Abstract

Adverse effects of wastewater on the hygiene of human and circumstances is a major issue in society. Appropriate refining systems with high efficiency is required to treat the wastewater. Sewage treatment plant plays a major and important role in conserving incredible nature of the environment. Microbiologically Induced Corrosion (MIC) is an important phenomenon in sewage structures which causes the deterioration of infrastructures. Huge capital has been spent and efforts have been made on wastewater treatment infrastructure to increase operating efficiency and reliability of compliance. The investments in reimbursement and maintenance of sewer structures upsurge with an increase in the rate of MIC. The focus of this review is to describe MIC in sewer structure and the factors influencing the corrosion such as the generation of Sulfuric acid (), Relative Humidity (RH), pH of the concrete structure and temperature. Modern developments in the design of Fiber Optical Sensors (FOSs) for observing the parameters including pH, Hydrogen Sulfide (), RH and temperature will be discussed.

1. Introduction

A growing population and overall economic growth are expected to contribute to an increase in water usage across sectors, especially in the agricultural sector. With increased water use in urban and rural areas, the production of wastewater would increase. Water contamination is primarily caused by municipal drainage, agricultural aquaculture wastewater and residential wastewater [1]. Wastewater from factories such as paper mills, dyeing and weaving factories, extraction and refining results in industrial wastewater. The wastewater from domestic farms refers to rural aquaculture water pollution and the sewage delivered by them is extremely huge. Even though the effect due to sewage is little, it will contaminate the living climate and drinking water, if it is directly discharged into the water bodies. Untreated or inadequately treated wastewater is an immediate danger to the atmosphere. Additionally, a release of untreated sewage into the water body causes extreme adulteration leading to eutrophication and inebriation of the sea creatures. The biochemical changes of toxins causing the arrival of destructive gases and upsetting the working of environment. Each of these components causes a change in the biotic conditions and the physiochemical structure of wastewater collectors. Sewage treatment is the mechanism of eliminating impurities from the waste stream and sewage including domestic effluents [2]. Various physical, chemical, and biological processes are employed to eliminate impurities and treated wastewater is processed to make it secure to let into the earth. Enhancing the water quality of treatment plants is a systematic project, including chemical treatment and microorganism sludge treatment. In biological treatment pollutant are processed by incubating bacteria and other microbes that absorb the organic matter in the sewage and separates from the water [3].

The sewer network is one of the most significant public frameworks for the general population. Because of the significance of these structures and the enormous venture (huge million USD), long life is necessary for this structure. It is extremely regular that concrete structures are used for this kind of infrastructure as the administration life necessity is 100 years or more. Hence, the sturdiness of cement for sewage structure has been a significant subject in the plan of the structures [4]. At present, concrete sewer pipes are going through a critical degree of erosion due to Hydrogen Sulfide () which promotes erosion [5]. Concrete at various phases of a plant might be presented to . This exposure is brought about by the metabolic process of bacteria present in sewer structures, which convert in sewer air into corrosive agent () presented on the concrete sewer walls [6]. Produced infiltrates the pores of the solid and responds to the composition of the sewer pipes resulting in erosion of rebars over long time exposure [7]. The event of such conditions leads to major destruction including concrete disintegration, large scale and miniature breaks, just as chipping. The inability to confine the solid sewer pipe deterioration will cause major reimbursement on the maintenance process.Wastewater treatment is considered to be the most essential engineering structure ensuring sanitary and hygienic conditions. Back in the 19th century, due to growing public health issues, major improvements were made in the sewage systems. A common aspect of modern sewer networks is that they are buried underground, and most average citizens do not know the size and sophistication of the systems. During their service life, sewage treatment plants can undergo severe structural loads, environment and weather conditions that can cause stress, cracking, and deformation [8]. Eventually, cracking can result in rapid penetration of hostile agents, significant degradation of concrete, or even structural failure. Infrastructures for water and sewage pipelines are vulnerable to rapid ageing, degradation, and the reduction of static and cyclic power. Corrosion of drainage systems is an important problem among many problems, impacting the entire sewage system and triggering substantial maintenance payments. Biologically induced corrosion is a very particular form of degradation process for sewer-exposed concrete that has intensified in recent days due to stricter government controls on the limits of the quality and toxicity of industrial wastewater to be discharged to sewer systems. It can substantially reduce the lifespan of concrete structures. The key objective of this analysis is to objectively analyse the factors such as pH, temperature, and humidity, which play a deciding role in the corrosion of sewage pipelines. The next section briefs about the wastewater treatment plant followed by biological corrosion and factors influencing the corrosion. Section 5 describes the role of different type of sensors in monitoring the factors affecting corrosion. Section 6 explains the importance of FOS in monitoring the parameters such as pH, , temperature and humidity, influencing MIC in sewage treatment.

2. Sewage Treatment Plant

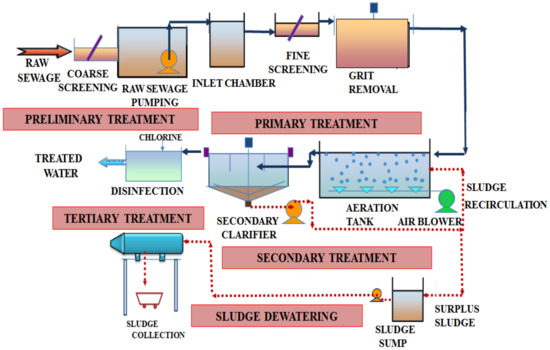

Based on physical, chemical and biological impurities the water will be treated and the treatment rely on the pollutants present in the water. Physical treatment includes removing impurities by physical processes such as screening, gravity settling, mechanical straining and skimming. Chemical treatment is usually preferred for treating industrial wastewater. There are many methods in achieving chemical treatments including coagulation, chemical precipitation, oxidation and reduction, neutralization and ion exchange [9]. Biological treatment is carried out using microbes to break down the organic matter in the waste water. As the sewage treatment includes both chemical and biological processes, organic content such as Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) have to be properly measured before being let into water bodies. Oxygen used by microorganisms to decompose the organic matter is denoted by BOD. COD denotes the level of oxygen used for oxidation. The measurement of BOD and COD values is important to access the toxins and biologically resistant organic substances. The composition of raw inlet sewage affects the intensity of treatment that comprises many complicated functions. Sewage treatment mostly constitutes the following stages (i) Preliminary treatment (ii) Primary treatment (iii) Secondary treatment (iv) Tertiary treatment as shown in Figure 1.

Figure 1.

Sewage Treatment Process.

The initial treatment removes the drifting materials such as tree limbs, papers, bits of clothes, wood and inorganic solids. In essential treatment, enormous suspended natural solids are separated by sedimentation in settling bowls. The fluid gushing at the source of optional treatment contains a lot of suspended natural material and has increased BOD (about 60% of the original).

In secondary treatment, organic wastes are processed either in aerobic or anaerobic condition to treat the output of primary treatment. In aerobic sewage treatment, aerobic bacteria digest the sewage and this type of bacteria requires air to survive. In anaerobic sewage treatment, sewage is decomposed by anaerobic bacteria where effluent produced cannot be discharged directly into the watercourse [3]. The tertiary treatment is the advanced treatment that involves improving the quality of effluent to an extent that it can be released into a delicate ecosystem.

The sewage treatment process needs long-lasting and competent tools to enhance online monitoring of several important factors including pH, BOD, COD, Chlorine, Ammonium, Phosphorus, and other important gases such as Methane (), etc. [10]. The aforementioned parameters influence the quality of treated water and also have adverse effects on the structural health of the plant. Specifically, water and sewage pipeline foundations are more susceptible to quick corrosion, worsening, static, and cyclic quality decreases.

3. Corrosion and Biofouling

In light of past investigations, water and sewage pipelines can be isolated into wastewater (gravity) sewers, wastewater power mains and measure lines in cleansing plants. They are constructed with different sorts of materials, constituting ferrous (counting ductile iron, solid metal and steel), concrete (counting strengthened concrete, porcelain-based structures including brick and clay) and plastic materials. Among them, concrete is a vital material in the manufacture of foundations that plays a primary role in the construction of structures processing storm-water waste and sewers [11,12]. Sewage pipelines are largely exposed to brutal ecological conditions including corrosive, biofouling environment and other destructive assaults that result in deterioration of the infrastructure. Metropolitan wastewater is comprised of homegrown, modern and metropolitan overflow sewage that consists of water (>95%) and different kinds of poisons [13]. Commonly, homegrown wastewater is made out of numerous pathogens and non-pathogenic microorganisms, natural/inorganic synthetics, suspended, broken up mixes and so forth [14]. Acidic and sulfide exposure of pipelines caused by microbial activities is the major reason behind biological and chemical corrosion [15]. Corrosion is generally termed as an unwanted characteristic cycle bringing about the slow demolition of materials including metals, concrete, etc. through chemical or electrochemical responses with the contiguous atmosphere [16]. Corrosion influences the quality of the material, rigidity, out looking and its performance. The reaction of elements with their surrounding structure causes various erosion problems including pitting of tubes, deterioration of various parts and corrosion fatigue. It is perceived that corrosion type and seriousness are emphatically relying on the surrounding environment, for which the marine climate is viewed as an important infrastructural deterioration [17,18].

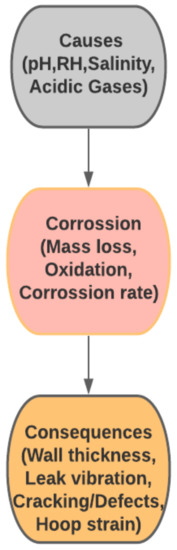

Biofouling is another issue in the water treatment process which is an unwanted aggregation of a biotic deposit on a surface. Biofouling may be regarded as a biotic type of organic fouling, while it is caused by organic matter extracted from microbial cell debris. It can be called an abiotic type of biofouling [19]. Treatment of wastewater polluted with anti-fouling chemicals is an emerging cost driver as the release of biocides is rapidly limited and will cause more effort and require unique treatment for the disposal of these compounds [20]. Performance monitoring of cleaning is typically carried out in the reverse phase as biofouling is identified by improvement of process parameters or product consistency. The corrosion and biofouling leads to structural destruction in sewage treatment plant and it has increased significant consideration for their high harmfulness [21]. Among different kinds of industrial structures, the water treatment framework is considered to be the most important designing structure that provides sanitary and sterile conditions [22]. An immediate requirement of reused water requires intense monitoring techniques to give reliable and continuous information in terms of in-situ checking. Various techniques were progressed to monitor and manage the deterioration of sewage structures through direct and indirect method is shown in Figure 2. Observing the corrosion depth, oxidation and mass loss is the direct method for monitoring corrosion. Earlier Ground-Penetrating-Radar (GPR) and ultrasound sensors, were used for corrosion depth monitoring in concrete structures. High humidity recorded in sewage structure restricts the performance of GPR. The sound coupling requirement for ultrasound sensors makes it difficult to use in rough surface of the sewer pipes. To overcome this problem drill resistance type depth sensor with effective predictive analysis was proposed by Giovanangeli et al. [23]. By analyzing the force–depth gradient with constant penetration depth and drill speed, a difference in material can be identified. In this way, the depth of microbial corroded regions can be determined. Measuring and managing the factors which cause and accelerate the process of corrosion is an indirect method of controlling corrosion. Certain pathogens generate compounds of sulfur through the organic process (metabolism). It is inferred that acid compounds generated through the metabolic cycle are threatened to materials such as concrete, steel, or cast iron. In sewage structures various factors namely pH of the concrete, RH, temperature and metabolic activities of bacteria influencing the corrosion.

Figure 2.

Corrosion: Causes and Consequences.

Pipelines are inevitably exposed to different kinds of erosion such as galvanic corrosion, microbiologially induced oxidation etc. [16]. It is hard to quantify the real erosion rate in sewer structures that requires a profound comprehension of the connection between deterioration rate and other factors accelerating the rate of corrosion including pH, RH, temperature, and concentration. Humidity reinforces the microbial erosion [24], temperature changes affect sulfide oxidation [25] and sewage pH influences biochemical cycle rates [26].

4. Microbiologically Induced Corrosion (MIC)

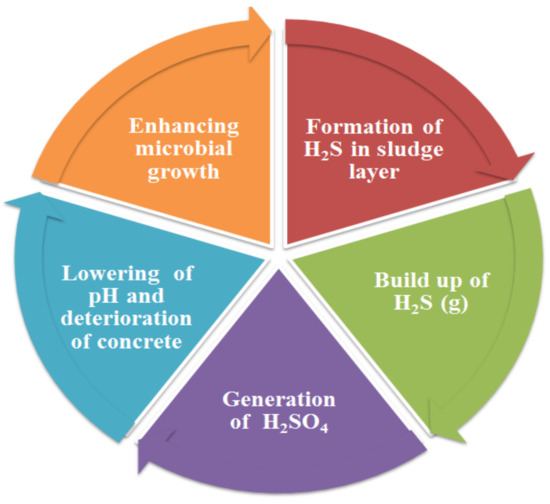

Certain sorts of bacteria generate sulfur compounds as the final product of their metabolic process. Two types of bacteria called Sulfate Reducing Bacteria (SRB) and Sulfate Oxidizing Bacteria (SOB) are the major sources for the acidifying environment. SRB is the type of anaerobic bacteria that remains inactive until oxygen supply cuts off at the layer of sludge. When anaerobic conditions create, SRB uses sulfate particles and decompose them into sulfide particles (). Sulfide responds with hydrogen particles in the wastewater to create bisulfite particles (). The development of occurs at temperatures over 15 C. particles respond with water thus generating in the disintegrated structure. particles ferment water and intense the number of hydrogen ions. This stimulates the generation of ion and gaseous . Factors prompting the generation of include the concentration of sulfides and pH around the value of 6 [27]. The generation of is greatly empowered with the existence of Thiobacillus bacteria. The generation in municipal sewage takes place in two-steps, i.e., bacteria generate sulfide ions and and the final product is metabolized by other bacteria to create oxidized sulfur compounds, which interacts with water to create acid.

Bacteria of the genus Thiobacillus is the generic bacteria in the decontamination plant which can oxidize sulfide, elemental sulfur, thiosulphate and polythionates. It includes two forms, one is a constraint to oxidize sulfur to and survive at neutral pH and another one which develops at lower pH use as an electron donor [15]. MIC is a very significant type of disintegrating mechanism for concrete structure exhibit in sewer environments that greatly affects the lifespan of concrete structures [28,29] and may reduce the life time from 100 years down to 30–50 years in worst cases down to 10 years or fewer [29,30]. Initially, it was conceived that the formation of due to oxidation of was entirely a chemical process. Various works were performed to reveal the process or events involved in MIC. Parker revealed the impact of microorganisms in the corrosive process through the interconnection of gas and the existence of sulfuric acid [31]. The process governing the commencement of MIC in the sewer system has been partitioned into several steps/stages according to different investigators. The widely accepted flow process is shown in Figure 3 and summarized below [32,33,34].

Figure 3.

Flow of Corrosion process in a Sewer.

- Generation of (aq) in the sewer: Sulfates in the sewer water are transformed to (aq) with the metabolic process of anaerobic SRB in biofilms under the waterline (or in the slime in Section 4 the highlighted ayer).

- Distribution of the (g): The gas-phase is liberated to the space above the sewage line with or without the assist of turbulence in the stream.

- Formation of : Aerobic sulfur-oxidizing bacteria converts (g) into sulfuric acid with the influence of RH temperature.

- Degradation of the concrete materials: Produced interacts with the concrete composition, results in a gradual deterioration of the concrete matrix.

Sources for sulfur compounds include organic substances such as proteins, lipids that exist in the wastewater of sewer. Sulfur reducing bacteria such as proteobacteria, firmicutes, and nitrospira below the water line are the main source for reducing sulfate into sulfide under anaerobic conditions [33]. Other factors affecting the formation of (aq) consist of BOD, amount of sulfate, sewage temperature, flow velocity and retention time. Aqueous radiated as gas to the upper part of sewers. Various factors such as pH, equilibrium condition between the gas and the liquid phase, temperature, RH and flow velocity influence the radiation of (aq).

The release of gaseous increase the concentration of gaseous in the over space of a sewer and stimulate the MIC [24]. The ventilation inside the sewer structure affects the accumulation of gaseous to a certain extent. Various abiotic (chemical) and biotic (biological) reactions lead to the formation of and finally causes erosion of the concrete. Other factors affecting the MIC process including wastewater characteristics (sulfate content, Dissolved Oxygen (DO), BOD and pH), environmental conditions(RH and temperature), concrete properties, microorganism, hydraulics and design are compiled in Table 1. DO and BOD are two of the most important variables that influence the characteristics of treated wastewater. The composition of concrete material also has a greater impact on the rate of corrosion. The real-time corrosion rate of various concrete materials with levels of 40–75 ppm was investigated [35]. The rate of corrosion in concrete made of ordinary Portland Cement (OPC) and siliceous Aggregate (SA) is greater than 7.5 mm/year. The composition of OPC and calcareous Aggregate, on the other hand, indicates 3.1 mm/year. The calcium aluminate cement (CAC) and SA composition has 1.9 mm/year, while the CAC and CA mixture has 0.6 mm/year. The Corrosion rates analyzed on different concrete material relies on concentration in sewage environment. Moisture in the sewer structures influence the rate of accumulation of and in turn it affects the rate of conversion of into sulfuric acid. RH, temperature, and pH have adverse influence on the generation of sulfuric acid.

Table 1.

Factors influencing Microbiologically Induced Corrosion rate.

Major Factors Influencing Corrosion

The predominant factor causing corrosion in sewers is , which is produced due to the direct reduction of sulfate by chemical/biological processes. Joseph et al. [24] demonstrated the environmental factors such as temperature, RH influencing oxidation of which is the main source for microbiologically induced corrosion. Influence of temperature, RH and with concrete coupons exposed to different combinations of the aforementioned three parameters over a long period was explored. It is inferred that under 50 ppm over the temperature 30 C, 25 C and 18 C, the surface pH has been diminished to 4.8, 3.5 and 1.8 respectively [24]. The pH reduction leads to the onset of active corrosion. Apart from other environmental conditions such as temperature, humidity in the range of 80% to 90% have a greater impact on corrosion. ARC(Australian Research Council) for SCORe (Sewer Corrosion and Odour Research Project) recognized that RH plays a vital role in the transformation of into . In the light of various investigations on MIC, it is inferred that concentration of , RH, temperature and pH are the vital factors affecting the rate of corrosion.

One of the immediate measures to address the sewer erosion issue is to quantify the measure of solid consumption itself. There is a great demand for the proficient innovation to quantify the erosion all through the sewer frameworks. The microorganisms that produce microbial on the concrete surface can be a useful metric for measuring corrosion. However, this necessitates the time consuming and difficult process of distinguishing the liable bacterial strains from other microbes in sewage pipes. The causes that create optimal living environments for bacteria are the next stage of intermediaries that could indirectly mean the amount of concrete corrosion [45]. In this way, levels in sewer air, optimum temperature, and humidity of sewer walls contribute to bacterial growth. The sewer environments require more reliable and more appropriate monitoring systems for the early prediction of corrosion rate [46,47]. Different types of sensors including humidity sensors, temperature sensors, pH sensors, and gas sensors have been used for efficient monitoring and automatic operation of plant equipment.

5. Sensors for Structural Health Monitoring (SHM)

Major sensor technologies that have been employed in concrete SHM systems exposed to harsh environments are

- Electromechanical(Piezoelectric) Sensors

- Electrochemical Sensors

- Fiber Optic Sensors

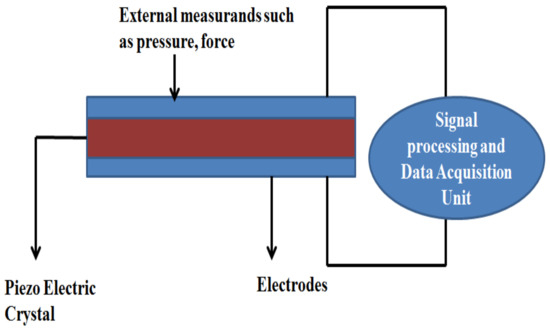

5.1. Electromechanical Sensors

The electromechanical sensor transforms mechanical stimulus into electrical signals. There are various types of electromechanical sensors including capacitive, resistive and piezoelectric. Micro-Electro-Mechanical Systems (MEMS) based on cobalt have been demonstrated for direct monitoring of phosphate in small microbial aggregates for in situ measurement within excited sludge for improved biological phosphorus eradication process [48]. Changes in factors such as acoustic emission, temperature, force, pressure, strain, or acceleration can be analyzed in terms of electric charges through piezoelectric-based sensors. Ceramic materials are the leading material used for the conversion of electrical energy into mechanical energy and vice versa. They possess reliable and rigidity over an extreme range of temperatures. The piezoelectric patches and smart patches were deployed for structural health monitoring, reconstruction and vibration damping [49,50,51]. Piezoelectric technology is mostly used in chemical sensors to carry out inexpensive real-time monitoring. The basic setup of piezoelectric-based sensors is shown in Figure 4. Based on Piezoresistivity principle, self sensing concrete were demonstrated for stress/strain detections through electrical resistivity of concrete made of polymer matrix composites. With the advent of Polymer matrix composites with electrically conductive elements such as carbon fiber (CF), carbon particle reinforced polymers, or hybrid composites made of aramidic/carbon or glass/carbon, Self sensing concretes were explored [52,53]. Similarly self sensing concretes based on capacitive effect also explored in [54]. Self sensing method is indeed in its early stages. Further research is needed to explore sensing repeatability and sensing activity in hostile climates.

Figure 4.

Basic setup of Electromechanical Sensor.

gas sensors based on piezoelectrically excited surface acoustic wave phenomena with a sensitive coating surface were demonstrated by Wang et al. [55]. With GPRS and wireless technology, massive optimization was carried out in monitoring and data acquisition. Li et al. [56] designed the different gas monitoring system with the integration of intelligent terminals, cloud servers and embedded technology. Moshizi developed the Flexible Piezoresistive Flow Sensor with the combination of internet of things(IOT) and wireless sensor network. The number of sensor nodes determine the coverage area and the sensor nodes used should withstand harsh sewer environment [57].

Potentiometric electrodes are rigid in structure and can withstand adverse environmental conditions. For pH sensing using solid-state potentiometric electrodes, electrically conducting metal oxides can be used as the operating component [58,59,60]. The more customary approach for pH measurement is the reference electrodes method, on which many works have been experimented with monocrystalline antimony electrode (Sb(s)) [61]. Even though they support temperatures as high as 350 C and reliable conversion capacity between electric energy mechanical energy, there is still a need for some corrections or enhancement in the design of piezoelectric-based transducers as sensors result in a false index on structural integrity. Other drawbacks including the inability to withstand humid environment, thermal impact on piezoelectric properties, gradual degradation of electrochemical properties and the impact of bonding layer between a PZT patch and the structure which restricts the enhancement of piezoelectric properties.

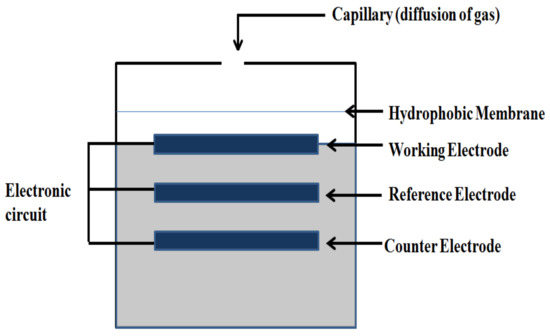

5.2. Electrochemical Sensors

Electrochemical devices transform the electrochemical reaction at analyte-electrode into an electrical signal. Depending on the variations in the potential difference, current flow and the conductivity of thin film it is classified as potentiometric, amperometric and conductometric sensors. The basic schematic of electrochemical sensor is shown in Figure 5. Nanocomposite-derived sensors based on various inorganic electrocatalysts including CuO/AgO agents show good correlation and response towards COD detection [62]. Sensors for pH detection based on electrochemical interaction is also widely in practice for harsh environment. Metal oxides-based pH sensors seeks greater importance because of their increased sensitivity, fast response time (<10 s), long lifetime (>1 year), ease of miniaturization, consistent in distinct atmospheres and biocompatibility [63]. Sewage treatment plants exhibit many toxic gases, including sulphide, , carbon dioxide, nitrous oxide and in-sewer gases that cause environmental emissions. Electrochemical-based sensors to detect nitrous oxide in a low-range from the gas stream are reported [64,65]. At a series of frequencies, the conductivity of a thin film or bulky material was traced to measure humidity through the conductivity of mixed oxide [66].

Figure 5.

Schematic of Electrochemical Sensor.

An electronic hygrometer measures the humidity through changes in electrical characteristics such as resistance and capacitance. Recently, Thiyagarajan et al. [67] demonstrated a surface moisture sensor dependent on electrical resistivity analysis. Surface moisture of sewer pipes was measured using the surface resistance of concrete at the desired location. Predictive Analytics Enabled Anomaly Detection Model was proposed to address anomalies(2.6%) present in the sensor data. Anomalies may have a variety of unpredictable triggers. The proposed model detects early sensor failure and calculates accurate sensor measurements.Emerging composite materials such as chitosan-CuO hybrid nanocomposite leads to the design of selective gas sensor operated at low temperature. Ali et al. [68] developed the conductive organic film embedded with CuO nanoparticles and recorded the sensitivity of 15 ppm with response of 14 s which is better than oxide semiconductors and organic polymers [69,70]. The above sensor produced good reversibility and mentioned response only at low temperature of 40 C. Thiyagarajan et al. [71] designed the instrument based on an infrared radiometer for non-contact temperature monitoring. The emissivity coefficient of concrete improved the accuracy of temperature estimation. The higher humidity in sewer structure affect the sensing through fogging on optical window. To prevent fogging, an antifog coating was applied to the optical window. Over the course of three months, the sensor was tested in real-time sewers. The sensor’s reliability was improved by replacing the antifog material after 96 days [72]. Even though these conventional detectors have acceptable lower detection limits and fast response, they are greatly influenced by temperature and humidity [73].

6. Fiber Optic Sensor for Corrosion Factor Analysis

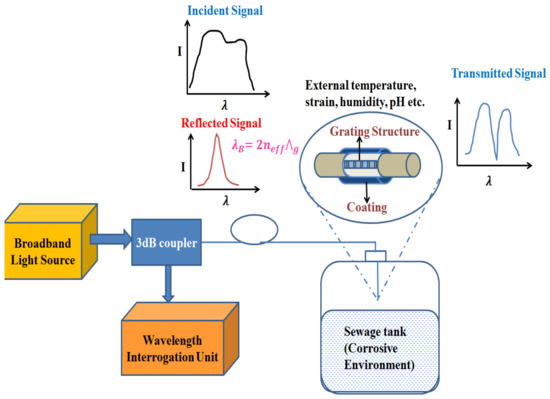

The tremendous growth in fiber optic communication and recent advances in optoelectronic devices lead to the development of fiber optic-based sensors. The optical sensors are based on monitoring variations in the guiding light attributes including amplitude, phase, frequency and polarization. Compared with other sensing technologies, optical fiber sensors have inherent characteristics such as increased sensitivity, compressed size and weight and resistance to Electro-Magnetic Interferences (EMI) [74,75,76,77,78,79]. Various experimental work has been carried on optical sensors based on the interferometric, Surface Plasmon Resonance (SPR), Fiber Bragg Grating (FBG), distributed grating, resonators and Lossy Mode Resonance (LMR). Among various techniques, sensors based on FBG are greatly influenced in SHM and the FBG structure was first discovered by Hill et al. [80]. After the discovery of FBG structure. Morey et al. [81] fabricated the FBG structure by exposing the fiber under UV light so that the intense interference pattern created leads to a structure with a periodically varied refractive index. The light at a particular wavelength is reflected at each refraction change and all the reflected signals having the same wavelength called Bragg wavelength are combined coherently. The remarkable achievements on various transducers have been reported only after the fabrication of FBG sensors by Morey et al. [81]. Any variations in strain and temperature experienced by the grating can be easily measured with the change in the wavelength of reflected light. Other external factors affecting RI, strain and temperature around the FBG can also be monitored. The principle of FBG sensing technology is shown in Figure 6.

Figure 6.

Experimental setup of Fiber Bragg Grating-based sensors.

In FBG sensors the parameters are measured with wavelength encoded signals and thus any fluctuations in signal intensity does not affect the measurement. Other than the inherent characteristics of fiber optic sensors, FBG-based sensors exhibit measurement stability, large multiplexing capacity, simultaneous measurement, selectivity towards measurand, low response time and simplicity in structure. Sensitivity, accuracy and dynamic range has been greatly enhanced with FBG structure [82]. Various FBG-based structures including apodized FBG [83], phase-shifted FBG [84], long period grating (LPG) [85] and tilted grating [86] also find their position in sensing. Each grating structure has its own attributes in tuning the spectral characteristics such as narrow FWHM, greater reflectivity, narrow line width, suppression of side lobes and selectivity towards measurands. FBG structures have been chosen depending on sensor requirement, position and parameter to be measured. For instance LPG based structure for fluorine detection was developed [87]. The fluorine concentration affects the effective refractive index which can be observed with the shift in cladding modes. Long period grating sensors coated with calix[4]resorcinarene for toluene monitoring were demonstrated with a detection limit of 40 ppm [88]. Embedded corrosion sensor was designed by Liu [89] to monitor the rebar corrosion. The corrosion status was monitored with the change in chloride ion content though the surrounding RI. The relation between corrosion rate and LPFG resonant peak wavelength was studied over a period of 66 to 112 days.

The grating structure has also been used with other fiber optic technologies such as SPR-based sensors. Surface plasmons is the confinement of evanescent waves on the surface of a metal surface due to the oscillations of free electrons caused by induced electromagnetic field with incident of light. SPR is broadly used for various chemical and biosensing applications. Grating assisted SPR based sensors have been demonstrated for Surrounding Refractive Index (SRI) change to realize both the characteristics of SPR and FBG. Sensors for SRI based on SPR and tilted bragg grating have been experimented by Manuylovich et al. [90]. Various parameters including temperature, humidity, various gases, etc.in sewer structure have been monitored with FBG-based sensors. The limitations with FOS are expensive interrogation system, fragility, need for experts for fabrication and deployment [91,92,93]. Many studies explored that conventional electrical sensors constituting electromechanical and electrochemical-based sensors failed to provide stable data because of shortened life time in harsh conditions, difficulty in multiplexing and performance degradation due to the acidic environment. Comparison of FOS with other sensing technologies are summarized in Table 2.

Table 2.

Comparison of FOS with Electrochemical and Electromechanical technologies.

The lifetime of sewer concrete structures has been a significant subject in the plan of the structures. Size of the sewer frameworks manufactured these days is enormous. For instance, in Singapore, Deep Tunnel Sewerage System (DTSS) was constructed for sewage collection, processing, redemption and clearance. In Qatar, the Public Works Authority initiated Inner Doha Re-sewerage Implementation Strategy (IDRIS) for sewerage infrastructure with the tunnel length of the sewer is almost 16 km with an inner radius of 2 m. Similarly, in UK, raw sewage and rainwater discharges are collected in the Thames Tideway Tunnel running for 25 km with an inner diameter of 7.2 m. The complication involved in the concerned problem are well acknowledged, as many factors are involved, e.g., sewage characteristics, the role of microorganisms (bacteria), surrounding factors, hydrodynamics of stream, concrete material properties and structural characteristics. To discuss consistent aspects extensively and to limit the scope, this work focuses on the factors such as temperature, pH, , RH and the monitoring of such parameters using optical sensors. Additionally, the sensors used to monitor are also discussed in detail.

6.1. Fiber Optic Gas Sensors

is the pollutant that commonly exists in wastewater processing plant as the process of purifying the sewage needs the proteins to sediment from the water in which they are suspended. Consecutive processing provides the potential for accumulation of . Therefore, it is important to make facilities for efficient monitoring of at low concentrations. High concentrations of nearly 1000 ppm or above adversely affect human health and may cause immediate death [100,101,102]. Various methods have been used for gas detection’s [103,104,105,106] and the conventional method is the electrochemical sensor which requires electricity to work and it is not suitable for chemically reactive and harsh environments [107]. The implicit characteristics of optical fibers such as electro-magnetic and corrosion resistant [7], chemical inertness and compact structure makes optical-based sensors to be highly suitable for harsh environment. With the invention of optical fiber-based sensors many optical-based sensors have been reported [108,109]. Coating materials such as graphene and other semiconductor oxides such as , are employed for the detection of along with optic fiber. As graphene exhibits good adsorption property due to its large surface area for an atomic monolayer, various graphene based sensors were developed [13,110,111]. Liu et al. [112] developed multi-point thin-core fiber MZI with copper/graphene oxide coating. Graphene coated on tapered hybrid Photonic Crystal Fiber (PCF) and Mach Zender Interferometer (MZI) structure was demonstrated for gas sensing where tapered PCF is placed between two single-mode fibers (SMFs) by fusion splicing techniques. Dual tapers with enlarged waist have been experimented by welding the PCF with SMF where nano copper/graphene were used to detect . PCF coated with TiO2/af-GQDs composite exhibits a high response time of 68 s with the sensitivity of 26.62 pm/ppm shows better linearity and selectivity for in the range of 0 ppm to 55 ppm [113].

is another important gas produced in the sewer systems. Monitoring concentration is important for the precise quantification of production and emission from sewers. Most conventional techniques of sensors are spectroscopic methods [114,115,116,117]. Sensors based on spectroscopic platforms perform well as individual units but generally having many backlogs such as spark hazard (peripheral and drive electronics), the challenge of multiplexing as a sensing array and cost of production makes it not suitable for harsh environment. Another major problem with the spectroscopic method is very small intensity changes for considerably large gas variation due to the narrow line width. This could be overcome by derived spectroscopy which increases the complexity of the sensing system. Other than this temperature dependency, humidity interference is also a major problem. Evanescent field sensor is also used where chemical selectivity is a major issue. Many works on microstructured fiber optics have been reported for gas sensing [118,119]. A hollow-core photonic crystal fiber-based sensor is also reported where holes of the fiber are filled with gas and a Fourier Spectroscopy method is used to absorb the transmission peak [120].

6.2. Fiber Optic pH Sensors

In the sewage treatment plant, pH plays a major role in corrosion and has to be properly monitored and maintained. The estimation of hydrogen-particle (pH) movement in water-based arrangements is a profoundly evolved region of innovation. Prior works depicted that the temperature, , pH and humidity play a vital role in accelerating the corrosion of sewage pipes. Portland concrete has a pH generally in the scope of 12.5 to 13.8 and it cannot resist lower pH conditions. Reduction in pH occurs due to the introduction of conditions such as chemical exposure, chloride particle ingression, corrosive assault or the carbonation response. Decrease in pH level can cause erosion and spalling making the precise estimation of pH in concrete vital, especially in regions with the most elevated likelihood of corrosion, for example, pipes in frameworks or flowing and sprinkle zones in sea structures. Estimation of concrete pH can be accomplished by destructive and non-destructive methods. Destructive method includes the expression method, the in-situ and ex-situ leaching methods [116,121,122,123]. The non-destructive method constitutes reference electrodes [61,124,125], embedding potentiometric pH electrodes [126,127], piezoelectric method and fiber optic based pH sensors [128]. Even though the potentiometric electrodes have a sturdy structure, the electrodes in high alkaline solution need to be calibrated frequently to obtain precise and consistent potential-pH responses.The general requirement of pH sensors for sewage treatment plants includes the capability of monitoring the pH in the range of 9 to 13 with high resolution and long lasting steadiness under elevated acidic environment and remotely accessible.

Few sensors discussed above are equipped for being used in pH estimation in an aggressive environment, including sewage. The significant expenses and tedious working strategies of traditional procedures have driven scientists to substitute with quicker elective techniques for wastewater qualities observing [129]. Another technology for monitoring pH in concrete structure is optical-based pH sensors. For the control of various wastewater qualities, such as pH, fiber optic technology is the most promising technique [130]. Dantan and Habel [131] explored optical pH sensor embedded in concrete of sewage structure. Ratiometric absorption technique was employed for the measurement of alkalinity in concrete structures. Sensors based on immobilization of Giemsa on triacetylcellulose membrane was demonstrated for wide range of pH monitoring (3.0–12.0) [132]. Fiber optic based pH sensors are usually designed with pH responsive element as a transducing membrane. The basic methods of measuring pH using fiber optics are observing pH-induced variations in absorbance or fluorescence intensity and optical signal characteristics. The fiber could monitor aqueous pH value through light signal characteristics with the help of the functional materials. Generally Fiber optic pH indicators are based on absorbance or fluorescence intensity and based on hygroscopic effect of coating with respect to pH variation [128,133,134,135]. Another sensor for pH measurement was demonstrated (AG-LPG) based on Air Gap-LPG fabricated in multimode fiber with sensitivity of −0.219 nm/pH for the range 1–7 and 0.248 nm/pH for the range of 8–14 [136].

Sensors rely on absorption or fluorescence intensity for humidity measurements often affected with instabilities caused by reduction in indicator concentration due to photo degradation, variations in light source amplitude or bending of fibers. Various transducing methods constitutes for insitu pH measurements such as pulsed laser beam [137], interferometer [138,139,140,141,142], resonator[143,144] and gratings [85] are summarized in Table 3. Current pH sensors have various limitations such as brittleness, chemical volatility of the chromophore at extreme pH values, indicator discharge and subsequent floating of the signal, a limited lifespan, confined pH range, a long response time, unstable response, vulnerability to thermal and chemical variations and lap over between their spectra at extreme pH measurements.

Table 3.

Summary of pH sensors based on optical fiber.

6.3. Fiber Optic Temperature Sensors

Temperature over the range of 20 C to 54 C along with RH of 80% to 90% in the harsh and acidic environment enhances MIC. Temperature enhances the formation of in a sewer system [148]. A large number of experimental works have been done on the measurement of temperature in harsh conditions [149,150,151,152,153,154]. DTS has been explored for the implementation of fiber optic DTS in harsh and corrosive sewer environments [155,156,157,158]. Optical Backscatter Reflectrometry (OBR) was used to create a sensor for simultaneous measurement of humidity and temperature. Fibers with polyimide and acrylate coatings were used in the designed sensor [159]. Data from fiber optic distributed temperature sensors installed in sewer networks was analyzed using an automated tool with a smart algorithm [160]. With the LPG structure, a temperature sensor with a precision of 1.13 °C for a distance of 21.8 km was proposed based on the random scattering effect. The aim of this experiment was to solve the problem of cross sensitivity in the Brillouin method [161]. Zou et al. [162] have demonstrated the fiber optic sensor working on the interferometric principle to monitor temperature and thus analyzing the effects of concrete hydration process. As glass-based silica is predominantly used for the fabrication of FOS, it provides ultimate resistance towards corrosion and withstands explosive atmosphere without compromising its sensing performance [163]. A FBG-based temperature sensor along with Fabry Perot Interferometer (FPI) used as pressure sensor was realized with remote operated vehicle for ocean environment [164]. Optical temperature sensor based on grating was developed to deploy in sewage tank and it shows good performance over the period greater than year [7]. Fiber Bragg Grating sensors proved to be a long time performer in sewer structures. Rente et al. [165] conducted the real time experiment for monitoring temperature and RH in Sydney sewage system with a wide range of sulfide levels with 95% RH. The team analyse the performance of the sensor after the 20 month exposure time. The outcome of the analysis revealed that the sensor is reliable in measuring the temperature and humidity data in harsh environments. Optical-based temperature sensors were experimented in sewers for various performance monitoring such as hydraulic performance, leakage monitoring [166], etc. Optical temperature sensor for hydraulics performance in sewer was experimented with backscatter light spectrum with less failure rate [167].

6.4. Fiber Optic Humidity Sensors

Observing exceptional RH levels provides early prediction of corrosion on concrete structures. It was observed that water and moisture lead to corrosion and carbonation [4]. Water will infiltrate the breaks, brought about by erosion and causes more harm to the structure. The air in the sewer has high humidity regularly above 90% and variable convergences of vaporous . Such a forceful climate makes the constant estimation of RH troublesome, but the impact of humidity on the rate of corrosion has to be overlooked. Exact and long haul RH estimations will empower a quantitative relationship between admissible in sewer air and worthy erosion rates ≤0.5 mm/year. Humidity sensors were realized in different forms constituting capacitive [168], resistive [169,170], electrical resonant [171] and mechanical resonant devices [172]. For measuring humidity, sensitive materials range from polymers to porous ceramics, porous silicon and electrolyte have been used. Various RH sensors were fabricated on different technologies, whereas most of the sensors are bulky, with a high response time (in minutes) and not suitable for harsh environmental conditions [96].

Conventional methods for humidity sensing include a mechanical hygrometer [173], chilled mirror hygrometer [174], wet and dry bulb psychrometer [175], Infra Red (IR) optical absorption hygrometer [176] and electronic hygrometer [170]. In a mechanical hygrometer, the humidity is measured with the displacement of the material through strain gauges. Even though the method is simple and inexpensive, it has inherent nonlinearity and hysteresis problems. This method does not apply to a rapidly changing environment [96]. The humidity is observed through dew point temperature in a Chilled Mirror hygrometer. It is the optical technology that provides more precise measurements but it is expensive and vulnerable to surface pollution [175]. Wet and dry bulb psychrometer measures humidity through temperature difference between wet and dry bulbs in the device. It can withstand harsh environments and it requires provisions to minimize the measurement error and inconsistency in the measurement. IR optical absorption technique is based on dual wavelength absorption techniques [177]. Optical sensors for humidity can be designed using various optical technologies such as optical absorption [178,179], interferometer [180,181,182], resonators [183,184], gratings [185,186,187] and LMR [188,189,190]. In optical absorption method, humidity is measured by tracking variations in the transmitted optical power caused due to the evanescent field interaction with a sensitive coating material such as Tungsten Disulfide () [178], reduced Graphene oxide (rGO) [179] and Zinc Oxide () [191]. Liehr et al. [192] developed optical attenuation based humidity sensor with polymer matrix optical fiber. The fiber used was fabricated with material which are readily reacted to humidity. Humidity induced attenuation was used to monitor the changes in humidity. Implementation of attenuation based humidity sensors are easy to deploy. Moreover polymer optical fibers offers higher fracture toughness and better sensitivity [193]. Although it tracks variations in the transmitted optical power, the changes in optical intensity also sensitive to unwanted factors such as fluctuations in the light source.

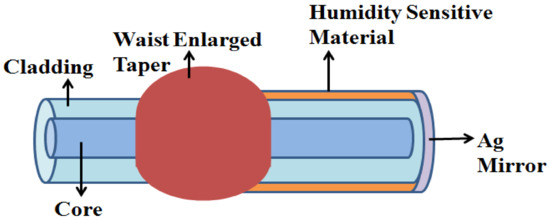

Another method of monitoring humidity is through the phase difference formed due to change in length of the cavity and Refractive Index(RI) called interferometric method [194]. Michelson Interferometer was realized with waist enlarged taper for humidity sensing with the sensitivity of 135 pm/%RH is shown in Figure 7 [195].

Figure 7.

Realization of Michelson Interferometer with waist enlarged taper for humidity sensing.

The interference is made sensitive to relative humidity by coating the structure with hygroscopic material [196]. Using Agarcose [197,198], PolyVinyl Alcohol (PVA) [199], or Poly Allylamine Hydrochloride (PAH) and Poly Acrylic Acid (PAA) [196], as the humidity sensitive material on PCF, enhances the sensitivity of the interferometric structure and thus attains 2.35 nm/%RH in the range 75% to 95%RH. But coating materials should be properly chosen for a wide range of humidity and to avoid non-linear behavior. With an appropriate coating, the tapering structure can be made sensitive to SRI and thus used as humidity sensors. The structure of LMR based device is also used for humidity sensing where evanescent field is excited by cladding etching, side polishing and tapering of optical fibers. Different types of materials, including metal oxides or polymers have been used for LMR generation. The availability of different materials enables these LMR based structures to be developed for different types of applications. LMR is achieved by etching the cladding or tapering, which makes the sensor structure more fragile and not suitable for harsh environments.

Another technique for deploying evanescent waves for humidity sensing is based on SPR. SPR can be realized by polishing or by reducing the cladding so that the evanescent wave is exposed to the surrounding medium. In practice, these configurations significantly affect the strength of the sensor probe and make it not suitable for practical applications, out of laboratory settings. Another approach to excite the SPR without etching or polishing is to use the tilted FBG inside the SPR. The tilted configuration excites the cladding mode which interacts with the coating material used for humidity sensing. The change in RH alters the RI and the thickness of the coating material, which in turn shifts the resonance wavelength of interacting cladding mode and can be monitored with the transmission spectrum.

FBG-based sensors are one of the devices delivering consistent performance for monitoring RH in acidic and aggressive environments [163]. A FBG-based structure is inherently sensitive to change in temperature and strain. RH can be monitored with hygroscopic materials coated on the FBG, which apply strain on swelling due to an increase in RH and vice versa. Different humidity transducing polymeric materials such as polyimide, di-uresil, PMMA, chitosan and agar were mostly used [185,189,200,201,202]. The sensitivity of such polymer coated FBG structures have been empowered by varying the coating methods, thickness and changes in the diameter of the fiber.

Various experimental works have been demonstrated with these optical structure. In 2016, Alwis et al. [7] developed RH sensor with polyimide coated fiber bragg grating where he used one more FBG for temperature compensation. The sensor probe is packed with 3D epoxy resin and the sensor was calibrated under laboratory conditions and revealed that the above designed sensor can withstand high humidity over the range of 98%RH and a chemically contaminated sewer environment. The humidity and temperature sensitivity remains constant at 5 pm/%RH and 9 pm/C respectively. Proper packaging of sensor probe results in a larger working duration without any deterioration in performance. Humidity sensor with two different types of coating has been evaluated for non-degradable performance over an extended period of time in an aggressive sewage environment [186]. To optimize the packaging of sensor probe, two different packaging such as 3D epoxy resin and PEEK material have been used. Durability, response time and stability measurement of the sensor have been carried out. Later in 2017, Ams et al. [149] reported the humidity sensor based on FBG packed with perforated stainless steel but with improved linearity and stability in performance. Type II-IR FBG in sensor tip is fabricated by Point-by-Point (PbP) technique using ultra short laser pulses in polyimide coated fiber cores. It is inferred that the response time of the sensor depends on the thickness of the polyimide coating. Thin coating provides less response time than a larger one. In 2019, Rente et al. [186] extended the work of Alwis et al. [7] for humidity sensing in real time sewer system in a Sydney wastewater plant with a large range of temperature variations. The sensor system has been enhanced with 4G technology, data logging and battery equipped power source. The sensor proved to be efficient in monitoring humidity over a long period of time (more than 6 months) in a harsh corrosive environment without any calibration. Humidity sensors based on various fiber optic technologies is summarized in Table 4.

Table 4.

Summary of fiber optical humidity sensors.

7. Conclusions

Increased population density, emerging technologies, and augmentation of industries leads to the mass generation of wastewater which can be gathered and processed through sewerage system. Microbial activities and other acids generated due to the treatment process makes the sewer infrastructure a more acidic and corrosive environment which leads to the corrosion of concrete structures. Exposure of sewer pipes to corrosive environment contrarily influences the reliability of these structures and overtime period results in the failure of the sewer framework. For a better understanding of corrosion behavior in such a large infrastructure, there is an immediate need to develop quantitative models that include the most appropriate monitoring and controlling equipment with efficient integration. Extensive development in the technology has paved the way for different technologies for prolonged real time monitoring and assessment of corrosive and harsh infrastructures such as sewage systems. Sewage infrastructures are greatly affected by Microbial Induced Corrosion (MIC). Various parameters influencing the MIC include the generation of hydrogen through the metabolic process of bacteria and other factors accelerating the MIC have been reviewed in this paper. Different types of sensing technologies that can be deployed in an aggressive environment along with their justifications have been discussed. The long term capability of various types of sensors are uncertain and it has to be thoroughly investigated in real time. Fiber optic- and FBG-based sensors attained greater attention for deployment in harsh environments because of its inherent sensing properties and immunity towards the corrosive environment. The efficiency of SHM depends on the integration of multiple sensors deployed at different locations of a structure. Fiber optic and FBG techniques are likely to exhibit more progressive performance in the innovation of sensor design.

Author Contributions

R.K., D.B.D. and S.D. selected the bibliography and decided the scheme for the review. B.R. contributed to the manuscript preparation. G.D. and D.B.D. critically revised the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This publication has emanated from research supported by EU Horizon 2020 project EUMarineRobots under Grant Agreement 731103) and RoboVaaS EU ERA-Net Co-fund award through Irish Marine Institute.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| FOS | Fiber Optic Sensors |

| MIC | Microbiologically Induced Corrosion |

| RH | Relative Humidity |

| BOD | Biological Oxygen Demand |

| COD | Chemical Oxygen Demand |

| SRB | Sulfur Reducing Bacteria |

| SOB | Sulfur Oxidizing Bacteria |

| DO | Dissolved Oxygen |

| MEMS | Micro-Electro-Mechanical Systems |

| SHM | Structural Health Monitoring |

| FBG | Fiber Bragg Grating |

| SPR | Surface Plasmon Resonance |

| LMR | Lossy Mode Resonance |

| PCF | Photonic Cyrstal Fiber |

| MZI | Mach Zender Interferometer |

| EMI | Electromagnetic Interferences |

| GPR | Ground-Penetrating-Radar |

References

- Zia, S.; Graham, D.; Dolfing, J. Wastewater Treatment: Biological; CRC Press: Boca Raton, FL, USA, 2013; pp. 2645–2655. [Google Scholar] [CrossRef]

- Bahadori, A. Sewage Treatment, Waste Management in the Chemical and Petroleum Industries; John Wiley & Sons, Ltd: Hoboken, NJ, USA, 2019; pp. 237–255. [Google Scholar] [CrossRef]

- Bhunia, P. Fundamentals of Biological Treatment. Compr. Water Qual. Purif. 2013, 3, 47–73. [Google Scholar] [CrossRef]

- Wu, M.; Wang, T.; Wu, K.; Kan, L. Microbiologically induced corrosion of concrete in sewer structures: A review of the mechanisms and phenomena. Constr. Build. Mater. 2020, 239, 117813. [Google Scholar] [CrossRef]

- Jiang, G.; Keller, J.; Bond, P.; Yuan, Z. Predicting concrete corrosion of sewers using artificial neural network. Water Res. 2016, 92. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; De Schryver, P.; De Gusseme, B.; Muynck, W.; Boon, N.; Verstraete, W. Chemical and Biological Technologies for Hydrogen Sulfide Emission Control in Sewer Systems: A Review. Water Res. 2008, 42, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Alwis, L.; Bustamante, H.; Bremer, K.; Roth, B.; Sun, T.; Grattan, K. Evaluation of the Durability and Performance of FBG-Based Sensors for Monitoring Moisture in an Aggressive Gaseous Waste Sewer Environment. J. Light. Technol. 2016, 35, 1. [Google Scholar] [CrossRef]

- Hobbs, D. Concrete Deterioration: Causes, Diagnosis, and Minimising Risk. Int. Mater. Rev. 2001, 46, 117–144. [Google Scholar] [CrossRef]

- Samer, M. Biological and Chemical Wastewater Treatment Processes; BoD–Books on Demand: Norderstedt, Germany, 2015; pp. 1–50. [Google Scholar] [CrossRef]

- Al-Dasoqi, N.; Mason, A.; Alkhaddar, R.; Al-Shamma, A. Use of Sensors in Wastewater Quality Monitoring—A Review of Available Technologies. In Proceedings of the World Environmental and Water Resources Congress 2011: Bearing Knowledge for Sustainability ASCE, Reston, VA, USA, 22–26 May 2011; pp. 3379–3388. [Google Scholar] [CrossRef]

- Asadnia, M.; Chua, L.; Qin, X.; Talei, A. Improved Particle Swarm Optimization-Based Artificial Neural Network for Rainfall-Runoff Modeling. J. Hydrol. Eng. 2014, 19. [Google Scholar] [CrossRef]

- Fisher, A.; Bullen, F.; Beal, D. The durability of cellulose fibre reinforced concrete pipes in sewage applications. Cem. Concr. Res. 2001, 31, 543–553. [Google Scholar] [CrossRef]

- Li, K.; Ma, X.; Zhang, Z.; Song, J.; Xu, Y.; Song, G. Sensitive refractive index sensing with tunable sensing range and good operation angle-polarization-tolerance using graphene concentric ring arrays. J. Phys. D Appl. Phys. 2014, 47, 405101. [Google Scholar] [CrossRef]

- Khadom, A.; Hassan, A.; Abod, B. Evaluation of environmentally friendly inhibitor for galvanic corrosion of steel–copper couple in petroleum waste water. Process. Saf. Environ. Prot. 2015, 98, 93–101. [Google Scholar] [CrossRef]

- Stanaszek-Tomal, E.; Fiertak, M. Biological Corrosion in the Sewage System and the Sewage Treatment Plant. Procedia Eng. 2016, 161, 116–120. [Google Scholar] [CrossRef]

- Cosham, A.; Hopkins, P.; Macdonald, K. Best practice for the assessment of defects in pipelines—Corrosion. Eng. Fail. Anal. 2007, 14, 1245–1265. [Google Scholar] [CrossRef]

- Ahmad, Z. Chapter 2—Basic Concepts in Corrosion. In Principles of Corrosion Engineering and Corrosion Control; Ahmad, Z., Ed.; Butterworth-Heinemann: Oxford, UK, 2006; pp. 9–56. [Google Scholar] [CrossRef]

- Kumari, U.; Samiappan, D.; Kumar, R.; Sudhakar, T. Fiber Optic Sensors in Ocean Observation: A Comprehensive Review. Optik 2018, 179. [Google Scholar] [CrossRef]

- Cheyne, I. Regulation of Marine Antifouling in International and EC Law; Wiley Online Library: Hoboken, NJ, USA, 2010; pp. 306–318. [Google Scholar] [CrossRef]

- Amy, G. Fundamental understanding of organic matter fouling of membranes. Desalination 2008, 231, 44–51. [Google Scholar] [CrossRef]

- Srivastava, P.; Abbassi, R.; Yadav, A.; Garaniya, V.; Jahromi, M. A review on the contribution of an electron flow in electroactive wetlands: Electricity generation and enhanced wastewater treatment. Chemosphere 2020, 126926. [Google Scholar] [CrossRef] [PubMed]

- Moskvicheva, E.; Sidyakin, P.; Shitov, D. Method of Corrosion Prevention in Steel Pressure Pipelines in Sewerage Systems. Procedia Eng. 2016, 150, 2381–2386. [Google Scholar] [CrossRef]

- Giovanangeli, N.; Piyathilaka, L.; Kodagoda, S.; Thiyagarajan, K.; Barclay, S.; Vitanage, D. Design and Development of Drill-Resistance Sensor Technology for Accurately Measuring Microbiologically Corroded Concrete Depths. In Proceedings of the 36th International Symposium on Automation and Robotics in Construction (ISARC), Banff, AL, Canada, 21–24 May 2019; Al-Hussein, M., Ed.; International Association for Automation and Robotics in Construction (IAARC): Banff, AL, Canada, 2019; pp. 735–742. [Google Scholar] [CrossRef]

- Joseph, A.; Keller, J.; Bustamante, H.; Bond, P. Surface neutralization and H2S oxidation at early stages of sewer corrosion: Influence of temperature, relative humidity and H2S concentration. Water Res. 2012, 46, 4235–4245. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, A.; Vollertsen, J.; Hvitved-Jacobsen, T. Kinetics and Stoichiometry of Aerobic Sulfide Oxidation in Wastewater from Sewers—Effects of pH and Temperature. Water Environ. Res. Res. Publ. Water Environ. Fed. 2006, 78, 275–283. [Google Scholar] [CrossRef]

- Sharma, K.; Ganigue, R.; Yuan, Z. PH dynamics in sewers and its modeling. Water Res. 2013, 47. [Google Scholar] [CrossRef]

- Kanagawa, T.; Kamagata, Y.; Aruga, S.; Kohno, T.; Horn, M.; Wagner, M. Phylogenetic Analysis of and Oligonucleotide Probe Development for Eikelboom Type 021N Filamentous Bacteria Isolated from Bulking Activated Sludge. Appl. Environ. Microbiol. 2000, 66, 5043–5052. [Google Scholar] [CrossRef]

- Monteny, J.; Vincke, E.; Beeldens, A.; De Belie, N.; Taerwe, L.; Van Gemert, D.; Verstraete, W. Chemical, microbiological, and in situ test methods for biogenic sulfuric acid corrosion of concrete. Cem. Concr. Res. 2000, 30, 623–634. [Google Scholar] [CrossRef]

- O’Connell, M.; McNally, C.; Richardson, M. Biochemical attack on concrete in wastewater applications: A state of the art review. Cem. Concr. Compos. 2010, 32, 479–485. [Google Scholar] [CrossRef]

- Jensen, H. Hydrogen Sulfide Induced Concrete Corrosion of Sewer Networks. Ph.D. Dissertation, Section of Environmental Engineering Institut for Kemi, Miljøog Bioteknologi, Aalborg Universitet, Aalborg, Denmark, 2009. [Google Scholar]

- Parker, C. The Corrosion of Concrete. Aust. J. Exp. Biol. Med Sci. 1945, 23, 91–98. [Google Scholar] [CrossRef]

- Valix, M.; Zamri, D.; Mineyama, H.; Cheung, W.H.; Shi, J.; Bustamante, H. Microbiologically Induced Corrosion of Concrete and Protective Coatings in Gravity Sewers. Chin. J. Chem. Eng. 2012, 20, 433–438. [Google Scholar] [CrossRef]

- House, M.; Weiss, W. Review of Microbially Induced Corrosion and Comments on Needs Related to Testing Procedures. In Proceedings of the International Conference on the Durability of Concrete Structures, West Lafayette, IN, USA, 24–26 July 2014; pp. 94–103. [Google Scholar] [CrossRef]

- Yuan, H.; Dangla, P.; Chatellier, P.; Chaussadent, T. Degradation modeling of concrete submitted to biogenic acid attack. Cem. Concr. Res. 2015, 70, 29–38. [Google Scholar] [CrossRef]

- Alexander, M.; Fourie, C. Performance of sewer pipe concrete mixtures with portland and calcium aluminate cements subject to mineral and biogenic acid attack. Mater. Struct. 2011, 44, 313–330. [Google Scholar] [CrossRef]

- Wu, L.; Hu, C.; Liu, W. The Sustainability of Concrete in Sewer Tunnel—A Narrative Review of Acid Corrosion in the City of Edmonton, Canada. Sustainability 2018, 10, 517. [Google Scholar] [CrossRef]

- Yang, W.; Vollertsen, J.; Hvitved-Jacobsen, T. Anoxic sulfide oxidation in wastewater of sewer networks. Water Sci. Technol. 2005, 52, 191–199. [Google Scholar] [CrossRef]

- Islander, R.L.; Devinny, J.S.; Mansfeld, F.; Postyn, A.; Shih, H. Microbial Ecology of Crown Corrosion in Sewers. J. Environ. Eng. 1991, 117, 751–770. [Google Scholar] [CrossRef]

- Yuan, H.; Dangla, P.; Chatellier, P.; Chaussadent, T. Design Manual: Sulfide Control in Sanitary Sewerage Systems; Environmental Protection Agency: Washington, DC, USA, 2015.

- Scrivener, K.; Belie, N. Bacteriogenic Sulfuric Acid Attack of Cementitious Materials in Sewage Systems; Springer: Dordrecht, The Netherlands, 2013; Volume 10, pp. 305–318. [Google Scholar] [CrossRef]

- Grengg, C.; Mittermayr, F.; Ukrainczyk, N.; Koraimann, G.; Kienesberger, S.; Dietzel, M. Advances in concrete materials for sewer systems affected by microbial induced concrete corrosion: A review. Water Res. 2018, 134, 341–352. [Google Scholar] [CrossRef]

- Mori, T.; Nonaka, T.; Tazaki, K.; Koga, M.; Hikosaka, Y.; Noda, S. Interactions of nutrients, moisture and pH on microbial corrosion of concrete sewer pipes. Water Res. 1992, 26, 29–37. [Google Scholar] [CrossRef]

- Pomeroy, R.D. Process Design Manual for Sulfide Control in Sanitary Sewerage Systems; US Environmental Protection Agency, Technology Transfer: Washington, DC, USA, 1974.

- House, M.; Cheng, L.; Banks, K.; Weiss, W. Concrete Resistance to Sulfuric Acid Immersion: The Influence of Testing Details and Mixture Design on Performance as It Relates to Microbially Induced Corrosion. Adv. Civ. Eng. Mater. 2019, 8, 20170134. [Google Scholar] [CrossRef]

- Wells, P.; Melchers, R.E. Microbial corrosion of sewer pipe in Australia-initial field results. In Proceedings of the 18th International Corrosion Congress Proceedings, Perth, Australia, 20–24 November 2011; Citeseer: University Park, PA, USA, 2011. [Google Scholar]

- Wells, T.; Melchers, R.E.; Bond, P. Factors involved in the long term corrosion of concrete sewers. In Proceedings of the Corrosion & Prevention—2009, Coffs Harbour, Australia, 15–18 November 2009; Volume 11, pp. 345–356. [Google Scholar]

- Wells, T.; Melchers, R. Modelling concrete deterioration in sewers using theory and field observations. Cem. Concr. Res. 2015, 77, 82–96. [Google Scholar] [CrossRef]

- Lee, W.; Lee, J.H.; Bishop, P.; Papautsky, I. Biological Application of Micro-Electro Mechanical Systems Microelectrode Array Sensors for Direct Measurement of Phosphate in the Enhanced Biological Phosphorous Removal Process. Water Environ. Res. Res. Publ. Water Environ. Fed. 2009, 81, 748–754. [Google Scholar] [CrossRef]

- Lvova, L. Multisensor Systems for Chemical Analysis Materials and Sensors; Jenny Stanford: Singapore, 2014. [Google Scholar] [CrossRef]

- Lvova, L.; Nadporozhskaya, M. 17-Chemical sensors for soil analysis: Principles and applications. In New Pesticides and Soil Sensors; Grumezescu, A.M., Ed.; Academic Press: Cambridge, MA, USA, 2017; pp. 637–678. [Google Scholar]

- Lvova, L.; Natale, C.; Paolesse, R. Chemical Sensors for Water Potability Assessment In Bottled Packaged Water; Grumezescu, A., Holban, A.M., Eds.; Elsevier Science: Amsterdam, The Netherlands, 2019; pp. 177–208. [Google Scholar] [CrossRef]

- Gupta, S.; Gonzalez, J.G.; Loh, K.J. Self-sensing concrete enabled by nano-engineered cement-aggregate interfaces. Struct. Health Monit. 2017, 16, 309–323. [Google Scholar] [CrossRef]

- Ubertini, F.; D’Alessandro, A.; Downey, A.; García-Macías, E.; Laflamme, S.; Castro-Triguero, R. Recent advances on SHM of reinforced concrete and masonry structures enabled by self-sensing structural materials. Proceedings 2017, 2, 119. [Google Scholar] [CrossRef]

- Chung, D.; Wang, Y. Capacitance-based stress self-sensing in cement paste without requiring any admixture. Cem. Concr. Compos. 2018, 94, 255–263. [Google Scholar] [CrossRef]

- Wang, X.; Wang, W.; Li, H.; Fu, C.; ke, Y.; He, S. Development of a SnO2/CuO-coated surface acoustic wave-based H2S sensor with switch-like response and recovery. Sens. Actuators Chem. 2012, 169, 10–16. [Google Scholar] [CrossRef]

- Li, Z.; Shi, Q.; Hu, W.; Li, Y. A sewer sensor monitoring system based on embedded system. In Proceedings of the 2018 13th IEEE Conference on Industrial Electronics and Applications (ICIEA), Wuhan, China, 31 May–2 June 2018; pp. 2817–2820. [Google Scholar]

- Abolpour Moshizi, S.; Azadi, S.; Belford, A.; Razmjou, A.; Wu, S.; Han, Z.J.; Asadnia, M. Development of an ultra-sensitive and flexible piezoresistive flow sensor using vertical graphene nanosheets. Nano-Micro Lett. 2020, 12, 1–18. [Google Scholar] [CrossRef]

- McMurray, H.; Douglas, P.; Abbot, D. Novel thick-film pH sensors based on ruthenium dioxide-glass composites. Sens. Actuators Chem. 1995, 28, 9–15. [Google Scholar] [CrossRef]

- Fog, A.; Buck, R.P. Electronic semiconducting oxides as pH sensors. Sens. Actuators 1984, 5, 137–146. [Google Scholar] [CrossRef]

- Du, R.G.; Hu, R.G.; Huang, R.S.; Lin, C. In Situ Measurement of Cl-Concentrations and pH at the Reinforcing Steel/Concrete Interface by Combination Sensors. Anal. Chem. 2006, 78, 3179–3185. [Google Scholar] [CrossRef] [PubMed]

- Daoudi, J.; Betelu, S.; Tzedakis, T.; Bertrand, J.; Ignatiadis, I. A Multi-Parametric Device with Innovative Solid Electrodes for Long-Term Monitoring of pH, Redox-Potential and Conductivity in a Nuclear Waste Repository. Sensors 2017, 17, 1372. [Google Scholar] [CrossRef]

- Gutiérrez-Capitán, M.; Baldi, A.; Gómez, R.; García, V.; Jiménez-Jorquera, C.; Fernández-Sánchez, C. Electrochemical nanocomposite-derived sensor for the analysis of chemical oxygen demand in urban wastewaters. Anal. Chem. 2015, 87, 2152–2160. [Google Scholar] [CrossRef]

- Manjakkal, L.; Szwagierczak, D.; Dahiya, R. Metal oxides based electrochemical pH sensors: Current progress and future perspectives. Prog. Mater. Sci. 2019, 109, 100635. [Google Scholar] [CrossRef]

- Marques, R.; Oehmen, A.; Pijuan, M. Novel Microelectrode-Based Online System for Monitoring N2O Gas Emissions during Wastewater Treatment. Environ. Sci. Technol. 2014, 48. [Google Scholar] [CrossRef]

- Lim, J.; Kim, J.; Friedman, J.; Lee, U.; Vieira, L.; Rosso, D.; Gerla, M.; Srivastava, M. SewerSnort: A Drifting Sensor for In-situ Wastewater Collection System Gas Monitoring. Ad Hoc Netw. 2011, 11. [Google Scholar] [CrossRef]

- Qu, W.; Meyer, J.U. Thick-film humidity sensor based on porous material. Meas. Sci. Technol. 1997, 8, 593–600. [Google Scholar] [CrossRef]

- Thiyagarajan, K.; Kodagoda, S.; Ranasinghe, R.; Vitanage, D.; Iori, G. Robust sensor suite combined with predictive analytics enabled anomaly detection model for smart monitoring of concrete sewer pipe surface moisture conditions. IEEE Sens. J. 2020, 20, 8232–8243. [Google Scholar] [CrossRef]

- Ali, F.I.; Mahmoud, S.T.; Awwad, F.; Greish, Y.E.; Abu-Hani, A.F. Low power consumption and fast response H2S gas sensor based on a chitosan-CuO hybrid nanocomposite thin film. Carbohydr. Polym. 2020, 236, 116064. [Google Scholar] [CrossRef]

- Ali, F.I.; Awwad, F.; Greish, Y.E.; Mahmoud, S.T. Hydrogen sulfide (H2S) gas sensor: A review. IEEE Sens. J. 2018, 19, 2394–2407. [Google Scholar] [CrossRef]

- Ali, F.I.; Awwad, F.; Greish, Y.E.; Abu-Hani, A.F.; Mahmoud, S.T. Fabrication of low temperature and fast response H2S gas sensor based on organic-metal oxide hybrid nanocomposite membrane. Org. Electron. 2020, 76, 105486. [Google Scholar] [CrossRef]

- Thiyagarajan, K.; Kodagoda, S.; Alvarez, J.K. An instrumentation system for smart monitoring of surface temperature. In Proceedings of the 2016 14th International Conference on Control, Automation, Robotics and Vision (ICARCV), Phuket, Thailand, 13–15 November 2016; pp. 1–6. [Google Scholar]

- Thiyagarajan, K.; Kodagoda, S.; Ranasinghe, R.; Vitanage, D.; Iori, G. Robust sensing suite for measuring temporal dynamics of surface temperature in sewers. Sci. Rep. 2018, 8, 1–11. [Google Scholar] [CrossRef]

- Raj, M.A.; John, S.A. Graphene-modified electrochemical sensors. In Graphene-Based Electrochemical Sensors for Biomolecules; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–41. [Google Scholar]

- Merzbacher, C.I.; Kersey, A.D.; Friebele, E.J. Fiber optic sensors in concrete structures: A review. Smart Mater. Struct. 1996, 5, 196–208. [Google Scholar] [CrossRef]

- Glisic, B. Sensing Solutions for Assessing and Monitoring Pipeline Systems; Woodhead Publishing: Cambridge, UK, 2014; Volume 1, pp. 422–460. [Google Scholar] [CrossRef]

- Leung, C. Fiber optic sensors in concrete: The future? NDT E Int. 2001, 34, 85–94. [Google Scholar] [CrossRef]

- Maaskant, R.; Alavie, T.; Measures, R.; Tadros, G.; Rizkalla, S.; Guha-Thakurta, A. Fiber-optic Bragg grating sensors for bridge monitoring. Cem. Concr. Compos. 1997, 19, 21–33. [Google Scholar] [CrossRef]

- Lee, B. Review of the Present Status of Optical Fiber Sensors. Opt. Fiber Technol. 2003, 9, 57–79. [Google Scholar] [CrossRef]

- Nanni, A.; Yang, C.; Pan, K.; Wang, J.; Michael, R. Fiber-optic sensors for concrete strain/stress measurement. ACI Mater. J. 1991, 88, 257–264. [Google Scholar]

- Hill, K.; Fujii, Y.; Johnson, D.C.; Kawasaki, B. Photosensitivity in optical fiber waveguides: Application to reflection filter fabrication. Appl. Phys. Lett. 1978, 32, 647–649. [Google Scholar] [CrossRef]

- Morey, W.W.; Ball, G.A.; Meltz, G. Photoinduced Bragg gratings in optical fibers. Opt. Photonics News 1994, 5, 8–14. [Google Scholar] [CrossRef]

- Chakravartula, V.; Dhanalakshmi Samiappan, R. Sensitivity enhancement analysis due to diferent coating materials of Fibre Bragg Grating based depth sensor for underwater applications. Opt. Quantum Electron. 2019, 52, 1–15. [Google Scholar]

- Kumari, C.U.; Samiappan, D.; Kumar, R.; Sudhakar, T. Development of a highly accurate and fast responsive salinity sensor based on Nuttall apodized Fiber Bragg Grating coated with hygroscopic polymer for ocean observation. Opt. Fiber Technol. 2019, 53, 102036. [Google Scholar] [CrossRef]

- Wang, H.; Guo, H.; Xiao, G.; Mrad, N.; Kazemi, A.; Ban, D. Phase-Shifted Fiber-Bragg-Grating-Based Humidity Sensor; International Society for Optics and Photonics: Bellingham, WA, USA, 2013; p. 872019. [Google Scholar] [CrossRef]

- Mishra, D.S.; Zou, B.; Chiang, K. Wide-Range pH Sensor Based on a Smart-Hydrogel-Coated Long-Period Fiber Grating. IEEE J. Sel. Top. Quantum Electron. 2016, 23. [Google Scholar] [CrossRef]

- Aldaba, A.L.; González-Vila, Á.; Debliquy, M.; Lopez-Amo, M.; Caucheteur, C.; Lahem, D. Polyaniline-coated tilted fiber Bragg gratings for pH sensing. Sens. Actuators B Chem. 2018, 254, 1087–1093. [Google Scholar] [CrossRef]

- Partridge, M.; Wong, R.; James, S.W.; Davis, F.; Higson, S.P.; Tatam, R.P. Long period grating based toluene sensor for use with water contamination. Sens. Actuators B Chem. 2014, 203, 621–625. [Google Scholar] [CrossRef]

- Jain, V.; Kumbhaj, S.; Sen, P. Long-period fiber grating sensor to determine fluoride contamination in water. RRJoPHY 2018, 7, 36–43. [Google Scholar]

- Liu, H.Y.; Liang, D.K.; Zeng, J.; Jin, J.; Wu, J.; Geng, J. Design of a long-period fiber grating sensor for reinforcing bar corrosion in concrete. J. Intell. Mater. Syst. Struct. 2012, 23, 45–51. [Google Scholar] [CrossRef]

- Manuylovich, E.; Tomyshev, K.; Butov, O. Method for Determining the Plasmon Resonance Wavelength in Fiber Sensors Based on Tilted Fiber Bragg Gratings. Sensors 2019, 19, 4245. [Google Scholar] [CrossRef]

- Ramakrishnan, M.; Rajan, G.; Semenova, Y.; Farrell, G. Overview of Fiber Optic Sensor Technologies for Strain/Temperature Sensing Applications in Composite Materials. Sensors 2016, 16, 99. [Google Scholar] [CrossRef]

- Ansari, F. State-of-the-art in the applications of fiber-optic sensors to cementitious composites. Cem. Concr. Compos. 1997, 19, 3–19. [Google Scholar] [CrossRef]

- Domingues, F.; Radwan, A. Optical Fiber Sensors for loT and Smart Devices; Springer: Berlin, Germany, 2017. [Google Scholar] [CrossRef]

- Sabri, N.; Aljunid, S.; Salim, M.; Fouad, S. Fiber Optic Sensors: Short Review and Applications; Springer: Singapore, 2015; Volume 204, pp. 299–311. [Google Scholar] [CrossRef]

- Werner, J.; Belz, M.; Klein, K.F.; Sun, T.; Grattan, K.T.V. Fast response time fiber optical pH and oxygen sensors. In Optical Fibers and Sensors for Medical Diagnostics and Treatment Applications XX; Gannot, I., Ed.; International Society for Optics and Photonics, SPIE: Bellingham, WA, USA, 2020; Volume 11233, pp. 188–195. [Google Scholar] [CrossRef]

- Yeo, T.; Sun, T.; Grattan, K. Fibre-optic sensor technologies for humidity and moisture measurement. Sens. Actuators A Phys. 2008, 144, 280–295. [Google Scholar] [CrossRef]

- Zhang, J.X.; Hoshino, K. Mechanical transducers: Cantilevers, acoustic wave sensors, and thermal sensors. Mol. Sens. Nanodevices 2014, 321–414. [Google Scholar]

- Ramos, S.; Yamanaka, H.; Zanoni, M. Electrochemical Sensors: A Powerful Tool in Analytical Chemistry. J. Braz. Chem. Soc. 2003, 14. [Google Scholar] [CrossRef]

- Swallow, J.G.; Kim, J.J.; Malone, J.M.; Chen, D.; Smith, J.F.; Bishop, S.R.; Tuller, H.L.; Van Vliet, K.J. Dynamic Chemical Expansion of Thin Film Non-Stoichiometric Oxides at Extreme Temperatures. ECS Meet. Abstr. 2016. [Google Scholar] [CrossRef]

- Kim, K.H.; Hong, Y.J.; Pal, R.; Jeon, E.C.; Koo, Y.S.; Sunwoo, Y. Investigation of carbonyl compounds in air from various industrial emission sources. Chemosphere 2008, 70, 807–820. [Google Scholar] [CrossRef]

- Guidotti, T. Hydrogen Sulfide. Int. J. Toxicol. 2010, 29, 569–581. [Google Scholar] [CrossRef]

- Kilburn, K.; Warshaw, R. Hydrogen Sulfide and Reduced-Sulfur Gases Adversely Affect Neurophysiological Functions. Toxicol. Ind. Health 1995, 11, 185–197. [Google Scholar] [CrossRef]