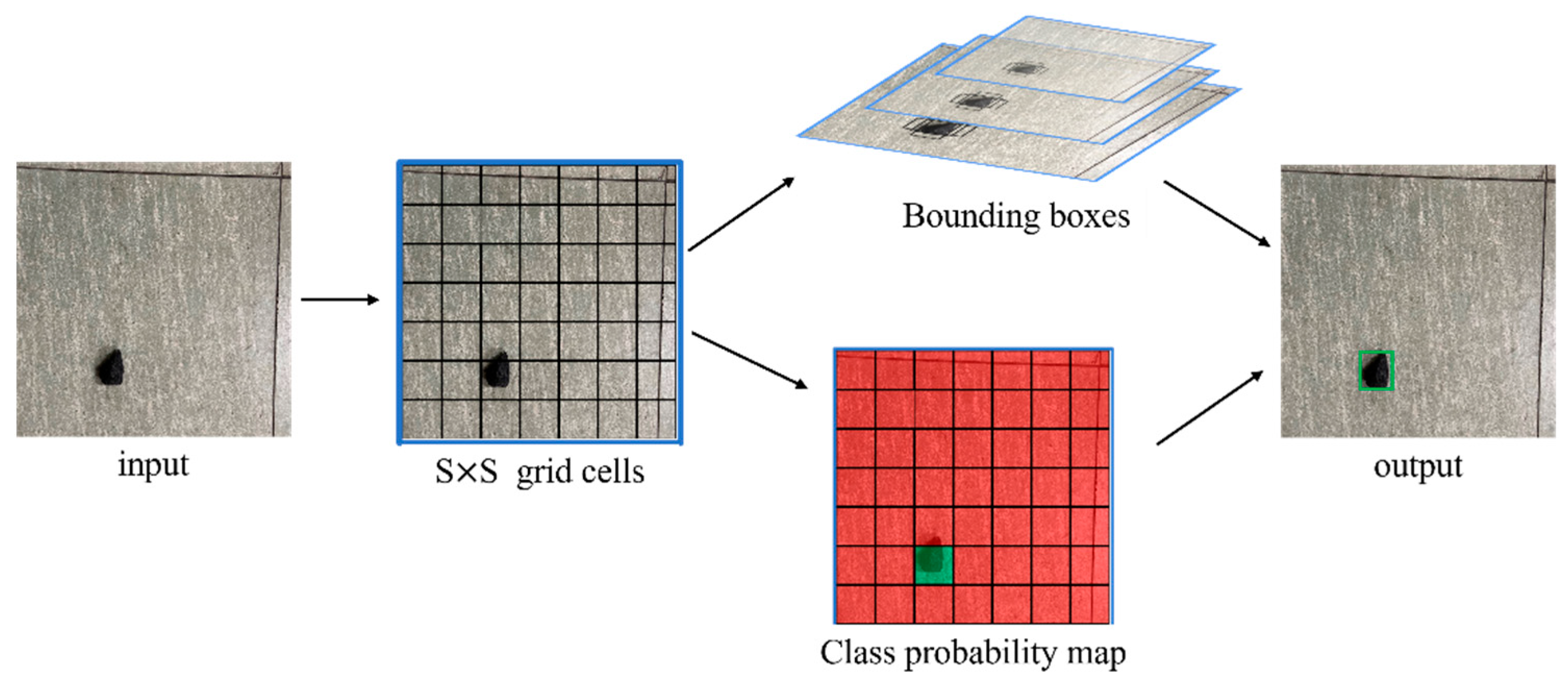

2.2. Coke Particle Detection Model

2.2.1. YOLOv3

2.2.2. Data Preparation and Model Training

2.2.3. Evaluating Indicator

2.3. Particle Size Statistics

2.3.1. Particle Size Measurement

2.3.2. Size Conversion

2.3.3. PSD Calculation

2.3.4. PSD Correction

3. Results and Discussion

3.1. Data Analysis

3.2. Model Development and Evaluation

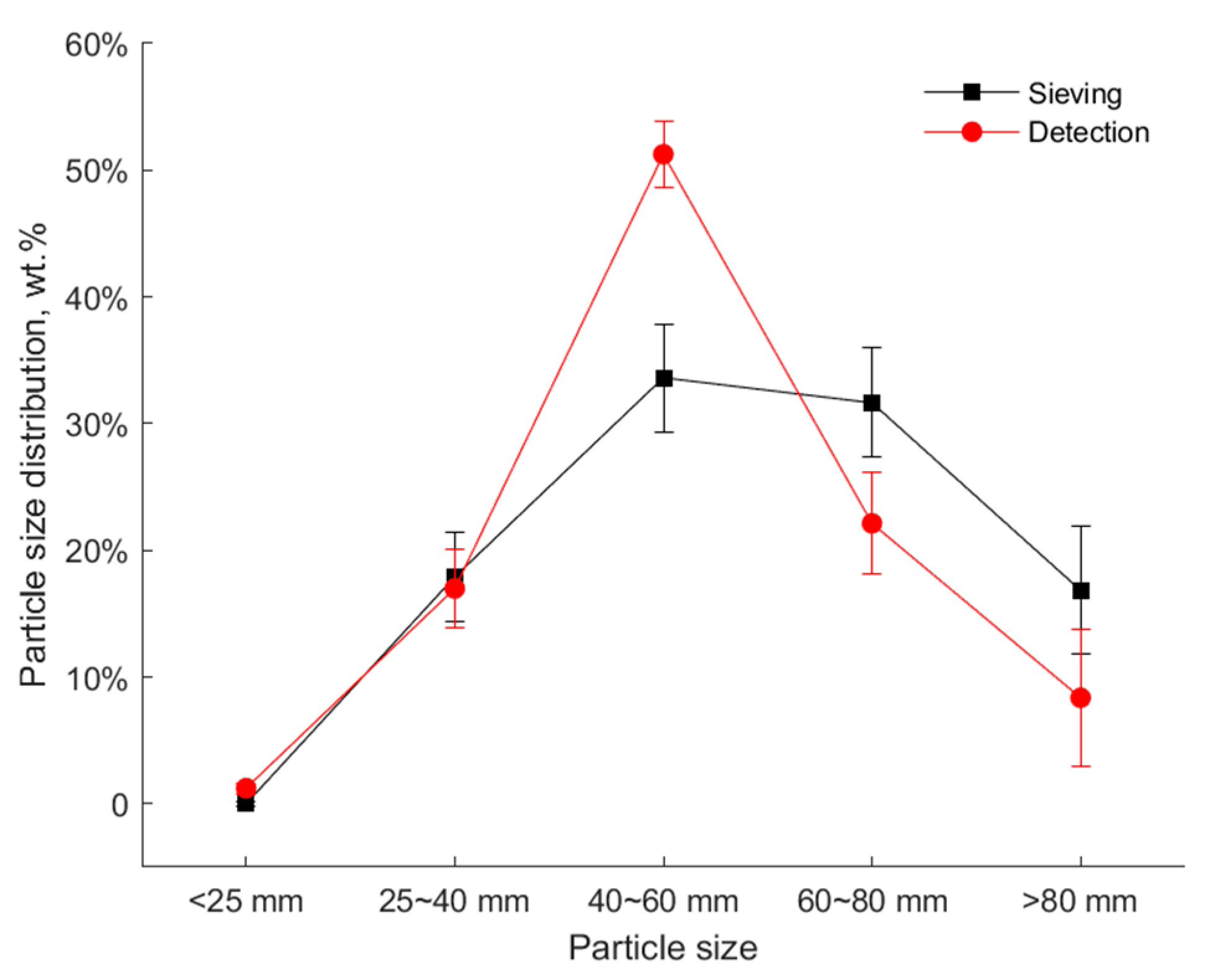

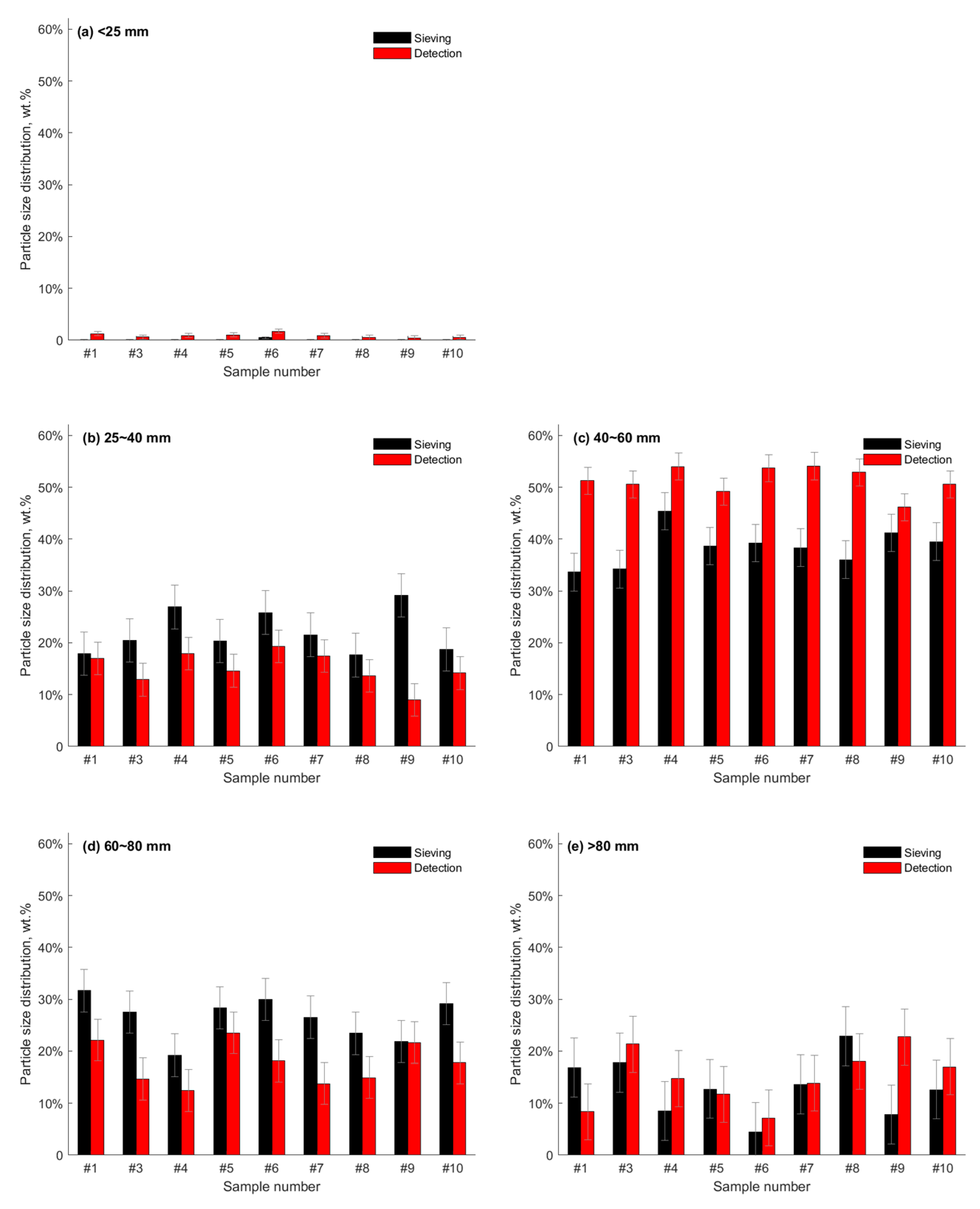

3.3. PSD Statistics

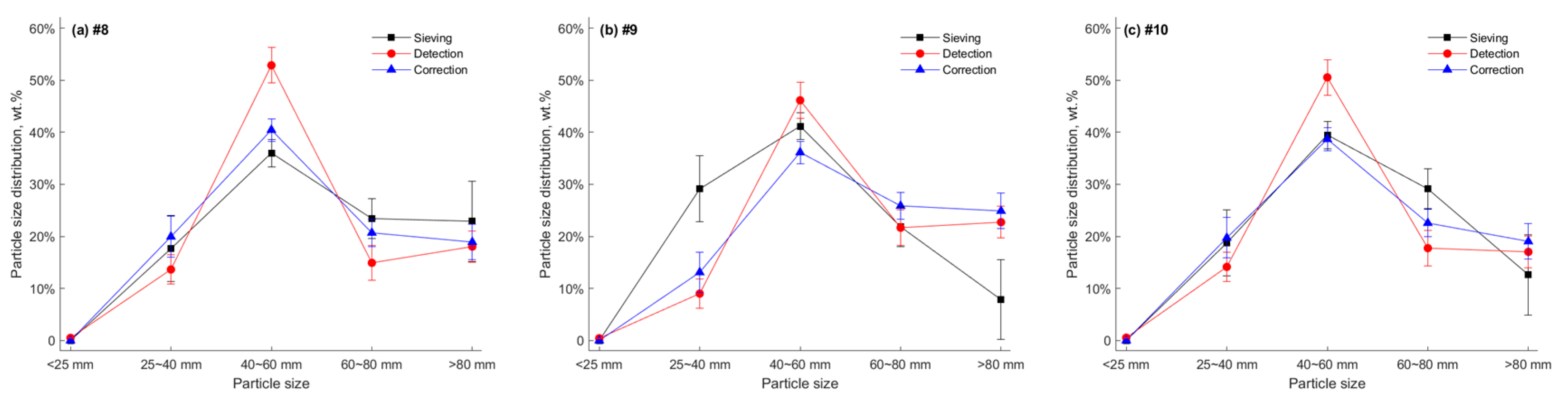

3.4. Data Acquisition PSD Error Correction

3.5. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Díez, M.A.; Alvarez, R.; Barriocanal, C. Coal for metallurgical coke production: Predictions of coke quality and future requirements for cokemaking. Int. J. Coal Geol. 2002, 50, 389–412. [Google Scholar] [CrossRef]

- Fernlund, J.M.R. The effect of particle form on sieve analysis: A test by image analysis. Eng. Geol. 1998, 50, 111–124. [Google Scholar] [CrossRef]

- Liang, G.; Dong, C.; Hu, B.; Zhu, H.; Yuan, H.; Jiang, Y.; Hao, G. Prediction of Moisture Content for Congou Black Tea Withering Leaves Using Image Features and Nonlinear Method. Sci. Rep. 2018, 8, 7854. [Google Scholar] [CrossRef] [PubMed]

- Bai, F.; Fan, M.; Yang, H.; Dong, L. Image segmentation method for coal particle size distribution analysis. Particuology 2021, 56, 163–170. [Google Scholar] [CrossRef]

- Jemwa, G.T.; Aldrich, C. Estimating size fraction categories of coal particles on conveyor belts using image texture modeling methods. Expert Syst. Appl. 2012, 39, 7947–7960. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, J.; Ding, L.; Zhao, Y. An improved estimation of coal particle mass using image analysis. Powder Technol. 2012, 229, 178–184. [Google Scholar] [CrossRef]

- Gorai, A.K.; Raval, S.; Patel, A.K.; Chatterjee, S.; Gautam, T. Design and development of a machine vision system using artificial neural network-based algorithm for automated coal characterization. Int. J. Coal Sci. Technol. 2021, 8, 737–755. [Google Scholar] [CrossRef]

- Başyiğit, M.; Özer, S.C.; Fişne, A. The relationship between coal surface chromaticity and coal quality parameters: A preliminary investigation. Int. J. Coal Prep. Util. 2021, 1–16. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, J.; Wang, Y.; Dou, D.; Xia, W. Ash content prediction of coarse coal by image analysis and GA-SVM. Powder Technol. 2014, 268, 429–435. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Y.; Hu, Q.; Zhang, Z.; Wang, L.; Liu, X.; Xia, X. Multi-information online detection of coal quality based on machine vision. Powder Technol. 2020, 374, 250–262. [Google Scholar] [CrossRef]

- Qiu, Z.; Dou, D.; Zhou, D.; Yang, J. On-line prediction of clean coal ash content based on image analysis. Measurement 2021, 173, 108663. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, J.; Su, X.; Ding, L.; Wang, Y. Multi-scale image segmentation of coal piles on a belt based on the Hessian matrix. Particuology 2013, 11, 549–555. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.; Liu, X.; Wang, L.; Xia, X. Efficient image segmentation based on deep learning for mineral image classification. Adv. Powder Technol. 2021, 32, 3885–3903. [Google Scholar] [CrossRef]

- Olivier, L.E.; Maritz, M.G.; Craig, I.K. Estimating ore particle size distribution using a deep convolutional neural network. IFAC-Pap. 2020, 53, 12038–12043. [Google Scholar] [CrossRef]

- Hamzeloo, E.; Massinaei, M.; Mehrshad, N. Estimation of particle size distribution on an industrial conveyor belt using image analysis and neural networks. Powder Technol. 2014, 261, 185–190. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, J.; Ding, L.; Zhao, Y. Estimation of coal particle size distribution by image segmentation. Int. J. Min. Sci. Technol. 2012, 22, 739–744. [Google Scholar] [CrossRef]

- Shrivastava, S.; Deb, D.; Bhattacharjee, S. Prediction of Particle Size Distribution Curves of Dump Materials Using Convolutional Neural Networks. Rock Mech. Rock Eng. 2022, 55, 471–479. [Google Scholar] [CrossRef]

- Yaghoobi, H.; Mansouri, H.; Ebrahimi Farsangi, M.A.; Nezamabadi-Pour, H. Determining the fragmented rock size distribution using textural feature extraction of images. Powder Technol. 2019, 342, 630–641. [Google Scholar] [CrossRef]

- Sinaice, B.B.; Owada, N.; Saadat, M.; Toriya, H.; Inagaki, F.; Bagai, Z.; Kawamura, Y. Coupling NCA dimensionality reduction with machine learning in multispectral rock classification problems. Minerals 2021, 11, 846. [Google Scholar] [CrossRef]

- Perez, C.A.; Saravia, J.A.; Navarro, C.F.; Schulz, D.A.; Aravena, C.M.; Galdames, F.J. Rock lithological classification using multi-scale Gabor features from sub-images, and voting with rock contour information. Int. J. Miner. Process. 2015, 144, 56–64. [Google Scholar] [CrossRef]

- Biran, O.; Cotton, C. Explanation and Justification in Machine Learning: A Survey. IJCAI-17 2017, 8, 8–13. [Google Scholar]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef] [PubMed]

- Ching, T.; Himmelstein, D.S.; Beaulieu-Jones, B.K.; Kalinin, A.A.; Do, B.T.; Way, G.P.; Ferrero, E.; Agapow, P.; Zietz, M.; Hoffman, M.M.; et al. Opportunities and obstacles for deep learning in biology and medicine. J. R. Soc. Interface 2018, 15, 1742–5662. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Zhang, C.; Liu, F.; Qiu, Z.; He, Y. Application of Deep Learning in Food: A Review. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1793–1811. [Google Scholar] [CrossRef]

- Kamilaris, A.; Prenafeta-Boldú, F.X. Deep learning in agriculture: A survey. Comput. Electron. Agric. 2018, 147, 70–90. [Google Scholar] [CrossRef]

- Fu, L.; Xu, X.; Jin, F.; Zhou, H. Evaluation of the particle size distribution of on-site rockfill using mask R-CNN deep learning model. In Proceedings of the 2021 7th International Conference on Hydraulic and Civil Engineering & Smart Water Conservancy and Intelligent Disaster Reduction Forum (ICHCE & SWIDR), Nanjing, China, 6 November 2021. [Google Scholar] [CrossRef]

- Duan, J.; Liu, X.; Wu, X.; Mao, C. Detection and segmentation of iron ore green pellets in images using lightweight U-net deep learning network. Neural Comput. Appl. 2020, 32, 5775–5790. [Google Scholar] [CrossRef]

- Li, D.; Wang, G.; Zhang, Y.; Wang, S. Coal gangue detection and recognition algorithm based on deformable convolution YOLOv3. IET Image Process. 2022, 16, 134–144. [Google Scholar] [CrossRef]

- Mora, C.F.; Kwan, A.K.H.; Chan, H.C. Particle Size Distribution Analysis of Coarse Aggregate Using Digital Image Processing. Cem. Concr. Res. 1998, 28, 921–932. [Google Scholar] [CrossRef]

- Chen, X.; Liu, F.; Hou, Q.; Lu, Y. Industrial high-temperature radar and imaging technology in blast furnace burden distribution monitoring process. In Proceedings of the 2009 9th International Conference on Electronic Measurement & Instruments, Nanjing, China, 16–19 August 2009. [Google Scholar] [CrossRef]

- Redmon, J.; Farhadi, A. YOLOv3: An Incremental Improvement. arXiv 2018, arXiv:1804.02767. [Google Scholar]

- Li, M. Analysis of Particle Size Distribution Based on Deep Learning and Study of Coke’s Moisture. Master’s Thesis, Shanghai University, Shanghai, China, 2021. [Google Scholar]

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You Only Look Once: Unified, Real-Time Object Detection. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Seattle, WA, USA, 27–30 June 2016. [Google Scholar] [CrossRef] [Green Version]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Seattle, WA, USA, 27–30 June 2016. [Google Scholar] [CrossRef]

- PaddlePaddle. 2021. Available online: https://github.com/PaddlePaddle/Paddle (accessed on 1 June 2021).

- Bernhardt, I.C.B. Particle Size Analysis: Classification and Sedimentation Methods; Chapman & Hall: London, UK, 1994; pp. 197–239. [Google Scholar]

- MATLAB. MATLAB (R2021b), (version 9.11.0); Windows; The MathWorks Inc.: Natick, MA, USA, 2021. [Google Scholar]

- Kim, H.; Haas, C.T.; Rauch, A.F.; Browne, C. 3D image segmentation of aggregates from laser profiling. Comput.-Aided Civ. Infrastruct. Eng. 2003, 18, 254–263. [Google Scholar] [CrossRef]

- Zhang, Z. Particle overlapping error correction for coal size distribution estimation by image analysis. Int. J. Miner. Process. 2016, 155, 136–139. [Google Scholar] [CrossRef]

- Liao, C.W.; Tarng, Y.S. On-line automatic optical inspection system for coarse particle size distribution. Powder Technol. 2009, 189, 508–513. [Google Scholar] [CrossRef]

| GPU | Video Mem | CPU | RAM | Disk |

|---|---|---|---|---|

| Tesla V100 | 16 GB | 4 Cores | 32 GB | 100 GB |

| Particle Size | Correction Coefficient |

|---|---|

| <25 mm | 3.24 |

| 25~40 mm | 1.04 |

| 40~60 mm | 0.91 |

| 60~80 mm | 1.06 |

| >80 mm | 0.96 |

| Group | #8 | #9 | #10 |

|---|---|---|---|

| Detection | 6.9% | 8.1% | 6.4% |

| Correction | 2.7% | 8.4% | 3.0% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Wang, X.; Yao, H.; Saxén, H.; Yu, Y. Analysis of Particle Size Distribution of Coke on Blast Furnace Belt Using Object Detection. Processes 2022, 10, 1902. https://doi.org/10.3390/pr10101902

Li M, Wang X, Yao H, Saxén H, Yu Y. Analysis of Particle Size Distribution of Coke on Blast Furnace Belt Using Object Detection. Processes. 2022; 10(10):1902. https://doi.org/10.3390/pr10101902

Chicago/Turabian StyleLi, Meng, Xu Wang, Hao Yao, Henrik Saxén, and Yaowei Yu. 2022. "Analysis of Particle Size Distribution of Coke on Blast Furnace Belt Using Object Detection" Processes 10, no. 10: 1902. https://doi.org/10.3390/pr10101902

APA StyleLi, M., Wang, X., Yao, H., Saxén, H., & Yu, Y. (2022). Analysis of Particle Size Distribution of Coke on Blast Furnace Belt Using Object Detection. Processes, 10(10), 1902. https://doi.org/10.3390/pr10101902