Overview of Gas Sensors Focusing on Chemoresistive Ones for Cancer Detection

Abstract

1. Introduction

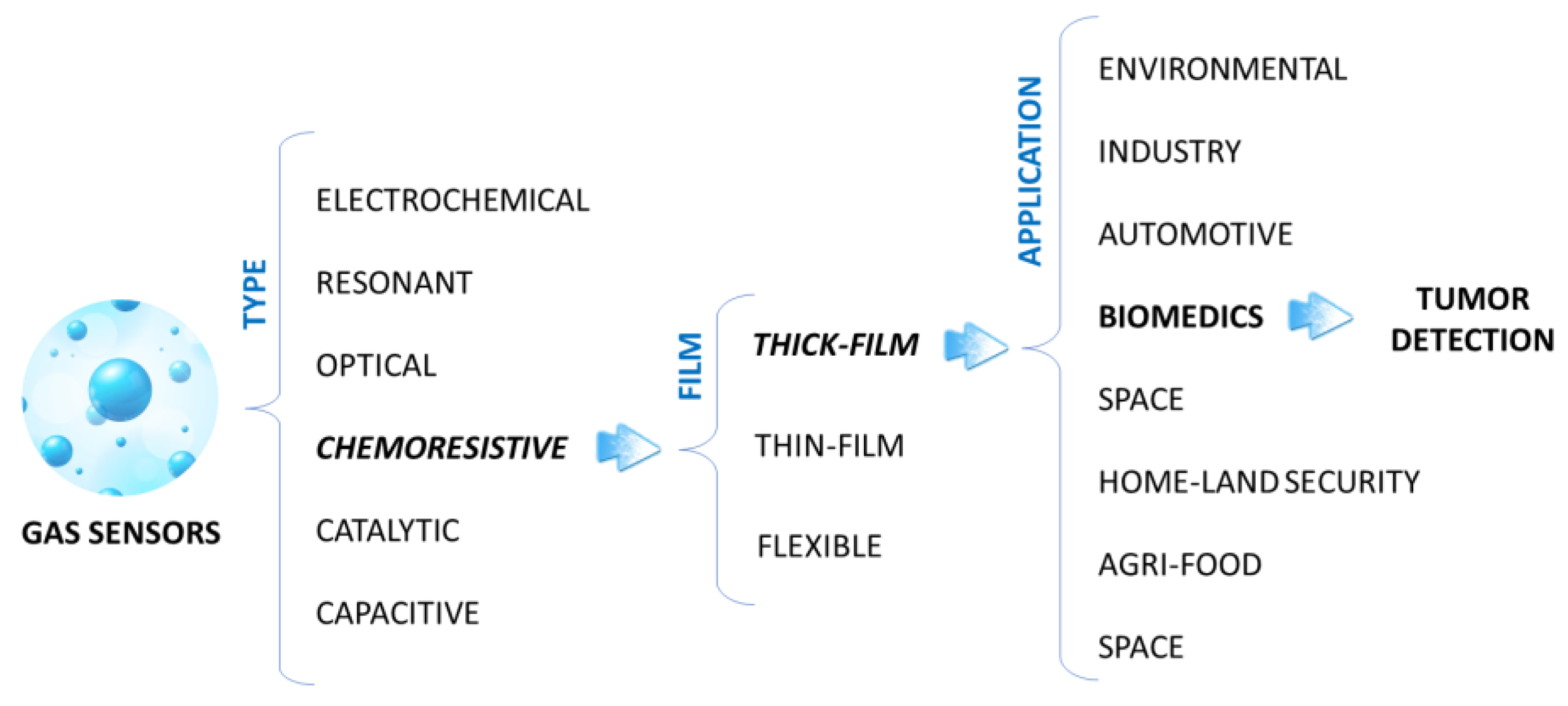

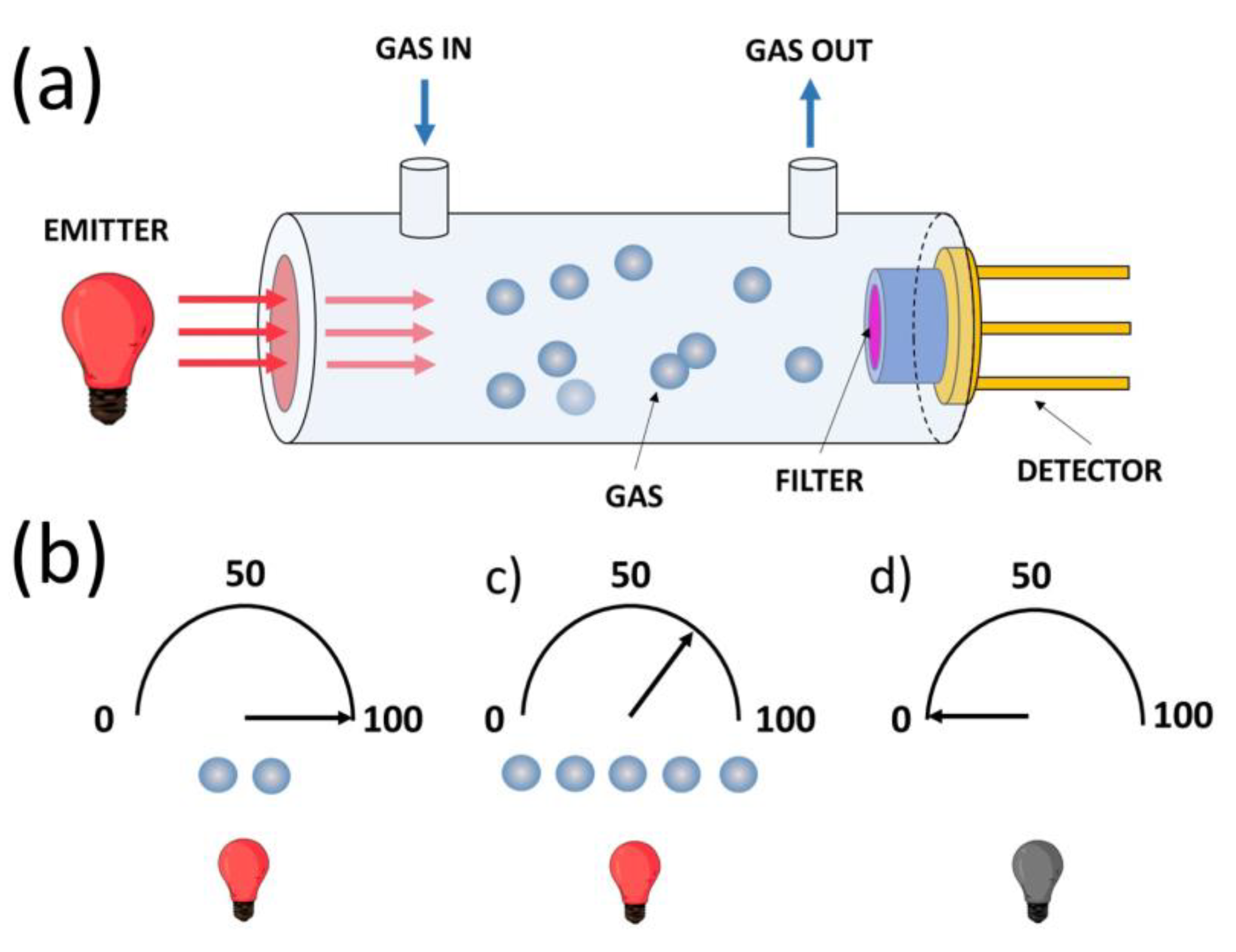

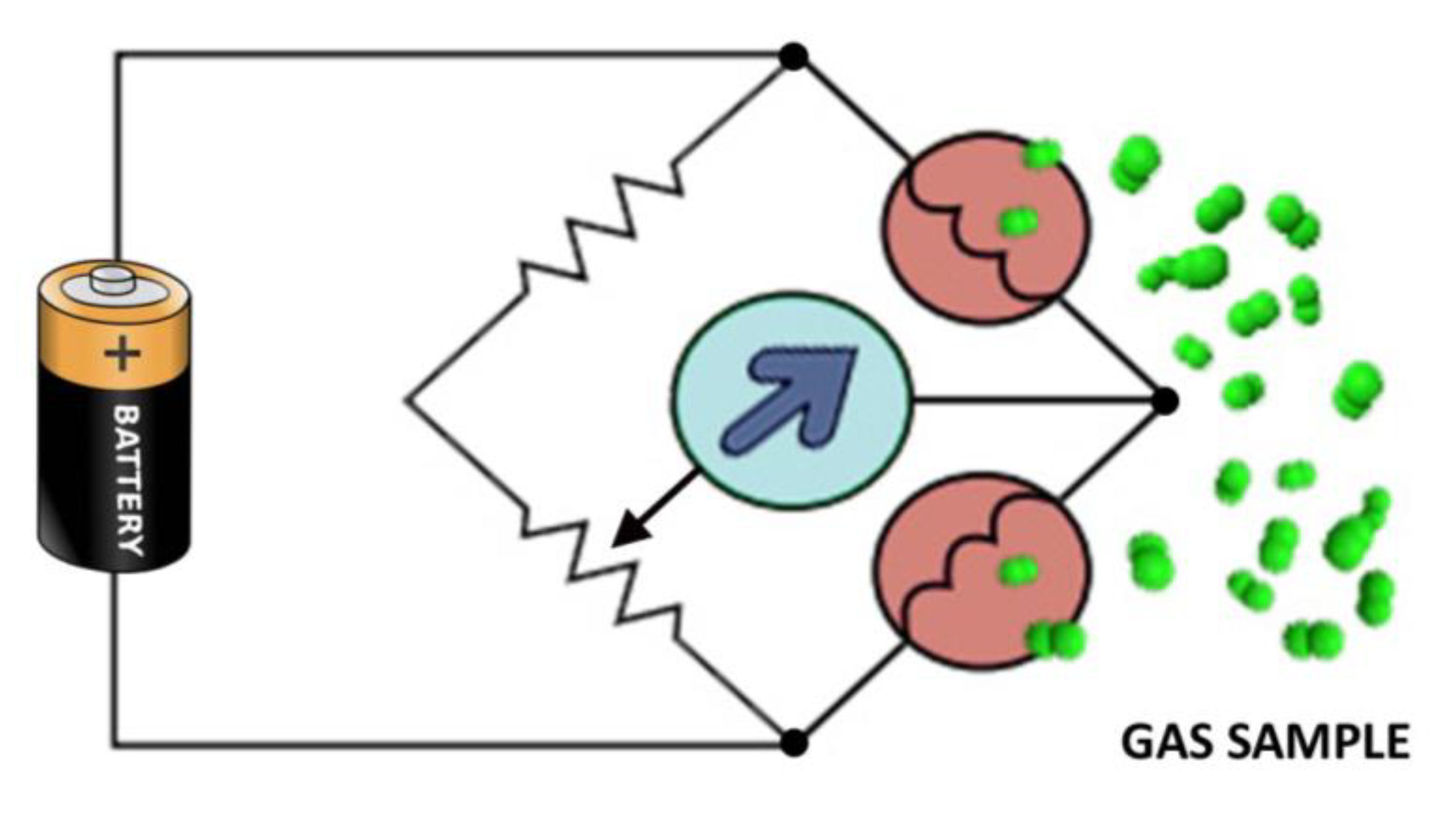

2. Gas Sensors

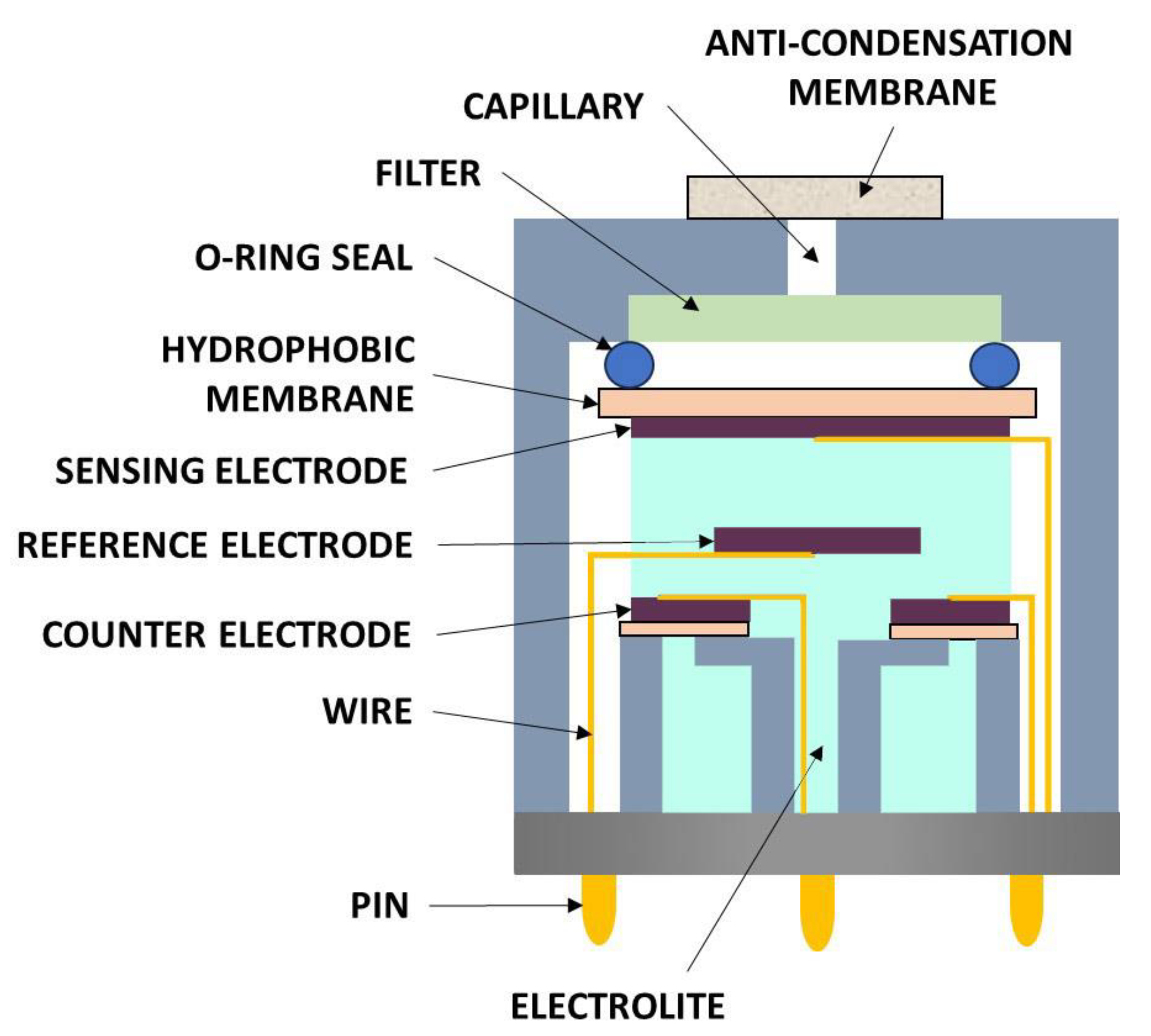

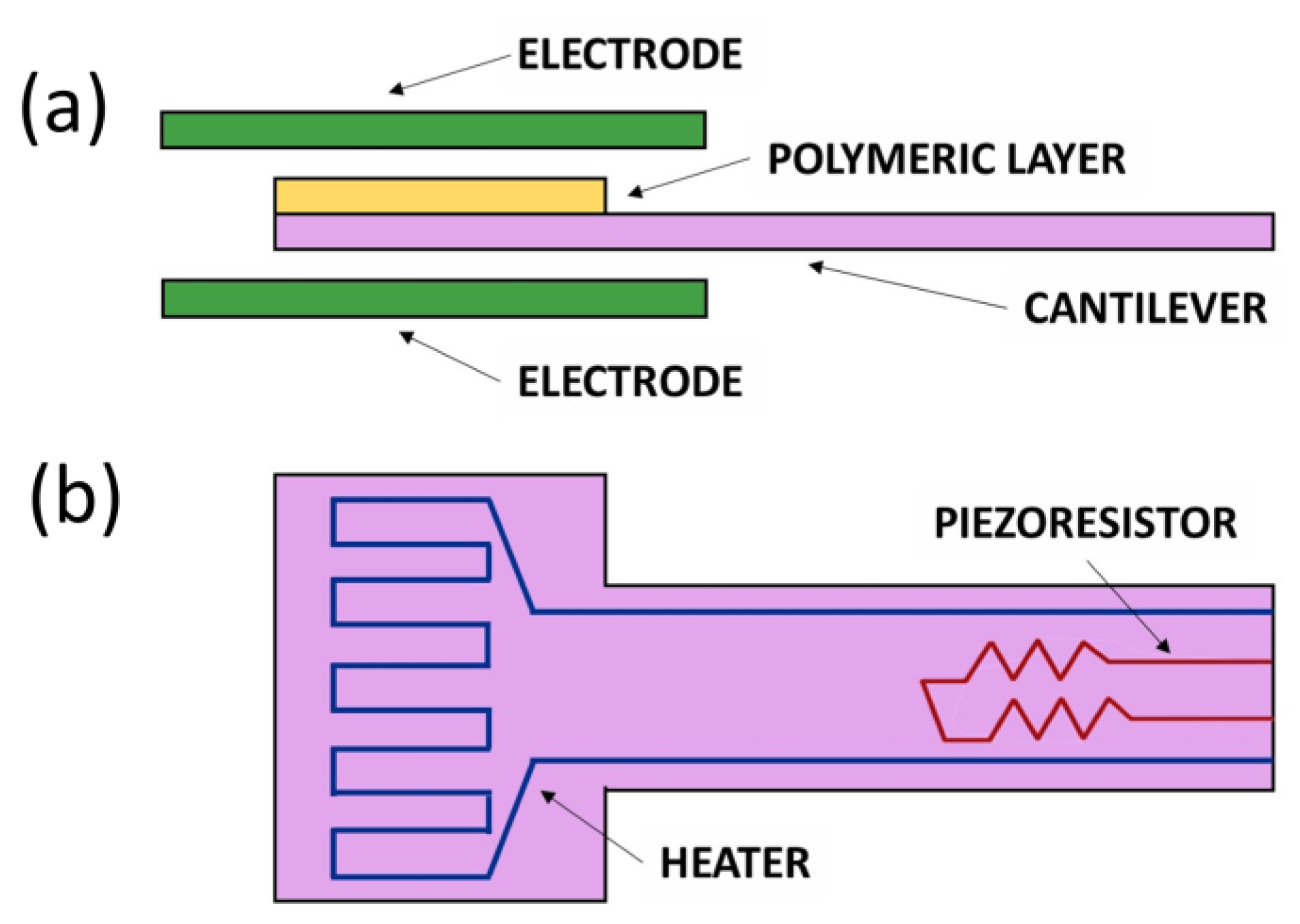

2.1. Main Sensor Types

- -

- High sensitivity (low detection limit of the gas target concentration in the surrounding environment);

- -

- Selectivity (high discrimination power of the gas target from the surrounding atmosphere);

- -

- Repeatability of response in the short, medium, and long term (stability);

- -

- Production reproducibility;

- -

- Cheapness;

- -

- Low power consumption;

- -

- Ease of use;

- -

- Durability;

- -

- Possibility of miniaturization;

- -

- Ease of interfacing with electronic devices.

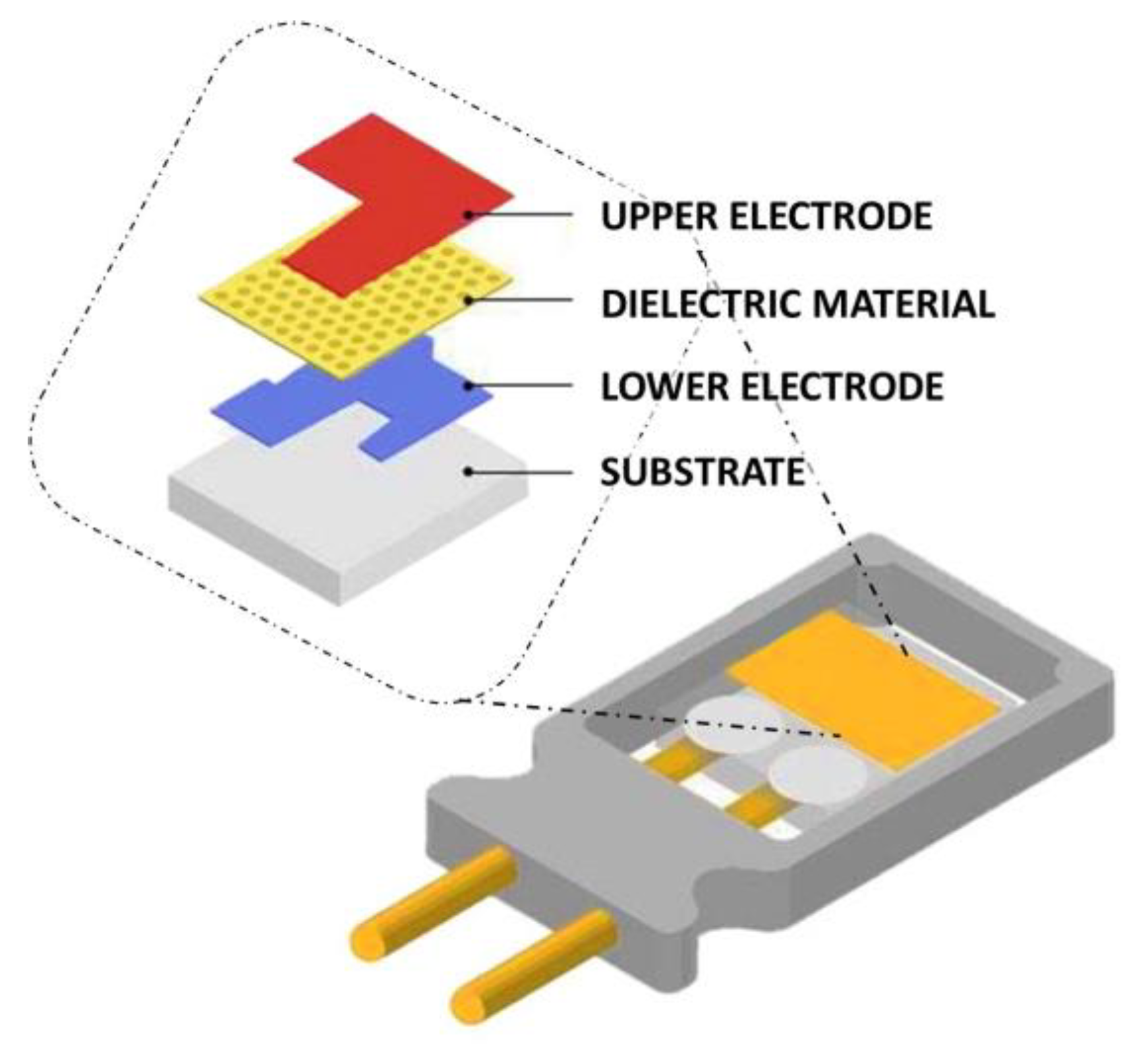

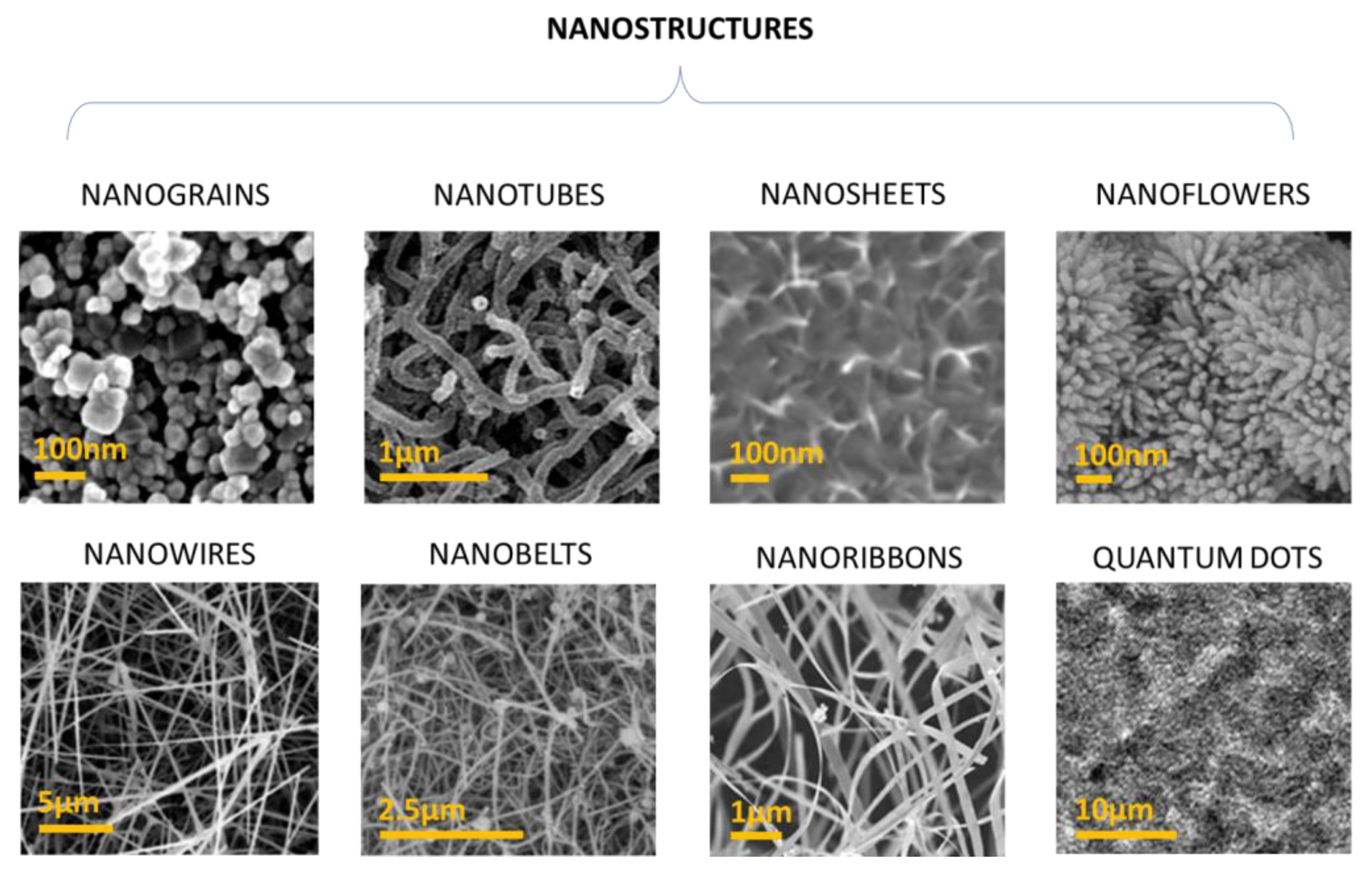

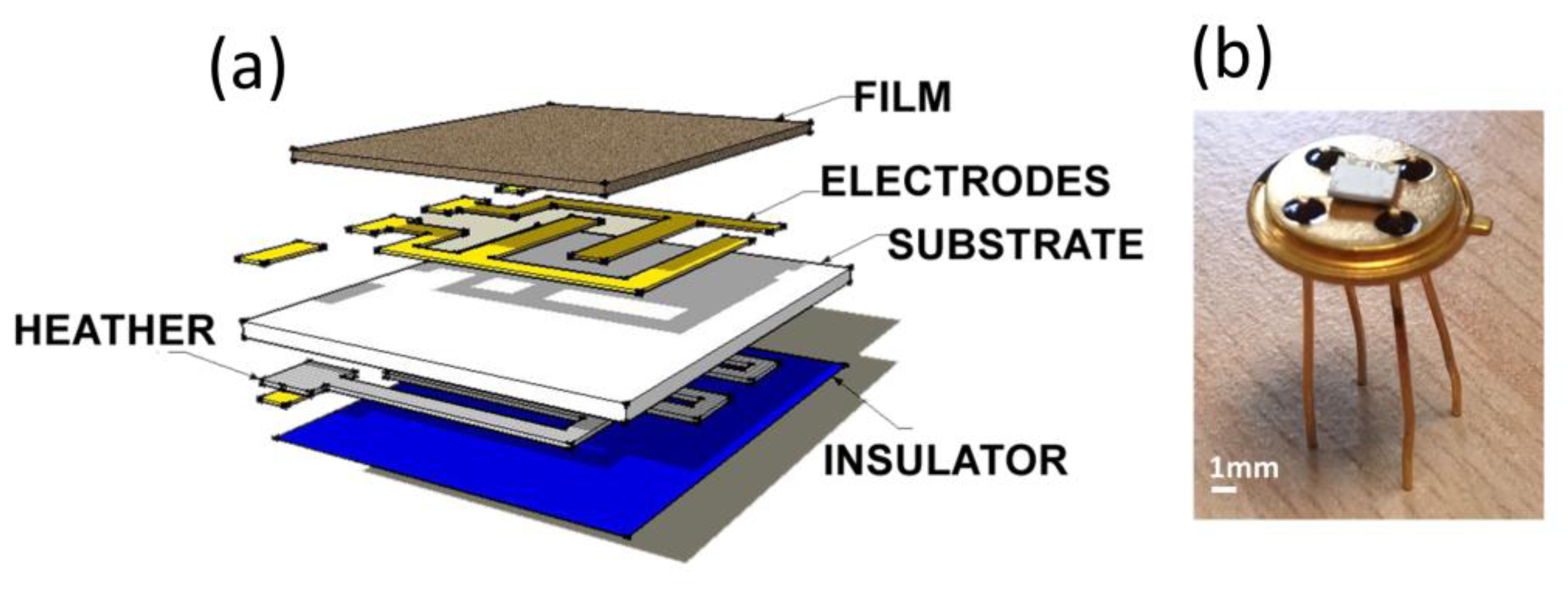

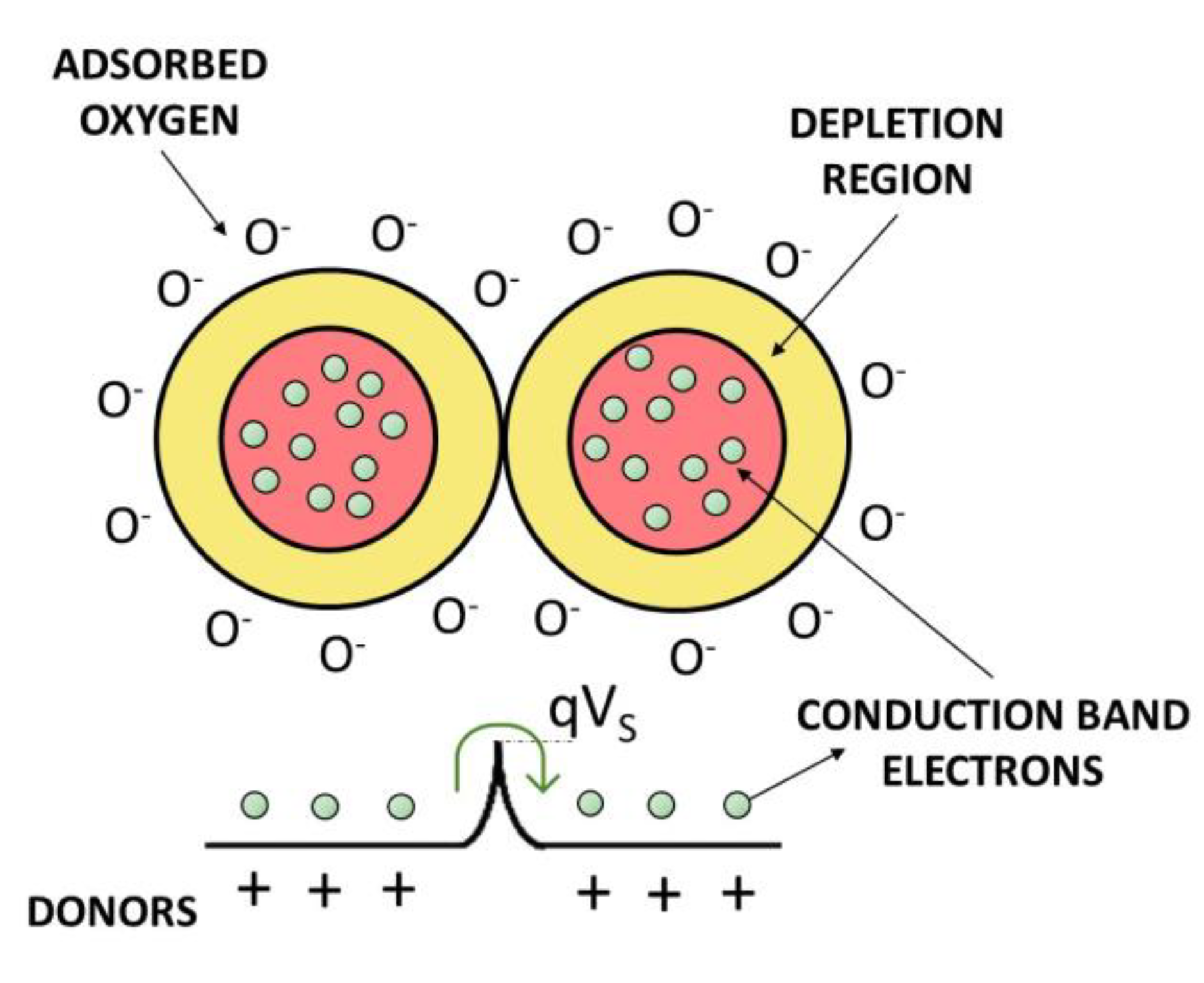

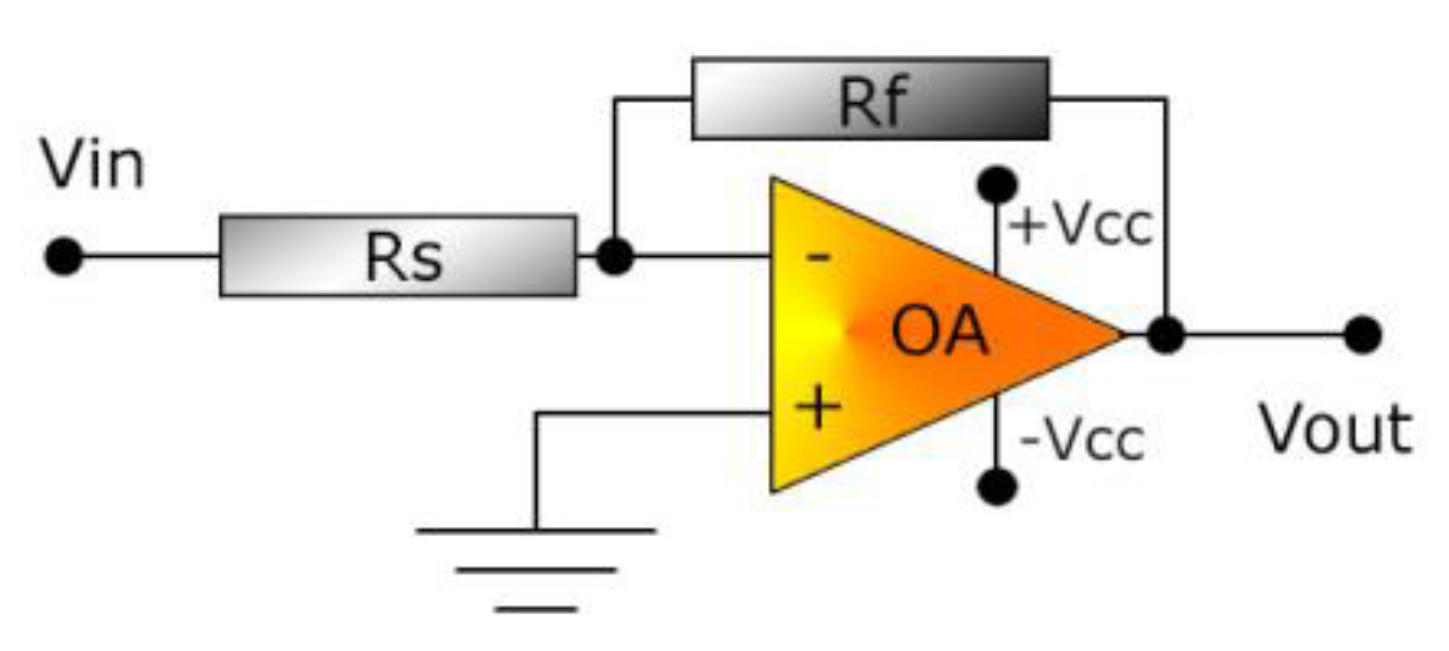

2.2. Chemoresistive Sensors

- -

- The hydrothermal method [53], which employs an aqueous solution as a reaction system in a dedicated closed vessel that is heated and pressurized in a controlled mode;

- -

- The “sol-gel” method [54], which involves the conversion of monomers into a colloidal solution (sol) acting as the precursor for an integrated network (gel) of either discrete particles or network polymers; this process has been chosen by the Sensor Laboratory (SL) team of the University of Ferrara for gas sensor production.

3. Main Chemoresistive Sensor Applications

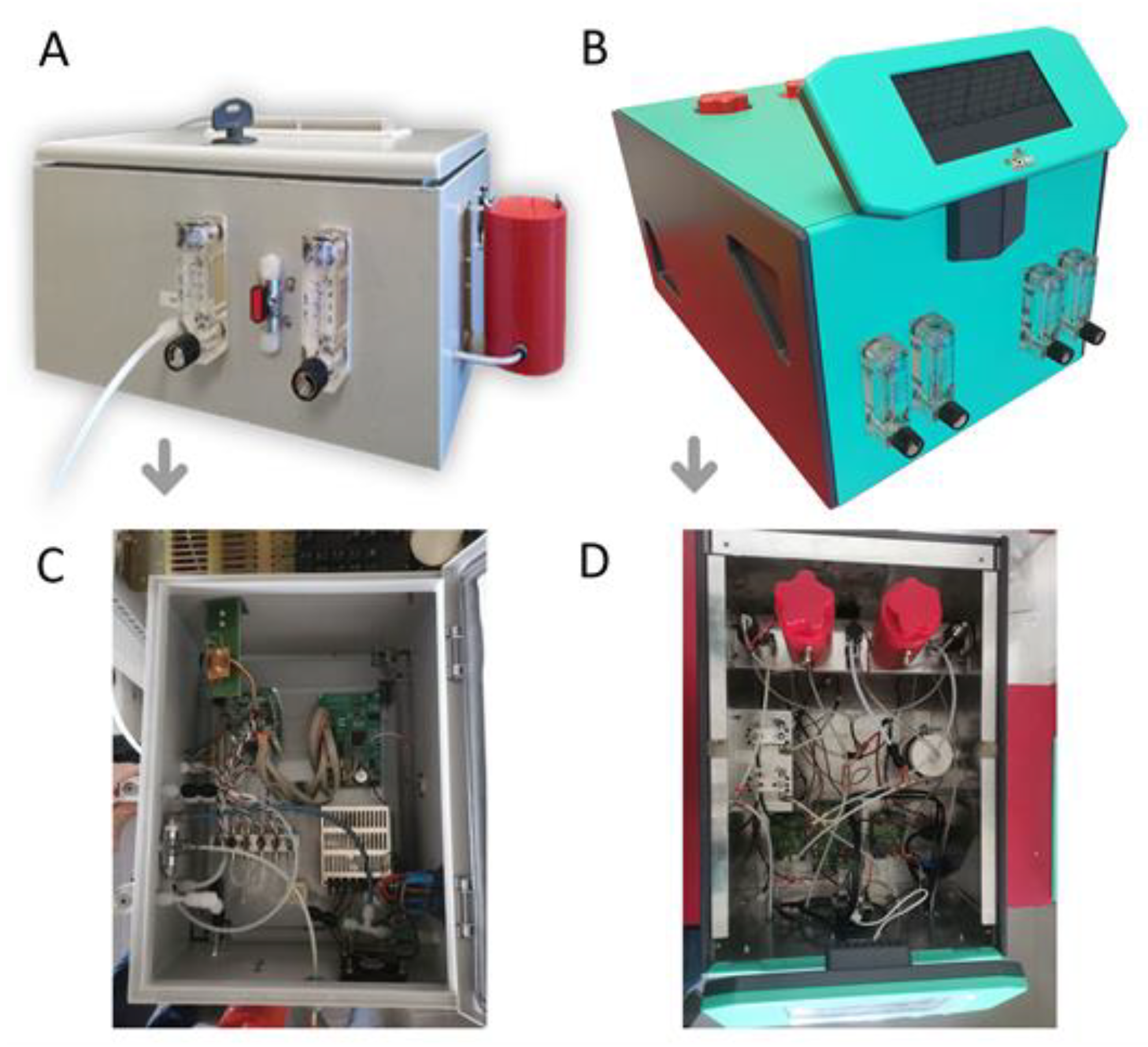

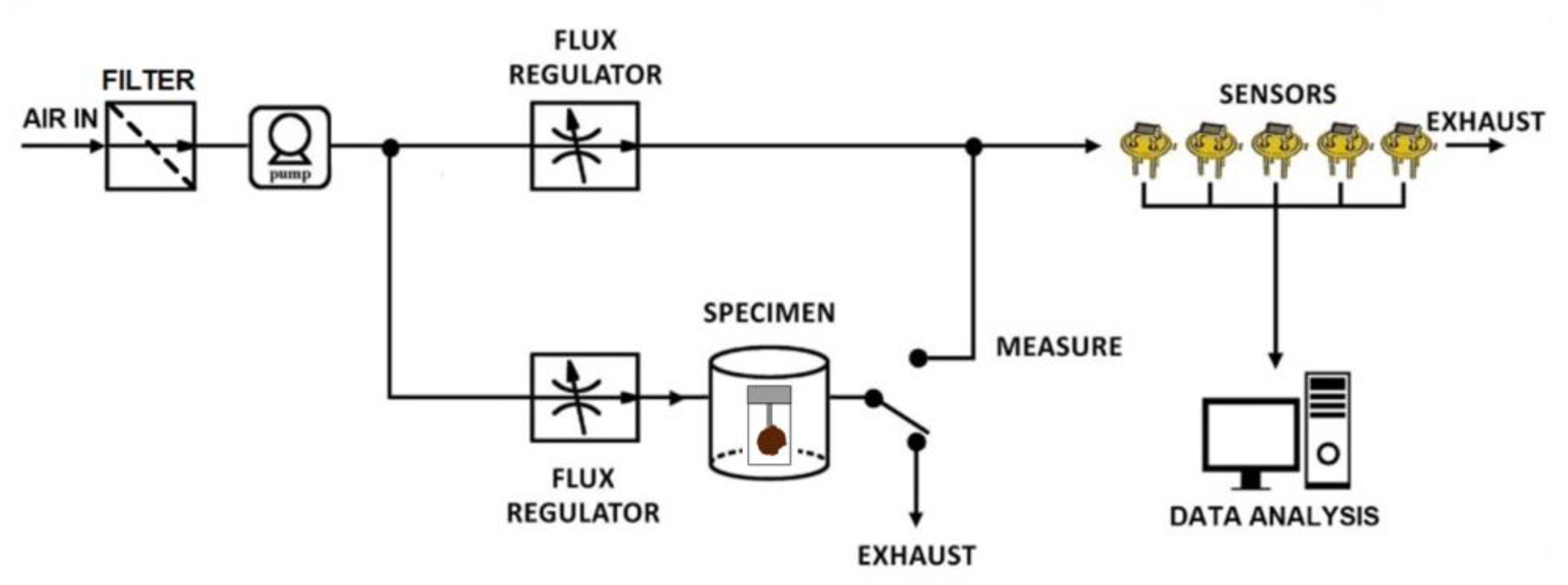

3.1. Tumor Screening

3.2. Tumor Monitoring

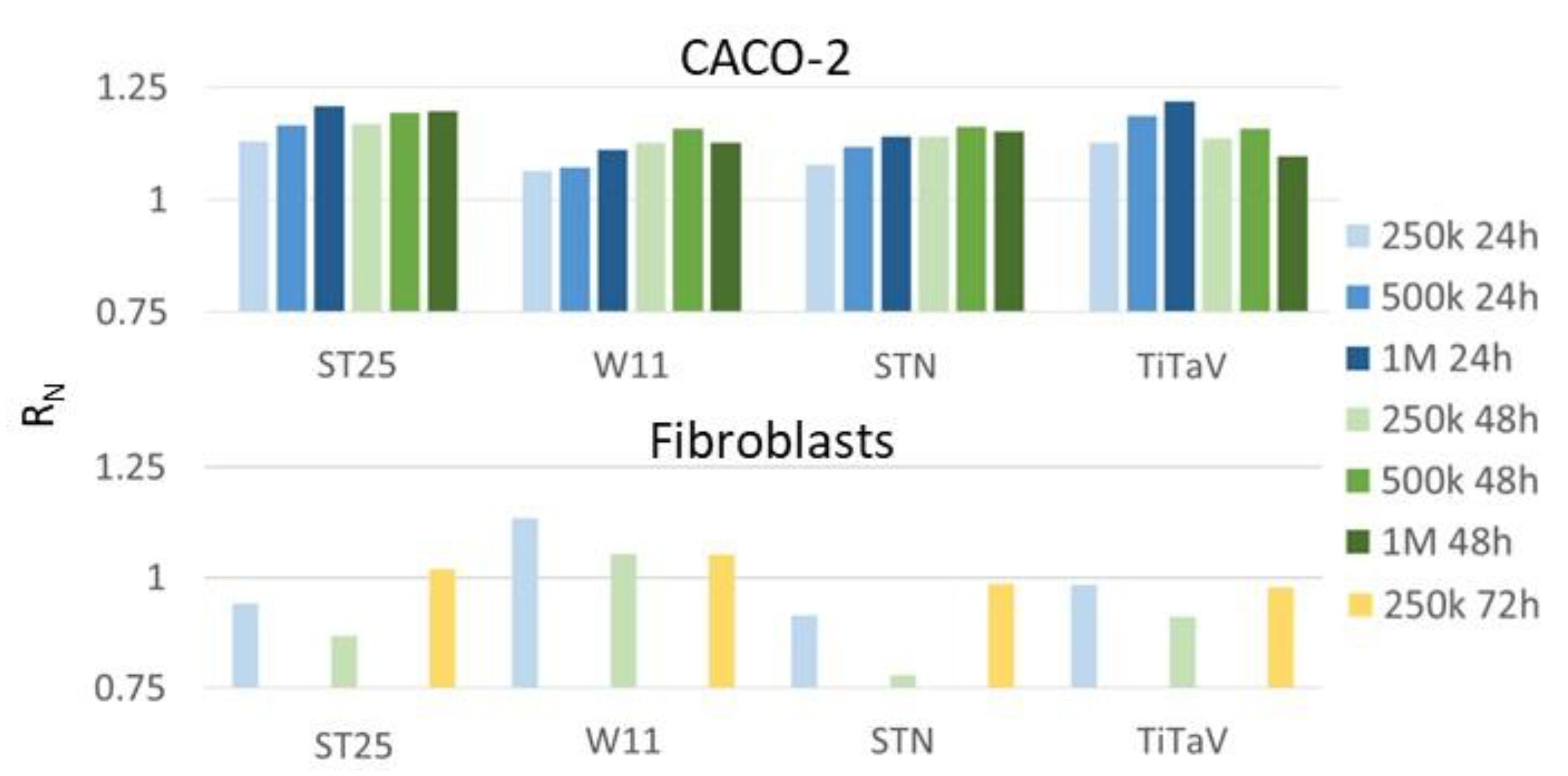

3.3. Basic Research on Biomarkers

| Cell Type | ST25 | STN | TiTaV |

|---|---|---|---|

| Fibroblasts | 1.11 | 0.78 | 1.17 |

| CACO-2 | 1.03 | 1.00 | 1.14 |

| RKO | 1.14 | 1.29 | 1.01 |

| HEK-293 | 1.12 | 1.12 | 1.15 |

| CHO | 1.08 | 1.33 | 1.20 |

| A549 | 1.35 | 1.06 | 1.30 |

4. Conclusions and Future Perspectives

5. Patents

- C. Malagù; G. Zonta; S. Gherardi; A. Giberti; N. Landini; A. Gaiardo, Dispositivo per lo screening preliminare di adenomi al colon-retto (2014), National #: RM2014A000595, European #: 3210013 (Germany, UK);

- C. Malagù, S. Gherardi, G. Zonta, N. Landini, A. Giberti, B. Fabbri, A. Gaiardo, G. Anania, G. Rispoli, L. Scagliarini, Combinazione di materiali semiconduttori nanoparticolati per uso nel distinguere cellule normali da cellule tumorali (2015), National #: 102015000057717.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shu, L.; Mukherjee, M.; Wu, X. Toxic Gas Boundary Area Detection in Large-Scale Petrochemical Plants with Industrial Wireless Sensor Networks. IEEE Commun. Mag. 2016, 54, 22–28. [Google Scholar] [CrossRef]

- Spector, Y.; Jacobson, E. Novel Technology for Flame & Gas Detection in the Petrochemical Industry. In Proceedings of the International Petroleum Conference and Exhibition of Mexico, Villahermosa, Mexico, 3–5 March 1998. [Google Scholar]

- Velasco, G.; Schnell, J.-P. Gas Sensors and Their Applications in the Automotive Industry. J. Phys. 1983, 16, 973. [Google Scholar] [CrossRef]

- Martinelli, G.; Carotta, M.C.; Ferroni, M.; Sadaoka, Y.; Traversa, E. Screen-Printed Perovskite-Type Thick Films as Gas Sensors for Environmental Monitoring. Sens. Actuators B Chem. 1999, 55, 99–110. [Google Scholar] [CrossRef]

- Sakumura, Y.; Koyama, Y.; Tokutake, H.; Hida, T.; Sato, K.; Itoh, T.; Akamatsu, T.; Shin, W. Diagnosis by Volatile Organic Compounds in Exhaled Breath from Lung Cancer Patients Using Support Vector Machine Algorithm. Sensors 2017, 17, 287. [Google Scholar] [CrossRef] [PubMed]

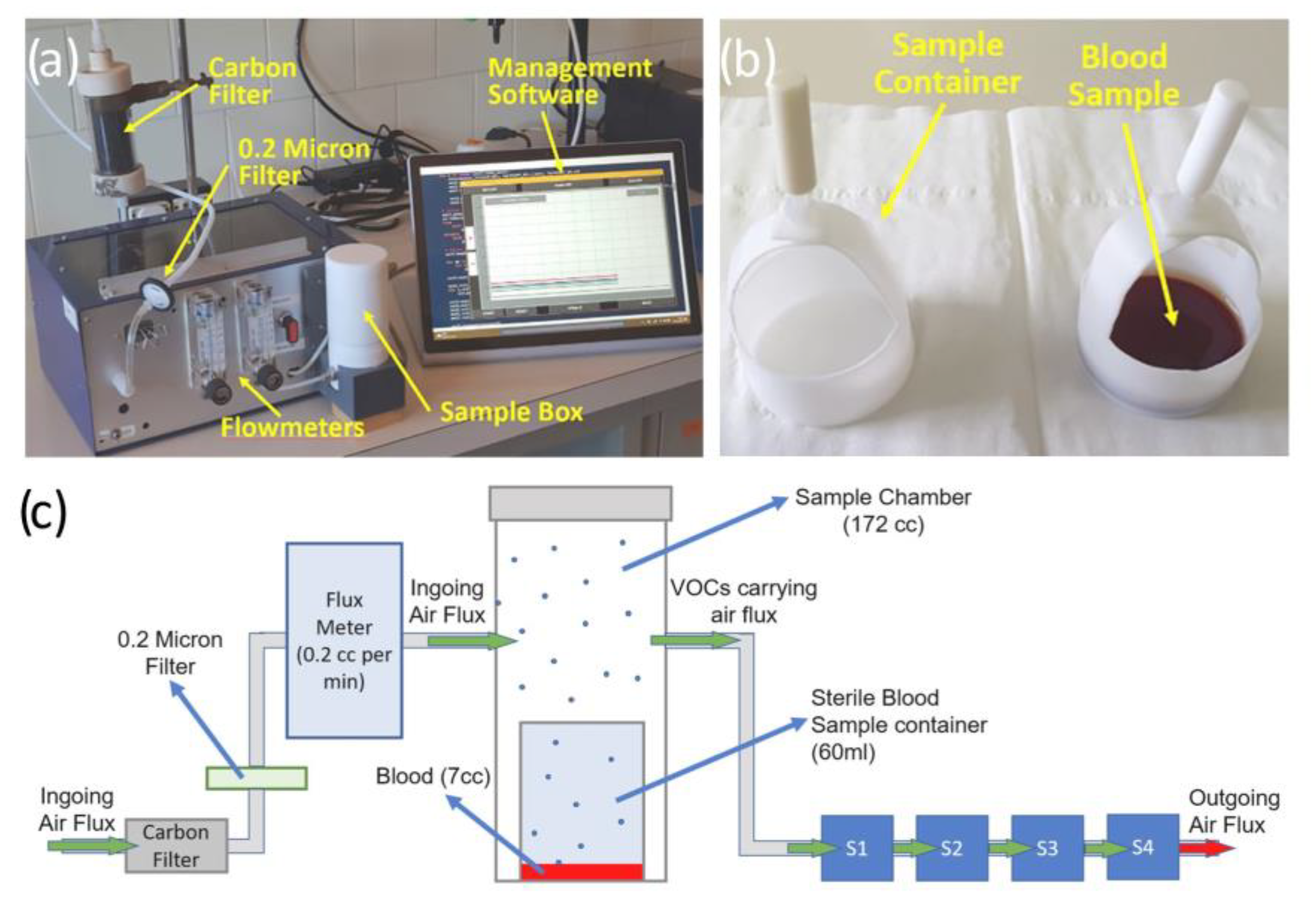

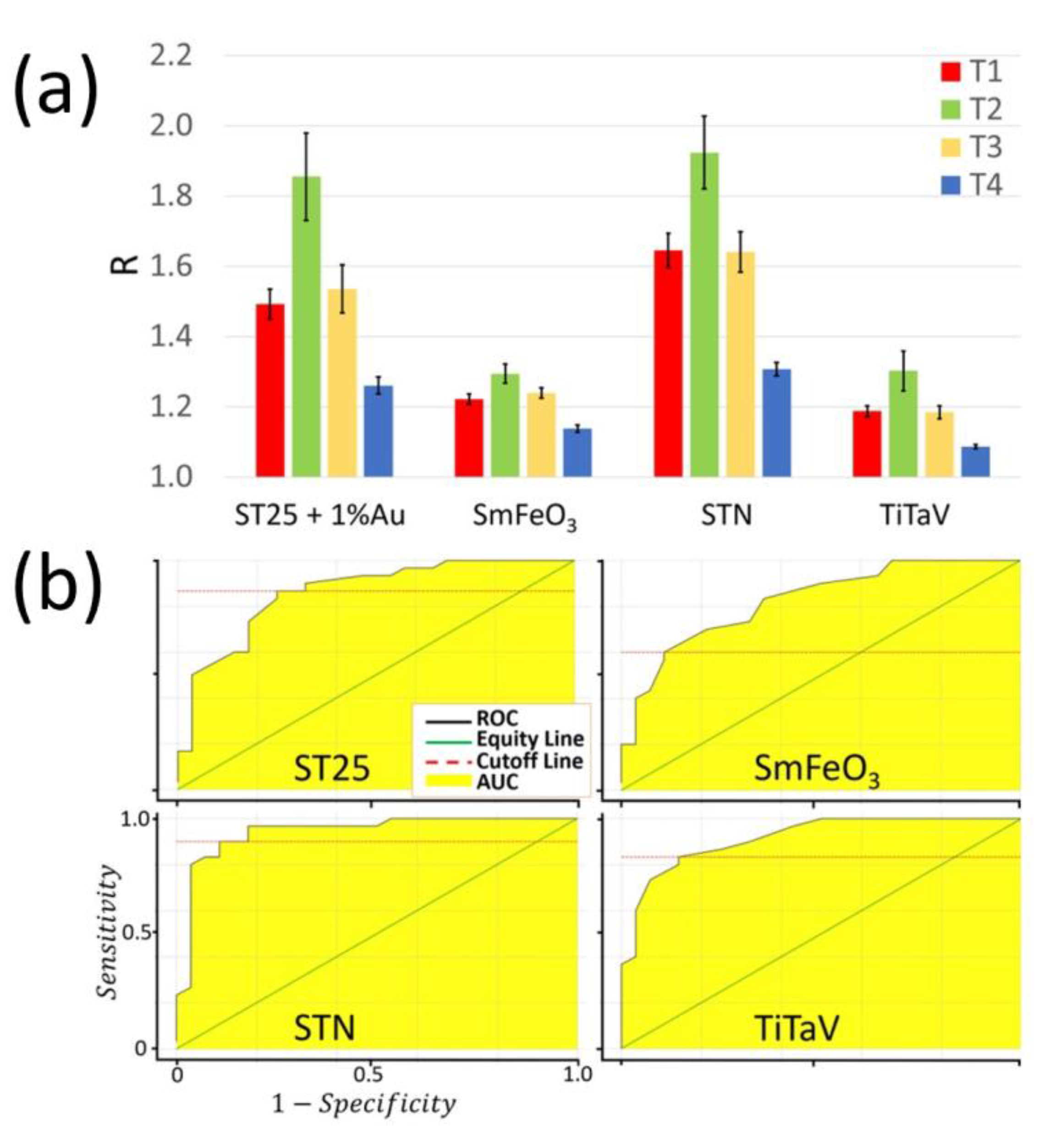

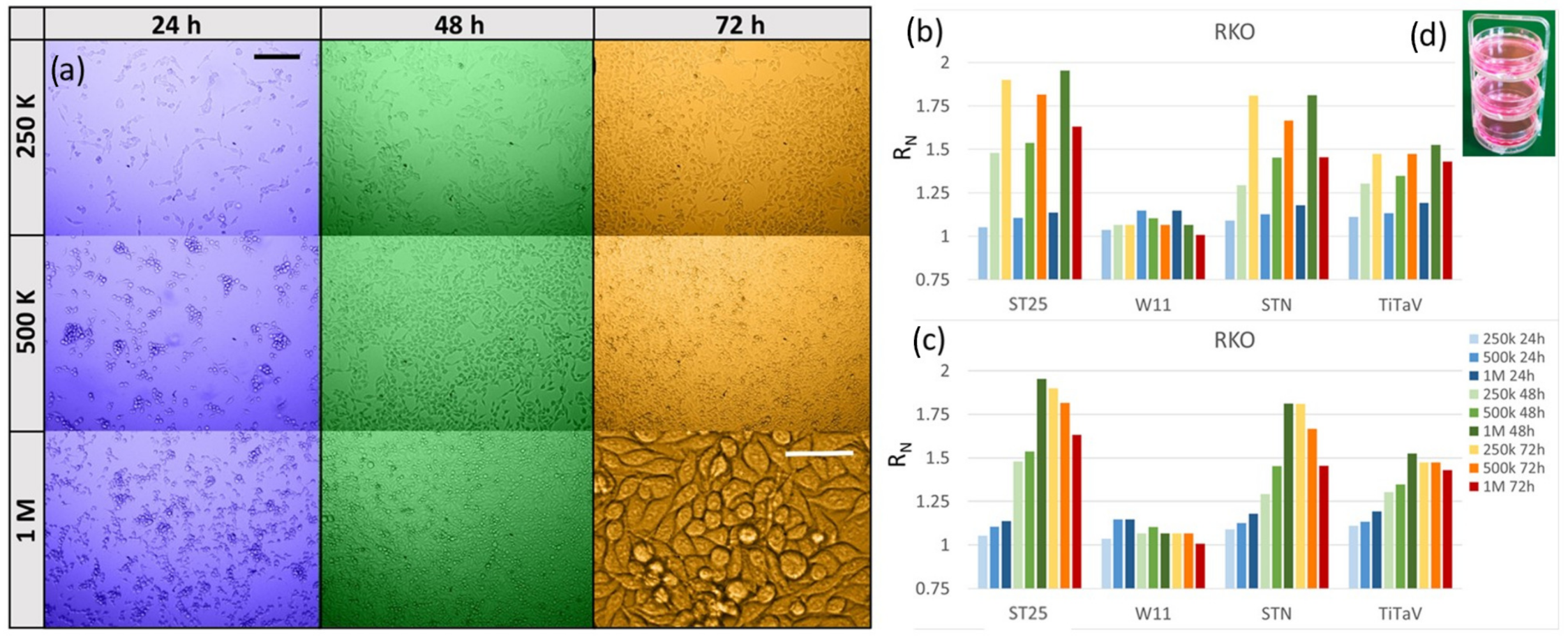

- Astolfi, M.; Rispoli, G.; Anania, G.; Artioli, E.; Nevoso, V.; Zonta, G.; Malagù, C. Tin, Titanium, Tantalum, Vanadium and Niobium Oxide Based Sensors to Detect Colorectal Cancer Exhalations in Blood Samples. Molecules 2021, 26, 466. [Google Scholar] [CrossRef] [PubMed]

- Astolfi, M.; Rispoli, G.; Anania, G.; Nevoso, V.; Artioli, E.; Landini, N.; Benedusi, M.; Melloni, E.; Secchiero, P.; Tisato, V.; et al. Colorectal Cancer Study with Nanostructured Sensors: Tumor Marker Screening of Patient Biopsies. Nanomaterials 2020, 10, E606. [Google Scholar] [CrossRef] [PubMed]

- Landini, N.; Anania, G.; Astolfi, M.; Fabbri, B.; Guidi, V.; Rispoli, G.; Valt, M.; Zonta, G.; Malagù, C. Nanostructured Chemoresistive Sensors for Oncological Screening and Tumor Markers Tracking: Single Sensor Approach Applications on Human Blood and Cell Samples. Sensors 2020, 20, 1411. [Google Scholar] [CrossRef] [PubMed]

- Hunter, G.W.; Chen, L.-Y.; Neudeck, P.G.; Knight, D.; Liu, C.-C.; Wu, Q.-H.; Zhou, H.-J. Chemical Gas Sensors for Aeronautic and Space Applications; NASA: Boston, MA, USA, 1997. [Google Scholar]

- Potyrailo, R.A.; Morris, W.G. Multianalyte Chemical Identification and Quantitation Using a Single Radio Frequency Identification Sensor. Anal. Chem. 2007, 79, 45–51. [Google Scholar] [CrossRef]

- Potyrailo, R.A.; Nagraj, N.; Surman, C.; Boudries, H.; Lai, H.; Slocik, J.M.; Kelley-Loughnane, N.; Naik, R.R. Wireless Sensors and Sensor Networks for Homeland Security Applications. TrAC Trends Anal. Chem. 2012, 40, 133–145. [Google Scholar] [CrossRef]

- Barreca, D.; Maccato, C.; Gasparotto, A. Metal Oxide Nanosystems As Chemoresistive Gas Sensors for Chemical Warfare Agents: A Focused Review. Adv. Mater. Interfaces 2022, 9, 2102525. [Google Scholar] [CrossRef]

- Love, C.; Nazemi, H.; El-Masri, E.; Ambrose, K.; Freund, M.S.; Emadi, A. A Review on Advanced Sensing Materials for Agricultural Gas Sensors. Sensors 2021, 21, 3423. [Google Scholar] [CrossRef] [PubMed]

- Chansin, G.; Pugh, D. Environmental Gas Sensors 2017–2027; CISION: Cambridge, UK, 2016. [Google Scholar]

- Reportlinker Environmental Gas Sensors 2017–2027. Available online: https://www.prnewswire.com/news-releases/environmental-gas-sensors-2017-2027-300377842.html (accessed on 24 July 2023).

- Ruiz Simões, F.; Xavier, M.G. Electrochemical Sensors. In Nanoscience and Its Applications; William Andrew: Norwich, NY, USA, 2017; pp. 155–178. ISBN 978-0-323-49780-0. [Google Scholar]

- Aloisio, D.; Donato, N. Development of Gas Sensors on Microstrip Disk Resonators. Procedia Eng. 2014, 87, 1083–1086. [Google Scholar] [CrossRef]

- Hodgkinson, J.; Tatam, R.P. Optical Gas Sensing: A Review. Meas. Sci. Technol. 2013, 24, 012004. [Google Scholar] [CrossRef]

- Franco, M.A.; Conti, P.P.; Andre, R.S.; Correa, D.S. A Review on Chemiresistive ZnO Gas Sensors. Sens. Actuators Rep. 2022, 4, 100100. [Google Scholar] [CrossRef]

- Velmathi, G.; Mohan, S.; Henry, R. Analysis and Review of Tin Oxide-Based Chemoresistive Gas Sensor. IETE Tech. Rev. 2016, 33, 323–331. [Google Scholar] [CrossRef]

- Arena, A.; Donato, N.; Saitta, G. Capacitive Humidity Sensors Based on MWCNTs/Polyelectrolyte Interfaces Deposited on Flexible Substrates. Microelectron. J. 2009, 40, 887–890. [Google Scholar] [CrossRef]

- Lee, E.-B.; Hwang, I.-S.; Cha, J.-H.; Lee, H.-J.; Lee, W.-B.; Pak, J.J.; Lee, J.-H.; Ju, B.-K. Micromachined Catalytic Combustible Hydrogen Gas Sensor. Sens. Actuators B Chem. 2011, 153, 392–397. [Google Scholar] [CrossRef]

- Bârsan, N.; Weimar, U. Understanding the Fundamental Principles of Metal Oxide Based Gas Sensors; the Example of CO Sensing with SnO2 Sensors in the Presence of Humidity. J. Phys. Condens. Matter 2003, 15, R813. [Google Scholar] [CrossRef]

- Astolfi, M.; Rispoli, G.; Gherardi, S.; Zonta, G.; Malagù, C. Reproducibility and Repeatability Tests on (SnTiNb)O2 Sensors in Detecting ppm-Concentrations of CO and Up to 40% of Humidity: A Statistical Approach. Sensors 2023, 23, 1983. [Google Scholar] [CrossRef]

- Gherardi, S.; Zonta, G.; Astolfi, M.; Malagù, C. Humidity Effects on SnO2 and (SnTiNb)O2 Sensors Response to CO and Two-Dimensional Calibration Treatment. Mater. Sci. Eng. B 2021, 265, 115013. [Google Scholar] [CrossRef]

- Parellada-Monreal, L.; Gherardi, S.; Zonta, G.; Malagù, C.; Casotti, D.; Cruciani, G.; Guidi, V.; Martínez-Calderón, M.; Castro-Hurtado, I.; Gamarra, D.; et al. WO3 Processed by Direct Laser Interference Patterning for NO2 Detection. Sens. Actuators B Chem. 2020, 305, 127226. [Google Scholar] [CrossRef]

- Alvarado, M.; La Flor, S.D.; Llobet, E.; Romero, A.; Ramírez, J.L. Performance of Flexible Chemoresistive Gas Sensors after Having Undergone Automated Bending Tests. Sensors 2019, 19, 5190. [Google Scholar] [CrossRef] [PubMed]

- Comini, E.; Faglia, G.; Sberveglieri, G.; Pan, Z.; Wang, Z.L. Stable and Highly Sensitive Gas Sensors Based on Semiconducting Oxide Nanobelts. Appl. Phys. Lett. 2002, 81, 1869–1871. [Google Scholar] [CrossRef]

- Wang, C.; Yin, L.; Zhang, L.; Xiang, D.; Gao, R. Metal Oxide Gas Sensors: Sensitivity and Influencing Factors. Sensors 2010, 10, 2088–2106. [Google Scholar] [CrossRef] [PubMed]

- Seiyama, T.; Kato, A.; Fujiishi, K.; Nagatani, M. A New Detector for Gaseous Components Using Semiconductive Thin Films. Anal. Chem. 1962, 34, 1502–1503. [Google Scholar] [CrossRef]

- Yamazoe, N. Toward Innovations of Gas Sensor Technology. Sens. Actuators B Chem. 2005, 108, 2–14. [Google Scholar] [CrossRef]

- Zonta, G.; Astolfi, M.; Casotti, D.; Cruciani, G.; Fabbri, B.; Gaiardo, A.; Gherardi, S.; Guidi, V.; Landini, N.; Valt, M.; et al. Reproducibility Tests with Zinc Oxide Thick-Film Sensors. Ceram. Int. 2019, 46. [Google Scholar] [CrossRef]

- Electrochemical Gas Sensors—Membrapor. Available online: https://www.membrapor.ch/electrochemical-gas-sensors/ (accessed on 24 July 2023).

- Panjan, P.; Ohtonen, E.; Tervo, P.; Virtanen, V.; Sesay, A.M. Shelf Life of Enzymatic Electrochemical Sensors. Procedia Technol. 2017, 27, 306–308. [Google Scholar] [CrossRef]

- Lange, D.; Brand, O.; Baltes, H. Resonant Gas Sensor. In CMOS Cantilever Sensor Systems: Atomic Force Microscopy and Gas Sensing Applications; Lange, D., Brand, O., Baltes, H., Eds.; Microtechnology and Mems; Springer: Berlin/Heidelberg, Germany, 2002; pp. 57–83. ISBN 978-3-662-05060-6. [Google Scholar]

- Hajjaj, A.Z.; Jaber, N.; Alcheikh, N.; Younis, M.I. A Resonant Gas Sensor Based on Multimode Excitation of a Buckled Microbeam. IEEE Sens. J. 2020, 20, 1778–1785. [Google Scholar] [CrossRef]

- Manzaneque, T.; Ghatkesar, M.K.; Alijani, F.; Xu, M.; Norte, R.A.; Steeneken, P.G. Resolution Limits of Resonant Sensors. Phys. Rev. Appl. 2023, 19, 054074. [Google Scholar] [CrossRef]

- Mishra, V.; Rashmi; Sukriti. Optical Gas Sensors; IntechOpen: London, UK, 2022; ISBN 978-1-80356-962-8. [Google Scholar]

- Wang, W. Advances in Chemical Sensors; IntechOpen: London, UK, 2012; ISBN 978-953-307-792-5. [Google Scholar]

- Pizzoferrato, R. Optical Chemical Sensors: Design and Applications. Sensors 2023, 23, 5284. [Google Scholar] [CrossRef] [PubMed]

- Catalytic Type—Operating Principle—Technology—FIGARO Engineering Inc. Available online: https://www.figaro.co.jp/en/technicalinfo/principle/catalytic-type.html (accessed on 24 July 2023).

- Principles, Advantages and Disadvantages of Common Sensors of Gas Detectors. Available online: https://www.aiyitec.com/info/principles-advantages-and-disadvantages-of-co-46102599.html (accessed on 19 September 2023).

- Ahmad, W.R.W.; Mamat, M.H.; Zoolfakar, A.S.; Khusaimi, Z.; Rusop, M. A Review on Hematite α-Fe2O3 Focusing on Nanostructures, Synthesis Methods and Applications. In Proceedings of the 2016 IEEE Student Conference on Research and Development (SCOReD), Kuala Lumpur, Malaysia, 13–14 December 2016; pp. 1–6. [Google Scholar]

- Ishihara, T.; Matsubara, S. Capacitive Type Gas Sensors. J. Electroceramics 1998, 2, 215–228. [Google Scholar] [CrossRef]

- Prior, E.M.; Brumbelow, K.; Miller, G.R. Measurement of Above-Canopy Meteorological Profiles Using Unmanned Aerial Systems. Hydrol. Process. 2020, 34, 865–867. [Google Scholar] [CrossRef]

- Bargougui, R.; Omri, K.; Mhemdi, A.; Ammar, S. Synthesis and Characterization of SnO2 Nanoparticles: Effect of Hydrolysis Rate on the Optical Properties. Adv. Mater. Lett. 2015, 6, 816–819. [Google Scholar] [CrossRef]

- Liu, Y.; Jiao, Y.; Qu, F.; Gong, L.; Wu, X. Facile Synthesis of Template-Induced SnO2 Nanotubes. J. Nanomater. 2013, 2013, e610964. [Google Scholar] [CrossRef]

- Park, M.-S.; Wang, G.-X.; Kang, Y.-M.; Wexler, D.; Dou, S.-X.; Liu, H.-K. Preparation and Electrochemical Properties of SnO2 Nanowires for Application in Lithium-Ion Batteries. Angew. Chem. 2007, 119, 764–767. [Google Scholar] [CrossRef]

- Choi, P.G.; Izu, N.; Shirahata, N.; Masuda, Y. SnO2 Nanosheets for Selective Alkene Gas Sensing. ACS Appl. Nano Mater. 2019, 2, 1820–1827. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, J.; Yang, J.; Wang, S. Pt Nanoparticles Functionalized 3D SnO2 Nanoflowers for Gas Sensor Application. Solid-State Electron. 2017, 130, 20–27. [Google Scholar] [CrossRef]

- Zou, R.; Hu, J.; Zhang, Z.; Chen, Z.; Liao, M. SnO2 Nanoribbons: Excellent Field-Emitters. CrystEngComm 2011, 13, 2289–2293. [Google Scholar] [CrossRef]

- Lu, X.; Wang, H.; Wang, Z.; Jiang, Y.; Cao, D.; Yang, G. Room-Temperature Synthesis of Colloidal SnO2 Quantum Dot Solution and Ex-Situ Deposition on Carbon Nanotubes as Anode Materials for Lithium Ion Batteries. J. Alloys Compd. 2016, 680, 109–115. [Google Scholar] [CrossRef]

- Fan, H.; Zheng, X.; Shen, Q.; Wang, W.; Dong, W. Hydrothermal Synthesis and Their Ethanol Gas Sensing Performance of 3-Dimensional Hierarchical Nano Pt/SnO2. J. Alloys Compd. 2022, 909, 164693. [Google Scholar] [CrossRef]

- Bokov, D.; Turki Jalil, A.; Chupradit, S.; Suksatan, W.; Javed Ansari, M.; Shewael, I.H.; Valiev, G.H.; Kianfar, E. Nanomaterial by Sol-Gel Method: Synthesis and Application. Adv. Mater. Sci. Eng. 2021, 2021, e5102014. [Google Scholar] [CrossRef]

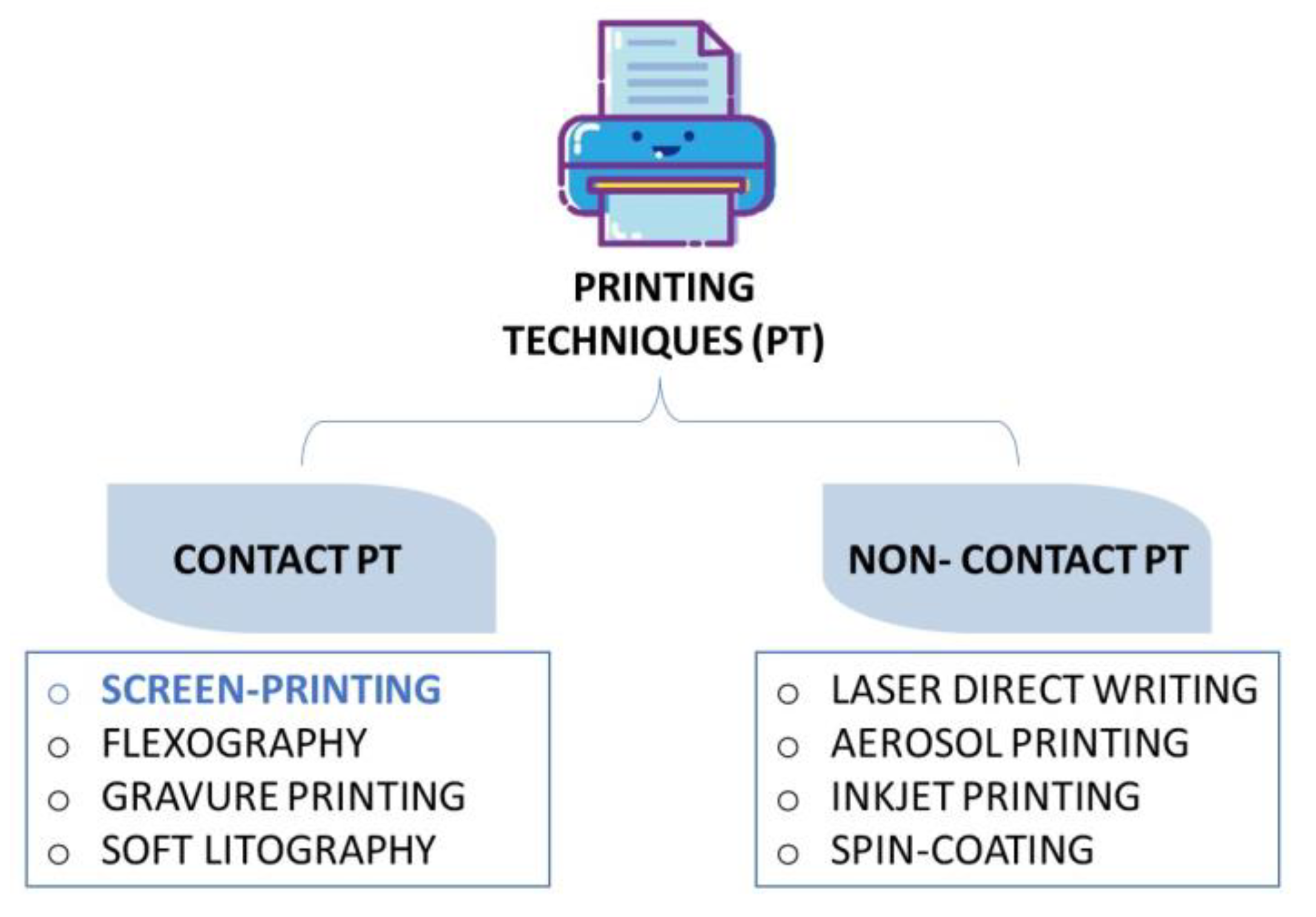

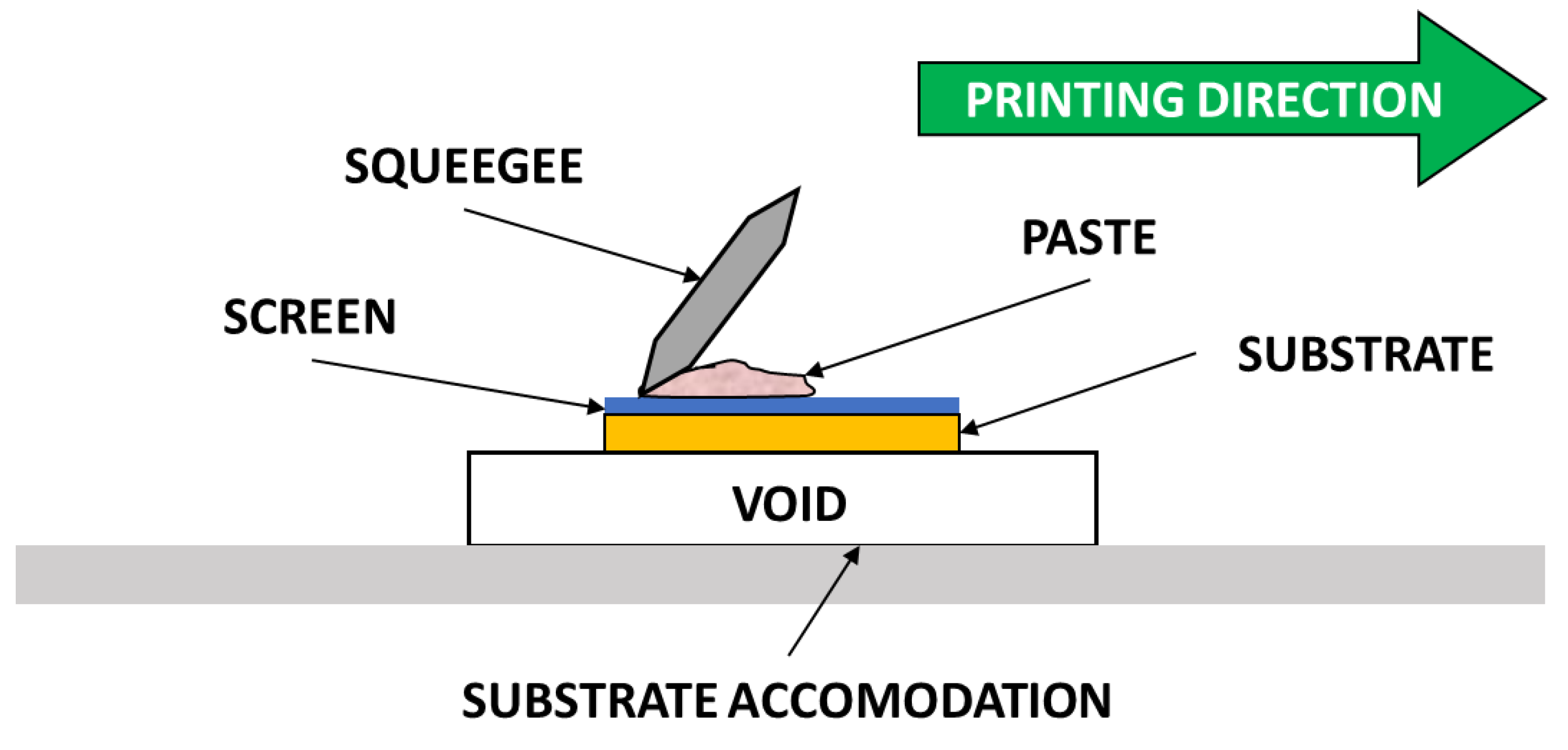

- Cruz, S.; Rocha, L.; Viana, J. Printing Technologies on Flexible Substrates for Printed Electronics; IntechOpen: London, UK, 2018; ISBN 978-1-78923-456-5. [Google Scholar]

- Simonenko, N.P.; Fisenko, N.A.; Fedorov, F.S.; Simonenko, T.L.; Mokrushin, A.S.; Simonenko, E.P.; Korotcenkov, G.; Sysoev, V.V.; Sevastyanov, V.G.; Kuznetsov, N.T. Printing Technologies as an Emerging Approach in Gas Sensors: Survey of Literature. Sensors 2022, 22, 3473. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Liu, X.; Zhang, J.; Kumar, M. Room-Temperature Gas Sensors Under Photoactivation: From Metal Oxides to 2D Materials. Nano-Micro Lett. 2020, 12, 164. [Google Scholar] [CrossRef] [PubMed]

- Imran, M.; Rashid, S.S.A.A.H.; Sabri, Y.; Motta, N.; Tesfamichael, T.; Sonar, P.; Shafiei, M. Template Based Sintering of WO3 Nanoparticles into Porous Tungsten Oxide Nanofibers for Acetone Sensing Applications. J. Mater. Chem. C 2019, 7, 2961–2970. [Google Scholar] [CrossRef]

- Espid, E.; Adeli, B.; Taghipour, F. Enhanced Gas Sensing Performance of Photo-Activated, Pt-Decorated, Single-Crystal ZnO Nanowires. J. Electrochem. Soc. 2019, 166, H3223. [Google Scholar] [CrossRef]

- Giberti, A.; Casotti, D.; Cruciani, G.; Fabbri, B.; Gaiardo, A.; Guidi, V.; Malagù, C.; Zonta, G.; Gherardi, S. Electrical Conductivity of CdS Films for Gas Sensing: Selectivity Properties to Alcoholic Chains. Sens. Actuators B Chem. 2015, 207, 504–510. [Google Scholar] [CrossRef]

- Gaiardo, A.; Fabbri, B.; Guidi, V.; Bellutti, P.; Giberti, A.; Gherardi, S.; Vanzetti, L.; Malagù, C.; Zonta, G. Metal Sulfides as Sensing Materials for Chemoresistive Gas Sensors. Sensors 2016, 16, 296. [Google Scholar] [CrossRef]

- Castro, M.S.; Aldao, C.M. Prebreakdown Conduction in Zinc Oxide Varistors: Thermionic or Tunnel Currents and One-step or Two-step Conduction Processes. Appl. Phys. Lett. 1993, 63, 1077–1079. [Google Scholar] [CrossRef]

- Blaustein, G.; Castro, M.S.; Aldao, C.M. Influence of Frozen Distributions of Oxygen Vacancies on Tin Oxide Conductance. Sens. Actuators B Chem. 1999, 55, 33–37. [Google Scholar] [CrossRef]

- Aldao, C.M.; Mirabella, D.A.; Ponce, M.A.; Giberti, A.; Malagù, C. Role of Intragrain Oxygen Diffusion in Polycrystalline Tin Oxide Conductivity. J. Appl. Phys. 2011, 109, 063723. [Google Scholar] [CrossRef][Green Version]

- Aldao, C.M.; Malagù, C. Non-Parabolic Intergranular Barriers in Tin Oxide and Gas Sensing. J. Appl. Phys. 2012, 112, 024518. [Google Scholar] [CrossRef]

- Aharon, M.; Elad, M.; Bruckstein, A. K-SVD: An Algorithm for Designing Overcomplete Dictionaries for Sparse Representation. IEEE Trans. Signal Process. 2006, 54, 4311–4322. [Google Scholar] [CrossRef]

- Zonta, G.; Astolfi, M.; de Togni, A.; Gaiardo, A.; Gherardi, S.; Guidi, V.; Landini, N.; Palmonari, C.; Malagù, C. Sensing Device for Colorectal Cancer Preventive Screening through Fecal Odor Analysis: Clinical Validation Outcomes. ECS Meet. Abstr. 2020, MA2020-01, 2032. [Google Scholar] [CrossRef]

- Zonta, G.; Fabbri, B.; Giberti, A.; Guidi, V.; Landini, N.; Malagù, C. Detection of Colorectal Cancer Biomarkers in the Presence of Interfering Gases. Procedia Eng. 2014, 87, 596–599. [Google Scholar] [CrossRef]

- Calderón-Garcidueñas, L.; Mora-Tiscareño, A.; Ontiveros, E.; Gómez-Garza, G.; Barragán-Mejía, G.; Broadway, J.; Chapman, S.; Valencia-Salazar, G.; Jewells, V.; Maronpot, R.R.; et al. Air Pollution, Cognitive Deficits and Brain Abnormalities: A Pilot Study with Children and Dogs. Brain Cogn. 2008, 68, 117–127. [Google Scholar] [CrossRef] [PubMed]

- Therivel, J.G.; Therivel, R. Introduction to Environmental Impact Assessment, 5th ed.; Routledge: London, UK, 2019; ISBN 978-0-429-47073-8. [Google Scholar]

- Schraufnagel, D.E.; Balmes, J.R.; Cowl, C.T.; De Matteis, S.; Jung, S.-H.; Mortimer, K.; Perez-Padilla, R.; Rice, M.B.; Riojas-Rodriguez, H.; Sood, A.; et al. Air Pollution and Noncommunicable Diseases: A Review by the Forum of International Respiratory Societies’ Environmental Committee, Part 2: Air Pollution and Organ Systems. Chest 2019, 155, 417–426. [Google Scholar] [CrossRef]

- Manisalidis, I.; Stavropoulou, E.; Stavropoulos, A.; Bezirtzoglou, E. Environmental and Health Impacts of Air Pollution: A Review. Front. Public Health 2020, 8, 14. [Google Scholar] [CrossRef]

- Carbon Monoxide. Available online: https://www.cdc.gov/nceh/features/copoisoning/index.html (accessed on 25 July 2023).

- Gaiardo, A.; Krik, S.; Valt, M.; Fabbri, B.; Tonezzer, M.; Feng, Z.; Guidi, V.; Bellutti, P. Development of a Sensor Array Based on Pt, Pd, Ag and Au Nanocluster Decorated SnO2 for Precision Agriculture. ECS Meet. Abstr. 2021, MA2021-01, 1550. [Google Scholar] [CrossRef]

- Gallardo, A.H. Hydrogeological Characterisation and Groundwater Exploration for the Development of Irrigated Agriculture in the West Kimberley Region, Western Australia. Groundw. Sustain. Dev. 2019, 8, 187–197. [Google Scholar] [CrossRef]

- Strati, V.; Albéri, M.; Anconelli, S.; Baldoncini, M.; Bittelli, M.; Bottardi, C.; Chiarelli, E.; Fabbri, B.; Guidi, V.; Raptis, K.G.C.; et al. Modelling Soil Water Content in a Tomato Field: Proximal Gamma Ray Spectroscopy and Soil–Crop System Models. Agriculture 2018, 8, 60. [Google Scholar] [CrossRef]

- Neethirajan, S.; Jayas, D.S.; Sadistap, S. Carbon Dioxide (CO2) Sensors for the Agri-Food Industry—A Review. Food Bioprocess Technol. 2009, 2, 115–121. [Google Scholar] [CrossRef]

- Ochoa-Muñoz, Y.H.; Mejía de Gutiérrez, R.; Rodríguez-Páez, J.E. Metal Oxide Gas Sensors to Study Acetone Detection Considering Their Potential in the Diagnosis of Diabetes: A Review. Molecules 2023, 28, 1150. [Google Scholar] [CrossRef] [PubMed]

- Mazzatenta, A.; Pokorski, M.; Sartucci, F.; Domenici, L.; Di Giulio, C. Volatile Organic Compounds (VOCs) Fingerprint of Alzheimer’s Disease. Respir. Physiol. Neurobiol. 2015, 209, 81–84. [Google Scholar] [CrossRef] [PubMed]

- Tisch, U.; Schlesinger, I.; Ionescu, R.; Nassar, M.; Axelrod, N.; Robertman, D.; Tessler, Y.; Azar, F.; Marmur, A.; Aharon-Peretz, J.; et al. Detection of Alzheimer’s and Parkinson’s Disease from Exhaled Breath Using Nanomaterial-Based Sensors. Nanomedicine 2013, 8, 43–56. [Google Scholar] [CrossRef] [PubMed]

- Nasiri, N.; Clarke, C. Nanostructured Chemiresistive Gas Sensors for Medical Applications. Sensors 2019, 19, 462. [Google Scholar] [CrossRef] [PubMed]

- Moon, H.G.; Jung, Y.; Han, S.D.; Shim, Y.-S.; Jung, W.-S.; Lee, T.; Lee, S.; Park, J.H.; Baek, S.-H.; Kim, J.-S.; et al. All Villi-like Metal Oxide Nanostructures-Based Chemiresistive Electronic Nose for an Exhaled Breath Analyzer. Sens. Actuators B Chem. 2018, 257, 295–302. [Google Scholar] [CrossRef]

- Aasi, A.; Aghaei, S.M.; Panchapakesan, B. Noble Metal (Pt or Pd)-Decorated Atomically Thin MoS2 as a Promising Material for Sensing Colorectal Cancer Biomarkers through Exhaled Breath. Int. J. Comput. Mater. Sci. Eng. 2024, 13, 2350014. [Google Scholar] [CrossRef]

- Hammoudi, N.; Ahmed, K.B.R.; Garcia-Prieto, C.; Huang, P. Metabolic Alterations in Cancer Cells and Therapeutic Implications. Chin. J. Cancer 2011, 30, 508–525. [Google Scholar] [CrossRef]

- Astolfi, M.; Rispoli, G.; Anania, G.; Zonta, G.; Malagù, C. Chemoresistive Nanosensors Employed to Detect Blood Tumor Markers in Patients Affected by Colorectal Cancer in a One-Year Follow Up. Cancers 2023, 15, 1797. [Google Scholar] [CrossRef]

- Zonta, G.; Malagù, C.; Gherardi, S.; Giberti, A.; Pezzoli, A.; De Togni, A.; Palmonari, C. Clinical Validation Results of an Innovative Non-Invasive Device for Colorectal Cancer Preventive Screening through Fecal Exhalation Analysis. Cancers 2020, 12, 1471. [Google Scholar] [CrossRef] [PubMed]

- Jang, M.; Kim, S.S.; Lee, J. Cancer Cell Metabolism: Implications for Therapeutic Targets. Exp. Mol. Med. 2013, 45, e45. [Google Scholar] [CrossRef] [PubMed]

- Van der Paal, J.; Neyts, E.C.; Verlackt, C.C.W.; Bogaerts, A. Effect of Lipid Peroxidation on Membrane Permeability of Cancer and Normal Cells Subjected to Oxidative Stress. Chem. Sci. 2016, 7, 489–498. [Google Scholar] [CrossRef] [PubMed]

- Masotti, L.; Casali, E.; Gesmundo, N.; Sartor, G.; Galeotti, T.; Borrello, S.; Piretti, M.V.; Pagliuca, G. Lipid Peroxidation in Cancer Cells: Chemical and Physical Studies. Ann. N. Y. Acad. Sci. 1988, 551, 47–57; discussion 57–58. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, K.; Podmore, I. Current Challenges in Volatile Organic Compounds Analysis as Potential Biomarkers of Cancer. J. Biomark. 2015, 2015, 981458. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Li, P.; Lian, A.; Sun, B.; Wang, X.; Guo, L.; Chi, C.; Liu, S.; Zhao, W.; Luo, S.; et al. Blood Volatile Compounds as Biomarkers for Colorectal Cancer. Cancer Biol. Ther. 2014, 15, 200–206. [Google Scholar] [CrossRef] [PubMed]

- Amann, A.; Mochalski, P.; Ruzsanyi, V.; Broza, Y.Y.; Haick, H. Assessment of the Exhalation Kinetics of Volatile Cancer Biomarkers Based on Their Physicochemical Properties. J. Breath Res. 2014, 8, 016003. [Google Scholar] [CrossRef]

- Bratulic, S.; Limeta, A.; Dabestani, S.; Birgisson, H.; Enblad, G.; Stålberg, K.; Hesselager, G.; Häggman, M.; Höglund, M.; Simonson, O.E.; et al. Noninvasive Detection of Any-Stage Cancer Using Free Glycosaminoglycans. Proc. Natl. Acad. Sci. USA 2022, 119, e2115328119. [Google Scholar] [CrossRef]

- Bajaj, J.S.; Saeian, K.; Schubert, C.M.; Hafeezullah, M.; Franco, J.; Varma, R.R.; Gibson, D.P.; Hoffmann, R.G.; Stravitz, R.T.; Heuman, D.M.; et al. Minimal Hepatic Encephalopathy Is Associated with Motor Vehicle Crashes: The Reality beyond the Driving Test. Hepatology 2009, 50, 1175–1183. [Google Scholar] [CrossRef]

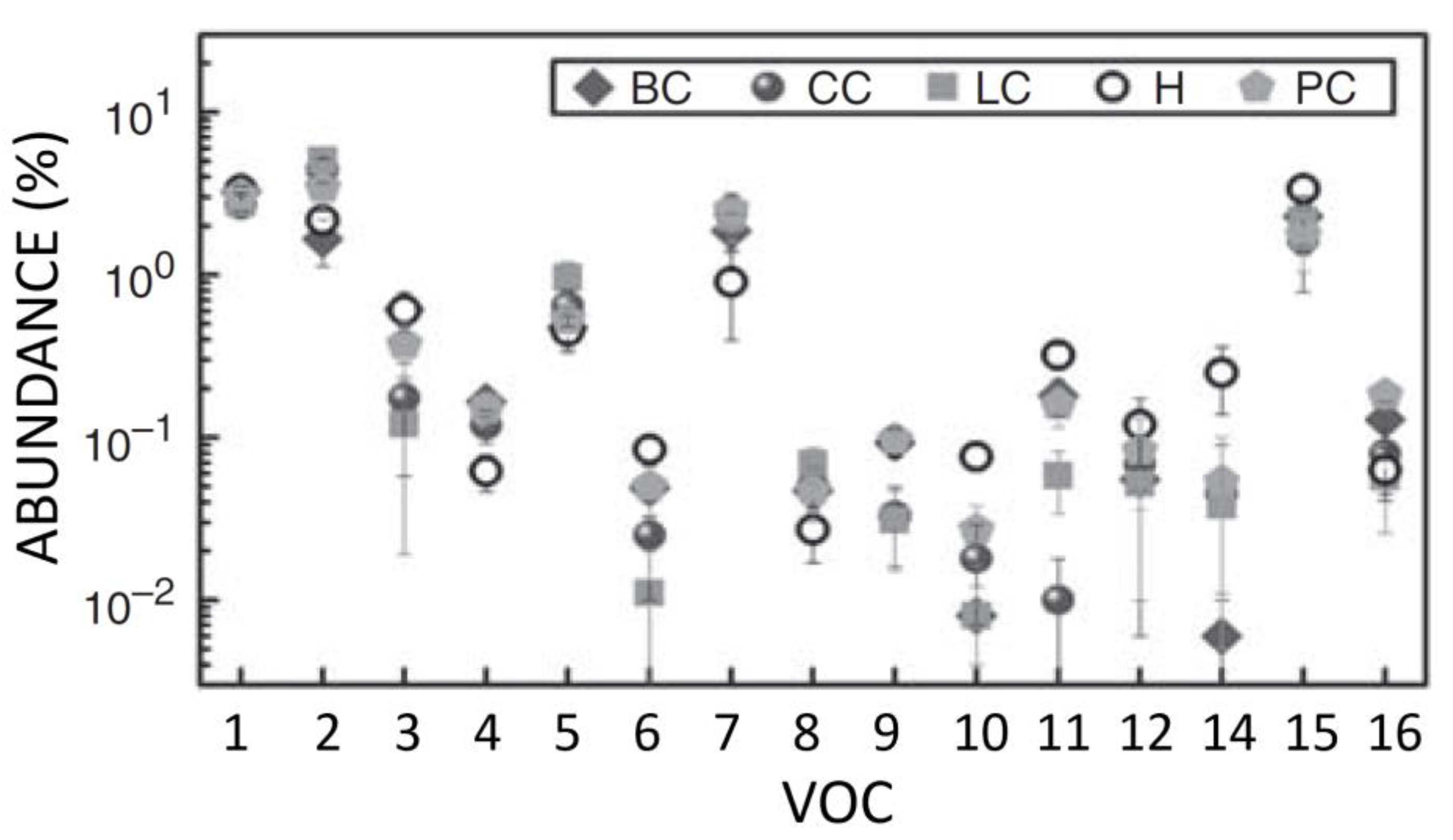

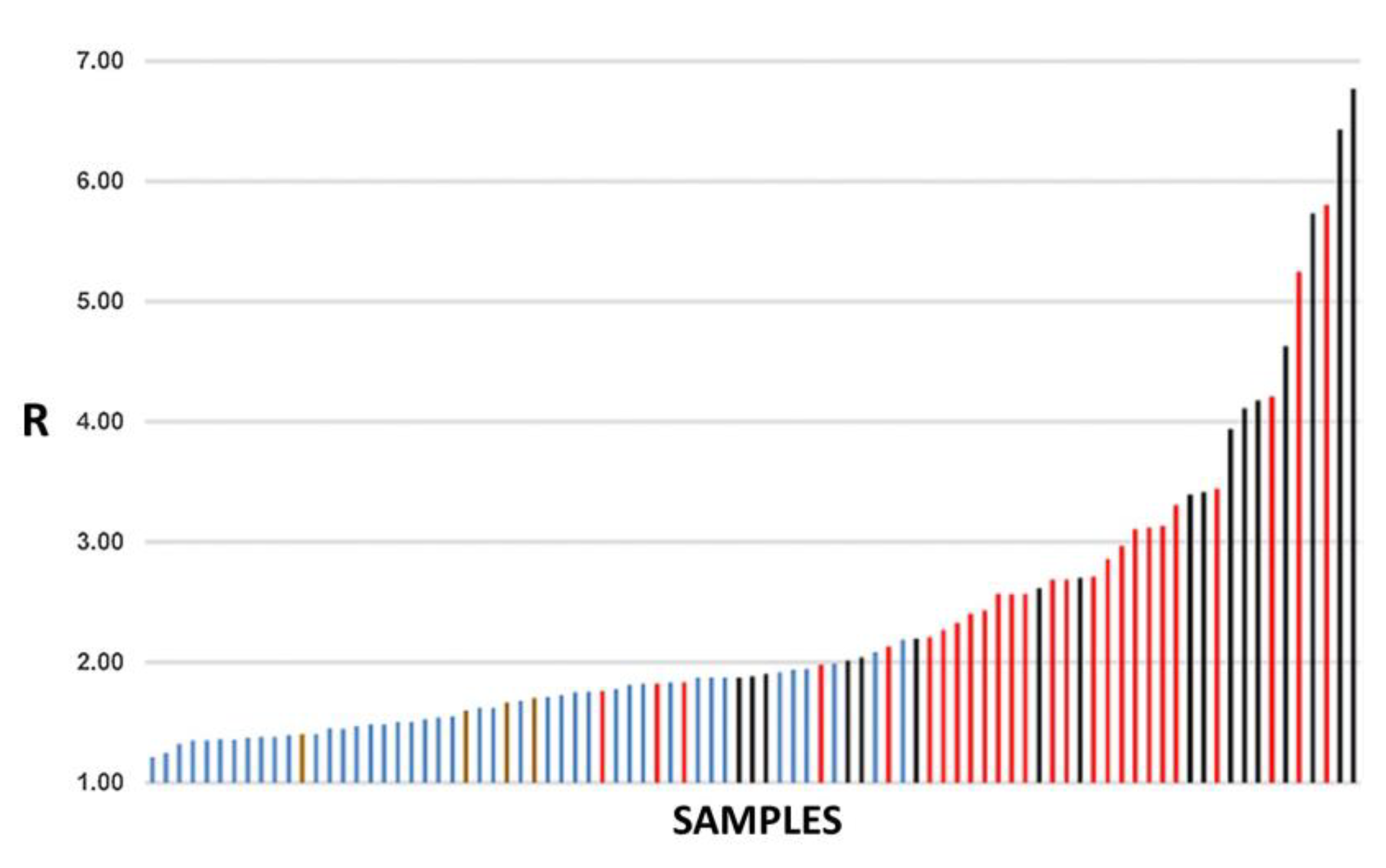

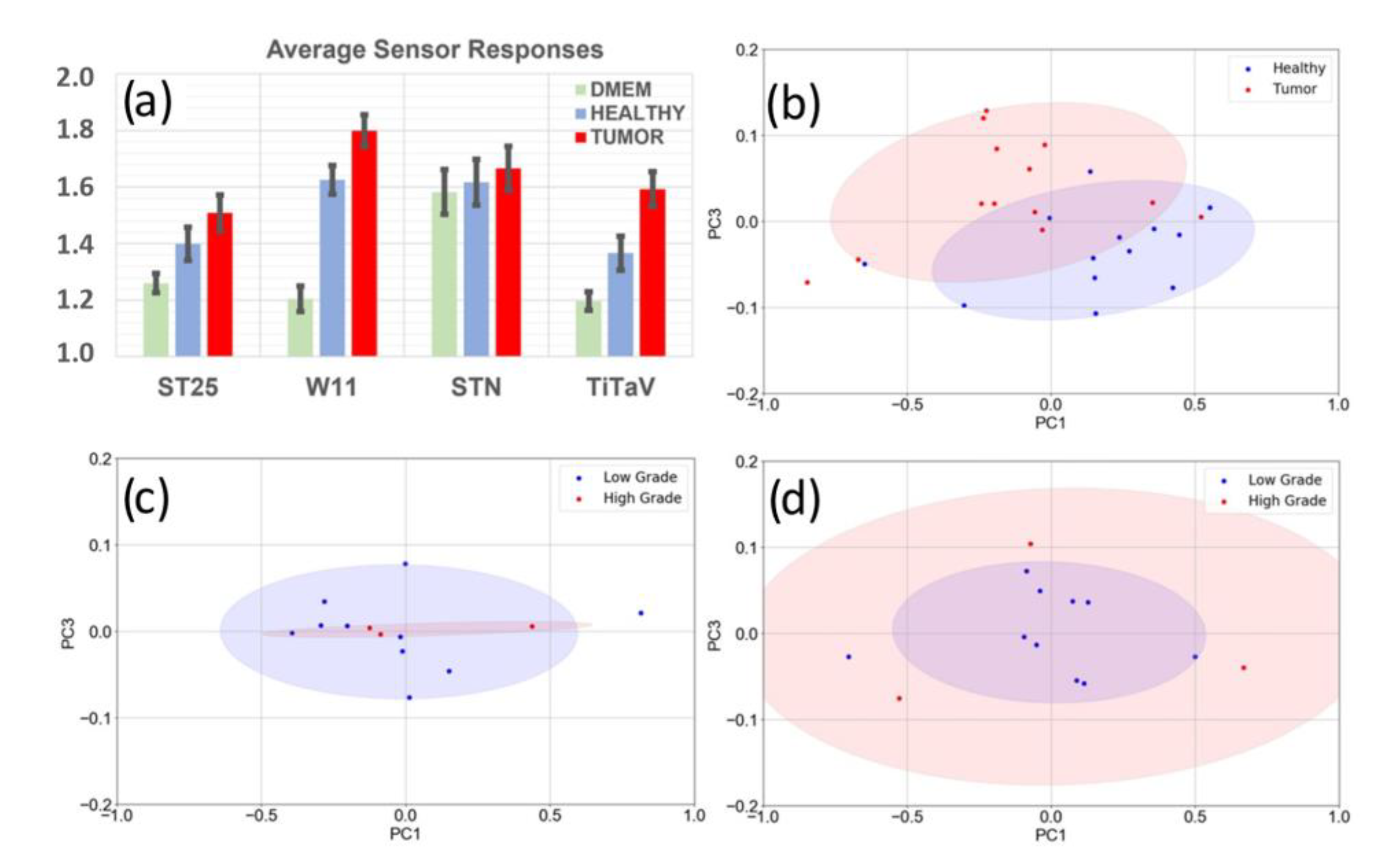

- Astolfi, M.; Rispoli, G.; Benedusi, M.; Zonta, G.; Landini, N.; Valacchi, G.; Malagù, C. Chemoresistive Sensors for Cellular Type Discrimination Based on Their Exhalations. Nanomaterials 2022, 12, 1111. [Google Scholar] [CrossRef]

- Ligor, M.; Ligor, T.; Bajtarevic, A.; Ager, C.; Pienz, M.; Klieber, M.; Denz, H.; Fiegl, M.; Hilbe, W.; Weiss, W.; et al. Determination of Volatile Organic Compounds in Exhaled Breath of Patients with Lung Cancer Using Solid Phase Microextraction and Gas Chromatography Mass Spectrometry. Clin. Chem. Lab. Med. 2009, 47, 550–560. [Google Scholar] [CrossRef] [PubMed]

- Mazzone, P.J. Analysis of Volatile Organic Compounds in the Exhaled Breath for the Diagnosis of Lung Cancer. J. Thorac. Oncol. 2008, 3, 774–780. [Google Scholar] [CrossRef] [PubMed]

- Bajtarevic, A.; Ager, C.; Pienz, M.; Klieber, M.; Schwarz, K.; Ligor, M.; Ligor, T.; Filipiak, W.; Denz, H.; Fiegl, M.; et al. Noninvasive Detection of Lung Cancer by Analysis of Exhaled Breath. BMC Cancer 2009, 9, 348. [Google Scholar] [CrossRef] [PubMed]

- Horvath, E.; Majlis, S.; Rossi, R.; Franco, C.; Niedmann, J.P.; Castro, A.; Dominguez, M. An Ultrasonogram Reporting System for Thyroid Nodules Stratifying Cancer Risk for Clinical Management. J. Clin. Endocrinol. Metab. 2009, 94, 1748–1751. [Google Scholar] [CrossRef] [PubMed]

- Altomare, D.F.; Di Lena, M.; Porcelli, F.; Trizio, L.; Travaglio, E.; Tutino, M.; Dragonieri, S.; Memeo, V.; de Gennaro, G. Exhaled Volatile Organic Compounds Identify Patients with Colorectal Cancer. Br. J. Surg. 2013, 100, 144–150. [Google Scholar] [CrossRef]

- de Meij, T.G.; Larbi, I.B.; van der Schee, M.P.; Lentferink, Y.E.; Paff, T.; Terhaar Sive Droste, J.S.; Mulder, C.J.; van Bodegraven, A.A.; de Boer, N.K. Electronic Nose Can Discriminate Colorectal Carcinoma and Advanced Adenomas by Fecal Volatile Biomarker Analysis: Proof of Principle Study. Int. J. Cancer 2014, 134, 1132–1138. [Google Scholar] [CrossRef] [PubMed]

- Zonta, G.; Anania, G.; Astolfi, M.; Feo, C.; Gaiardo, A.; Gherardi, S.; Alessio, G.; Guidi, V.; Landini, N.; Palmonari, C.; et al. Chemoresistive Sensors for Colorectal Cancer Preventive Screening through Fecal Odor: Double-Blind Approach. Sens. Actuators B Chem. 2019, 301, 127062. [Google Scholar] [CrossRef]

- Bax, C.; Lotesoriere, B.J.; Sironi, S.; Capelli, L. Review and Comparison of Cancer Biomarker Trends in Urine as a Basis for New Diagnostic Pathways. Cancers 2019, 11, 1244. [Google Scholar] [CrossRef]

- Chandrapalan, S.; Arasaradnam, R.P. Urine as a Biological Modality for Colorectal Cancer Detection. Expert Rev. Mol. Diagn. 2020, 20, 489–496. [Google Scholar] [CrossRef]

- Monedeiro, F.; Dos Reis, R.B.; Peria, F.M.; Sares, C.T.G.; De Martinis, B.S. Investigation of Sweat VOC Profiles in Assessment of Cancer Biomarkers Using HS-GC-MS. J. Breath Res. 2020, 14, 026009. [Google Scholar] [CrossRef]

- Gao, F.; Liu, C.; Zhang, L.; Liu, T.; Wang, Z.; Song, Z.; Cai, H.; Fang, Z.; Chen, J.; Wang, J.; et al. Wearable and Flexible Electrochemical Sensors for Sweat Analysis: A Review. Microsyst. Nanoeng. 2023, 9, 1. [Google Scholar] [CrossRef] [PubMed]

- Peng, G.; Hakim, M.; Broza, Y.Y.; Billan, S.; Abdah-Bortnyak, R.; Kuten, A.; Tisch, U.; Haick, H. Detection of Lung, Breast, Colorectal, and Prostate Cancers from Exhaled Breath Using a Single Array of Nanosensors. Br. J. Cancer 2010, 103, 542–551. [Google Scholar] [CrossRef] [PubMed]

- Di Lena, M.; Porcelli, F.; Altomare, D.F. Volatile Organic Compounds as New Biomarkers for Colorectal Cancer: A Review. Color. Dis. 2016, 18, 654–663. [Google Scholar] [CrossRef] [PubMed]

- COD. Available online: http://bioinf.modares.ac.ir/software/COD/ (accessed on 24 July 2023).

- Phillips, M.; Gleeson, K.; Hughes, J.M.; Greenberg, J.; Cataneo, R.N.; Baker, L.; McVay, W.P. Volatile Organic Compounds in Breath as Markers of Lung Cancer: A Cross-Sectional Study. Lancet 1999, 353, 1930–1933. [Google Scholar] [CrossRef] [PubMed]

- Bond, A.; Greenwood, R.; Lewis, S.; Corfe, B.; Sarkar, S.; O’Toole, P.; Rooney, P.; Burkitt, M.; Hold, G.; Probert, C. Volatile Organic Compounds Emitted from Faeces as a Biomarker for Colorectal Cancer. Aliment. Pharmacol. Ther. 2019, 49, 1005–1012. [Google Scholar] [CrossRef] [PubMed]

- da Costa, B.R.B.; De Martinis, B.S. Analysis of Urinary VOCs Using Mass Spectrometric Methods to Diagnose Cancer: A Review. Clin. Mass Spectrom. 2020, 18, 27–37. [Google Scholar] [CrossRef]

- Janfaza, S.; Banan Nojavani, M.; Khorsand, B.; Nikkhah, M.; Zahiri, J. Cancer Odor Database (COD): A Critical Databank for Cancer Diagnosis Research. Database 2017, 2017, bax055. [Google Scholar] [CrossRef]

- Janfaza, S.; Banan Nojavani, M.; Nikkhah, M.; Alizadeh, T.; Esfandiar, A.; Ganjali, M.R. A Selective Chemiresistive Sensor for the Cancer-Related Volatile Organic Compound Hexanal by Using Molecularly Imprinted Polymers and Multiwalled Carbon Nanotubes. Microchim. Acta 2019, 186, 137. [Google Scholar] [CrossRef]

- Sung, H.; Ferlay, J.; Siegel, R.L.; Laversanne, M.; Soerjomataram, I.; Jemal, A.; Bray, F. Global Cancer Statistics 2020: GLOBOCAN Estimates of Incidence and Mortality Worldwide for 36 Cancers in 185 Countries. CA Cancer J. Clin. 2021, 71, 209–249. [Google Scholar] [CrossRef]

- Common Cancer Types—NCI. Available online: https://www.cancer.gov/types/common-cancers (accessed on 24 July 2023).

- Siegel, R.L.; Miller, K.D.; Wagle, N.S.; Jemal, A. Cancer Statistics, 2023. CA Cancer J. Clin. 2023, 73, 17–48. [Google Scholar] [CrossRef]

- Ahmadipour, M.; Pang, A.L.; Ardani, M.R.; Pung, S.-Y.; Ooi, P.C.; Hamzah, A.A.; Mohd Razip Wee, M.F.; Aniq Shazni Mohammad Haniff, M.; Dee, C.F.; Mahmoudi, E.; et al. Detection of Breath Acetone by Semiconductor Metal Oxide Nanostructures-Based Gas Sensors: A Review. Mater. Sci. Semicond. Process. 2022, 149, 106897. [Google Scholar] [CrossRef]

- Borowik, P.; Adamowicz, L.; Tarakowski, R.; Wacławik, P.; Oszako, T.; Ślusarski, S.; Tkaczyk, M. Development of a Low-Cost Electronic Nose for Detection of Pathogenic Fungi and Applying It to Fusarium Oxysporum and Rhizoctonia Solani. Sensors 2021, 21, 5868. [Google Scholar] [CrossRef] [PubMed]

- Yuan, H.; Li, N.; Fan, W.; Cai, H.; Zhao, D. Metal-Organic Framework Based Gas Sensors. Adv. Sci. 2022, 9, 2104374. [Google Scholar] [CrossRef]

- Vajhadin, F.; Mazloum-Ardakani, M.; Amini, A. Metal Oxide-Based Gas Sensors for the Detection of Exhaled Breath Markers. Med. Devices Sens. 2021, 4, e10161. [Google Scholar] [CrossRef] [PubMed]

- Peled, N.; Hakim, M.; Bunn, P.A.; Miller, Y.E.; Kennedy, T.C.; Mattei, J.; Mitchell, J.D.; Hirsch, F.R.; Haick, H. Non-Invasive Breath Analysis of Pulmonary Nodules. J. Thorac. Oncol. 2012, 7, 1528–1533. [Google Scholar] [CrossRef] [PubMed]

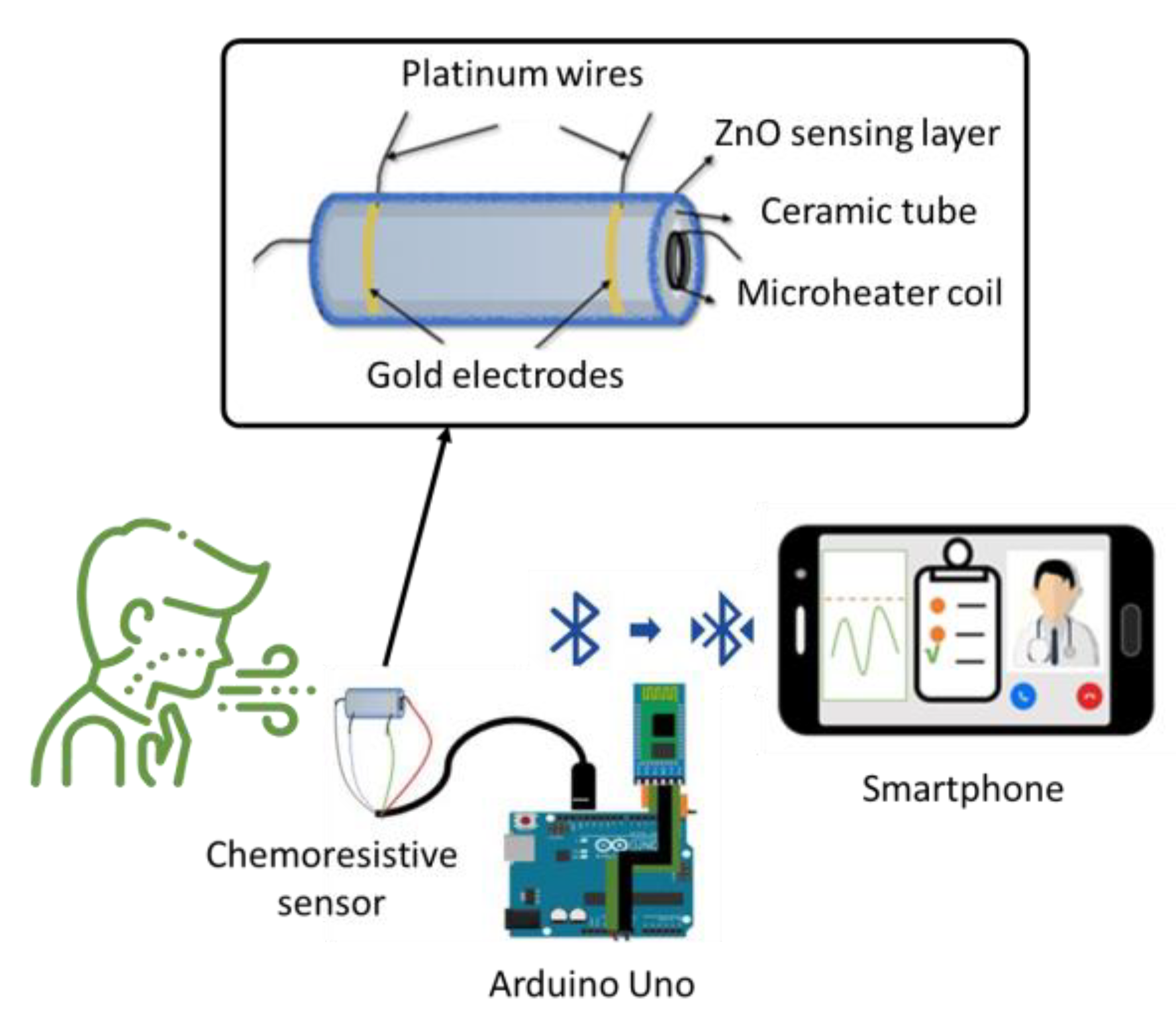

- Salimi, M.; Milani Hosseini, S.M.R. Smartphone-Based Detection of Lung Cancer-Related Volatile Organic Compounds (VOCs) Using Rapid Synthesized ZnO Nanosheet. Sens. Actuators B Chem. 2021, 344, 130127. [Google Scholar] [CrossRef]

- Li, G.; Zhu, X.; Liu, J.; Li, S.; Liu, X. Metal Oxide Semiconductor Gas Sensors for Lung Cancer Diagnosis. Chemosensors 2023, 11, 251. [Google Scholar] [CrossRef]

- Lett, L.; George, M.; Slater, R.; De Lacy Costello, B.; Ratcliffe, N.; García-Fiñana, M.; Lazarowicz, H.; Probert, C. Investigation of Urinary Volatile Organic Compounds as Novel Diagnostic and Surveillance Biomarkers of Bladder Cancer. Br. J. Cancer 2022, 127, 329–336. [Google Scholar] [CrossRef]

- Pinto, J.; Carapito, Â.; Amaro, F.; Lima, A.R.; Carvalho-Maia, C.; Martins, M.C.; Jerónimo, C.; Henrique, R.; de Lourdes Bastos, M.; de Pinho, P.G. Discovery of Volatile Biomarkers for Bladder Cancer Detection and Staging through Urine Metabolomics. Metabolites 2021, 11, 199. [Google Scholar] [CrossRef]

- Colorectal Cancer Statistics|How Common Is Colorectal Cancer? Available online: https://www.cancer.org/cancer/types/colon-rectal-cancer/about/key-statistics.html (accessed on 24 July 2023).

- Cancer of the Colon and Rectum—Cancer Stat Facts. Available online: https://seer.cancer.gov/statfacts/html/colorect.html (accessed on 24 July 2023).

- Tomlin, J.; Lowis, C.; Read, N.W. Investigation of Normal Flatus Production in Healthy Volunteers. Gut 1991, 32, 665–669. [Google Scholar] [CrossRef]

- Sonoda, H.; Kohnoe, S.; Yamazato, T.; Satoh, Y.; Morizono, G.; Shikata, K.; Morita, M.; Watanabe, A.; Morita, M.; Kakeji, Y.; et al. Colorectal Cancer Screening with Odour Material by Canine Scent Detection. Gut 2011, 60, 814–819. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Lorenzi, M.F.; Goddard, K.; Spinelli, J.J.; Gotay, C.; McBride, M.L. Late Morbidity Leading to Hospitalization among 5-Year Survivors of Young Adult Cancer: A Report of the Childhood, Adolescent and Young Adult Cancer Survivors Research Program. Int. J. Cancer 2014, 134, 1174–1182. [Google Scholar] [CrossRef] [PubMed]

- Malagù, C.; Gherardi, S.; Zonta, G.; Landini, N.; Giberti, A.; Fabbri, B.; Gaiardo, A.; Anania, G.; Rispoli, G.; Scagliarini, L. Combinazione Di Materiali Semiconduttori Nanoparticolati per Uso Nel Distinguere Cellule Normali Da Cellule Tumorali. Italian Patent 102015000057717, 10 February 2015. [Google Scholar]

- Allison, J.E.; Fraser, C.G.; Halloran, S.P.; Young, G.P. Population Screening for Colorectal Cancer Means Getting FIT: The Past, Present, and Future of Colorectal Cancer Screening Using the Fecal Immunochemical Test for Hemoglobin (FIT). Gut Liver 2014, 8, 117–130. [Google Scholar] [CrossRef] [PubMed]

- Zonta, G.; Anania, G.; de Togni, A.; Gaiardo, A.; Gherardi, S.; Giberti, A.; Guidi, V.; Landini, N.; Palmonari, C.; Ricci, L.; et al. Use of Gas Sensors and FOBT for the Early Detection of Colorectal Cancer. Proceedings 2017, 1, 398. [Google Scholar] [CrossRef]

- Jolliffe, I.T.; Cadima, J. Principal Component Analysis: A Review and Recent Developments. Philos. Trans. R. Soc. A 2016, 374, 20150202. [Google Scholar] [CrossRef]

- Grazzini, G.; Ventura, L.; Zappa, M.; Ciatto, S.; Confortini, M.; Rapi, S.; Rubeca, T.; Visioli, C.B.; Halloran, S.P. Influence of Seasonal Variations in Ambient Temperatures on Performance of Immunochemical Faecal Occult Blood Test for Colorectal Cancer Screening: Observational Study from the Florence District. Gut 2010, 59, 1511–1515. [Google Scholar] [CrossRef] [PubMed]

- Astolfi, M.; Zonta, G.; Landini, N.; Gherardi, S.; Rispoli, G.; Anania, G.; Benedusi, M.; Guidi, V.; Palmonari, C.; Secchiero, P. Chemoresistive Nanostructured Sensors for Tumor Pre-Screening. Multidiscip. Digit. Publ. Inst. Proc. 2019, 14, 29. [Google Scholar]

- Guardamagna, I.; Lonati, L.; Savio, M.; Stivala, L.A.; Ottolenghi, A.; Baiocco, G. An Integrated Analysis of the Response of Colorectal Adenocarcinoma Caco-2 Cells to X-ray Exposure. Front. Oncol. 2021, 11, 688919. [Google Scholar] [CrossRef]

- Sticozzi, C.; Belmonte, G.; Pecorelli, A.; Cervellati, F.; Leoncini, S.; Signorini, C.; Ciccoli, L.; De Felice, C.; Hayek, J.; Valacchi, G. Scavenger Receptor B1 Post-Translational Modifications in Rett Syndrome. FEBS Lett. 2013, 587, 2199–2204. [Google Scholar] [CrossRef]

| Cancer Type | Estimated New Cases | Estimated Deaths |

|---|---|---|

| Bladder | 82,290 | 16,710 |

| Breast (female) | 297,790 | 43,170 |

| Breast (male) | 2800 | 530 |

| Colorectal | 153,020 | 52,550 |

| Endometrial | 66,200 | 13,030 |

| Kidney | 81,800 | 14,890 |

| Leukemia | 59,610 | 23,710 |

| Liver and Intrahepatic Bile Duct | 41,210 | 29,380 |

| Lung (Including Bronchus) | 238,340 | 127,070 |

| Melanoma | 97,610 | 7990 |

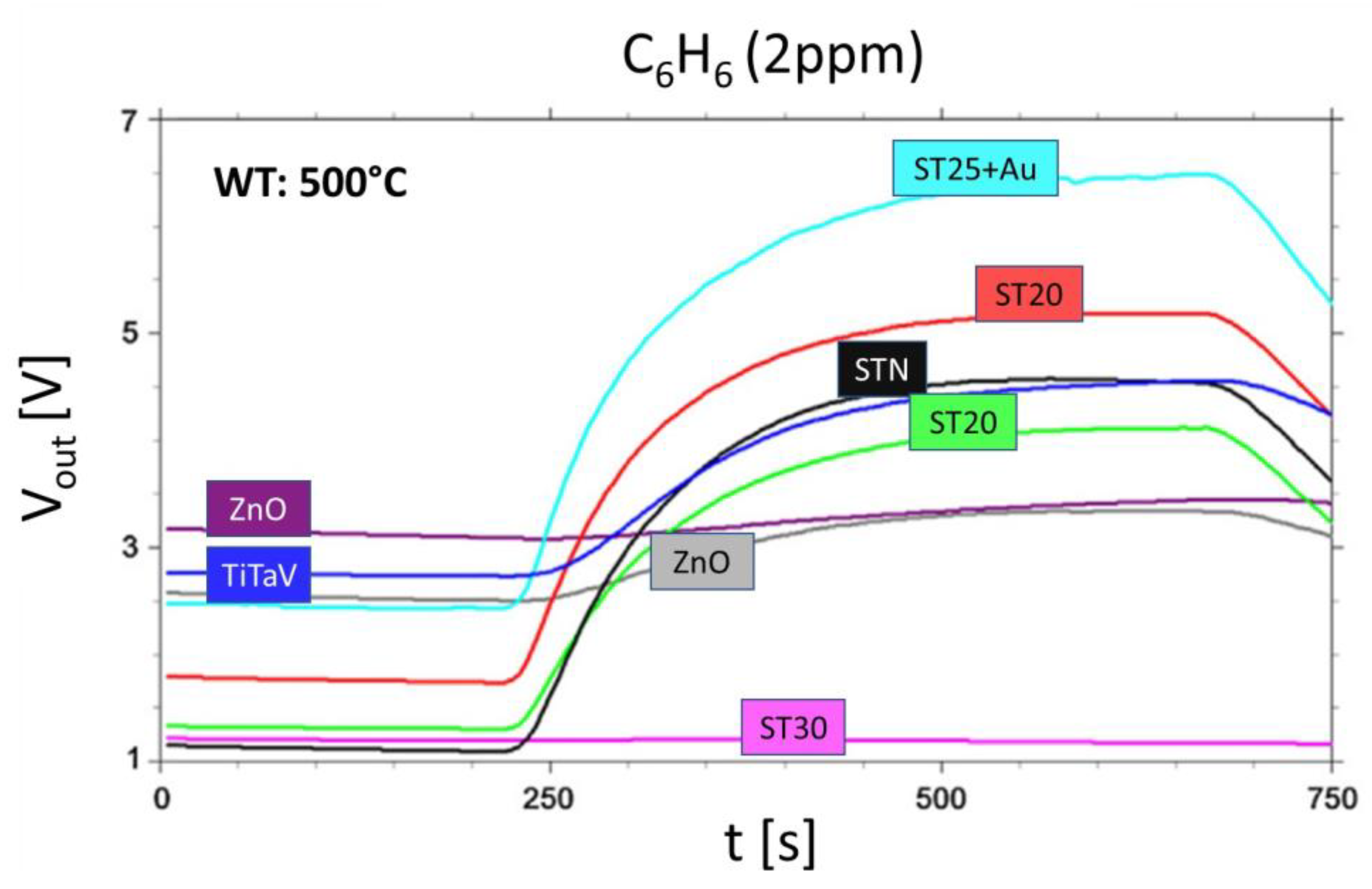

| Code | WT (°C) | Materials | Nanostructure Average Size (nm) |

|---|---|---|---|

| SmFeO3 | 350 | Iron and Samarium oxides | 63 |

| TiTaV | 450 | Titanium, tantalum, and vanadium oxides | 52 |

| ST20 | 450 | Tin and Titanium oxide (20%) | 36 |

| In2O3 | 350 | Indium Oxide | 53 |

| ST25 + Au | 450 | Tin and Titanium oxide (25%) with the addition of gold nanoparticles | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zonta, G.; Rispoli, G.; Malagù, C.; Astolfi, M. Overview of Gas Sensors Focusing on Chemoresistive Ones for Cancer Detection. Chemosensors 2023, 11, 519. https://doi.org/10.3390/chemosensors11100519

Zonta G, Rispoli G, Malagù C, Astolfi M. Overview of Gas Sensors Focusing on Chemoresistive Ones for Cancer Detection. Chemosensors. 2023; 11(10):519. https://doi.org/10.3390/chemosensors11100519

Chicago/Turabian StyleZonta, Giulia, Giorgio Rispoli, Cesare Malagù, and Michele Astolfi. 2023. "Overview of Gas Sensors Focusing on Chemoresistive Ones for Cancer Detection" Chemosensors 11, no. 10: 519. https://doi.org/10.3390/chemosensors11100519

APA StyleZonta, G., Rispoli, G., Malagù, C., & Astolfi, M. (2023). Overview of Gas Sensors Focusing on Chemoresistive Ones for Cancer Detection. Chemosensors, 11(10), 519. https://doi.org/10.3390/chemosensors11100519