Dual-Control-Gate Reconfigurable Ion-Sensitive Field-Effect Transistor with Nickel-Silicide Contacts for Adaptive and High-Sensitivity Chemical Sensing Beyond the Nernst Limit

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

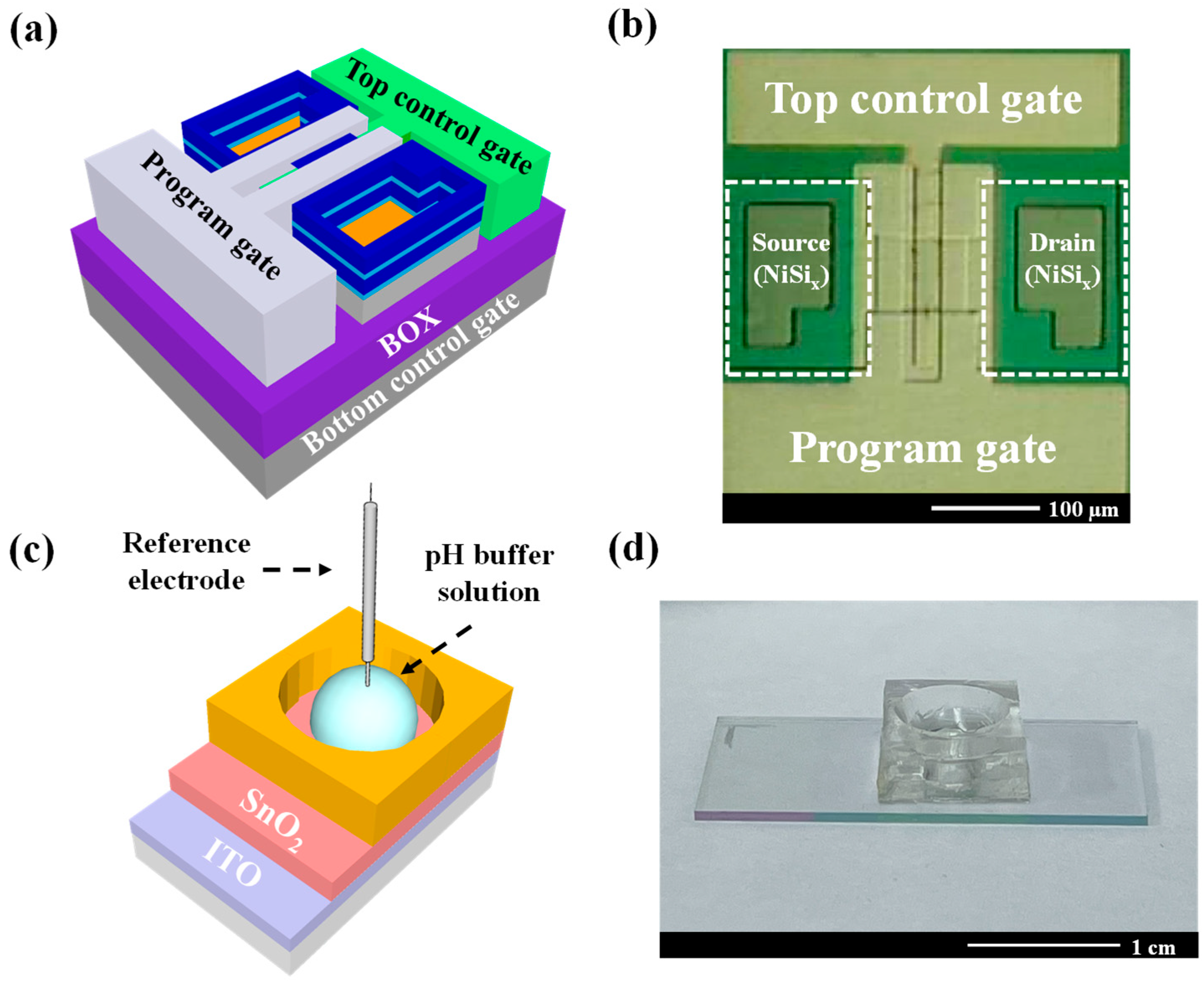

2.2. Fabrication of R-ISFET Transducer Unit and SnO2-Based EG-Sensing Membrane

2.3. Device Characteristics

3. Results and Discussion

3.1. Characterization of Ni-Silicide S/D for Ambipolar Conduction

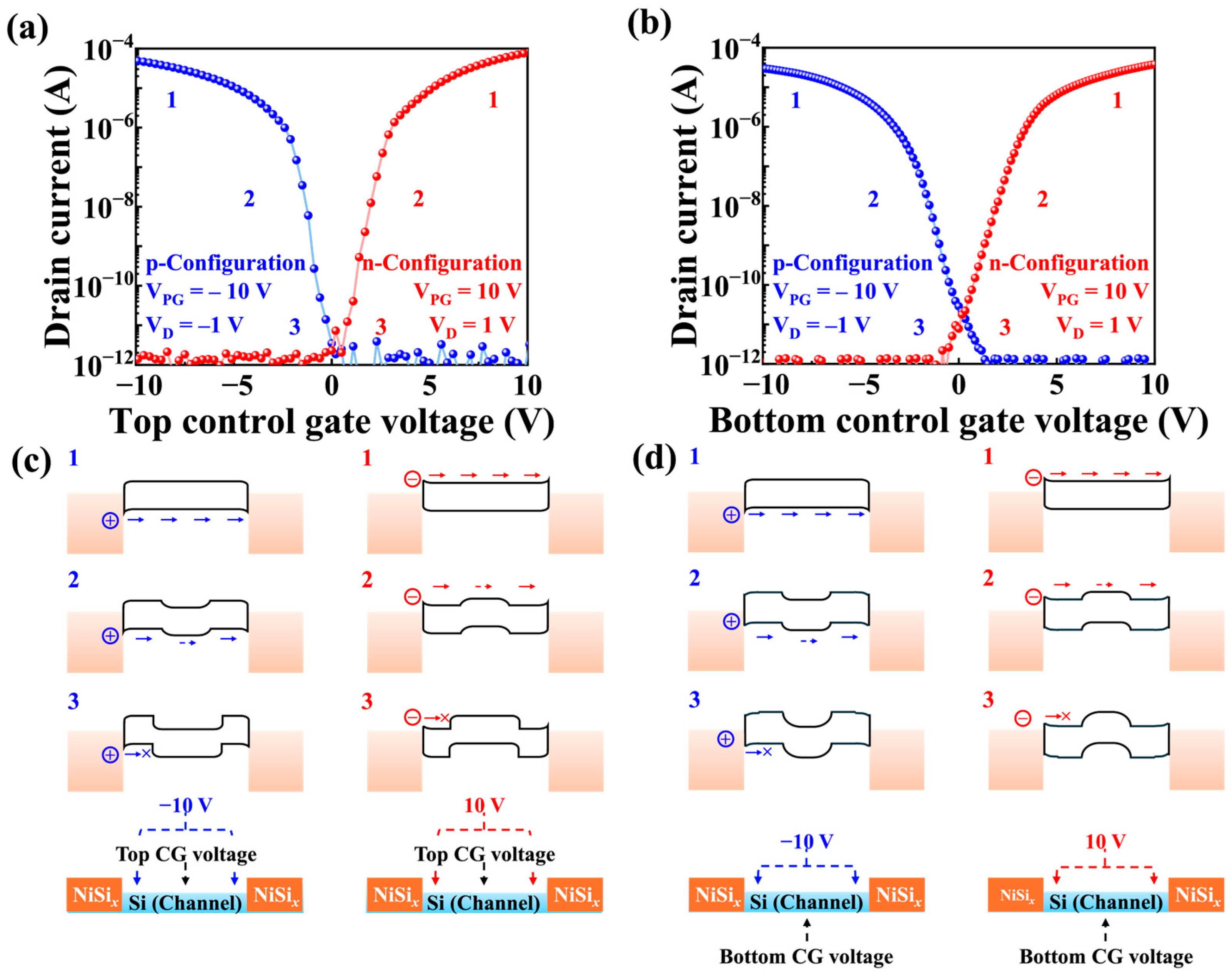

3.2. Electrical Characteristics of R-ISFET with Dynamic Reconfigurability

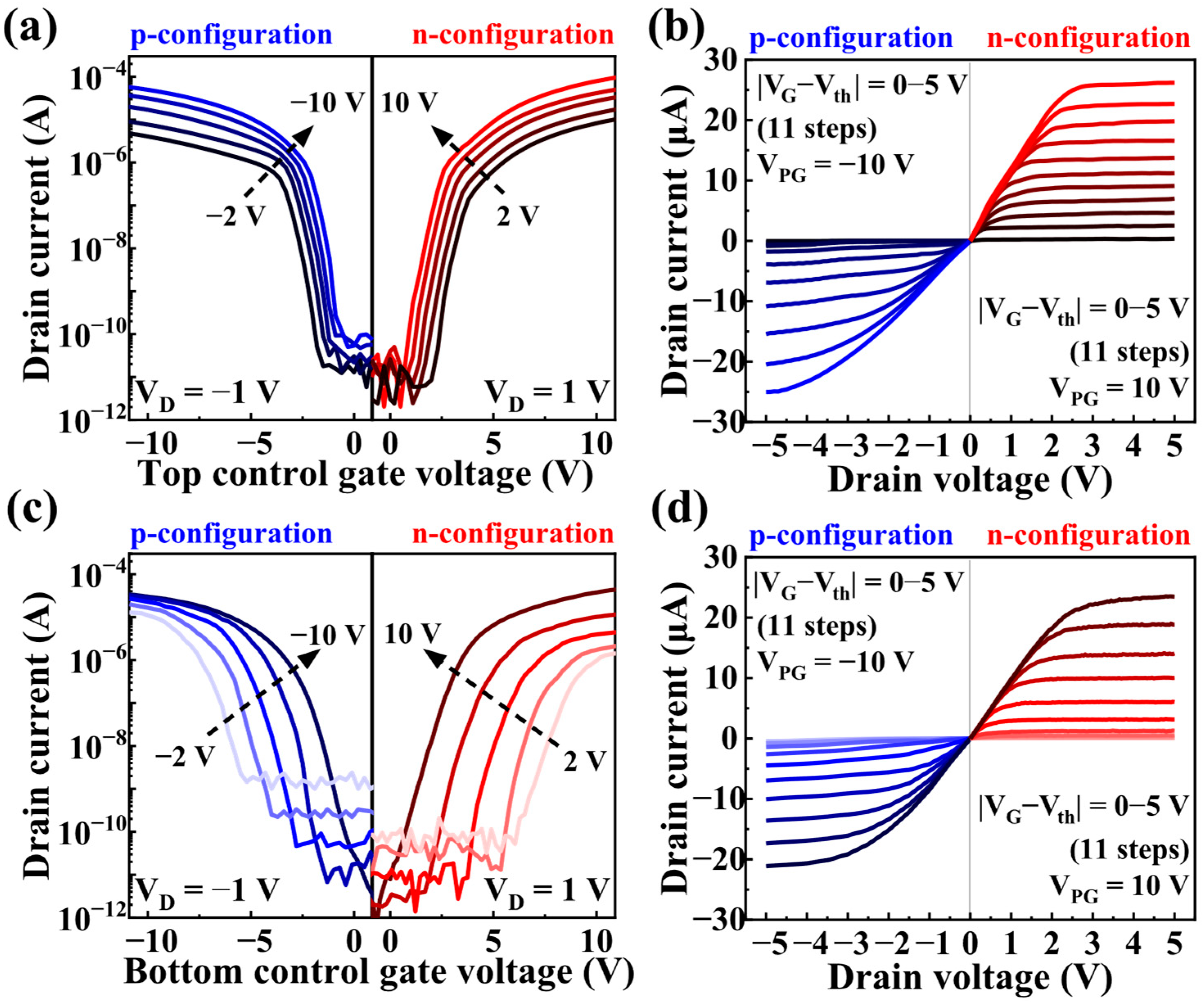

3.3. Electrical Characteristics of R-ISFET with Enhanced Dynamic Reconfigurability

3.4. Sensing Performance of the R-ISFET Sensor

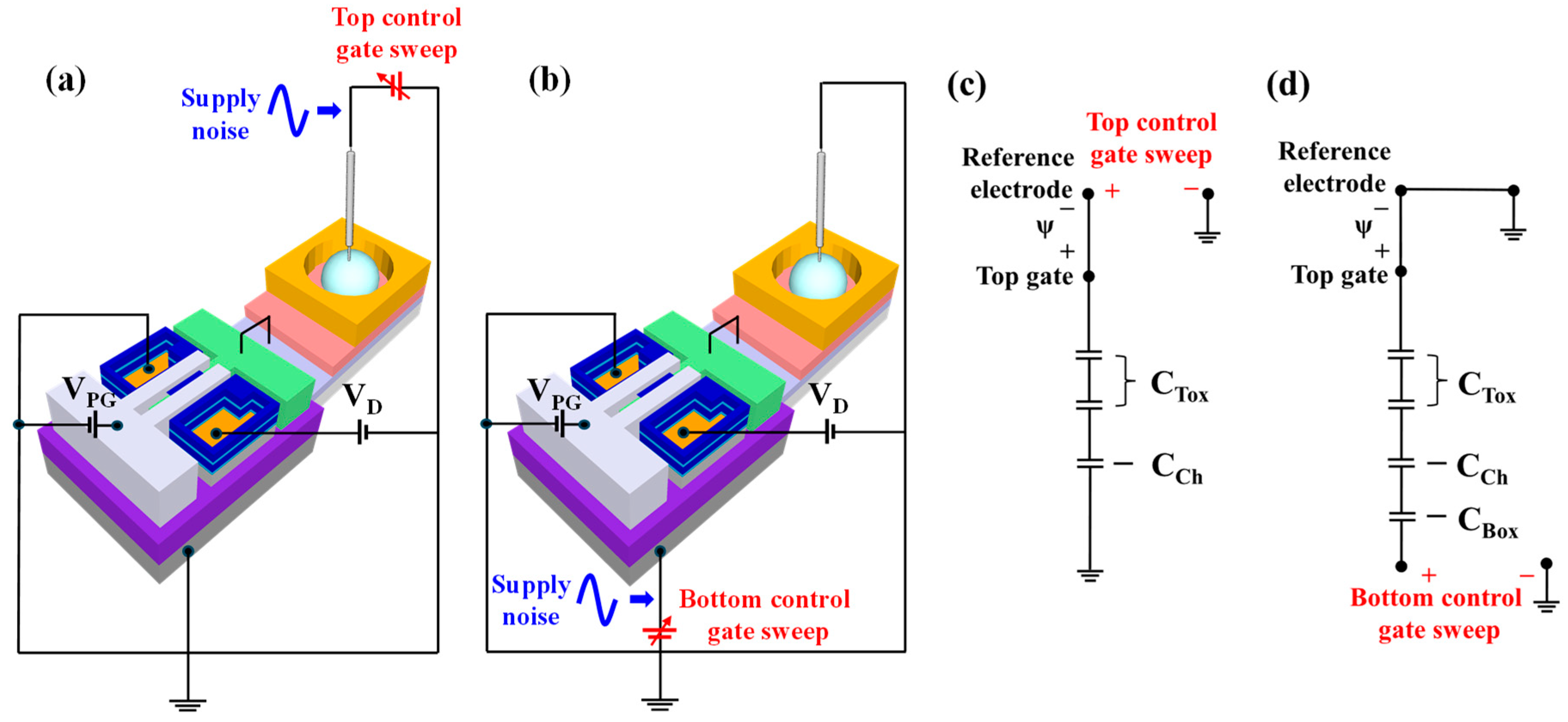

3.4.1. DCG Mechanism and Operating Modes

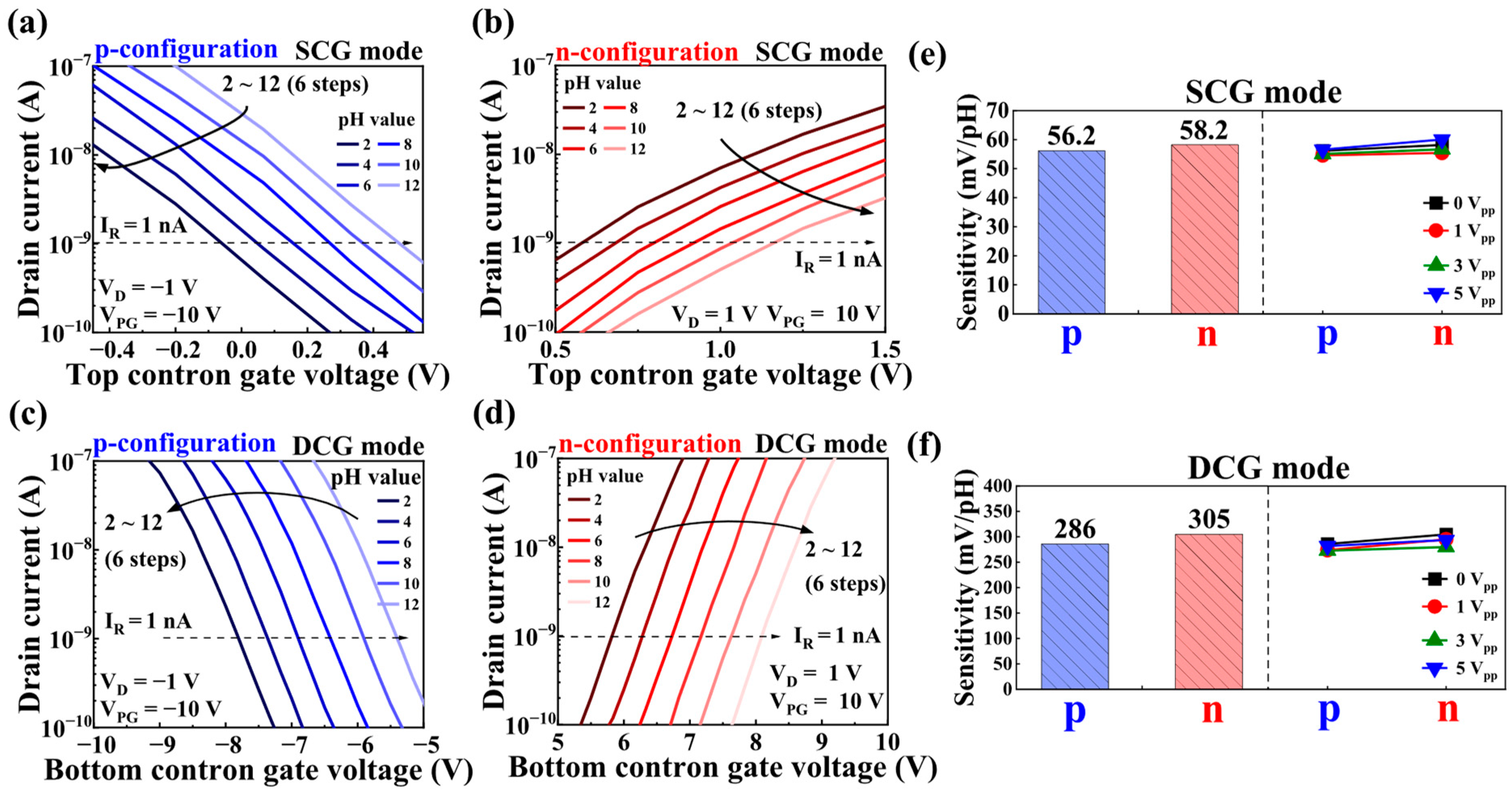

3.4.2. pH Sensing Performance of the R-ISFET Sensor

3.5. Non-Ideal Effects of the R-ISFET Sensor

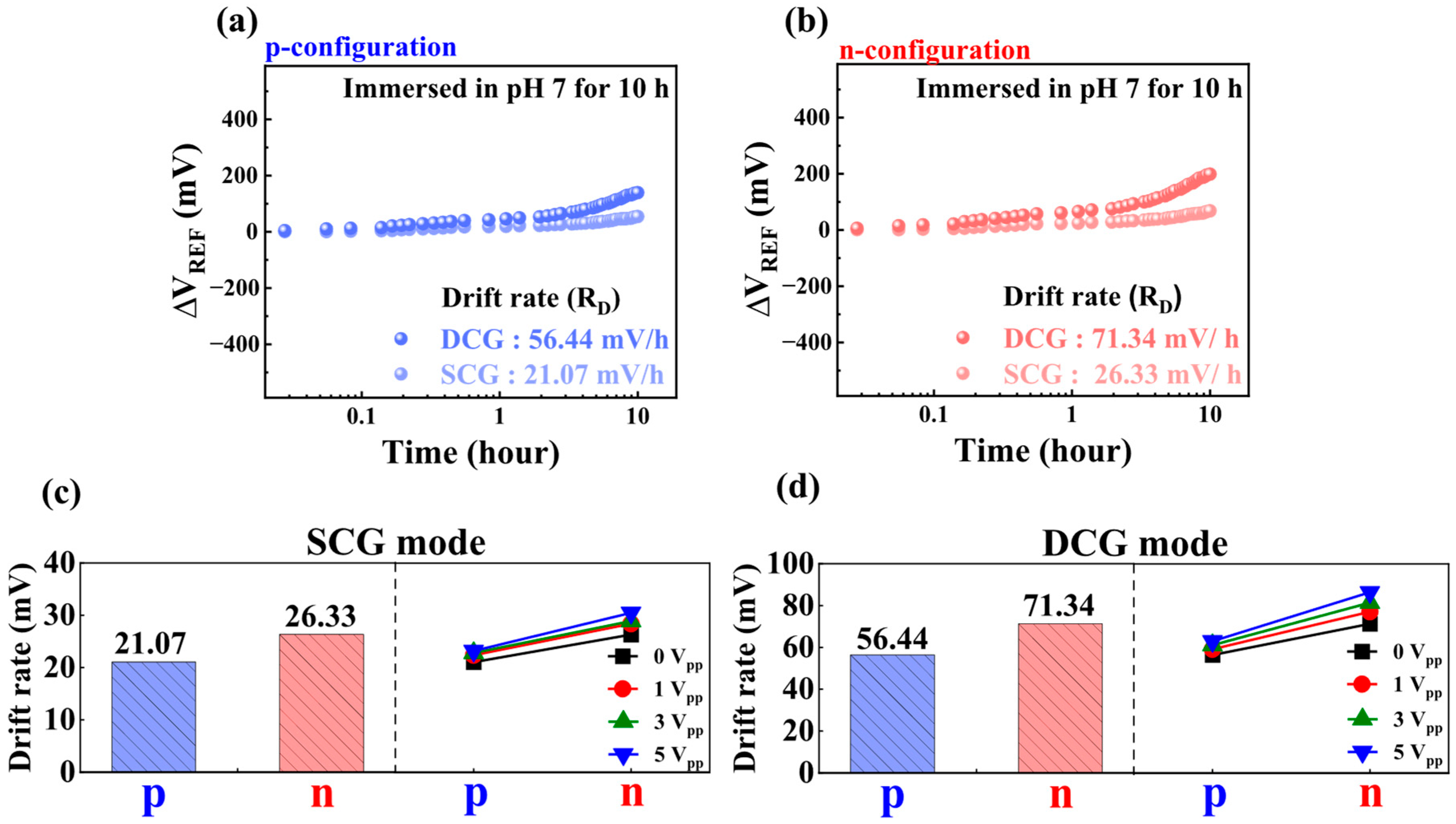

3.5.1. Hysteresis Effect

3.5.2. Drift Effect

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, Y.; Wu, Y.; Mishra, A.; Acha, V.; Andrews, T.; Hornsby, P.J. Biosensor technology in aging research and age-related diseases. Ageing Res. Rev. 2012, 11, 1–9. [Google Scholar] [CrossRef]

- Pejcic, B.; De Marco, R.; Parkinson, G. The role of biosensors in the detection of emerging infectious diseases. Analyst 2006, 131, 1079–1090. [Google Scholar] [CrossRef]

- Kim, D.; Min, J.; Ko, S.H. Recent Developments and Future Directions of Wearable Skin Biosignal Sensors. Adv. Sens. Res. 2024, 3, 2300118. [Google Scholar] [CrossRef]

- Wadhera, T.; Kakkar, D.; Wadhwa, G.; Raj, B. Recent Advances and Progress in Development of the Field Effect Transistor Biosensor: A Review. J. Electron. Mater. 2019, 48, 7635–7646. [Google Scholar] [CrossRef]

- Singh, D.; Patil, G.C. Performance Analysis of Feedback Field-Effect Transistor-Based Biosensor. IEEE Sens. J. 2020, 20, 13269–13276. [Google Scholar] [CrossRef]

- Holgado, M.; Maigler, M.; Santamaría, B.; Hernandez, A.; Lavín, A.; Laguna, M.; Sanza, F.; Granados, D.; Casquel, R.; Portilla, J.; et al. Towards reliable optical label-free point-of-care (PoC) biosensing devices. Sens. Actuators B Chem. 2016, 236, 765–772. [Google Scholar] [CrossRef]

- Narayan, R. (Ed.) Medical Biosensors for Point of Care (POC) Applications; Woodhead Publishing: Cambridge, UK, 2016. [Google Scholar]

- Cheon, J.; Qin, J.; Lee, L.P.; Lee, H. Advances in Biosensor Technologies for Infection Diagnostics. Accounts Chem. Res. 2022, 55, 121–122. [Google Scholar] [CrossRef]

- Han, Y.D.; Chun, H.J.; Yoon, H.C. Low-cost Point-of-Care Biosensors Using Common Electronic Components as Transducers. BioChip J. 2020, 14, 32–47. [Google Scholar] [CrossRef]

- Shi, X.; Pu, H.; Shi, L.L.; He, T.-C.; Chen, J. Advancing transistor-based point-of-care (POC) biosensors: Additive manufacturing technologies and device integration strategies for real-life sensing. Nanoscale 2025, 17, 9804–9833. [Google Scholar] [CrossRef]

- Amen, M.T.; Pham, T.T.T.; Cheah, E.; Tran, D.P.; Thierry, B. Metal-Oxide FET Biosensor for Point-of-Care Testing: Overview and Perspective. Molecules 2022, 27, 7952. [Google Scholar] [CrossRef]

- Al-Younis, Z.K.; Almajidi, Y.Q.; Mansouri, S.; Ahmad, I.; Turdialiyev, U.; Alsaab, H.O.; Ramadan, M.F.; Joshi, S.K.; Alawadi, A.H.; Alsaalamy, A. Label-Free Field Effect Transistors (FETs) for Fabrication of Point-of-Care (POC) Biomedical Detection Probes. Crit. Rev. Anal. Chem. 2024, 1–22. [Google Scholar] [CrossRef]

- Gao, A.; Lu, N.; Wang, Y.; Li, T. Robust ultrasensitive tunneling-FET biosensor for point-of-care diagnostics. Sci. Rep. 2016, 6, 22554. [Google Scholar] [CrossRef]

- Li, J.; Wijaya, L.N.A.; Jang, D.W.; Hu, Y.; You, J.; Cai, Y.; Gao, Z.; Mi, Y.; Luo, Z. 2D Materials-Based Field-Effect Transistor Biosensors for Healthcare. Small 2025, 21, e2408961. [Google Scholar] [CrossRef]

- Cao, S.; Sun, P.; Xiao, G.; Tang, Q.; Sun, X.; Zhao, H.; Zhao, S.; Lu, H.; Yue, Z. ISFET-based sensors for (bio)chemical applications: A review. Electrochem. Sci. Adv. 2023, 3, e2100207. [Google Scholar] [CrossRef]

- Rani, D.; Singh, Y.; Salker, M.; Vu, X.T.; Ingebrandt, S.; Pachauri, V. Point-of-care-ready nanoscale ISFET arrays for sub-picomolar detection of cytokines in cell cultures. Anal. Bioanal. Chem. 2020, 412, 6777–6788. [Google Scholar] [CrossRef] [PubMed]

- Pijanowska, D.G.; Torbicz, W. pH-ISFET based urea biosensor. Sens. Actuators B Chem. 1997, 44, 370–376. [Google Scholar] [CrossRef]

- Chou, J.C.; Wang, Y.F. Preparation and study on the drift and hysteresis properties of the tin oxide gate ISFET by the sol–gel method. Sens. Actuators B Chem. 2002, 86, 58–62. [Google Scholar] [CrossRef]

- Bergveld, P. Development of an Ion-Sensitive Solid-State Device for Neurophysiological Measurements. IEEE Trans. Biomed. Eng. 1970, BME–17, 70–71. [Google Scholar] [CrossRef] [PubMed]

- Bergveld, P. Thirty years of ISFETOLOGY: What happened in the past 30 years and what may happen in the next 30 years. Sens. Actuators B Chem. 2003, 88, 1–20. [Google Scholar] [CrossRef]

- Jakobson, C.G.; Nemirovsky, Y. 1/f noise in ion sensitive field effect transistors from subthreshold to saturation. IEEE Trans. Electron Devices 1999, 46, 259–261. [Google Scholar] [CrossRef]

- Panahi, A.; Sadighbayan, D.; Forouhi, S.; Ghafar-Zadeh, E. Recent Advances of Field-Effect Transistor Technology for Infectious Diseases. Biosensors 2021, 11, 103. [Google Scholar] [CrossRef]

- Kim, Y.-U.; Cho, W.-J. High-Performance Bidirectional Chemical Sensor Platform Using Double-Gate Ion-Sensitive Field-Effect Transistor with Microwave-Assisted Ni-Silicide Schottky-Barrier Source/Drain. Chemosensors 2022, 10, 122. [Google Scholar] [CrossRef]

- Mikolajick, T.; Heinzig, A.; Trommer, J.; Baldauf, T.; Weber, W. The RFET—A reconfigurable nanowire transistor and its application to novel electronic circuits and systems. Semicond. Sci. Technol. 2017, 32, 043001. [Google Scholar] [CrossRef]

- Zheng, S.; Zhou, J.; Wang, C.; Li, K.; Fang, C.; Li, X.; Liang, J.; Liu, Y.; Hao, Y.; Han, G. A Ferroelectric Reconfigurable Memory with Excitatory and Inhibitory Synaptic Responses. In Proceedings of the 2024 IEEE International Conference on IC Design and Technology (ICICDT), Singapore, 25–27 September 2024; pp. 1–4. [Google Scholar] [CrossRef]

- Jang, H.-J.; Cho, W.-J. Performance Enhancement of Capacitive-Coupling Dual-gate Ion-Sensitive Field-Effect Transistor in Ultra-Thin-Body. Sci. Rep. 2014, 4, 5284. [Google Scholar] [CrossRef]

- Kang, J.W.; Cho, W.J. Achieving enhanced pH sensitivity using capacitive coupling in extended gate FET sensors with various high-K sensing films. Solid-State Electron. 2019, 152, 29–32. [Google Scholar] [CrossRef]

- Cho, S.-K.; Cho, W.-J. Ultra-high sensitivity pH-sensors using silicon nanowire channel dual-gate field-effect transistors fabricated by electrospun polyvinylpyrrolidone nanofibers pattern template transfer. Sens. Actuators B Chem. 2021, 326, 128835. [Google Scholar] [CrossRef]

- Bhatt, D.; Panda, S. Dual-Gate Ion-Sensitive Field-Effect Transistors: A Review. Electrochem. Sci. Adv. 2021, 1, 10. [Google Scholar] [CrossRef]

- Biswas, A.; Rajan, C.; Samajdar, D.P. A Novel RFET Sensor for Label-Free Biomolecule Detection. Silicon 2022, 14, 9533–9541. [Google Scholar] [CrossRef]

- Reyes, P.I.; Ku, C.-J.; Duan, Z.; Lu, Y.; Solanki, A.; Lee, K.-B. ZnO Thin Film Transistor Immunosensor with High Sensitivity and Selectivity. Appl. Phys. Lett. 2011, 98, 173702. [Google Scholar] [CrossRef]

- Lee, J.; Dak, P.; Lee, Y.; Park, H.; Choi, W.; Alam, M.A.; Kim, S. Two-Dimensional Layered MoS2 Biosensors Enable Highly Sensitive Detection of Biomolecules. Sci. Rep. 2014, 4, 7352. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Li, X.; Lee, Y.-K.; Zhang, A. Direct Label-Free Protein Detection in High Ionic Strength Solution and Human Plasma Using Dual-Gate Nanoribbon-Based Ion-Sensitive Field-Effect Transistor Biosensor. Biosens. Bioelectron. 2018, 117, 276–282. [Google Scholar] [CrossRef]

- Pullano, S.A.; Critello, C.D.; Mahbub, I.; Tasneem, N.T.; Shamsir, S.; Islam, S.K.; Greco, M.; Fiorillo, A.S. EGFET-Based Sensors for Bioanalytical Applications: A Review. Sensors 2018, 18, 4042. [Google Scholar] [CrossRef] [PubMed]

- van der Spiegel, J.; Lauks, I.; Chan, P.; Babic, D. The extended gate chemically sensitive field effect transistor as multi-species microprobe. Sens. Actuators 1983, 4, 291–298. [Google Scholar] [CrossRef]

- Chen, J.-C.; Chou, J.-C.; Sun, T.-P.; Hsiung, S.-K. Portable urea biosensor based on the extended-gate field effect transistor. Sens. Actuators B Chem. 2003, 91, 180–186. [Google Scholar] [CrossRef]

- Knoll, L.; Zhao, Q.T.; Habicht, S.; Urban, C.; Ghyselen, B.; Mantl, S. Ultrathin Ni Silicides With Low Contact Resistance on Strained and Unstrained Silicon. IEEE Electron Device Lett. 2010, 31, 350–352. [Google Scholar] [CrossRef]

- Kim, G.B.; Yoo, D.-J.; Baik, H.K.; Myoung, J.-M.; Lee, S.M.; Oh, S.H.; Park, C.G. Improved thermal stability of Ni silicide on Si (100) through reactive deposition of Ni. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2003, 21, 319–322. [Google Scholar] [CrossRef]

- Min, J.-G.; Lee, D.-H.; Kim, Y.-U.; Cho, W.-J. Implementation of Ambipolar Polysilicon Thin-Film Transistors with Nickel Silicide Schottky Junctions by Low-Thermal-Budget Microwave Annealing. Nanomaterials 2022, 12, 628. [Google Scholar] [CrossRef]

- Seger, J.; Hellström, P.-E.; Lu, J.; Malm, B.G.; von Haartman, M.; Östling, M.; Zhang, S.-L. Lateral encroachment of Ni-silicides in the source/drain regions on ultrathin silicon-on-insulator. Appl. Phys. Lett. 2005, 86, 253507. [Google Scholar] [CrossRef]

- Bhaskaran, M.; Sriram, S.; Mitchell, D.; Short, K.; Holland, A.; Mitchell, A. Microstructural investigation of nickel silicide thin films and the silicide–silicon interface using transmission electron microscopy. Micron 2009, 40, 11–14. [Google Scholar] [CrossRef]

- Chiu, W.-L.; Chiu, C.-H.; Chen, J.-Y.; Huang, C.-W.; Huang, Y.-T.; Lu, K.-C.; Hsin, C.-L.; Yeh, P.-H.; Wu, W.-W. Single-crystalline δ-Ni2Si nanowires with excellent physical properties. Nanoscale Res. Lett. 2013, 8, 290. [Google Scholar] [CrossRef]

- Navarro, C.; Barraud, S.; Martinie, S.; Lacord, J.; Jaud, M.-A.; Vinet, M. Reconfigurable field effect transistor for advanced CMOS: Advantages and limitations. Solid-state Electron. 2017, 128, 155–162. [Google Scholar] [CrossRef]

- Nishioka, Y.; Shinriki, H.; Mukai, K. Influence of SiO2 at the Ta2O5/Si interface on dielectric characteristics of Ta2O5 capacitors. J. Appl. Phys. 1987, 61, 2335–2338. [Google Scholar] [CrossRef]

- Krauss, T.; Wessely, F.; Schwalke, U. An electrostatically doped planar device concept. In Proceedings of the 9th IEEE International Conference on Design & Technology of Integrated Systems in Nanoscale Era (DTIS), Santorini, Greece, 6–8 May 2014; pp. 1–4. [Google Scholar] [CrossRef]

- Kim, J.B.; Fuentes-Hernandez, C.; Kim, S.-J.; Potscavage, W., Jr.; Choi, S.; Kippelen, B. Ambipolar thin-film transistors with a co-planar channel geometry. Org. Electron. 2010, 11, 1351–1356. [Google Scholar] [CrossRef]

- Nomura, K.; Kamiya, T.; Hosono, H. Ambipolar oxide thin-film transistor. Adv. Mater. 2011, 23, 3431–3434. [Google Scholar] [CrossRef]

- Go, J.; Nair, P.R.; Alam, M.A. Theory of signal and noise in double-gated nanoscale electronic pH sensors. J. Appl. Phys. 2012, 112, 34516. [Google Scholar] [CrossRef]

- Wu, T.; Alharbi, A.; You, K.-D.; Kisslinger, K.; Stach, E.A.; Shahrjerdi, D. Experimental study of the detection limit in dual-gate biosensors using ultrathin silicon transistors. ACS Nano 2017, 11, 7241–7249. [Google Scholar] [CrossRef]

- Um, J.; Kim, S.E. Homo-Junction pn Diode Using p-Type SnO and n-Type SnO2 Thin Films. ECS Solid State Lett. 2014, 3, P94–P98. [Google Scholar] [CrossRef]

- Achour, R.; Said, B.; Boubaker, B. Preparation of n-type semiconductor SnO2 thin films. J. Semicond. 2013, 34, 083002. [Google Scholar] [CrossRef]

- Kurzweil, P. Metal oxides and ion-exchanging surfaces as pH sensors in liquids: State-of-the-art and outlook. Sensors 2009, 9, 4955–4985. [Google Scholar] [CrossRef]

- Varghese, O.K.; Grimes, C.A. Metal Oxide Nanoarchitectures for Environmental Sensing. J. Nanosci. Nanotechnol. 2003, 3, 277–293. [Google Scholar] [CrossRef] [PubMed]

- Peighambardoust, S.J.; Rowshanzamir, S.; Amjadi, M. Review of the proton exchange membranes for fuel cell applications. Int. J. Hydrog. Energy 2010, 35, 9349–9384. [Google Scholar] [CrossRef]

- Kim, S.; Kwon, D.W.; Kim, S.; Lee, R.; Kim, T.-H.; Mo, H.-S.; Kim, D.H.; Park, B.-G. Analysis of current drift on p-channel pH-Sensitive SiNW ISFET by capacitance measurement. Curr. Appl. Phys. 2018, 18, S68–S74. [Google Scholar] [CrossRef]

- Chen, D.Y.; Chan, P.K. An Intelligent ISFET Sensory System with Temperature and Drift Compensation for Long-Term Monitoring. IEEE Sens. J. 2008, 8, 1948–1959. [Google Scholar] [CrossRef]

- Zeng, H.; Takahashi, T.; Kanai, M.; Zhang, G.; He, Y.; Nagashima, K.; Yanagida, T. Long-Term Stability of Oxide Nanowire Sensors via Heavily Doped Oxide Contact. ACS Sens. 2017, 2, 1854–1859. [Google Scholar] [CrossRef]

- Jakob, M.H.; Dong, B.; Gutsch, S.; Chatelle, C.; Krishnaraja, A.; Weber, W.; Zacharias, M. Label-Free SnO2 Nanowire FET Biosensor for Protein Detection. Nanotechnology 2017, 28, 245503. [Google Scholar] [CrossRef]

| Operation Mode | Configuration | VTH (V) | Ion/off (A/A) | μFE (c/V∙s) | SS (mV/dec) |

|---|---|---|---|---|---|

| Top CG operation | n | 1.6 | 105 | 464 | 347 |

| p | −1.1 | 104 | 371 | 328 | |

| Bottom CG operation | n | 2.1 | 106 | 262 | 575 |

| p | −1.5 | 106 | 204 | 600 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.-J.; Lee, S.-H.; Choi, S.-H.; Cho, W.-J. Dual-Control-Gate Reconfigurable Ion-Sensitive Field-Effect Transistor with Nickel-Silicide Contacts for Adaptive and High-Sensitivity Chemical Sensing Beyond the Nernst Limit. Chemosensors 2025, 13, 281. https://doi.org/10.3390/chemosensors13080281

Lee S-J, Lee S-H, Choi S-H, Cho W-J. Dual-Control-Gate Reconfigurable Ion-Sensitive Field-Effect Transistor with Nickel-Silicide Contacts for Adaptive and High-Sensitivity Chemical Sensing Beyond the Nernst Limit. Chemosensors. 2025; 13(8):281. https://doi.org/10.3390/chemosensors13080281

Chicago/Turabian StyleLee, Seung-Jin, Seung-Hyun Lee, Seung-Hwa Choi, and Won-Ju Cho. 2025. "Dual-Control-Gate Reconfigurable Ion-Sensitive Field-Effect Transistor with Nickel-Silicide Contacts for Adaptive and High-Sensitivity Chemical Sensing Beyond the Nernst Limit" Chemosensors 13, no. 8: 281. https://doi.org/10.3390/chemosensors13080281

APA StyleLee, S.-J., Lee, S.-H., Choi, S.-H., & Cho, W.-J. (2025). Dual-Control-Gate Reconfigurable Ion-Sensitive Field-Effect Transistor with Nickel-Silicide Contacts for Adaptive and High-Sensitivity Chemical Sensing Beyond the Nernst Limit. Chemosensors, 13(8), 281. https://doi.org/10.3390/chemosensors13080281