A Systematic Review of the Applications of Electronic Nose and Electronic Tongue in Food Quality Assessment and Safety

Abstract

1. Introduction

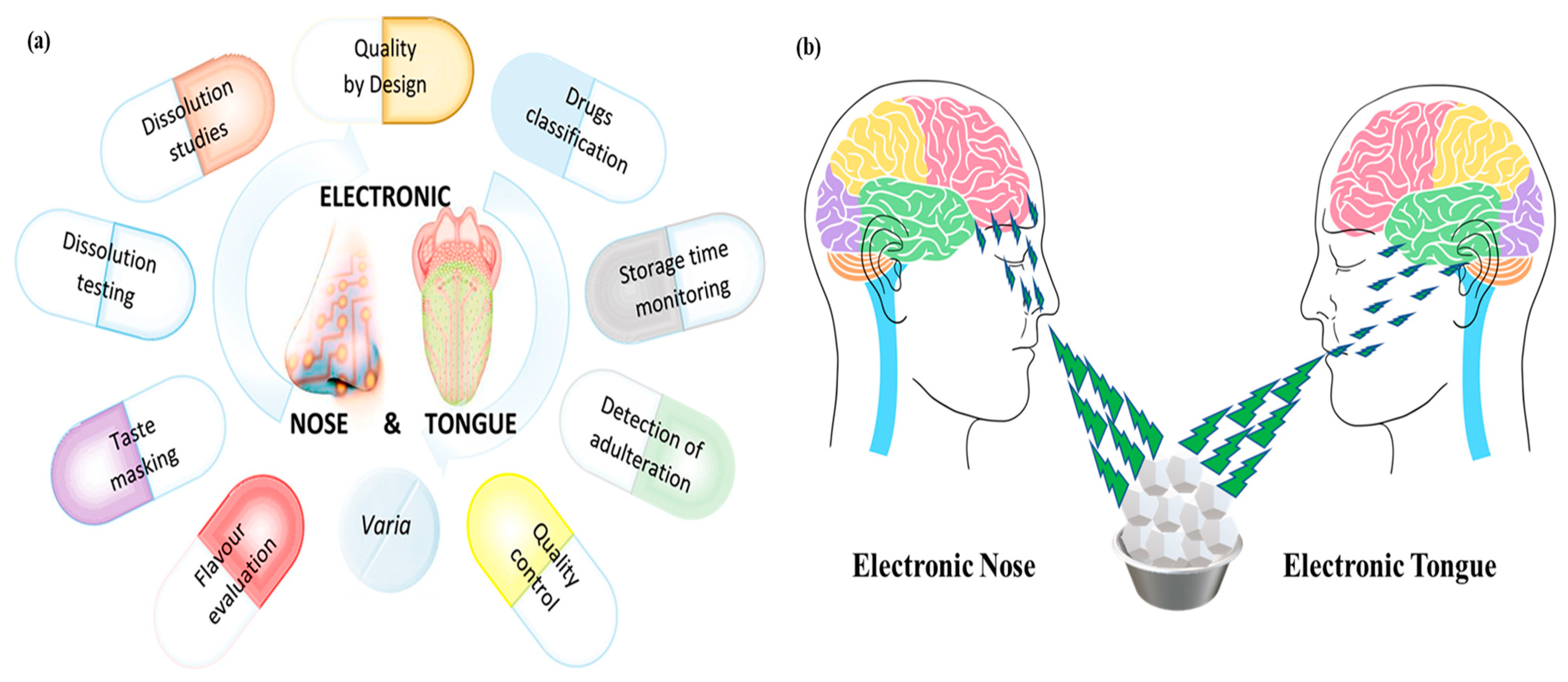

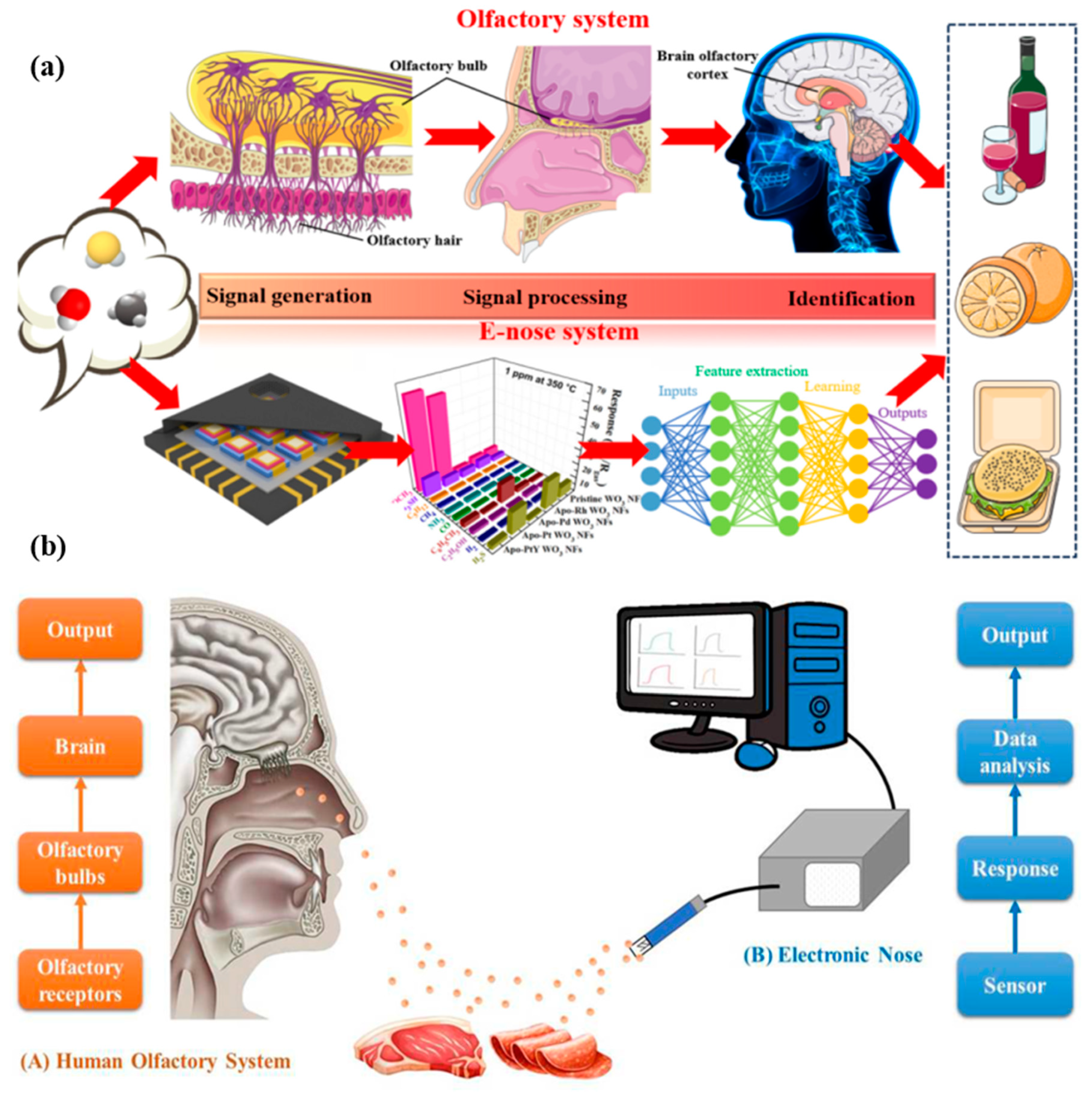

2. Fundamentals of E-Nose and E-Tongue Technologies

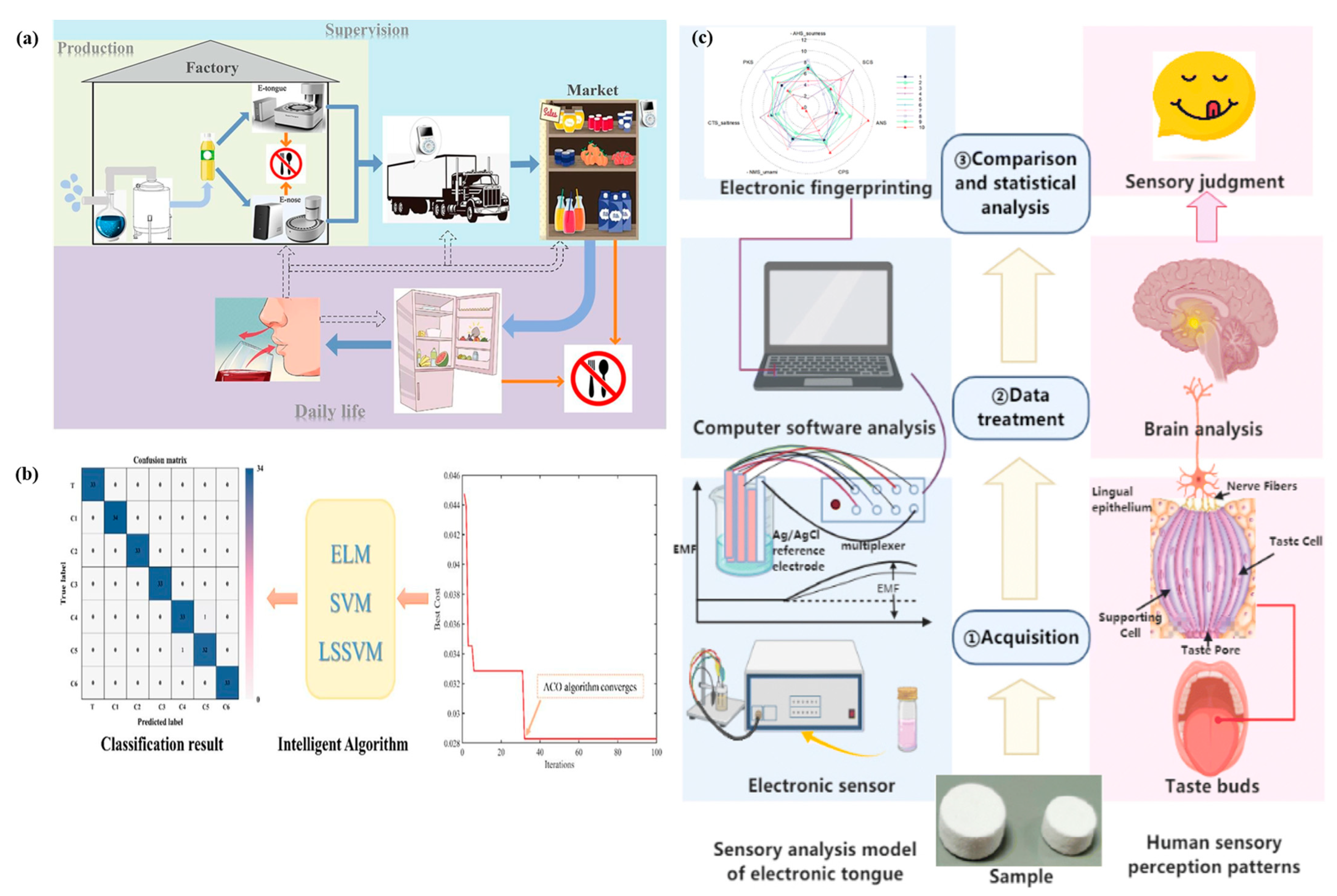

3. Necessity of E-Nose and E-Tongue in Food Quality Analysis

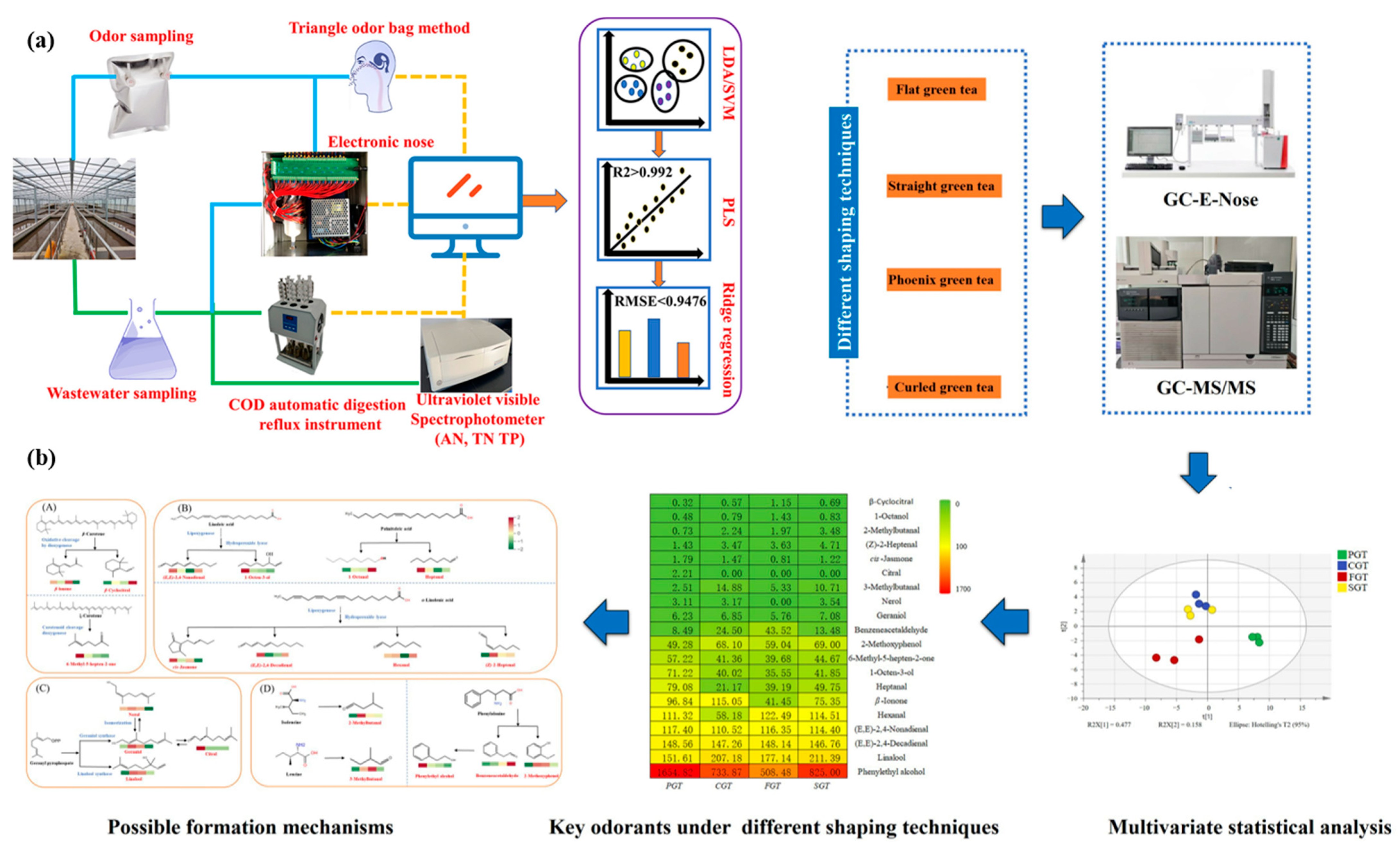

4. Applications of E-Nose and E-Tongue in Food Quality Assessment

5. Emerging Research and Applications of E-Nose in Food Quality Measurement

6. Advancements in E-Nose Technology for Food Quality Assessment

7. Emerging Research and Applications of E-Tongue in Food Quality Measurement

8. Advancements in E-Tongue Technology for Food Quality Assessment

| No. | Sensor Type | Sensor Array Material | Analytes Detected | Sample Matrix | Detection Limit | Reference |

|---|---|---|---|---|---|---|

| 1 | E-nose | MOS | VOCs | Beef | 0.1 ppm | [56] |

| 2 | E-tongue | Lipid Membrane | Caffeine, Catechins | Tea | — | [57] |

| 3 | E-nose | QCM | Sulfur Compounds | Fish | 0.05 ppm | [58] |

| 4 | E-tongue | Potentiometric | Sugars, Acids | Fruit Juice | — | [59] |

| 5 | E-nose | Conducting Polymer | Ammonia, VOCs | Chicken | 0.2 ppm | [60] |

| 6 | E-tongue | Voltammetric | Sodium, Potassium | Tomato Sauce | — | [61] |

| 7 | E-nose | MOS | Esters, Aldehydes | Olive Oil | 0.1 ppm | [62] |

| 8 | E-tongue | Impedance | Bitterness, Umami | Beer | — | [63] |

| 9 | E-nose | SAW | Ethanol, VOCs | Wine | 0.3 ppm | [64] |

| 10 | E-tongue | Biosensor | Sucralose, Bitterness | Pharmaceuticals | — | [65] |

| 11 | E-nose | Hybrid (MOS + QCM) | Methane, Ethanol, VOCs | Milk | 0.05 ppm | [66] |

| 12 | E-tongue | Lipid Membranes | Taste Profile | Dairy | — | [67] |

| 13 | E-nose | Metal Oxide | Ammonia, Trimethylamine | Shrimp | 0.1 ppm | [68] |

| 14 | E-tongue | Voltammetric | Polyphenols | Red Wine | — | [69] |

| 15 | E-nose | Colorimetric Sensor Array | VOCs | Mango | — | [70] |

| 16 | E-tongue | Potentiometric Array | Chloride, Organic Acids | Pickled Vegetables | — | [71] |

| 17 | E-nose | Optical Fiber Sensors | Aldehydes, Acids | Dairy | — | [72] |

| 18 | E-tongue | Impedance | Taste compounds | Soy Sauce | — | [73] |

| 19 | E-nose | MOS | VOCs | Sausages | 0.2 ppm | [74] |

| 20 | E-tongue | Electrochemical | Organic Acids | Fruit Juices | — | [75] |

| 21 | E-nose | Polymer Nanocomposite | Alcohols, VOCs | Beer | 0.05 ppm | [76] |

| 22 | E-tongue | Enzyme-Modified Electrodes | Sweeteners | Soft Drinks | — | [77] |

| 23 | E-nose | MOS | VOCs | Mushrooms | — | [78] |

| 24 | E-tongue | ChemFET | Salts, Acids | Sauces | — | [79] |

| 25 | E-nose | Paper-Based Sensor Array | Aroma Profile | Chocolate | — | [80] |

| 26 | E-tongue | Impedance | Taste Profile | Milk | — | [81] |

| 27 | E-nose | Gas Sensor Network | VOCs | Stored Fruits | — | [82] |

| 28 | E-tongue | Potentiometric | Tannins, Bitterness | Black Tea | — | [83] |

| 29 | E-nose | MOS | VOC Fingerprinting | Yogurt | 0.1 ppm | [84] |

| 30 | E-tongue | Voltammetric | Organic Compounds | Fruit Purees | — | [85] |

| 31 | E-nose | QCM | Alcohols, Esters | Cheese | — | [86] |

| 32 | E-tongue | Hybrid Sensor | Saltiness, Acidity | Snacks | — | [87] |

| 33 | E-nose | CNT-Based Sensor | Ethanol, VOCs | Kombucha | 0.1 ppm | [88] |

| 34 | E-tongue | Electrochemical | Amino Acids | Tofu | — | [89] |

| 35 | E-nose | Biopolymer Sensor | Aromatics | Spices | — | [90] |

| 36 | E-tongue | Voltammetric | Acids, Esters | Vinegar | — | [91] |

| 37 | E-nose | Colorimetric Array | VOC Fingerprints | Green Tea | — | [92] |

| 38 | E-tongue | Impedance | Mineral Content | Mineral Water | — | [93] |

| 39 | E-nose | SAW | Aromatics | Nuts | — | [94] |

| 40 | E-tongue | Lipid Membrane | Taste Profile | Ice Cream | — | [95] |

| 41 | E-nose | Optical Sensor Array | VOCs | Dried Herbs | — | [96] |

| 42 | E-tongue | Potentiometric | Sourness, Bitterness | Sauces | — | [97] |

| 43 | E-nose | Hybrid (MOS + Optical) | Spoilage VOCs | Fish | 0.05 ppm | [98] |

| 44 | E-tongue | Conductometric | Taste Compounds | Packaged Foods | — | [99] |

| 45 | E-nose | CNT-Film Sensor | Aromatics | Roasted Coffee | — | [100] |

| 46 | E-tongue | Voltammetric | Sugar Content | Juices | — | [101] |

| 47 | E-nose | Electrochemical Array | Aldehydes | Meat | 0.1 ppm | [102] |

| 48 | E-tongue | Enzyme-Modified Electrodes | Bitterness, Artificial Sweeteners | Diet Sodas | — | [103] |

| 49 | E-nose | Flexible Gas Sensor Array | VOCs | Packaged Fish | — | [104] |

| 50 | E-tongue | Hybrid Array | Salts, Organic Acids | Soups | — | [105] |

9. Challenges Facing E-Nose and E-Tongue Technologies

10. Future Aspects and Challenges of E-Nose and E-Tongue

11. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wilson, A.D. Electronic-Nose Applications in Forensic Science and for Analysis of Food, Beverage, and Environmental Samples. Chemosensors 2020, 8, 44. [Google Scholar] [CrossRef]

- Wilson, A.D. Progress in Electronic-Nose Technologies for Environmental Monitoring and Food Safety: A Review. Sensors 2021, 21, 6124. [Google Scholar] [CrossRef]

- Riul, A.; Dantas, C.A.R.; Miyazaki, C.M.; Oliveira, O.N. Recent Advances in Electronic Tongues. Biosens. Bioelectron. 2010, 26, 428–434. [Google Scholar] [CrossRef]

- Wilson, A.D. The Role of Electronic-Nose Technology in Food and Beverage Analysis. Chemosensors 2023, 11, 25. [Google Scholar] [CrossRef]

- Tahara, Y.; Toko, K. Recent Advances in Electronic Tongue Technology for Food Quality and Safety. Trends Food Sci. Technol. 2023, 132, 58–71. [Google Scholar] [CrossRef]

- Galvan, D.; Aquino, A.; Effting, L.; Mantovani, A.C.G.; Bona, E.; Conte-Junior, C.A. E-sensing and nanoscale-sensing devices associated with data processing algorithms applied to food quality control: A systematic review. Crit. Rev. Food Sci. Nutr. 2021, 62, 6605–6645. [Google Scholar] [CrossRef]

- Li, X.; Guo, Z.; Wang, Y. Advances in E-Nose and E-Tongue Sensors for Food Quality Assessment. Sensors 2022, 22, 1687. [Google Scholar] [CrossRef]

- Peris, M.; Escuder-Gilabert, L. A 21st Century Technique for Food Control: Electronic Noses. Anal. Chim. Acta 2009, 638, 1–15. [Google Scholar] [CrossRef]

- Rock, F.; Barsan, N.; Weimar, U. Electronic Nose: Current Status and Future Trends. Chem. Rev. 2008, 108, 705–725. [Google Scholar] [CrossRef]

- Loutfi, A.; Coradeschi, S.; Mani, G.K.; Shankar, P.; Rayappan, J.B.B. Electronic Noses for Food Quality: A Review. J. Food Eng. 2015, 144, 103–111. [Google Scholar] [CrossRef]

- Śliwińska, M.; Wiśniewska, P.; Dymerski, T.; Wardencki, W.; Namieśnik, J. Advances in Electronic Noses and Tongues for Food Authenticity Testing. Adv. Food Authent. Test. 2015, 201–225. [Google Scholar] [CrossRef]

- Chen, P.; Liu, Y.; Zhang, S. Development of a Graphene-Based Electronic Tongue for Food Authentication. Food Chem. 2022, 383, 132390. [Google Scholar] [CrossRef]

- Yang, D.; Qi, X.; Zhang, X. A Portable Multi-Channel E-Nose for the Detection of Food Spoilage. Chemosensors 2023, 11, 12. [Google Scholar] [CrossRef]

- Roy, R.B.; Tudu, B.; Shaw, L.; Jana, A.; Bhattacharyya, N.; Bandyopadhyay, R. Instrumental testing of tea by combining the responses of electronic nose and tongue. J. Food Eng. 2012, 110, 356–363. [Google Scholar] [CrossRef]

- Natale, C.D.; Paolesse, R.; Martinelli, E.; Capuano, R. Solid-State Gas Sensors for Artificial Olfaction. Chem. Rev. 2019, 119, 2506–2531. [Google Scholar] [CrossRef]

- Zhang, S.; Du, Y.; Zhang, C.; Zhang, H. Application of an Electronic Tongue in Food Analysis. Food Chem. 2019, 292, 131–143. [Google Scholar] [CrossRef]

- Xu, M.; Wang, J.; Zhu, L. The qualitative and quantitative assessment of tea quality based on E-nose, E-tongue and E-eye combined with chemometrics. Food Chem. 2019, 289, 482–489. [Google Scholar] [CrossRef]

- Haddi, Z.; Mabrouk, S.; Bougrini, M.; Tahri, K.; Sghaier, K.; Barhoumi, H.; El Bari, N.; Maaref, A.; Jaffrezic-Renault, N.; Bouchikhi, B. E-Nose and e-Tongue combination for improved recognition of fruit juice samples. Food Chem. 2014, 150, 246–253. [Google Scholar] [CrossRef]

- Tonacci, A.; Scafile, A.; Billeci, L.; Sansone, F. Electronic Nose and Tongue for Assessing Human Microbiota. Chemosensors 2022, 10, 85. [Google Scholar] [CrossRef]

- Zhang, Z.; Zang, M.; Zhang, K.; Wang, S.; Li, D.; Li, X. Effect of two types of thermal processing methods on the aroma and taste profiles of three commercial plant-based beef analogues and beef by GC-MS, E-nose, E-tongue, and sensory evaluation. Food Control. 2023, 146, 109551. [Google Scholar] [CrossRef]

- Zou, Y.; Wan, H.; Zhang, X.; Ha, D.; Wang, P. Electronic Nose and Electronic Tongue. In Bioinspired Smell and Taste Sensors; Wang, P., Liu, Q., Wu, C., Hsia, K., Eds.; Springer: Dordrecht, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, J.; Zhao, J. Determination of Tea Quality by Electronic Nose. J. Food Eng. 2007, 82, 180–186. [Google Scholar] [CrossRef]

- Xiao, Z.; Niu, M.; Niu, Y. Comparative Study on Volatile Compounds and Taste Components of Different Durian Cultivars Based on GC-MS, UHPLC, HPAEC-PAD, E-Tongue and E-Nose. Molecules 2021, 27, 1264. [Google Scholar] [CrossRef]

- Han, F.; Zhang, D.; Aheto, J.H.; Feng, F.; Duan, T. Integration of a low-cost electronic nose and a voltammetric electronic tongue for red wines identification. Food Sci. Nutr. 2020, 8, 4330–4339. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, X.; Mao, Q.; Zhang, Q.; Zhou, Y.; Huang, G.; Liu, L.; Yang, Q.; Zhang, Y.; Guo, F.; et al. Characterization of prepared soft-shelled turtle dishes of different pretreatment combined with irradiation based on flavor profiles using E-nose, E-tongue and HS-SPME-GC–MS. Food Chem. X 2025, 27, 102352. [Google Scholar] [CrossRef]

- Wasilewski, T.; Migoń, D.; Gębicki, J.; Kamysz, W. Critical review of electronic nose and tongue instruments prospects in pharmaceutical analysis. Anal. Chim. Acta 2019, 1077, 14–29. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Méndez, M.L.; De Saja, J.A.; González-Antón, R.; García-Hernández, C.; Medina-Plaza, C.; García-Cabezón, C.; Martín-Pedrosa, F. Electronic Noses and Tongues in Wine Industry. Front. Bioeng. Biotechnol. 2016, 4, 212083. [Google Scholar] [CrossRef] [PubMed]

- Qiu, S.; Wang, J.; Gao, L. Qualification and quantisation of processed strawberry juice based on electronic nose and tongue. LWT—Food Sci. Technol. 2014, 60, 115–123. [Google Scholar] [CrossRef]

- Shen, C.; Cai, Y.; Wu, X.; Gai, S.; Wang, B.; Liu, D. Characterization of selected commercially available grilled lamb shashliks based on flavor profiles using GC-MS, GC × GC-TOF-MS, GC-IMS, E-nose and E-tongue combined with chemometrics. Food Chem. 2023, 423, 136257. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, H.; Lin, L.; Du, X.; Tang, S.; Liu, H.; Yang, H. The qualitative and quantitative assessment of xiaochaihu granules based on e-eye, e-nose, e-tongue and chemometrics. J. Pharm. Biomed. Anal. 2021, 205, 114298. [Google Scholar] [CrossRef]

- Jung, H.Y.; Kwak, H.S.; Kim, M.J.; Kim, Y.; Kim, O.; Kim, S.S. Comparison of a descriptive analysis and instrumental measurements (electronic nose and electronic tongue) for the sensory profiling of Korean fermented soybean paste (doenjang). J. Sens. Stud. 2017, 32, e12282. [Google Scholar] [CrossRef]

- Zhai, Z.; Liu, Y.; Li, C.; Wang, D.; Wu, H. Electronic Noses: From Gas-Sensitive Components and Practical Applications to Data Processing. Sensors 2023, 24, 4806. [Google Scholar] [CrossRef] [PubMed]

- Munekata, P.E.; Finardi, S.; De Souza, C.K.; Meinert, C.; Pateiro, M.; Hoffmann, T.G.; Domínguez, R.; Bertoli, S.L.; Kumar, M.; Lorenzo, J.M. Applications of Electronic Nose, Electronic Eye and Electronic Tongue in Quality, Safety and Shelf Life of Meat and Meat Products: A Review. Sensors 2022, 23, 672. [Google Scholar] [CrossRef]

- Liu, X.; Wang, X.; Cheng, Y.; Wu, Y.; Yan, Y.; Li, Z. Variations in volatile organic compounds in Zhenyuan Daocai samples at different storage durations evaluated using E-nose, E-tongue, gas chromatography, and spectrometry. LWT 2022, 173, 114186. [Google Scholar] [CrossRef]

- Lvova, L.; Jahatspanian, I.; Mattoso, L.H.; Correa, D.S.; Oleneva, E.; Legin, A.; Di Natale, C.; Paolesse, R. Potentiometric E-Tongue System for Geosmin/Isoborneol Presence Monitoring in Drinkable Water. Sensors 2019, 20, 821. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Li, X.; Chen, D.; Weng, X.; Chang, Z. Development of an electronic nose to characterize water quality parameters and odor concentration of wastewater emitted from different phases in a wastewater treatment plant. Water Res. 2023, 235, 119878. [Google Scholar] [CrossRef]

- Tang, J.; Hu, J.; Zhou, X.; Wang, Q.; Jiang, Y.; Yuan, H.; Wang, Y.; Yang, Y. Influence of Different Shaping Techniques on the Aroma Quality and Volatile Metabolites of Green Tea Revealed by Gas Chromatography Electronic Nose and Gas Chromatography-Tandem Mass Spectrometry. Foods 2024, 14, 816. [Google Scholar] [CrossRef]

- Gao, P.; Han, L.; Zhou, X. Sensor Fusion in E-Nose and E-Tongue Systems for Enhanced Accuracy. Sens. Actuators B Chem. 2023, 381, 133289. [Google Scholar] [CrossRef]

- Tibaduiza, D.; Anaya, M.; Gómez, J.; Sarmiento, J.; Perez, M.; Lara, C.; Ruiz, J.; Osorio, N.; Rodriguez, K.; Hernandez, I. Electronic Tongues and Noses: A General Overview. Biosensors 2024, 14, 190. [Google Scholar] [CrossRef]

- Buratti, S.; Benedetti, S.; Scampicchio, M.; Pangerod, E. Characterization and classification of Italian Barbera wines by using an electronic nose and an amperometric electronic tongue. Anal. Chim. Acta 2004, 525, 133–139. [Google Scholar] [CrossRef]

- Wilson, A.D.; Baietto, M. Applications of E-Nose Technology in Food Industry. Innov. Food Sci. Emerg. Technol. 2022, 76, 103067. [Google Scholar] [CrossRef]

- Benedetti, S.; Buratti, S.; Spinardi, A.; Mannino, S.; Mignani, I. Electronic nose as a non-destructive tool to characterise peach cultivars and to monitor their ripening stage during shelf-life. Postharvest Biol. Technol. 2008, 47, 181–188. [Google Scholar] [CrossRef]

- Ghasemi-Varnamkhasti, M.; Apetrei, C.; Lozano, J.; Anyogu, A. Electronic Noses and Tongues: Beyond Human Senses. Biosensors 2019, 9, 31. [Google Scholar] [CrossRef]

- Mohd Ali, M.; Hashim, N.; Abd Aziz, S.; Lasekan, O. Principles and recent advances in electronic nose for quality inspection of agricultural and food products. Trends Food Sci. Technol. 2020, 99, 1–10. [Google Scholar] [CrossRef]

- Wilson, A.D. Application of Electronic-Nose Technologies and VOC-Biomarkers for the Noninvasive Early Diagnosis of Gastrointestinal Diseases. Sensors 2018, 18, 2613. [Google Scholar] [CrossRef] [PubMed]

- Ghasemi-Varnamkhasti, M.; Apetrei, C.; Lozano, J.; Anyogu, A. Potential use of electronic noses, electronic tongues and biosensors as multisensor systems for spoilage examination in foods. Trends Food Sci. Technol. 2018, 80, 71–92. [Google Scholar] [CrossRef]

- García, R.; González, A.; Díaz, C. Development of a Miniaturized E-Nose for Real-Time Food Spoilage Detection. Sens. Actuators B Chem. 2023, 382, 133315. [Google Scholar] [CrossRef]

- Gabrieli, G.; Muszynski, M.; Ruch, P. Electronic noses and tongues: Current trends and future needs. Digit. Sens. Sci. 2022, 117–133. [Google Scholar] [CrossRef]

- Bougrini, M.; Tahri, K.; Haddi, Z.; El Bari, N.; Llobet, E.; Jaffrezic-Renault, N.; Bouchikhi, B. Aging time and brand determination of pasteurized milk using a multisensor e-nose combined with a voltammetric e-tongue. Mater. Sci. Eng. C 2014, 45, 348–358. [Google Scholar] [CrossRef]

- Xu, M.; Yang, L.; Peng, W.; Liu, J.; Xie, S.; Li, Y.; Wu, J. A Novel Method for the Discrimination of Semen Arecae and Its Processed Products by Using Computer Vision, Electronic Nose, and Electronic Tongue. Evid. -Based Complement. Altern. Med. 2014, 2015, 753942. [Google Scholar] [CrossRef]

- Lu, L.; Hu, Z.; Hu, X.; Li, D.; Tian, S. Electronic tongue and electronic nose for food quality and safety. Food Res. Int. 2022, 162, 112214. [Google Scholar] [CrossRef]

- Ren, G.; Li, T.; Wei, Y.; Ning, J.; Zhang, Z. Estimation of Congou black tea quality by an electronic tongue technology combined with multivariate analysis. Microchem. J. 2021, 163, 105899. [Google Scholar] [CrossRef]

- Wang, Z.; Li, J.; Hong, X.; Han, X.; Liu, B.; Li, X.; Zhang, H.; Gao, J.; Liu, N.; Gao, X.; et al. Taste Masking Study Based on an Electronic Tongue: The Formulation Design of 3D Printed Levetiracetam Instant-Dissolving Tablets. Pharm. Res. 2021, 38, 831–842. [Google Scholar] [CrossRef]

- Liu, J.; Qian, J.; Adil, M.; Bi, Y.; Wu, H.; Hu, X.; Wang, Z.; Zhang, W. Bioinspired integrated triboelectric electronic tongue. Microsyst. Nanoeng. 2024, 10, 57. [Google Scholar] [CrossRef] [PubMed]

- Serrano, N.; Ariño, C.; Esteban, M.; Manuel, J. Voltammetric Electronic Tongues in Food Analysis. Sensors 2018, 19, 4261. [Google Scholar] [CrossRef]

- Binson, V.A.; George, M.M.; Sibichan, M.A.; Raj, M.; Prasad, K. Freshness Evaluation of Beef using MOS Based E-Nose. In Proceedings of the 2023 International Conference on Intelligent Data Communication Technologies and Internet of Things (IDCIoT), Bengaluru, India, 5–7 January 2023; pp. 792–797. [Google Scholar] [CrossRef]

- He, J.; Yu, W.; Liu, P. Electronic Tongue for Tea Quality and Flavor Evaluation. J. Sci. Food Agric. 2023, 103, 2147–2158. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, R.; Li, M. Evaluation of Freshness in Fish Using an E-Nose System. J. Food Sci. Technol. 2023, 60, 42–55. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, S.; Wang, J. Artificial Intelligence for Food Quality Assessment: A Review. Trends Food Sci. Technol. 2020, 95, 52–61. [Google Scholar] [CrossRef]

- Haugen, J.; Kvaal, K. Electronic nose and artificial neural network. Meat Sci. 1997, 49, S273–S286. [Google Scholar] [CrossRef]

- Tahara, Y.; Toko, K. Electronic Tongues—A Review. IEEE Sens. J. 2013, 13, 3001–3011. [Google Scholar] [CrossRef]

- García-Martínez, T.; Caro, I.; García-González, D.L. Identification of Olive Oil Authenticity Using an E-Nose System. Foods 2023, 12, 364. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, J.; Zhang, Y. Monitoring the Fermentation Process of Beer with an Electronic Tongue. J. Inst. Brew. 2013, 119, 98–103. [Google Scholar] [CrossRef]

- López, P.; Palacios, O.; Marín, L. Next-Generation E-Nose and E-Tongue Technologies for Food Authentication. Food Chem. 2022, 396, 133778. [Google Scholar] [CrossRef]

- Chen, T.; Wang, R.; Lu, Z. Portable E-Nose for Dairy Quality Monitoring: A Comparative Study with GC-MS. Food Chem. 2022, 385, 132648. [Google Scholar] [CrossRef]

- Li, W.; Sun, Y.; Wu, J. Hybrid Sensor Arrays for Multi-Component Analysis in Food E-Nose Applications. Sens. Actuators B Chem. 2022, 368, 132037. [Google Scholar] [CrossRef]

- Winquist, F.; Bjorklund, R.; Krantz-Rülcker, C.; Lundström, I.; Östergren, K.; Skoglund, T. An electronic tongue in the dairy industry. Sens. Actuators B Chem. 2005, 111–112, 299–304. [Google Scholar] [CrossRef]

- Srinivasan, P.; Robinson, J.; Geevaretnam, J.; Rayappan, J.B.B. Development of electronic nose (Shrimp-Nose) for the determination of perishable quality and shelf-life of cultured Pacific white shrimp (Litopenaeus Vannamei). Sens. Actuators B Chem. 2020, 317, 128192. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, H.S.; Cho, H. Development of an Electronic Tongue System for the Evaluation of Korean Fermented Sauces. Sensors 2023, 23, 2645. [Google Scholar] [CrossRef]

- Vagin, M.; Winquist, F. Electronic noses and tongues in food safety assurance. High Throughput Screen. Food Saf. Assess. 2014, 265–283. [Google Scholar] [CrossRef]

- Apetrei, C. Voltammetric Electronic Tongue for the Detection of Adulterated Olive Oils. Sensors 2023, 23, 1234. [Google Scholar] [CrossRef]

- Balivo, A.; Cipolletta, S.; Tudisco, R.; Iommelli, P.; Sacchi, R.; Genovese, A. Electronic Nose Analysis to Detect Milk Obtained from Pasture-Raised Goats. Appl. Sci. 2022, 13, 861. [Google Scholar] [CrossRef]

- Singh, P.; Verma, A.; Sharma, S. Smart Nanosensor Arrays for Beer Freshness Detection Using Electronic Nose. Food Chem. 2022, 381, 132356. [Google Scholar] [CrossRef]

- Grassi, S.; Benedetti, S.; Magnani, L.; Pianezzola, A.; Buratti, S. Seafood freshness: E-nose data for classification purposes. Food Control 2022, 138, 108994. [Google Scholar] [CrossRef]

- Liu, Y.; Gao, Z.; Wang, J. A Paper-Based Electronic Nose for On-Site Spoilage Detection in Fruit. Sensors 2023, 23, 4356. [Google Scholar] [CrossRef]

- Kim, J.Y.; Haque, F.; Lee, J.H.; Park, Y.J.; Seo, J.H.; Mativenga, M.; Walker, B. Practical organic electronic noses using semi-permeable polymer membranes. Appl. Mater. Today 2024, 37, 102137. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Wu, H. Real-Time Quality Monitoring of Fresh Meat Using an AI-Assisted E-Nose. Food Control 2022, 141, 109206. [Google Scholar] [CrossRef]

- Arroyo, P.; Suárez, J.I.; Lozano, J. Triangular Test of Amanita Mushrooms by Using Electronic Nose and Sensory Panel. Foods 2019, 8, 414. [Google Scholar] [CrossRef] [PubMed]

- Martínez, M.A.; García, P.; Pérez, F. Enhancing Food Authentication with Sensor Fusion: Integration of E-Nose and E-Tongue Systems. Foods 2023, 12, 679. [Google Scholar] [CrossRef]

- Zhao, T.; Ma, R.; Zhang, W. Machine Learning for Odor Recognition Using an E-Nose. Comput. Electron. Agric. 2022, 198, 106988. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, B.; Hu, Y. Electrochemical Tongue Based on Enzyme-Modified Electrodes for Beverage Authentication. Food Chem. 2023, 396, 133877. [Google Scholar] [CrossRef]

- Apetrei, C.; Apetrei, I.M. Voltammetric Electronic Tongue for the Detection of Milk Adulteration. Sensors 2022, 22, 2385. [Google Scholar] [CrossRef]

- Xu, Q.; Yin, X.; Huo, X.; Zhao, X.; Wu, L.; Zhou, Y.; Huang, J. Development of a colorimetric sensor array with weighted RGB strategy for quality differentiation of Anji white tea. J. Food Eng. 2025, 391, 112458. [Google Scholar] [CrossRef]

- Sun, Z.; Li, Q.; Zhang, H. Wireless Sensor Network-Based E-Nose for Real-Time Fruit Ripeness Detection. Sensors 2022, 22, 3456. [Google Scholar] [CrossRef]

- Valdez, L.F.; Gutiérrez, J.M. Chocolate Classification by an Electronic Nose with Pressure Controlled Generated Stimulation. Sensors 2016, 16, 1745. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Lin, J.; Chen, L. E-Nose Coupled with Chemometrics for Cheese Aroma Profiling. Food Chem. 2022, 387, 132938. [Google Scholar] [CrossRef]

- Chen, X.; Liu, R.; Wang, J. Hybrid Electronic Tongue for Snack Food Flavor Analysis. Sensors 2022, 22, 1053. [Google Scholar] [CrossRef]

- Seesaard, T.; Wongchoosuk, C. Recent Progress in Electronic Noses for Fermented Foods and Beverages Applications. Fermentation 2022, 8, 302. [Google Scholar] [CrossRef]

- Sun, H.; Liu, L.; He, W.; Cao, C.; Song, X.; Zhao, M.; Zhang, J.; Su, G. Aggregates from the concentration process for soybean protein isolate hydrolysates: Impacts, characteristics and preventive strategies. LWT 2023, 186, 115129. [Google Scholar] [CrossRef]

- Babu, P.J. Nanotechnology mediated intelligent and improved food packaging. Int. Nano Lett. 2022, 12, 1–14. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, H.; Wang, Q. Voltammetric Electronic Tongue for Acidity Estimation in Vinegar. Food Chem. 2022, 386, 132702. [Google Scholar] [CrossRef]

- Gao, D.; Sun, X.; Lin, W. Colorimetric Sensor Array-Based E-Nose for Green Tea Quality Discrimination. Sensors 2023, 23, 578. [Google Scholar] [CrossRef]

- Vagin, M.Y.; Eriksson, M.; Winquist, F. Drinking Water Analysis Using Electronic Tongues. Electron. Noses Tongues Food Sci. 2015, 255–264. [Google Scholar] [CrossRef]

- Apetrei, C.; De Saja, J.A. SAW Sensor-Based Electronic Nose for Nut Classification. Sensors 2023, 23, 2124. [Google Scholar] [CrossRef]

- Wu, X.; Tahara, Y.; Yatabe, R.; Toko, K. Taste Sensor: Electronic Tongue with Lipid Membranes. Anal. Sci. 2020, 36, 147–159. [Google Scholar] [CrossRef]

- Liu, K.; Wang, P.; Yang, M. Optical Electronic Nose for Detecting Herbal Tea Volatiles. Chemosensors 2023, 11, 301. [Google Scholar] [CrossRef]

- Cai, T.; Hai, N.; Guo, P.; Feng, Z.; Zhang, Y.; Wang, J.; Yu, Z.; Liu, H.; Ding, L. Characteristics of Umami Taste of Soy Sauce Using Electronic Tongue, Amino Acid Analyzer, and MALDI−TOF MS. Foods 2023, 13, 2242. [Google Scholar] [CrossRef]

- Zhao, Y.; Guo, X.; Wang, L. Multi-Sensor E-Nose for Fish Freshness Evaluation with Hybrid Algorithms. Sensors 2023, 23, 3610. [Google Scholar] [CrossRef]

- Bett-Garber, K.L.; Watson, M.A.; Lea, J.M.; Bai, J.; Baldwin, E.; Raithore, S. Efficacy of Monitoring the Sensory Taste Characteristics in Pomegranate Juice with Electronic Tongue and Chemical Measurements. J. Food Qual. 2014, 37, 383–394. [Google Scholar] [CrossRef]

- Huang, S.; Riemenschneider, L.; Panes-Ruiz, L.A.; Ibarlucea, B.; Cuniberti, G. Discrimination of Complex Mixtures Using Carbon Nanotubes-based Multichannel Electronic Nose: Coffee Aromas. In Proceedings of the 2023 IEEE Nanotechnology Materials and Devices Conference (NMDC), Paestum, Italy, 22–25 October 2023; pp. 124–128. [Google Scholar] [CrossRef]

- Zhou, M.; Wang, Y.; Fang, L. Sugar Quantification in Juices Using Voltammetric Electronic Tongue. Food Chem. 2023, 403, 134112. [Google Scholar] [CrossRef]

- Magnaghi, L.R.; Capone, F.; Zanoni, C.; Alberti, G.; Quadrelli, P.; Biesuz, R. Colorimetric Sensor Array for Monitoring, Modelling and Comparing Spoilage Processes of Different Meat and Fish Foods. Foods 2020, 9, 684. [Google Scholar] [CrossRef]

- Podrażka, M.; Bączyńska, E.; Kundys, M.; Jeleń, P.S.; Witkowska Nery, E. Electronic Tongue—A Tool for All Tastes? Biosensors 2018, 8, 3. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, J.; Huang, H. Flexible Gas Sensor Array for VOC Detection in Packaged Fish. Sensors 2023, 23, 6099. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, C.W.; Park, S.; Choi, S.; Park, S.H.; Nam, G.B.; Ryu, J.; Eom, T.H.; Kim, B.; Kim, C.; et al. MXene-based high performance microfluidic pH sensors for electronic tongue. Sens. Actuators B Chem. 2024, 409, 135636. [Google Scholar] [CrossRef]

- Roy, M.; Yadav, B.K. Electronic nose for detection of food adulteration: A review. J. Food Sci. Technol. 2022, 59, 846–858. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Chen, Y. Electronic nose and its application in the food industry: A review. Eur. Food Res. Technol. 2024, 250, 21–67. [Google Scholar] [CrossRef]

- Shi, H.; Zhang, M.; Adhikari, B. Advances of electronic nose and its application in fresh foods: A review. Crit. Rev. Food Sci. Nutr. 2018, 58, 2700–2710. [Google Scholar] [CrossRef]

- Gliszczyńska-Świgło, A.; Chmielewski, J. Electronic Nose as a Tool for Monitoring the Authenticity of Food. A Review. Food Anal. Methods 2017, 10, 1800–1816. [Google Scholar] [CrossRef]

- Di Rosa, A.R.; Leone, F.; Cheli, F.; Chiofalo, V. Fusion of electronic nose, electronic tongue and computer vision for animal source food authentication and quality assessment—A review. J. Food Eng. 2017, 210, 62–75. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, M.; Bhandari, B.; Adhikari, B. Application of electronic tongue for fresh foods quality evaluation: A review. Food Rev. Int. 2018, 34, 746–769. [Google Scholar] [CrossRef]

- Tan, J.; Xu, J. Applications of electronic nose (e-nose) and electronic tongue (e-tongue) in food quality-related properties determination: A review. Artif. Intell. Agric. 2019, 4, 104–115. [Google Scholar] [CrossRef]

- Calvini, R.; Pigani, L. Toward the Development of Combined Artificial Sensing Systems for Food Quality Evaluation: A Review on the Application of Data Fusion of Electronic Noses, Electronic Tongues and Electronic Eyes. Sensors 2021, 22, 577. [Google Scholar] [CrossRef]

- Vanaraj, R.; Arumugam, B.; Mayakrishnan, G.; Kim, I.S.; Kim, S.C. A Review on Electrospun Nanofiber Composites for an Efficient Electrochemical Sensor Applications. Sensors 2022, 23, 6705. [Google Scholar] [CrossRef]

- Ramkumar, V.; Kamachiyappan, P.; Manjunath, R.; Balamurugan, S.; Ashokkumar, A.; Ashraf Ali, M.; Kim, S. Simple chalcone-based chemosensor for colorimetric naked-eye detection of Al3+ and Cu2+ ions. Opt. Mater. 2021, 123, 111881. [Google Scholar] [CrossRef]

- Vanaraj, R.; Periyannan, J.; Mayakrishnan, G.; Kim, S.C.; Muniyandi, M. Surface modified and advanced magnetoelastic sensors for biomedical application. Surf. Interfaces 2024, 48, 104247. [Google Scholar] [CrossRef]

- Bai, B.; Zhang, L.; Zhang, Y.; Feng, B.; Bo, T.; Zhang, J.; Fan, S.; Yang, Y. Comparative analysis of flavor characteristics of two rounds of Qingxiangxing Baijiu by GC×GC-TOFMS, HS-GC-IMS, GC-E-nose and E-tongue. Food Biosci. 2024, 63, 105789. [Google Scholar] [CrossRef]

- Bayinbate, B.; Yang, L.; Badar, I.H.; Liu, Y.; Zhang, L.; Hu, Y.; Xu, B. Characterization of flavor profile of beef jerky from different regions of China using gas chromatography–mass spectrometry, electronic tongue, and electronic nose. Food Chem. X 2024, 25, 102245. [Google Scholar] [CrossRef]

- Kh, A.A.; Mi, S.; Tian, H.; Xu, X.; Abdo, A.A.A.; Aleryani, H.; Wang, X. Evaluation of flavor characteristics in Chinese wheat flour paste using electronic-nose, electronic-tongue, and headspace-gas chromatography-ion mobility spectrometry at different fermentation stages. J. Sci. Food Agric. 2025, 105, 2454–2465. [Google Scholar] [CrossRef] [PubMed]

- Gil, M.; Rudy, M.; Stanisławczyk, R. Electronic Sensing Technologies in Food Quality Assessment: A Comprehensive Literature Review. Appl. Sci. 2024, 15, 1530. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, C.; Sun, L.; Li, M.; Zhu, Y.; Deng, W.; Yu, J.; Zhang, W.; Song, Z. Investigating flavor and quality characteristics in Chinese bacon from different regions using integrated GC-IMS, electronic sensory assessment, and sensory analysis. Meat Sci. 2025, 220, 109709. [Google Scholar] [CrossRef]

- Zheng, W.; Yuan, Q.; Zhang, A.; Lei, Y.; Pan, G. Data augmentation of flavor information for electronic nose and electronic tongue: An olfactory-taste synesthesia model combined with multiblock reconstruction method. Expert Syst. Appl. 2025, 272, 126810. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vanaraj, R.; I.P, B.; Mayakrishnan, G.; Kim, I.S.; Kim, S.-C. A Systematic Review of the Applications of Electronic Nose and Electronic Tongue in Food Quality Assessment and Safety. Chemosensors 2025, 13, 161. https://doi.org/10.3390/chemosensors13050161

Vanaraj R, I.P B, Mayakrishnan G, Kim IS, Kim S-C. A Systematic Review of the Applications of Electronic Nose and Electronic Tongue in Food Quality Assessment and Safety. Chemosensors. 2025; 13(5):161. https://doi.org/10.3390/chemosensors13050161

Chicago/Turabian StyleVanaraj, Ramkumar, Bincy I.P, Gopiraman Mayakrishnan, Ick Soo Kim, and Seong-Cheol Kim. 2025. "A Systematic Review of the Applications of Electronic Nose and Electronic Tongue in Food Quality Assessment and Safety" Chemosensors 13, no. 5: 161. https://doi.org/10.3390/chemosensors13050161

APA StyleVanaraj, R., I.P, B., Mayakrishnan, G., Kim, I. S., & Kim, S.-C. (2025). A Systematic Review of the Applications of Electronic Nose and Electronic Tongue in Food Quality Assessment and Safety. Chemosensors, 13(5), 161. https://doi.org/10.3390/chemosensors13050161