Development of Gas Sensors and Their Applications in Health Safety, Medical Detection, and Diagnosis

Abstract

1. Introduction

2. Exploration and Optimization of Novel Sensitive Materials

2.1. Nanomaterials (NMs)

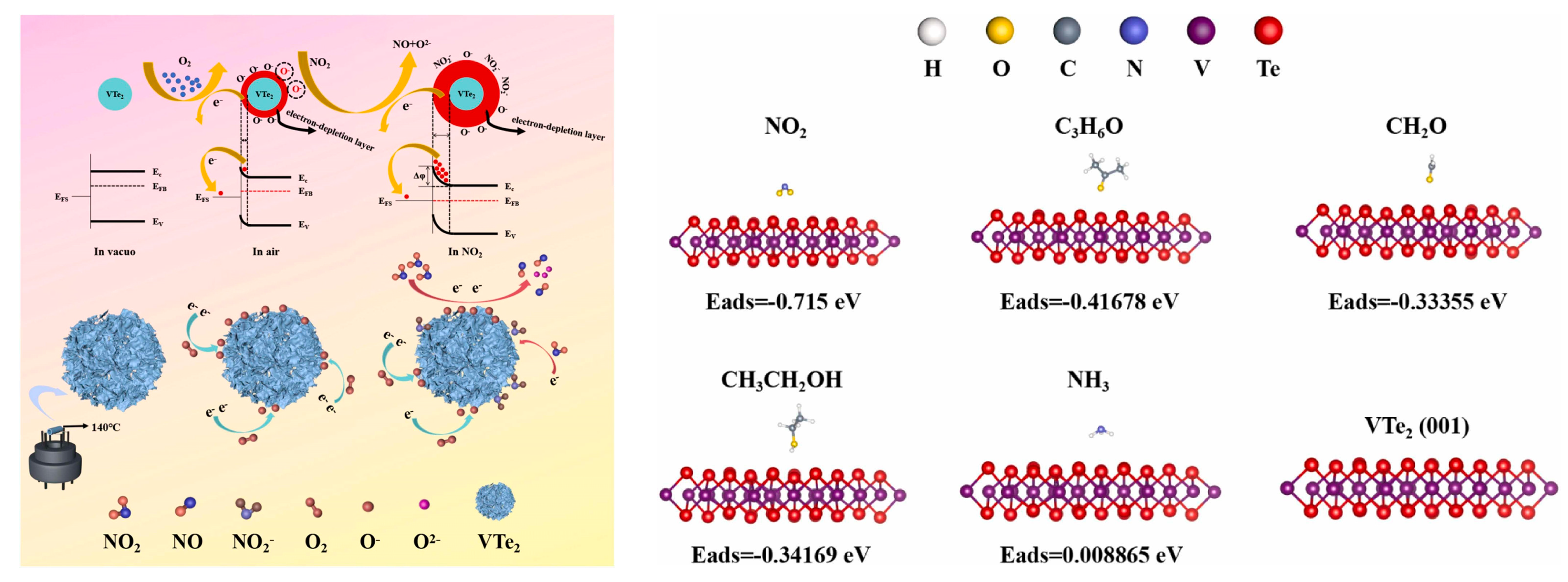

2.1.1. Low-Latitude Nanomaterials

2.1.2. 3D Nanomaterials

2.2. Metal Oxides (MOXs)

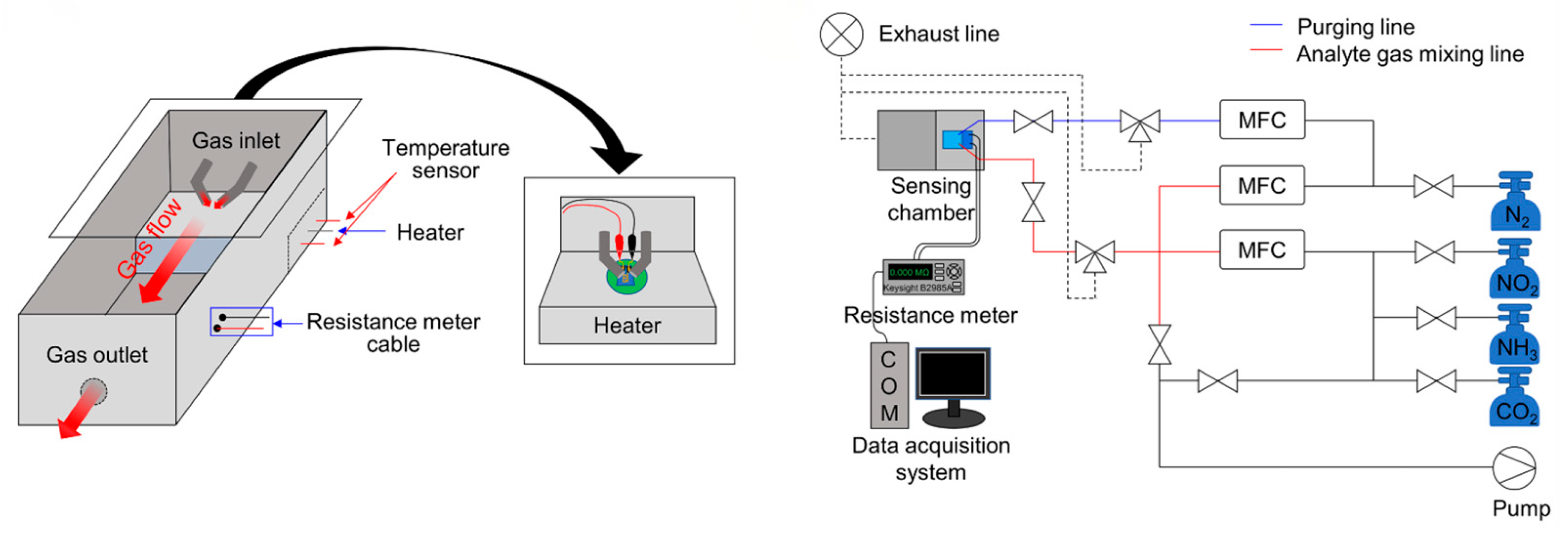

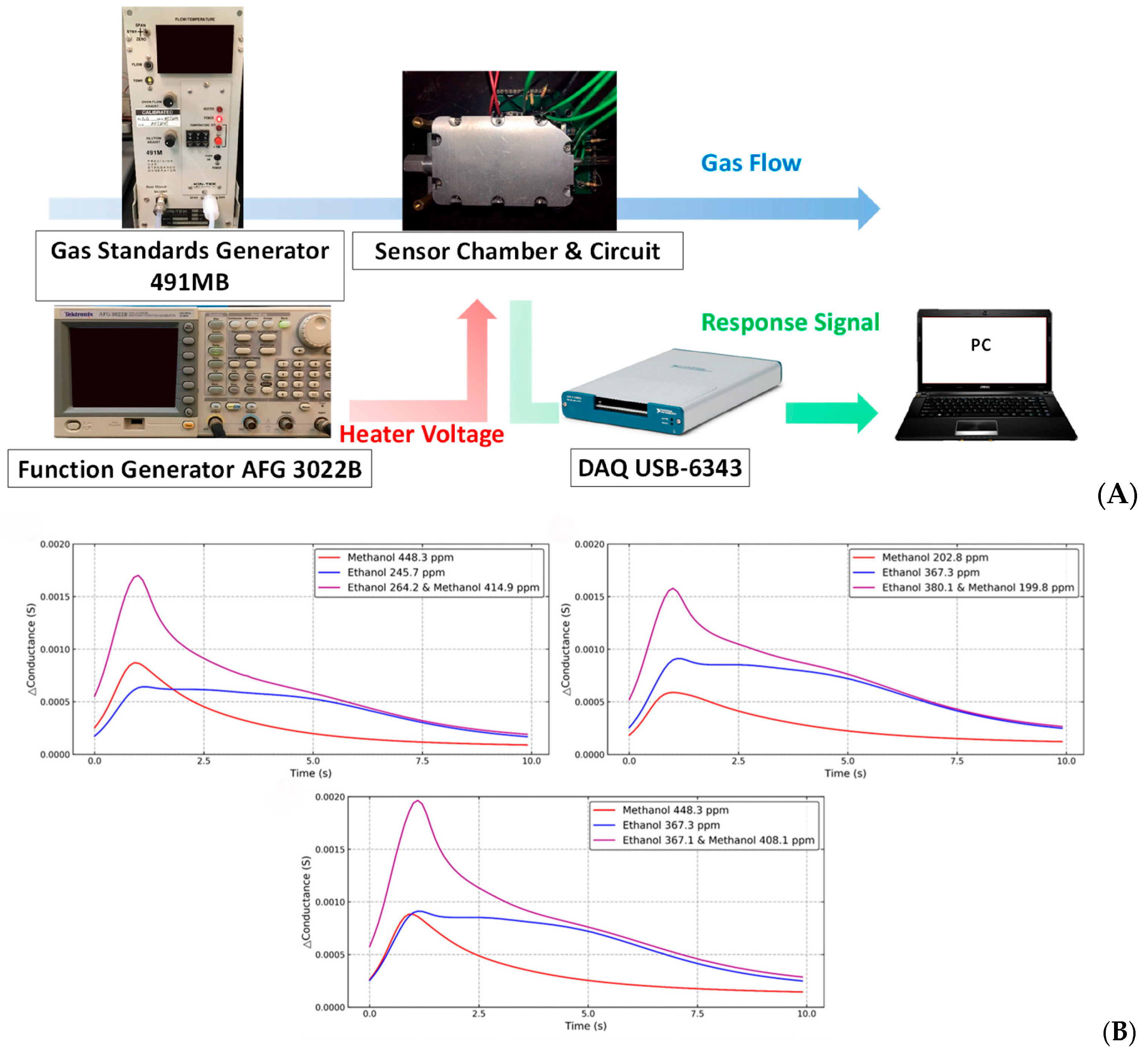

2.2.1. Influencing Factors of MOX Gas Sensors

2.2.2. Performance Optimization of MOX Gas Sensors

2.3. Emerging Sensitive Materials

2.3.1. Metal-Organic Frameworks (MOF)

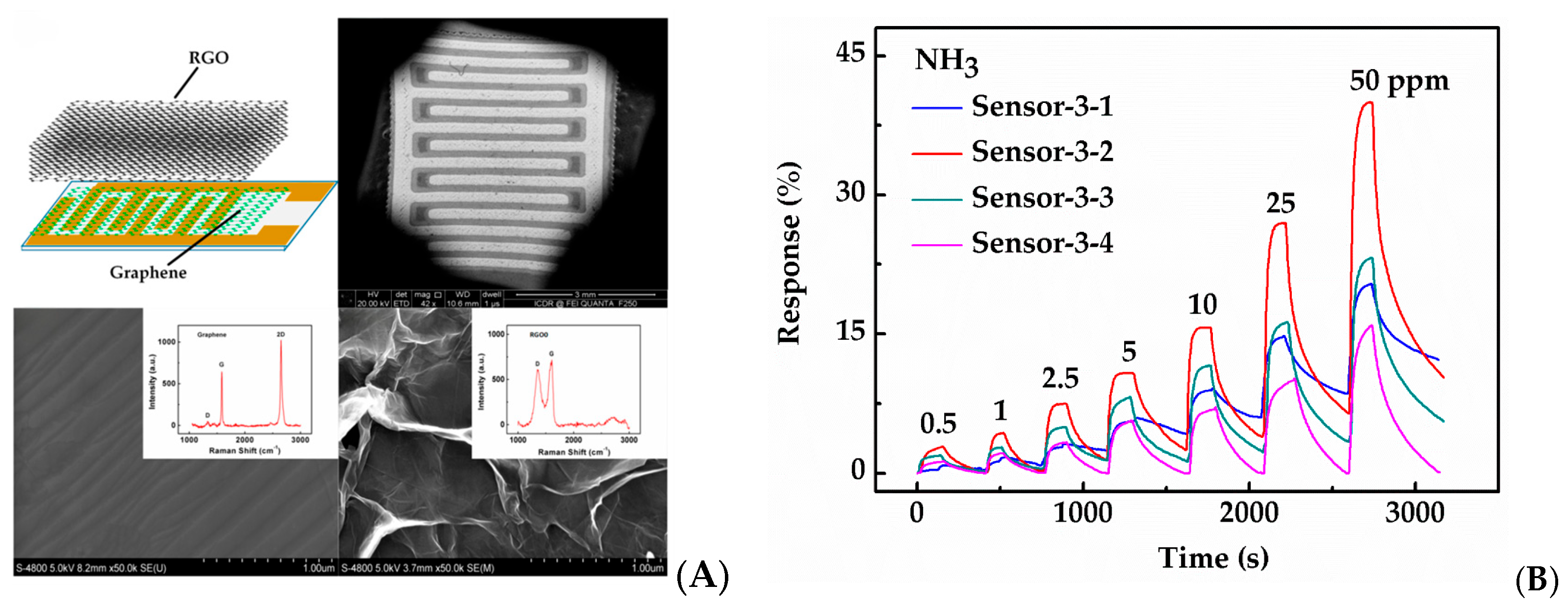

2.3.2. Graphene

3. Innovation of Sensor Structure Design

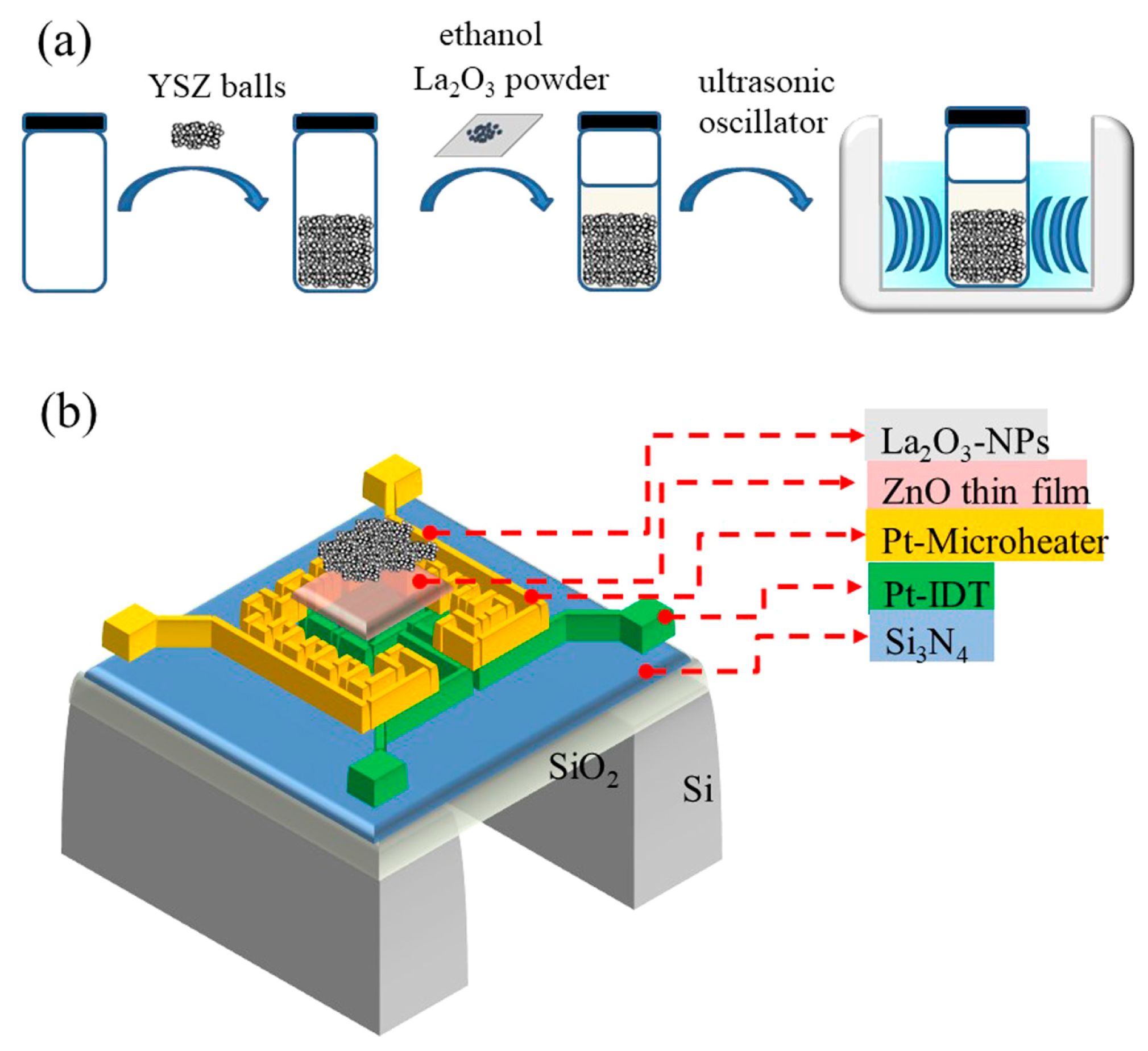

3.1. Integration of Micro-Electro-Mechanical System (MEMS) Technology

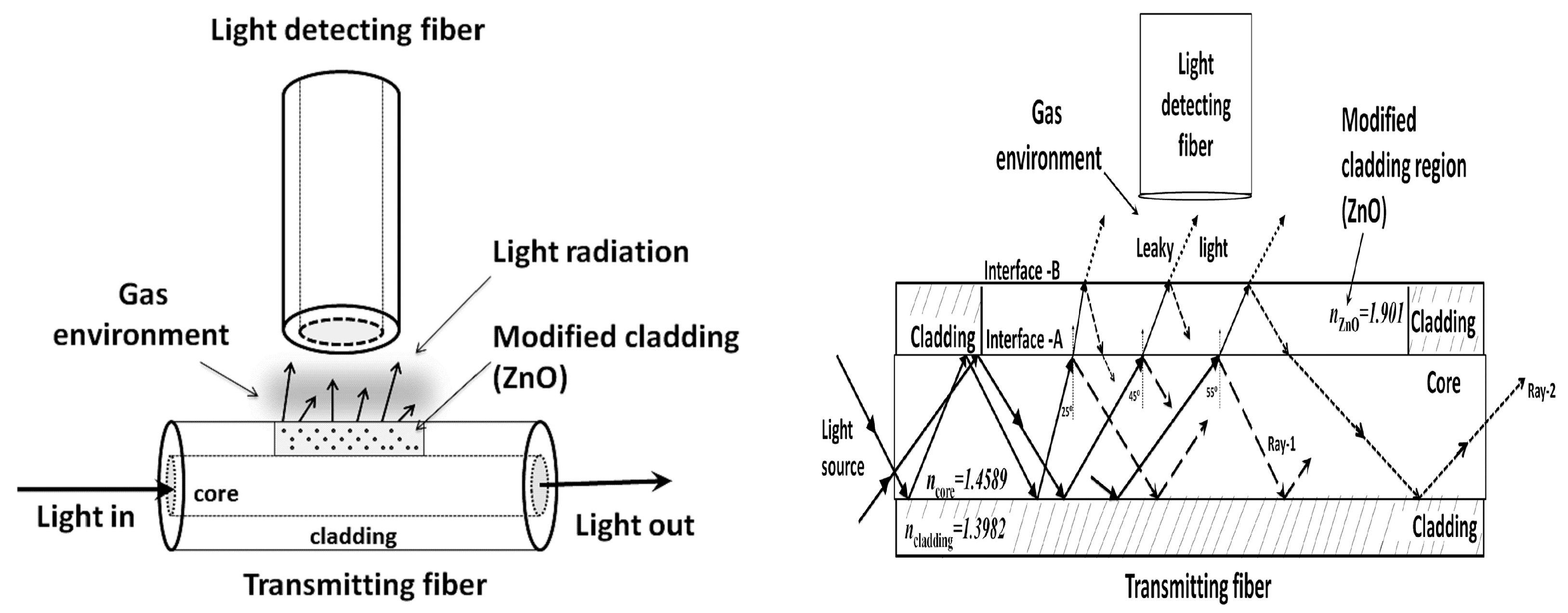

3.2. Optical Gas Sensor

3.3. Other Innovative Structural Design

4. Gas Sensor in the Field of Health and Safety and Medical Applications

4.1. Indoor Air Quality Monitoring

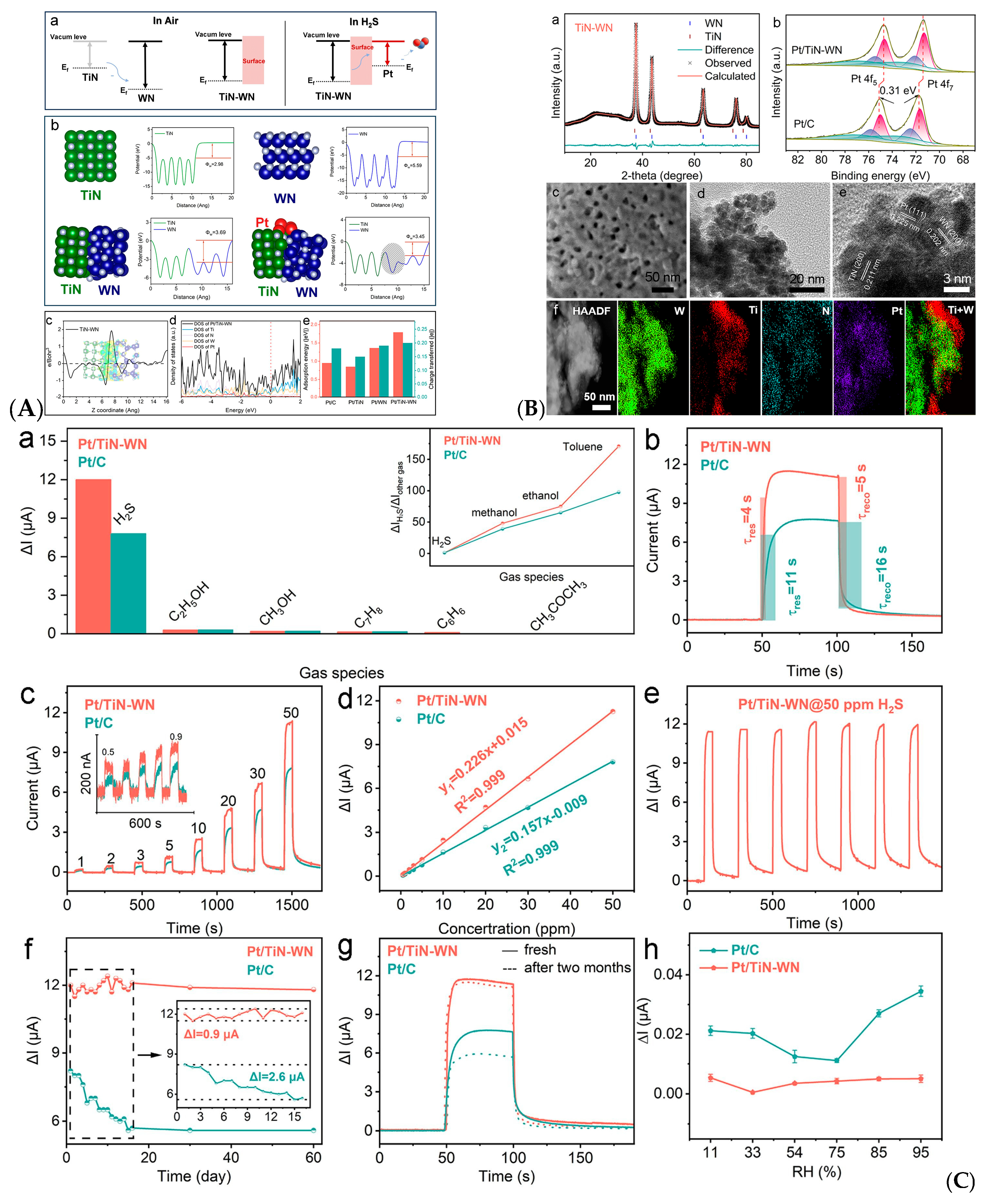

4.2. Monitoring of Toxic Gases in Industrial Environments

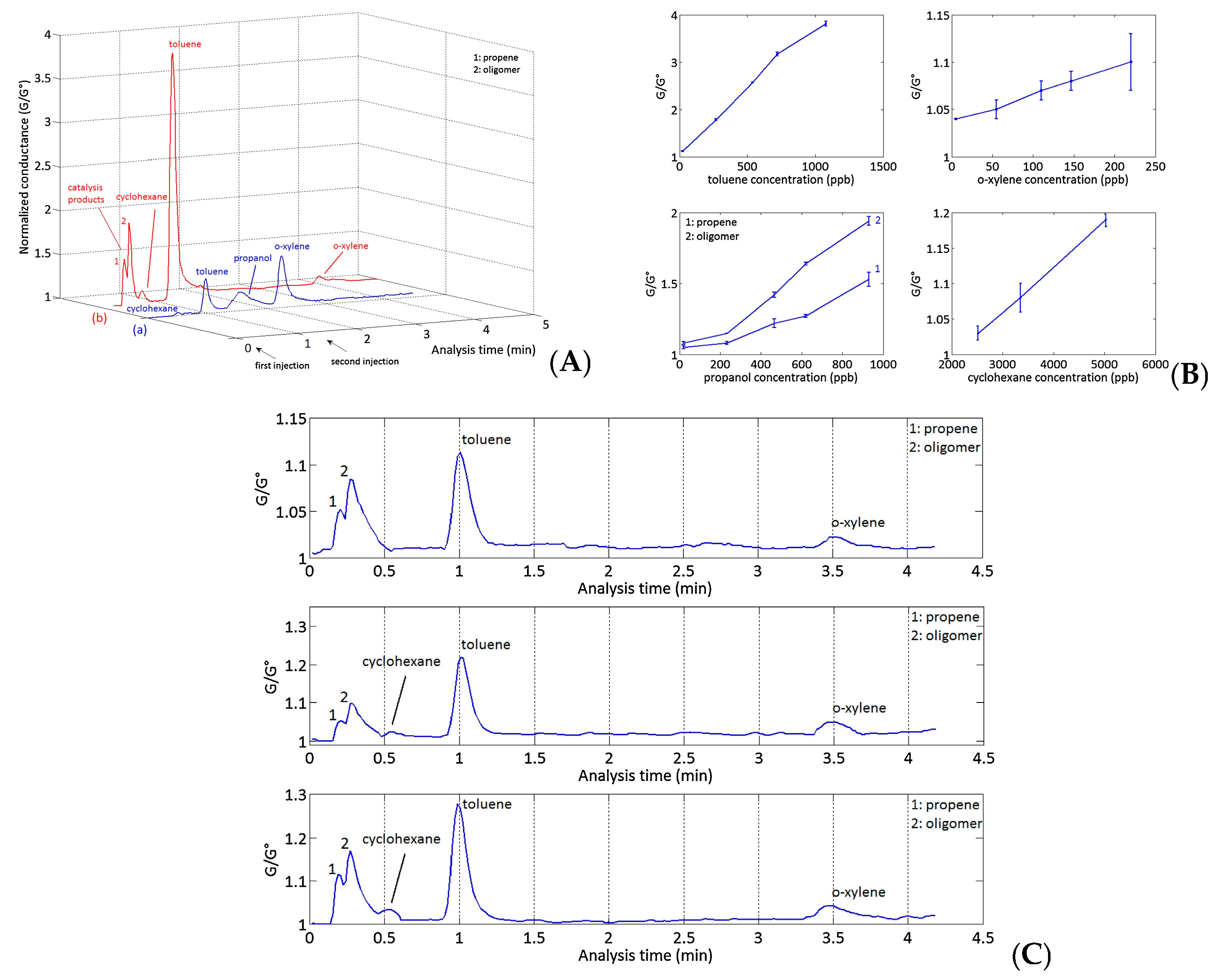

4.3. Detection of Biomarkers in Human Exhaled Gas

5. Existing Challenges and Future Development Trends

5.1. Existing Challenges

5.2. Future Trends

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MEMS | Micro-electro-mechanical Systems |

| VOCs | Volatile organic compounds |

| NMs | Nanomaterials |

| 0D | Zero-dimensional |

| 1D | One-dimensional |

| 2D | Two-dimensional |

| 3D | Three-dimensional |

| RH | Relative humidity |

| MOS | Metal oxide semiconductor |

| MOF | Metal-organic frameworks |

| MINA | Microheater integrated nanotube array |

| ppt | parts per trillion |

| NFs | Nanoflakes |

| NSs | Nanosheets |

| BZC | Basic zinc carbonate |

| MOX | Metal oxide |

| NIR | Near-infrared |

| NDIR | Non-dispersive infrared |

| TCD | Thermal conductivity detector |

| MMF | Multimode fiber |

| RGO | Reduced graphene oxide |

| CdS | Cadmium sulfide |

| CdSe | Cadmium selenide |

| CdTe | Cadmium telluride |

| AQI | Air quality index |

| ppb | parts per billion |

| CNN | Convolution neural network |

| ANN | Artificial neural network |

| IAQ | Indoor air quality |

References

- Taheri, M.; Deen, I.A.; Packirisamy, M.; Deen, M.J. Metal Oxide -Based Electrical/Electrochemical Sensors for Health Monitoring Systems. Trac-Trends Anal. Chem. 2024, 171, 117509. [Google Scholar] [CrossRef]

- Korotcenkov, G. Practical Aspects in Design of One-Electrode Semiconductor Gas Sensors: Status Report. Sens. Actuator B-Chem. 2007, 121, 664–678. [Google Scholar] [CrossRef]

- Sun, X.; Shi, Y.; Wang, H.; Shao, X.; Yang, L.; Li, X.; Wang, M. Research Progress on Moisture Resistance of Gas Sensors. Clean-Soil Air Water 2024, 52, 2300086. [Google Scholar] [CrossRef]

- Ren, M.; Xu, H.; Dong, C.; Zhang, Z. Toward a Gas Sensor Interface Circuit—A Review. IEEE Sensors J. 2022, 22, 18253–18265. [Google Scholar] [CrossRef]

- Tang, Y.; Zhao, Y.; Liu, H. Room-Temperature Semiconductor Gas Sensors: Challenges and Opportunities. ACS Sens. 2022, 7, 3582–3597. [Google Scholar] [CrossRef]

- Lee, D.-Y.; Yu, J.-B.; Byun, H.-G.; Kim, H.-J. Chemoresistive Sensor Readout Circuit Design for Detecting Gases with Slow Response Time Characteristics. Sensors 2022, 22, 1102. [Google Scholar] [CrossRef]

- Kim, J.Y.; Kaganovich, I.; Lee, H.-C. Review of the Gas Breakdown Physics and Nanomaterial-Based Ionization Gas Sensors and Their Applications. Plasma Sources Sci. Technol. 2022, 31, 033001. [Google Scholar] [CrossRef]

- Lun, D.; Xu, K. Recent Progress in Gas Sensor Based on Nanomaterials. Micromachines 2022, 13, 919. [Google Scholar] [CrossRef]

- Choi, S.-J.; Kim, I.-D. Recent Developments in 2D Nanomaterials for Chemiresistive-Type Gas Sensors. Electron. Mater. Lett. 2018, 14, 221–260. [Google Scholar] [CrossRef]

- Potyrailo, R.A.; Scherer, B.; Brewer, J.; Ruffalo, R. Boosting Stability of Photonic Multi-Gas Sensors. In Proceedings of the 2022 IEEE SENSORS, Dallas, TX, USA, 30 October–2 November 2022; IEEE: New York, NY, USA, 2022. [Google Scholar]

- Wang, Z.; Bu, M.; Hu, N.; Zhao, L. An Overview on Room-Temperature Chemiresistor Gas Sensors Based on 2D Materials: Research Status and Challenge. Compos. Part B Eng. 2023, 248, 110378. [Google Scholar] [CrossRef]

- Aldhafeeri, T.; Tran, M.-K.; Vrolyk, R.; Pope, M.; Fowler, M. A Review of Methane Gas Detection Sensors: Recent Developments and Future Perspectives. Inventions 2020, 5, 28. [Google Scholar] [CrossRef]

- Asri, M.I.A.; Hasan, M.N.; Fuaad, M.R.A.; Yunos, Y.M.; Ali, M.S.M. MEMS Gas Sensors: A Review. IEEE Sens. J. 2021, 21, 18381–18397. [Google Scholar] [CrossRef]

- Mane, S.A.; Nadargi, D.Y.; Nadargi, J.D.; Aldossary, O.M.; Tamboli, M.S.; Dhulap, V.P. Design, Development and Validation of a Portable Gas Sensor Module: A Facile Approach for Monitoring Greenhouse Gases. Coatings 2020, 10, 1148. [Google Scholar] [CrossRef]

- Barandun, G.; Gonzalez-Macia, L.; Lee, H.S.; Dincer, C.; Guder, F. Challenges and Opportunities for Printed Electrical Gas Sensors. ACS Sens. 2022, 7, 2804–2822. [Google Scholar] [CrossRef]

- Srivastava, S.; Sharma, T.; Deshwal, M. Study of Nanostructured Metal Oxide Semiconductor Based Gas Sensors for Toxic Gas Detection. In Proceedings of the 2023 International Conference on Sustainable Emerging Innovations in Engineering and Technology (ICSEIET), Ghaziabad, India, 14 September 2023; IEEE: New York, NY, USA; pp. 657–662. [Google Scholar]

- Gomri, S.; Contaret, T.; Seguin, J.-L. A New Gases Identifying Method with MOX Gas Sensors Using Noise Spectroscopy. IEEE Sensors J. 2018, 18, 6489–6496. [Google Scholar] [CrossRef]

- Mannan, M.; Al-Ghamdi, S.G. Indoor Air Quality in Buildings: A Comprehensive Review on the Factors Influencing Air Pollution in Residential and Commercial Structure. Int. J. Environ. Res. Public Health 2021, 18, 3276. [Google Scholar] [CrossRef]

- Nandan, A.; Siddiqui, N.A.; Singh, C.; Aeri, A. Occupational and Environmental Impacts of Indoor Air Pollutant for Different Occupancy: A Review. Toxicol. Environ. Health Sci. 2021, 13, 303–322. [Google Scholar] [CrossRef]

- Lopez, L.R.; Dessi, P.; Cabrera-Codony, A.; Rocha-Melogno, L.; Kraakman, B.; Naddeo, V.; Balaguer, M.D.; Puig, S. CO2 in Indoor Environments: From Environmental and Health Risk to Potential Renewable Carbon Source. Sci. Total Environ. 2023, 856, 159088. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, Y.; Gopalan, S.; Luo, F.; Amreen, K.; Singh, R.K.; Goel, S.; Lin, Z.; Naidu, R. Review and Perspective: Gas Separation and Discrimination Technologies for Current Gas Sensors in Environmental Applications. ACS Sens. 2023, 8, 1373–1390. [Google Scholar] [CrossRef]

- Rodenas Garcia, M.; Spinazze, A.; Branco, P.T.B.S.; Borghi, F.; Villena, G.; Cattaneo, A.; Di Gilio, A.; Mihucz, V.G.; Gomez Alvarez, E.; Lopes, S.I.; et al. Review of Low-Cost Sensors for Indoor Air Quality: Features and Applications. Appl. Spectrosc. Rev. 2022, 57, 747–779. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, C.; Liang, C.; Liu, Y.; Li, H.; Zhang, C.; Duan, X.; Pan, Y. Sensitive Materials Used in Surface Acoustic Wave Gas Sensors for Detecting Sulfur-Containing Compounds. Polymers 2024, 16, 457. [Google Scholar] [CrossRef]

- Krishnan, A.K.; Panicker, S.T.; Sandeep, S.; Jithin, S.; Daniel, J.J.; Sajjad, T. Electrochemical Based Gas Sensing for Ambient Air Quality Monitoring in Opencast Coal Mines. In Proceedings of the 2022 First International Conference on Electrical, Electronics, Information and Communication Technologies (ICEEICT), Trichy, India, 16 February 2022; IEEE: New York, NY, USA; pp. 1–8. [Google Scholar]

- Dinu, L.A.; Buiculescu, V.; Baracu, A.M. Recent Progress on Nanomaterials for NO2 Surface Acoustic Wave Sensors. Nanomaterials 2022, 12, 2120. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, L.; Sun, S.; Wang, J.; Yan, W. One-Dimensional Nanomaterials in Resistive Gas Sensor: From Material Design to Application. Chemosensors 2021, 9, 198. [Google Scholar] [CrossRef]

- Bannov, A.G.; Popov, M.V.; Brester, A.E.; Kurmashov, P.B. Recent Advances in Ammonia Gas Sensors Based on Carbon Nanomaterials. Micromachines 2021, 12, 186. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, T.; Liang, R.; Wei, M. Application of Zero-Dimensional Nanomaterials in Biosensing. Front. Chem. 2020, 8, 320. [Google Scholar] [CrossRef]

- Yang, M.; Jin, H.; Sun, Z.; Gui, R. Experimental Synthesis, Functionalized Modifications and Potential Applications of Monoelemental Zero-Dimensional Boron Nanomaterials. J. Mater. Chem. A 2022, 10, 5111–5146. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, Z.; Zheng, C.; Jin, G.; Shen, X.; Wu, L. VTe2 Nanospheres for NO2 Gas Sensors. Sens. Actuators A Phys. 2024, 379, 115935. [Google Scholar] [CrossRef]

- Yang, T.; Liu, Y.; Wang, H.; Duo, Y.; Zhang, B.; Ge, Y.; Zhang, H.; Chen, W. Recent Advances in 0D Nanostructure-Functionalized Low-Dimensional Nanomaterials for Chemiresistive Gas Sensors. J. Mater. Chem. C 2020, 8, 7272–7299. [Google Scholar] [CrossRef]

- Nasiri, N.; Clarke, C. Nanostructured Gas Sensors for Medical and Health Applications: Low to High Dimensional Materials. Biosensors 2019, 9, 43. [Google Scholar] [CrossRef]

- Lin, J.; Kilani, M.; Mao, G. Recent Advances in Integrating 1D Nanomaterials into Chemiresistive Gas Sensor Devices. Adv. Mater. Technol. 2023, 8, 2202038. [Google Scholar] [CrossRef]

- Tang, W.; Chen, Z.; Song, Z.; Wang, C.; Wan, Z.; Chan, C.L.J.; Chen, Z.; Ye, W.; Fan, Z. Microheater Integrated Nanotube Array Gas Sensor for Parts-Per-Trillion Level Gas Detection and Single Sensor-Based Gas Discrimination. ACS Nano 2022, 16, 10968–10978. [Google Scholar] [CrossRef] [PubMed]

- Ahn, S.; Chun, K.W.; Park, C. Long-Term Stability Test for Femtosecond Laser-Irradiated SnO2-Nanowire Gas Sensor for C7H8 Gas Sensing. Photonics 2024, 11, 550. [Google Scholar] [CrossRef]

- Kiani, M.; Rehman, M.U.; Tian, X.; Yakobson, B. Two-Dimensional Nanomaterials for the Development of Efficient Gas Sensors: Recent Advances, Challenges, and Future Perspectives. Adv. Mater. Technol. 2022, 7, 2101252. [Google Scholar] [CrossRef]

- Xie, Q.; Ding, Y.; Wang, Q.; Song, P. Fabrication of 1D/2D In2O3 Nanofibers/Ti3C2TX MXene Composites for High Performance Detection of Trimethylamine at Low Temperature. Sens. Actuator B-Chem. 2024, 405, 135338. [Google Scholar] [CrossRef]

- Korotcenkov, G.; Tolstoy, V.P. Current Trends in Nanomaterials for Metal Oxide-Based Conductometric Gas Sensors: Advantages and Limitations—Part 2: Porous 2D Nanomaterials. Nanomaterials 2023, 13, 237. [Google Scholar] [CrossRef]

- Ryu, J.; Shim, S.; Song, J.; Park, J.; Kim, H.S.; Lee, S.-K.; Shin, J.C.; Mun, J.; Kang, S.-W. Effect of Measurement System Configuration and Operating Conditions on 2D Material-Based Gas Sensor Sensitivity. Nanomaterials 2023, 13, 573. [Google Scholar] [CrossRef]

- Wang, F.; Yeap, S.P.; Cheok, C.Y.; Ang, C.K.; Saidur, R. Progress and Insights on Graphene and MXene-Based Emerging 2-Dimensional Conductive Nanomaterials for Fabrication of Flexible Gas Sensors. ChemBioEng Rev. 2023, 10, 907–923. [Google Scholar] [CrossRef]

- Mirzaei, A.; Lee, M.H.; Safaeian, H.; Kim, T.-U.; Kim, J.-Y.; Kim, H.W.; Kim, S.S. Room Temperature Chemiresistive Gas Sensors Based on 2D MXenes. Sensors 2023, 23, 8829. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, J.; Wang, L.; Yang, T.; Guo, X.; Wu, S.; Wang, S. 3D Hierarchically Porous ZnO Structures and Their Functionalization by Au Nanoparticles for Gas Sensors. J. Mater. Chem. 2011, 21, 349–356. [Google Scholar] [CrossRef]

- Xue, D.; Zhang, S.; Zhang, Z. Hydrothermally Prepared Porous 3D SnO2 Microstructures for Methane Sensing at Lower Operating Temperature. Mater. Lett. 2019, 237, 336–339. [Google Scholar] [CrossRef]

- Zhu, M.; Pi, Y.; Zhang, H. Ethanol Gas Sensor Based on SnO2 Hierarchical Nanostructure. In Communications, Signal Processing, and Systems; Liang, Q., Wang, W., Liu, X., Na, Z., Jia, M., Zhang, B., Eds.; Lecture Notes in Electrical Engineering; Springer: Singapore, 2020; Volume 571, pp. 1445–1449. ISBN 9789811394089. [Google Scholar]

- Xiong, J.; Xiao, P.; Wu, Q.; Wang, X.; Hu, Z. Synthesis and Gas-Sensing Properties of ZnO Porous Microflowers. Acta Chim. Sin. 2014, 72, 433–439. [Google Scholar] [CrossRef]

- Yeh, Y.-M.; Chang, S.-J.; Wang, P.H.; Hsueh, T.-J. A Room-Temperature TiO2-Based Ammonia Gas Sensor with Three-Dimensional Through-Silicon-Via Structure. ECS J. Solid State Sci. Technol. 2022, 11, 067002. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, B.; Yao, S.; Li, H.; Chen, C.; Bala, H.; Zhang, Z. Improved Triethylamine Sensing Properties of Fish-Scale-like Porous SnO2 Nanosheets by Decorating with Ag Nanoparticles. J. Mater. 2022, 8, 518–525. [Google Scholar] [CrossRef]

- Alali, K.T.; Liu, J.; Aljebawi, K.; Liu, Q.; Chen, R.; Yu, J.; Zhang, M.; Wang, J. 3D Hybrid Ni-Multiwall Carbon Nanotubes/Carbon Nanofibers for Detecting Sarin Nerve Agent at Room Temperature. J. Alloys Compd. 2019, 780, 680–689. [Google Scholar] [CrossRef]

- Yun, J.; Cho, M.; Lee, K.; Kang, M.; Park, I. A Review of Nanostructure-Based Gas Sensors in a Power Consumption Perspective. Sens. Actuators B Chem. 2022, 372, 132612. [Google Scholar] [CrossRef]

- Yang, D.; Gopal, R.A.; Lkhagvaa, T.; Choi, D. Metal-Oxide Gas Sensors for Exhaled-Breath Analysis: A Review. Meas. Sci. Technol. 2021, 32, 102004. [Google Scholar] [CrossRef]

- Yu, Y.; Tan, Y.; Niu, W.; Zhao, S.; Hao, J.; Shi, Y.; Dong, Y.; Liu, H.; Huang, C.; Gao, C.; et al. Advances in Synthesis and Applications of Single-Atom Catalysts for Metal Oxide-Based Gas Sensors. Materials 2024, 17, 1970. [Google Scholar] [CrossRef]

- Li, B.; Zhou, Q.; Peng, S.; Liao, Y. Recent Advances of SnO2-Based Sensors for Detecting Volatile Organic Compounds. Front. Chem. 2020, 8, 321. [Google Scholar] [CrossRef]

- Cheng, J.P.; Wang, J.; Li, Q.Q.; Liu, H.G.; Li, Y. A Review of Recent Developments in Tin Dioxide Composites for Gas Sensing Application. J. Ind. Eng. Chem. 2016, 44, 1–22. [Google Scholar] [CrossRef]

- Abdullah, A.N.; Kamarudin, K.; Mamduh, S.M.; Adom, A.H. Development of MOX Gas Sensors Module for Indoor Air Contaminant Measurement. IOP Conf. Ser. Mater. Sci. Eng. 2019, 705, 012029. [Google Scholar] [CrossRef]

- Boiger, R.; Defregger, S.; Kock, A.; Mucke, M.; Wimmer-Teubenbacher, R.; Toschkoff, G. Temperature Modulated Operation of SnO2-Based Gas Sensor Arrays. In Proceedings of the 2018 12th International Conference on Advanced Semiconductor Devices and Microsystems (ASDAM), Smolenice, Slovakia, 21–24 October 2018; IEEE: New York, NY, USA; pp. 1–4. [Google Scholar]

- Nabil Abdullah, A.; Kamarudin, K.; Muhammad Mamduh, S.; Hamid Adom, A.; Hadi Mohd Juffry, Z. Effect of Environmental Temperature and Humidity on Different Metal Oxide Gas Sensors at Various Gas Concentration Levels. IOP Conf. Ser. Mater. Sci. Eng. 2020, 864, 012152. [Google Scholar] [CrossRef]

- Abdullah, A.N.; Kamarudin, K.; Kamarudin, L.M.; Adom, A.H.; Mamduh, S.M.; Mohd Juffry, Z.H.; Bennetts, V.H. Correction Model for Metal Oxide Sensor Drift Caused by Ambient Temperature and Humidity. Sensors 2022, 22, 3301. [Google Scholar] [CrossRef]

- Jung, G.; Jeong, Y.; Hong, Y.; Wu, M.; Hong, S.; Shin, W.; Park, J.; Jang, D.; Lee, J.-H. SO2 Gas Sensing Characteristics of FET- and Resistor-Type Gas Sensors Having WO3 as Sensing Material. Solid-State Electron. 2020, 165, 107747. [Google Scholar] [CrossRef]

- Jung, G.; Shin, W.; Hong, S.; Jeong, Y.; Park, J.; Kim, D.; Bae, J.-H.; Park, B.-G.; Lee, J.-H. Comparison of the Characteristics of Semiconductor Gas Sensors with Different Transducers Fabricated on the Same Substrate. Sens. Actuator B-Chem. 2021, 335, 129661. [Google Scholar] [CrossRef]

- Wen, W.-C.; Chou, T.-I.; Tang, K.-T. A Gas Mixture Prediction Model Based on the Dynamic Response of a Metal-Oxide Sensor. Micromachines 2019, 10, 598. [Google Scholar] [CrossRef]

- Djeziri, M.; Benmoussa, S.; Bendahan, M.; Seguin, J.-L. Review on Data-Driven Approaches for Improving the Selectivity of MOX-Sensors. Microsyst. Technol. 2024, 30, 791–807. [Google Scholar] [CrossRef]

- Berwal, P.; Sihag, S.; Rani, S.; Kumar, A.; Jatrana, A.; Singh, P.; Dahiya, R.; Kumar, A.; Dhillon, A.; Sanger, A.; et al. Hybrid Metal Oxide Nanocomposites for Gas-Sensing Applications: A Review. Ind. Eng. Chem. Res. 2023, 62, 14835–14852. [Google Scholar] [CrossRef]

- Müller, G.; Sberveglieri, G. Origin of Baseline Drift in Metal Oxide Gas Sensors: Effects of Bulk Equilibration. Chemosensors 2022, 10, 171. [Google Scholar] [CrossRef]

- Nguyen, V.D.; Nguyen, X.T.; Trinh, M.N.; Dang, T.T.L.; Chu, M.H.; Hugo, N.; Tonezzer, M.; Nguyen, V.H.; Nguyen, D.H. Design and Fabrication of Effective Gradient Temperature Sensor Array Based on Bilayer SnO2/Pt for Gas Classification. Sens. Actuator B-Chem. 2022, 351, 130979. [Google Scholar] [CrossRef]

- Wang, C.; Song, Y.; Zhao, M.; Lu, H.; Wang, J.; Zou, X. Material Design and Mechanism Interpretation of Metal Oxide Nanofibers for Improving Gas Sensitivity. Coord. Chem. Rev. 2025, 531, 216492. [Google Scholar] [CrossRef]

- Helwig, A.; Hackner, A.; Mueller, G.; Zappa, D.; Sberveglieri, G. Self-Test Procedures for Gas Sensors Embedded in Microreactor Systems. Sensors 2018, 18, 453. [Google Scholar] [CrossRef]

- Ullah, S.; Rehman, A.U.; Najam, T.; Hossain, I.; Anjum, S.; Ali, R.; Shahid, M.U.; Shah, S.S.A.; Nazir, M.A. Advances in Metal-Organic Framework@activated Carbon (MOF@AC) Composite Materials: Synthesis, Characteristics and Applications. J. Ind. Eng. Chem. 2024, 137, 87–105. [Google Scholar] [CrossRef]

- Mohanty, B.; Kumari, S.; Yadav, P.; Kanoo, P.; Chakraborty, A. Metal-Organic Frameworks (MOFs) and MOF Composites Based Biosensors. Coord. Chem. Rev. 2024, 519, 216102. [Google Scholar] [CrossRef]

- Li, W.; Liang, Z.; Wang, P.; Ma, Q. The Luminescent Principle and Sensing Mechanism of Metal-Organic Framework for Bioanalysis and Bioimaging. Biosens. Bioelectron. 2024, 249, 116008. [Google Scholar] [CrossRef]

- Nguyen, N.T.T.; Nguyen, T.T.T.; Ge, S.; Liew, R.K.; Nguyen, D.T.C.; Tran, T.V. Recent Progress and Challenges of MOF-Based Nanocomposites in Bioimaging, Biosensing and Biocarriers for Drug Delivery. Nanoscale Adv. 2024, 6, 1800–1821. [Google Scholar] [CrossRef]

- Karuppasamy, K.; Sharma, B.; Vikraman, D.; Lee, J.-H.; Islam, M.; Santhoshkumar, P.; Kim, H.-S. Metal Organic Framework-Derived Ni4Mo/MoO2@C Composite Nanospheres as the Sensing Materials for Hydrogen Sulfide Detection. J. Alloys Compd. 2022, 900, 163421. [Google Scholar] [CrossRef]

- Yang, C.-R.; Cheng, P.-W.; Tseng, S.-F. Highly Responsive and Selective NO2 Gas Sensors Based on Titanium Metal Organic Framework (Ti-MOF) with Pyromellitic Acid. Sens. Actuator A-Phys. 2023, 354, 114301. [Google Scholar] [CrossRef]

- Montoro, C.; Kim, J.-Y.; Mirzaei, A.; Lee, J.-H.; Sayegh, S.; Makhoul, E.; Iatsunskyi, I.; Coy, E.; Bechelany, M.; Kim, H.W.; et al. MOF-Derived Metal Oxide (Cu, Ni, Zn) Gas Sensors with Excellent Selectivity towards H2S, CO and H2 Gases. Compos. Part B Eng. 2024, 283, 111637. [Google Scholar] [CrossRef]

- Lee, J.-H.; Nguyen, T.-B.; Nguyen, D.-K.; Kim, J.-H.; Kim, J.-Y.; Phan, B.T.; Kim, S.S. Gas Sensing Properties of Mg-Incorporated Metal–Organic Frameworks. Sensors 2019, 19, 3323. [Google Scholar] [CrossRef]

- Sturluson, A.; Sousa, R.; Zhang, Y.; Huynh, M.T.; Laird, C.; York, A.H.P.; Silsby, C.; Chang, C.-H.; Simon, C.M. Curating Metal–Organic Frameworks To Compose Robust Gas Sensor Arrays in Dilute Conditions. ACS Appl. Mater. Interfaces 2020, 12, 6546–6564. [Google Scholar] [CrossRef]

- Dong, Q.; Xiao, M.; Chu, Z.; Li, G.; Zhang, Y. Recent Progress of Toxic Gas Sensors Based on 3D Graphene Frameworks. Sensors 2021, 21, 3386. [Google Scholar] [CrossRef]

- Cruz-Martinez, H.; Rojas-Chavez, H.; Montejo-Alvaro, F.; Pena-Castaneda, Y.A.; Matadamas-Ortiz, P.T.; Medina, D.I. Recent Developments in Graphene-Based Toxic Gas Sensors: A Theoretical Overview. Sensors 2021, 21, 1992. [Google Scholar] [CrossRef]

- Hernaez, M. Applications of Graphene-Based Materials in Sensors. Sensors 2020, 20, 3196. [Google Scholar] [CrossRef]

- Xie, T.; Wang, Q.; Wallace, R.M.; Gong, C. Understanding and Optimization of Graphene Gas Sensors. Appl. Phys. Lett. 2021, 119, 013104. [Google Scholar] [CrossRef]

- Tang, X.; Debliquy, M.; Lahem, D.; Yan, Y.; Raskin, J.-P. A Review on Functionalized Graphene Sensors for Detection of Ammonia. Sensors 2021, 21, 1443. [Google Scholar] [CrossRef]

- Travan, C.; Bergmann, A. NO2 and NH3 Sensing Characteristics of Inkjet Printing Graphene Gas Sensors. Sensors 2019, 19, 3379. [Google Scholar] [CrossRef]

- Wang, C.; Lei, S.; Li, X.; Guo, S.; Cui, P.; Wei, X.; Liu, W.; Liu, H. A Reduced GO-Graphene Hybrid Gas Sensor for Ultra-Low Concentration Ammonia Detection. Sensors 2018, 18, 3147. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, M.; Dong, L.; Sun, Y.; Su, Y.; Xue, Z.; Di, Z. Gas Sensor Based on Defective Graphene/Pristine Graphene Hybrid towards High Sensitivity Detection of NO2. AIP Adv. 2019, 9, 075207. [Google Scholar] [CrossRef]

- Estevez, A.; Perez, N.; Casanova-Chafer, J.; Llobet, E.; Beriain, A. RFID Gas Sensor for In-Field Detection of Chemical Threats: Evaluation of Batteryless Discontinuous Operation. In Proceedings of the 2022 IEEE Sensors, Dallas, TX, USA, 30 October 2022; IEEE: New York, NY, USA; pp. 1–4. [Google Scholar]

- Ando, M.; Kawasaki, H.; Tamura, S.; Haramoto, Y.; Shigeri, Y. Recent Advances in Gas Sensing Technology Using Non-Oxide II-VI Semiconductors CdS, CdSe, and CdTe. Chemosensors 2022, 10, 482. [Google Scholar] [CrossRef]

- Aksoy, B.; Sel, E.; Kuyumcu Savan, E.; Ateş, B.; Köytepe, S. Recent Progress and Perspectives on Polyurethane Membranes in the Development of Gas Sensors. Crit. Rev. Anal. Chem. 2021, 51, 619–630. [Google Scholar] [CrossRef]

- Banerjee, A. Design of Enhanced Sensitivity Gas Sensors by Using 1D Defect Ternary Photonic Band Gap Structures. Indian J. Phys. 2020, 94, 535–539. [Google Scholar] [CrossRef]

- Wu, Y.; Lei, M.; Xia, X. Research Progress of MEMS Gas Sensors: A Comprehensive Review of Sensing Materials. Sensors 2024, 24, 8125. [Google Scholar] [CrossRef]

- Hashwan, S.S.B.S.; Khir, M.H.M.; Nawi, I.M.; Ahmad, M.R.; Hanif, M.; Zahoor, F.; Al-Douri, Y.; Algamili, A.S.; Bature, U.I.; Alabsi, S.S.; et al. A Review of Piezoelectric MEMS Sensors and Actuators for Gas Detection Application. Discov. Nano 2023, 18, 25. [Google Scholar] [CrossRef]

- Zhang, C.; Jiang, W.; Ghosh, A.; Wang, G.; Wu, F.; Zhang, H. Miniaturized Langasite MEMS Micro-Cantilever Beam Structured Resonator for High Temperature Gas Sensing. Smart Mater. Struct. 2020, 29, 055002. [Google Scholar] [CrossRef]

- Hsueh, T.-J.; Lee, S.-H. A La2O3-NPs/ZnO/MEMS SO2 Gas Sensor. J. Electrochem. Soc. 2021, 168, 027508. [Google Scholar] [CrossRef]

- Hsueh, T.-J.; Lee, S.-H. A La2O3 Nanoparticle SO2 Gas Sensor That Uses a ZnO Thin Film and Au Adsorption. J. Electrochem. Soc. 2021, 168, 077507. [Google Scholar] [CrossRef]

- Hsueh, T.-J.; Li, P.-S.; Fang, S.-Y.; Hsu, C.-L. A Vertical CuO-NWS/MEMS NO2 Gas Sensor That Is Produced by Sputtering. Sens. Actuators B Chem. 2022, 355, 131260. [Google Scholar] [CrossRef]

- Hsueh, T.-J.; Ding, R.-Y. A Room Temperature ZnO-NPs/MEMS Ammonia Gas Sensor. Nanomaterials 2022, 12, 3287. [Google Scholar] [CrossRef]

- Xu, S.; Zhou, N.; Shi, M.; Zhang, C.; Chen, D.; Mao, H. Overview of the MEMS Pirani Sensors. Micromachines 2022, 13, 945. [Google Scholar] [CrossRef]

- Zhang, Y.; Xie, D.; Yang, Y.; Xing, C.; Chen, D.; Xu, L. High Heat Transfer Efficiency MEMS Thermal Conductivity Gas Sensor for Hydrogen. IEEE Sens. J. 2024, 24, 29678–29686. [Google Scholar] [CrossRef]

- Sun, J.; Chen, T.; Tan, T.; Wang, D.; Zhu, X.; Zhang, X.; Peng, H.; Luan, Z. Fabrication and Characterization of a Novel Micro-Thermal Conductivity Detector for Monitoring Small-Molecule Gases. IEEE Sens. J. 2020, 20, 11115–11121. [Google Scholar] [CrossRef]

- Shaporin, A.; Wecker, J.; Runge, J.; Voigt, S.; Melzer, M.; Kurth, S.; Hiller, K. High Precision Electrostatic MEMS Actuators for In-Plane Fabry-Pérot Gas Sensors. In Proceedings of the 2024 25th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Catania, Italy, 7–10 April 2024; pp. 1–5. [Google Scholar]

- Yang, J.; Cheng, Y.; Yuan, Y.; Li, X.; Zhang, Z.; Xu, M.; Wang, D.; Mu, J.; Mei, Y.; Zhang, Y. Design and Optimization of an Integrated MEMS Gas Chamber with High Transmissivity. Digit. Commun. Netw. 2021, 7, 82–91. [Google Scholar] [CrossRef]

- Majhi, S.M.; Mirzaei, A.; Kim, H.W.; Kim, S.S.; Kim, T.W. Recent Advances in Energy-Saving Chemiresistive Gas Sensors: A Review. Nano Energy 2021, 79, 105369. [Google Scholar] [CrossRef]

- Popa, D.; Udrea, F. Towards Integrated Mid-Infrared Gas Sensors. Sensors 2019, 19, 2076. [Google Scholar] [CrossRef]

- Zheng, C.; Pi, M.; Song, F.; Li, Y.; Peng, Z.; Guan, G.; Zhang, L.; Ma, Y.; Min, Y.; Ye, W.; et al. Recent Progress in Infrared Absorption Spectroscopy for Gas Sensing with Discrete Optics, Hollow-Core Fibers and On-Chip Waveguides. J. Light. Technol. 2023, 41, 4079–4096. [Google Scholar] [CrossRef]

- Yan, X.; Tan, Y.; Wang, Y.; Chen, G.; Xia, W.; Zhou, G.; Luo, H.; Liu, H.; Gong, T.; Zhang, X. Near-Infrared Spectral MEMS Gas Sensor for Multi-Component Food Gas Detection. Micromachines 2025, 16, 135. [Google Scholar] [CrossRef]

- Glöckler, J.; Jaeschke, C.; Kocaoez, Y.; Kokoric, V.; Tuetuencue, E.; Mitrovics, J.; Mizaikoff, B. iHWG-MOX: A Hybrid Breath Analysis System via the Combination of Substrate-Integrated Hollow Waveguide Infrared Spectroscopy with Metal Oxide Gas Sensors. ACS Sens. 2020, 5, 1033–1039. [Google Scholar] [CrossRef]

- Trieu-Vuong, D.; Choi, I.-Y.; Son, Y.-S.; Kim, J.-C. A Review on Non-Dispersive Infrared Gas Sensors: Improvement of Sensor Detection Limit and Interference Correction. Sens. Actuator B-Chem. 2016, 231, 529–538. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, C.; Ci, G.; Zhao, X.; Lv, J.; Liang, J.; Ming, A.; Wei, F.; Mao, C. Development of High-Precision NO2 Gas Sensor Based on Non-Dispersive Infrared Technology. Sensors 2024, 24, 4146. [Google Scholar] [CrossRef]

- Shi, J.; Jiang, Y.; Duan, Z.; Li, J.; Yuan, Z.; Tai, H. Designing an Optical Gas Chamber with Stepped Structure for Non-Dispersive Infrared Methane Gas Sensor. Sens. Actuator A-Phys. 2024, 367, 115052. [Google Scholar] [CrossRef]

- He, T.; Wang, W.; He, B.-G.; Chen, J. Review on Optical Fiber Sensors for Hazardous-Gas Monitoring in Mines and Tunnels. IEEE Trans. Instrum. Meas. 2023, 72, 7003722. [Google Scholar] [CrossRef]

- Chen, W.; Wang, J.; Wan, F.; Wang, P. Review of Optical Fibre Sensors for Electrical Equipment Characteristic State Parameters Detection. High Volt. 2019, 4, 271–281. [Google Scholar] [CrossRef]

- Lopez-Torres, D.; Elosua, C.; Arregui, F.J. Optical Fiber Sensors Based on Microstructured Optical Fibers to Detect Gases and Volatile Organic Compounds-A Review. Sensors 2020, 20, 2555. [Google Scholar] [CrossRef]

- Allsop, T.; Neal, R. A Review: Application and Implementation of Optic Fibre Sensors for Gas Detection. Sensors 2021, 21, 6755. [Google Scholar] [CrossRef]

- Ashry, I.; Mao, Y.; Wang, B.; Hveding, F.; Bukhamsin, A.; Ng, T.K.; Ooi, B.S. A Review of Distributed Fiber-Optic Sensing in the Oil and Gas Industry. J. Light. Technol. 2022, 40, 1407–1431. [Google Scholar] [CrossRef]

- Devendiran, S.; Sastikumar, D. Gas Sensing Based on Detection of Light Radiation from a Region of Modified Cladding (Nanocrystalline ZnO) of an Optical Fiber. Opt. Laser Technol. 2017, 89, 186–191. [Google Scholar] [CrossRef]

- Chen, L.; Guo, H.; Sassa, F.; Chen, B.; Hayashi, K. SERS Gas Sensors Based on Multiple Polymer Films with High Design Flexibility for Gas Recognition. Sensors 2021, 21, 5546. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, L.; Li, K.H.H.; Tan, O.K. Microhotplates for Metal Oxide Semiconductor Gas Sensor Applications—Towards the CMOS-MEMS Monolithic Approach. Micromachines 2018, 9, 557. [Google Scholar] [CrossRef]

- Pareek, V.; Chaudhury, S.; Singh, S. Online Pattern Recognition of Time-Series Gas Sensor Data with Adaptive 2D-CNN Ensemble. In Proceedings of the 11th IEEE International Conference on Intelligent Data Acquisition and Advanced Computing Systems: Technology and Applications (IDAACS’2021), Cracov, Poland, 22–25 September 2021; IEEE: New York, NY, USA, 2021; Volume 2, pp. 679–683. [Google Scholar]

- He, H.; Wang, P.; Li, X.; Zhang, Y.; Zhang, X. Highly Reliable RS-PUF Based on Reconfigurable Gas Sensor Array. IEEE Sens. J. 2024, 24, 16875–16882. [Google Scholar] [CrossRef]

- Wu, W.; Haick, H. Materials and Wearable Devices for Autonomous Monitoring of Physiological Markers. Adv. Mater. 2018, 30, 1705024. [Google Scholar] [CrossRef]

- Wu, L.; Yuan, X.; Tang, Y.; Wageh, S.; Al-Hartomy, O.A.A.; Al-Sehemi, A.G.G.; Yang, J.; Xiang, Y.; Zhang, H.; Qin, Y. MXene Sensors Based on Optical and Electrical Sensing Signals: From Biological, Chemical, and Physical Sensing to Emerging Intelligent and Bionic Devices. PhotoniX 2023, 4, 15. [Google Scholar] [CrossRef]

- Wang, J.; Li, X.; Liu, M.; Zhang, P.; Tao, T.H.; Qin, N. Bionic Mechanical Hand Integrated with Artificial Olfactory Sensor Array for Enhanced Object Recognition. In Proceedings of the 2023 IEEE 36th International Conference on Micro Electro Mechanical Systems, MEMS, Munich, Germany, 15–19 January 2023; IEEE: New York, NY, USA, 2023; pp. 209–212. [Google Scholar]

- Dong, L.; Xue, B.; Wei, G.; Yuan, S.; Chen, M.; Liu, Y.; Su, Y.; Niu, Y.; Xu, B.; Wang, P. Highly Promising 2D/1D BP-C/CNT Bionic Opto-Olfactory Co-Sensory Artificial Synapses for Multisensory Integration. Adv. Sci. 2024, 11, 2403665. [Google Scholar] [CrossRef]

- Lv, E.; Wang, T.; Yue, X.; Wang, H.; Zeng, J.; Shu, X.; Wang, J. Wearable SERS Sensor Based on Bionic Sea Urchin-Cavity Structure for Dual in-Situ Detection of Metabolites and VOCs Gas. Chem. Eng. J. 2024, 499, 156020. [Google Scholar] [CrossRef]

- Wu, X.; Shi, S.; Jiang, J.; Lin, D.; Song, J.; Wang, Z.; Huang, W. Bionic Olfactory Neuron with In-Sensor Reservoir Computing for Intelligent Gas Recognition. Adv. Mater. 2025, 37, 2419159. [Google Scholar] [CrossRef]

- Yan, L. Analysis of Indoor Air Pollution of Decoration and Control Measures. In Proceedings of the 3rd International Conference on Advances in Environment Research, Beijing, China, 23–25 May 2017; Liu, K.F.R., Albuquerque, T., Strauss, E.J., Eds.; IoP Publishing Ltd.: Bristol, UK, 2017; Volume 68, p. 012004. [Google Scholar]

- Wang, Y. Study on the Influence of Building Materials on Indoor Pollutants and Pollution Sources. In IOP Conference Series: Earth and Environmental Science, Proceedings of the 2017 3rd International Conference on Environmental Science and Material Application (ESMA2017), Chongqing, China, 25–26 November 2017; VOLS 1–4; IoP Publishing Ltd.: Bristol, UK, 2018; Volume 108, p. 042024. [Google Scholar]

- Xu, Z.; Jin, Y. Main indoor air pollutants and their health impacts. Wei Sheng Yan Jiu 2003, 32, 279–283. [Google Scholar]

- Verissimo, M.I.S. A Critical Review of the Analytical Performance of the Most Recent MOS-Based Gas Sensors for Indoor Air Quality Monitoring of WHO Priority Pollutants. Trac-Trends Anal. Chem. 2024, 178, 117813. [Google Scholar] [CrossRef]

- Ou, L.-X.; Liu, M.-Y.; Zhu, L.-Y.; Zhang, D.W.; Lu, H.-L. Recent Progress on Flexible Room-Temperature Gas Sensors Based on Metal Oxide Semiconductor. Nano-Micro Lett. 2022, 14, 206. [Google Scholar] [CrossRef]

- Goel, N.; Kunal, K.; Kushwaha, A.; Kumar, M. Metal Oxide Semiconductors for Gas Sensing. Eng. Rep. 2023, 5, e12604. [Google Scholar] [CrossRef]

- Zhang, D.; Yang, Z.; Yu, S.; Mi, Q.; Pan, Q. Diversiform Metal Oxide-Based Hybrid Nanostructures for Gas Sensing with Versatile Prospects. Coord. Chem. Rev. 2020, 413, 213272. [Google Scholar] [CrossRef]

- Zhai, L.; Dai, X.; Zhu, G.; Rao, F.; Wang, S.; Yang, J.; Zhu, L.; Shi, X.; Huang, Y.; Jia, Y.; et al. High Sensitivity and Fast Response Sensor for Formaldehyde Based on In2O3/Sn2O3 Heterojunction. Colloid Surf. A-Physicochem. Eng. Asp. 2023, 678, 132457. [Google Scholar] [CrossRef]

- Sendi, A.; Fau, P.; Kahn, M.L.; Fajerwerg, K.; Bley, V.; Talhi, C.; Blanc, F.; Menini, P. Performance of MOX Gas Sensors Obtained by Mixing P-Type and N-Type Metal Oxides for Relaible Indoor Air Quality Monitoring. In Proceedings of the 2019 20th International Conference on Solid-State Sensors, Actuators and Microsystems & Eurosensors XXXIII (TRANSDUCERS & EUROSENSORS XXXIII), Berlin, Germany, 23–27 June 2019; IEEE: Berlin, Germany; pp. 1305–1308. [Google Scholar]

- Wang, W.; Zhang, Q.; Lv, R.; Wu, D.; Zhang, S. Enhancing Formaldehyde Selectivity of SnO2 Gas Sensors with the ZSM-5 Modified Layers. Sensors 2021, 21, 3947. [Google Scholar] [CrossRef] [PubMed]

- Jeon, S.; Oh, K.; Choi, Y.; Park, J.; Park, H. Highly Dispersed Pt-Incorporated Mesoporous Fe2O3 for Low-Level Sensing of Formaldehyde Gas. Nanomaterials 2023, 13, 659. [Google Scholar] [CrossRef] [PubMed]

- Sarif, R.; Al-Okby, M.F.R.; Roddelkopf, T.; Thurow, K. MOBILE GAS SENSING FOR LABORATORY INFRASTRUCTURE. IIUMEJ 2024, 25, 178–207. [Google Scholar] [CrossRef]

- Lee, J.; Min, H.; Choe, Y.-S.; Lee, Y.G.; Kim, K.; Lee, H.-S.; Lee, W. Highly Sensitive and Selective Detection of Benzene, Toluene, Xylene, and Formaldehyde Using Au-Coated SnO2 Nanorod Arrays for Indoor Air Quality Monitoring. Sens. Actuator B-Chem. 2023, 394, 134359. [Google Scholar] [CrossRef]

- Tiele, A.; Esfahani, S.; Covington, J. Design and Development of a Low-Cost, Portable Monitoring Device for Indoor Environment Quality. J. Sens. 2018, 2018, 5353816. [Google Scholar] [CrossRef]

- Agbroko, S.O.; Covington, J. A Novel, Low-Cost, Portable PID Sensor for the Detection of Volatile Organic Compounds. Sens. Actuators B Chem. 2018, 275, 10–15. [Google Scholar] [CrossRef]

- Gong, X.; Li, Z.; Zhao, L.; Wang, T.; Jin, R.; Yan, X.; Liu, F.; Sun, P.; Lu, G. Indoor Air Quality Monitoring System with High Accuracy of Gas Classification and Concentration Prediction via Selective Mechanism Research. ACS Sens. 2024, 9, 5828–5838. [Google Scholar] [CrossRef]

- Oh, J.; Kim, S.H.; Lee, M.-J.; Hwang, H.; Ku, W.; Lim, J.; Hwang, I.-S.; Lee, J.-H.; Hwang, J.-H. Machine Learning-Based Discrimination of Indoor Pollutants Using an Oxide Gas Sensor Array: High Endurance against Ambient Humidity and Temperature. Sens. Actuator B-Chem. 2022, 364, 131894. [Google Scholar] [CrossRef]

- Zhao, D.; Zhang, H.; Pan, J. Solving Optimization of a Mine Gas Sensor Layout Based on a Hybrid GA-DBPSO Algorithm. IEEE Sensors J. 2019, 19, 6400–6409. [Google Scholar] [CrossRef]

- Al-Okby, M.F.R.; Neubert, S.; Roddelkopf, T.; Fleischer, H.; Thurow, K. Evaluating of IAQ-Index and TVOC Parameter-Based Sensors for Hazardous Gases Detection and Alarming Systems. Sensors 2022, 22, 1473. [Google Scholar] [CrossRef]

- Nigam, H.; Saini, A.K.; Banerjee, S.; Kumar, A. Indoor Environment Air Quality Monitoring and Its Notification to Building Occupants. In Proceedings of the Proceedings of the 2019 IEEE Region 10 Conference (Tencon 2019) Technology, Knowledge, and Society, Kerala, India, 17–20 October 2019; IEEE: New York, NY, USA, 2019; pp. 2444–2448. [Google Scholar]

- Jion, M.M.M.F.; Jannat, J.N.; Mia, M.Y.; Ali, M.A.; Islam, M.S.; Ibrahim, S.M.; Pal, S.C.; Islam, A.; Sarker, A.; Malafaia, G.; et al. A Critical Review and Prospect of NO2 and SO2 Pollution over Asia: Hotspots, Trends, and Sources. Sci. Total Environ. 2023, 876, 162851. [Google Scholar] [CrossRef] [PubMed]

- Behera, S.N.; Sharma, M.; Aneja, V.P.; Balasubramanian, R. Ammonia in the Atmosphere: A Review on Emission Sources, Atmospheric Chemistry and Deposition on Terrestrial Bodies. Environ. Sci. Pollut. Res. 2013, 20, 8092–8131. [Google Scholar] [CrossRef]

- Wei, J.; Li, Z.; Wang, J.; Li, C.; Gupta, P.; Cribb, M. Ground-Level Gaseous Pollutants (NO2, SO2, and CO) in China: Daily Seamless Mapping and Spatiotemporal Variations. Atmos. Chem. Phys. 2023, 23, 1511–1532. [Google Scholar] [CrossRef]

- Liu, H.; Zhai, S.; Kong, Y.; Wang, Z.; Song, G.; Song, H.; Liang, L.; Liu, X.; Jiang, X.; Wu, L. Synergistic Effects of Gaseous Pollutants on Hospital Admissions for Cardiovascular Disease in Liuzhou, China. Environ. Sci. Pollut. Res. 2022, 29, 9841–9851. [Google Scholar] [CrossRef]

- Cui, M.; Zhan, C.; Wu, W.; Guo, D.; Song, Y. Acute Gaseous Air Pollution Exposure and Hospitalizations for Acute Ischemic Stroke: A Time-Series Analysis in Tianjin, China. Int. J. Environ. Res. Public Health 2022, 19, 13344. [Google Scholar] [CrossRef]

- Prasad, P.; Raut, P.; Goel, S.; Barnwal, R.P.; Bodhe, G.L. Electronic Nose and Wireless Sensor Network for Environmental Monitoring Application in Pulp and Paper Industry: A Review. Environ. Monit. Assess. 2022, 194, 855. [Google Scholar] [CrossRef]

- Wright, R.F.; Lu, P.; Devkota, J.; Lu, F.; Ziomek-Moroz, M.; Ohodnicki, P.R. Corrosion Sensors for Structural Health Monitoring of Oil and Natural Gas Infrastructure: A Review. Sensors 2019, 19, 3964. [Google Scholar] [CrossRef]

- Ramaiyan, K.P.; Mukundan, R. Electrochemical Sensors for Air Quality Monitoring. Electrochem. Soc. Interface 2019, 28, 59–63. [Google Scholar] [CrossRef]

- Chen, T.-W.; Ramachandran, R.; Chen, S.-M.; Anushya, G.; Ramachandran, K. Graphene and Perovskite-Based Nanocomposite for Both Electrochemical and Gas Sensor Applications: An Overview. Sensors 2020, 20, 6755. [Google Scholar] [CrossRef]

- Medvedeva, E.; Baranov, A.; Samotaev, N. Investigation of Electrochemical Sensors with Thin Film Nanocomposite Pt/C Electrodes Obtained by Magnetron Sputtering. In Proceedings of the 2nd International Telecommunication Conference Advanced Micro-and Nanoelectronic Systems and Technologies, Moscow, Russia, 1–2 June 2017; IoP Publishing Ltd.: Bristol, UK, 2019; Volume 498, p. 012027. [Google Scholar]

- Zhang, Z.; Yang, J.; Zhu, C.; Xu, M.; Yan, X.; Chu, J.; Zhu, X.; Yang, M. Design of a Dual-Phase TiN-WN Electrochemical Sensor for H2S Detection. J. Colloid Interface Sci. 2025, 682, 332–339. [Google Scholar] [CrossRef]

- Van Nguyen, M.; Kim, T.-U.; Nguyen, L.H.T.; Mirzaei, A.; Pham, A.T.T.; Tran, T.Q.; Mai, N.X.D.; Tran, N.Q.; Kim, Y.; Phan, T.B.; et al. Efficient Low-Temperature Detection of CO Gas by Various Metalated Porphyrinic-Al-Based MOF (Cu and Co) Materials. Sens. Actuator B-Chem. 2025, 424, 136915. [Google Scholar] [CrossRef]

- Kim, J.-H.; Mirzaei, A.; Kim, H.W.; Kim, S.S. Realization of Au-Decorated WS2 Nanosheets as Low Power-Consumption and Selective Gas Sensors. Sens. Actuator B-Chem. 2019, 296, 126659. [Google Scholar] [CrossRef]

- Kim, J.-H.; Kim, J.-Y.; Mirzaei, A.; Kim, H.W.; Kim, S.S. Synergistic Effects of SnO2 and Au Nanoparticles Decorated on WS2 Nanosheets for Flexible, Room-Temperature CO Gas Sensing. Sens. Actuator B-Chem. 2021, 332, 129493. [Google Scholar] [CrossRef]

- Jung, G.; Hong, S.; Jeong, Y.; Shin, W.; Park, J.; Kim, D.; Lee, J.-H. Highly Selective and Low-Power Carbon Monoxide Gas Sensor Based on the Chain Reaction of Oxygen and Carbon Monoxide to WO3. ACS Appl. Mater. Interfaces 2022, 14, 17950–17958. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, F.; Pei, M.; Jiang, W. RGO/CuCl-Based Flexible Gas Sensor for High-Concentration Carbon Monoxide Gas Detection at Room Temperature. Micromachines 2024, 15, 737. [Google Scholar] [CrossRef]

- Madan, J.; Pandey, R.; Chaujar, R. Conducting Polymer Based Gas Sensor Using PNIN- Gate All Around-Tunnel FET. Silicon 2020, 12, 2947–2955. [Google Scholar] [CrossRef]

- Klein, L.; Ramachandran, M.; van Kessel, T.; Nair, D.; Hinds, N.; Hamann, H.; Sosa, N. Wireless Sensor Networks for Fugitive Methane Emissions Monitoring in Oil and Gas Industry. In Proceedings of the 2018 IEEE International Congress on Internet of Things (ICIOT), San Francisco, CA, USA, 2–7 July 2018; pp. 41–48. [Google Scholar]

- Thriumani, R.; Zakaria, A.; Hashim, Y.Z.H.-Y.; Jeffree, A.I.; Helmy, K.M.; Kamarudin, L.M.; Omar, M.I.; Shakaff, A.Y.M.; Adom, A.H.; Persaud, K.C. A Study on Volatile Organic Compounds Emitted by In-Vitro Lung Cancer Cultured Cells Using Gas Sensor Array and SPME-GCMS. BMC Cancer 2018, 18, 362. [Google Scholar] [CrossRef]

- Luo, Y.; Xu, Z.; He, X.-L.; Tang, X.-P.; Wu, N.-Y.; Huang, D.; Dong, M.; Huang, J. Electrical Gas Sensors Based on Metal–Organic Frameworks for Breath Diagnosis. Microchem. J. 2024, 199, 109992. [Google Scholar] [CrossRef]

- Rath, R.J.J.; Farajikhah, S.; Oveissi, F.; Dehghani, F.; Naficy, S. Chemiresistive Sensor Arrays for Gas/Volatile Organic Compounds Monitoring: A Review. Adv. Eng. Mater. 2023, 25, 2200830. [Google Scholar] [CrossRef]

- Duan, L.; Liu, H.; Xia, K.; Guo, Z.; Li, Y.; Deng, S.; Sun, L.; Hou, Z. Gas Sensing Performance Regulating of ZIF-8 Encapsulated WO3 Nanosheets. Ceram. Int. 2024, 50, 50989–51001. [Google Scholar] [CrossRef]

- Luo, Y.; Ly, A.; Lahem, D.; Zhang, C.; Debliquy, M. A Novel Low-Concentration Isopropanol Gas Sensor Based on Fe-Doped ZnO Nanoneedles and Its Gas Sensing Mechanism. J. Mater. Sci. 2021, 56, 3230–3245. [Google Scholar] [CrossRef]

- Liang, H.; Liu, N.; Lin, J.; Meng, Y.; Ni, J.; Gao, B.; Tan, Z.; Song, X.-Z.; Wang, X. Narrow-Band HoFeO3 Nanostructure-Based Gas Sensor for n-Propanol Detection. ACS Appl. Nano Mater. 2024, 7, 7573–7581. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, D.; Mi, Q. A High-Performance Room Temperature Benzene Gas Sensor Based on CoTiO3 Covered TiO2 Nanospheres Decorated with Pd Nanoparticles. Sens. Actuators B Chem. 2022, 350, 130830. [Google Scholar] [CrossRef]

- Gong, C.; Chen, M.; Song, F.; Yin, P.; Zhao, X.; You, X.; Fu, H.; Yu, S.; Liu, X.; Zhang, K.; et al. A Highly Sensitive Toluene Gas Sensor Based on Pd/PdO Decorated SnO2 Prepared by Electrospinning. ACS Appl. Electron. Mater. 2024, 6, 6036–6048. [Google Scholar] [CrossRef]

- Gregis, G.; Sanchez, J.-B.; Bezverkhyy, I.; Guy, W.; Berger, F.; Fierro, V.; Bellat, J.-P.; Celzard, A. Detection and Quantification of Lung Cancer Biomarkers by a Micro-Analytical Device Using a Single Metal Oxide-Based Gas Sensor. Sens. Actuators B Chem. 2018, 255, 391–400. [Google Scholar] [CrossRef]

- Lee, D.-S. Early Screening of Lung Cancer Through Multi-Modal Gas Sensors-Based Breath Analysis Sensor System and Machine Learning. In Proceedings of the 2024 IEEE SENSORS, Kobe, Japan, 20–23 October 2024; pp. 1–2. [Google Scholar]

- Marzorati, D.; Mainardi, L.; Sedda, G.; Gasparri, R.; Spaggiari, L.; Cerveri, P. A Metal Oxide Gas Sensors Array for Lung Cancer Diagnosis Through Exhaled Breath Analysis. In Proceedings of the 2019 41st Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), 23–27 July 2019; pp. 1584–1587. [Google Scholar]

- Zhang, L.; Khan, K.; Zou, J.; Zhang, H.; Li, Y. Recent Advances in Emerging 2D Material-Based Gas Sensors: Potential in Disease Diagnosis. Adv. Mater. Inter. 2019, 6, 1901329. [Google Scholar] [CrossRef]

- Ryabtsev, S.V.; Shaposhnick, A.V.; Lukin, A.N.; Domashevskaya, E.P. Application of Semiconductor Gas Sensors for Medical Diagnostics. Sens. Actuators B Chem. 1999, 59, 26–29. [Google Scholar] [CrossRef]

- Kaloumenou, M.; Skotadis, E.; Lagopati, N.; Efstathopoulos, E.; Tsoukalas, D. Breath Analysis: A Promising Tool for Disease Diagnosis—The Role of Sensors. Sensors 2022, 22, 1238. [Google Scholar] [CrossRef]

- Lombardo, L.; Grassini, S.; Parvis, M.; Donato, N.; Gullino, A. Niobium Pentaoxide Thin-Film Gas Sensor for Portable Acetone Sensing. In Proceedings of the 2021 15th International Conference on Advanced Technologies, Systems and Services in Telecommunications (TELSIKS), Berlin, Germany, 20 October 2021; IEEE: Nis, Serbia, 2021; pp. 317–320. [Google Scholar]

- Kao, K.-W.A.; Cheng, C.-J.; Gwo, S.; Yeh, J.A. A Semiconductor Gas System of Healthcare for Liver Disease Detection Using Ultrathin InN-Based Sensor. Meet. Abstr. 2015, MA2015-01, 1426. [Google Scholar] [CrossRef]

- Astuti, S.; Mukhammad, Y.; Duli, S.J.; Putra, A.; Setiawatie, E.; Triyana, K. Gas Sensor Array System Properties for Detecting Bacterial Biofilms. J. Med. Signals. Sens. 2019, 9, 158. [Google Scholar] [CrossRef]

- Shooshtari, M. Ammonia Gas Sensors Based on Multi-Wall Carbon Nanofiber Field Effect Transistors by Using Gate Modulation. Colloids Surf. A Physicochem. Eng. Asp. 2025, 704, 135563. [Google Scholar] [CrossRef]

- Haick, H.; Tang, N. Artificial Intelligence in Medical Sensors for Clinical Decisions. ACS Nano 2021, 15, 3557–3567. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Wang, R. Development of Gas Sensors and Their Applications in Health Safety, Medical Detection, and Diagnosis. Chemosensors 2025, 13, 190. https://doi.org/10.3390/chemosensors13050190

Wang J, Wang R. Development of Gas Sensors and Their Applications in Health Safety, Medical Detection, and Diagnosis. Chemosensors. 2025; 13(5):190. https://doi.org/10.3390/chemosensors13050190

Chicago/Turabian StyleWang, Jiayu, and Rui Wang. 2025. "Development of Gas Sensors and Their Applications in Health Safety, Medical Detection, and Diagnosis" Chemosensors 13, no. 5: 190. https://doi.org/10.3390/chemosensors13050190

APA StyleWang, J., & Wang, R. (2025). Development of Gas Sensors and Their Applications in Health Safety, Medical Detection, and Diagnosis. Chemosensors, 13(5), 190. https://doi.org/10.3390/chemosensors13050190