A Comprehensive Review of Advanced Sensor Technologies for Fire Detection with a Focus on Gasistor-Based Sensors

Abstract

1. Introduction

2. Fundamentals of Fire Detection and Sensor Technology

2.1. Fire Characteristics and Indicators

2.1.1. Smoke

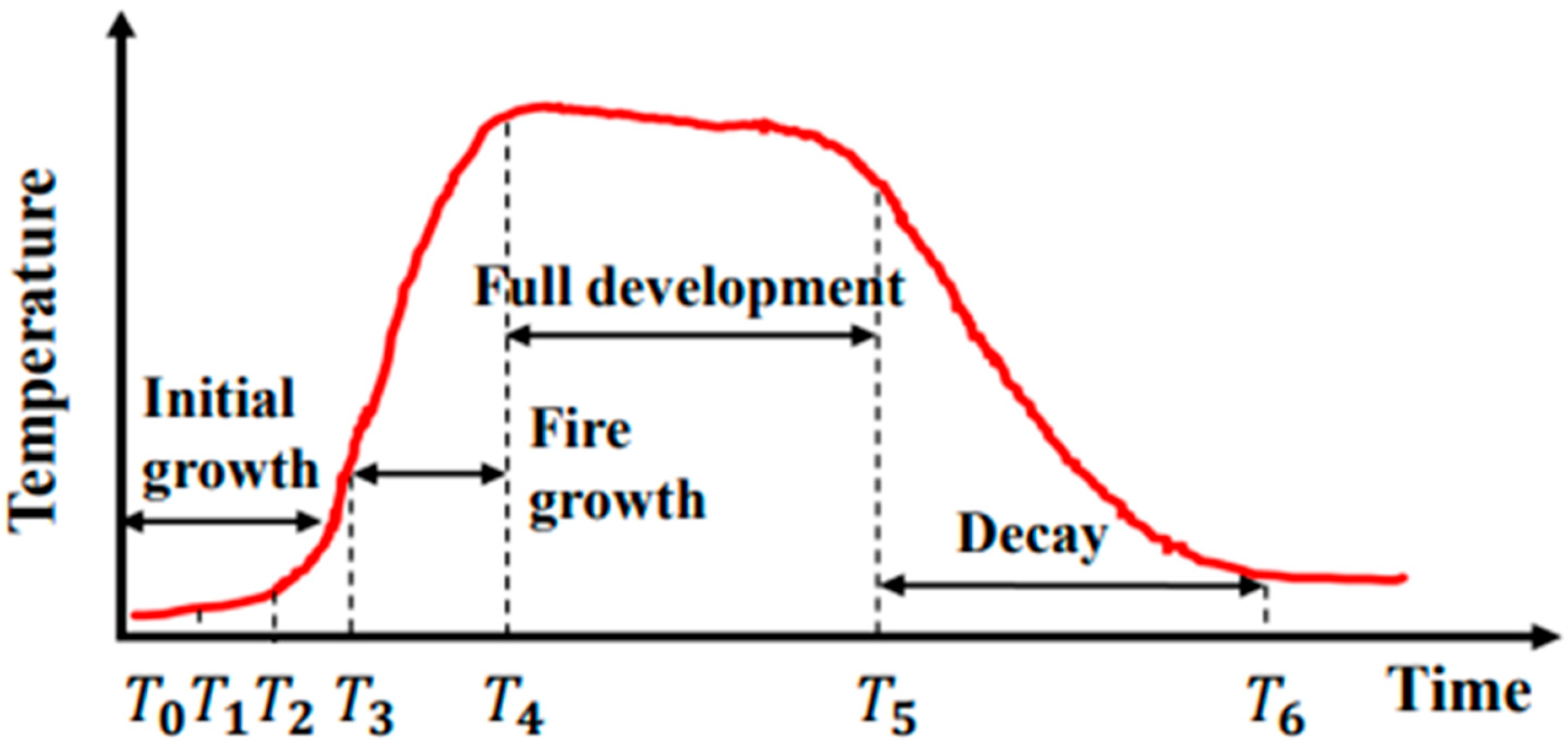

2.1.2. Thermal Energy

2.1.3. Gas Emissions

3. Main Toxicants for Fire Emissions

3.1. Carbon Dioxide

3.2. Carbon Monoxide

3.3. Hydrogen Cyanide

3.4. Halogen Acids

3.5. Nitrogen Oxides

4. Key Requirements for Fire Detectors

4.1. Sensitivity and Selectivity

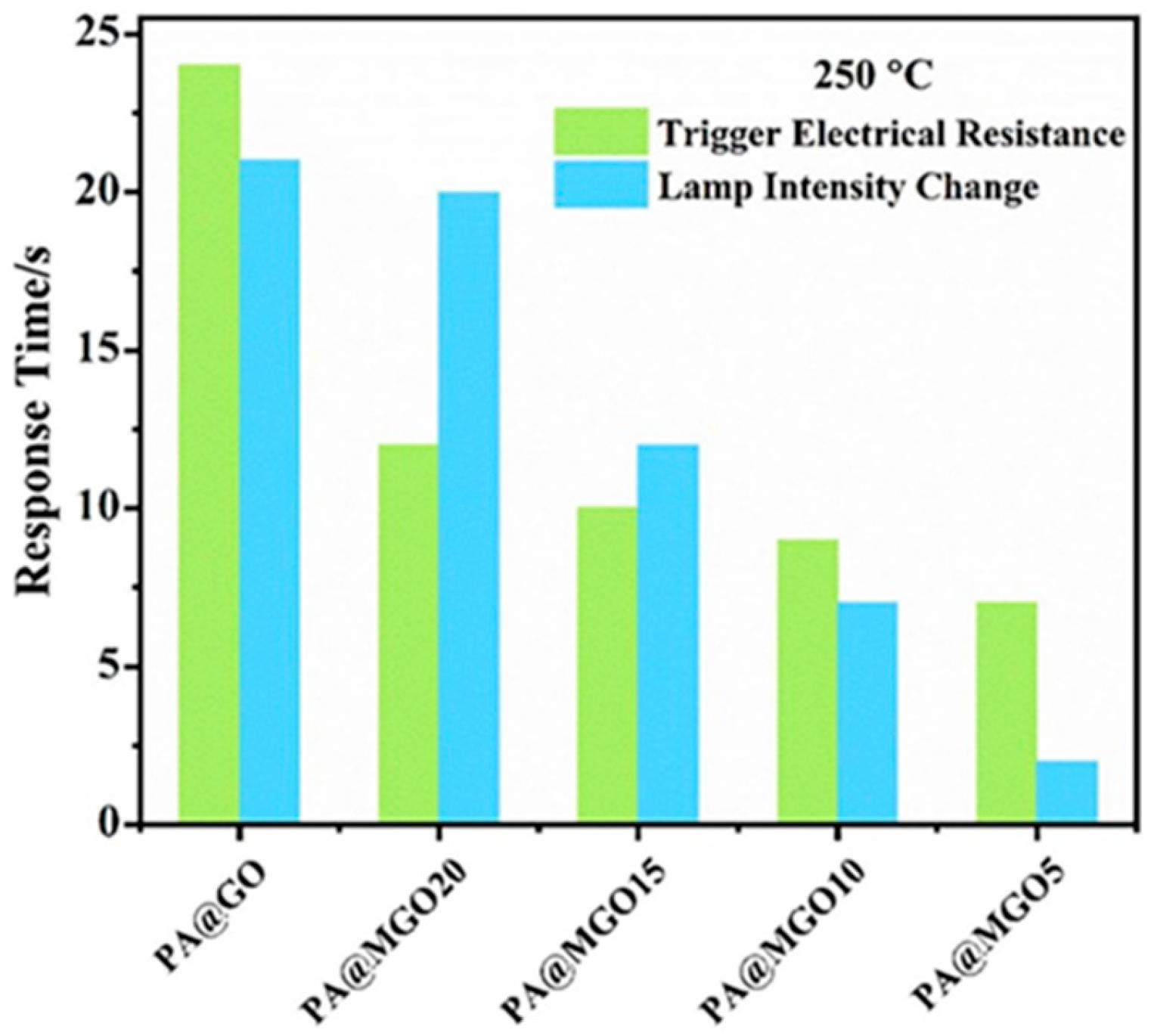

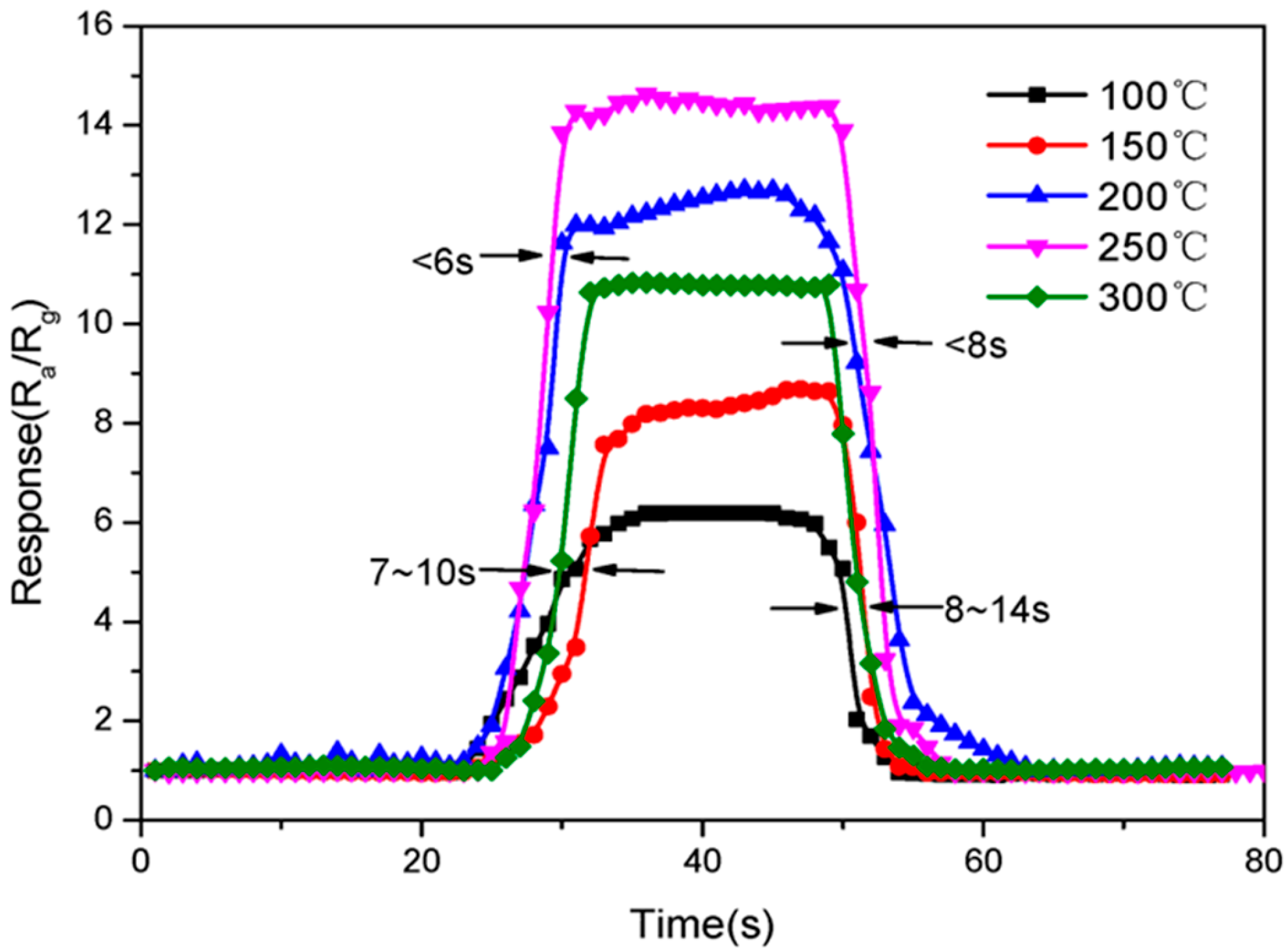

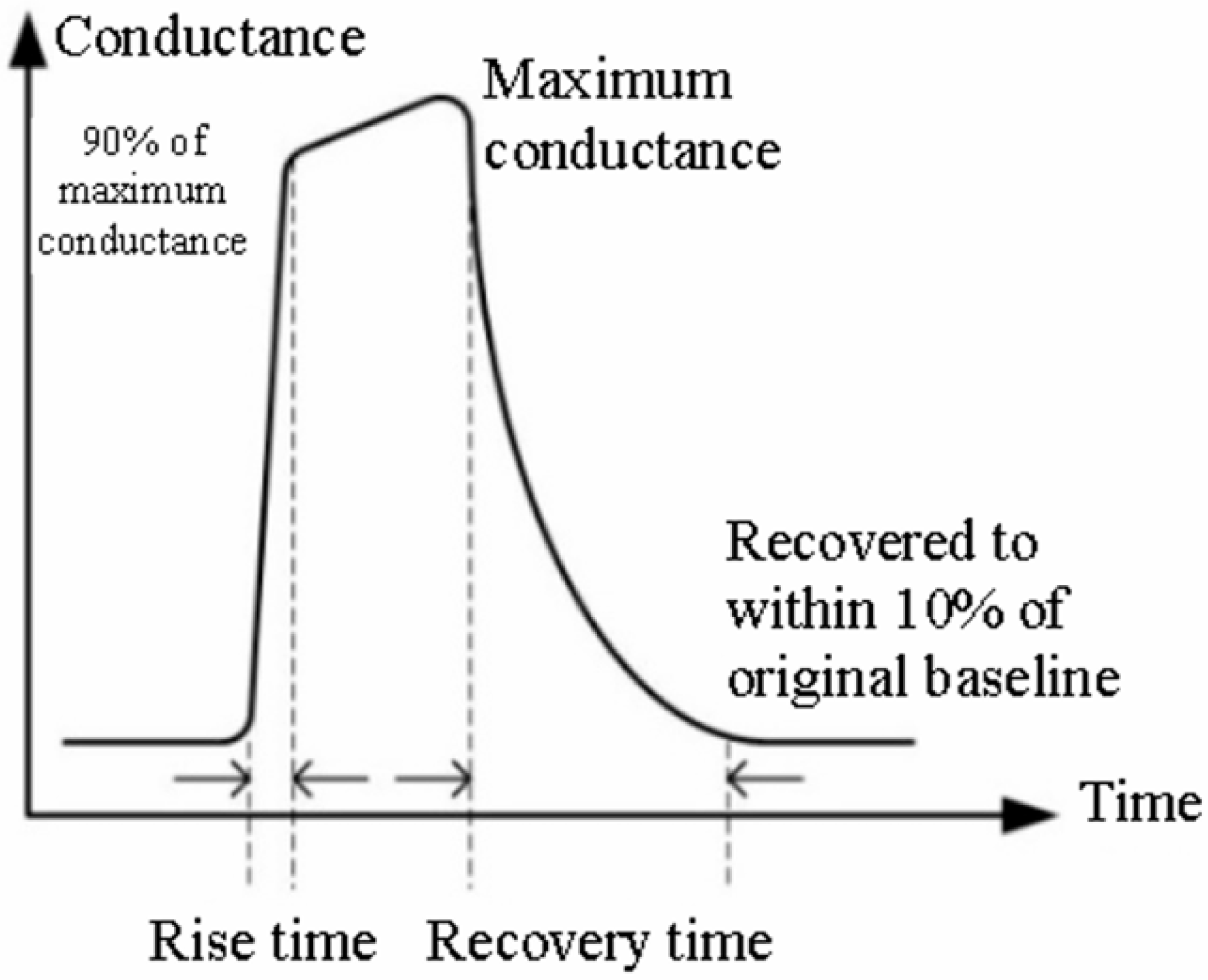

4.2. Response and Recovery Time

5. Conventional Sensor Technologies for Fire Detection

5.1. Smoke Detectors

5.2. Types of Smoke Detection Techniques

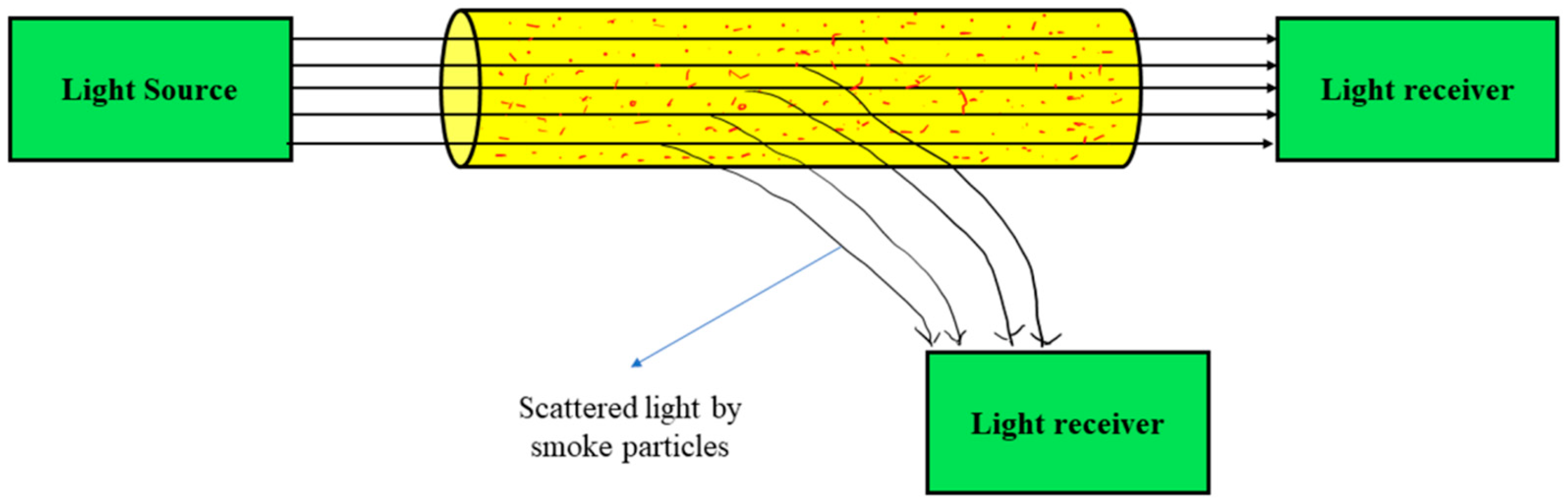

5.2.1. Optical Smoke Detection

5.2.2. Ionization Smoke Detection

5.2.3. Photoelectric Smoke Detectors

5.2.4. Advanced Smoke Detection Techniques Using Visual Surveillance

| Technique | Principle | Applications | Advantages | Limitations | References |

|---|---|---|---|---|---|

| Optical Smoke Detection | Measures light scattering or absorption by smoke particles. | Residential and commercial settings. | Sensitive to large particles; reduces false alarms with multi-wavelength illumination. | False alarms due to dust and aerosols; limited to smoldering fires. | [15,76,80,81] |

| Ionization Smoke Detection | Detects ion flow changes caused by smoke particles using radioactive sources (e.g., Americium–241). | Suitable for detecting flaming fires. | Highly responsive to small particles. | Handling radioactive materials; declining usage. | [74,76] |

| Multisensing Systems | Combines optical, ionization, and gas sensing techniques with algorithms. | Differentiates fire-related smoke from non-combustion sources, like cooking aerosols. | Reduces false alarms; enhances sensitivity and specificity. | Higher complexity; requires integration of multiple sensors and algorithms. | [75,78,81,84] |

| Advanced Visual Surveillance | Uses CCTV cameras and image processing (e.g., color, texture, and motion analysis). | Historical sites, paper mills, cement plants, power plants. | Real-time detection with CNNs and YOLOv2; reduced false positives. | Requires sufficient ambient light; limitations in low-light conditions. | [84,87,90,92] |

| Algorithmic Detection | Employs techniques like CNNs, Adaboost, and Bayesian networks for enhanced pattern recognition. | Both interior and outdoor scenarios with challenging environments, like haze. | High accuracy with adequate datasets; adaptable for diverse environments. | High computational requirements; response time limitations in some models. | [84,88,91,93] |

5.3. Heat Detectors

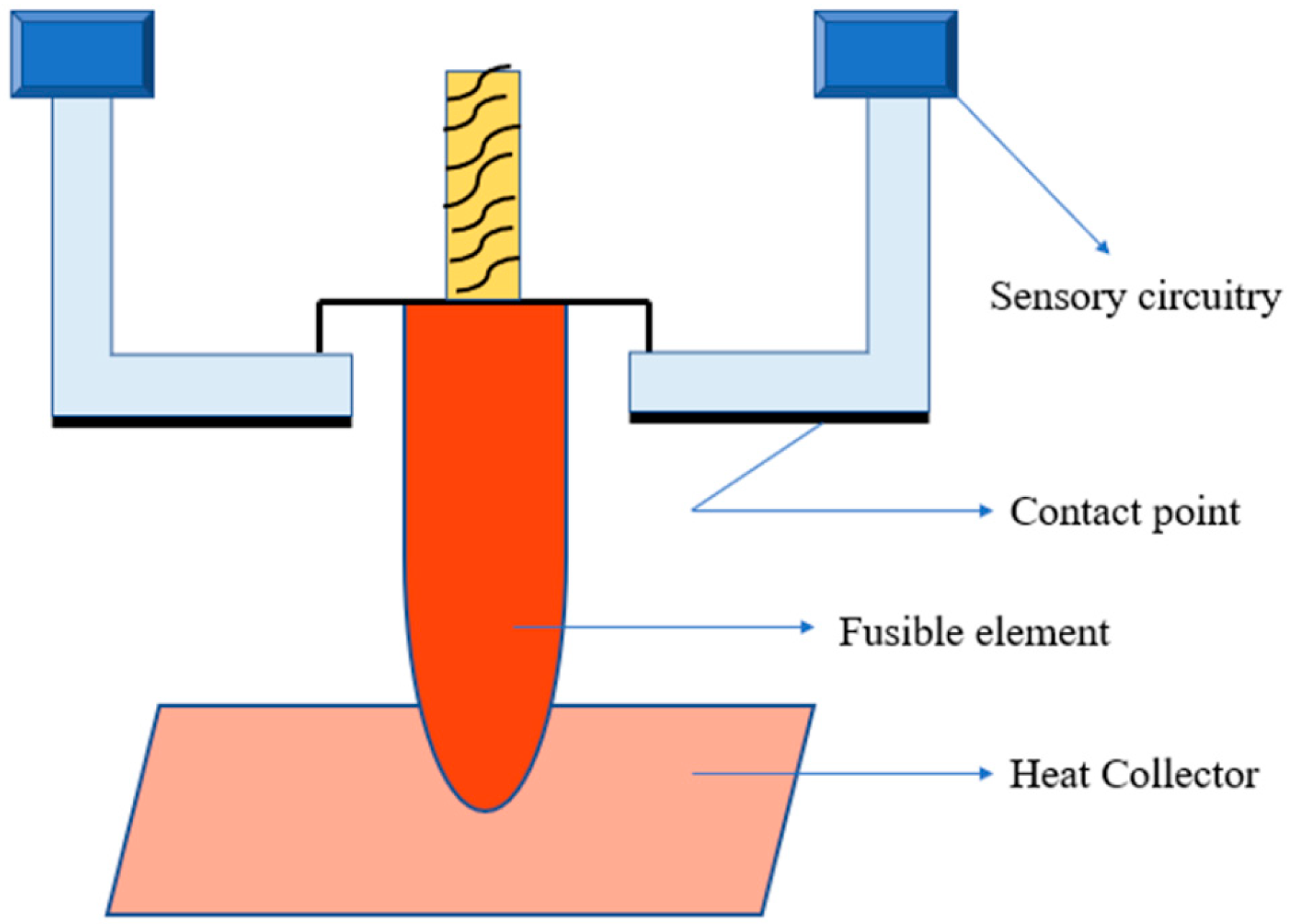

5.3.1. Fixed Temperature Heat Detectors

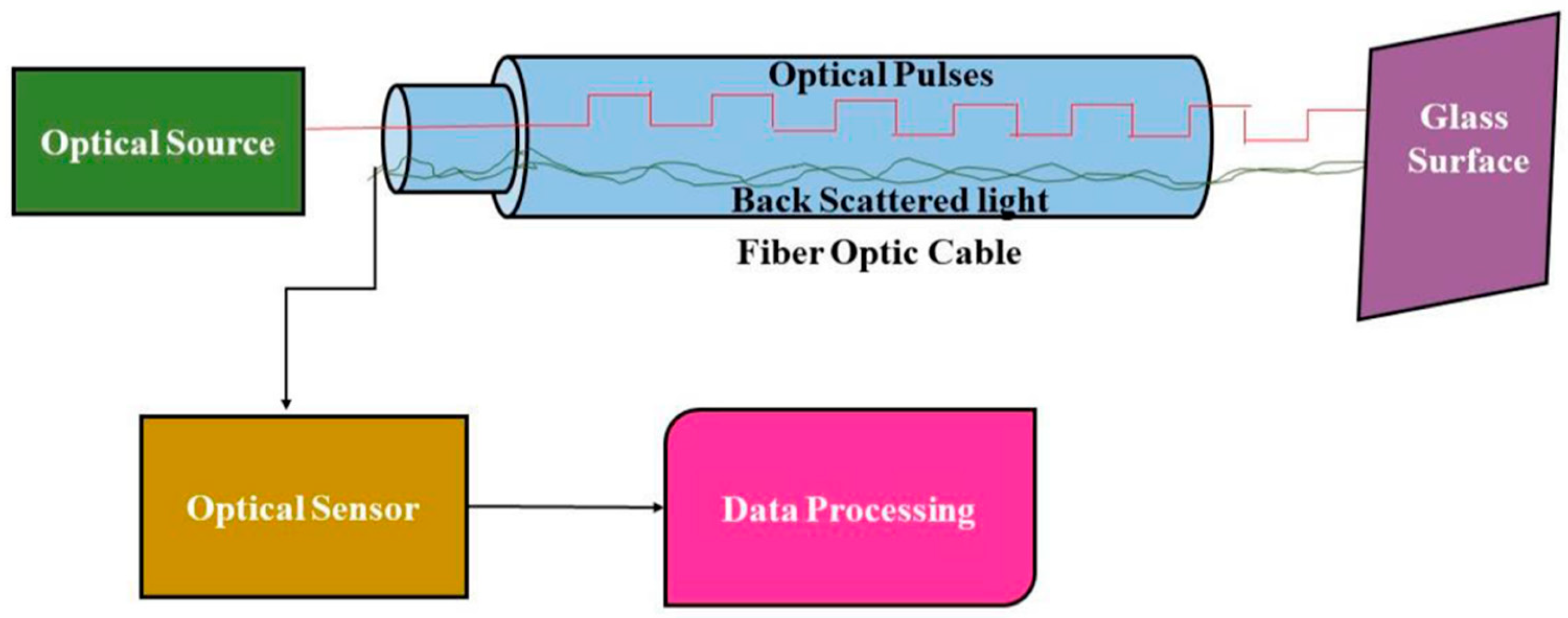

5.3.2. Distributed Optical Fiber Heat Sensing Techniques

5.3.3. Thermal-Radiation-Based Techniques for Flame Detection

5.4. Flame Detectors

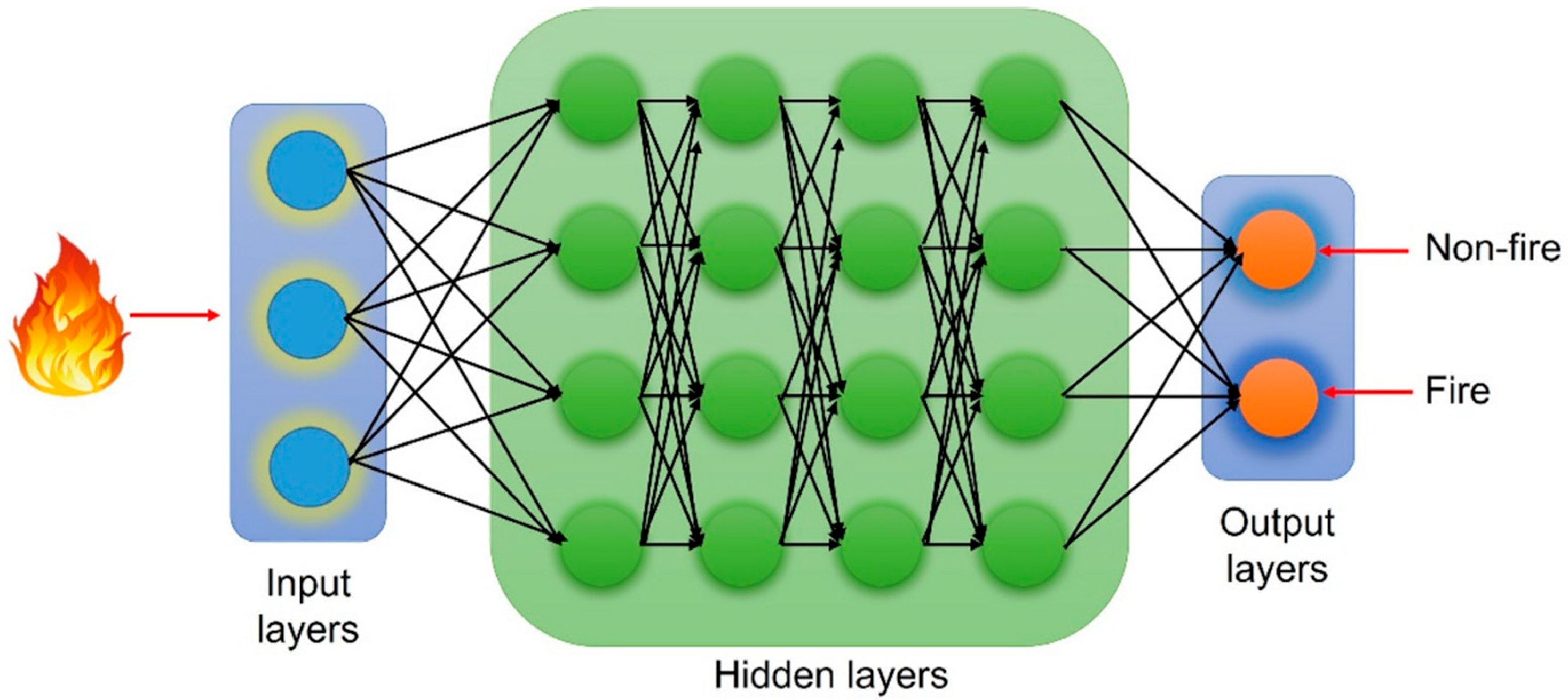

5.4.1. Deep Learning-Based Flame Detection

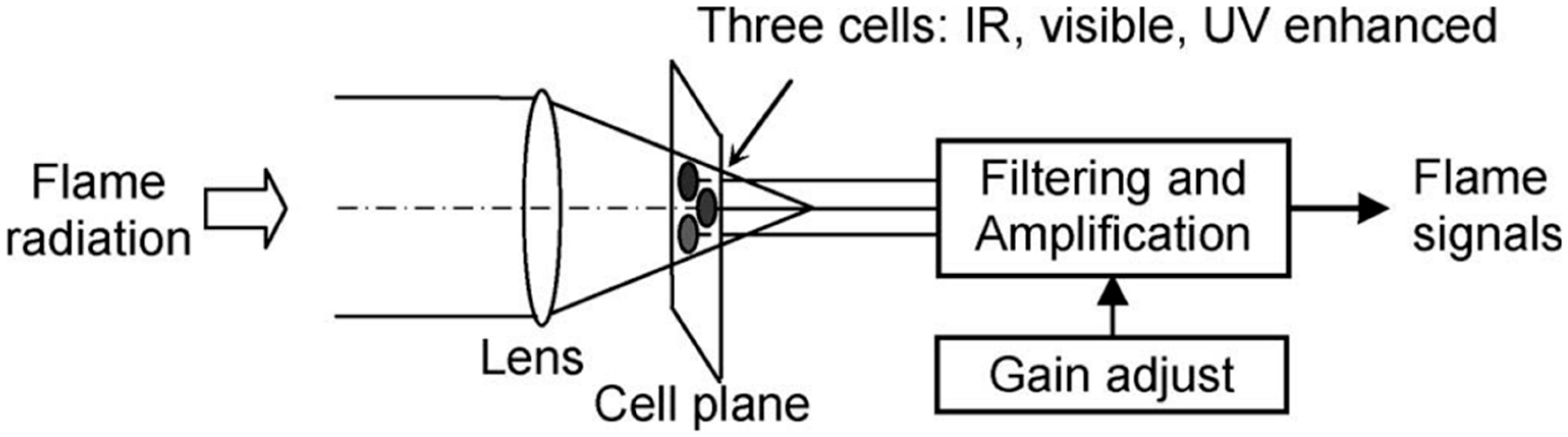

5.4.2. Multicell Flame Monitor for Enhanced Stability and Self-Checking in Combustion Systems

5.4.3. Ultraviolet Flame Detectors

5.4.4. Infrared (IR) Sensors for Fire Detection

5.5. Gas Sensors

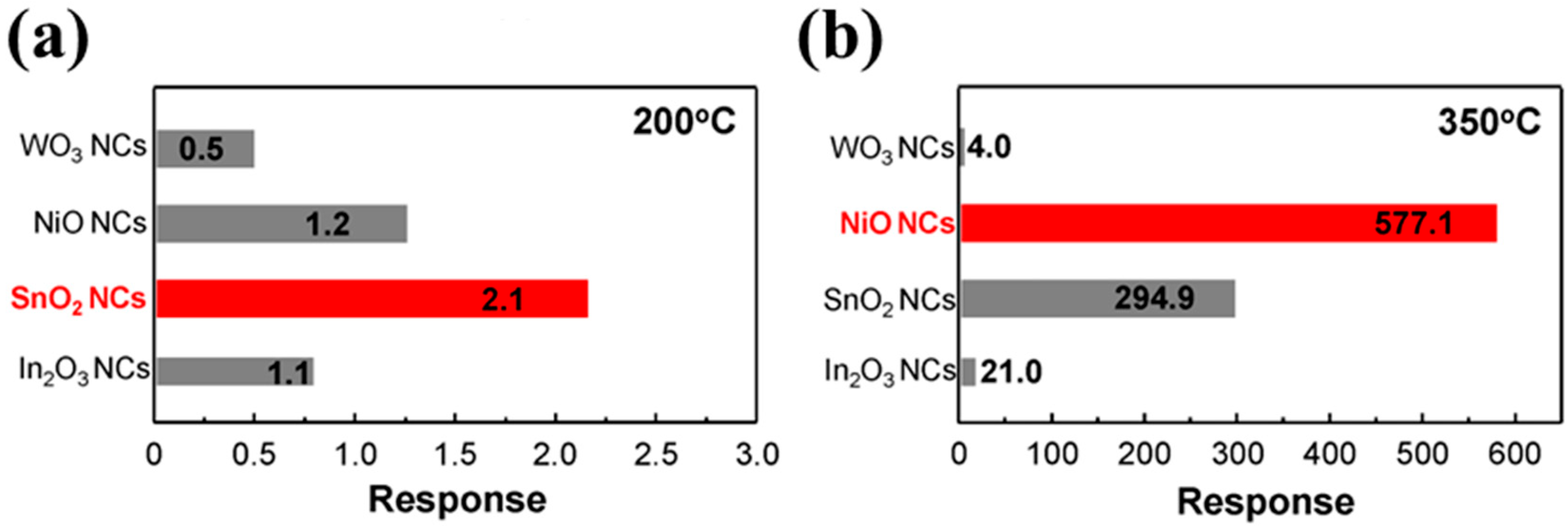

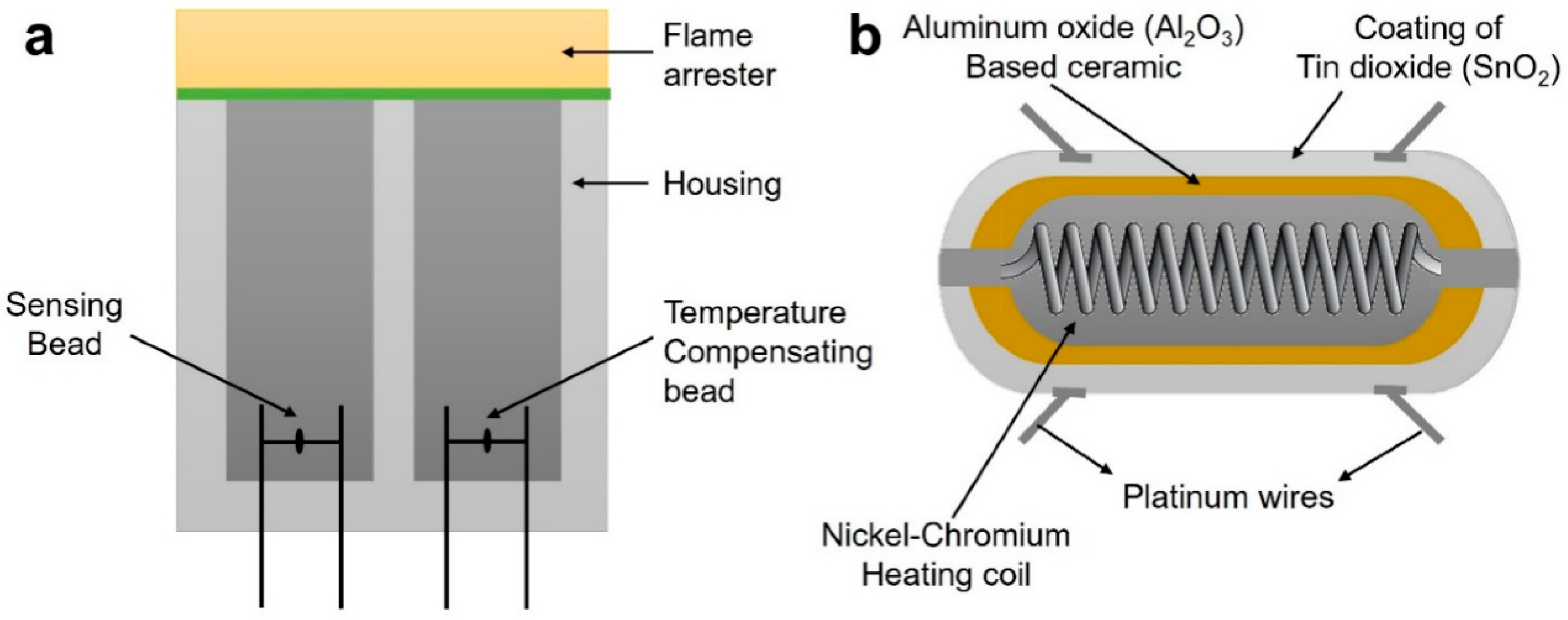

5.5.1. Metal Oxide Semiconductor Gas Sensors

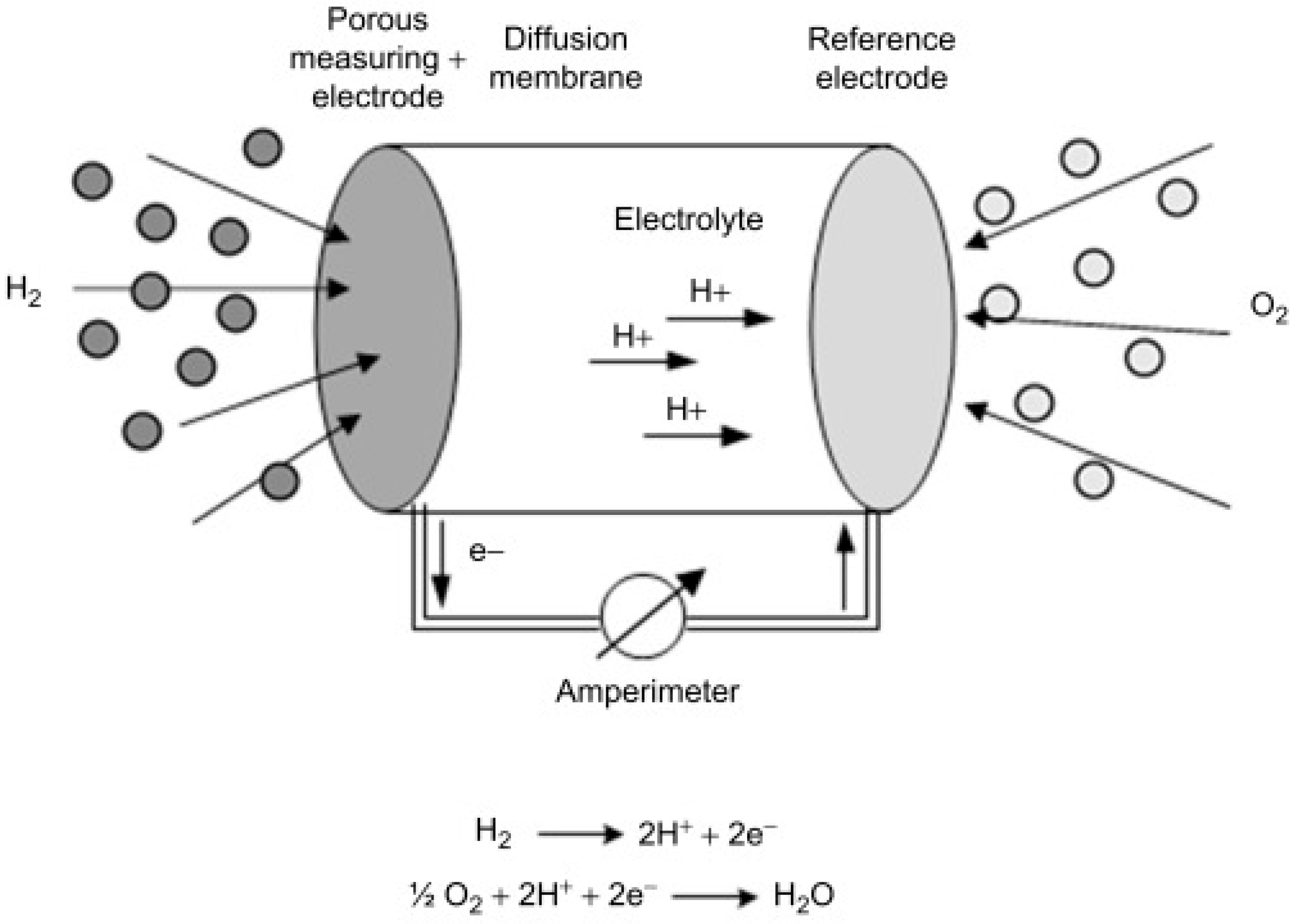

5.5.2. Electrochemical Sensors

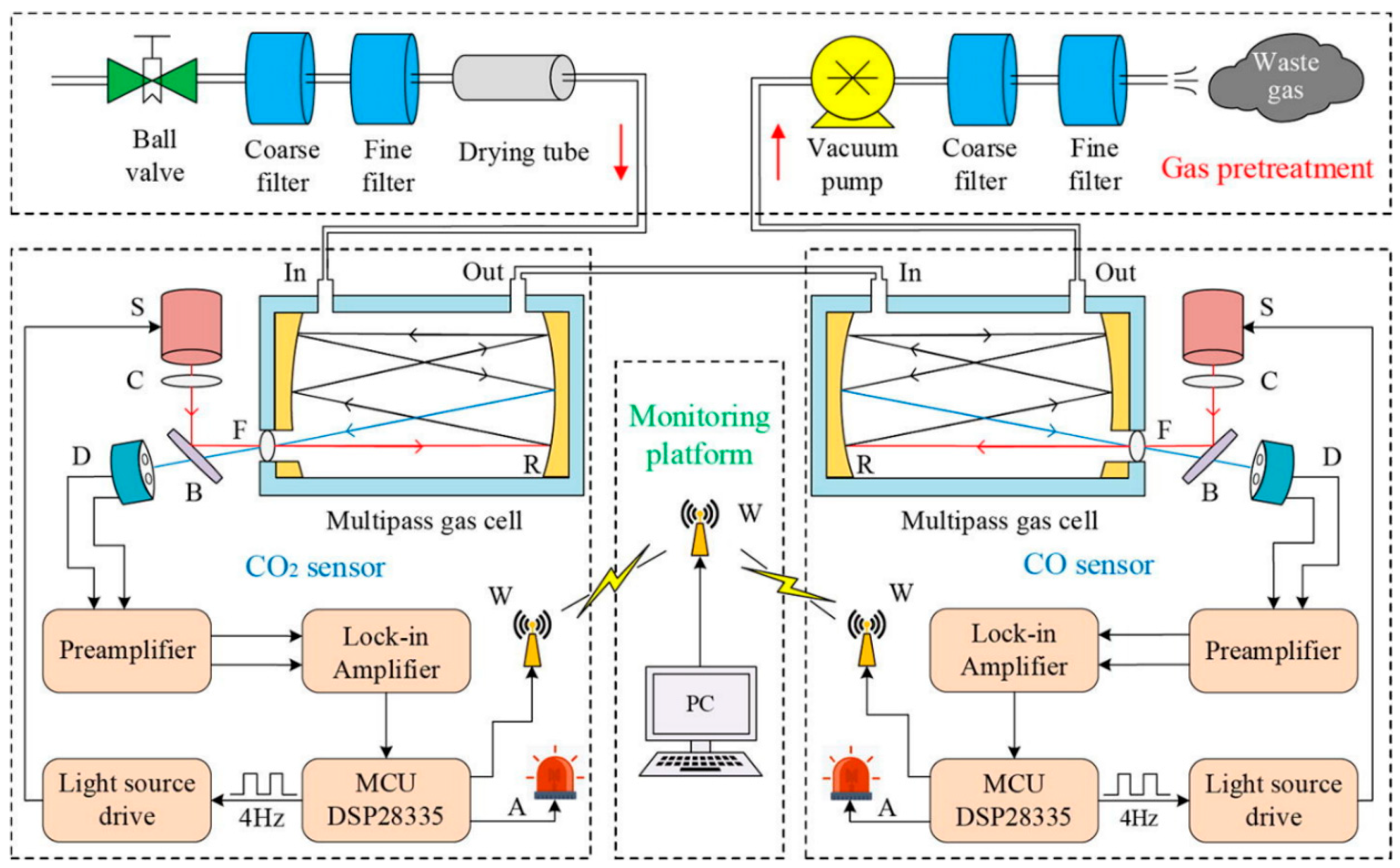

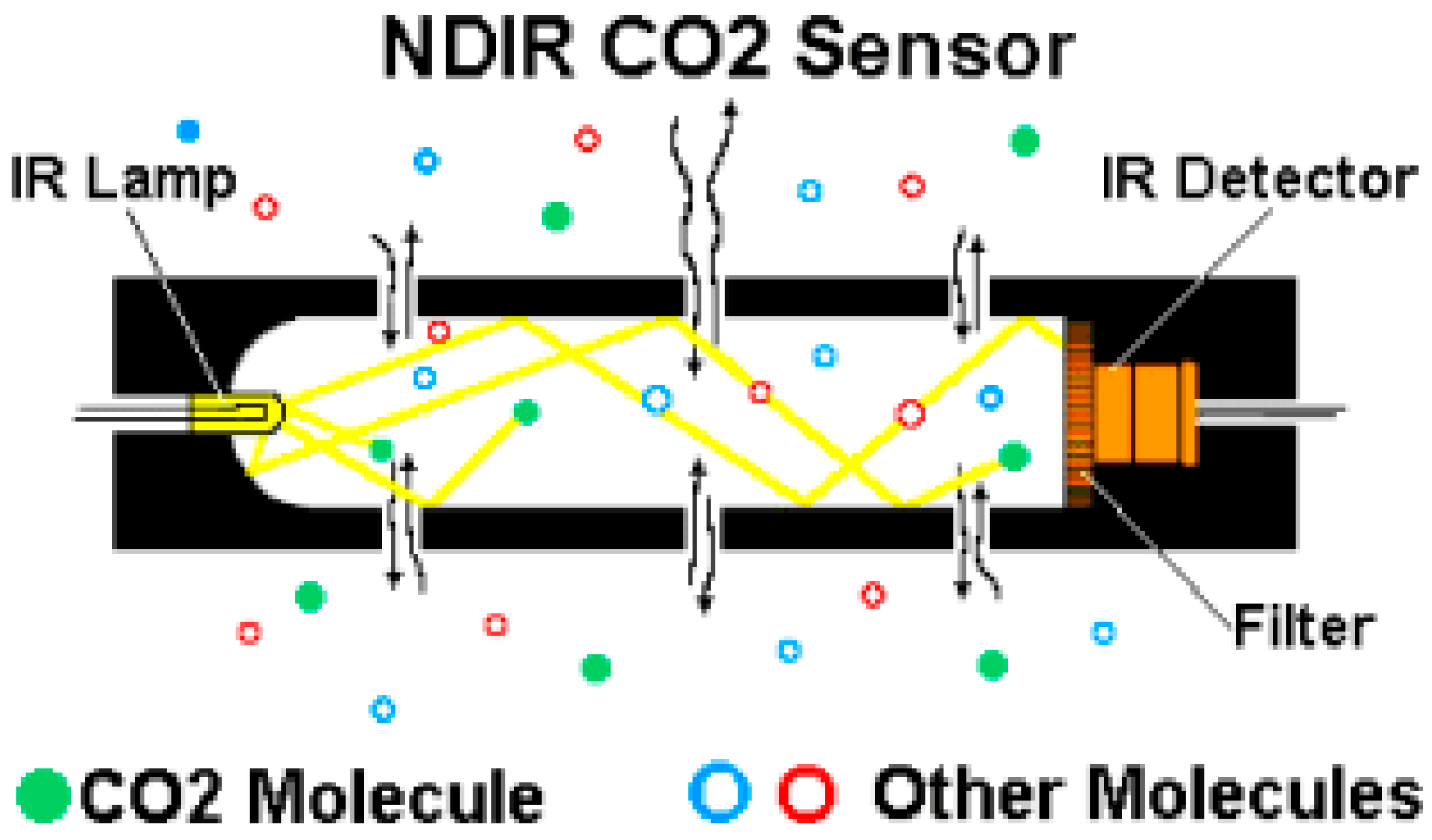

5.5.3. Nondispersive Infrared Sensors

6. Advances in Gas Sensing for Fire Detection

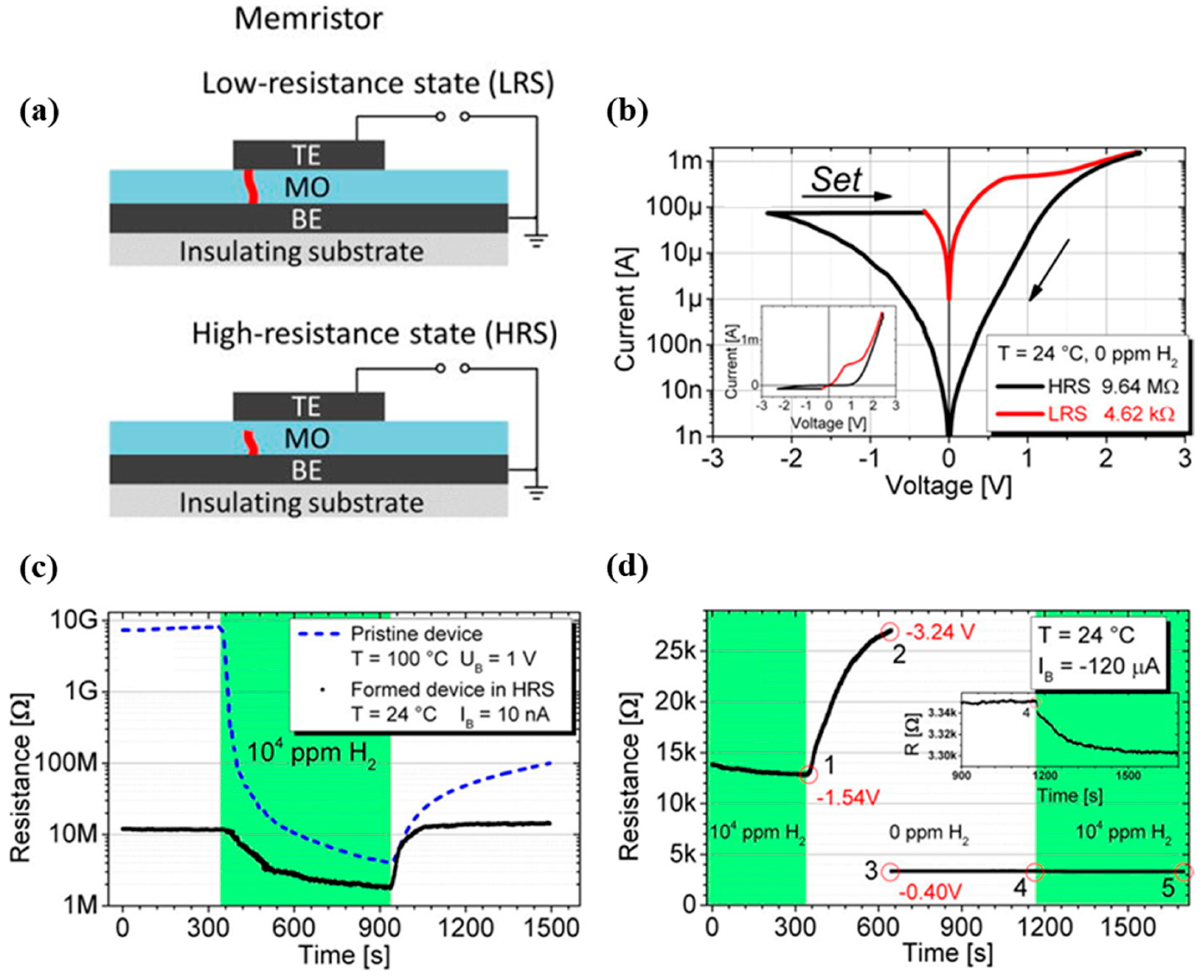

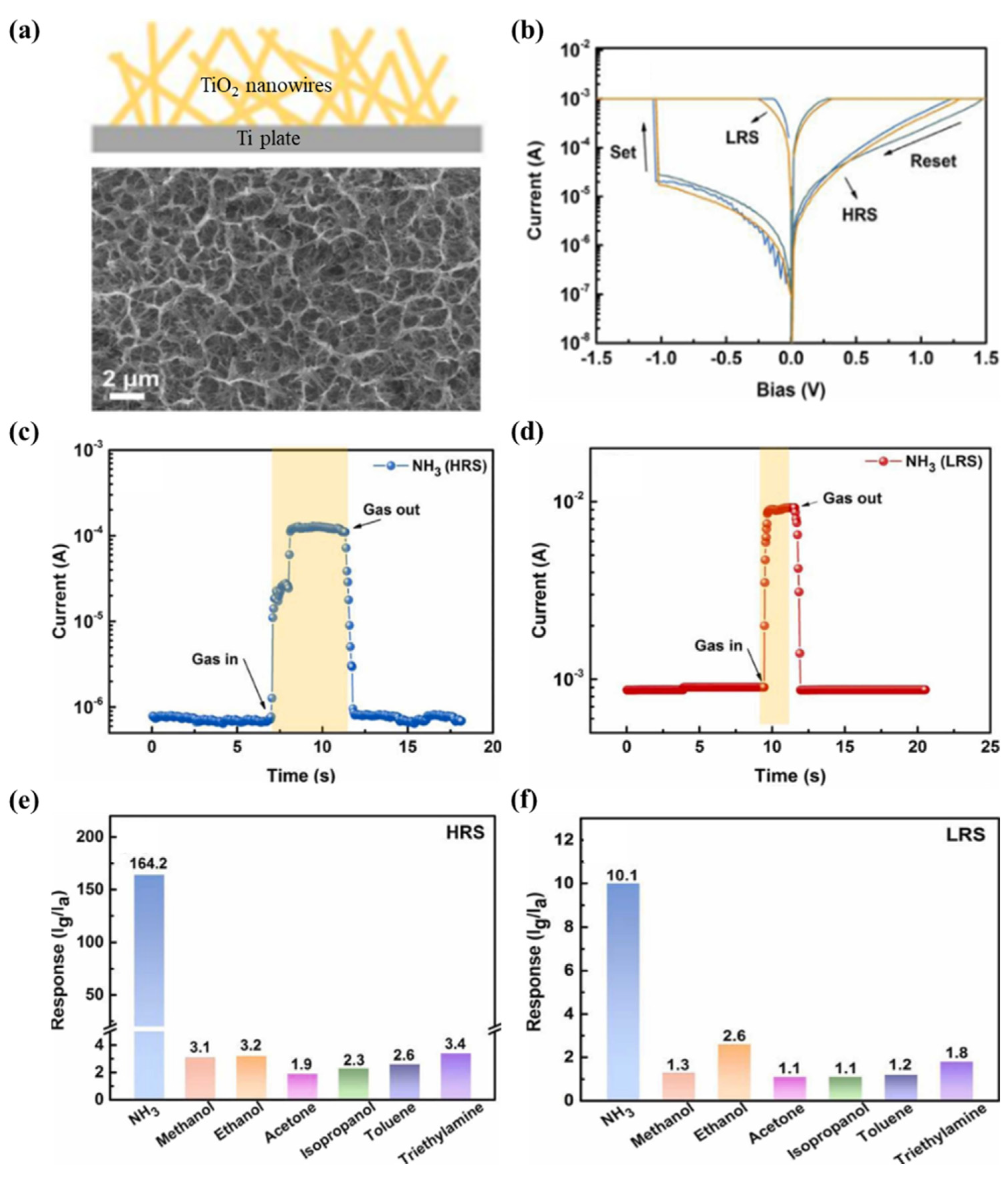

6.1. Gasistors

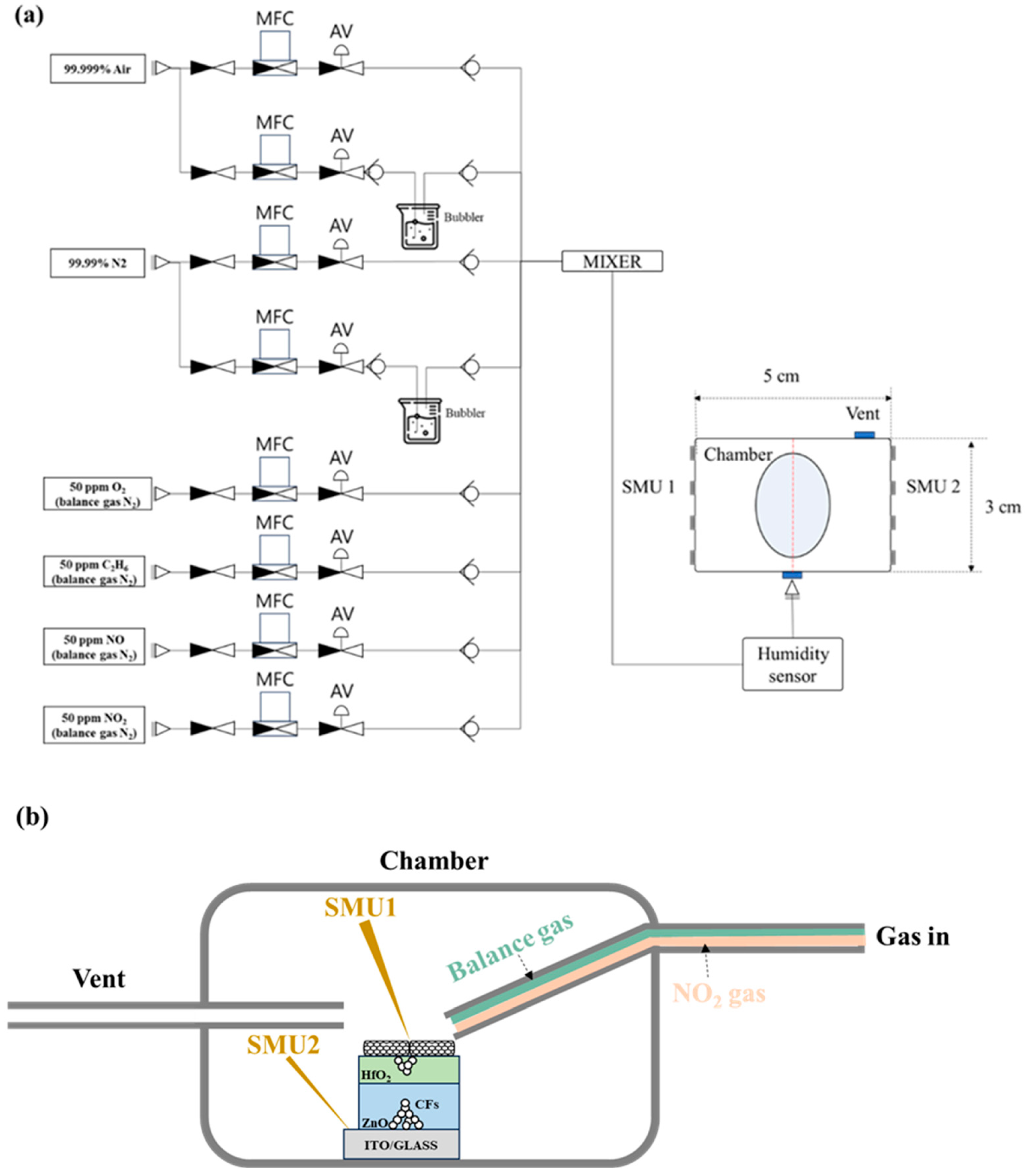

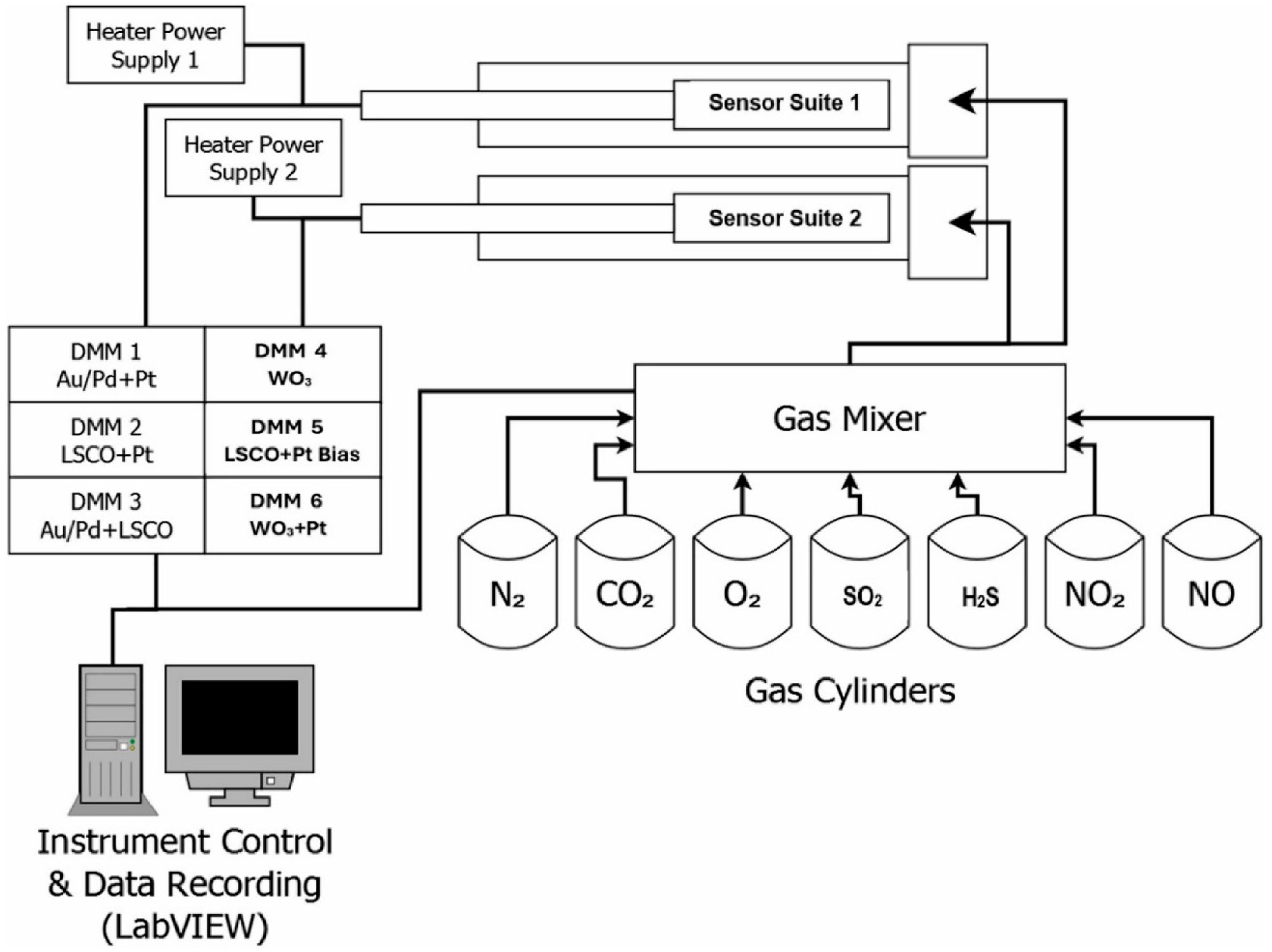

6.2. Experimental Setup

6.3. Comparative Analysis of Gasistors and Traditional MOS Sensors

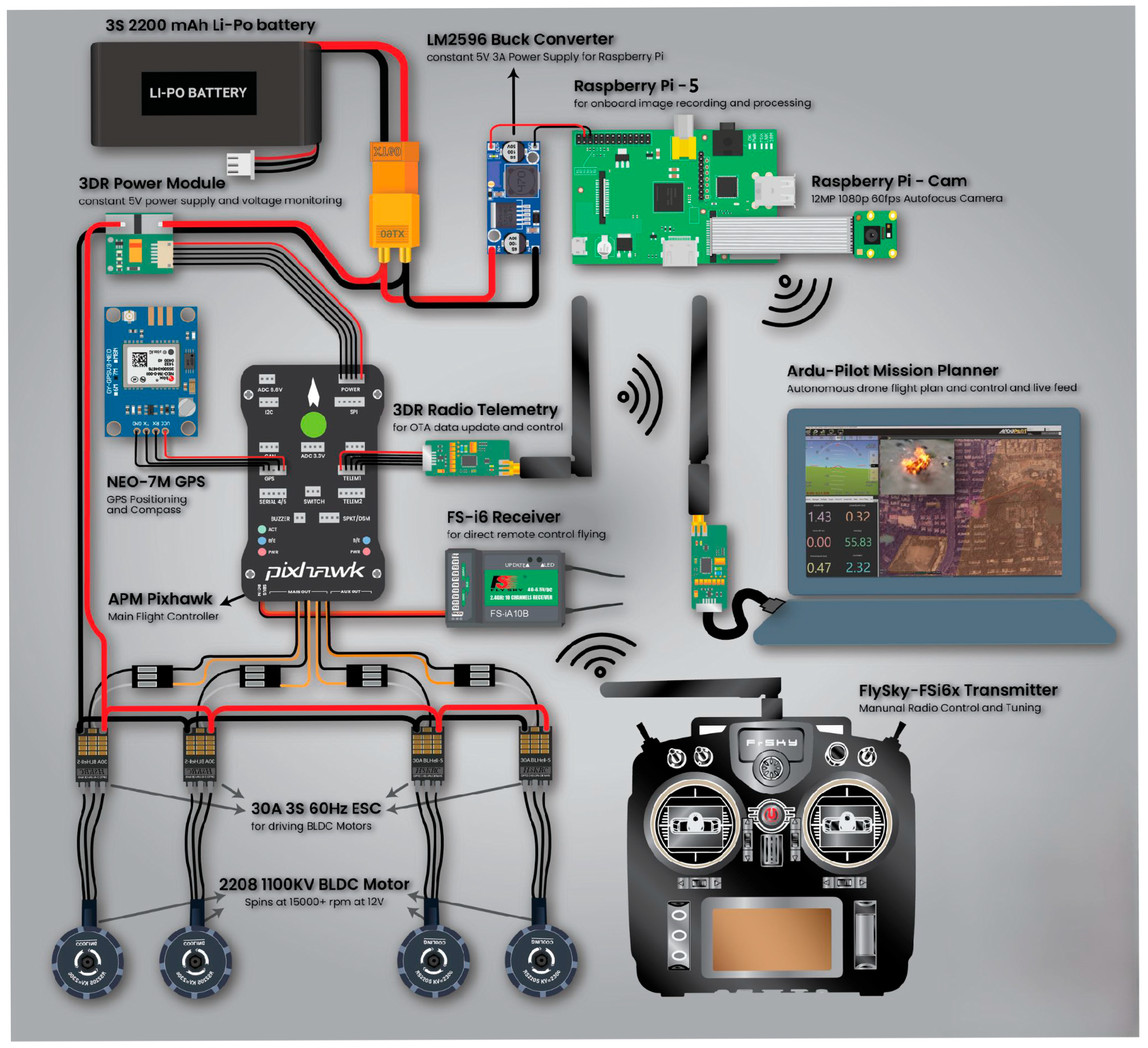

7. Deep Learning and Artificial Intelligence in Fire Detection

7.1. Data Collection and Preprocessing Methods for Early Fire Detection

7.2. Comparative Approaches in Fire Detection Model Design

7.3. Real-World Applications of Deep Learning-Based Fire Detection Models

8. Challenges and Future Directions

8.1. Challenges

8.2. Future Directions

9. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sulthana, S.F.; Wise, C.T.A.; Ravikumar, C.V.; Anbazhagan, R.; Idayachandran, G.; Pau, G. Review study on recent developments in fire sensing methods. IEEE Access 2023, 11, 90269–90282. [Google Scholar] [CrossRef]

- Khan, F.; Xu, Z.; Sun, J.; Khan, F.M.; Ahmed, A.; Zhao, Y. Recent advances in sensors for fire detection. Sensors 2022, 22, 3310. [Google Scholar] [CrossRef] [PubMed]

- Fonollosa, J.; Solórzano, A.; Marco, S. Chemical sensor systems and associated algorithms for fire detection: A review. Sensors 2018, 18, 553. [Google Scholar] [CrossRef] [PubMed]

- Avazov, K.; Mukhiddinov, M.; Makhmudov, F.; Cho, Y.I. Fire detection method in smart city environments using a deep-learning-based approach. Electronics 2021, 11, 73. [Google Scholar] [CrossRef]

- He, X.; Feng, Y.; Xu, F.; Chen, F.-F.; Yu, Y. Smart fire alarm systems for rapid early fire warning: Advances and challenges. Chem. Eng. J. 2022, 450, 137927. [Google Scholar] [CrossRef]

- Liu, Z.; Kim, A.K. Review of recent developments in fire detection technologies. J. Fire Prot. Eng. 2003, 13, 129–151. [Google Scholar] [CrossRef]

- Ali, M.; Lee, D.; Ahmad, I.; Kim, H.-D. Recent progress in memristor-based gas sensor (Gasistor; gas sensor + memristor): Device modeling, mechanisms, performance, and prospects. Sens. Actuators Rep. 2024, 9, 100269. [Google Scholar] [CrossRef]

- Bordbar, H.; Alinejad, F.; Conley, K.; Ala-Nissila, T.; Hostikka, S. Flame detection by heat from the infrared spectrum: Optimization and sensitivity analysis. Fire Saf. J. 2022, 133, 103673. [Google Scholar] [CrossRef]

- Ali, M.; Lee, D.; Ahmad, I.; Chae, M.; Kim, K.H.; Kim, H. Enhanced response and recovery observed in CNTs gas sensor using ZnO/HfO2 bilayer memristor heater. Sens. Actuators B Chem. 2025, 431, 137403. [Google Scholar] [CrossRef]

- Ali, M.; Lee, D.; Chae, M.; Ahmad, I.; Kim, H.-D. Advances in MXene-based synaptic devices and sensors. Mater. Today Phys. 2024, 45, 101456. [Google Scholar] [CrossRef]

- Qiu, P.; Qin, Y.; Xia, Q. Ultrasensitive memristor-based gas sensor (gasistor) with gas-triggered switch and memory function for dilute NH3 detection. Sens. Actuators B Chem. 2022, 373, 132730. [Google Scholar] [CrossRef]

- Kim, T.; Lee, D.; Chae, M.; Kim, K.-H.; Kim, H.-D. Enhancing the resistive switching properties of transparent HfO2-based memristor devices for reliable gasistor applications. Sensors 2024, 24, 6382. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, I.; Ali, M.; Kim, H.-D. Role of en-APTAS Membranes in Enhancing the NO2 Gas-Sensing Characteristics of Carbon Nanotube/ZnO-Based Memristor Gas Sensors. Biosensors 2024, 14, 635. [Google Scholar] [CrossRef]

- De Iacovo, A.; Venettacci, C.; Colace, L.; Scopa, L.; Foglia, S. High responsivity fire detectors based on PbS colloidal quantum dot photoconductors. IEEE Photonics Technol. Lett. 2017, 29, 703–706. [Google Scholar] [CrossRef]

- Tewarson, A.; Chin, W.; Shuford, R. Materials specifications, standards, and testing. In Handbook of Building Materials for Fire Protection; McGraw-Hill Professional: New York, NY, USA, 2004; p. 1. [Google Scholar]

- Hurley, M.J.; Gottuk, D.T.; Hall, J.R., Jr.; Harada, K.; Kuligowski, E.D.; Puchovsky, M.; Watts, J.M., Jr.; Wieczorek, C.J. SFPE Handbook of Fire Protection Engineering; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Perera, I.E.; Litton, C.D. A detailed study of the properties of smoke particles produced from both flaming and non-flaming combustion of common mine combustibles. Fire Saf. Sci 2011, 10, 213–226. [Google Scholar] [CrossRef]

- Fabian, T.Z.; Pravinray, D.G. Smoke Characterization Project; National Fire Protection Association: Quincy, MA, USA, 2007. [Google Scholar]

- Gubbi, J.; Marusic, S.; Palaniswami, M. Smoke detection in video using wavelets and support vector machines. Fire Saf. J. 2009, 44, 1110–1115. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Y.; Liao, M.; Sun, Y.; Wang, S.; Sun, X.; Shi, X.; Kang, Y.; Tian, M.; Bao, T. FireSonic: Design and Implementation of an Ultrasound Sensing-Based Fire Type Identification System. Sensors 2024, 24, 4360. [Google Scholar] [CrossRef]

- Babrauskas, V.; Peacock, R.D. Heat release rate: The single most important variable in fire hazard. Fire Saf. J. 1992, 18, 255–272. [Google Scholar] [CrossRef]

- Linden, O.; Braun, U.; Kubon, C.; Hölemann, H. Experimentelle untersuchungen zu den einsatz-und einbaubedingungen von brandmeldern mit gassensoren. In Technischer Bericht; Bergische Universtität: Wuppertal, Germany, 2001. [Google Scholar]

- Meyer, J.T.; Georgiadis, A.; Persaud, K.; Scorsonne, E. Detection of significant tracer gases by means of polymer gas sensors. Chem. Ing. Tech. 2005, 77, 1144. [Google Scholar] [CrossRef]

- Bryner, R.; Gann, N. Combustion products and their effects on life safety. Fire Prot. Handb. 2008, 1, 6–11. [Google Scholar]

- Pitts, W.M. The global equivalence ratio concept and the formation mechanisms of carbon monoxide in enclosure fires. Prog. Energy Combust. Sci. 1995, 21, 197–237. [Google Scholar] [CrossRef]

- Beyler, C.L.; Hirschler, M.M. Thermal decomposition of polymers. SFPE Handb. Fire Prot. Eng. 2002, 2, 111–131. [Google Scholar]

- Chandler, L.; Hirschler, M.; Smith, G. A heated tube furnace test for the emission of acid gas from PVC wire coating materials: Effects of experimental procedures and mechanistic considerations. Eur. Polym. J. 1987, 23, 51–61. [Google Scholar] [CrossRef]

- Beitel, J.; Bertelo, C.; Carroll, W., Jr.; Grand, A.F.; Hirschler, M.M.; Smith, G. Hydrogen chloride transport and decay in a large apparatus: II. Variables affecting hydrogen chloride decay. J. Fire Sci. 1987, 5, 105–145. [Google Scholar] [CrossRef]

- Paul, K.T.; Hull, T.R.; Lebek, K.; Stec, A.A. Fire smoke toxicity: The effect of nitrogen oxides. Fire Saf. J. 2008, 43, 243–251. [Google Scholar] [CrossRef]

- Gutmacher, D.; Hoefer, U.; Wöllenstein, J. Gas sensor technologies for fire detection. Sens. Actuators B Chem. 2012, 175, 40–45. [Google Scholar] [CrossRef]

- Solórzano, A.; Eichmann, J.; Fernández, L.; Ziems, B.; Jiménez-Soto, J.M.; Marco, S.; Fonollosa, J. Early fire detection based on gas sensor arrays: Multivariate calibration and validation. Sens. Actuators B Chem. 2022, 352, 130961. [Google Scholar] [CrossRef]

- Solórzano, A.; Fonollosa, J.; Fernández, L.; Eichmann, J.; Marco, S. Fire detection using a gas sensor array with sensor fusion algorithms. In Proceedings of the 2017 ISOCS/IEEE International Symposium on Olfaction and Electronic Nose (ISOEN), Montreal, QC, Canada, 28–31 May 2017; pp. 1–3. [Google Scholar]

- Chen, S.-J.; Hovde, D.C.; Peterson, K.A.; Marshall, A.W. Fire detection using smoke and gas sensors. Fire Saf. J. 2007, 42, 507–515. [Google Scholar] [CrossRef]

- Manorathna, A.Y.S.; Sachintha Gayashan, W.K.; Tharushika, W.A.V.; Rathnayaka, R.M.S.T.; Weerasinghe, L.; Zoysa, R.D. Intelligent Fire Detection and Response System with Dynamic Nozzle Control and Evacuation Planning. In Proceedings of the 2024 3rd International Conference on Automation, Computing and Renewable Systems (ICACRS), Pudukkottai, India, 4–6 December 2024; pp. 179–184. [Google Scholar]

- Kanwal, K.; Liaquat, A.; Mughal, M.; Abbasi, A.R.; Aamir, M. Towards Development of a Low Cost Early Fire Detection System Using Wireless Sensor Network and Machine Vision. Wirel. Pers. Commun. 2017, 95, 475–489. [Google Scholar] [CrossRef]

- Cheng, C.; Sun, F.; Zhou, X. One fire detection method using neural networks. Tsinghua Sci. Technol. 2011, 16, 31–35. [Google Scholar] [CrossRef]

- Lei, Q.; Lv, Z.; Chen, M.; Peng, P.; Li, Y. A multi-level warning battery energy storage system fire warning and alarm integration technology. In Proceedings of the 2024 3rd International Conference on Energy, Power and Electrical Technology (ICEPET), Chengdu, China, 17–19 May 2024; pp. 302–309. [Google Scholar]

- Pohle, R.; Simon, E.; Schneider, R.; Fleischer, M.; Sollacher, R.; Gao, H.; Müller, K.; Jauch, P.; Loepfe, M.; Frerichs, H.P.; et al. Fire detection with low power fet gas sensors. Sens. Actuators B Chem. 2007, 120, 669–672. [Google Scholar] [CrossRef]

- Hoefer, U.; Gutmachera, D. Fire Gas Detection. Procedia Eng. 2012, 47, 1446–1459. [Google Scholar] [CrossRef]

- Reimann, P.; Schütze, A. Fire detection in coal mines based on semiconductor gas sensors. Sens. Rev. 2012, 32, 47–58. [Google Scholar] [CrossRef]

- Hong, G.-H.; Le, T.-C.; Lin, G.-Y.; Cheng, H.-W.; Yu, J.-Y.; Dejchanchaiwong, R.; Tekasakul, P.; Tsai, C.-J. Long-term field calibration of low-cost metal oxide VOC sensor: Meteorological and interference gas effects. Atmos. Environ. 2023, 310, 119955. [Google Scholar] [CrossRef]

- Abdullah, A.N.; Kamarudin, K.; Mamduh, S.M.; Adom, A.H.; Juffry, Z.H.M. Effect of environmental temperature and humidity on different metal oxide gas sensors at various gas concentration levels. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; p. 012152. [Google Scholar]

- Burman, D.; Ghosh, R.; Santra, S.; Guha, P.K. Highly proton conducting MoS2/graphene oxide nanocomposite based chemoresistive humidity sensor. Rsc Adv. 2016, 6, 57424–57433. [Google Scholar] [CrossRef]

- Lee, K.; Shim, Y.-S.; Song, Y.G.; Han, S.D.; Lee, Y.-S.; Kang, C.-Y. Highly Sensitive Sensors Based on Metal-Oxide Nanocolumns for Fire Detection. Sensors 2017, 17, 303. [Google Scholar] [CrossRef]

- Li, X.; Sánchez del Río Saez, J.; Ao, X.; Yusuf, A.; Wang, D.-Y. Highly-sensitive fire alarm system based on cellulose paper with low-temperature response and wireless signal conversion. Chem. Eng. J. 2022, 431, 134108. [Google Scholar] [CrossRef]

- Podržaj, P.; Hashimoto, H. Intelligent Space as a Framework for Fire Detection and Evacuation. Fire Technol. 2008, 44, 65–76. [Google Scholar] [CrossRef]

- Liu, X.; Cheng, S.; Liu, H.; Hu, S.; Zhang, D.; Ning, H. A survey on gas sensing technology. Sensors 2012, 12, 9635–9665. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, D.; Qin, L.; Zhao, P.; Liu, F.; Chuai, X.; Sun, P.; Liang, X.; Gao, Y.; Sun, Y. Preparation and gas sensing properties of hierarchical leaf-like SnO2 materials. Sens. Actuators B Chem. 2018, 255, 2944–2951. [Google Scholar] [CrossRef]

- Long, H.; Zeng, W.; Zhang, H. Synthesis of WO3 and its gas sensing: A review. J. Mater. Sci. Mater. Electron. 2015, 26, 4698–4707. [Google Scholar] [CrossRef]

- Wang, X.; Meng, Y.; Li, G.-D.; Zou, Y.; Cao, Y.; Zou, X. UV-assisted, template-free synthesis of ultrathin nanosheet-assembled hollow indium oxide microstructures for effective gaseous formaldehyde detection. Sens. Actuators B Chem. 2016, 224, 559–567. [Google Scholar] [CrossRef]

- Zeng, Y.; Qiao, L.; Bing, Y.; Wen, M.; Zou, B.; Zheng, W.; Zhang, T.; Zou, G. Development of microstructure CO sensor based on hierarchically porous ZnO nanosheet thin films. Sens. Actuators B Chem. 2012, 173, 897–902. [Google Scholar] [CrossRef]

- Donarelli, M.; Milan, R.; Rigoni, F.; Drera, G.; Sangaletti, L.; Ponzoni, A.; Baratto, C.; Sberveglieri, G.; Comini, E. Anomalous gas sensing behaviors to reducing agents of hydrothermally grown α-Fe2O3 nanorods. Sens. Actuators B Chem. 2018, 273, 1237–1245. [Google Scholar] [CrossRef]

- Liu, B.; Wang, L.; Ma, Y.; Yuan, Y.; Yang, J.; Wang, M.; Liu, J.; Zhang, X.; Ren, Y.; Du, Q. Enhanced gas–sensing properties and sensing mechanism of the foam structures assembled from NiO nanoflakes with exposed {1 1 1} facets. Appl. Surf. Sci. 2019, 470, 596–606. [Google Scholar] [CrossRef]

- Dou, Z.; Cao, C.; Chen, Y.; Song, W. Fabrication of porous Co3O4 nanowires with high CO sensing performance at a low operating temperature. Chem. Commun. 2014, 50, 14889–14891. [Google Scholar] [CrossRef]

- Ding, C.; Ma, Y.; Lai, X.; Yang, Q.; Xue, P.; Hu, F.; Geng, W. Ordered large-pore mesoporous Cr2O3 with ultrathin framework for formaldehyde sensing. ACS Appl. Mater. Interfaces 2017, 9, 18170–18177. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, K.; Liu, K.; Xu, J.; Zheng, Z. Metal oxide resistive sensors for carbon dioxide detection. Coord. Chem. Rev. 2022, 472, 214758. [Google Scholar] [CrossRef]

- Srivastava, S. Study of gas sensor detection for NOX Gas: A review. Mater. Today Proc. 2021, 37, 3709–3712. [Google Scholar] [CrossRef]

- To, D.T.H.; Myung, N.V. Critical review of hydrogen cyanide (HCN) sensors and their applications. Sens. Actuators Rep. 2024, 8, 100254. [Google Scholar] [CrossRef]

- Yan, Y.; Shimizu, Y.; Miura, N.; Yamazoe, N. Characteristics and sensing mechanism of SOx sensor using stabilized zirconia and metal sulphate. Sens. Actuators B Chem. 1993, 12, 77–81. [Google Scholar] [CrossRef]

- Souda, N.; Shimizu, Y. Sensing properties of solid electrolyte SO2 sensor using metal-sulfide electrode. J. Mater. Sci. 2003, 38, 4301–4305. [Google Scholar] [CrossRef]

- Wang, L.; Kumar, R.V. Thick film miniaturized HCl gas sensor. Sens. Actuators B Chem. 2004, 98, 196–203. [Google Scholar] [CrossRef]

- Misra, S.C.K.; Mathur, P.; Yadav, M.; Tiwari, M.K.; Garg, S.C.; Tripathi, P. Preparation and characterization of vacuum deposited semiconducting nanocrystalline polymeric thin film sensors for detection of HCl. Polymer 2004, 45, 8623–8628. [Google Scholar] [CrossRef]

- Tan, Q.; Fang, J.; Liu, W.; Xiong, J.; Zhang, W. Acetone Sensing Properties of a Gas Sensor Composed of Carbon Nanotubes Doped With Iron Oxide Nanopowder. Sensors 2015, 15, 28502–28512. [Google Scholar] [CrossRef]

- Jamal, R.K.; Aadim, K.A.; Al-Zaidi, Q.G.; Taaban, I.N. Hydrogen gas sensors based on electrostatically spray deposited nickel oxide thin film structures. Photonic Sens. 2015, 5, 235–240. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, X.; Neri, G.; Pinna, N. Nanostructured materials for room-temperature gas sensors. Adv. Mater. 2016, 28, 795–831. [Google Scholar] [CrossRef]

- Korotcenkov, G. Metal oxides for solid-state gas sensors: What determines our choice? Mater. Sci. Eng. B 2007, 139, 1–23. [Google Scholar] [CrossRef]

- Qian, L.; Rahmati, F.; Li, F.; Zhang, T.; Wang, T.; Zhang, H.; Yan, S.; Zheng, Y. Recent advances in 2D MXene-based heterostructures for gas sensing: Mechanisms and applications in environmental and biomedical fields. Nanoscale 2025, 17, 8975–8998. [Google Scholar] [CrossRef]

- Kim, H.-J.; Lee, J.-H. Highly sensitive and selective gas sensors using p-type oxide semiconductors: Overview. Sens. Actuators B Chem. 2014, 192, 607–627. [Google Scholar] [CrossRef]

- Sharma, S.; Tomar, M.; Puri, N.K.; Gupta, V. NO2 Sensing Properties of WO3 Thin Films Deposited by Rf-Magnetron Sputtering. In Conference Papers in Science; Wiley Online Library: Hoboken, NJ, USA, 2014; p. 683219. [Google Scholar]

- Yavari, F.; Koratkar, N. Graphene-based chemical sensors. J. Phys. Chem. Lett. 2012, 3, 1746–1753. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Park, S.; Park, S.; Lee, C. Acetone sensing of Au and Pd-decorated WO3 nanorod sensors. Sens. Actuators B Chem. 2015, 209, 180–185. [Google Scholar] [CrossRef]

- Sowah, R.A.; Ofoli, A.R.; Krakani, S.N.; Fiawoo, S.Y. Hardware design and web-based communication modules of a real-time multisensor fire detection and notification system using fuzzy logic. IEEE Trans. Ind. Appl. 2016, 53, 559–566. [Google Scholar] [CrossRef]

- Krüger, S.; Despinasse, M.-C.; Raspe, T.; Nörthemann, K.; Moritz, W. Early fire detection: Are hydrogen sensors able to detect pyrolysis of house hold materials? Fire Saf. J. 2017, 91, 1059–1067. [Google Scholar] [CrossRef]

- Fleming, J.M. Photoelectric and Ionization Detectors—A Review of The Literature Re–Visited. Retrieved Dec. 2004, 31, 2010. [Google Scholar]

- Gottuk, D.T.; Peatross, M.J.; Roby, R.J.; Beyler, C.L. Advanced fire detection using multi-signature alarm algorithms. Fire Saf. J. 2002, 37, 381–394. [Google Scholar] [CrossRef]

- Vojtisek-Lom, M. Total diesel exhaust particulate length measurements using a modified household smoke alarm ionization chamber. J. Air Waste Manag. Assoc. 2011, 61, 126–134. [Google Scholar] [CrossRef]

- Stec, A.A. Fire toxicity–The elephant in the room? Fire Saf. J. 2017, 91, 79–90. [Google Scholar] [CrossRef]

- Brunner, C.; Peynot, T.; Vidal-Calleja, T. Combining multiple sensor modalities for a localisation robust to smoke. In Proceedings of the 2011 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Francisco, CA, USA, 25–30 September 2011; IEEE: New York, NY, USA, 2011; pp. 2489–2496. [Google Scholar]

- Deng, T.; Zeng, J.; Wang, S.; Yan, S.; Chen, A. An optical fire detector with enhanced response sensitivities for black smoke based on the polarized light scattering. Meas. Sci. Technol. 2019, 30, 115203. [Google Scholar] [CrossRef]

- To, H.; Fong, N. Investigation of the performance and improvement of optical smoke detectors. Procedia Eng. 2013, 62, 985–993. [Google Scholar] [CrossRef]

- Park, S.; Han, K.W.; Lee, K. A study on fire detection technology through spectrum analysis of smoke particles. In Proceedings of the 2020 International Conference on Information and Communication Technology Convergence (ICTC), Jeju Island, Republic of Korea, 21–23 October 2020; IEEE: New York, NY, USA, 2020; pp. 1563–1565. [Google Scholar]

- Aspey, R.A.; Brazier, K.J.; Spencer, J.W. Multiwavelength sensing of smoke using a polychromatic LED: Mie extinction characterization using HLS analysis. IEEE Sens. J. 2005, 5, 1050–1056. [Google Scholar] [CrossRef]

- Kruell, W.; Schultze, T.; Tobera, R.; Willms, I. Analysis of dust properties to solve the complex problem of non-fire sensitivity testing of optical smoke detectors. Procedia Eng. 2013, 62, 859–867. [Google Scholar] [CrossRef]

- Saponara, S.; Elhanashi, A.; Gagliardi, A. Real-time video fire/smoke detection based on CNN in antifire surveillance systems. J. Real-Time Image Process. 2021, 18, 889–900. [Google Scholar] [CrossRef]

- Jeong, J.-Y.; Ryou, H.-S. A study on smoke movement in room fires with various pool fire location. KSME Int. J. 2002, 16, 1485–1496. [Google Scholar] [CrossRef]

- Liu, B.; Alvarez-Ossa, D.; Kherani, N.P.; Zukotynski, S.; Chen, K.P. Gamma-free smoke and particle detector using tritiated foils. IEEE Sens. J. 2007, 7, 917–918. [Google Scholar] [CrossRef]

- Li, M.; Xu, W.; Xu, K.; Fan, J.; Hou, D. Review of fire detection technologies based on video image. J. Theor. Appl. Inf. Technol. 2013, 49, 700–707. [Google Scholar]

- Yuan, F. Video-based smoke detection with histogram sequence of LBP and LBPV pyramids. Fire Saf. J. 2011, 46, 132–139. [Google Scholar] [CrossRef]

- Yuan, F.; Fang, Z.; Wu, S.; Yang, Y.; Fang, Y. Real-time image smoke detection using staircase searching-based dual threshold AdaBoost and dynamic analysis. IET Image Process. 2015, 9, 849–856. [Google Scholar] [CrossRef]

- Qureshi, W.S.; Ekpanyapong, M.; Dailey, M.N.; Rinsurongkawong, S.; Malenichev, A.; Krasotkina, O. QuickBlaze: Early fire detection using a combined video processing approach. Fire Technol. 2016, 52, 1293–1317. [Google Scholar] [CrossRef]

- Li, P.; Zhao, W. Image fire detection algorithms based on convolutional neural networks. Case Stud. Therm. Eng. 2020, 19, 100625. [Google Scholar] [CrossRef]

- Muhammad, K.; Ahmad, J.; Baik, S.W. Early fire detection using convolutional neural networks during surveillance for effective disaster management. Neurocomputing 2018, 288, 30–42. [Google Scholar] [CrossRef]

- Ko, B.; Cheong, K.-H.; Nam, J.-Y. Early fire detection algorithm based on irregular patterns of flames and hierarchical Bayesian Networks. Fire Saf. J. 2010, 45, 262–270. [Google Scholar] [CrossRef]

- Drysdale, D. An Introduction to Fire Dynamics; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Weise, D.R.; Johnson, T.J.; Reardon, J. Particulate and trace gas emissions from prescribed burns in southeastern US fuel types: Summary of a 5-year project. Fire Saf. J. 2015, 74, 71–81. [Google Scholar] [CrossRef]

- Vander Wal, R.L.; Fujiyama-Novak, J.H. Leading fire signatures of spacecraft materials: Light gases, condensables, and particulates. Fire Saf. J. 2011, 46, 506–519. [Google Scholar] [CrossRef]

- Ferguson, L.; Jenicak, C. Alarm and Detection Systems. In Fundamentals of Fire Protection for the Safety Professional; The Scarecrow Press Inc.: Mitchellville, MD, USA, 2005; pp. 181–199. [Google Scholar]

- Cote, A.E. Operation of Fire Protection Systems; Jones & Bartlett Learning: Burlington, MA, USA, 2003. [Google Scholar]

- Bao, Y.; Huang, Y.; Hoehler, M.S.; Chen, G. Review of fiber optic sensors for structural fire engineering. Sensors 2019, 19, 877. [Google Scholar] [CrossRef]

- Meacham, B.J. International developments in fire sensor technology. J. Fire Prot. Eng. 1994, 6, 89–98. [Google Scholar] [CrossRef]

- Thévenaz, L.; Niklès, M.; Fellay, A.; Facchini, M.; Robert, P.A. Truly distributed strain and temperature sensing using embedded optical fibers. In Proceedings of the Smart Structures and Materials 1998: Sensory Phenomena and Measurement Instrumentation for Smart Structures and Materials, San Diego, CA, USA, 2–4 March 1998; SPIE: Bellingham, WT, USA, 1998; pp. 301–314. [Google Scholar]

- Bao, X.; Dhliwayo, J.; Heron, N.; Webb, D.J.; Jackson, D.A. Experimental and theoretical studies on a distributed temperature sensor based on Brillouin scattering. J. Light. Technol. 1995, 13, 1340–1348. [Google Scholar] [CrossRef]

- Hoff, H. Using distributed fibre optic sensors for detecting fires and hot rollers on conveyor belts. In Proceedings of the 2017 2nd International Conference for Fibre-optic and Photonic Sensors for Industrial and Safety Applications (OFSIS), Brisbane, Australia, 8–10 January 2017; IEEE: New York, NY, USA, 2017; pp. 70–76. [Google Scholar]

- Read, T.; Bour, O.; Bense, V.; Le Borgne, T.; Goderniaux, P.; Klepikova, M.; Hochreutener, R.; Lavenant, N.; Boschero, V. Characterizing groundwater flow and heat transport in fractured rock using fiber-optic distributed temperature sensing. Geophys. Res. Lett. 2013, 40, 2055–2059. [Google Scholar] [CrossRef]

- Van Emmerik, T.; Rimmer, A.; Lechinsky, Y.; Wenker, K.; Nussboim, S.; Van de Giesen, N. Measuring heat balance residual at lake surface using distributed temperature sensing. Limnol. Oceanogr. Methods 2013, 11, 79–90. [Google Scholar] [CrossRef]

- Shen, D.; Chen, X.; Nguyen, M.; Yan, W.Q. Flame detection using deep learning. In Proceedings of the 2018 4th International Conference on Control, Automation and Robotics (ICCAR), Auckland, New Zealand, 20–23 April 2018; IEEE: New York, NY, USA, 2018; pp. 416–420. [Google Scholar]

- Xu, L.; Yan, Y. A new flame monitor with triple photovoltaic cells. IEEE Trans. Instrum. Meas. 2006, 55, 1416–1421. [Google Scholar] [CrossRef]

- Matsuzaki, A.; Yamanaka, T.; Hashimoto, A.; Sakamoto, K.; Sato, S.; Yoshikawa, K.; Tsujitake, S.; Watanabe, N.; Hiraki, T.; Iida, M. New products for boiler safety operation. In Proceedings of the International Joint Power Generation Conference, Singapore, 18–21 November 1991. [Google Scholar]

- Starikovskaia, S.M. Plasma assisted ignition and combustion. J. Phys. D Appl. Phys. 2006, 39, R265. [Google Scholar] [CrossRef]

- Gorokhov, E.; Magunov, A.; Feshchenko, V.; Altukhov, A. Solar-blind UV flame detector based on natural diamond. Instrum. Exp. Tech. 2008, 51, 280–283. [Google Scholar] [CrossRef]

- Docquier, N.; Candel, S. Combustion control and sensors: A review. Prog. Energy Combust. Sci. 2002, 28, 107–150. [Google Scholar] [CrossRef]

- Striganov, A.R.; Sventitskii, N.S. Tables of Spectral Lines of Neutral and Ionized Atoms; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Laux, C.O.; Spence, T.; Kruger, C.; Zare, R. Optical diagnostics of atmospheric pressure air plasmas. Plasma Sources Sci. Technol. 2003, 12, 125. [Google Scholar] [CrossRef]

- Blank, T.; Gol’Dberg, Y.A. Mechanisms of current flow in metal-semiconductor ohmic contacts. Semiconductors 2007, 41, 1263–1292. [Google Scholar] [CrossRef]

- Monroy, E.; Omnès, F.; Calle, F. Wide-bandgap semiconductor ultraviolet photodetectors. Semicond. Sci. Technol. 2003, 18, R33. [Google Scholar] [CrossRef]

- Ye, W.-L.; Zheng, C.-T.; Cheng, X.-Y.; Wu, F.-P.; Chen, M.-M.; Wang, Y.-D. Mid-infrared ppm-level methane detection device using small-size absorption pool and dual-channel lock-in amplifier. Infrared Phys. Technol. 2015, 71, 339–346. [Google Scholar] [CrossRef]

- Wu, H.; Dong, L.; Yin, X.; Sampaolo, A.; Patimisco, P.; Ma, W.; Zhang, L.; Yin, W.; Xiao, L.; Spagnolo, V. Atmospheric CH4 measurement near a landfill using an ICL-based QEPAS sensor with VT relaxation self-calibration. Sens. Actuators B Chem. 2019, 297, 126753. [Google Scholar] [CrossRef]

- Pi, M.; Zheng, C.; Ji, J.; Zhao, H.; Peng, Z.; Lang, J.; Liang, L.; Zhang, Y.; Wang, Y.; Tittel, F.K. Surface-enhanced infrared absorption spectroscopic chalcogenide waveguide sensor using a silver island film. ACS Appl. Mater. Interfaces 2021, 13, 32555–32563. [Google Scholar] [CrossRef]

- Li, Y.; Yu, L.; Zheng, C.; Ma, Z.; Yang, S.; Song, F.; Zheng, K.; Ye, W.; Zhang, Y.; Wang, Y. Development and field deployment of a mid-infrared CO and CO2 dual-gas sensor system for early fire detection and location. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2022, 270, 120834. [Google Scholar] [CrossRef]

- Wiedinmyer, C.; Neff, J.C. Estimates of CO2 from fires in the United States: Implications for carbon management. Carbon Balance Manag. 2007, 2, 10. [Google Scholar] [CrossRef] [PubMed]

- Prashanth Kumar Reddy, A.; Sathwik Reddy, E.; Bhaskar, T.; Yadav, B.P.; Singh, A.K. Design of fire and gas detection system for a process plant: A review. In Advances in Industrial Safety Select Proceedings of HSFEA 2018; Springer: Berlin/Heidelberg, Germany, 2020; pp. 271–280. [Google Scholar]

- Jabłoński, K.; Grychowski, T. The Method for Easy Identifying Zero Temperature Drift of Catalytic Bead Sensor. In Proceedings of the 2018 XV International Scientific Conference on Optoelectronic and Electronic Sensors (COE), Warsaw, Poland, 17–20 June 2018; IEEE: New York, NY, USA, 2018; pp. 1–4. [Google Scholar]

- Mann, D.P.; Pratt, K.F.; Paraskeva, T.; Parkin, I.P.; Williams, D.E. Transition metal exchanged zeolite layers for selectivity enhancement of metal-oxide semiconductor gas sensors. IEEE Sens. J. 2007, 7, 551–556. [Google Scholar] [CrossRef]

- Lu, S.; Hu, X.; Zheng, H.; Qiu, J.; Tian, R.; Quan, W.; Min, X.; Ji, P.; Hu, Y.; Cheng, S. Highly selective, ppb-level xylene gas detection by Sn2+-doped NiO flower-like microspheres prepared by a one-step hydrothermal method. Sensors 2019, 19, 2958. [Google Scholar] [CrossRef]

- Fang, J.; Zhu, Y.; Wu, D.; Zhang, C.; Xu, S.; Xiong, D.; Yang, P.; Wang, L.; Chu, P.K. Preparation of SnO2 nanoparticles doped with palladium and graphene and application for ethanol detection. IEEE Sens. J. 2017, 17, 6240–6245. [Google Scholar] [CrossRef]

- Zhang, H.-J.; Meng, F.-N.; Liu, L.-Z.; Chen, Y.-J. Convenient route for synthesis of alpha-Fe2O3 and sensors for H2S gas. J. Alloys Compd. 2019, 774, 1181–1188. [Google Scholar] [CrossRef]

- Borgohain, R.; Das, R.; Mondal, B.; Yordsri, V.; Thanachayanont, C.; Baruah, S. ZnO/ZnS core-shell nanostructures for low-concentration NO2 sensing at room temperature. IEEE Sens. J. 2018, 18, 7203–7208. [Google Scholar] [CrossRef]

- Basu, S.; Bhattacharyya, P. Recent developments on graphene and graphene oxide based solid state gas sensors. Sens. Actuators B Chem. 2012, 173, 1–21. [Google Scholar] [CrossRef]

- Sakthivel, B.; Nammalvar, G. Selective ammonia sensor based on copper oxide/reduced graphene oxide nanocomposite. J. Alloys Compd. 2019, 788, 422–428. [Google Scholar] [CrossRef]

- Wang, Z.; Sackmann, A.; Gao, S.; Weimar, U.; Lu, G.; Liu, S.; Zhang, T.; Barsan, N. Study on highly selective sensing behavior of ppb-level oxidizing gas sensors based on Zn2SnO4 nanoparticles immobilized on reduced graphene oxide under humidity conditions. Sens. Actuators B Chem. 2019, 285, 590–600. [Google Scholar] [CrossRef]

- Hu, H.; Yang, X.; Guo, X.; Khaliji, K.; Biswas, S.R.; García de Abajo, F.J.; Low, T.; Sun, Z.; Dai, Q. Gas identification with graphene plasmons. Nat. Commun. 2019, 10, 1131. [Google Scholar] [CrossRef]

- Naik, A.; Parkin, I.; Binions, R. Gas sensing studies of an NN hetero-junction array based on SnO2 and ZnO composites. Chemosensors 2016, 4, 3. [Google Scholar] [CrossRef]

- Prajapati, C.S.; Soman, R.; Rudraswamy, S.; Nayak, M.; Bhat, N. Single chip gas sensor array for air quality monitoring. J. Microelectromech. Syst. 2017, 26, 433–439. [Google Scholar] [CrossRef]

- Zhang, L.; Rahimabady, M.; Tan, S.Y.; Tan, C.Y.; Chen, S.; Chen, Y.F.; Yao, K.; Humbert, A.; Soccol, D.; Zang, K. P (VDF-HFP) polymer as sensing material for capacitive carbon dioxide sensors. IEEE Sens. J. 2017, 17, 4349–4356. [Google Scholar] [CrossRef]

- Riches, J.; Chapman, A.; Beardon, J. The Detection of Fire Precursors Using Chemical Sensors. In Proceedings of the 8th International Fire Science and Engineering Conference, Edinburgh, UK, 5–7 June 1999. [Google Scholar]

- Mandayo, G.G.; Castaño, E.; Gracia, F.J. Carbon monoxide detector fabricated on the basis of a tin oxide novel doping method. IEEE Sens. J. 2002, 2, 322–328. [Google Scholar] [CrossRef]

- Juang, F.-R.; Fang, Y.-K.; Chiang, Y.-T.; Chou, T.-H.; Lin, C.-I.; Lin, C.-W.; Liou, Y.-W. Comparative study of carbon monoxide gas sensing mechanism for the LTPS MOS Schottky diodes with various metal oxides. IEEE Sens. J. 2010, 11, 1227–1232. [Google Scholar] [CrossRef]

- Adib, M.; Eckstein, R.; Hernandez-Sosa, G.; Sommer, M.; Lemmer, U. SnO2 nanowire-based aerosol jet printed electronic nose as fire detector. IEEE Sens. J. 2017, 18, 494–500. [Google Scholar] [CrossRef]

- Mirzaei, A.; Lee, J.-H.; Majhi, S.M.; Weber, M.; Bechelany, M.; Kim, H.W.; Kim, S.S. Resistive gas sensors based on metal-oxide nanowires. J. Appl. Phys. 2019, 126, 241102. [Google Scholar] [CrossRef]

- Miyake, M. Electrochemical functions. In Carbon Alloys; Elsevier: Amsterdam, The Netherlands, 2003; pp. 435–445. [Google Scholar]

- Jia, X.; Roels, J.; Baets, R.; Roelkens, G. A miniaturised, fully integrated NDIR CO2 sensor on-chip. Sensors 2021, 21, 5347. [Google Scholar] [CrossRef]

- Dubey, R.; Telles, A.; Nikkel, J.; Cao, C.; Gewirtzman, J.; Raymond, P.A.; Lee, X. Low-Cost CO2 NDIR Sensors: Performance Evaluation and Calibration Using Machine Learning Techniques. Sensors 2024, 24, 5675. [Google Scholar] [CrossRef]

- Goel, N.; Kunal, K.; Kushwaha, A.; Kumar, M. Metal oxide semiconductors for gas sensing. Eng. Rep. 2023, 5, e12604. [Google Scholar] [CrossRef]

- Donarelli, M.; Prezioso, S.; Perrozzi, F.; Giancaterini, L.; Cantalini, C.; Treossi, E.; Palermo, V.; Santucci, S.; Ottaviano, L. Graphene oxide for gas detection under standard humidity conditions. 2D Mater. 2015, 2, 035018. [Google Scholar] [CrossRef]

- Liu, X.; Zheng, W.; Kumar, R.; Kumar, M.; Zhang, J. Conducting polymer-based nanostructures for gas sensors. Coord. Chem. Rev. 2022, 462, 214517. [Google Scholar] [CrossRef]

- Chae, M.; Lee, D.; Kim, H.-D. Low-power consumption IGZO memristor-based gas sensor embedded in an internet of things monitoring system for isopropanol alcohol gas. Micromachines 2023, 15, 77. [Google Scholar] [CrossRef]

- Ahmad, I.; Lee, D.; Chae, M.; Kim, H.-D. Advanced recovery and enhanced humidity tolerance of CNTs gas sensor using a filament heater. Chem. Eng. J. 2024, 496, 154014. [Google Scholar] [CrossRef]

- Chae, M.; Lee, D.; Kim, H.D. Dynamic Response and Swift Recovery of Filament Heater-Integrated Low-Power Transparent CNT Gas Sensor. Adv. Funct. Mater. 2024, 34, 2405260. [Google Scholar] [CrossRef]

- Vidiš, M.; Plecenik, T.; Moško, M.; Tomašec, S.; Roch, T.; Satrapinskyy, L.; Grančič, B.; Plecenik, A. Gasistor: A memristor based gas-triggered switch and gas sensor with memory. Appl. Phys. Lett. 2019, 115, 093504. [Google Scholar] [CrossRef]

- Lee, D.; Yun, M.J.; Kim, K.H.; Kim, S.; Kim, H.-D. Advanced recovery and high-sensitive properties of memristor-based gas sensor devices operated at room temperature. ACS Sens. 2021, 6, 4217–4224. [Google Scholar] [CrossRef]

- Qiu, P.; Qin, Y.; Xia, Q. Ultrasensitive gas sensor developed from SnS/TiO2-based memristor for dilute methanol detection at room temperature. Sens. Actuators B Chem. 2023, 392, 134038. [Google Scholar] [CrossRef]

- Lee, D.; Jung, J.; Kim, S.; Kim, H.-D. Gas detection and recovery characteristics at room temperature observed in a Zr3N4-based memristor sensor array. Sens. Actuators B Chem. 2023, 376, 132993. [Google Scholar] [CrossRef]

- Lee, D.; Jung, J.; Kim, K.H.; Bae, D.; Chae, M.; Kim, S.; Kim, H.-d. Highly sensitive oxygen sensing characteristics observed in IGZO based gasistor in a mixed gas ambient at room temperature. ACS Sens. 2022, 7, 2567–2576. [Google Scholar] [CrossRef]

- Haidry, A.A.; Ebach-Stahl, A.; Saruhan, B. Effect of Pt/TiO2 interface on room temperature hydrogen sensing performance of memristor type Pt/TiO2/Pt structure. Sens. Actuators B Chem. 2017, 253, 1043–1054. [Google Scholar] [CrossRef]

- Dehghani, N.; Yousefiazari, E. A gas sensor comprising two back-to-back connected Au/TiO2 Schottky diodes. Mater. Res. Express 2018, 5, 046304. [Google Scholar] [CrossRef]

- Lee, D.; Chae, M.; Kim, H.-D. Response characteristic in discontinuous NO gas flows for boron nitride memristor gas sensor devices. Sens. Actuators B Chem. 2024, 401, 135063. [Google Scholar] [CrossRef]

- Qiu, P.; Liu, H.; Hu, C.; Liu, J.; Fu, C.; Qin, Y. Advances in memristive gas sensors: A review. Talanta 2025, 293, 128058. [Google Scholar] [CrossRef]

- Xie, R.; Lu, J.; Liu, Y. Carbon monoxide gas sensing properties of SnO2 modified metal-organic skeleton derived NiO. Sens. Actuators A Phys. 2024, 367, 115038. [Google Scholar] [CrossRef]

- Lee, D.; Chae, M.; Jung, J.; Kim, H.-D. Correlation between sensing accuracy and read margin of a memristor-based NO gas sensor array estimated by neural network analysis. ACS Sens. 2023, 8, 2105–2114. [Google Scholar] [CrossRef]

- Kim, J.-H.; Katoch, A.; Kim, H.W.; Kim, S.S. Realization of ppm-level CO detection with exceptionally high sensitivity using reduced graphene oxide-loaded SnO2 nanofibers with simultaneous Au functionalization. Chem. Commun. 2016, 52, 3832–3835. [Google Scholar] [CrossRef]

- Wang, P.; Yuan, T.; Yuan, H.; Zheng, X.; Ijaz, H.; Hui, J.; Fan, D.; Zhao, Y.; Hu, S. PdO/SnO2 heterostructure for low-temperature detection of CO with fast response and recovery. RSC Adv. 2019, 9, 22875–22882. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, T.; Wu, X.; Huang, X. Predicting transient building fire based on external smoke images and deep learning. J. Build. Eng. 2022, 47, 103823. [Google Scholar] [CrossRef]

- Fernando, L.; Ghali, R.; Akhloufi, M.A. SWIFT: Simulated Wildfire Images for Fast Training Dataset. Remote Sens. 2024, 16, 1627. [Google Scholar] [CrossRef]

- El-Madafri, I.; Peña, M.; Olmedo-Torre, N. Dual-Dataset Deep Learning for Improved Forest Fire Detection: A Novel Hierarchical Domain-Adaptive Learning Approach. Mathematics 2024, 12, 534. [Google Scholar] [CrossRef]

- Altaf, M.; Yasir, M.; Dilshad, N.; Kim, W. An Optimized Deep-Learning-Based Network with an Attention Module for Efficient Fire Detection. Fire 2025, 8, 15. [Google Scholar] [CrossRef]

- Diaconu, B.M. Recent advances and emerging directions in fire detection systems based on machine learning algorithms. Fire 2023, 6, 441. [Google Scholar] [CrossRef]

- Nadeem, M.; Dilshad, N.; Alghamdi, N.S.; Dang, L.M.; Song, H.-K.; Nam, J.; Moon, H. Visual intelligence in smart cities: A lightweight deep learning model for fire detection in an IoT environment. Smart Cities 2023, 6, 2245–2259. [Google Scholar] [CrossRef]

- Titu, M.F.S.; Pavel, M.A.; Michael, G.K.O.; Babar, H.; Aman, U.; Khan, R. Real-Time Fire Detection: Integrating Lightweight Deep Learning Models on Drones with Edge Computing. Drones 2024, 8, 483. [Google Scholar] [CrossRef]

- Safak, E.; BARIŞÇI, N. Real-time fire and smoke detection for mobile devices using deep learning. J. Fac. Eng. Archit. Gazi Univ. 2023, 38, 2179–2190. [Google Scholar]

- Kwon, H.; Choi, S.; Woo, W.; Jung, H. Evaluating Segmentation-Based Deep Learning Models for Real-Time Electric Vehicle Fire Detection. Fire 2025, 8, 66. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J.L.; Loboichenko, V.; Divizinyuk, M.; Wilk-Jakubowski, G.; Shevchenko, R.; Ivanov, S.; Strelets, V. Acoustic Waves and Their Application in Modern Fire Detection Using Artificial Vision Systems: A Review. Sensors 2025, 25, 935. [Google Scholar] [CrossRef]

- Aminaho, E.N.; Aminaho, N.S.; Hossain, M.; Faisal, N.H.; Aminaho, K.A. Design of a hybrid artificial intelligence system for real-time quantification of impurities in gas streams: Application in CO2 capture and storage. Gas Sci. Eng. 2025, 134, 205546. [Google Scholar] [CrossRef]

- Ali, A.W.; Kurnaz, S. Optimizing Deep Learning Models for Fire Detection, Classification, and Segmentation Using Satellite Images. Fire 2025, 8, 36. [Google Scholar] [CrossRef]

- Sarikaya Basturk, N. Forest fire detection in aerial vehicle videos using a deep ensemble neural network model. Aircr. Eng. Aerosp. Technol. 2023, 95, 1257–1267. [Google Scholar] [CrossRef]

- Dogra, S.K.; Jayanthu, S.; Samal, A.K.; Pramanik, J.; Pani, S.K. Machine learning approach to implement mine fire predicting for underground coal mines. In Proceedings of the 2021 2nd Global Conference for Advancement in Technology (GCAT), Bangalore, India, 1–3 October 2021; pp. 1–4. [Google Scholar]

- Wang, Z.; Zhang, T.; Huang, X. Predicting real-time fire heat release rate by flame images and deep learning. Proc. Combust. Inst. 2023, 39, 4115–4123. [Google Scholar] [CrossRef]

- Lu, S.; Jones, E.; Zhao, L.; Sun, Y.; Qin, K.; Liu, J.; Li, J.; Abeysekara, P.; Mueller, N.; Oliver, S. Onboard ai for fire smoke detection using hyperspectral imagery: An emulation for the upcoming Kanyini hyperscout-2 mission. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2024, 17, 9629–9640. [Google Scholar] [CrossRef]

- Fouda, M.M.; Sakib, S.; Fadlullah, Z.M.; Nasser, N.; Guizani, M. A lightweight hierarchical AI model for UAV-enabled edge computing with forest-fire detection use-case. IEEE Netw. 2022, 36, 38–45. [Google Scholar] [CrossRef]

- Qadir, Z.; Le, K.; Bao, V.N.Q.; Tam, V.W. Deep learning-based intelligent post-bushfire detection using UAVs. IEEE Geosci. Remote Sens. Lett. 2023, 21, 5000605. [Google Scholar] [CrossRef]

- Dilshad, N.; Khan, S.U.; Alghamdi, N.S.; Taleb, T.; Song, J. Toward efficient fire detection in IoT environment: A modified attention network and large-scale data set. IEEE Internet Things J. 2023, 11, 13467–13481. [Google Scholar] [CrossRef]

- Talaat, F.M.; ZainEldin, H. An improved fire detection approach based on YOLO-v8 for smart cities. Neural Comput. Appl. 2023, 35, 20939–20954. [Google Scholar] [CrossRef]

- Yang, X.; Deng, Y.; Yang, H.; Liao, Y.; Cheng, X.; Zou, Y.; Wu, L.; Deng, Y. Functionalization of mesoporous semiconductor metal oxides for gas sensing: Recent advances and emerging challenges. Adv. Sci. 2023, 10, 2204810. [Google Scholar] [CrossRef]

- Luan, S.; Hu, J.; Ma, M.; Tian, J.; Liu, D.; Wang, J.; Wang, J. The enhanced sensing properties of MOS-based resistive gas sensors by Au functionalization: A review. Dalton Trans. 2023, 52, 8503–8529. [Google Scholar] [CrossRef]

- Imash, A.; Smagulova, G.; Kaidar, B.; Keneshbekova, A.; Kazhdanbekov, R.; Velasco, L.F.; Mansurov, Z. Chemoresistive Gas Sensors Based on Electrospun 1D Nanostructures: Synergizing Morphology and Performance Optimization. Sensors 2024, 24, 6797. [Google Scholar] [CrossRef]

- Dinh, T.-V.; Choi, I.-Y.; Son, Y.-S.; Kim, J.-C. A review on non-dispersive infrared gas sensors: Improvement of sensor detection limit and interference correction. Sens. Actuators B Chem. 2016, 231, 529–538. [Google Scholar] [CrossRef]

- Chen, G.; Li, J.; Zhu, H.; Wang, Y.; Ji, H.; Meng, F. Optical fiber gas sensor with multi-parameter sensing and environmental anti-interference performance. J. Ind. Inf. Integr. 2024, 38, 100565. [Google Scholar] [CrossRef]

- Kim, T.; Kim, H.-D. The Superior Response and High Reproducibility of the Memristor-Integrated Low-Power Transparent SnO2 Gas Sensor. Micromachines 2024, 15, 1411. [Google Scholar] [CrossRef] [PubMed]

| Test-Fire | Combustion Material | Combustion Products |

|---|---|---|

| TF1 | Open beech-wood fire (with ethanol) | CO2, CO, H2, H2O, NO, NO2, methane, acetylene, ethane, ethene, styrol, chlorobenzene, ethanol, etc. |

| TF2 | Smoldering beech-wood fire | CO, H2, H2O, CO2, NO, HCl, methane, ethane, ethene, aromatic hydrocarbons (benzene, toluol, xylene, styrol, chlorobenzene), acrolein, formaldehyde, formic acid, acetic acid, etc. |

| TF3 | Glowing smoldering cotton | CO, H2, NO, CO2, H2O, methane, acetylene, ethane, ethene, benzene, acetaldehyde, formaldehyde, ethanol, etc. |

| TF4 | Open polyurethane-foam fire | CO2, CO, H2O, NO, NO2, N2O, HCN, NH3, amines, ethane, styrol, acetone, etc. |

| TF5 | Open n-heptane fire (3% toluol) | CO2, CO, H2, H2O, NO, NO2, ethane, ethene, styrol, chlorobenzene, ethanol, octane-n, hexane, etc. |

| TF6 | Open ethanol/alcohol fire (liquid) | CO2, CO, H2, H2O, NO, ethane, styrol, ethanol, etc. |

| Fire Gases | Types of Sensing Materials to Detect Gas | Reference |

|---|---|---|

| CO | SnO2, WO3, In2O3, ZnO, α–Fe2O3, NiO, Co3O4, Cr2O3 | [48,49,50,51,52,53,54,55] |

| CO2 | SnO2, ZnO, TiO2, La2O3, CdO, CeO2, In2O3, WO3 | [56] |

| NOx | ZnO, In2O3, SnO2, ZnCr2O3, WO3/YSZ/Pt, Pt–WO3/TiO2, yttria-stabilized zirconia | [57] |

| HCN | CuO, Ni(OH)2, AiN nanotube, Boron sheet | [58] |

| SOx | Metal Sulfides, stabilized zirconia (YSZ)/metal sulphates | [59,60] |

| HCl | Nd–SrCeO3, polyaniline copolymer nanocomposite thin films | [61,62] |

| Sensing Material | Target Gas | Response Time (s) | Recovery time (s) | Constraints/Limitations | Ref |

|---|---|---|---|---|---|

| SnO2 | CO, C2H6, VOCs | 10–30 | 20–40 | Requires high temperature (~200 °C); affected by humidity. | [65] |

| TiO2 | NH3, CO | 1–2 | 5–10 | Sensitive to humidity; can operate at RT with nanostructures. | [66] |

| In2O3 | NO2, CO | ~15 | ~25 | Moderate selectivity may require doping for enhanced performance. | [47] |

| MXene | CO, VOCs | <2 | <5 | Prone to oxidation; requires stabilization. | [67] |

| NiO | H2, CO | 3–8 | 10–20 | Operates at higher temperature (~300–350 °C); moderate stability. | [68] |

| WO3 | NO2 | ~ 30 | ~60 | Good sensitivity but slower recovery; temp-dependent. | [69] |

| Graphene/GO/rGO | NH3, VOCs, CO | <5 | <10 | Highly sensitive; humidity can impact response. | [70] |

| Ta2O5 | NO, C2H6 | <1 | >300 | Excellent sensitivity but slow natural recovery; enhanced by bias. | [71] |

| Technique | Mechanism | Applications | Advantages | Challenges |

|---|---|---|---|---|

| Fixed-Temperature Detectors | Activates at ≥58 °C; fusible elements melt to trigger. | Fire sprinklers, industrial use | Reliable; simple; cost-effective | Non-restorable; thermal lag |

| Distributed Fiber Sensing | Measures temperature via Raman/Brillouin backscatter. | Conveyor belts, groundwater flow | High sensitivity; wide range | Complex setup; environmental noise |

| Thermal Radiation Detection | Infrared spectra analyzed via low-pass filters. | Hangars, petroleum facilities | Rapid; highly selective | False positives from hot surfaces or sunlight |

| Sensor Type | Target Gas | Response Time | Operating Temp | Model/Source |

|---|---|---|---|---|

| Electrochemical Sensor | CO | ~15–60 s | Ambient | Figaro TGS5042 |

| MOS Sensor | CO, VOCs | ~10–30 s | 150–300 °C | Figaro TGS2611 |

| NDIR Sensor | CO2 | ~20–30 s | Ambient | Senseair S8 |

| IR Flame detector | Open flame | <5 s | −40–75 °C | Honeywell FS24X |

| Electrochemical Sensor | CO | ~30–60 s | 0–50 °C | FECS40-1000 |

| NDIR Sensor | CO2 | <120 s | 0–50 °C | CDM7162-C00 |

| Optical Sensor | Flame | <0.01 s | 20–50 °C | UVTRON R2868 |

| Optical Sensor | Flame | <0.039 s | −40–85 °C | Honeywell SS2 |

| Optical Sensor | Flame | <120 s | 0–40 °C | Honeywell i3 Series 4WITAR-B |

| Target Gas | Sensing Material | Driven Source | Concentration (ppm) | Response (Rair/Rgas) | Recovery Time (S) | Ref. |

|---|---|---|---|---|---|---|

NO2 | CNT-based gasistor | MHH MHN | 10 | 1.46 1.77 | 0.001 | [148] |

NO2 | CNT-based gasistor | MH (HRS) | 50 | 52 | 0.001 | [147] |

CH3OH | ISnS/TiO2-based gasistor | RT | 1 | 85.2 | 0.65 | [151] |

NO | Zr3N4-based gasistor | RT | 0.05 | 25.8 | 0.0000016 | [152] |

| NO C2H6 O2 | HfO2-based gasistor | RT | 50 | 5.2 1.6 4.7 | 0.00000009 | [150] |

O2 | IGZO-based gasistor | RT | 0.5 | 14 | 0.00009 | [153] |

H2 | TiO2-based gasistor | Dry air Humid air | 10000 | ~5 × 104 ~6 × 105 | 180 11 | [154] |

Ethanol | TiO2-based gasistor | 350–750 °C | 1000 | ~15 | _ | [155] |

NO | Bn- based gas sensor | RT | 5 | 18 | 81 | [156] |

| IPA | a-IGZO | RT | 10 | 2.51 | 0.000005 | [146] |

| Category | Model | Data Size | Predction | Performance | Platform | Reference |

|---|---|---|---|---|---|---|

| Lightweight | Flame Net | Fire images (RGB) | Fire classification (binary) | Accuracy 99.4%, F1-score 0.99 | Smart city, Raspberry Pi | [167] |

| Lightweight | YOLOv8n | Fire scene images | Fire classification (real-time) | Accuracy 95.21%, F1-score 0.985 | DJI drone + Raspberry Pi 5 | [168] |

| Lightweight | Mobile CNN | Smoke and fire images | Real-time smoke/fire detection | Accuracy 98.37% | Mobile device | [169] |

| Lightweight | DT/NB | CO/O2 gas ratio | Fire hazard (binary) | DT: 100%, NB: 93.8% | Coal mine, embedded | [175] |

| High-performance | XGBoost | Gas sensor data (Cr470, Au475) | Sensor error & gas concentration | R2 > 0.99 | Industrial sensing | [172] |

| High-performance | EO CNN | EO satellite data | Fire detection/classification | Fire ratio > 0.8 | Satellite-based monitoring | [173] |

| High-performance | VGG16-Flame | Flame images + HRR | HRR estimation | R2 > 0.8 | Indoor/outdoor fire scenes | [176] |

| High-performance | Random Forest | Fire size, location, resources | Fire duration prediction | Classification error: 8.13% | National wildfire database | [177] |

| Sensor Type | Effectiveness (Sensitivity/Selectivity) | Limitations | Real-World Deployment Readiness | Ref |

|---|---|---|---|---|

| Gasistors | High sensitivity, fast response | Humidity/temperature sensitivity | High (compact, low power, IOT compatible) | [149] |

| MOS Sensors | Moderate sensitivity | High power, slow recovery | Moderate (requires heater, bulkier) | [183] |

| Electrochemical | High selectivity | Short lifespan, calibration needed | Moderate (limited by environmental factors) | [184] |

| NDIR | Accurate for CO2 | Large size, expensive | Low (complex optics, high cost) | [185] |

| Optical Smoke Sensor | Early smoke detection | False alarms (dust/steam) | High (widely deployed but prone to nuisance alarms) | [186] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, M.; Ahmad, I.; Geun, I.; Hamza, S.A.; Ijaz, U.; Jang, Y.; Koo, J.; Kim, Y.-G.; Kim, H.-D. A Comprehensive Review of Advanced Sensor Technologies for Fire Detection with a Focus on Gasistor-Based Sensors. Chemosensors 2025, 13, 230. https://doi.org/10.3390/chemosensors13070230

Ali M, Ahmad I, Geun I, Hamza SA, Ijaz U, Jang Y, Koo J, Kim Y-G, Kim H-D. A Comprehensive Review of Advanced Sensor Technologies for Fire Detection with a Focus on Gasistor-Based Sensors. Chemosensors. 2025; 13(7):230. https://doi.org/10.3390/chemosensors13070230

Chicago/Turabian StyleAli, Mohsin, Ibtisam Ahmad, Ik Geun, Syed Ameer Hamza, Umar Ijaz, Yuseong Jang, Jahoon Koo, Young-Gab Kim, and Hee-Dong Kim. 2025. "A Comprehensive Review of Advanced Sensor Technologies for Fire Detection with a Focus on Gasistor-Based Sensors" Chemosensors 13, no. 7: 230. https://doi.org/10.3390/chemosensors13070230

APA StyleAli, M., Ahmad, I., Geun, I., Hamza, S. A., Ijaz, U., Jang, Y., Koo, J., Kim, Y.-G., & Kim, H.-D. (2025). A Comprehensive Review of Advanced Sensor Technologies for Fire Detection with a Focus on Gasistor-Based Sensors. Chemosensors, 13(7), 230. https://doi.org/10.3390/chemosensors13070230