Perspectives on the Current State of Bioprinted Skin Substitutes for Wound Healing

Abstract

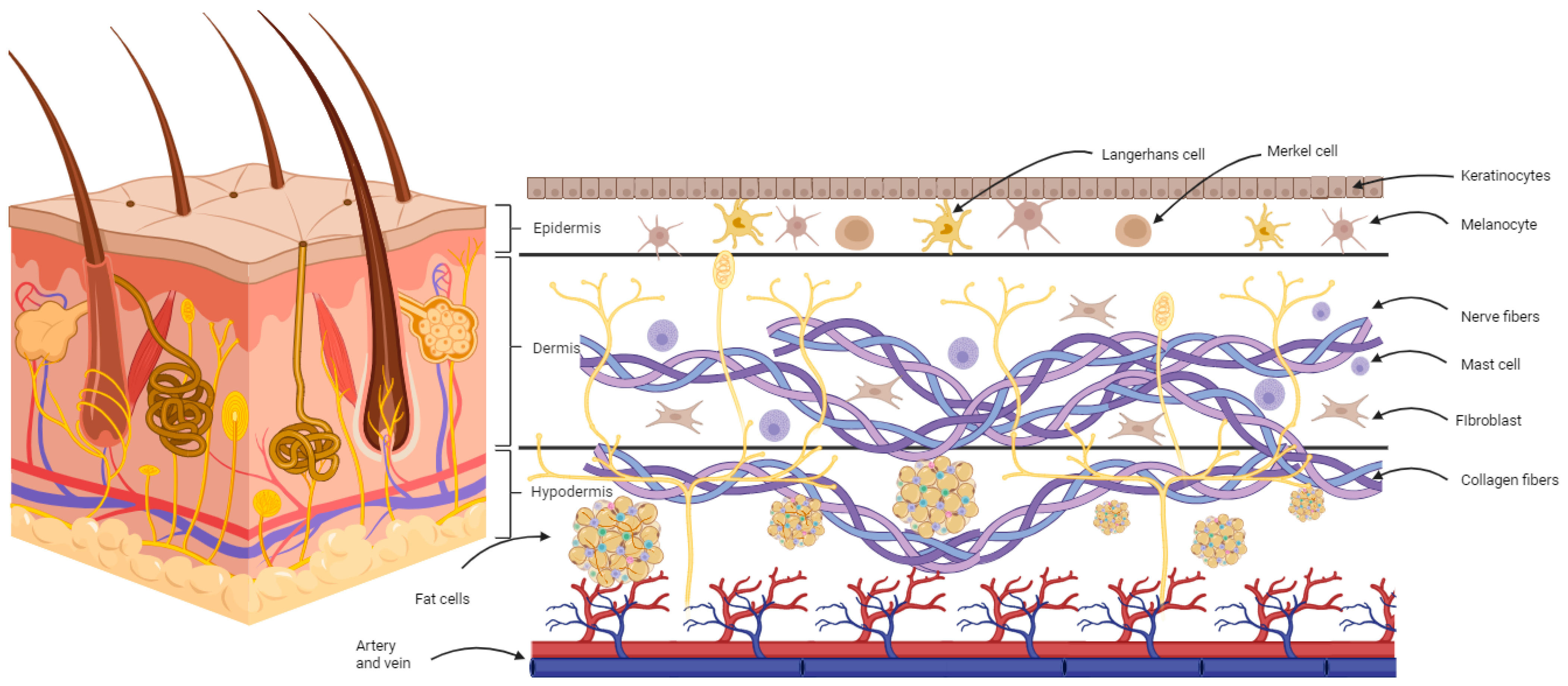

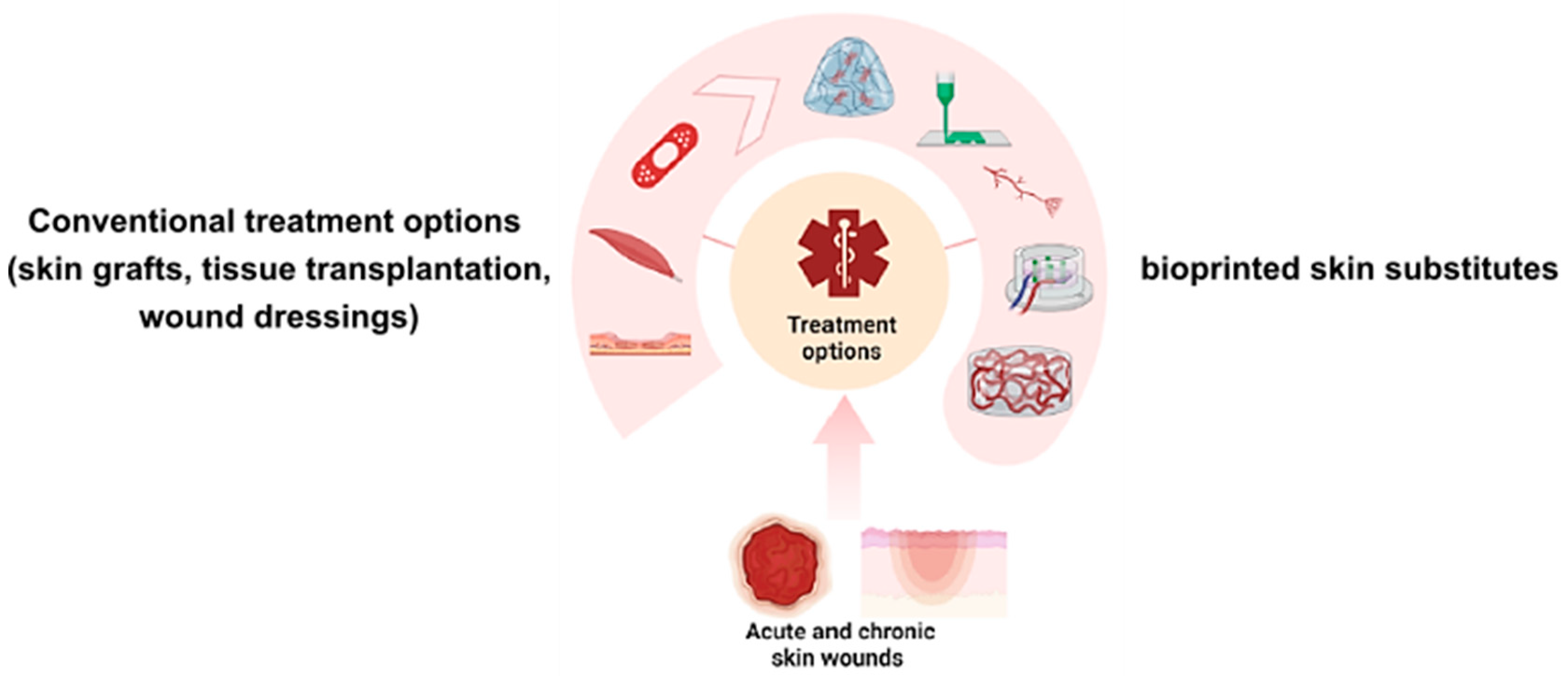

:1. Introduction

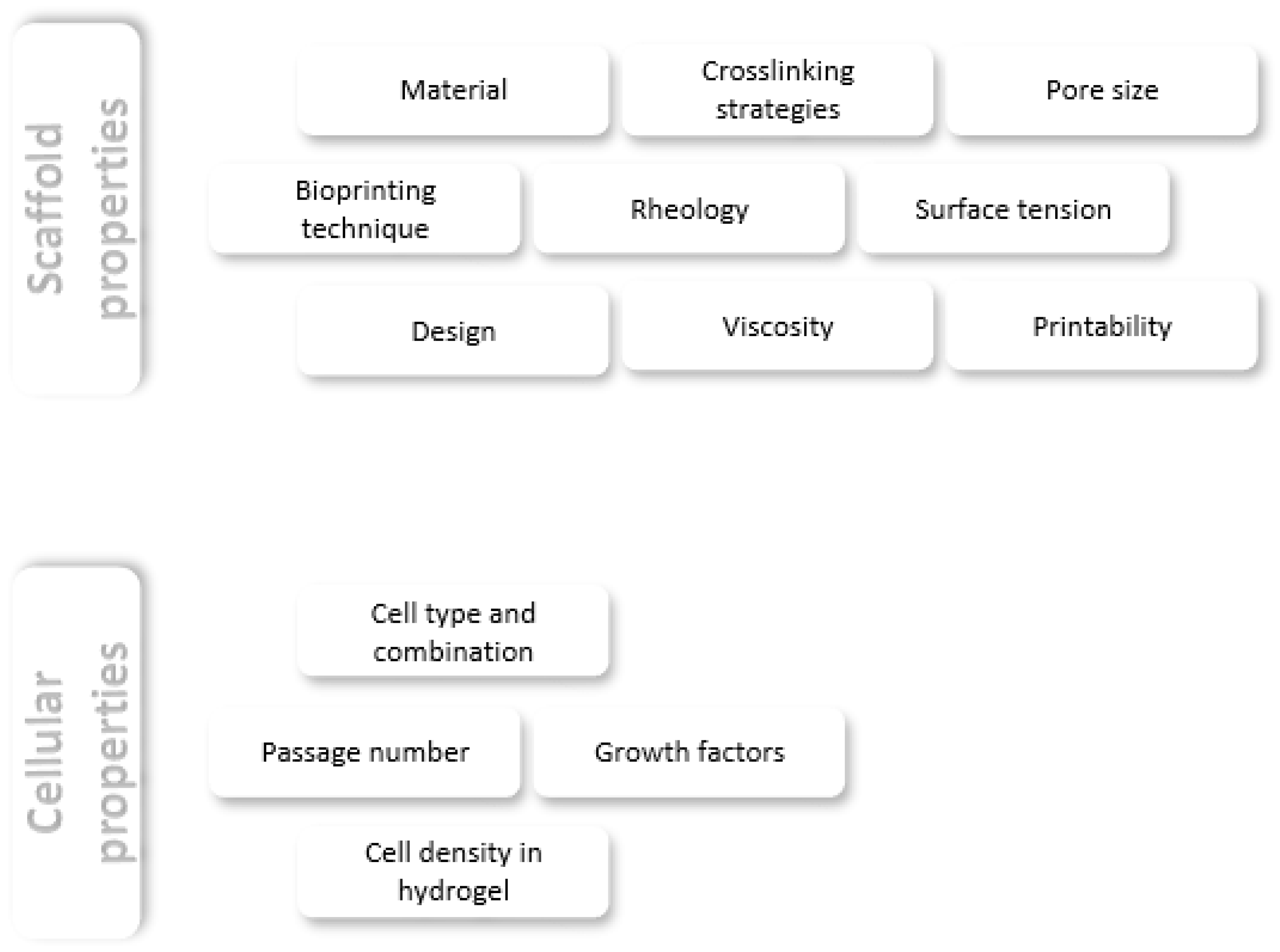

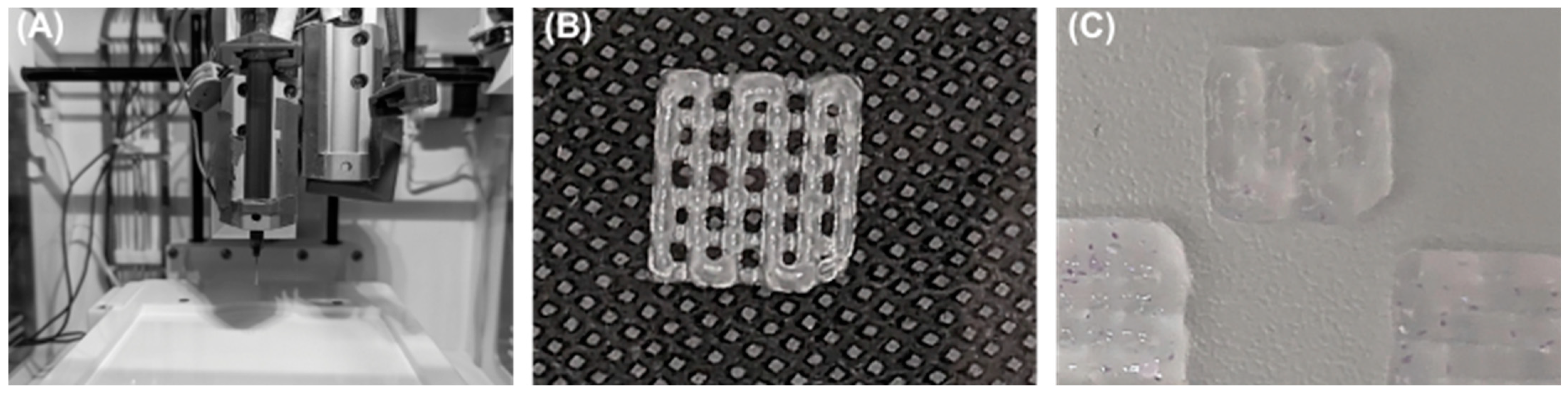

2. Bioprinting Technique

3. Biomaterials

4. Cell Types

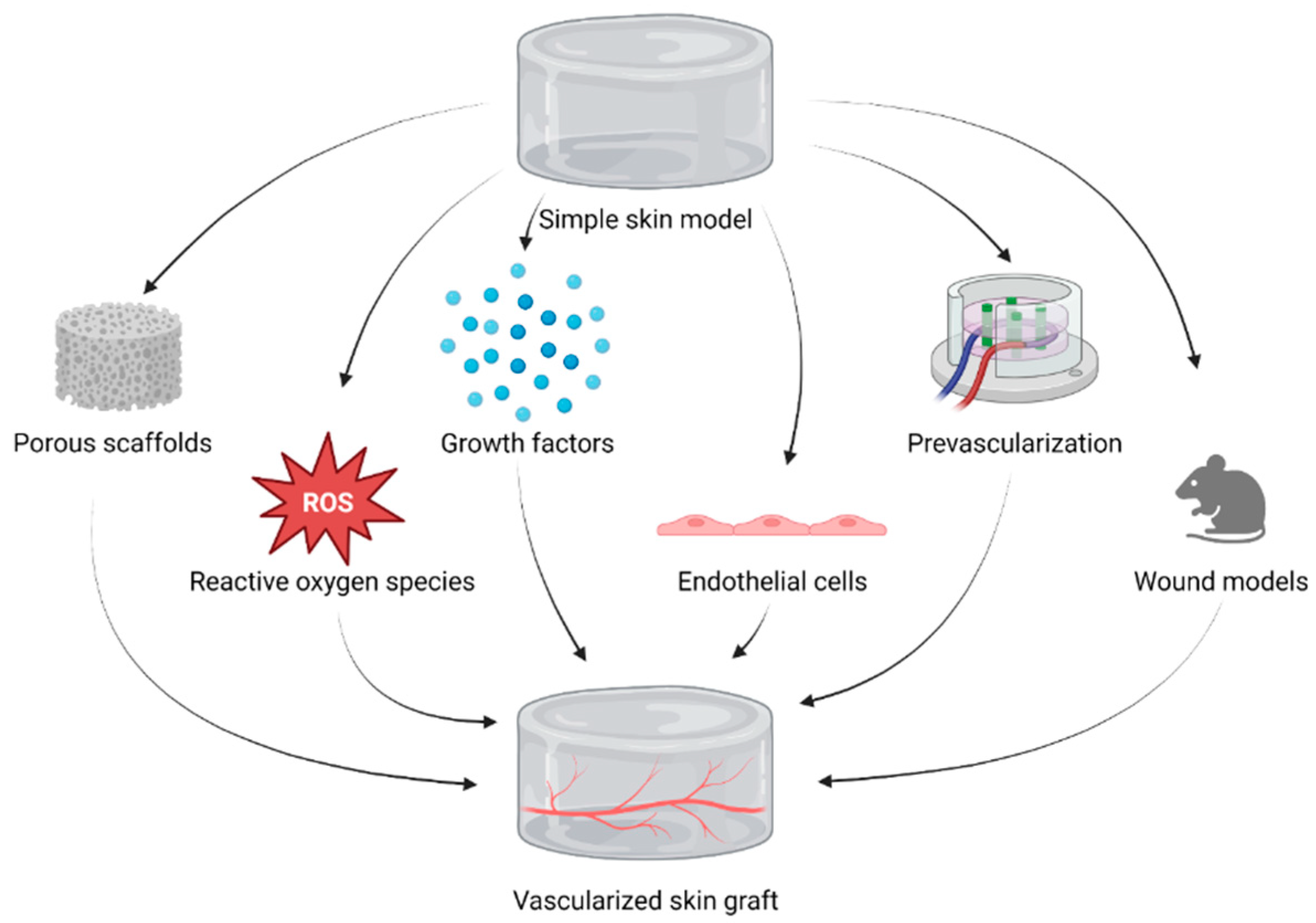

5. Vascularization Strategies

6. Challenges and Limitations in the Clinical Application of Bioprinted Constructs as Skin Graft Substitutes

7. Comparison to Other Methods for Bioengineered Skin Graft Fabrication and Current Clinical and Experimental Applications

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Potten, C.S.; Booth, C. Keratinocyte stem cells: A commentary. J. Investig. Dermatol. 2002, 119, 888–899. [Google Scholar] [CrossRef] [PubMed]

- Li, W.J.; Zhan, P.; De Clercq, E.; Lou, H.; Liu, X. Current drug research on PEGylation with small molecular agents. Prog. Polym. Sci. 2013, 38, 421–444. [Google Scholar] [CrossRef]

- Zhu, J. Bioactive modification of poly(ethylene glycol) hydrogels for tissue engineering. Biomaterials 2010, 31, 4639–4656. [Google Scholar] [CrossRef] [PubMed]

- Johnsen, S.; Ermuth, T.; Tanczos, E.; Bannasch, H.; Horch, R.E.; Zschocke, I.; Peschen, M.; Schopf, E.; Vanscheidt, W.; Augustin, M. Treatment of therapy-refractive ulcera cruris of various origins with autologous keratinocytes in fibrin sealant. Vasa 2005, 34, 25–29. [Google Scholar] [CrossRef] [PubMed]

- Tottoli, E.M.; Dorati, R.; Genta, I.; Chiesa, E.; Pisani, S.; Conti, B. Skin Wound Healing Process and New Emerging Technologies for Skin Wound Care and Regeneration. Pharmaceutics 2020, 12, 735. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.S.; Ahn, M.; Cho, W.W.; Gao, G.; Jang, J.N.; Cho, D.W. Engineering of diseased human skin equivalent using 3D cell printing for representing pathophysiological hallmarks of type 2 diabetes in vitro. Biomaterials 2021, 272, 120776. [Google Scholar] [CrossRef] [PubMed]

- Seite, S.; Bensadoun, R.J.; Mazer, J.M. Prevention and treatment of acute and chronic radiodermatitis. Breast Cancer Targets Ther. 2017, 9, 551–557. [Google Scholar] [CrossRef] [PubMed]

- Bernier, J.; Bonner, J.; Vermorken, J.B.; Bensadoun, R.J.; Dummer, R.; Giralt, J.; Kornek, G.; Hartley, A.; Mesia, R.; Robert, C.; et al. Consensus guidelines for the management of radiation dermatitis and coexisting acne-like rash in patients receiving radiotherapy plus EGFR inhibitors for the treatment of squamous cell carcinoma of the head and neck. Ann. Oncol. 2008, 19, 142–149. [Google Scholar] [CrossRef]

- Kim, J.H.; Kolozsvary, A.J.J.; Jenrow, K.A.; Brown, S.L. Mechanisms of radiation-induced skin injury and implications for future clinical trials. Int. J. Radiat. Biol. 2013, 89, 311–318. [Google Scholar] [CrossRef]

- Jones, M.W.; Cooper, J.S. Hyperbaric Therapy for Skin Grafts and Flaps. In StatPearls; StatPearls Publishing: Treasure Island, FL, USA, 2023. [Google Scholar]

- Rakel, B.A.; Bermel, M.A.; Abbott, L.I.; Baumler, S.K.; Burger, M.R.; Dawson, C.J.; Heinle, J.A.; Ocheltree, I.M. Split-thickness skin graft donor site care: A quantitative synthesis of the research. Appl. Nurs. Res. 1998, 11, 174–182. [Google Scholar] [CrossRef]

- Pleguezuelos-Beltran, P.; Galvez-Martin, P.; Nieto-Garcia, D.; Marchal, J.A.; Lopez-Ruiz, E. Advances in spray products for skin regeneration. Bioact. Mater. 2022, 16, 187–203. [Google Scholar] [CrossRef] [PubMed]

- Sorgel, C.A.; Schmid, R.; Kengelbach-Weigand, A.; Promny, T.; Horch, R.E. Air-Pressure-Supported Application of Cultured Human Keratinocytes in a Fibrin Sealant Suspension as a Potential Clinical Tool for Large-Scale Wounds. J. Clin. Med. 2022, 11, 5032. [Google Scholar] [CrossRef] [PubMed]

- Vig, K.; Chaudhari, A.; Tripathi, S.; Dixit, S.; Sahu, R.; Pillai, S.; Dennis, V.A.; Singh, S.R. Advances in Skin Regeneration Using Tissue Engineering. Int. J. Mol. Sci. 2017, 18, 789. [Google Scholar] [CrossRef] [PubMed]

- Phillips, T.J.; Bhawan, J.; Leigh, I.M.; Baum, H.J.; Gilchrest, B.A. Cultured Epidermal Autografts and Allografts—A Study of Differentiation and Allograft Survival. J. Am. Acad. Dermatol. 1990, 23, 189–198. [Google Scholar] [CrossRef] [PubMed]

- Meyer, A.A.; Pruitt, B.A.; Herndon, D.N.; Heimbach, D.M.; Bessey, P.Q.; Munster, A.M. Cultured skin for massive burns—A prospective, controlled trial—Discussion. Ann. Surg. 1996, 224, 375–377. [Google Scholar]

- Gallico, G.G.; Oconnor, N.E.; Compton, C.C.; Kehinde, O.; Green, H. Permanent Coverage of Large Burn Wounds with Autologous Cultured Human Epithelium. N. Engl. J. Med. 1984, 311, 448–451. [Google Scholar] [CrossRef]

- Horch, R.E.; Wagner, G.; Bannasch, H.; Kengelbach-Weigand, A.; Arkudas, A.; Schmitz, M. Keratinocyte Monolayers on Hyaluronic Acid Membranes as “Upside-Down” Grafts Reconstitute Full-Thickness Wounds. Med. Sci. Monit. 2019, 25, 6702–6710. [Google Scholar] [CrossRef]

- Bannasch, H.; Unterberg, T.; Fohn, M.; Weyand, B.; Horch, R.E.; Stark, G.B. Cultured keratinocytes in fibrin with decellularised dermis close porcine full-thickness wounds in a single step. Burns 2008, 34, 1015–1021. [Google Scholar] [CrossRef]

- Weng, T.; Zhang, W.; Xia, Y.; Wu, P.; Yang, M.; Jin, R.; Xia, S.; Wang, J.; You, C.; Han, C.; et al. 3D bioprinting for skin tissue engineering: Current status and perspectives. J. Tissue Eng. 2021, 12, 20417314211028574. [Google Scholar] [CrossRef]

- Jensen, C.; Teng, Y. Is It Time to Start Transitioning from 2D to 3D Cell Culture? Front. Mol. Biosci. 2020, 7, 33. [Google Scholar] [CrossRef]

- Kapalczynska, M.; Kolenda, T.; Przybyla, W.; Zajaczkowska, M.; Teresiak, A.; Filas, V.; Ibbs, M.; Blizniak, R.; Luczewski, L.; Lamperska, K. 2D and 3D cell cultures—A comparison of different types of cancer cell cultures. Arch. Med. Sci. 2018, 14, 910–919. [Google Scholar] [PubMed]

- Ravi, M.; Paramesh, V.; Kaviya, S.R.; Anuradha, E.; Solomon, F.D.P. 3D Cell Culture Systems: Advantages and Applications. J. Cell Physiol. 2015, 230, 16–26. [Google Scholar] [CrossRef] [PubMed]

- Groll, J.; Boland, T.; Blunk, T.; Burdick, J.A.; Cho, D.W.; Dalton, P.D.; Derby, B.; Forgacs, G.; Li, Q.; Mironov, V.A.; et al. Biofabrication: Reappraising the definition of an evolving field. Biofabrication 2016, 8, 013001. [Google Scholar] [CrossRef] [PubMed]

- Guillemot, F.; Mironov, V.; Nakamura, M. Bioprinting is coming of age: Report from the International Conference on Bioprinting and Biofabrication in Bordeaux (3B′09). Biofabrication 2010, 2, 010201. [Google Scholar] [CrossRef]

- Dey, M.; Ozbolat, I.T. 3D bioprinting of cells, tissues and organs. Sci. Rep. 2020, 10, 14023. [Google Scholar] [CrossRef]

- Manita, P.G.; Garcia-Orue, I.; Santos-Vizcaino, E.; Hernandez, R.M.; Igartua, M. 3D Bioprinting of Functional Skin Substitutes: From Current Achievements to Future Goals. Pharmaceuticals 2021, 14, 362. [Google Scholar] [CrossRef]

- Mandrycky, C.; Wang, Z.J.; Kim, K.; Kim, D.H. 3D bioprinting for engineering complex tissues. Biotechnol. Adv. 2016, 34, 422–434. [Google Scholar] [CrossRef]

- Sun, W.; Starly, B.; Daly, A.C.; Burdick, J.A.; Groll, J.; Skeldon, G.; Shu, W.; Sakai, Y.; Shinohara, M.; Nishikawa, M.; et al. The bioprinting roadmap. Biofabrication 2020, 12, 022002. [Google Scholar] [CrossRef]

- Bernal, P.N.; Delrot, P.; Loterie, D.; Li, Y.; Malda, J.; Moser, C.; Levato, R. Volumetric Bioprinting of Complex Living-Tissue Constructs within Seconds. Adv. Mater. 2019, 31, e1904209. [Google Scholar] [CrossRef]

- Discher, D.E.; Janmey, P.; Wang, Y.L. Tissue cells feel and respond to the stiffness of their substrate. Science 2005, 310, 1139–1143. [Google Scholar] [CrossRef]

- Williams, D.; Thayer, P.; Martinez, H.; Gatenholm, E.; Khademhosseini, A. A perspective on the physical, mechanical and biological specifications of bioinks and the development of functional tissues in 3D bioprinting. Bioprinting 2018, 9, 19–36. [Google Scholar] [CrossRef]

- Gungor-Ozkerim, P.S.; Inci, I.; Zhang, Y.S.; Khademhosseini, A.; Dokmeci, M.R. Bioinks for 3D bioprinting: An overview. Biomater. Sci. 2018, 6, 915–946. [Google Scholar] [CrossRef] [PubMed]

- Stratesteffen, H.; Kopf, M.; Kreimendahl, F.; Blaeser, A.; Jockenhoevel, S.; Fischer, H. GelMA-collagen blends enable drop-on-demand 3D printablility and promote angiogenesis. Biofabrication 2017, 9, 045002. [Google Scholar] [CrossRef] [PubMed]

- Cowman, M.K.; Schmidt, T.A.; Raghavan, P.; Stecco, A. Viscoelastic Properties of Hyaluronan in Physiological Conditions. F1000Research 2015, 4, 622. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Orue, I.; Pedraz, J.L.; Hernandez, R.M.; Igartua, M. Nanotechnology-based delivery systems to release growth factors and other endogenous molecules for chronic wound healing. J. Drug Deliv. Sci. Technol. 2017, 42, 2–17. [Google Scholar] [CrossRef]

- Barros, N.R.; Kim, H.J.; Gouidie, M.J.; Lee, K.; Bandaru, P.; Banton, E.A.; Sarikhani, E.; Sun, W.J.; Zhang, S.M.; Cho, H.J.; et al. Biofabrication of endothelial cell, dermal fibroblast, and multilayered keratinocyte layers for skin tissue engineering. Biofabrication 2021, 13, 035030. [Google Scholar] [CrossRef]

- Zorlutuna, P.V.N.; Khademhosseini, A. The expanding world of tissue engineering: The building blocks and new applications of tissue engineered constructs. IEEE Rev. Biomed. Eng. 2013, 6, 47–62. [Google Scholar] [CrossRef]

- Sathish, J.G.; Sethu, S.; Bielsky, M.C.; de Haan, L.; French, N.S.; Govindappa, K.; Green, J.; Griffiths, C.E.; Holgate, S.; Jones, D.; et al. Challenges and approaches for the development of safer immunomodulatory biologics. Nat. Rev. Drug Discov. 2013, 12, 306–324. [Google Scholar] [CrossRef]

- Ashammakhi, N.; Ahadian, S.; Xu, C.; Montazerian, H.; Ko, H.; Nasiri, R.; Barros, N.; Khademhosseini, A. Bioinks and bioprinting technologies to make heterogeneous and biomimetic tissue constructs. Mater. Today Bio 2019, 1, 100008. [Google Scholar] [CrossRef]

- Rios-Galacho, M.; Martinez-Moreno, D.; Lopez-Ruiz, E.; Galvez-Martin, P.; Marchal, J.A. An Overview on the Manufacturing of Functional and Mature Cellular Skin Substitutes. Tissue Eng. Part B-Rev. 2022, 28, 1035–1052. [Google Scholar] [CrossRef]

- Zoller, N.; Valesky, E.; Butting, M.; Hofmann, M.; Kippenberger, S.; Bereiter-Hahn, J.; Bernd, A.; Kaufmann, R. Clinical application of a tissue-cultured skin autograft: An alternative for the treatment of non-healing or slowly healing wounds? Dermatology 2014, 229, 190–198. [Google Scholar] [CrossRef]

- Werner, S.; Krieg, T.; Smola, H. Keratinocyte-fibroblast interactions in wound healing. J. Investig. Dermatol. 2007, 127, 998–1008. [Google Scholar] [CrossRef]

- Baltazar, T.; Merola, J.; Catarino, C.; Xie, C.B.; Kirkiles-Smith, N.C.; Lee, V.; Hotta, S.; Dai, G.; Xu, X.; Ferreira, F.C.; et al. Three Dimensional Bioprinting of a Vascularized and Perfusable Skin Graft Using Human Keratinocytes, Fibroblasts, Pericytes, and Endothelial Cells. Tissue Eng. Part A 2020, 26, 227–238. [Google Scholar] [CrossRef] [PubMed]

- Mazini, L.; Rochette, L.; Admou, B.; Amal, S.; Malka, G. Hopes and Limits of Adipose-Derived Stem Cells (ADSCs) and Mesenchymal Stem Cells (MSCs) in Wound Healing. Int. J. Mol. Sci. 2020, 21, 1306. [Google Scholar] [CrossRef]

- Hosseini, M.; Brown, J.; Shafiee, A. Strategies to Induce Blood Vessel Ingrowth into Skin Grafts and Tissue-Engineered Substitutes. Tissue Eng. Part C-Methods 2022, 28, 113–126. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.S.; Gao, G.; Kim, J.Y.; Cho, D.W. 3D Cell Printing of Perfusable Vascularized Human Skin Equivalent Composed of Epidermis, Dermis, and Hypodermis for Better Structural Recapitulation of Native Skin. Adv. Healthc. Mater. 2019, 8, 1801019. [Google Scholar] [CrossRef]

- Hanjaya-Putra, D.; Bose, V.; Shen, Y.I.; Yee, J.; Khetan, S.; Fox-Talbot, K.; Steenbergen, C.; Burdick, J.A.; Gerecht, S. Controlled activation of morphogenesis to generate a functional human microvasculature in a synthetic matrix. Blood 2011, 118, 804–815. [Google Scholar] [CrossRef] [PubMed]

- Arjunan, K.P.; Clyne, A.M. A Nitric Oxide Producing Pin-to-Hole Spark Discharge Plasma Enhances Endothelial Cell Proliferation and Migration. Plasma Med. 2011, 1, 279–293. [Google Scholar] [CrossRef]

- Choi, S.W.; Zhang, Y.; MacEwan, M.R.; Xia, Y.N. Neovascularization in Biodegradable Inverse Opal Scaffolds with Uniform and Precisely Controlled Pore Sizes. Adv. Healthc. Mater. 2013, 2, 145–154. [Google Scholar] [CrossRef]

- Cury, V.; Moretti AI, S.; Assis, L.; Bossini, P.; de Souza Crusca, J.; Neto, C.B.; Fangel, R.; de Souza, H.P.; Hamblin, M.R.; Parizotto, N.A. Low level laser therapy increases angiogenesis in a model of ischemic skin flap in rats mediated by VEGF, HIF-1α and MMP-2. J. Photochem. Photobiol. B Biol. 2013, 125, 164–170. [Google Scholar] [CrossRef] [PubMed]

- Laschke, M.W.; Rucker, M.; Jensen, G.; Carvalho, C.; Mulhaupt, R.; Gellrich, N.C.; Menger, M.D. Improvement of Vascularization of PLGA Scaffolds by Inosculation of In Situ-Preformed Functional Blood Vessels with the Host Microvasculature. Ann. Surg. 2008, 248, 939–948. [Google Scholar] [CrossRef]

- Wong, R.; Donno, R.; Leon-Valdivieso, C.Y.; Roostalu, U.; Derby, B.; Tirelli, N.; Wong, J.K. Angiogenesis and tissue formation driven by an arteriovenous loop in the mouse. Sci. Rep. 2019, 9, 10478. [Google Scholar] [CrossRef]

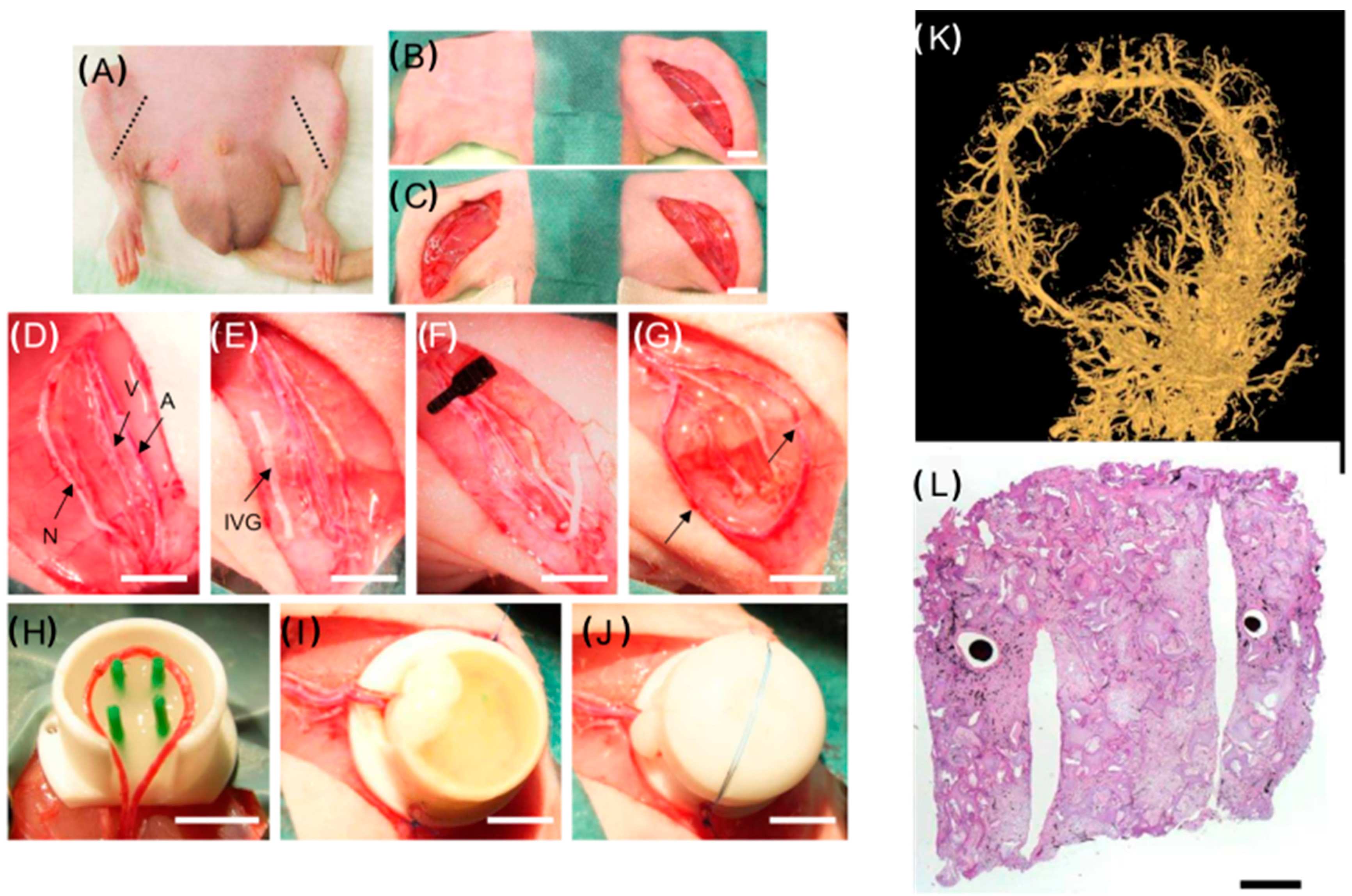

- Weigand, A.; Beier, J.P.; Arkudas, A.; Al-Abboodi, M.; Polykandriotis, E.; Horch, R.E.; Boos, A.M. The Arteriovenous (AV) Loop in a Small Animal Model to Study Angiogenesis and Vascularized Tissue Engineering. J. Vis. Exp. 2016, 117, e54676. [Google Scholar]

- Mori, N.; Morimoto, Y.; Takeuchi, S. Skin integrated with perfusable vascular channels on a chip. Biomaterials 2017, 116, 48–56. [Google Scholar] [CrossRef] [PubMed]

- Yan, Q.; Dong, H.H.; Su, J.; Han, J.H.; Song, B.; Wei, Q.S.; Shi, Y.S. A Review of 3D Printing Technology for Medical Applications. Engineering 2018, 4, 729–742. [Google Scholar] [CrossRef]

- Olejnik, A.; Semba, J.A.; Kulpa, A.; Danczak-Pazdrowska, A.; Rybka, J.D.; Gornowicz-Porowska, J. 3D Bioprinting in Skin Related Research: Recent Achievements and Application Perspectives. ACS Synth. Biol. 2022, 11, 26–38. [Google Scholar] [CrossRef]

- Matai, I.; Kaur, G.; Seyedsalehi, A.; McClinton, A.; Laurencin, C.T. Progress in 3D bioprinting technology for tissue/organ regenerative engineering. Biomaterials 2020, 226, 119536. [Google Scholar] [CrossRef] [PubMed]

- Gao, C.; Lu, C.X.; Jian, Z.A.; Zhang, T.R.; Chen, Z.J.; Zhu, Q.G.; Tai, Z.G.; Liu, Y.Y. 3D bioprinting for fabricating artificial skin tissue. Colloid. Surf. B 2021, 208, 112041. [Google Scholar] [CrossRef]

- El Ghalbzouri, A.; Lamme, E.N.; van Blitterswijk, C.; Koopman, J.; Ponec, M. The use of PEGT/PBT as a dermal scaffold for skin tissue engineering. Biomaterials 2004, 25, 2987–2996. [Google Scholar] [CrossRef] [PubMed]

- Moiemen, N.S.C.; Hartmann-Fritsch, F.; Neuhaus, K.; Reichmann, E.; Löw, A. First time compassionate use of laboratory engineered autologous Zurich skin in a massively burned child. Burn. Open 2021, 5, 113–117. [Google Scholar] [CrossRef]

- Vijayavenkataraman, S.; Lu, W.F.; Fuh, J.Y.H. 3D bioprinting—An Ethical, Legal and Social Aspects (ELSA) framework. Bioprinting 2016, 1–2, 11–21. [Google Scholar] [CrossRef]

- Tarassoli, S.P.; Jessop, Z.M.; Al-Sabah, A.; Gao, N.; Whitaker, S.; Doak, S.; Whitaker, I.S. Skin tissue engineering using 3D bioprinting: An evolving research field. J. Plast. Reconstr. Aesthetic Surg. 2018, 71, 615–623. [Google Scholar] [CrossRef]

- Bernd, A.; Hollander, D.; Pannike, A.; Kippenberger, S.; Muller, J.; Stein, M.; Kaufmann, R. Benzylester hyaluronic acid membranes as substrate for cultivation and transplantation of autologous keratinocytes for the treatment of non-healing wounds. J. Investig. Dermatol. 1996, 107, 450. [Google Scholar]

- Poskitt, K.R.; James, A.H.; Lloyd-Davies, E.R.; Walton, J.; McCollum, C. Pinch skin grafting or porcine dermis in venous ulcers: A randomised clinical trial. Br. Med. J. Clin. Res. Ed. 1987, 294, 674–676. [Google Scholar] [CrossRef]

- Boyce, S.T.; Hansbrough, J.F. Biologic attachment, growth, and differentiation of cultured human epidermal keratinocytes on a graftable collagen and chondroitin-6-sulfate substrate. Surgery 1988, 103, 421–431. [Google Scholar] [PubMed]

- Prenosil, J.E.; Kino-Oka, M. Computer controlled bioreactor for large-scale production of cultured skin grafts. Ann. N. Y. Acad. Sci. 1999, 875, 386–397. [Google Scholar] [CrossRef]

- Akita, S.; Hayashida, K.; Yoshimoto, H.; Fujioka, M.; Senju, C.; Morooka, S.; Nishimura, G.; Mukae, N.; Kobayashi, K.; Anraku, K.; et al. Novel Application of Cultured Epithelial Autografts (CEA) with Expanded Mesh Skin Grafting Over an Artificial Dermis or Dermal Wound Bed Preparation. Int. J. Mol. Sci. 2017, 19, 57. [Google Scholar] [CrossRef] [PubMed]

- Horch, R.E.; Bannasch, H.; Stark, G.B. Transplantation of cultured autologous keratinocytes in fibrin sealant biomatrix to resurface chronic wounds. Transpl. Proc. 2001, 33, 642–644. [Google Scholar] [CrossRef]

- Jorgensen, A.M.; Varkey, M.; Gorkun, A.; Clouse, C.; Xu, L.; Chou, Z.S.; Murphy, S.V.; Molnar, J.; Lee, S.J.; Yoo, J.J.; et al. Bioprinted Skin Recapitulates Normal Collagen Remodeling in Full-Thickness Wounds. Tissue Eng. Part A 2020, 26, 512–526. [Google Scholar] [CrossRef] [PubMed]

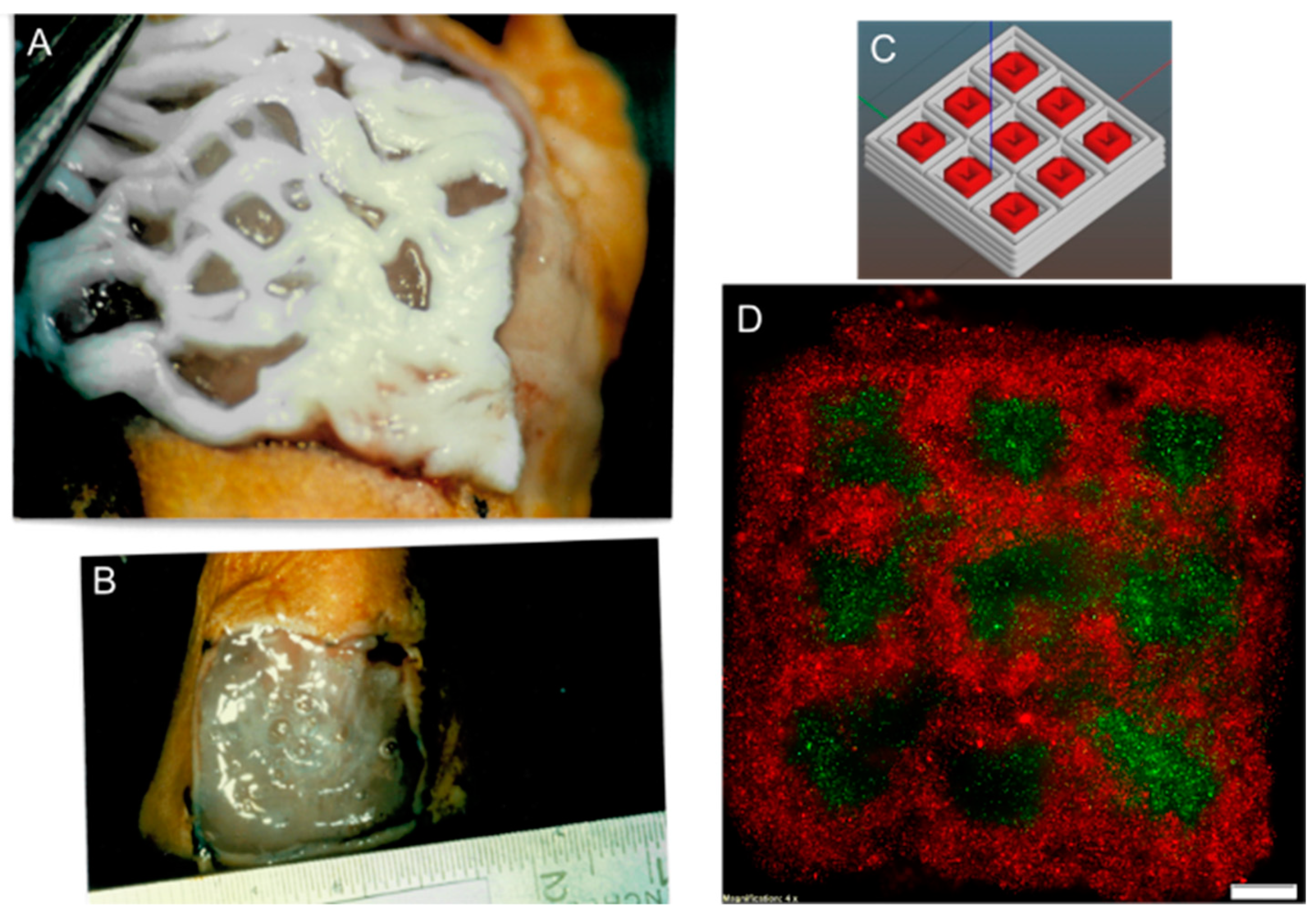

- Kim, B.S.; Kwon, Y.W.; Kong, J.S.; Park, G.T.; Gao, G.; Han, W.; Kim, M.B.; Lee, H.; Kim, J.H.; Cho, D.W. 3D cell printing of in vitro stabilized skin model and in vivo pre-vascularized skin patch using tissue-specific extracellular matrix bioink: A step towards advanced skin tissue engineering. Biomaterials 2018, 168, 38–53. [Google Scholar] [CrossRef] [PubMed]

- Albanna, M.; Binder, K.W.; Murphy, S.V.; Kim, J.; Qasem, S.A.; Zhao, W.X.; Tan, J.; El-Amin, I.B.; Dice, D.D.; Marco, J.; et al. In Situ Bioprinting of Autologous Skin Cells Accelerates Wound Healing of Extensive Excisional Full-Thickness Wounds. Sci. Rep. 2019, 9, 1856. [Google Scholar] [CrossRef] [PubMed]

- Phang, S.J.; Basak, S.; Teh, H.X.; Packirisamy, G.; Fauzi, M.B.; Kuppusamy, U.R.; Neo, Y.P.; Looi, M.L. Advancements in Extracellular Matrix-Based Biomaterials and Biofabrication of 3D Organotypic Skin Models. Acs Biomater. Sci. Eng. 2022, 8, 3220–3241. [Google Scholar] [CrossRef] [PubMed]

- Michael, S.; Sorg, H.; Peck, C.T.; Koch, L.; Deiwick, A.; Chichkov, B.; Vogt, P.M.; Reimers, K. Tissue Engineered Skin Substitutes Created by Laser-Assisted Bioprinting Form Skin-Like Structures in the Dorsal Skin Fold Chamber in Mice. PLoS ONE 2013, 8, e57741. [Google Scholar] [CrossRef]

- Tavakoli, S.; Klar, A.S. Bioengineered Skin Substitutes: Advances and Future Trends. Appl. Sci. 2021, 11, 1493. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sörgel, C.A.; Cai, A.; Schmid, R.; Horch, R.E. Perspectives on the Current State of Bioprinted Skin Substitutes for Wound Healing. Biomedicines 2023, 11, 2678. https://doi.org/10.3390/biomedicines11102678

Sörgel CA, Cai A, Schmid R, Horch RE. Perspectives on the Current State of Bioprinted Skin Substitutes for Wound Healing. Biomedicines. 2023; 11(10):2678. https://doi.org/10.3390/biomedicines11102678

Chicago/Turabian StyleSörgel, Celena A., Aijia Cai, Rafael Schmid, and Raymund E. Horch. 2023. "Perspectives on the Current State of Bioprinted Skin Substitutes for Wound Healing" Biomedicines 11, no. 10: 2678. https://doi.org/10.3390/biomedicines11102678

APA StyleSörgel, C. A., Cai, A., Schmid, R., & Horch, R. E. (2023). Perspectives on the Current State of Bioprinted Skin Substitutes for Wound Healing. Biomedicines, 11(10), 2678. https://doi.org/10.3390/biomedicines11102678