Carbon Nanotube-Based Self-Powered Sensors for Autonomous Environmental and Biomedical Monitoring

Abstract

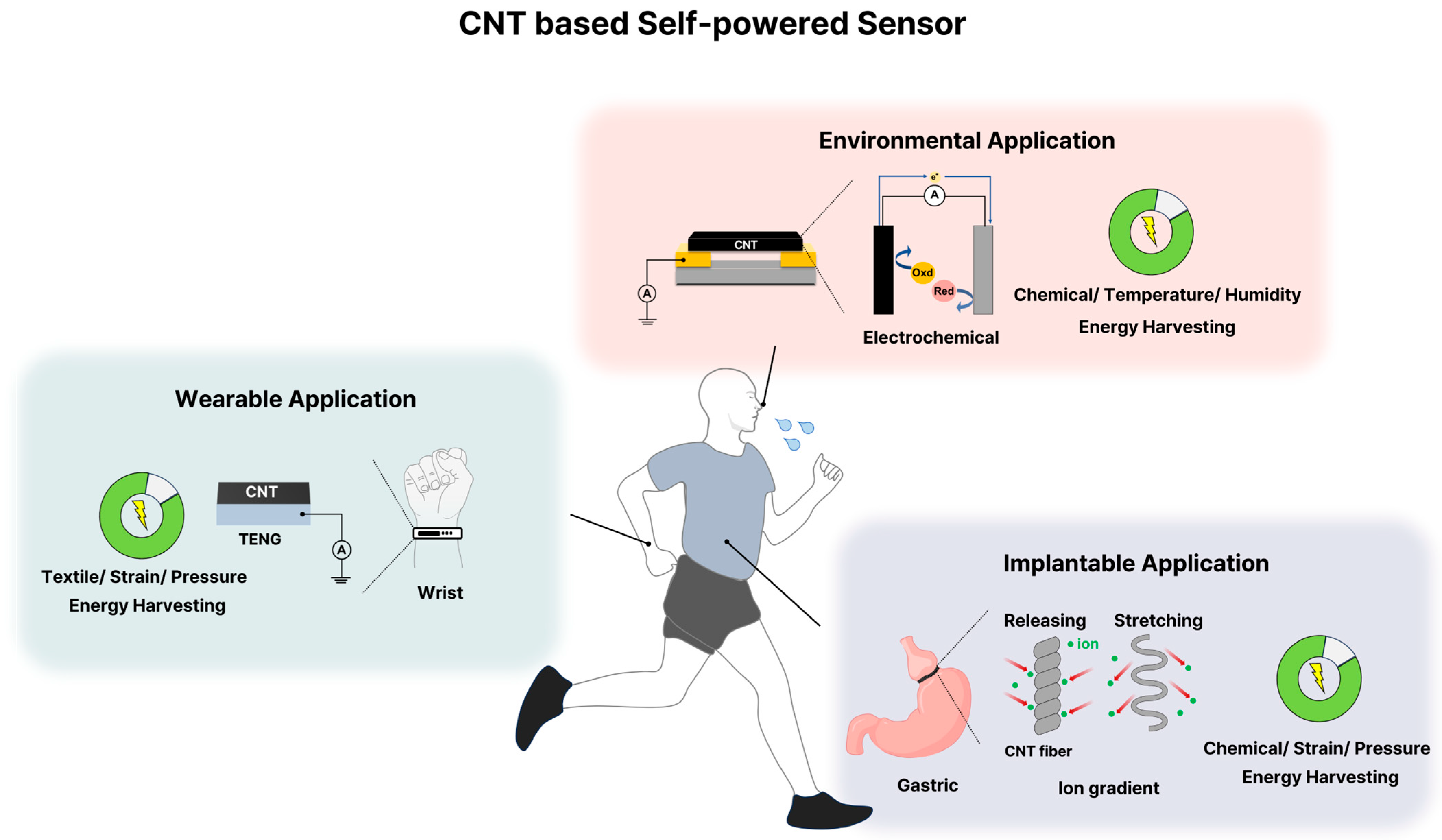

1. Introduction

2. Multifunctional Roles of CNTs in Self-Powered Sensors

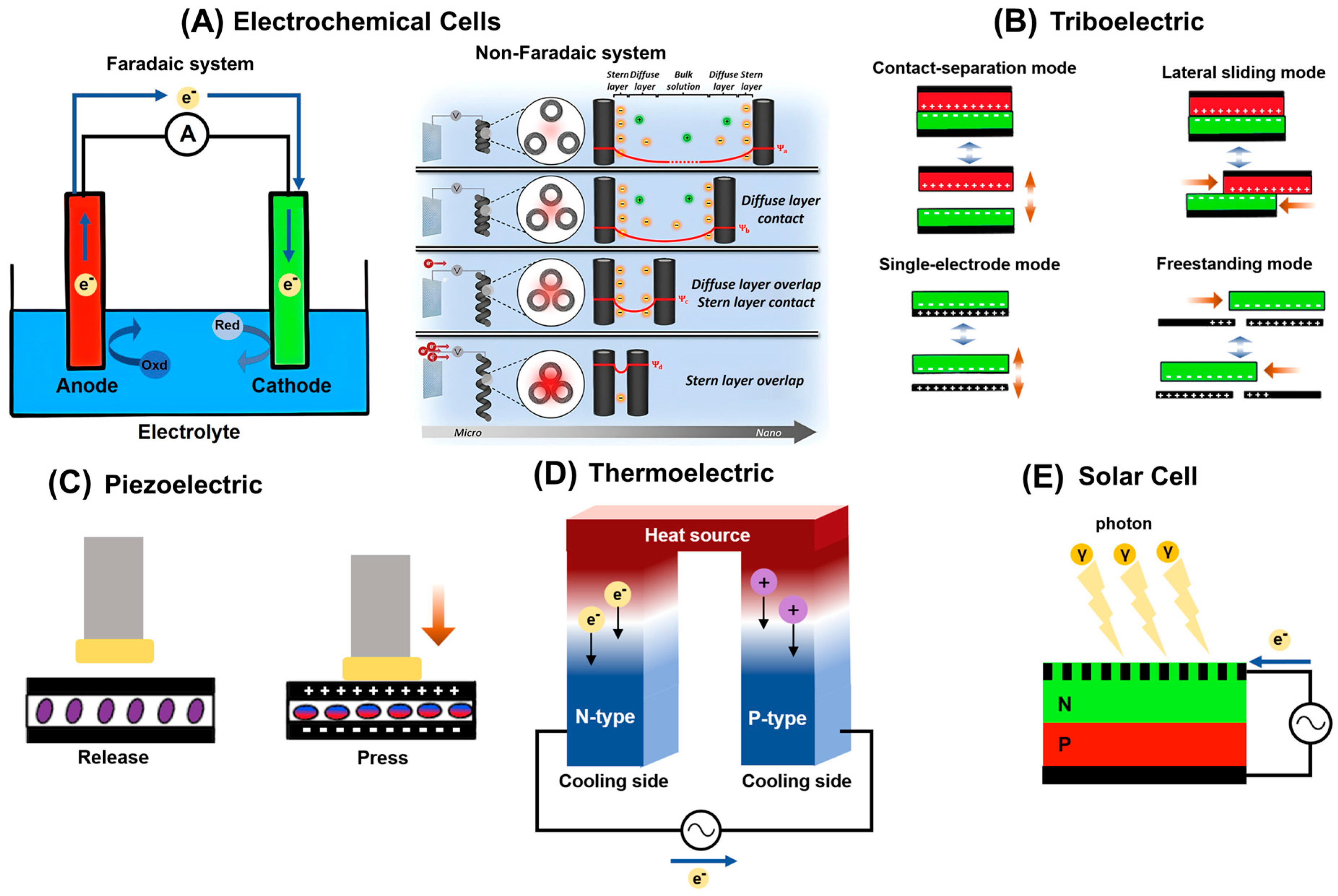

3. Environmental Sensors

3.1. Electrochemical Sensor

3.2. Triboelectric Sensor

3.3. Photoelectric Sensor

3.4. Piezoelectric Sensor

3.5. Thermoelectric Sensor

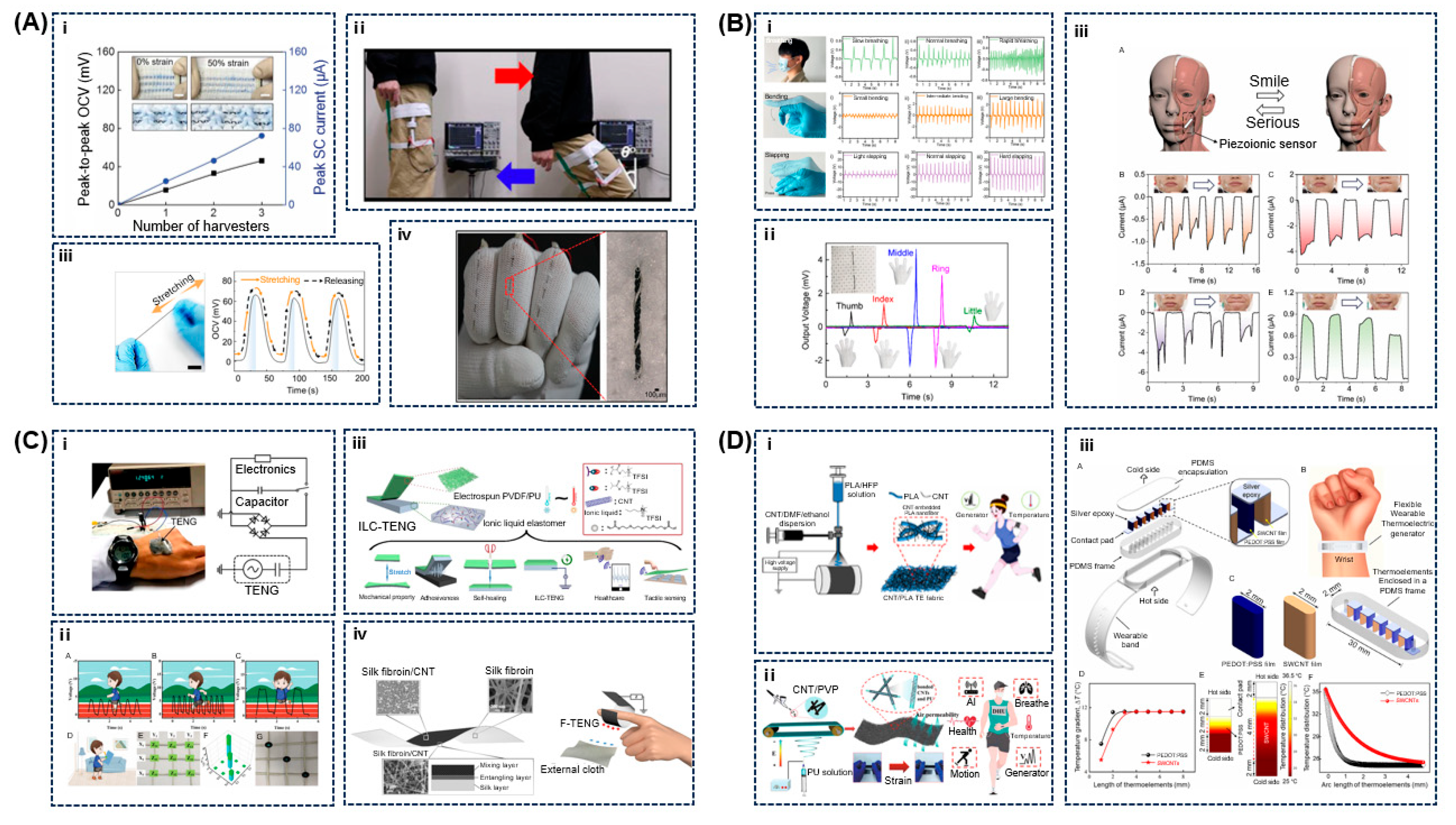

4. Wearable Sensors

4.1. Electrochemical Sensor

4.2. Piezoelectric Sensor

4.3. Triboelectric Sensor

4.4. Thermoelectric Sensor

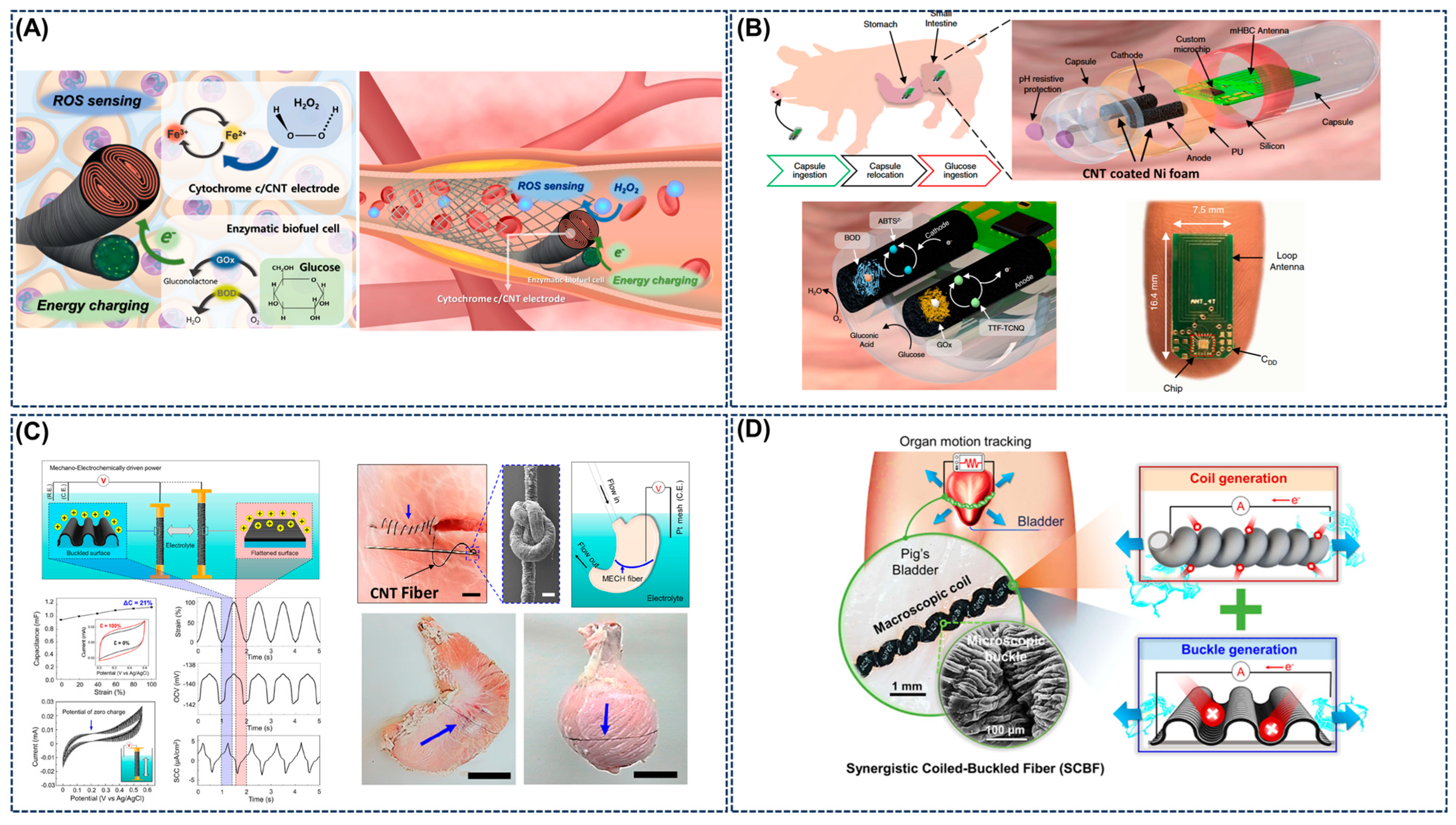

5. Implantable Sensors

5.1. Electrochemical–Redox-Type Biofuel Cell

5.2. Mechanoelectrical

6. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Hu, X.; Bao, X.; Zhang, M.; Fang, S.; Liu, K.; Wang, J.; Liu, R.; Kim, S.H.; Baughman, R.H.; Ding, J. Recent Advances in Carbon Nanotube-Based Energy Harvesting Technologies. Adv. Mater. 2023, 35, 2303035. [Google Scholar] [CrossRef]

- Kim, K.J.; Oh, S.; Kim, Y.; Park, C.-L.; Song, Y.-C.; Lee, H.; Kim, E.S.; Suh, D.; Lim, S.C.; Kim, H.; et al. Understanding Piezoionic Effects in Chemo–Mechanical Energy Harvesting by Carbon Nanotube Yarn Twists. Adv. Energy Mater. 2024, 14, 2303343. [Google Scholar] [CrossRef]

- Guo, H.; Dong, C.; Han, Q.; Jiang, H.; Sun, H.; Sun, X.; Zhang, S.; Peng, H. Advancing Carbon Nanotube Fibers: Addressing Challenges from Production to Application. ACS Cent. Sci. 2025, 11, 855–867. [Google Scholar] [CrossRef] [PubMed]

- Zhou, T.; Yu, Y.; He, B.; Wang, Z.; Xiong, T.; Wang, Z.; Liu, Y.; Xin, J.; Qi, M.; Zhang, H.; et al. Ultra-compact MXene fibers by continuous and controllable synergy of interfacial interactions and thermal drawing-induced stresses. Nat. Commun. 2022, 13, 4564. [Google Scholar] [CrossRef]

- Sehrawat, M.; Rani, M.; Sharma, S.; Bharadwaj, S.; Falzon, B.G.; Singh, B.P. Floating catalyst chemical vapour deposition (FCCVD) for direct spinning of CNT aerogel: A review. Carbon 2024, 219, 118747. [Google Scholar] [CrossRef]

- Marquez, K.P.; Sisican, K.M.D.; Ibabao, R.P.; Malenab, R.A.J.; Judicpa, M.A.N.; Henderson, L.; Zhang, J.; Usman, K.A.S.; Razal, J.M. Understanding the Chemical Degradation of Ti3C2Tx MXene Dispersions: A Chronological Analysis. Small Sci. 2024, 4, 2400150. [Google Scholar] [CrossRef] [PubMed]

- Lee, A.; Shekhirev, M.; Anayee, M.; Gogotsi, Y. Multi-year study of environmental stability of Ti3C2Tx MXene films. Graphene 2D Mater. 2024, 9, 77–85. [Google Scholar] [CrossRef]

- Kotamraju, B.P.; Eggers, T.E.; McCallum, G.A.; Durand, D.M. Selective chronic recording in small nerve fascicles of sciatic nerve with carbon nanotube yarns in rats. J. Neural Eng. 2023, 20, 066041. [Google Scholar] [CrossRef]

- Monthioux, M.; Kuznetsov, V.L. Who should be given the credit for the discovery of carbon nanotubes? Carbon 2006, 44, 1621–1623. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Iijima, S.; Ichihashi, T. Single-shell carbon nanotubes of 1-nm diameter. Nature 1993, 363, 603–605. [Google Scholar] [CrossRef]

- Bethune, D.S.; Kiang, C.H.; de Vries, M.S.; Gorman, G.; Savoy, R.; Vazquez, J.; Beyers, R. Cobalt-catalysed growth of carbon nanotubes with single-atomic-layer walls. Nature 1993, 363, 605–607. [Google Scholar] [CrossRef]

- Thess, A.; Lee, R.; Nikolaev, P.; Dai, H.; Petit, P.; Robert, J.; Xu, C.; Lee, Y.H.; Kim, S.G.; Rinzler, A.G.; et al. Crystalline Ropes of Metallic Carbon Nanotubes. Science 1996, 273, 483–487. [Google Scholar] [CrossRef]

- Nikolaev, P.; Bronikowski, M.J.; Bradley, R.K.; Rohmund, F.; Colbert, D.T.; Smith, K.A.; Smalley, R.E. Gas-phase catalytic growth of single-walled carbon nanotubes from carbon monoxide. Chem. Phys. Lett. 1999, 313, 91–97. [Google Scholar] [CrossRef]

- Hata, K.; Futaba, D.N.; Mizuno, K.; Namai, T.; Yumura, M.; Iijima, S. Water-Assisted Highly Efficient Synthesis of Impurity-Free Single-Walled Carbon Nanotubes. Science 2004, 306, 1362–1364. [Google Scholar] [CrossRef]

- O’Connell, M.J.; Bachilo, S.M.; Huffman, C.B.; Moore, V.C.; Strano, M.S.; Haroz, E.H.; Rialon, K.L.; Boul, P.J.; Noon, W.H.; Kittrell, C.; et al. Band Gap Fluorescence from Individual Single-Walled Carbon Nanotubes. Science 2002, 297, 593–596. [Google Scholar] [CrossRef] [PubMed]

- Arnold, M.S.; Green, A.A.; Hulvat, J.F.; Stupp, S.I.; Hersam, M.C. Sorting carbon nanotubes by electronic structure using density differentiation. Nat. Nanotechnol. 2006, 1, 60–65. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, Z.; Du, X.; Logan, J.M.; Sippel, J.; Nikolou, M.; Kamaras, K.; Reynolds, J.R.; Tanner, D.B.; Hebard, A.F.; et al. Transparent, Conductive Carbon Nanotube Films. Science 2004, 305, 1273–1276. [Google Scholar] [CrossRef]

- Ericson, L.M.; Fan, H.; Peng, H.; Davis, V.A.; Zhou, W.; Sulpizio, J.; Wang, Y.; Booker, R.; Vavro, J.; Guthy, C.; et al. Macroscopic, Neat, Single-Walled Carbon Nanotube Fibers. Science 2004, 305, 1447–1450. [Google Scholar] [CrossRef]

- Hughes, K.J.; Iyer, K.A.; Bird, R.E.; Ivanov, J.; Banerjee, S.; Georges, G.; Zhou, Q.A. Review of Carbon Nanotube Research and Development: Materials and Emerging Applications. ACS Appl. Nano Mater. 2024, 7, 18695–18713. [Google Scholar] [CrossRef]

- Zeng, W.; Shu, L.; Li, Q.; Chen, S.; Wang, F.; Tao, X.-M. Fiber-Based Wearable Electronics: A Review of Materials, Fabrication, Devices, and Applications. Adv. Mater. 2014, 26, 5310–5336. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric Nanogenerators as New Energy Technology for Self-Powered Systems and as Active Mechanical and Chemical Sensors. ACS Nano 2013, 7, 9533–9557. [Google Scholar] [CrossRef]

- Zhang, L.; Shi, X.-L.; Yang, Y.-L.; Chen, Z.-G. Flexible thermoelectric materials and devices: From materials to applications. Mater. Today 2021, 46, 62–108. [Google Scholar] [CrossRef]

- Majdecka, D.; Draminska, S.; Janusek, D.; Krysinski, P.; Bilewicz, R. A self-powered biosensing device with an integrated hybrid biofuel cell for intermittent monitoring of analytes. Biosens. Bioelectron. 2018, 102, 383–388. [Google Scholar] [CrossRef]

- Zhang, M.; Fang, S.; Nie, J.; Fei, P.; Aliev, A.E.; Baughman, R.H.; Xu, M. Self-Powered, Electrochemical Carbon Nanotube Pressure Sensors for Wave Monitoring. Adv. Funct. Mater. 2020, 30, 2004564. [Google Scholar] [CrossRef]

- Sim, H.J.; Lee, D.Y.; Gwac, H.; Lee, S.; Jeon, J.; Kim, S.J.; Kim, Y.-K.; Kim, C.-S.; Kim, Y.-J.; Kwon, S.; et al. Vertically Aligned Carbon Nanotube Mechano-Electrochemical Generator for Ultralow-Frequency Ocean Wave Monitoring. Adv. Sci. 2025, 12, 2503578. [Google Scholar] [CrossRef]

- Chen, K.; Gao, M.; Liu, X.; Xing, H.; Sun, H.; Wang, H.; Lou, A.; Song, X.; Liu, W.; Guo, H. Self-Powered Linear Pressure Sensor Based on MXene/CNT Nanofluid Membrane. Small 2025, 21, 2411706. [Google Scholar] [CrossRef]

- Eryanto, G.; Tseng, S.-F. Self-powered paper-based humidity sensors with MgCl2/CNTs composites. Sens. Actuators A Phys. 2024, 376, 115606. [Google Scholar] [CrossRef]

- Vafaiee, M.; Ejehi, F.; Mohammadpour, R. CNT-PDMS foams as self-powered humidity sensors based on triboelectric nanogenerators driven by finger tapping. Sci. Rep. 2023, 13, 370. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Chang, J.; Zhi, H.; Li, C.; Feng, L. A PDA functionalized CNT/PANI self-powered sensing system for meat spoilage biomarker NH3 monitoring. Sens. Actuators B Chem. 2022, 356, 131292. [Google Scholar] [CrossRef]

- Lan, L.; Xiong, J.; Gao, D.; Li, Y.; Chen, J.; Lv, J.; Ping, J.; Ying, Y.; Lee, P.S. Breathable Nanogenerators for an On-Plant Self-Powered Sustainable Agriculture System. ACS Nano 2021, 15, 5307–5315. [Google Scholar] [CrossRef]

- Guo, S.-Y.; Hu, X.-G.; Hou, P.-X.; Liu, Z.; Zhao, Y.-M.; Li, Y.-G.; Zhang, F.; Liu, C.; Cheng, H.-M. A self-powered flexible gas-sensing system based on single-wall carbon nanotube films. Cell Rep. Phys. Sci. 2022, 3, 101163. [Google Scholar] [CrossRef]

- Bhaduri, A.; Singh, S.; Gupta, M.K. Self-Powered Fluoride Ion Detectors Based on Piezoelectric Nanogenerators with Filler Materials Comprising Mn-Doped BaTiO3 Nanostructures and Carbon Nanotubes. ACS Appl. Nano Mater. 2023, 6, 6637–6652. [Google Scholar] [CrossRef]

- Sharma, M.; Sharma, A.K.; Shukla, S.K. Self-powered potentiometric sensor for chlorpyrifos over nano copper oxide infused chitosan grafted polypyrrole electrode. Inorg. Chem. Commun. 2025, 171, 113530. [Google Scholar] [CrossRef]

- Lv, C.; Zhou, Z.; Li, Y.; Lu, S.; Bai, Y. Multi-responsive shape memory porous composites for self-powered sensors and self-sensing actuators. Chem. Eng. J. 2023, 477, 147059. [Google Scholar] [CrossRef]

- Bai, Y.; Lv, C.; Liao, Y.; Niu, L.; Li, Y.; Wen, D.; Niu, L. Light-responsive shape memory actuators with integrated self-powered sensing function based on polyvinylidene fluoride composites. Eur. Polym. J. 2024, 220, 113458. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, D.; Chen, X.; Zhang, H.; Tang, M.; Wang, J. Multifunctional respiration-driven triboelectric nanogenerator for self-powered detection of formaldehyde in exhaled gas and respiratory behavior. Nano Energy 2022, 102, 107711. [Google Scholar] [CrossRef]

- Xia, S.Y.; Guo, L.Y.; Tao, L.Q.; Long, Y.; Huang, Z.; Wu, J.; Li, J. Self-Powered Paper-Based Pressure Sensor Driven by Triboelectric Nanogenerator for Detecting Dynamic and Static Forces. IEEE Trans. Electron. Devices 2023, 70, 732–738. [Google Scholar] [CrossRef]

- Liu, L.; Li, G.H.; Wang, Y.; Wang, Y.Y.; Li, T.; Zhang, T.; Qin, S.J. A photovoltaic self-powered gas sensor based on a single-walled carbon nanotube/Si heterojunction. Nanoscale 2017, 9, 18579–18583. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Chung, H.Y.; Tsang, D.C.W.; Huang, N.M.; Xie, Z.; Lim, H.N.; Ok, Y.S.; Ng, Y.H. Scavenger-free and self-powered photocathodic sensing system for aqueous hydrogen peroxide monitoring by CuO/ZnO nanostructure. Chem. Eng. Sci. 2020, 226, 115886. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, Z.; Wei, J.; Dai, Z.; Hao, N.; Wang, K. A dual-photoelectrode photofuel cell based self-powered aptasensor using a multimeter as a direct visual readout strategy. Chem. Commun. 2021, 57, 5973–5976. [Google Scholar] [CrossRef]

- Bai, C.; Zhang, J.; Yang, K.; Zhang, Z.; Zhang, H. A vertical stretchable self-powered light sensor based on thermogalvanic gel electrolyte via photo-thermal-electric conversion. Sens. Actuators A Phys. 2023, 354, 114305. [Google Scholar] [CrossRef]

- Wan, K.; Kernin, A.; Ventura, L.; Zeng, C.; Wang, Y.; Liu, Y.; Vilatela, J.J.; Lu, W.; Bilotti, E.; Zhang, H. Toward Self-Powered Sensing and Thermal Energy Harvesting in High-Performance Composites via Self-Folded Carbon Nanotube Honeycomb Structures. ACS Appl. Mater. Interfaces 2023, 15, 44212–44223. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.H.; Haines, C.S.; Li, N.; Kim, K.J.; Mun, T.J.; Choi, C.; Di, J.; Oh, Y.J.; Oviedo, J.P.; Bykova, J.; et al. Harvesting electrical energy from carbon nanotube yarn twist. Science 2017, 357, 773–778. [Google Scholar] [CrossRef] [PubMed]

- Moon, J.H.; Kim, B.J.; Jang, Y.; Mun, T.J.; Kim, H.; Kim, S.J. Self-Powered Inertial Sensor Based on Carbon Nanotube Yarn. IEEE Trans. Ind. Electron. 2021, 68, 8904–8910. [Google Scholar] [CrossRef]

- Sim, H.J.; Gwac, H.; Kim, S.J.; Oh, J.-M.; Choi, C. Soft and elastic hygroelectric fiber for wearable human monitoring textiles. Chem. Eng. J. 2024, 495, 153486. [Google Scholar] [CrossRef]

- Gwac, H.; Jang, Y.; Moon, J.H.; Kim, S.J. Wearable Multi-Plied Potentiometric Sensor based on Carbon Nanotube Yarn for Electronic Tongue. Adv. Mater. Technol. 2024, 9, 2302194. [Google Scholar] [CrossRef]

- Huang, Q.; Jiang, Y.; Duan, Z.; Wu, Y.; Yuan, Z.; Guo, J.; Zhang, M.; Tai, H. Ion gradient induced self-powered flexible strain sensor. Nano Energy 2024, 126, 109689. [Google Scholar] [CrossRef]

- Huang, Q.; Jiang, Y.; Duan, Z.; Wu, Y.; Yuan, Z.; Zhang, M.; Zhao, Q.; Zhang, Y.; Liu, B.; Tai, H. Electrochemical self-powered strain sensor for static and dynamic strain detections. Nano Energy 2023, 118, 108997. [Google Scholar] [CrossRef]

- Su, C.; Huang, X.; Zhang, L.; Zhang, Y.; Yu, Z.; Chen, C.; Ye, Y.; Guo, S. Robust superhydrophobic wearable piezoelectric nanogenerators for self-powered body motion sensors. Nano Energy 2023, 107, 108095. [Google Scholar] [CrossRef]

- Li, M.; Qiao, J.; Zhu, C.; Hu, Y.; Wu, K.; Zeng, S.; Yang, W.; Zhang, H.; Wang, Y.; Wu, Y.; et al. Gel-Electrolyte-Coated Carbon Nanotube Yarns for Self-Powered and Knittable Piezoionic Sensors. ACS Appl. Electron. Mater. 2021, 3, 944–954. [Google Scholar] [CrossRef]

- Wang, W.; Xu, L.; Zhang, L.; Zhang, A.; Zhang, J. Self-Powered Integrated Sensing System with In-Plane Micro-Supercapacitors for Wearable Electronics. Small 2023, 19, e2207723. [Google Scholar] [CrossRef]

- Chen, Y.; Pu, X.; Liu, M.; Kuang, S.; Zhang, P.; Hua, Q.; Cong, Z.; Guo, W.; Hu, W.; Wang, Z.L. Shape-Adaptive, Self-Healable Triboelectric Nanogenerator with Enhanced Performances by Soft Solid–Solid Contact Electrification. ACS Nano 2019, 13, 8936–8945. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Zhu, W.; Lu, X.; Wang, C. Mechanically robust, stretchable, autonomously adhesive, and environmentally tolerant triboelectric electronic skin for self-powered healthcare monitoring and tactile sensing. Nano Energy 2022, 102, 107636. [Google Scholar] [CrossRef]

- Wu, J.; Zhou, X.; Luo, J.; Zhou, J.; Lu, Z.; Bai, Z.; Fan, Y.; Chen, X.; Zheng, B.; Wang, Z.; et al. Stretchable and Self-Powered Mechanoluminescent Triboelectric Nanogenerator Fibers toward Wearable Amphibious Electro-Optical Sensor Textiles. Adv. Sci. 2024, 11, 2401109. [Google Scholar] [CrossRef]

- Su, M.; Kim, B. Silk Fibroin-Carbon Nanotube Composites based Fiber Substrated Wearable Triboelectric Nanogenerator. ACS Appl. Nano Mater. 2020, 3, 9759–9770. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, M.; Kong, J.; Li, H.; He, C. Flexible, durable, green thermoelectric composite fabrics for textile-based wearable energy harvesting and self-powered sensing. Compos. Sci. Technol. 2023, 243, 110245. [Google Scholar] [CrossRef]

- Hasan, M.N.; Ahmad Asri, M.I.; Saleh, T.; Muthalif, A.G.A.; Mohamed Ali, M.S. Wearable thermoelectric generator with vertically aligned PEDOT:PSS and carbon nanotubes thermoelements for energy harvesting. Int. J. Energy Res. 2022, 46, 15824–15836. [Google Scholar] [CrossRef]

- He, X.; Shi, J.; Hao, Y.; He, M.; Cai, J.; Qin, X.; Wang, L.; Yu, J. Highly stretchable, durable, and breathable thermoelectric fabrics for human body energy harvesting and sensing. Carbon Energy 2022, 4, 621–632. [Google Scholar] [CrossRef]

- Li, H.; Zhang, W.; Ding, Q.; Jin, X.; Ke, Q.; Li, Z.; Wang, D.; Huang, C. Facile Strategy for Fabrication of Flexible, Breathable, and Washable Piezoelectric Sensors via Welding of Nanofibers with Multiwalled Carbon Nanotubes (MWCNTs). ACS Appl. Mater. Interfaces 2019, 11, 38023–38030. [Google Scholar] [CrossRef]

- Mahanty, B.; Ghosh, S.K.; Maity, K.; Roy, K.; Sarkar, S.; Mandal, D. All-fiber pyro- and piezo-electric nanogenerator for IoT based self-powered health-care monitoring. Mater. Adv. 2021, 2, 4370–4379. [Google Scholar] [CrossRef]

- Li, J.; Yin, J.; Wee, M.G.V.; Chinnappan, A.; Ramakrishna, S. A Self-Powered Piezoelectric Nanofibrous Membrane as Wearable Tactile Sensor for Human Body Motion Monitoring and Recognition. Adv. Fiber Mater. 2023, 5, 1417–1430. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, X.; Lu, C. Skin-Inspired and Self-Powered Piezoionic Sensors for Smart Wearable Applications. Small 2025, 21, 2410594. [Google Scholar] [CrossRef] [PubMed]

- Matsunaga, M.; Hirotani, J.; Kishimoto, S.; Ohno, Y. High-output, transparent, stretchable triboelectric nanogenerator based on carbon nanotube thin film toward wearable energy harvesters. Nano Energy 2020, 67, 104297. [Google Scholar] [CrossRef]

- Wang, N.; Zhang, L.; Liu, J.; Li, C. An integrally underwater self-healable droplet-based triboelectric nanogenerator. J. Mater. Chem. A 2022, 10, 20509–20516. [Google Scholar] [CrossRef]

- Sim, H.J.; Choi, C.; Kim, S.H.; Kim, K.M.; Lee, C.J.; Kim, Y.T.; Lepró, X.; Baughman, R.H.; Kim, S.J. Stretchable Triboelectric Fiber for Self-powered Kinematic Sensing Textile. Sci. Rep. 2016, 6, 35153. [Google Scholar] [CrossRef] [PubMed]

- Cui, Y.; He, X.; Liu, W.; Zhu, S.; Zhou, M.; Wang, Q. Highly Stretchable, Sensitive, and Multifunctional Thermoelectric Fabric for Synergistic-Sensing Systems of Human Signal Monitoring. Adv. Fiber Mater. 2024, 6, 170–180. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, C.; Chen, Y.; Wang, L.; Huang, X.; Zeng, L.; Lv, W. Self-powered PEDOT: PSS/CSWCNT/Mxenes thermoelectric films and wearable electronics devices. Surf. Interfaces 2024, 50, 104526. [Google Scholar] [CrossRef]

- Gao, F.-L.; Min, P.; Gao, X.-Z.; Li, C.; Zhang, T.; Yu, Z.-Z.; Li, X. Integrated temperature and pressure dual-mode sensors based on elastic PDMS foams decorated with thermoelectric PEDOT:PSS and carbon nanotubes for human energy harvesting and electronic-skin. J. Mater. Chem. A 2022, 10, 18256–18266. [Google Scholar] [CrossRef]

- Zhang, J.L.; Wang, Y.H.; Huang, K.; Huang, K.J.; Jiang, H.; Wang, X.M. Enzyme-based biofuel cells for biosensors and in vivo power supply. Nano Energy 2021, 84, 105853. [Google Scholar] [CrossRef]

- Cooney, M.J.; Svoboda, V.; Lau, C.; Martin, G.; Minteer, S.D. Enzyme catalysed biofuel cells. Energy Environ. Sci. 2008, 1, 320–337. [Google Scholar] [CrossRef]

- Zhu, Y.; Sun, S.; Yin, X.; Liu, Y.; Yang, W.; Chen, Y. Carbon Nanotube-Gold Nanoparticle-Based Self-Powered Electrochemical Biosensors for Highly Sensitive and Stable Detection of Myoglobin. ACS Appl. Nano Mater. 2023, 6, 11085–11094. [Google Scholar] [CrossRef]

- Zhao, M.; Wang, L.; Xu, H. Immobilization of gold nanoparticles on electrospun polyacrylonitrile/carbon nanotube nanofiber for self-powered electrochemical biosensing of myoglobin. Mater. Chem. Phys. 2025, 339, 130722. [Google Scholar] [CrossRef]

- Park, T.; Lee, D.Y.; Jo, J.K.; Kim, S.J.; Jang, Y. Dual-functional carbon nanotube yarn supercapacitor for real-time reactive oxygen species monitoring and sustainable energy supply in implantable device. J. Power Sources 2024, 624, 235540. [Google Scholar] [CrossRef]

- De la Paz, E.; Maganti, N.H.; Trifonov, A.; Jeerapan, I.; Mahato, K.; Yin, L.; Sonsa-ard, T.; Ma, N.; Jung, W.; Burns, R.; et al. A self-powered ingestible wireless biosensing system for real-time in situ monitoring of gastrointestinal tract metabolites. Nat. Commun. 2022, 13, 7405. [Google Scholar] [CrossRef]

- Sim, H.J.; Choi, C. Microbuckled Mechano-electrochemical Harvesting Fiber for Self-Powered Organ Motion Sensors. Nano Lett. 2022, 22, 8695–8703. [Google Scholar] [CrossRef]

- Sim, H.J.; Kim, J.; Son, W.; Lee, J.M.; Lee, D.Y.; Kim, Y.-J.; Kim, Y.-K.; Kim, S.J.; Oh, J.-M.; Choi, C. Synergistic effect of microscopic buckle and macroscopic coil for self-powered organ motion sensor. Nano Energy 2024, 128, 109889. [Google Scholar] [CrossRef]

- Lee, J.; Ko, S.; Kwon, C.H.; Lima, M.D.; Baughman, R.H.; Kim, S.J. Carbon Nanotube Yarn-Based Glucose Sensing Artificial Muscle. Small 2016, 12, 2085–2091. [Google Scholar] [CrossRef]

- Jang, Y.; Kim, S.M.; Kim, K.J.; Sim, H.J.; Kim, B.-J.; Park, J.W.; Baughman, R.H.; Ruhparwar, A.; Kim, S.J. Self-Powered Coiled Carbon-Nanotube Yarn Sensor for Gastric Electronics. ACS Sens. 2019, 4, 2893–2899. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Zulkifli, M.Y.B.; Chai, M.; Lin, R.; Wang, J.; Chen, Y.; Chen, V.; Hou, J. Recent advances in enzymatic biofuel cells enabled by innovative materials and techniques. Exploration 2023, 3, 20220145. [Google Scholar] [CrossRef]

- Fredj, Z.; Rong, G.; Sawan, M. Recent Advances in Enzymatic Biofuel Cells to Power Up Wearable and Implantable Biosensors. Biosensors 2025, 15, 218. [Google Scholar] [CrossRef] [PubMed]

| Working Principle | Sensor Type | Active Materials | Total Power | Limit of Detection | Application | References |

|---|---|---|---|---|---|---|

| Electrochemical | Pressure | CNT sheet | OCV: 2.4 mV Power Density: 1.28 mW/m2 | 10 Pa | Ocean wave monitoring | [25] |

| Pressure | VACNT forest + Silicone rubber composite | OCV: 350 mV Power Density: 6 W/m2 | 0.01 Hz | Ocean wave monitoring | [26] | |

| Humidity | MgCl2 | OCV: 1.07 V Power: 1.984 μW | N/A | Humidity monitoring | [28] | |

| Triboelectric | Bio | CuO + Chitosan + PPy | N/A | 0.75 μM | Pesticide monitoring | [34] |

| Pressure | PVA | OCV: 26.5 V Power Density: 4.57 W/m2 | 0.2 kPa | Human motion monitoring | [35] | |

| Pressure | PVDF | OCV: 0.127 V/Pa | 5 kPa | Pressure monitoring | [36] | |

| Humidity | PDMS | OCV: 35 V | N/A | Humidity monitoring | [29] | |

| Gas | PDA-PANI | OCV: 30 V | 38 ppb | Meat spoilage detection | [30] | |

| Gas | MXene (Ti3C2Tx) | OCV: 136 V Power: 27 μW | 10 ppb | Respiratory monitoring | [37] | |

| Pressure | rGO + PI + Copper | OCV: 250 V Power Density: 700 mW/cm2 | 5 kPa | Pressure monitoring | [38] | |

| Pressure | PVDF-HFP | Power Density: 330.6 μW/cm2 | N/A | Plant health monitoring | [31] | |

| Photoelectric | Gas | n-type silicon | OCV: 181 mV | 100 ppb | Gas monitoring | [39] |

| Gas | n-type silicon | OCV: 0.5 V | 1 ppm | Gas monitoring | [32] | |

| Chemical | CuO/ZnO nanostructure | Current Density: 0.18 mA/cm2 | 8 μM | H2O2 monitoring | [40] | |

| Chemical | B-TiO2 photoanode + Cu2O/3DNG photocathode | OCV: 0.664 V Power Density: 10.77 mW/cm2 | 0.33 pg/ml | On-site SMZ monitoring | [41] | |

| Piezoelectric | Chemical | Mn-doped BaTiO3 | OCV: 43.6 V | 1.18 μM | Fluoride detection in water | [33] |

| Thermoelectric | Physical | honeycomb structures | OCV: 21 mV | N/A | Healthcare | [43] |

| Working Principle | Sensor Type | Active Materials | Total Power | Limit of Detection | Application | References |

|---|---|---|---|---|---|---|

| Electrochemical | Fiber | CNT | OCV: 50 mV | 30 mM | Electronic tongue | [47] |

| Fiber/Strain | CNT | OCV: 1.46 mV | 1.9 m/s2 | Inertial sensor | [45] | |

| Fiber/Humidity | CNT | 2.5 mW/m2 | RH 90% | Respiration monitoring | [46] | |

| Fiber/Strain | CNT | 250 W/kg | 30% | Strain monitoring | [44] | |

| Piezoelectric | Film | PVDF/MWCNT | 34 μW/cm2 | 7.5 V/kPa | Healthcare monitoring | [61] |

| Film | PVDF-HFP/MWCNT | 0.62 V | 15 N | Electric skin | [60] | |

| Film | PVT/PFE/CNT | 65 V | RH 90% | Human behavior monitoring | [50] | |

| Film | PVDF/BTO/CNT | - | 5 bar | Human behavior monitoring | [62] | |

| Strain | CNT | 0.47 mW/g | 30% | Human behavior monitoring | [51] | |

| Film/strain | MXene/CNT | 9.56 μW/cm2 | 100% | Human behavior monitoring | [52] | |

| Film | Graphene/CNT | 0.62 μA | 7 mm | Human behavior monitoring | [63] | |

| Triboelectric | Film/strain | PDMS/CNT | 10 mW | 35% | Glove sensor | [64] |

| Film | PDMS/CNT | 410 mW/m2 | 2 Hz | Human behavior monitoring | [53] | |

| Film/strain | PVDF/PU/CNT | 2.444 mW/m2 | 100% | Healthcare monitoring | [54] | |

| Fiber/Strain | PVDF/CNT | 24 mV | 50% | Human behavior monitoring | [66] | |

| Fiber/strain | ZnS:Cu/CNT | 28 V | 200% | Human behavior monitoring | [55] | |

| Film | Silk/CNT | 317.4 μW/cm2 | N/A | Human behavior monitoring | [56] | |

| Thermoelectric | Textile | PEDOT/CNT | 227.1 nW/mK2 | 13.8 μV/K | Human behavior monitoring | [67] |

| Film | PEDOT:PSS/CSWCNT | 79.23 μW/mK2 | 21.69 μV/K | Human behavior monitoring | [68] | |

| Foam | PEDOT:PSS/PDA/CNT | N/A | 40.5 mV/K | Electric skin | [69] | |

| Film | PEDOT:PSS/SWCNT | 0.15 μW/cm2°C | 11.24 °C | Wrist band | [58] | |

| Film/strain | PVP/CNT | 586 pW | 51 μV/K | Human behavior monitoring | [59] | |

| Fabric | PLA/CNT | 37.3 nW/cm2 | 62.9 μV/K | Human behavior monitoring | [57] |

| Working Principle | Sensor Type | Active Materials | Total Power | Limit of Detection | Application | References |

|---|---|---|---|---|---|---|

| Electrochemical (Biofuel cell) | Aptamer-based Mb sensor (Bio) | CNT–AuNP, GOx, aptamer | OCV drop (sensitivity 23.0 mV/decade) | 0.011 ng/mL Mb | Implantable myoglobin detection | [72] |

| Aptamer-based Mb sensor (Bio) | Carboxylated CNT-AuNP electrospun nanofiber | OCV drop, Power ~19 μW/cm2 | 0.23 ng/mL Mb | Implantable myoglobin sensing | [73] | |

| ROS sensor + supercapacitor (Bio) | CNT yarn, Cytochrome c | OCV 0.42 V, supercapacitor retained 96.45% | 49.02 μA μM−1 cm−2 (sensitivity) | ROS monitoring, smart stent | [74] | |

| Glucose biosensor (Bio) | CNT-coated Ni foam, GOx | OCV 0.57 V | LOD 4.656 mM, range 3–90 mM | In vivo glucose monitoring (porcine model) | [75] | |

| Mechano-electrochemical | Glucose-responsive actuator | MWNT yarn, HA-cholesterol-boronic acid nanogel | N/A | 5–100 mM glucose | Implantable glucose sensing via actuator motion | [78] |

| Strain/volume sensor (Twistron) | Coiled CNT yarn | OCV ~37 mV at 30% strain | 10–30% strain, ~3–12 mL volume | Gastric motility monitoring | [79] | |

| Strain/pressure sensor | Microbuckled CNT yarn + elastomer | OCV ~20 mV, SCC ~1.5 μA | ~60 kPa, 40–60 mL volume | Bladder and cardiac motion sensing | [76] | |

| Organ motion sensor | MWNT-coated elastomeric SCBF | OCV ~15 mV, 121 A/kg, 16 W/kg | 0.12 mV/% strain, 0.78 μA/kg/% strain | Implantable organ pressure and volume sensing | [77] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.; Noh, Y.; Kim, H.; Jang, Y. Carbon Nanotube-Based Self-Powered Sensors for Autonomous Environmental and Biomedical Monitoring. Chemosensors 2025, 13, 388. https://doi.org/10.3390/chemosensors13110388

Kim M, Noh Y, Kim H, Jang Y. Carbon Nanotube-Based Self-Powered Sensors for Autonomous Environmental and Biomedical Monitoring. Chemosensors. 2025; 13(11):388. https://doi.org/10.3390/chemosensors13110388

Chicago/Turabian StyleKim, Minwoo, Younghun Noh, Hyunsoo Kim, and Yongwoo Jang. 2025. "Carbon Nanotube-Based Self-Powered Sensors for Autonomous Environmental and Biomedical Monitoring" Chemosensors 13, no. 11: 388. https://doi.org/10.3390/chemosensors13110388

APA StyleKim, M., Noh, Y., Kim, H., & Jang, Y. (2025). Carbon Nanotube-Based Self-Powered Sensors for Autonomous Environmental and Biomedical Monitoring. Chemosensors, 13(11), 388. https://doi.org/10.3390/chemosensors13110388