Optimized Application of Sustainable Development Strategy in International Engineering Project Management

Abstract

1. Introduction

2. Literature Review

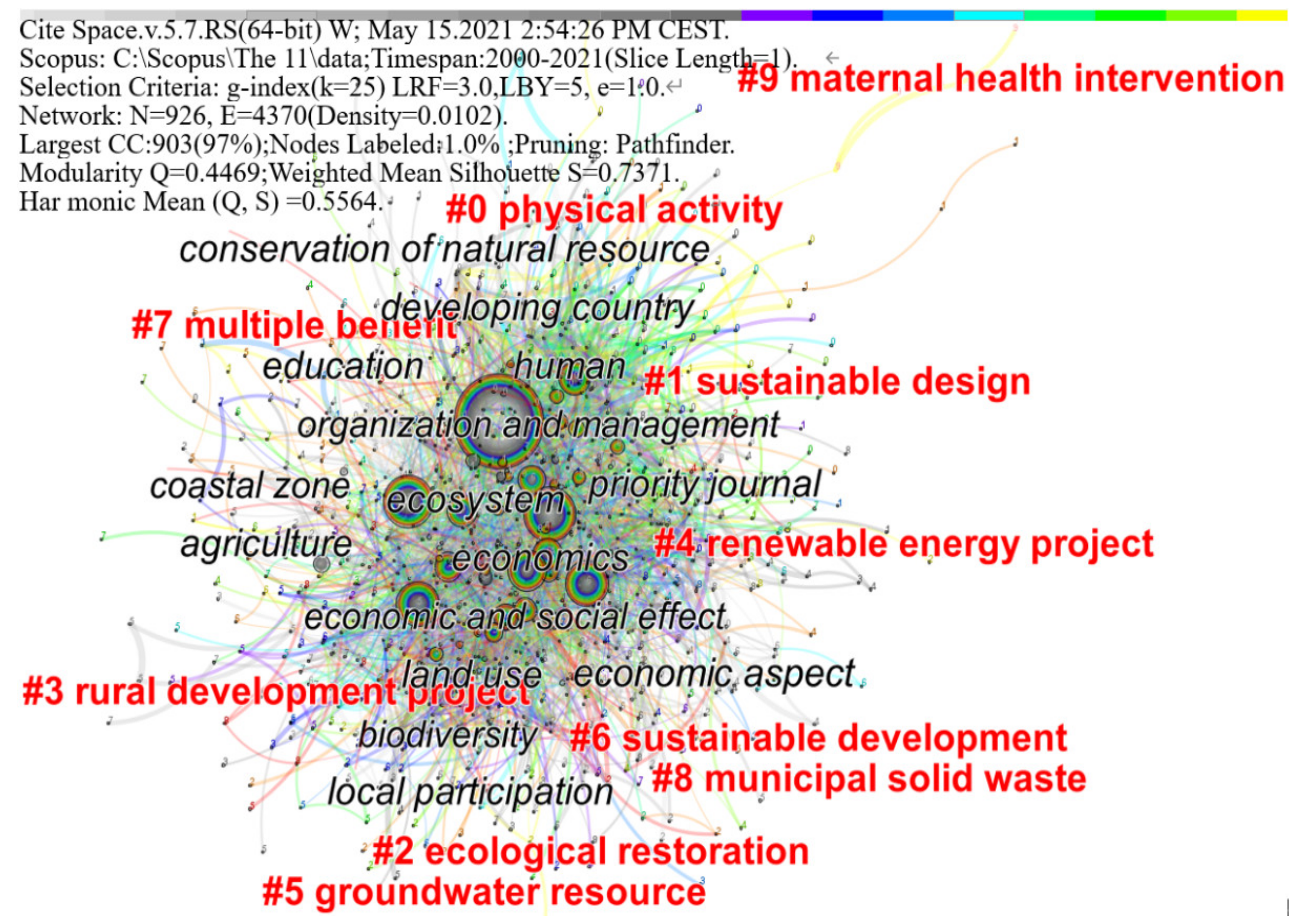

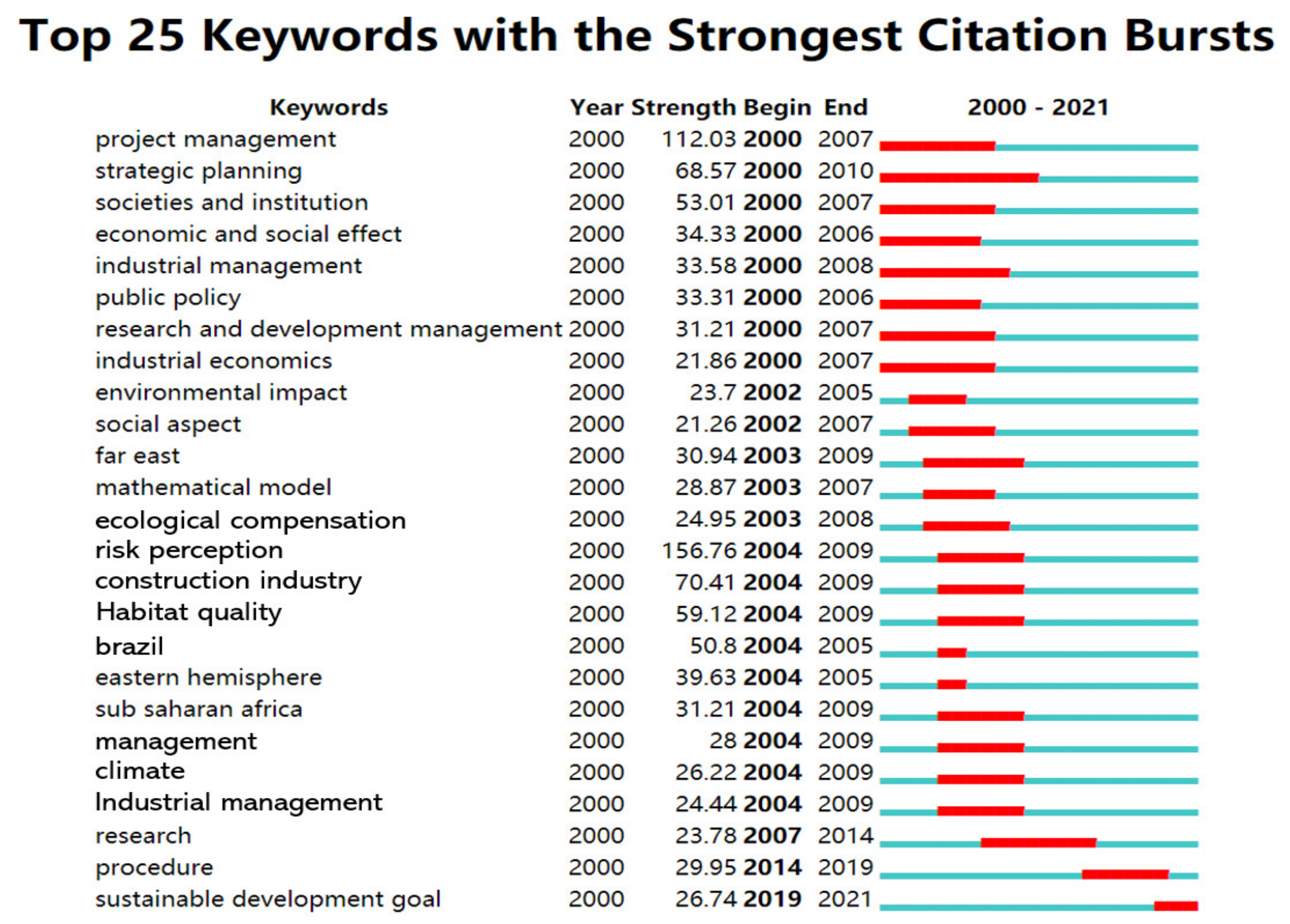

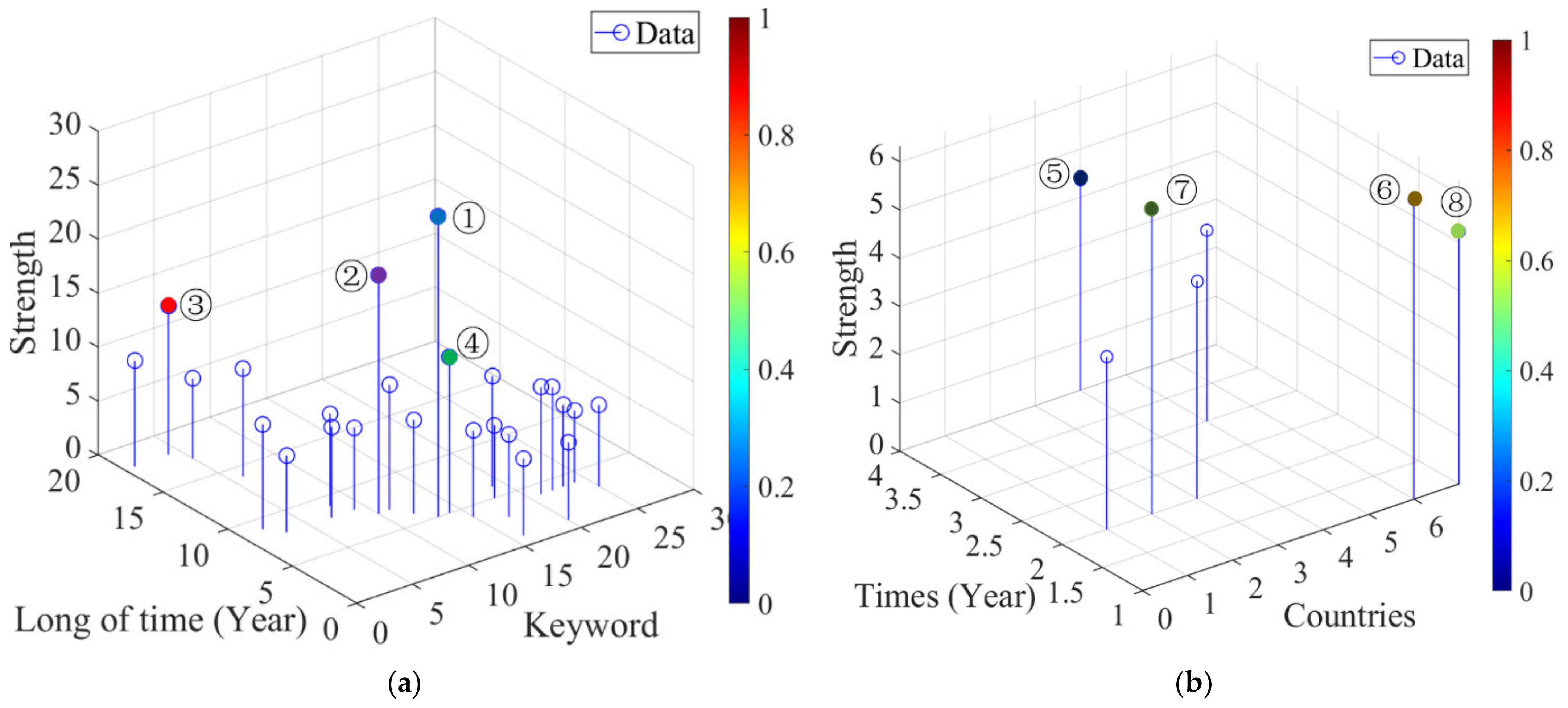

2.1. Visual Clustering Coupling Analysis

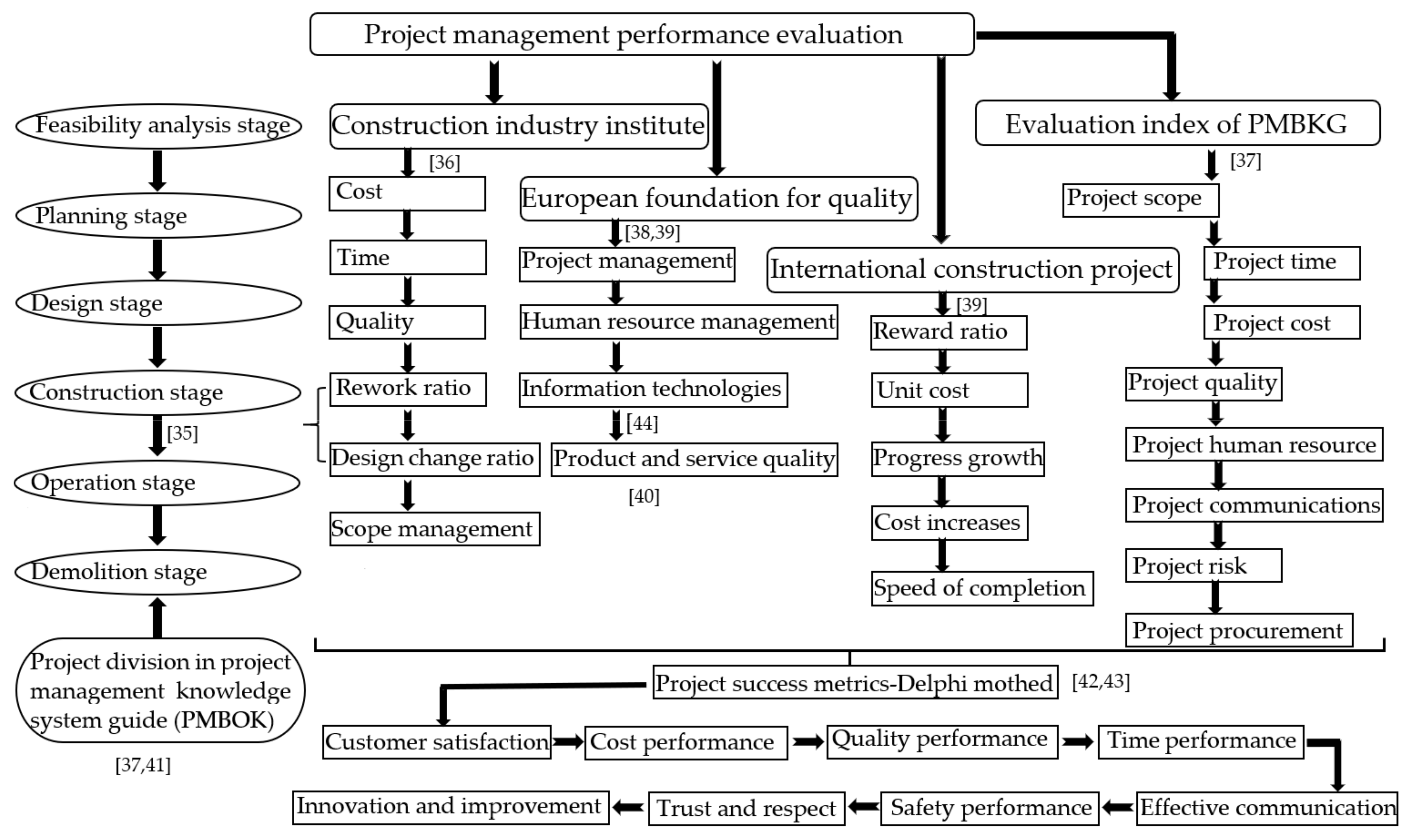

2.2. Current International System Assessment

3. Methodology and Modeling

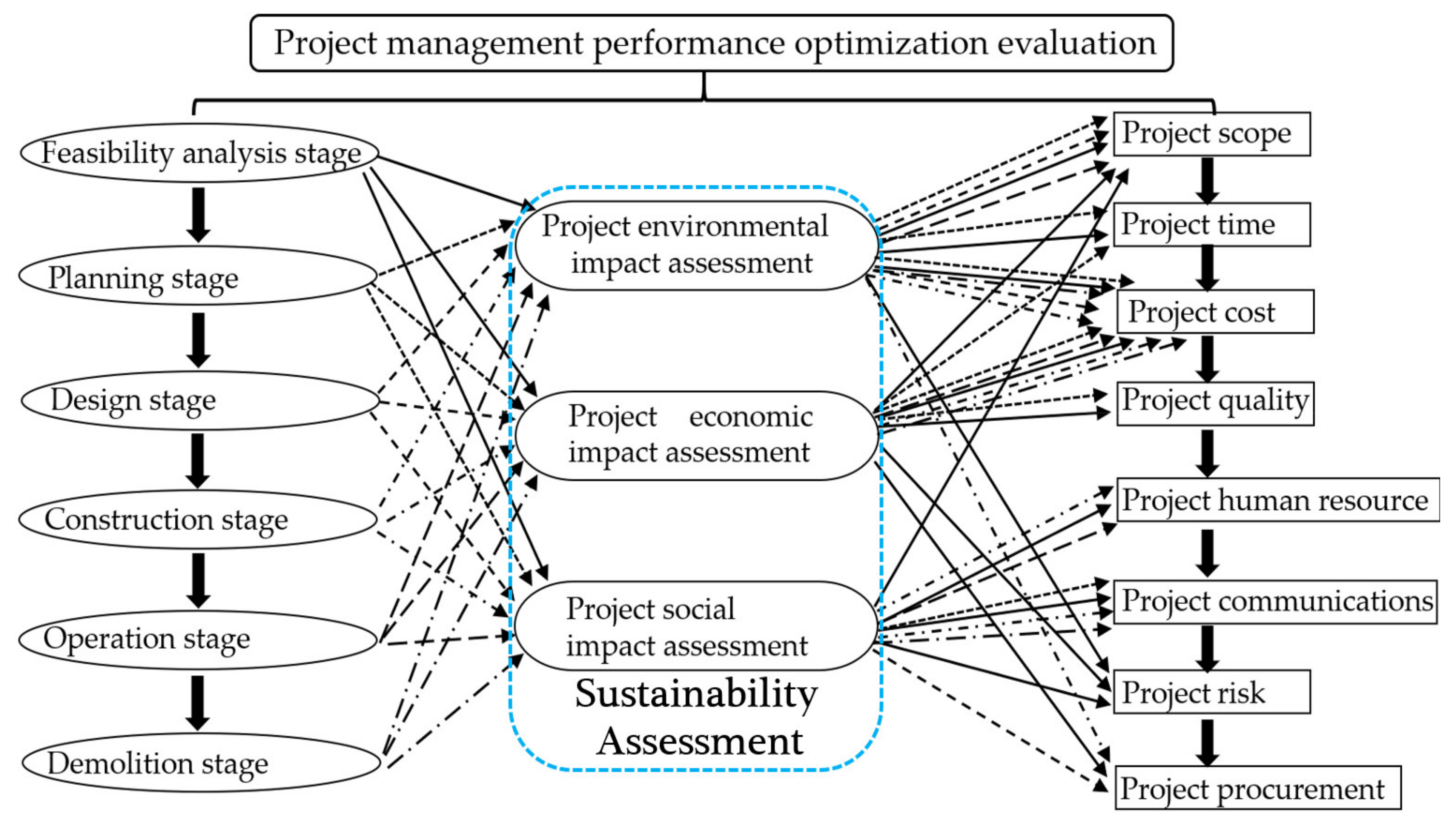

3.1. Construction Project Management

3.2. Environmental Impact during the Construction Phase

3.3. Project Construction Economic Cost

3.4. Cubic Spline Interpolation

4. Case Analysis and Management Design

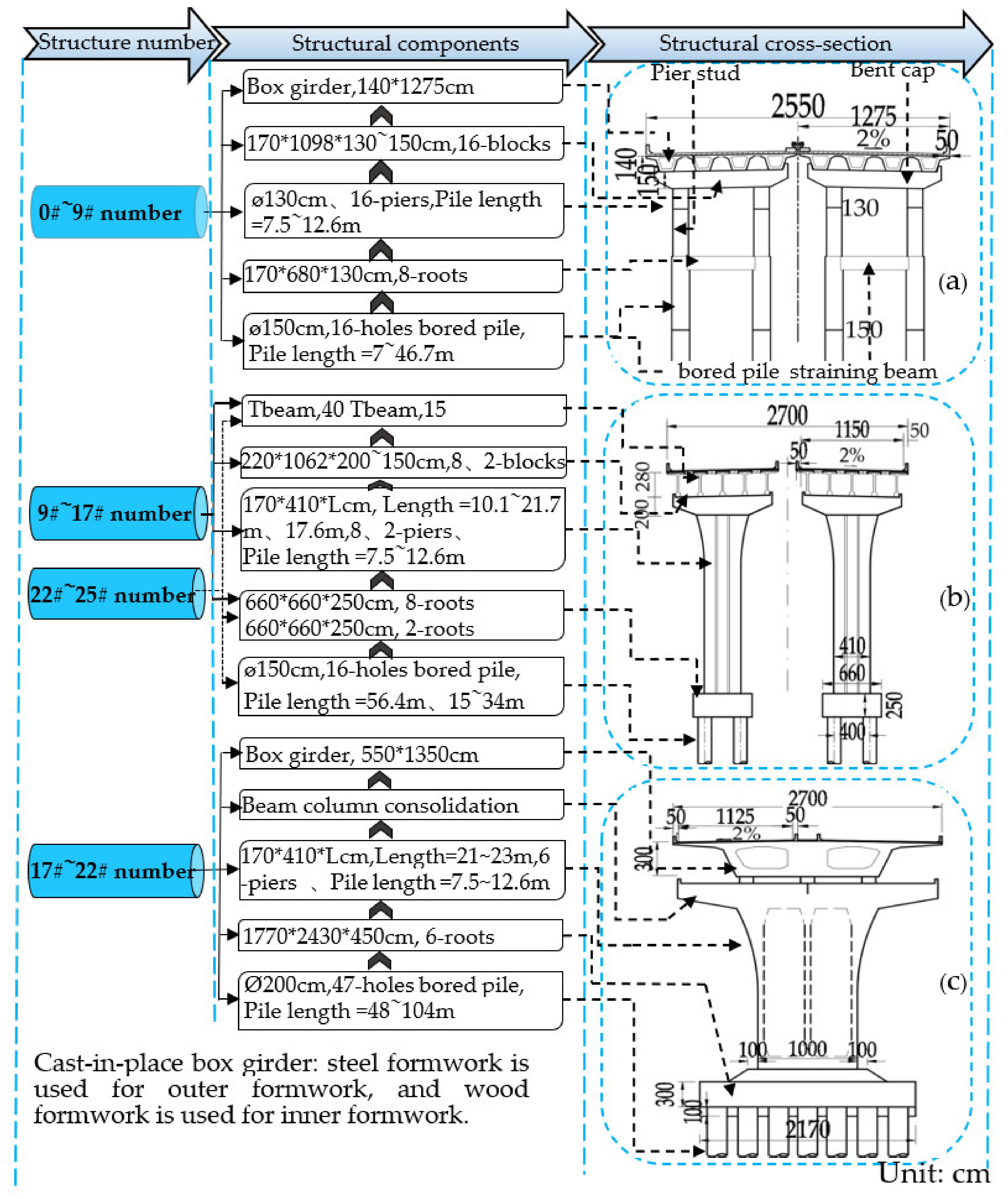

4.1. Case Characteristics Analysis

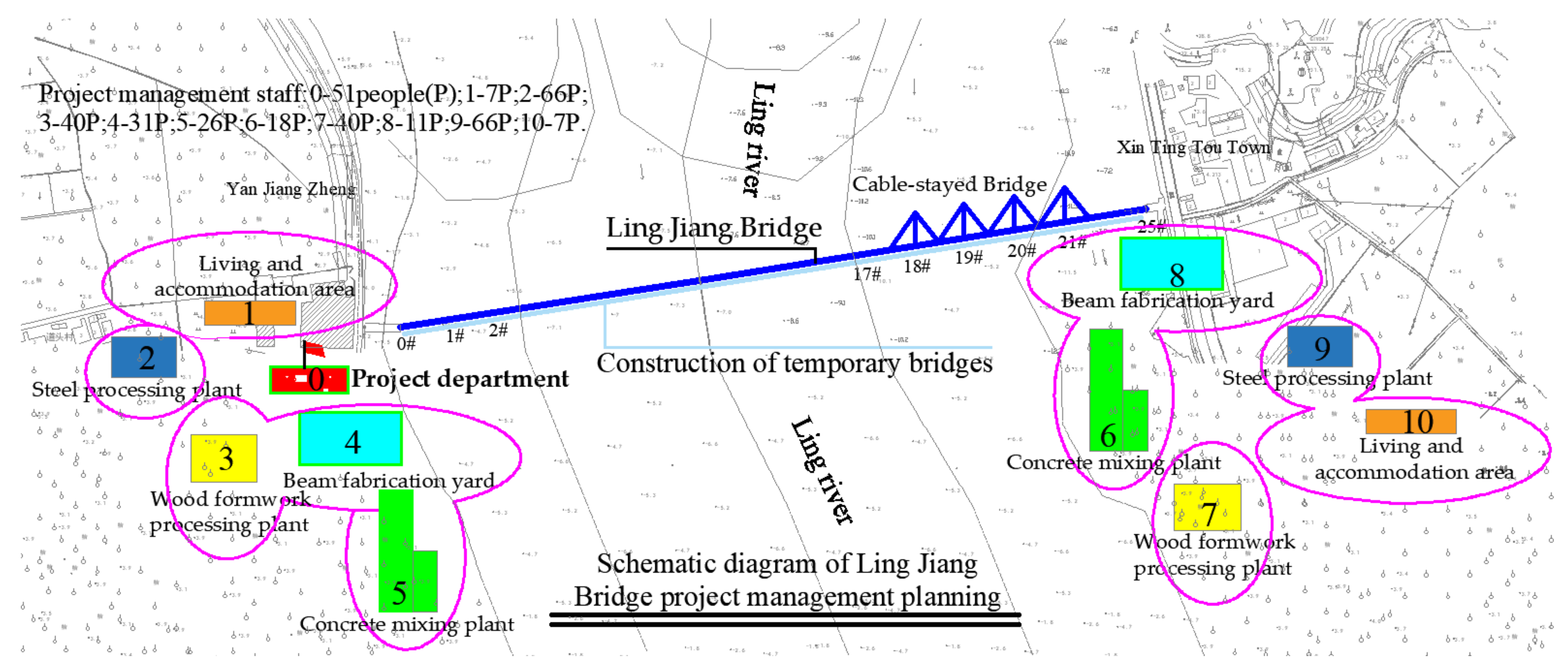

- The construction site is narrow and spans the Ling Jiang River, which has an average tidal range of 4.02 m. During the construction period, it is necessary to ensure the normal navigation of 1000-tonne maritime ships. The local Bureau of Maritime Affairs approved the construction period of the main bridge to be 913 days.

- The construction site is affected by the natural climate in much of the year. The Mei Yu flood season is from March to June, and the typhoon season is from July to September.

- The bridge structure is complex; the construction of supporting auxiliary facilities uses up the construction period.

- Many workers engaging in professional types of work are required because of the short construction period, resulting in high risks for personnel management.

- Experienced management and technical personnel are required, such as full-time safety, power, structure, construction, quality, and test engineers, due to the difficulties relating to safety, progress, and quality management.

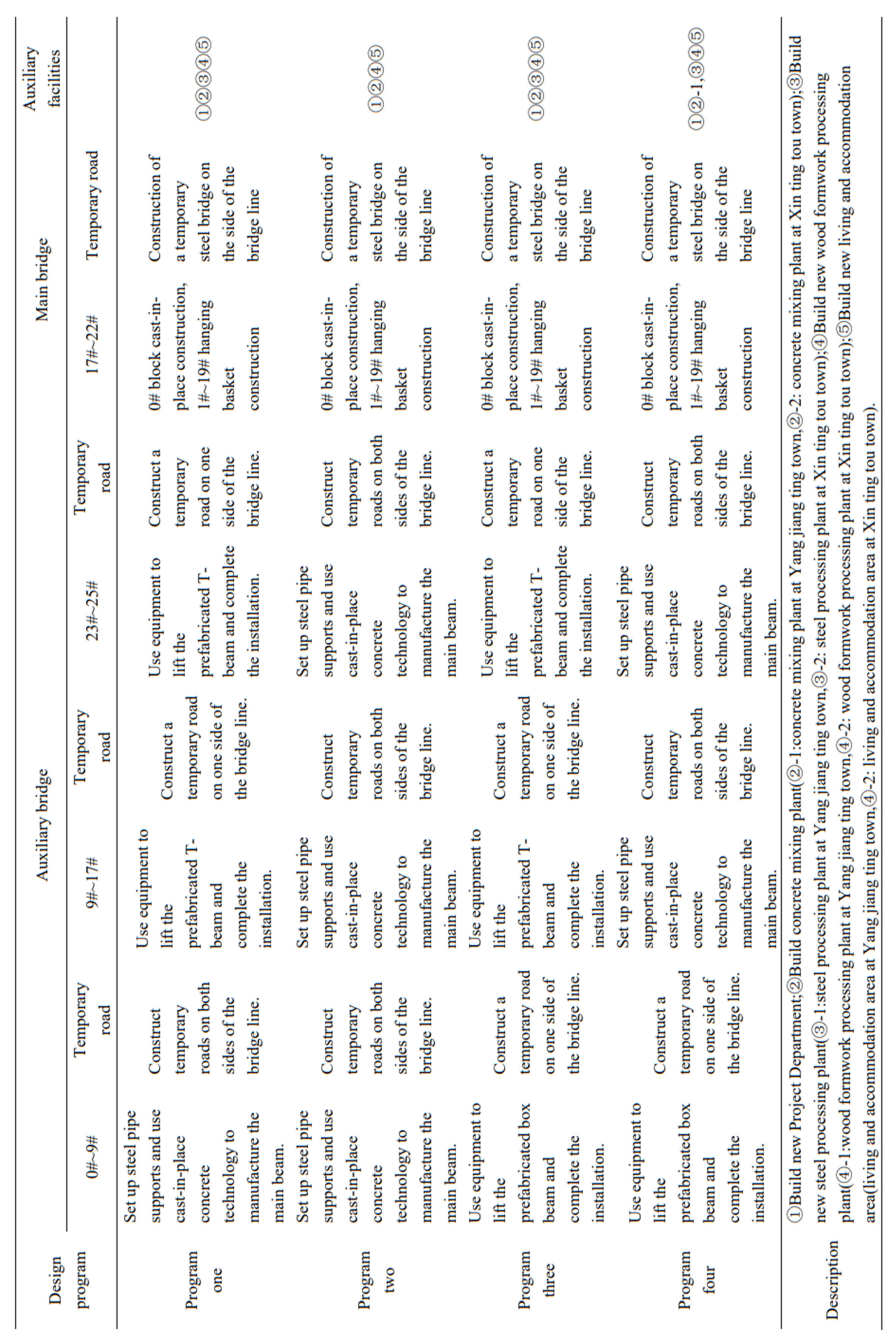

4.2. Project Management Planning and Design

5. Results and Discussion

- For sections 0#~17# and 22#~25#, the original ground was compacted within a depth of 100 cm; the compacted surface is compacted layer by layer and then backfilled with 60 cm of 37 lime earth, and a 20 cm layer of C20 was poured on the lime earth.

- For sections 17#~20# and 21#~23#, a temporary steel bridge was built as a temporary passage. The foundation of the temporary steel bridge was made of ø820 mm × 10 mm steel pipes with a length of 3500~4000 cm. The pile driver was pressed into the stressed rock stratum to a depth of 50~80 cm in the river. The steel pipe piles were arranged in two rows, with a vertical spacing of 1200 cm and a horizontal spacing of 400 cm (Figure 6).

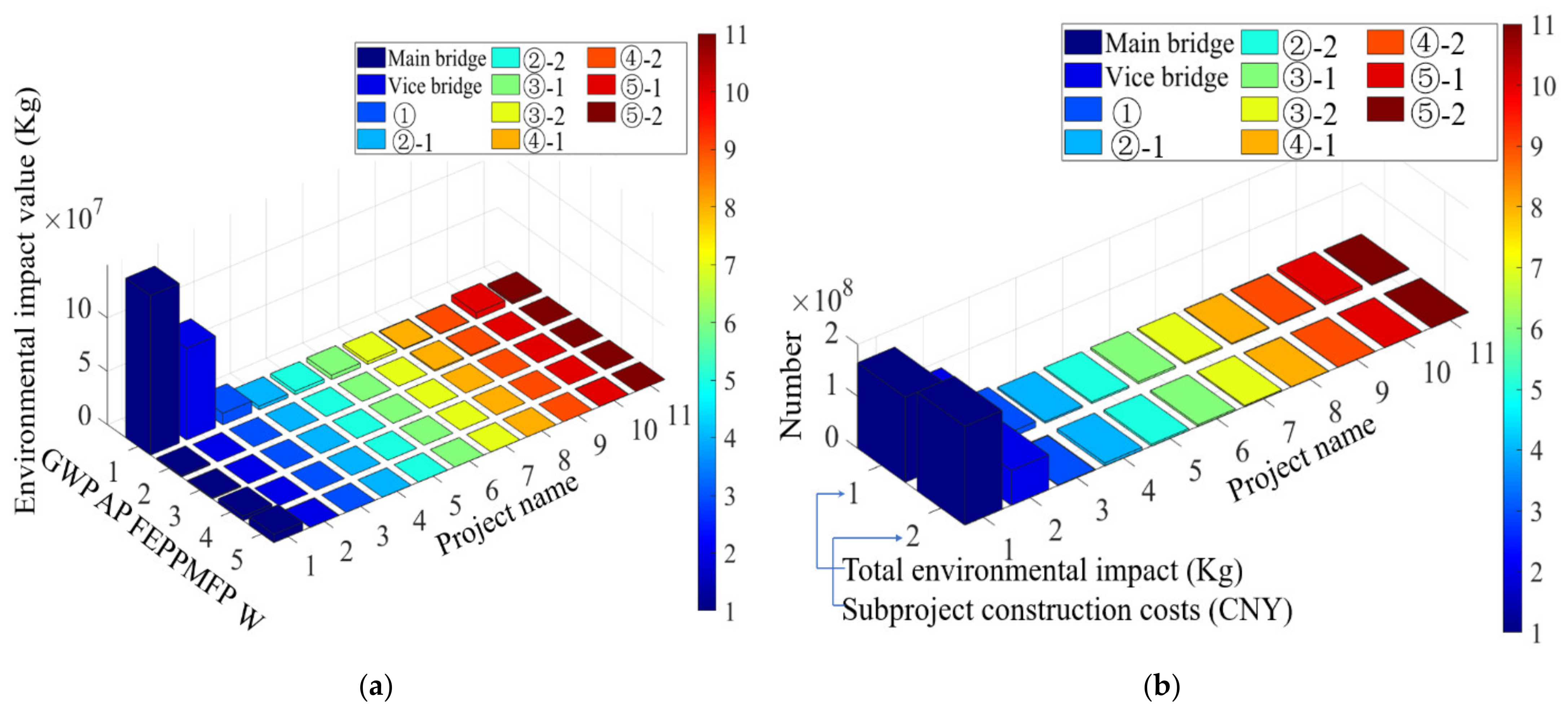

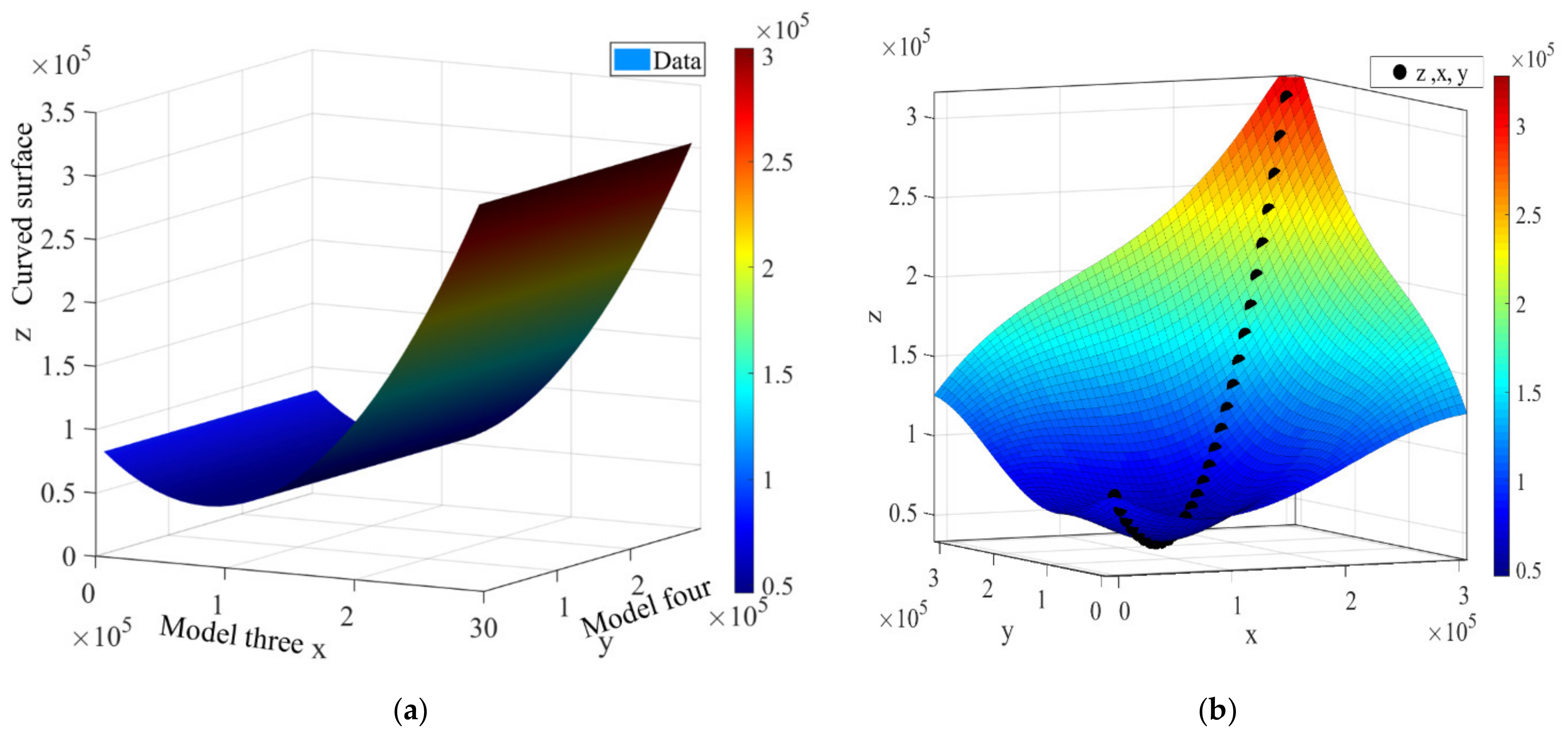

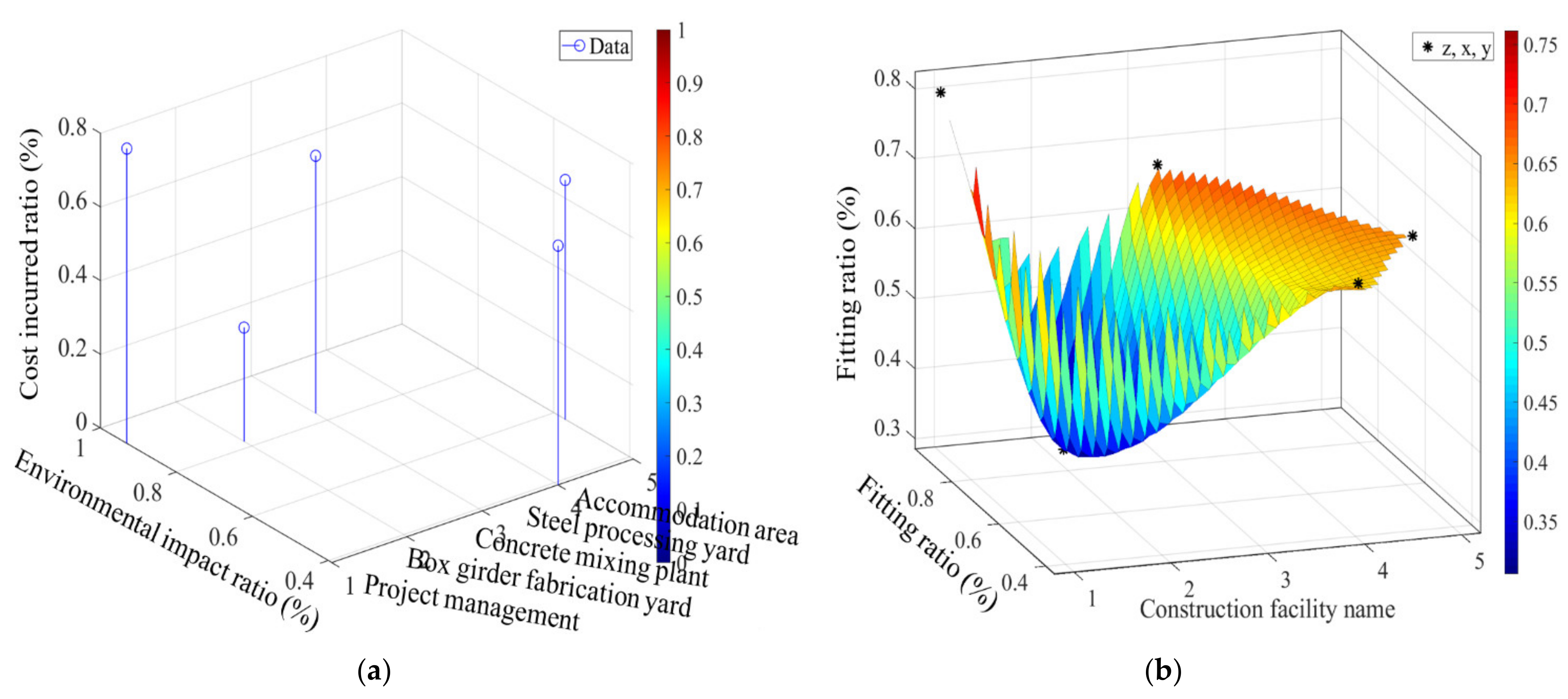

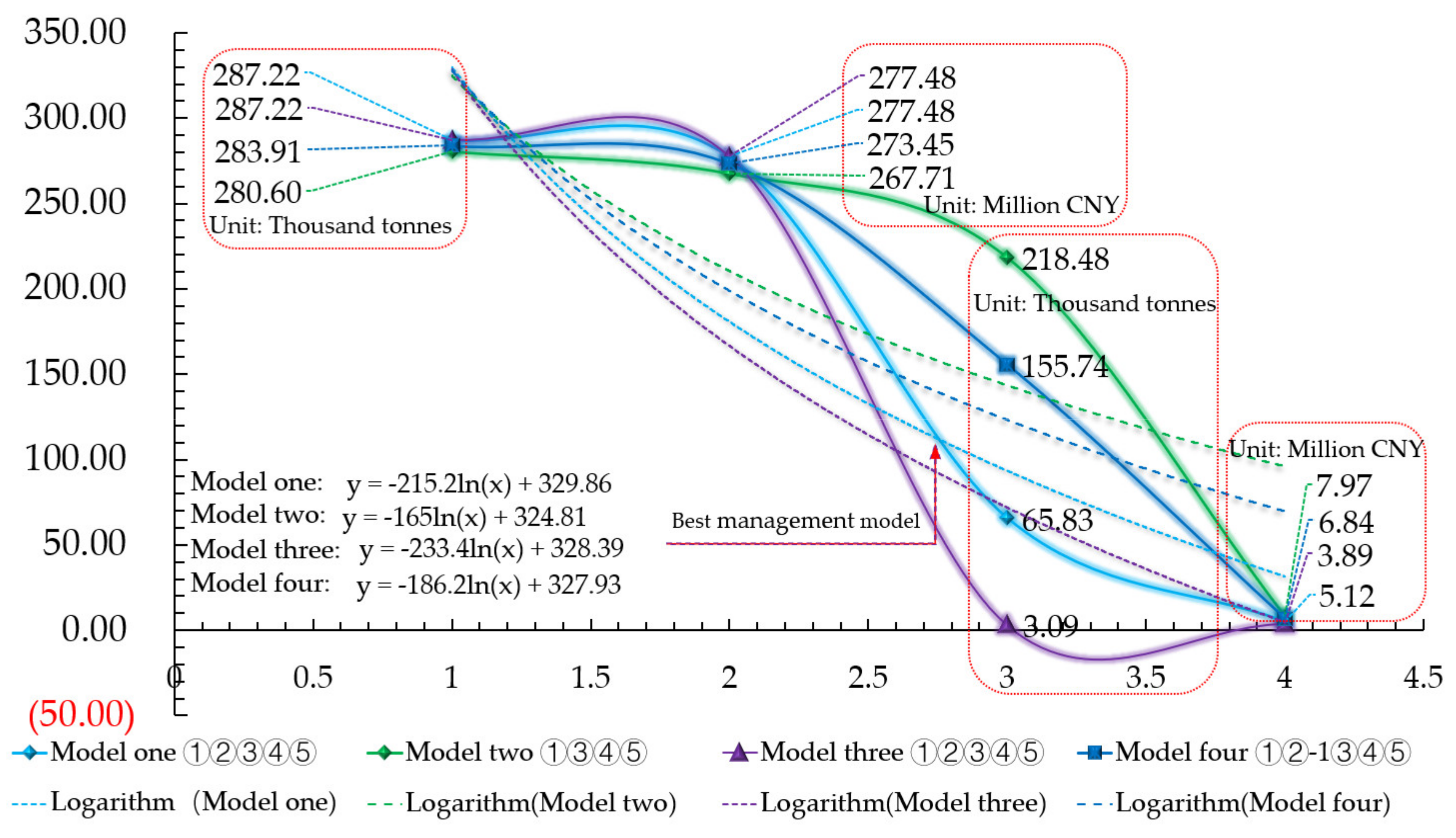

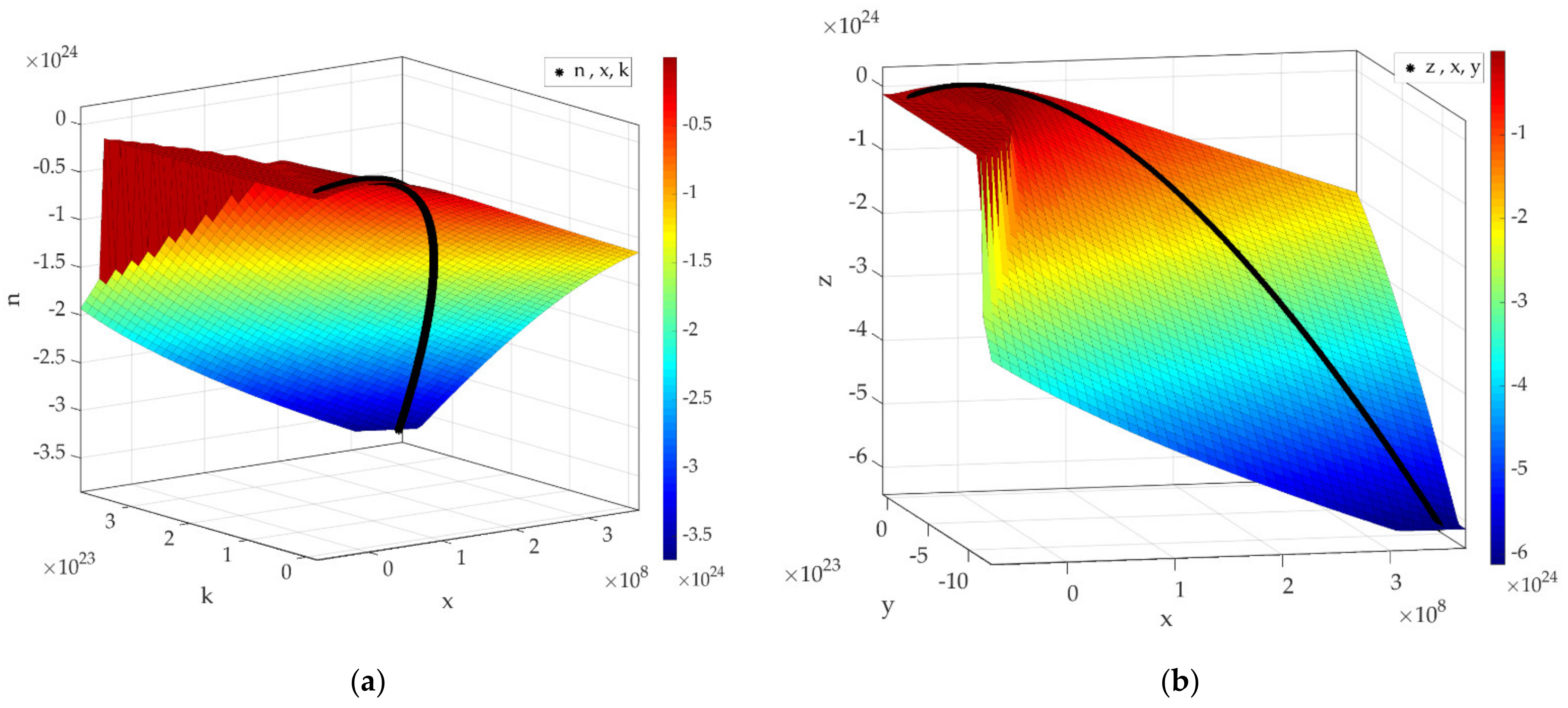

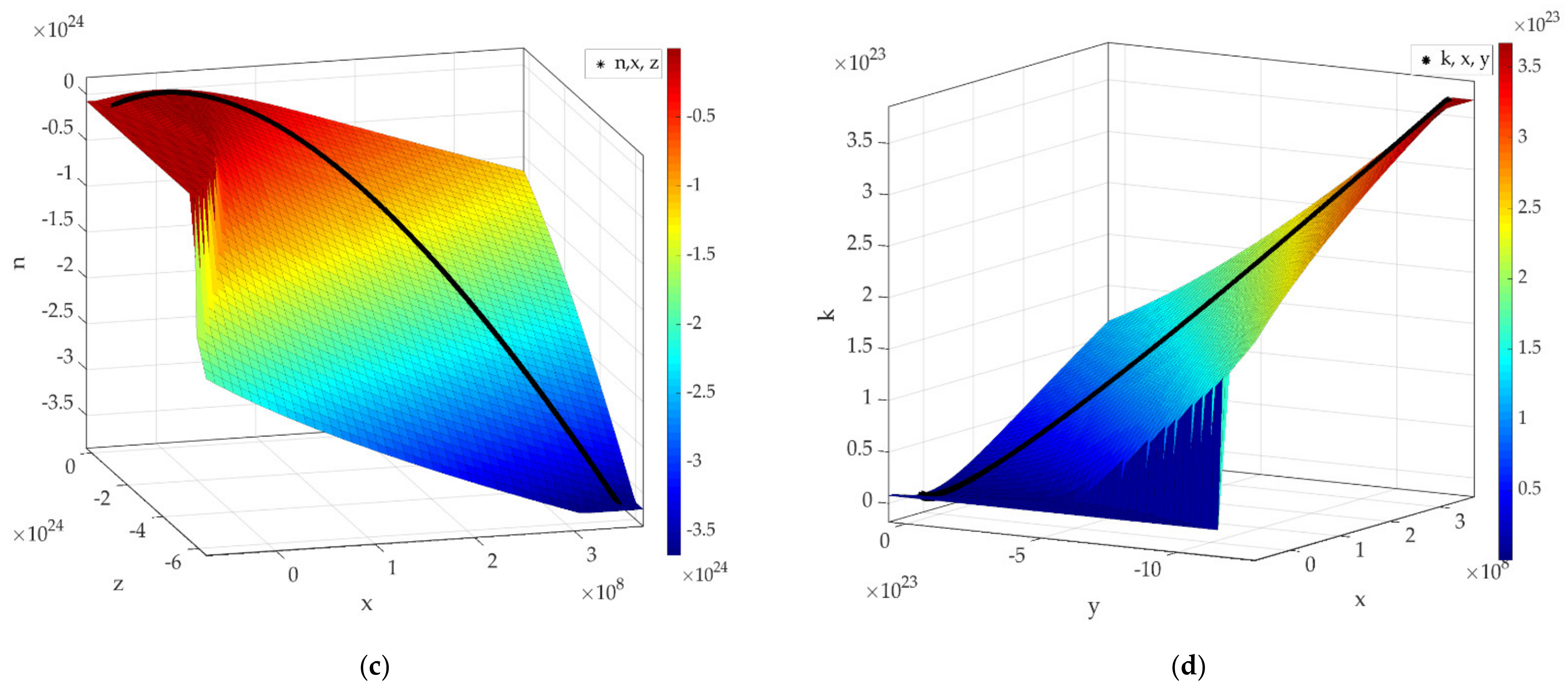

5.1. Algorithm Optimization Assessment

- Model 1: f(x, y) = (−4e + 07).*x + (−1e + 07).*x.^2 + (4e + 08).

- Model 2: f(x, z) = (2e + 08).*x + (−5e + 07).*x.^2 + (2e + 08).

- Model 3: f(x, k) = (−1e + 08).*x + (3e + 06).*x.^2 + (4e + 08).

- Model 4: f(x, n) = (8e + 07).*x + (−3e + 07).*x.^2 + (2e + 08).

- 1.

- SSE = 0 (the sum of squared errors of the corresponding points of the fitted data and the original data. The closer the SSE is to 0, the more successful the data prediction).

- 2.

- The smaller the Std value (in the interval of y, z, n, k) the better the model.Matlab calculation program:>>clear all;% The first set of analyses;>>x = [−50,000,000:100,000:350,000,000];>>y = (−4e + 07).*x + (−1e + 07).*x.^2 + (4e + 08);>>z = (2e + 08).*x + (−5e + 07).*x.^2 + (2e + 08);>>stem3(x, y, z);>>cftool(x, y, z);Fitting conclusion:1a, In f(x, k, n): x∈(1.5e + 08), Std∈(1.155e + 08); n∈(1.075e + 23), Std∈(1.100e + 23).2b, In f(x, y, z): x∈(1.5e + 08), Std∈(1.155e + 08); y∈(−3.584e + 23), Std∈(3.665e + 23).3c, In f(x, z, n): x∈(1.5e + 08), Std∈(1.155e + 08); z∈(−1.792e + 24), Std∈(1.833e + 24).4d, In f(x, y, k): x∈(1.5e + 08), Std∈(1.155e + 08); k∈(−3.584e + 23), Std∈(3.665e + 23).

5.2. Evaluation System Innovation

6. Conclusions and Future Trends

Author Contributions

Funding

Conflicts of Interest

References

- Stocker, T.F.; Qin, D.; Plattner, G.-K.; Tignor, M.M.B.; Allen, S.K.; Boschung, J.; Nauels, A.; Xia, Y.; Bex, V.; Midgley, P.M. Climate Change 2013-the Fifth Assessment Report on Climate Change Edited; Department of Energy Office of Scientific and Technical Information: Washington, WA, USA, 2013. Available online: https://www.osti.gov/etdeweb/biblio/22221318 (accessed on 18 May 2021).

- García-Segura, T.; Penadés-Plà, V.; Yepes, V. Sustainable bridge design by metamodel-assisted multi-objective optimization and decision-making under uncertainty. J. Clean. Prod. 2018, 202, 904–915. [Google Scholar] [CrossRef]

- Wang, Y.; Liang, S. Carbon dioxide mitigation target of China in 2020 and key economic sectors. Energy Policy 2013, 58, 90–96. [Google Scholar] [CrossRef]

- Lin, B.; Liu, H. CO2 mitigation potential in China’s building construction industry: A comparison of energy performance. Build. Environ. 2015, 94, 239–251. [Google Scholar] [CrossRef]

- Zhou, Z.; Alcalá, J.; Yepes, V. Environmental, Economic and Social Impact Assessment: Study of Bridges in China’s Five Major Economic Regions. Int. J. Environ. Res. Public Health 2020, 18, 122. [Google Scholar] [CrossRef]

- Caruso, G.; Gattone, S.; Fortuna, F.; Di Battista, T. Cluster Analysis for mixed data: An application to credit risk evaluation. Socio-Econ. Plan. Sci. 2021, 73, 100850. [Google Scholar] [CrossRef]

- D’Adamo, I.; Gastaldi, M.; Morone, P. The post COVID-19 green recovery in practice: Assessing the profitability of a policy proposal on residential photovoltaic plants. Energy Policy 2020, 147, 111910. [Google Scholar] [CrossRef]

- Dobrovolskienė, N.; Pozniak, A.; Tvaronavičienė, M. Assessment of the Sustainability of a Real Estate Project Using Multi-Criteria Decision Making. Sustainability 2021, 13, 4352. [Google Scholar] [CrossRef]

- Elsevier Scopus. Available online: https://www.elsevier.com/solutions/scopus (accessed on 20 May 2021).

- Chen, C. CiteSpace: Visualizing Patterns and Trends in Scientific Literature. 2021. Available online: http://cluster.cis.drexel.edu/~cchen/citespace/ (accessed on 21 May 2021).

- Invernizzi, D.C.; Locatelli, G.; Brookes, N.J. Characterising nuclear decommissioning projects: An investigation of the project characteristics that affect the project performance. Constr. Manag. Econ. 2020, 38, 947–963. [Google Scholar] [CrossRef]

- Yun, L.; Wan, J.; Wang, G.; Bai, J.; Zhang, B. Exploring the missing link between top management team characteristics and megaproject performance. Eng. Constr. Arch. Manag. 2020, 27, 1039–1064. [Google Scholar] [CrossRef]

- Elghaish, F.; Abrishami, S. A centralised cost management system: Exploiting EVM and ABC within IPD. Eng. Constr. Arch. Manag. 2020, 28, 549–569. [Google Scholar] [CrossRef]

- Owusu-Manu, D.-G.; Debrah, C.; Amissah, L.; Edwards, D.J.; Chileshe, N. Exploring the linkages between project managers’ mindset behaviour and project leadership style in the Ghanaian construction industry. Eng. Constr. Arch. Manag. 2020, 1–22. [Google Scholar] [CrossRef]

- Vilventhan, A.; Rajadurai, R. 4D Bridge Information Modelling for management of bridge projects: A case study from India. Built Environ. Proj. Asset Manag. 2019, 10, 423–435. [Google Scholar] [CrossRef]

- Liang, R.; Chong, H.-Y. A hybrid group decision model for green supplier selection: A case study of megaprojects. Eng. Constr. Arch. Manag. 2019, 26, 1712–1734. [Google Scholar] [CrossRef]

- Yadollahi, M.; Nazari, R.; Spanos, N.J.; Minner, N. An application of fuzzy factor analysis for sustainable bridge maintenance and retrofit projects. Int. J. Manag. Sci. Eng. Manag. 2016, 12, 225–236. [Google Scholar] [CrossRef]

- Brockmann, C.; Brezinski, H.; Erbe, A. Innovation in Construction Megaprojects. J. Constr. Eng. Manag. 2016, 142, 04016059. [Google Scholar] [CrossRef]

- Ravindra, R.; Fatemi-Nayeri, H. Managing Challenges and Mitigating Risks in Design, Construction, and Product Conformity of the Shared Path Bridge over Epping Road at Marsfield. Pr. Period. Struct. Des. Constr. 2016, 21, 04016002. [Google Scholar] [CrossRef]

- Larsson, J.; Lu, W.; Krantz, J.; Olofsson, T. Discrete Event Simulation Analysis of Product and Process Platforms: A Bridge Construction Case Study. J. Constr. Eng. Manag. 2016, 142, 04015097. [Google Scholar] [CrossRef]

- Ballesteros-Pérez, P.; Del Campo-Hitschfeld, M.L.; González-Naranjo, M.A.; González-Cruz, M.C. Climate and construction delays: Case study in Chile. Eng. Constr. Arch. Manag. 2015, 22, 596–621. [Google Scholar] [CrossRef]

- Gao, T.; Ergan, S.; Akinci, B.; Garrett, J.H. Proactive Productivity Management at Job Sites: Understanding Characteristics of Assumptions Made for Construction Processes during Planning Based on Case Studies and Interviews. J. Constr. Eng. Manag. 2014, 140, 04013054. [Google Scholar] [CrossRef]

- Jensen, P.A. Knowledge transfer from facilities management to building projects: A typology of transfer mechanisms. Arch. Eng. Des. Manag. 2012, 8, 170–179. [Google Scholar] [CrossRef][Green Version]

- Williams, T. Identifying Success Factors in Construction Projects: A Case Study. Proj. Manag. J. 2016, 47, 97–112. [Google Scholar] [CrossRef]

- Müller, R.; Turner, R. The Influence of Project Managers on Project Success Criteria and Project Success by Type of Project. Eur. Manag. J. 2007, 25, 298–309. [Google Scholar] [CrossRef]

- Wilker, J.; Rusche, K.; Rymsa-Fitschen, C. Improving Participation in Green Infrastructure Planning. Plan. Pr. Res. 2016, 31, 229–249. [Google Scholar] [CrossRef]

- Shen, L.; Wu, Y.; Zhang, X. Key Assessment Indicators for the Sustainability of Infrastructure Projects. J. Constr. Eng. Manag. 2011, 137, 441–451. [Google Scholar] [CrossRef]

- Feng, Q.; Chen, H.; Shi, X.; Wei, J. Stakeholder games in the evolution and development of green buildings in China: Government-led perspective. J. Clean. Prod. 2020, 275, 122895. [Google Scholar] [CrossRef]

- Yu, H.; Solvang, W.D.; Chen, C. A green supply chain network design model for enhancing competitiveness and sustainability of companies in high north arctic regions. Int. J. Energy Environ. 2014, 5, 403–418. Available online: https://www.researchgate.net/publication/265301217 (accessed on 31 May 2021).

- Lin, Y.-Q.; Guo, C.-X.; Tan, Y. The incentive and coordination strategy of sustainable construction supply chain based on robust optimisation. J. Control. Decis. 2020, 7, 126–159. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Abu Aisheh, Y.I.; Abuzuhri, I.O. Factors Affecting Sustainability Performance during the Construction Stage in Building Projects-Consultants’ Perspective. Open Constr. Build. Technol. J. 2020, 14, 17–26. [Google Scholar] [CrossRef]

- Meharie, M.G.; Gariy, Z.C.A.; Mutuku, R.N.N.; Mengesha, W.J. Prioritizing Key Duration Estimation Accuracy Factors in Highway Infrastructure Projects Using Fuzzy AHP. Open Civ. Eng. J. 2019, 13, 92–108. [Google Scholar] [CrossRef]

- Zhong, Y. Research on Construction Engineering Project Management Optimization Based on C4.5 Improved Algorithm. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 688, p. 055036. [Google Scholar]

- Baudrit, C.; Taillandier, F.; Tran, T.T.P.; Breysse, D. Uncertainty Processing and Risk Monitoring in Construction Projects Using Hierarchical Probabilistic Relational Models. Comput. Civ. Infrastruct. Eng. 2019, 34, 97–115. [Google Scholar] [CrossRef]

- Cho, K.; Hong, T.; Hyun, C. Effect of project characteristics on project performance in construction projects based on structural equation model. Expert Syst. Appl. 2009, 36, 10461–10470. [Google Scholar] [CrossRef]

- Kang, Y.; O’Brien, W.J.; Thomas, S.; Chapman, R.E. Impact of Information Technologies on Performance: Cross Study Comparison. J. Constr. Eng. Manag. 2008, 134, 852–863. [Google Scholar] [CrossRef]

- PMBOK. PMBOK Guide and Standards Project Management. PA, USA. 2021. Available online: https://www.pmi.org/pmbok-guide-standards (accessed on 21 May 2021).

- Qureshi, T.M.; Warraich, A.S.; Hijazi, S.T. Significance of project management performance assessment (PMPA) model. Int. J. Proj. Manag. 2009, 27, 378–388. [Google Scholar] [CrossRef]

- Chou, J.-S.; Yang, J.-G. Project Management Knowledge and Effects on Construction Project Outcomes: An Empirical Study. Proj. Manag. J. 2012, 43, 47–67. [Google Scholar] [CrossRef]

- Ling, F.Y.; Low, S.P.; Wang, S.; Egbelakin, T. Models for Predicting Project Performance in China Using Project Management Practices Adopted by Foreign AEC Firms. J. Constr. Eng. Manag. 2008, 134, 983–990. [Google Scholar] [CrossRef]

- Zwikael, O. The Relative Importance of the PMBOK® Guide’s Nine Knowledge Areas during Project Planning. Proj. Manag. J. 2009, 40, 94–103. [Google Scholar] [CrossRef]

- Yeung, J.F.; Chan, A.P.; Chan, D.W. Developing a Performance Index for Relationship-Based Construction Projects in Australia: Delphi Study. J. Manag. Eng. 2009, 25, 59–68. [Google Scholar] [CrossRef]

- Hoogmartens, R.; Van Passel, S.; Van Acker, K.; Dubois, M. Bridging the gap between LCA, LCC and CBA as sustainability assessment tools. Environ. Impact Assess. Rev. 2014, 48, 27–33. [Google Scholar] [CrossRef]

- Kang, H.; Lee, Y.; Kim, S. Sustainable building assessment tool for project decision makers and its development process. Environ. Impact Assess. Rev. 2016, 58, 34–47. [Google Scholar] [CrossRef]

- Dikmen, I.; Qazi, A.; Erol, H.; Birgonul, M.T. Meta-Modeling of Complexity-Uncertainty-Performance Triad in Construction Projects. Eng. Manag. J. 2021, 33, 30–44. [Google Scholar] [CrossRef]

- Haque, T.S.; Chakraborty, A.; Mondal, S.P.; Alam, S. Approach to solve multi-criteria group decision-making problems by exponential operational law in generalised spherical fuzzy environment. CAAI Trans. Intell. Technol. 2020, 5, 106–114. [Google Scholar] [CrossRef]

- Ning, W.; Yingbo, J. Analysis on Key Factors to Affect Construction Industrialization Development in China. In Proceedings of the 2010 3rd International Conference on Information Management, Innovation Management and Industrial Engineering, Kunming, China, 26–28 November 2010; Volume 2, pp. 64–67. [Google Scholar]

- Pellicer, E.; Yepes, V.; Correa, C.L.; Alarcón, L.F. Model for Systematic Innovation in Construction Companies. J. Constr. Eng. Manag. 2014, 140, 4014001. [Google Scholar] [CrossRef]

- De Melo, J.C.F.; Salerno, M.S.; Freitas, J.S.; Bagno, R.B.; Brasil, V.C. From open innovation projects to open innovation project management capabilities: A process-based approach. Int. J. Proj. Manag. 2020, 38, 278–290. [Google Scholar] [CrossRef]

- Landi, D.; Marconi, M.; Bocci, E.; Germani, M. Comparative life cycle assessment of standard, cellulose-reinforced and end of life tires fiber-reinforced hot mix asphalt mixtures. J. Clean. Prod. 2020, 248, 119295. [Google Scholar] [CrossRef]

- Kim, K.; Lee, G.; Kim, S. A Study on the Application of Blockchain Technology in the Construction Industry. KSCE J. Civ. Eng. 2020, 24, 2561–2571. [Google Scholar] [CrossRef]

- Behera, P.; Mohanty, R.; Prakash, A. Understanding Construction Supply Chain Management. Prod. Plan. Control. 2015, 26, 1332–1350. [Google Scholar] [CrossRef]

- Navarro, I.; Yepes, V.; Martí, J.V. Social life cycle assessment of concrete bridge decks exposed to aggressive environments. Environ. Impact Assess. Rev. 2018, 72, 50–63. [Google Scholar] [CrossRef]

- Mirza, E.; Ehsan, N. Quantification of Project Execution Complexity and its Effect on Performance of Infrastructure Development Projects. Eng. Manag. J. 2017, 29, 108–123. [Google Scholar] [CrossRef]

- Laine, T.; Korhonen, T.; Suomala, P. The dynamics of repairing multi-project control practice: A project governance viewpoint. Int. J. Proj. Manag. 2020, 38, 405–418. [Google Scholar] [CrossRef]

- Zhou, Z.; Alcalá, J.; Yepes, V. Bridge Carbon Emissions and Driving Factors Based on a Life-Cycle Assessment Case Study: Cable-Stayed Bridge over Hun He River in Liaoning, China. Int. J. Environ. Res. Public Health 2020, 17, 5953. [Google Scholar] [CrossRef]

- LaClair, T.J.; Truemner, R. Modeling of Fuel Consumption for Heavy-Duty Trucks and the Impact of Tire Rolling Resistance. SAE Tech. Pap. Ser. 2005. [Google Scholar] [CrossRef]

- Sannino, A.; Postiglione, G.; Bollen, M. Feasibility of a DC network for commercial facilities. IEEE Trans. Ind. Appl. 2003, 39, 1499–1507. [Google Scholar] [CrossRef]

- Richards, T.J.; Hamilton, S.F. Food waste in the sharing economy. Food Policy 2018, 75, 109–123. [Google Scholar] [CrossRef]

- Bai, S.; Zhang, X.; Xiang, Y.; Wang, X.; Zhao, X.; Ren, N. HIT.WATER scheme: An integrated LCA-based decision-support platform for evaluation of wastewater discharge limits. Sci. Total Environ. 2019, 655, 1427–1438. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Zhang, L.; Zhang, J. Energy consumption by rural migrant workers and urban residents with a hukou in China: Quality-of-life-related factors and built environment. Nat. Hazards 2019, 99, 1431–1453. [Google Scholar] [CrossRef]

- Frangopol, D.M.; Dong, Y.; Sabatino, S. Bridge life-cycle performance and cost: Analysis, prediction, optimisation and decision-making. Struct. Infrastruct. Eng. 2017, 13, 1239–1257. [Google Scholar] [CrossRef]

- Bozejko, W.; Hejducki, Z.; Wodecki, M. Flowshop scheduling of construction processes with uncertain parameters. Arch. Civ. Mech. Eng. 2019, 19, 194–204. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, D.Y.; Frangopol, D.M.; Jin, W. Inclusion of environmental impacts in life-cycle cost analysis of bridge structures. Sustain. Resilient Infrastruct. 2019, 5, 252–267. [Google Scholar] [CrossRef]

- General Code for Design of Highway Bridges and Culverts” (JTG D60-2015). Ministry of Transport of the People’s Republic of China: Beijing, China. 2015. Available online: https://www.mot.gov.cn/jiaotongtushu/201512/t20151229_1967723.html (accessed on 16 May 2021). (In Chinese)

- Dehestani, H.; Ordokhani, Y.; Razzaghi, M. Application of the modified operational matrices in multiterm variable-order time-fractional partial differential equations. Math. Methods Appl. Sci. 2019, 42, 7296–7313. [Google Scholar] [CrossRef]

- Martinsuo, M.; Geraldi, J. Management of project portfolios: Relationships of project portfolios with their contexts. Int. J. Proj. Manag. 2020, 38, 441–453. [Google Scholar] [CrossRef]

- Panwar, A.; Jha, K.N. A many-objective optimization model for construction scheduling. Constr. Manag. Econ. 2019, 37, 727–739. [Google Scholar] [CrossRef]

- Penadés-Plà, V.; Martí, J.V.; García-Segura, T.; Yepes, V. Life-Cycle Assessment: A Comparison between Two Optimal Post-Tensioned Concrete Box-Girder Road Bridges. Sustainability 2017, 9, 1864. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V.; Frangopol, D. Multi-objective design of post-tensioned concrete road bridges using artificial neural networks. Struct. Multidiscip. Optim. 2017, 56, 139–150. [Google Scholar] [CrossRef]

- Afshari, A.R. Methods for Selection of Construction Project Manager: Case Study. J. Constr. Eng. Manag. 2017, 143, 06017003. [Google Scholar] [CrossRef]

- Wiewiora, A.; Chang, A.; Smidt, M. Individual, project and organizational learning flows within a global project-based organization: Exploring what, how and who. Int. J. Proj. Manag. 2020, 38, 201–214. [Google Scholar] [CrossRef]

- Ministry of Transport, Code for Pile Foundation of Port Engineering (JTJ254-98). Beijing, China. 2020. Available online: http://www.mot.gov.cn/xiazaizhongxin/ziliaoxiazai/201705/P020200709631687274876.pdf (accessed on 18 May 2021).

- Mathworks Matlab and Training. MA, USA. 2021. Available online: https://matlabacademy.mathworks.com/?s_tid=pl_learn (accessed on 20 May 2021).

- Zhou, Z.-W.; Alcalá, J.; Kripka, M.; Yepes, V. Life Cycle Assessment of Bridges Using Bayesian Networks and Fuzzy Mathematics. Appl. Sci. 2021, 11, 4916. [Google Scholar] [CrossRef]

| References | Limitation (Analysis of the Representative Articles) |

|---|---|

| [11] | The research is mainly based on questionnaires, without the establishment of a systematic framework and model, and lacks data analysis. |

| [12] | Restricted data research leads to limited availability, questionnaire surveys in a specific institutional context affect the generalization of results, and the discussion mechanism is not sound. |

| [13] | The application of an integrated project delivery centralized cost management system needs to be proved by research. |

| [14] | Data analysis is one-sided, and the use of Ghanaian construction industry data can ensure the success of projects in other developing countries. |

| [15] | Used 4D bridge information management model technology for bridge monitoring. Explained a method of project management without specific indicators, data, and framework standards for assessment. |

| [16] | Extending the results to other research areas may not effectively minimize the environmental hazards, and the standard and standard weight are uncertain. Inherent human prejudice and subjective judgment system theory. |

| [17] | To identify and overcome the scarcity of elements, we need to develop a complete green bridge rating system and theoretical research framework. |

| [18] | Due to the particularity and complexity of construction projects, there is no systematic research framework, so it is difficult to promote. |

| [19] | The specific research and analysis process is very clear, aiming at the analysis of the whole process of a single bridge. |

| [20] | The research focuses on the possibility of, problems with and knowledge gap related to the use of product platforms in the construction environment, and their popularization needs to be further studied. |

| [21] | The research is carried out in Chile. In order to transfer the results to any other country, the diversity of environments and climates in other countries must be taken into account. |

| [22] | The diversity of construction projects and the uncertainty of information sources have an impact on productivity, and the framework has limitations. |

| [23] | The research focuses on the theoretical derivation and analysis. |

| [24] | The results of the effect on the success of the project cannot be applied or confirmed. |

| [25] | We studied samples from Europe, North America, Australia, and other countries, and determined that the complexity of the project is the main criterion for success. There is a lack of further research on whether the project is consistent with international projects. |

| [26] | The study dealt with the implementation of green building from the planning phase, without an in-depth study of the entire life cycle. Whether the application of the concept is in line with the implementation of international infrastructure remains to be further studied. |

| [27] | Whether the research field can be expanded, the evaluation and optimization criteria and the selection of the best scheme need to be improved. |

| [28] | This paper studies the reasons for promoting the development of green building by modeling. The specific construction environment, specific regional model, specific conditions, and expansion research require innovative analysis. |

| [29] | The model is mainly used for the design and planning of a supply chain operating in the Gao Bei region. Whether it is fully applicable to supply chains operating in other regions needs to be studied. |

| [30] | In the case of limited uncertainty, a case study is proposed on how to maintain environmental and social benefits. It requires fine research and promotion. |

| [31] | There are many factors considered in the research process, and the depth needs to be specified. Focusing on the impact factors would strengthen the depth of the analysis. |

| [32] | In the early stages of the application of fuzzy analysis, this paper considers the explanation of the basic concepts of fuzzy mathematics, and in the later stages, it considers the problem of distinguishing membership degrees for important influencing factors. |

| [33] | The lack of application of research results, analysis methods and factors of the problem. |

| Number | Cost Name | Tax Rate | Calculation Method |

|---|---|---|---|

| 1 | Direct project cost | Quote the fixed tax rate. | According to “JTG 3830-2018” budget |

| 2 | insurance | 3.00% | 1 × 2 |

| 3 | Environmental protection fee | 1,500,000 | Fixed costs |

| 4 | Safety production fee | 1.50% | 1 × 4 |

| 5 | Management information fee | 200,000 | Fixed costs |

| 6 | Temporary road construction, maintenance, and demolition | 0.16% | 1 × 8 |

| 7 | Temporary land occupation, occupying the river | 0.25% | 1 × 9 |

| 8 | Temporary alms for project construction | 0.24% | 1 × 8 |

| 9 | Standard chemical site construction) | 0.42% | 1 × 9 |

| 10 | Provisional amount | 5.00% | (1 + 2 + 3 + 4 + 5 + 6 = 7 + 8 + 9) × 10 |

| 11 | Project construction cost | 11 = 1 + ........... + 10 |

| Project Name | Number (Tonne) | Ratio (%) | Project Name | Cost Incurred (CNY) | Ratio (%) |

|---|---|---|---|---|---|

| Material preparation stage | 164,038.23 | 57.11 | Main bridge | 190,231,873 | 68.56 |

| Construction stage | 86,384.14 | 30.08 | Vice bridge | 67,245,171.51 | 24.23 |

| ① | 10,931.43 | 3.81 | ① | 1,433,139.42 | 0.52 |

| ②-1 | 3310.94 | 1.15 | ②-1 | 5,740,563.26 | 2.07 |

| ②-2 | 3310.94 | 1.15 | ②-2 | 4,029,419.28 | 1.45 |

| ③-1 | 4030.53 | 1.4 | ③-1 | 3,737,910.48 | 1.35 |

| ③-2 | 2777.80 | 0.97 | ③-2 | 2,627,562.34 | 0.95 |

| ④-1 | 2033.43 | 0.71 | ④-1 | 870,203 | 0.31 |

| ④-2 | 1530.26 | 0.53 | ④-2 | 739,672.55 | 0.27 |

| ⑤-1 | 6458.23 | 2.25 | ⑤-1 | 410,046.44 | 0.15 |

| ⑤-2 | 2418.26 | 0.84 | ⑤-2 | 410,046.44 | 0.15 |

| Project Management Model | Design Number | Material and Construction Phase | Increase Auxiliary Facilities | ||

|---|---|---|---|---|---|

| EIN (Tonne) | CI (TC) | EIN (Tonne) | CI (TC) | ||

| Model one | ① ②③④⑤ | 287,224.18 | 27,747.56 | 65,830.38 | 511.58 |

| Model two | ① ③④⑤ | 280,602.31 | 26,770.56 | 218,480.51 | 796.97 |

| Model three | ① ②③④⑤ | 287,224.18 | 27,747.56 | 3092.05 | 388.74 |

| Model four | ① ②-1③④⑤ | 283,913.25 | 27,344.62 | 155,742.18 | 683.55 |

| PM | AF | 0#~9# | 9#~17# | 17#~22# | 22#~25# | ||||

|---|---|---|---|---|---|---|---|---|---|

| EIN (Tonne) | CI (TC) | EIN (Tonne) | CI (TC) | EIN (Tonne) | CI (TC) | EIN (Tonne) | CI (TC) | ||

| Model one | SPB | 62,292.59 | 93.37 | \ | \ | \ | \ | \ | \ |

| TR | 891.49 | 58.95 | 783.70 | 51.82 | 1561.74 | 2.87.55 | 300.86 | 19.89 | |

| Model two | SPB | 171,813.20 | 2.40.97 | 0 | 0 | \ | \ | 42,044.96 | 66.08 |

| TR | 2458.89 | 1.62.59 | 0 | 0 | 1561.74 | 2.87.55 | 601.72 | 39.79 | |

| Model three | SPB | \ | \ | \ | \ | \ | \ | \ | \ |

| TR | 1229.44 | 81.29 | 1561.74 | 2.87.55 | 300.86 | 19.89 | |||

| Model four | SPB | \ | \ | 109,520.61 | 1.57.02 | \ | \ | 42,044.96 | 66.08 |

| TR | 445.75 | 29.47 | 1567.39 | 1.03.65 | 156.1.74 | 2.87.55 | 601.72 | 39.79 | |

| Pier Number | 9#~17# | 17#~22# | 22#~25# |

|---|---|---|---|

| Structural style | Prefabricated T-beam, installed on site. | On-site hanging basket method construction. | Prefabricated T-beam installed on site. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Z.; Alcalá, J.; Yepes, V. Optimized Application of Sustainable Development Strategy in International Engineering Project Management. Mathematics 2021, 9, 1633. https://doi.org/10.3390/math9141633

Zhou Z, Alcalá J, Yepes V. Optimized Application of Sustainable Development Strategy in International Engineering Project Management. Mathematics. 2021; 9(14):1633. https://doi.org/10.3390/math9141633

Chicago/Turabian StyleZhou, Zhiwu, Julián Alcalá, and Víctor Yepes. 2021. "Optimized Application of Sustainable Development Strategy in International Engineering Project Management" Mathematics 9, no. 14: 1633. https://doi.org/10.3390/math9141633

APA StyleZhou, Z., Alcalá, J., & Yepes, V. (2021). Optimized Application of Sustainable Development Strategy in International Engineering Project Management. Mathematics, 9(14), 1633. https://doi.org/10.3390/math9141633