1. Introduction

The human body must break down proteins, which are ingested through food. Proteins break down into amino acids, leaving behind ammonia and carbon dioxide as byproducts. Among the two byproducts, ammonia is toxic and must be eliminated from the body. Several enzymes produced by the liver convert ammonia into urea through chemical reactions, which are then excreted from the body through urine by the kidneys. The urea produced can be described as a product of protein metabolism. In the body, the liver is responsible for the production of urea to exclude toxic ammonia and the kidney is responsible for its removal. For this reason, unstable levels of urea in the body can cause significant damage to these vital organs. The failure of the liver to convert ammonia into urea may cause toxic ammonia to accumulate in the body and severely affect the nervous system. There is a physiological range of urea concentrations in blood between 3.3–6.7 mM, and levels greater than 30 mM indicate abnormal kidney/renal function, which frequently leads to dialysis [

1]. It is also possible to suffer from serious health problems if your blood urea level declines. It is therefore essential that the kidney and liver function properly in the human body to perform their roles of detecting urea in blood and urine, both to maintain normal urea concentrations and prevent abnormal concentrations of urea in the blood.

Relevant literature reports on a variety of biosensors that can detect urea. It has been reported that these biosensors function using different methodologies, such as chromatographic [

2], chemiluminometric [

3], spectrophotometry [

4], colorimetric [

5], fluorometry [

6], conductimetry [

7], amperometry [

8], and potentiometry [

9]. Conventional methods are labor-intensive, costly, require highly trained personnel to analyze samples, and in the presence of electromagnetic interference, the data obtained by the electrochemical sensors may be erroneous. There are several drawbacks associated with these methods of urea detection that must be overcome and a fast, highly sensitive, and selective urea sensor is needed. Biosensors with suitable combinations of biorecognition elements and transducer mechanisms are needed to overcome the problems associated with detecting urea in biological fluids. Biosensors utilize a combination of biorecognition elements and transducers to detect bio/chemical entities, where these two elements are spatially connected [

10]. Transducer surfaces are immobilized with biorecognition elements such as enzymes, antibodies, DNA/RNA, cells, etc., and can interact with analytes of interest without additional reagents. The interaction between the biorecognition element and the incoming analyte causes physicochemical changes to occur over the transducer surface, which converts these changes into detectable signals. Furthermore, these signals are analyzed to determine the targeted analyte. Due to their high specificity, stability, reusability, accuracy, reproducibility, and cost-effectiveness, enzymes have demonstrated their potential as biorecognition elements and usefulness for detecting a wide range of analytes.

Over the past few decades, enzyme-based biosensors have been extensively studied and developed [

10]. For an efficient sensing application, a wide selection of transducer mechanisms is also important, and thus surface plasmon resonance (SPR) has gained significant recognition in chemical/biosensing [

11,

12,

13]. Sensors based on SPR provide rapid and sensitive detection of a wide variety of analytes, are impervious to electromagnetic interference, and can be used for remote monitoring and online analysis. For the realization of SPR, Kretschmann configurations are the most popular. A high-index prism whose base is coated with a thin metal layer is kept in contact with a dielectric medium (sensing medium). The metal/dielectric interface generates surface plasmons (charge density oscillations) at a certain angle when light impinges on the prism base. For sensor design to be more feasible and easier to use, the high-index prism is eventually replaced by optical fiber. Fiber optic sensors offer high sensitivity, miniaturization, compact size, lightweight sensor probes, low cost, and online monitoring capabilities. SPR is realized using optical fiber and the wavelength interrogation method. An unclad portion of the fiber is coated with a thin metal film that is in contact with a dielectric sensor. By guiding light energy into the core of the fiber, surface plasmons are generated at the metal-dielectric interface. SPR can only be achieved if the wave vector of surface plasmons matches the evanescent wave vector (exponentially decaying field of electromagnetic energy at the fiber core/metal region due to total internal reflection). During resonance, light energy is transferred to the metal layer to support the generation of surface plasmons, resulting in a sharp decline in transmission spectra. There is a decline at a particular wavelength known as a resonance wavelength. Any change in the dielectric property (refractive index) of the sensing layer will alter this resonance wavelength. In addition to changing the dielectric constant of the sensing layer, the interaction between the sensing layer and the analyte of interest can also change the resonance condition or wavelength. Sensors respond to analytes of interest by changing their resonance wavelength, which is observed as a shift in transmitted light spectrums [

14,

15,

16,

17,

18,

19,

20,

21].

It is also challenging to maintain an enzyme’s structural stability (native conformation) during any biochemical reaction, due to the importance of enzymes as biorecognition elements due to their catalytic properties. The immobilization of enzymes in biosensors can reduce these limitations by improving their functional efficiency and reproducibility [

22]. The immobilization of enzymes can be accomplished by entrapping them in membranes, physically adsorbing them, entrapping them in a matrix, and covalently attaching them to transducer elements. In one way or another, all these methods connect the biorecognition elements to the sensing layer (transducer layer). When enzymes are immobilized, they can tolerate temperature changes and pH variations that may slow their reaction rate. In comparison to other methods of enzyme immobilization, gel entrapment is quite useful since it prevents enzyme leakage and allows substrate and product-free movement.

Using optical fiber as a sensor platform, we fabricate and characterize a sensitive and selective urea biosensor based on the surface plasmon resonance phenomenon. Thermal evaporation is used to coat the plasmonic material Ag followed by ITO on the unclad fiber core of the sensing region. Afterward, the enzyme-entrapped gel layer is deposited over the plasmonic material using a dip coating method. Coating the Ag with ITO protects the sensor from oxidation and renders it more sensitive [

23,

24,

25,

26,

27,

28]. Several experiments are conducted to optimize the sensing layer, in which all possible parameters affecting its performance are carefully considered. Using scanning electron microscopy, the morphological studies of the prepared sensing layer are confirmed. Using sample solutions prepared in buffer solutions with varying urea concentrations, the sensor probe is characterized. A range of physicochemical concentrations of urea are covered by the sample solutions, and SPR spectra are recorded at each concentration. In addition to its simplicity of design, miniaturized sensor probe, lower sample volume requirement, compactness, and remote sensing capability, the proposed sensor offers several advantages.

2. Materials and Methods

2.1. Materials

We prepared a phosphate buffer solution of 0.1 M and a pH level of 7 using sodium dihydrogen phosphate dihydrate (NaH2PO4·2H2O) and sodium hydrogen phosphate dihydrate (Na2HPO4·2H2O) from Merck (Bengaluru, India). Water was purchased from Millipore® systems to prepare the buffer and gel. To measure the pH level of a buffer, a commercial pH analyzer (Elico L1 614) was used. Sodium hydroxide and glacial acetic acid were purchased from Fisher Scientific. The following were available from Sisco Research Laboratories Pvt. Ltd. (Mumbai, India): acrylamide-bisacrylamide premix powder, ammonium persulfate, and N-tetramethyl ethylenediamine. The enzyme urease was purchased from Sigma Aldrich Ltd., and plastic-clad silica (PCS) optical fiber of 0.37 numerical aperture (NA) and 600 µm core diameter was obtained from Fiberguide Industries. The crosslinking reagent was acrylamide-bisacrylamide (AM-BIS) while the catalyst was Tetramethyl ethylenediamine (TEMED) and the initiator is Ammonium persulfate (APS). These chemicals were used without any further purification in the experiments. Wire made of silver (Ag) (99.99% pure) was obtained from a local vendor. Silver is used to realize SPR and hence a 40 nm thick silver layer over the unclad core of the fiber is deposited using the thermal evaporation method.

2.2. Sensor Probe Fabrication

Plastic-clad silica fiber was used to fabricate an optical sensor probe with a numerical aperture of 0.37 and a core diameter of 600 m. A 1 cm length of the fiber’s cladding was removed from its center portion, exposing the core to the environment. We carefully removed the cladding with a stainless-steel blade. Afterward, the unclad core was cleaned twice with deionized water and acetone, bombarded with plasma ions at 2.5 × 10−2 bar pressure in a vacuum chamber for 3 to 5 min, and coated with silver and ITO. Using a thermal evaporation system and a vacuum chamber pressure of 5 × 10−6 mbar, a thin layer of Ag and ITO was formed.

Several experiments were performed to determine the thickness of Ag and ITO to generate plasmon waves when the evanescent field penetrated these layers. Thermal evaporation coating systems also contain a continuous flow of water for cooling purposes to prevent overheating. An accurate 0.1 nm quartz crystal microbalance (QCM) digital thickness monitor was used to measure the thickness of coated materials. The thin film’s deposition rate was set to 0.04 nm/s to achieve a uniform coating.

The Ag and ITO-coated portion of the fiber was then further immobilized with urease using gel entrapment. Throughout the gel, the bio-recognition element is encapsulated by a porous matrix for the purpose of transducing and analyzing the interaction between the biorecognition layer and the analyte. To facilitate enzyme immobilization, a 0.1 M phosphate buffer with a pH level of 7 was prepared using deionized water. The urease enzyme was dissolved in 0.1 M buffer and 30% AM-BIS (30:1) to prepare the gel for immobilization. Furthermore, 10% APS and catalyst TEMED were added to the buffer solution to dissolve the urease enzyme. As soon as the catalyst TEMED was added to the solution, polymerization began. The process of polymerizing requires almost 15 min, so that the enzyme gets trapped in the gel and prevented from being released. After polymerization, the Ag/ITO-coated sensor probe was washed and dipped into the enzyme-entrapped gel for another 15 min. The probe was then removed from the gel solution, washed with buffer again, and allowed to dry for a few minutes before being characterized with different concentrations of the urea analyte. A refrigerator was used to store probes when they were not in use.

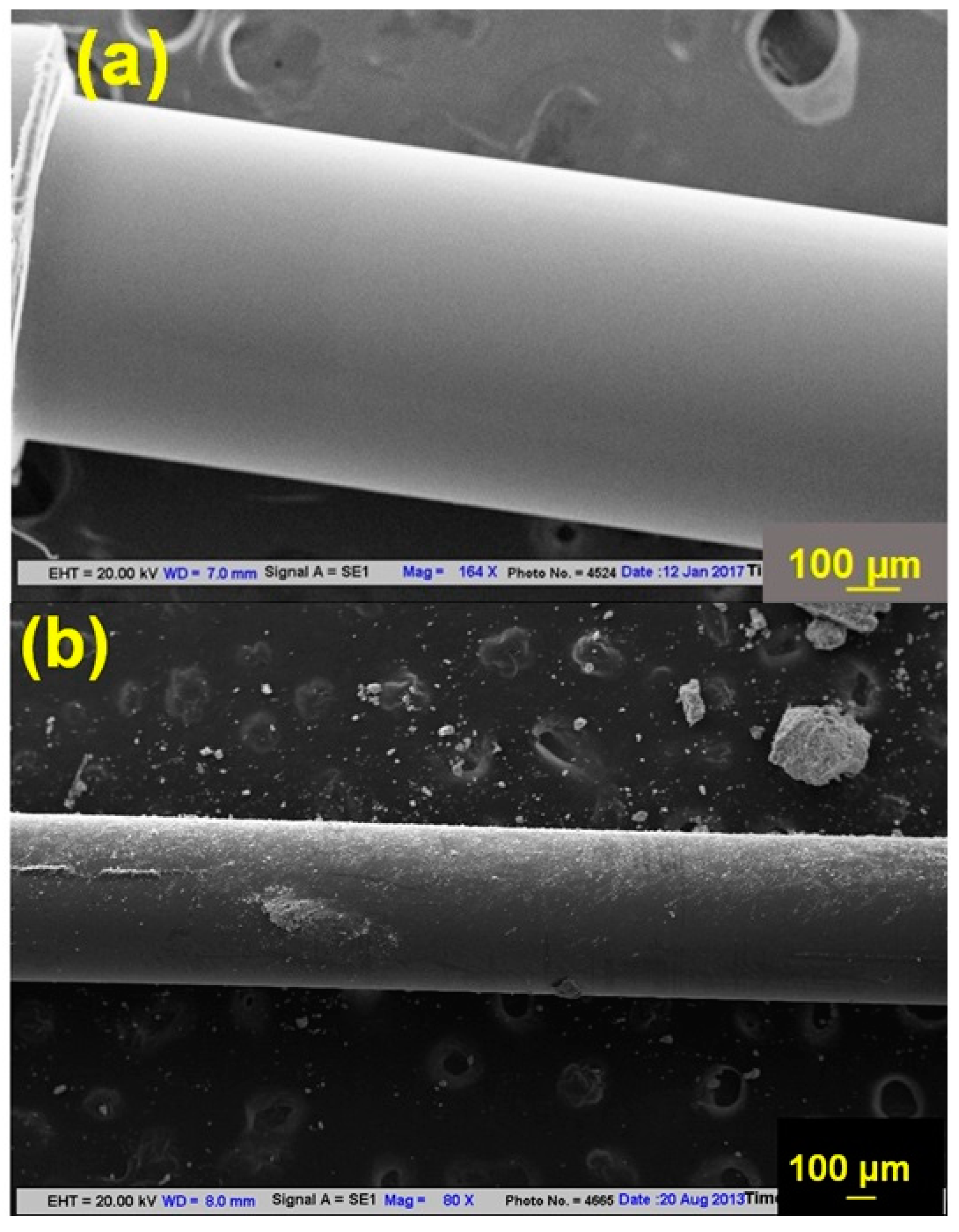

For morphological analysis,

Figure 1 shows SEM images of Ag-coated probes and Ag/ITO-coated probes with enzyme-entrapped gel layers. By encapsulating an enzyme-entrapped gel layer over an Ag/ITO-coated fiber core, a significant interaction area is created for incoming analytes, increasing the sensor’s sensitivity.

2.3. Sample Preparation

All sample solutions of urea (0–160 mM), were prepared in the 0.1 M and pH 7 buffer via repeated dilution method. The refractive indices of all sample solutions were measured using Abbe’s refractometer, having a measurement accuracy of 0.001 in white light, and these indices were found to be the same as for the buffer in terms of the measurement accuracy of the refractometer.

2.4. Experimental Set-Up

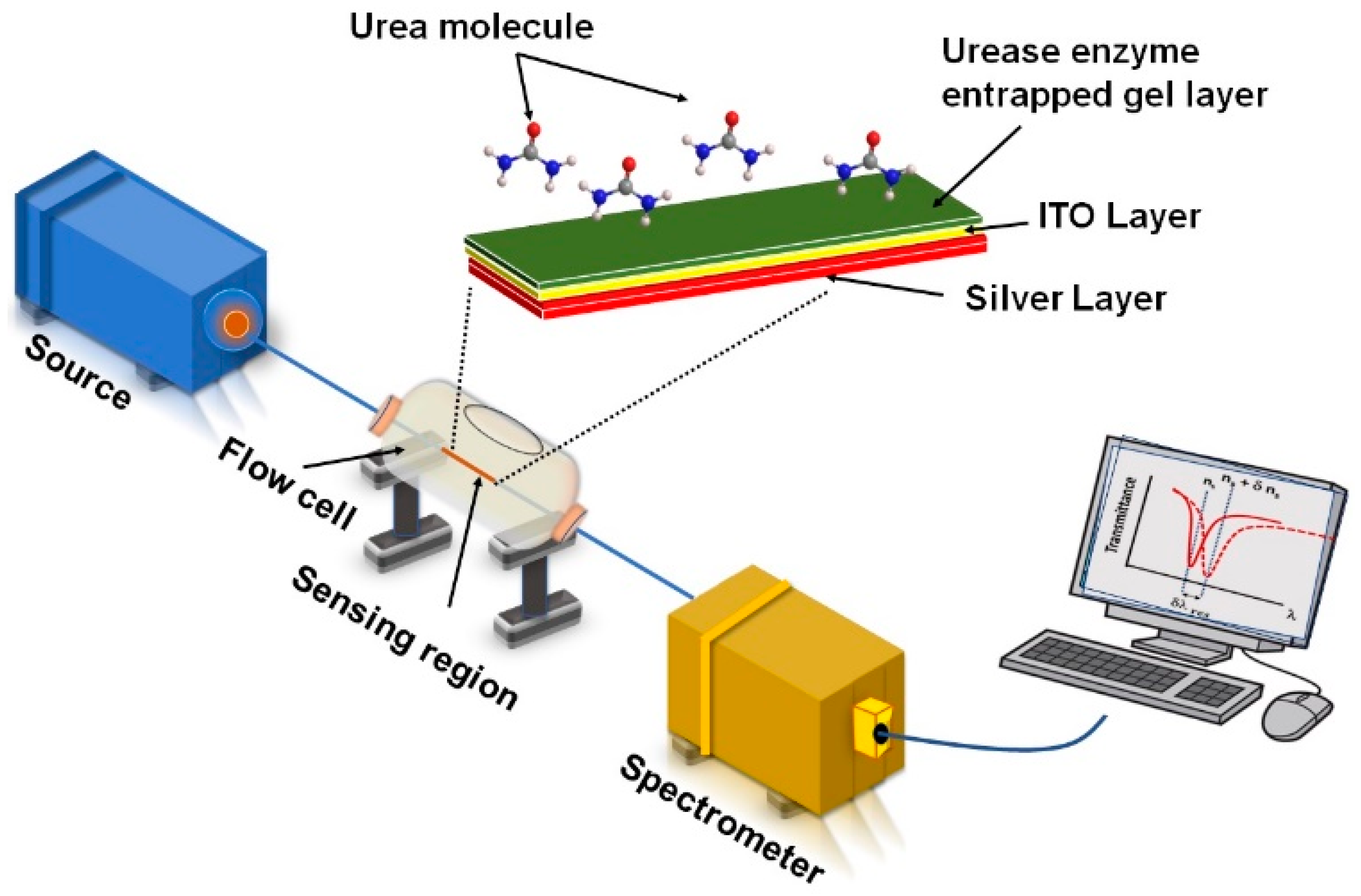

Figure 2 depicts the experimental setup for characterizing urea. Using a polychromatic tungsten halogen lamp at one end, a broad spectrum of wavelengths was guided into the fiber core, and a glass flow cell was used. At the other end of the fiber core, a spectrometer (Avasoft 3648) was connected to a computer to record the SPR spectra of different concentrations of analyte solutions. As analyte solutions were poured into the flow cell, they contacted the sensing region of the sensor probe. With a surgical syringe, sample solutions can be injected and ejected from the glass flow cell. Flow cells are designed to provide sufficient space for washing the sensor probe after each cycle of probe characterization to remove the previous solution.

During the injection and ejection of the sample, it was also ensured that the gel layer would not be damaged. Rubber corks were used to fix sensor probe ends into flow cells after they were cleaved with tungsten blades. To achieve maximum light coupling in the fiber core, the source and spectrometer were kept at three-dimensional stages while the flow cell was fixed.

3. Results and Discussion

3.1. Sensing Principle

Due to the interaction between the analyte (urea) and the sensing layer (gel-entrapped urease enzyme), urea sensing functions by changing the effective refractive index of the sensing layer. The following equation represents the hydrolysis of urea by urease into ammonia and carbon dioxide.

Ammonia production increases pH locally, which changes the effective refractive index of the sensing layer because of the swelling of the gel layer. Swelling of the gel layer causes an increase in the volume of the sensing layer, and hence, the effective refractive index decreases [

28,

29,

30,

31]. The SPR spectrum measures the change in refractive index by changing the resonance wavelength.

3.2. Optimization of Experimental Parameters

By optimizing various parameters that could influence sensor performance, a sensor probe was designed to develop the most efficient urea sensor. Throughout the optimization process, one parameter was changed at a time while all others remained the same. A sensor probe was optimized by testing it for urea concentrations ranging from 0 to 160 mM and recording corresponding SPR spectra for evaluating the shift in resonance wavelength. Optimizing the parameter for enhanced sensor performance was evaluated using the shift in resonance wavelength.

3.2.1. The Thickness of the ITO Layer over the Ag-Coated Probe

In the proposed plasmonic sensor, Ag provides the basis for the generation of surface plasmons in the sensor probe. The ITO layer prevents the Ag layer from oxidizing, therefore increasing the sensor’s sensitivity. Silver’s oxidation tendency could affect the efficiency of surface plasmon excitation at the metal/dielectric interface, which impacts sensor sensitivity. By coating silver with ITO, the silver layer is unable to contact the air, thereby preventing oxidation. Additionally, when the ITO layer is present, the evanescent field at the ITO–gel interface is enhanced due to its high refractive index, thus enhancing sensitivity [

28].

Optimizing the thickness of the ITO layer is crucial for improved sensor performance due to its direct influence on sensitivity. As evanescent fields at the interface directly affect sensitivity, it is very important that the ITO layer be the correct thickness of any material coated over an Ag layer. The present study involved the preparation of five sensor probes with different ITO layers e.g., 5 nm, 7 nm, 8 nm, 10 nm, and 12 nm, over Ag coating, and the characterization of these probes with urea concentrations between 0 mM and 160 mM. During testing of the varying thicknesses of the ITO layer, the enzyme concentration and pH level of urea samples were fixed to 2.2 mg and pH 7, respectively.

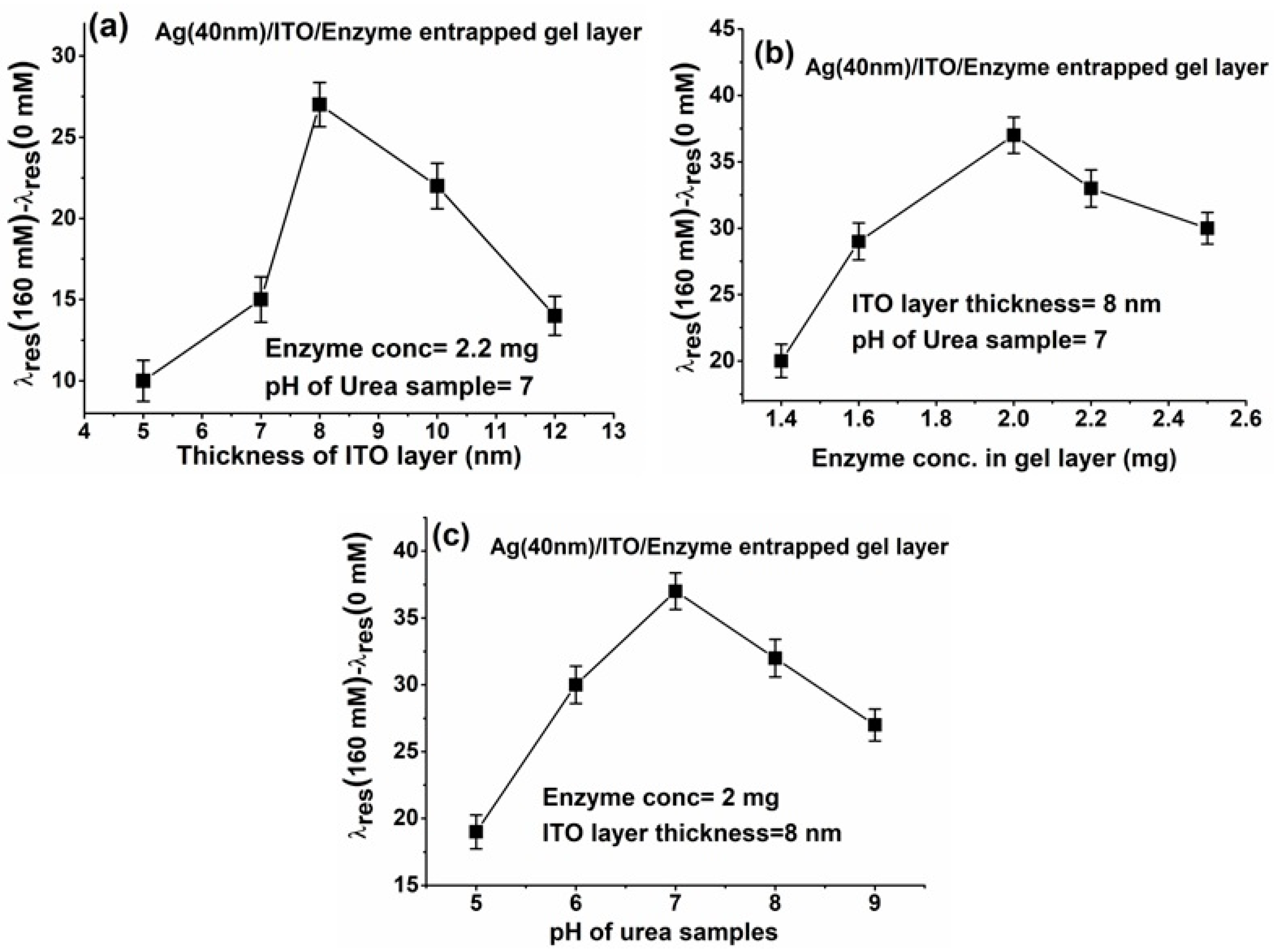

Figure 3a shows the variation of the ITO layer thickness with total wavelength shift. Our results show that the resonance wavelength is shifted the most at 8 nm of ITO layer thickness. When increasing the thickness of the ITO layer, the resonance wavelength shift decreases. As the evanescent field intensity at the interface decreases with thickness above 8 nm, the shift may also decrease.

3.2.2. The Concentration of Enzyme in the Gel Matrix

Whenever a biosensor is used to measure a specific analyte, enzymes play a vital role in providing excellent specificity to the sensor. An enzyme acts as a biocatalyst and regulates metabolic reactions within the human body. Analytes can interact with enzymes through their active sites. It is necessary to immobilize enzymes in a support matrix to maintain their reactivity. Our study used the gel entrapment technique to immobilize enzymes effectively. A gel matrix must tightly hold enzymes inside to prevent leaks, as well as to interact with analytes, which can diffuse into the matrix. The concentration of enzymes plays an important role in this arrangement. Gel matrices must be able to hold enzyme concentrations properly at their limit. Various concentrations of enzyme, including 1.4 mg, 1.6 mg, 2 mg, 2.2 mg, and 2.5 mg, were entrapped in a gel layer and used to fabricate five different sensor probes. Two extreme concentrations of urea samples of pH 7 were used to characterize these sensor probes with varying enzyme concentrations and optimized ITO layer thickness of 8 nm.,

Figure 3b shows how the total shift in the resonance wavelength changes with varying concentrations of enzyme entrapped in the gel layer Observing that the resonance wavelength shift as the enzyme concentration increased, we found that the wavelength was the greatest for enzyme concentrations equal to 2 mg. As the enzyme concentration in the gel matrix increased, the shift in the resonance wavelength decreased, suggesting that the gel matrix could no longer hold the greater enzyme concentration [

32].

3.2.3. pH Values of Urea Samples

An enzyme’s function is strongly influenced by the pH value of the surrounding environment. For an enzyme to function properly, pH 7 is considered the ideal value. With pH values below and above pH 7, enzyme active sites are altered, resulting in a decreased enzyme reaction rate [

22]. Sensor performance is negatively impacted by unsterilized pH values because denatured enzymes interact poorly with analytes. It is therefore important to monitor the pH values of urea samples. A sensor probe fabricated with a 40 nm Ag layer, an 8 nm ITO layer, and 2 mg enzyme concentration in the gel layer has now been characterized using urea samples with different pH levels. To characterize the sensor probe prepared with optimized Ag and ITO thicknesses, two extreme concentrations of urea with different pH values were taken. Based on the pH value of the sample,

Figure 3c displays the variation in the total shift of the resonance wavelength. Increasing the pH value from 5 to 7 increased the shift in resonance wavelength. The total shift in resonance wavelength decreases as we increase the pH value of the solution. As a result, pH 7 shows the maximum shift in resonance wavelength [

33].

3.3. Optimized Sensor Probe Characterization

To fabricate the sensor probe with optimized parameters, a 40 nm thick layer of Ag was applied to the unclad fiber, followed by an 8 nm thick layer of ITO over the Ag coating, followed by an enzyme-entrapped gel layer containing 2 mg of the enzyme. A shift in resonance wavelength was determined by comparing their transmittance spectra with different concentrations of urea used to characterize this optimized sensor probe.

We have increased the concentration of urea from 0 mM to 160 mM in

Figure 4a, which shows the SPR response of the sensor for different concentrations of urea in a sodium phosphate buffer solution. The transmitted light intensity shifted blue/negative at 0–60 mM concentration of urea, indicating a decrease in the effective refractive index of the sensing medium. As shown in

Figure 4b, a calibration curve has been extracted from

Figure 4a by plotting the resonance wavelength with urea concentrations. When urea concentrations ranged from 0 mM to 160 mM, we observed a blue shift in the resonance wavelength equal to 37 nm. In

Figure 4c, the derivative of the equation fitting the curve in

Figure 4b concerning urea concentration was measured to evaluate the probe’s sensitivity. The sensor has a maximum sensitivity of 0.59387 nm/mM for 0 mM urea concentration and is more sensitive at lower concentrations. Due to the limited number of enzyme active sites in gel-entrapped enzymes, sensitivity decreases at higher urea concentrations. In the repeated experiments with the same probes and with different probes at least ten times, the sensor probes displayed the same behavior throughout the process. Using all collected data, the standard deviation was calculated and plotted as an error bar in

Figure 4b. In addition to its sensitivity, the performance of a sensor depends on its limit of detection (LOD), which refers to the lowest concentration of analyte that can be detected. Based on the relationship between spectrometer resolution and sensor sensitivity near minimum concentration, LOD is calculated as follows [

34,

35]:

In the present case, = 0.333 nm for the spectral resolution and SC=0 for the sensitivity near minimum concentration, resulting in an LOD of 0.56 mM.

As shown in

Table 1, the proposed sensor is compared to other existing urea sensors. In many cases, conventional urea sensing methods such as chromatography, conductometry, spectrophotometry, colorimetry, fluorometry, potentiometry, etc., offer lower LOD than the proposed sensor. Conventional urea sensors also suffer from some unavoidable shortcomings, such as labor-intensive instrumentation, complexity, cost, the need for highly trained personnel, a lengthy procedure, slow response times, the limited ability to detect analytes within a narrow concentration range, and the inability to monitor remotely or online. This sensor targets and overcomes almost all these issues. Sensors based on optical fiber SPR are more sensitive to urea than those that use ZIF-8/urease composite for urea detection [

35]. As far as metal organic framework (MOF )studies are concerned, they are still in the early stages of development, while the proposed work follows a well-established approach. As compared to the ZIF-8/urease composite sensor, the proposed sensor covers a wider range of urea concentrations from 0 to 160 mM, which enhances its capabilities.

3.4. Stability, Repeatability, and Response Time

To ensure repeatability and stability, samples of urea concentrations ranging from 0 mM to 160 mM were used. In the first step, a 10 mM urea sample was poured into the flow cell, and its SPR spectrum was recorded to obtain the resonance wavelength. A second SPR spectrum was recorded after the sample remained in the vicinity of the probe for 1 min. The resonance wavelengths at which the decrease in the SPR spectrum occurred were identified from these two spectra. Resonance wavelengths are sustained over time, indicating balanced behavior from the sensor probe. After removing the 10 mM urea concentration, a 160 mM urea sample was added, and the same procedure for recording the spectrum was followed as in the first case to ensure the reusability of the probe. The resonance wavelengths were evaluated again to determine the nature of stability. We consider this to be one cycle of evaluation. In the same procedure of measurements, the 160 mM urea sample was removed, and the 10 mM urea sample was added. The reusability and repeatability of the probe are demonstrated by the differences in resonance wavelengths between the second and first cycles for the 10 mM urea sample. For the 160 mM sample, the same procedure was followed.

Figure 5a shows three cycles of repeatability and stability measurements on the probe. The resonance wavelengths for 10 mM and 160 mM were estimated to be around 721 nm and 690 nm, respectively. The stabilized/saturated maximum response time of the optimized sensor probe was analyzed for a 60 mM urea concentration sample after a time gap of 1 min to monitor the stability of the sensor. In this study, urea was poured into the flow cell and the time variation of transmitted light intensity at a 700 nm wavelength was recorded, which is shown in

Figure 5b. Approximately 10 s after pouring the sample, the normalized transmittance decreases and saturates. Therefore, the sensor’s response time is 10 s. Since the sensor has a urease enzyme entrapped in the gel as the sensing layer, the sensor was found to be selective for urea detection. Various reported studies [

38,

39] have proven that urease is highly selective towards the urea.

4. Conclusions

In conclusion, we propose a fiber optic urea biosensor utilizing alternate layers of Ag/ITO/enzyme encapsulated gel over an unclad fiber core as a sensing element. We selected the sensing layer components based on their unique properties toward effective urea detection. Sensor probes are designed with all optimized parameters, including the thickness of the ITO layer, the concentration of enzymes in the gel matrix, and the pH value of urea samples. A buffer solution of 0.1 M and pH 7 is used to characterize the optimized sensor probe with varying concentrations of urea ranging from 0 to 160 mM. In preparing urea samples, it is important to consider the physicochemical range of urea concentrations in biofluids such as blood and urine. Each urea concentration is determined by the resonance wavelength obtained from the characterization of the sensor probe. In comparison to other studies of urea sensing, the sensor shows better LOD values. Stability, repeatability, and rapid response time are all excellent characteristics of this sensor. Based on the blue shift in SPR response curves corresponding to different urea concentrations, it is evident that the sensing layer and urea interact well, making it possible to develop commercial sensing systems.