Developing a New Robust Swarm-Based Algorithm for Robot Analysis

Abstract

1. Introduction

1.1. Swarm Intelligence

1.2. Particle Swarm Optimization

1.3. PSO and Robot Parameter Identification

2. Kinematic Model of Robots

2.1. Robot Configurations

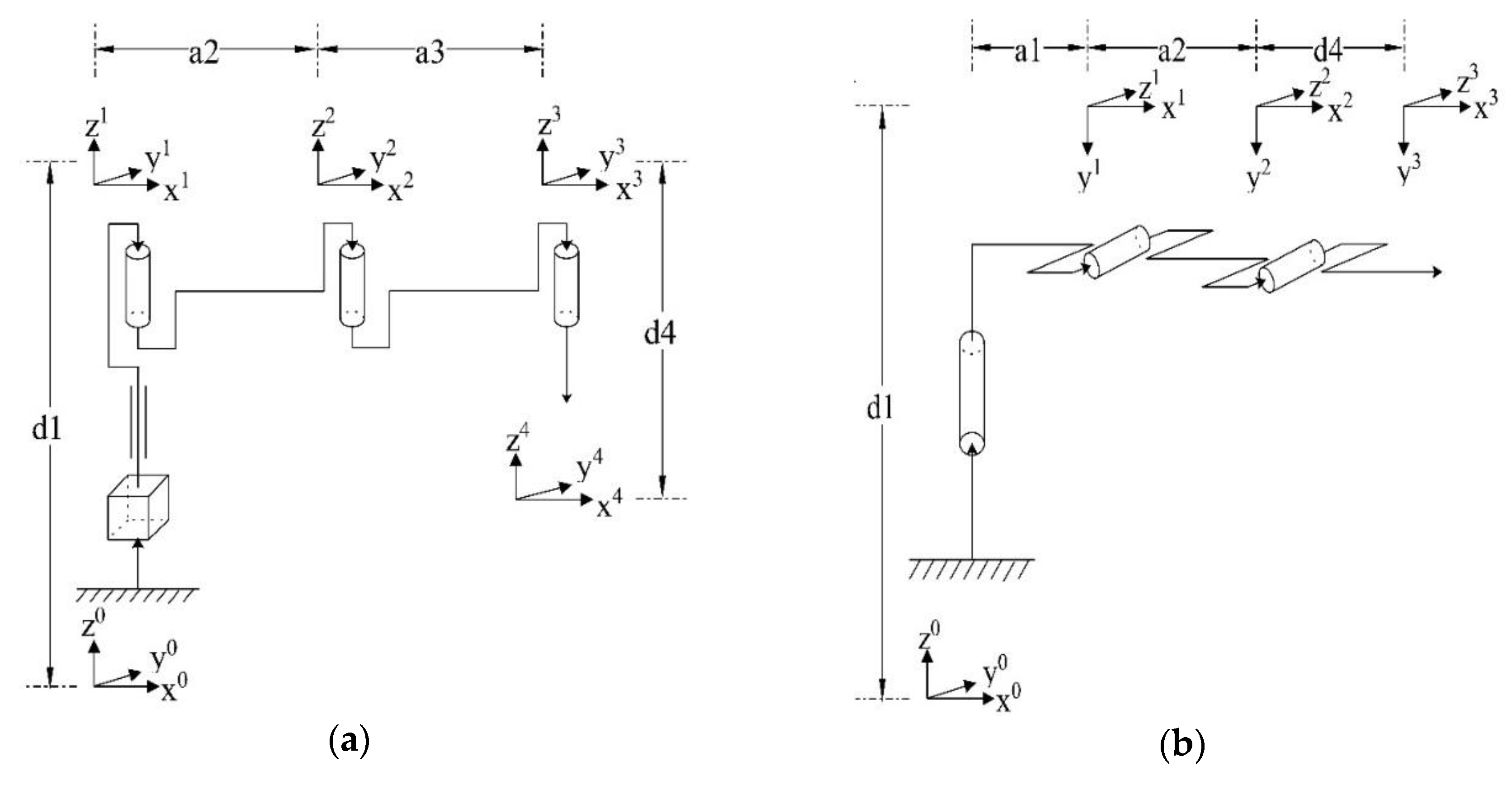

- Scara Robot Configuration: The Selective Compliance Assembly Robot (SCARA) is one of the earliest industrial manipulators patented in 1981, it is usually a 4- or 5-DOF manipulator with all revolute joint, except one. In this analysis, a 4DOF SCARA manipulator shall be analyzed. The first joint of the manipulator being the prismatic joint, the other joints are revolute, parallel to each other and pointing along the direction of gravity. The SCARA manipulator is shown in Figure 1a and the DH-parameters are tabulated in Table 1.

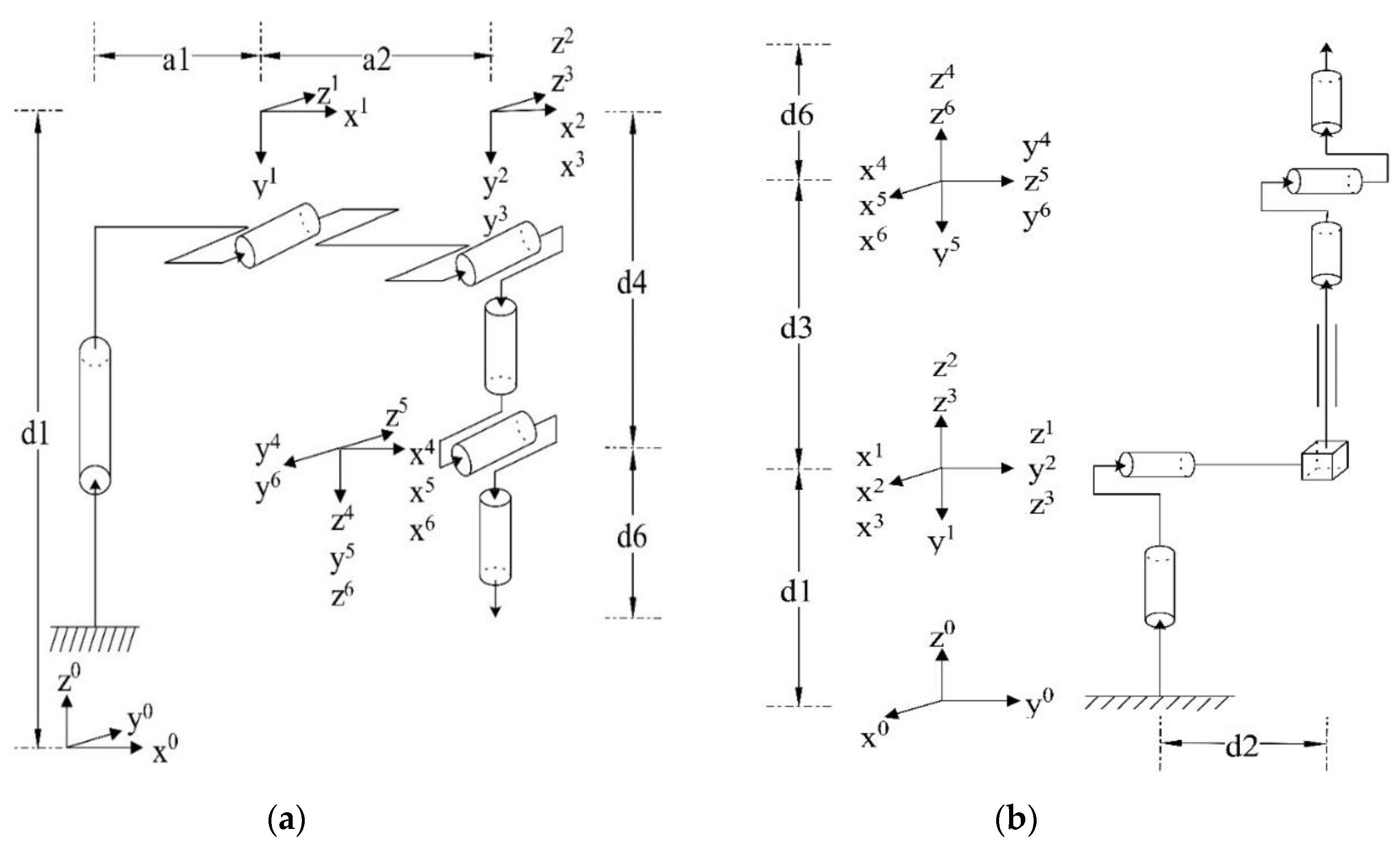

- Articulate Robot Configuration: The articulate manipulator is the most popular robot configurations used in industrial workspaces, its analysis and solutions are trivial, therefore a very high accuracy can be achieved. All the joints of the articulated robot are revolute with the first joint pointing along the direction of gravity.The second third and fifth joints are parallel to each other and perpendicular to the first joint axis. The fourth and sixth joints are coincident and perpendicular to all the other joints. Three articulated manipulators were used in this analysis, one 3DOF articulated manipulator and two 6DOF articulated manipulators with significantly different sizes. The 3DOF articulate manipulator is configured exactly like the first three joints of the 6DOF articulate manipulator previously described. Figure 1b shows the 3DOF while Figure 2a shows the 6DOF robot configurations, their D-H parameters are tabulated in Table 2, Table 3 and Table 4.

- Stanford Robot Configuration: The Stanford manipulator is also a 6DOF manipulator with five revolute joints and one prismatic joint. It is configured very much like the articulate arm except that the third arm is prismatic. The Stanford manipulator is shown in Figure 2b with its detailed D-H parameters defined in Table 5.

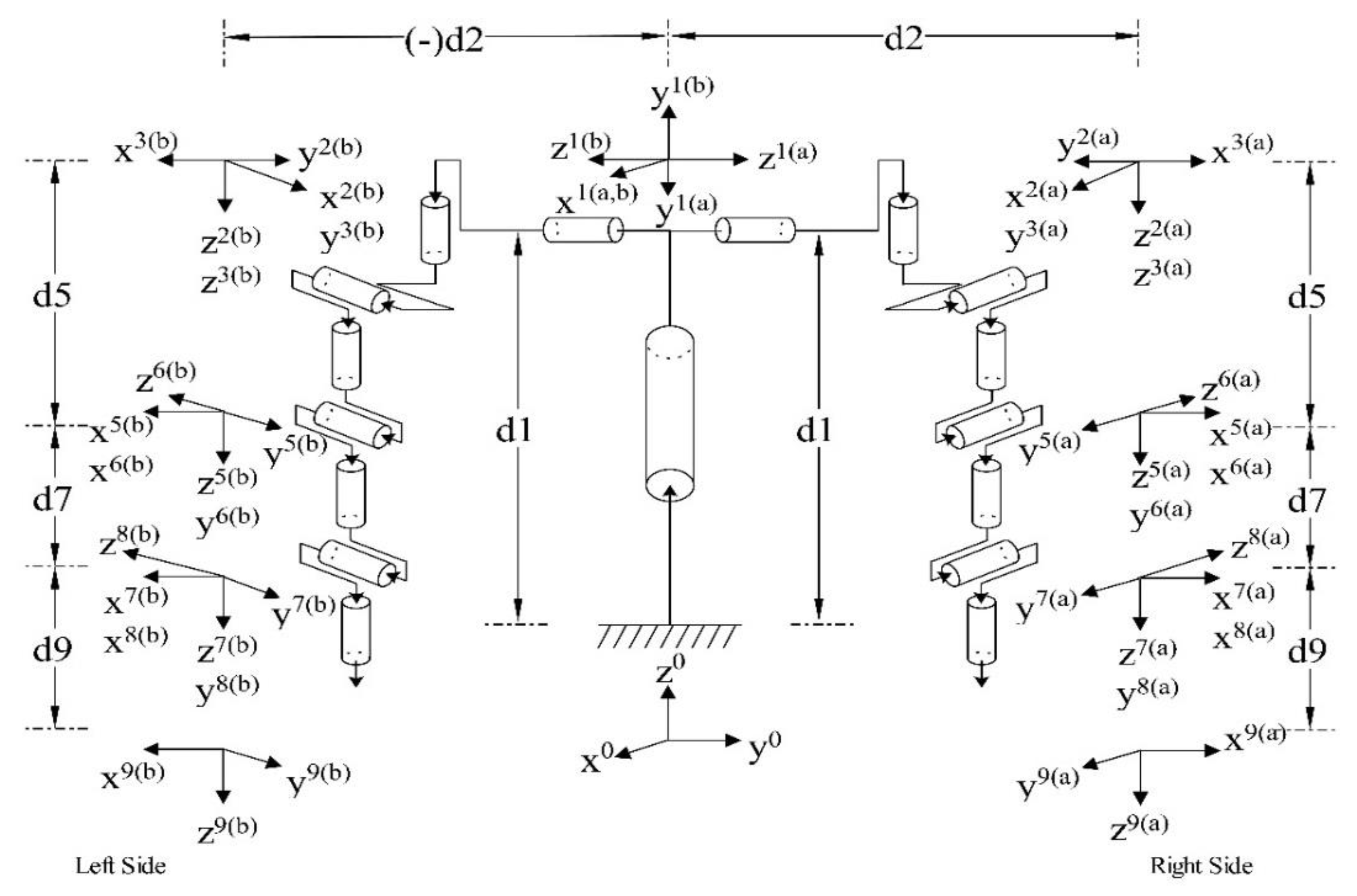

- Dual-Arm Robot Configuration: The dual-arm robot is the most dexterous of the manipulators with a total of 17DOF which are all revolute. It is configured such that the first joint at the ‘base’ of the structure is pointing along the direction of gravity. The third joint is parallel to the first joint and coincident with the fourth joint. The fifth, seventh, and ninth joints are also coincident with the third joint.

2.2. Fitness Function

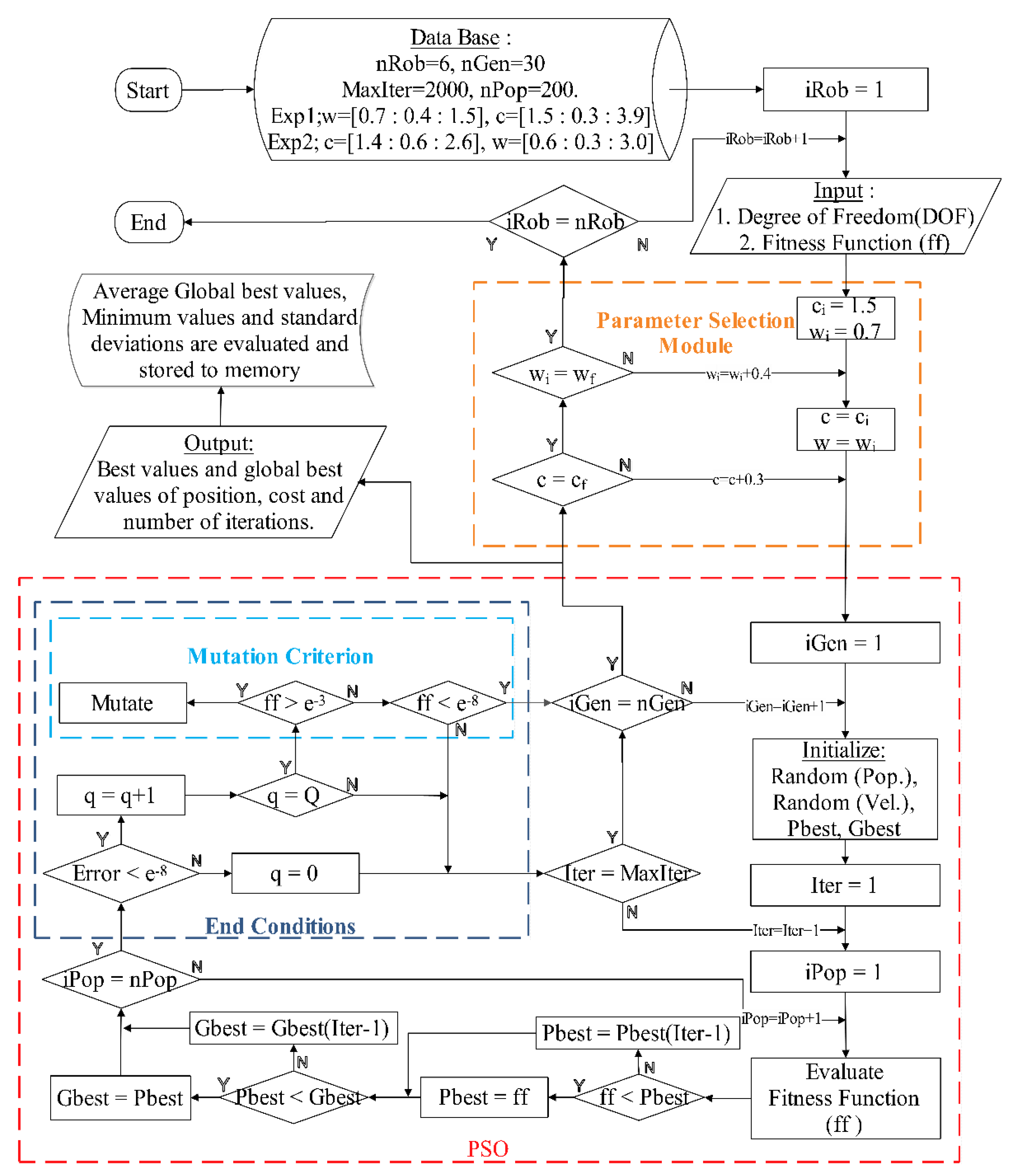

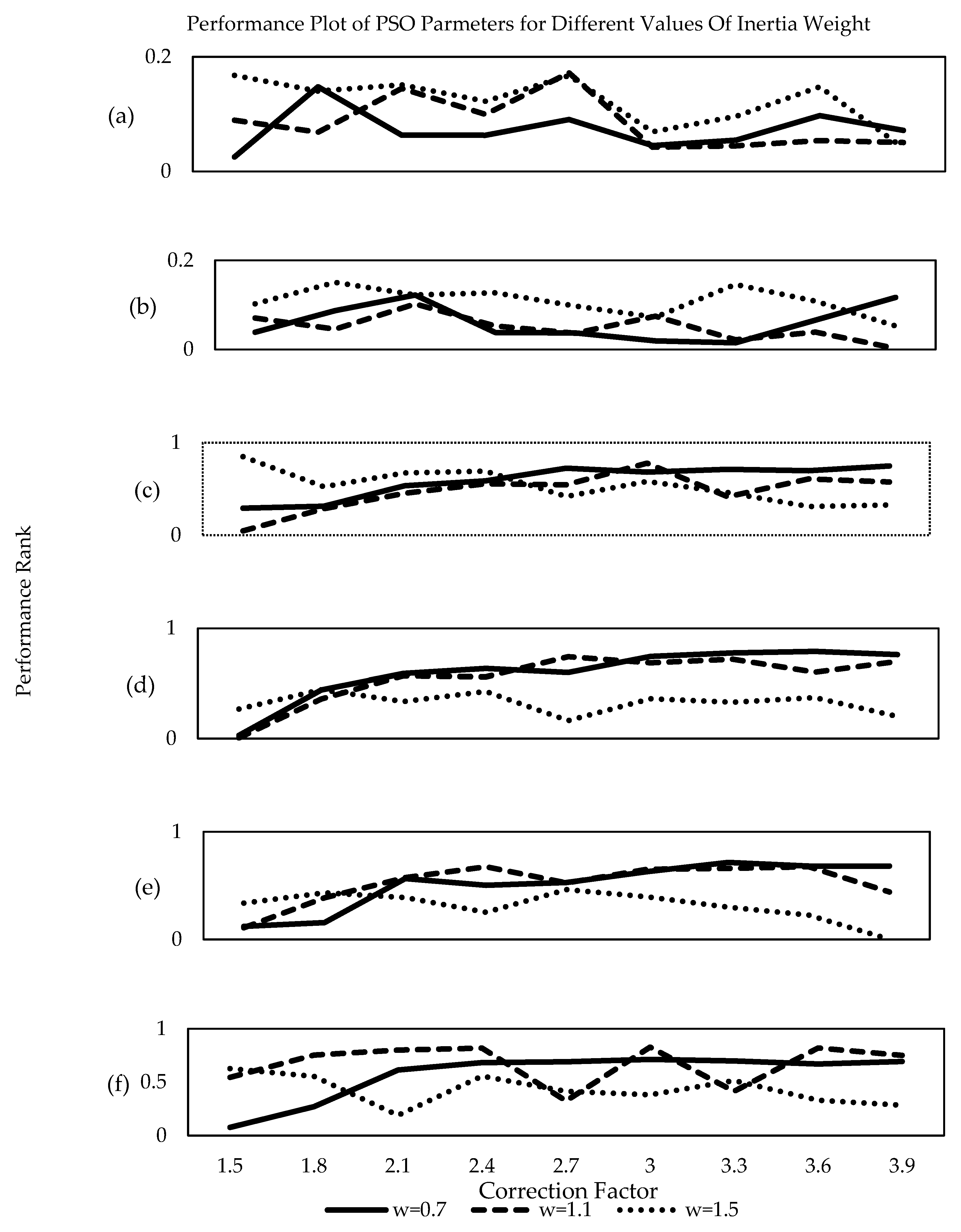

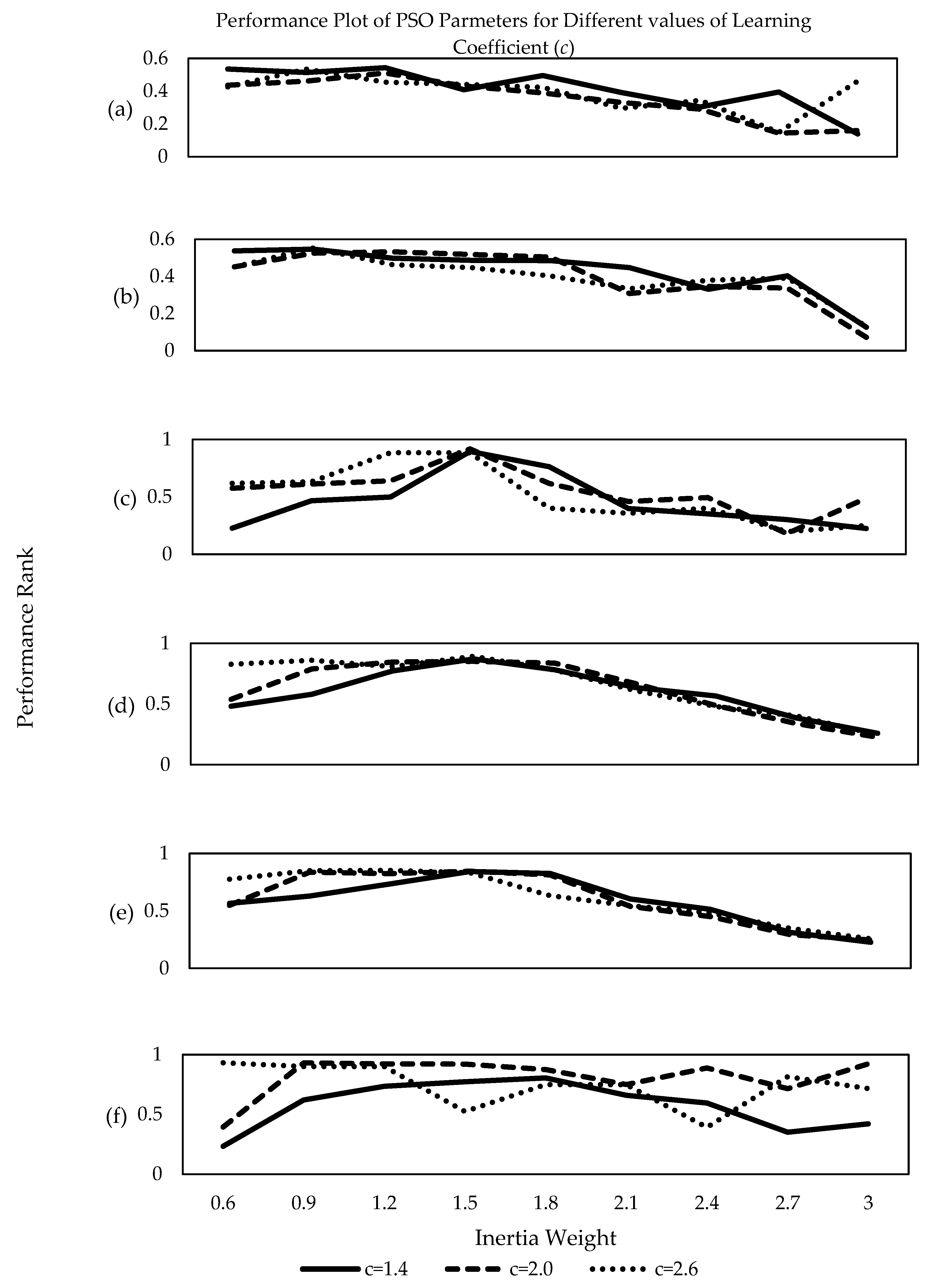

3. Determining New PSO Parameters

3.1. Observations

3.2. Deductions

4. Adaptive Computation Technique

- PSO1: The linear decreasing inertia weight was reported in [40] where inertia weight (w) decreases linearly from 0.9 to 0.4, the governing equation for updating the w iswhere wmax and wmin are values of the initial and final inertia weight, tmax is the maximum number of iterations while titer is the current iteration.

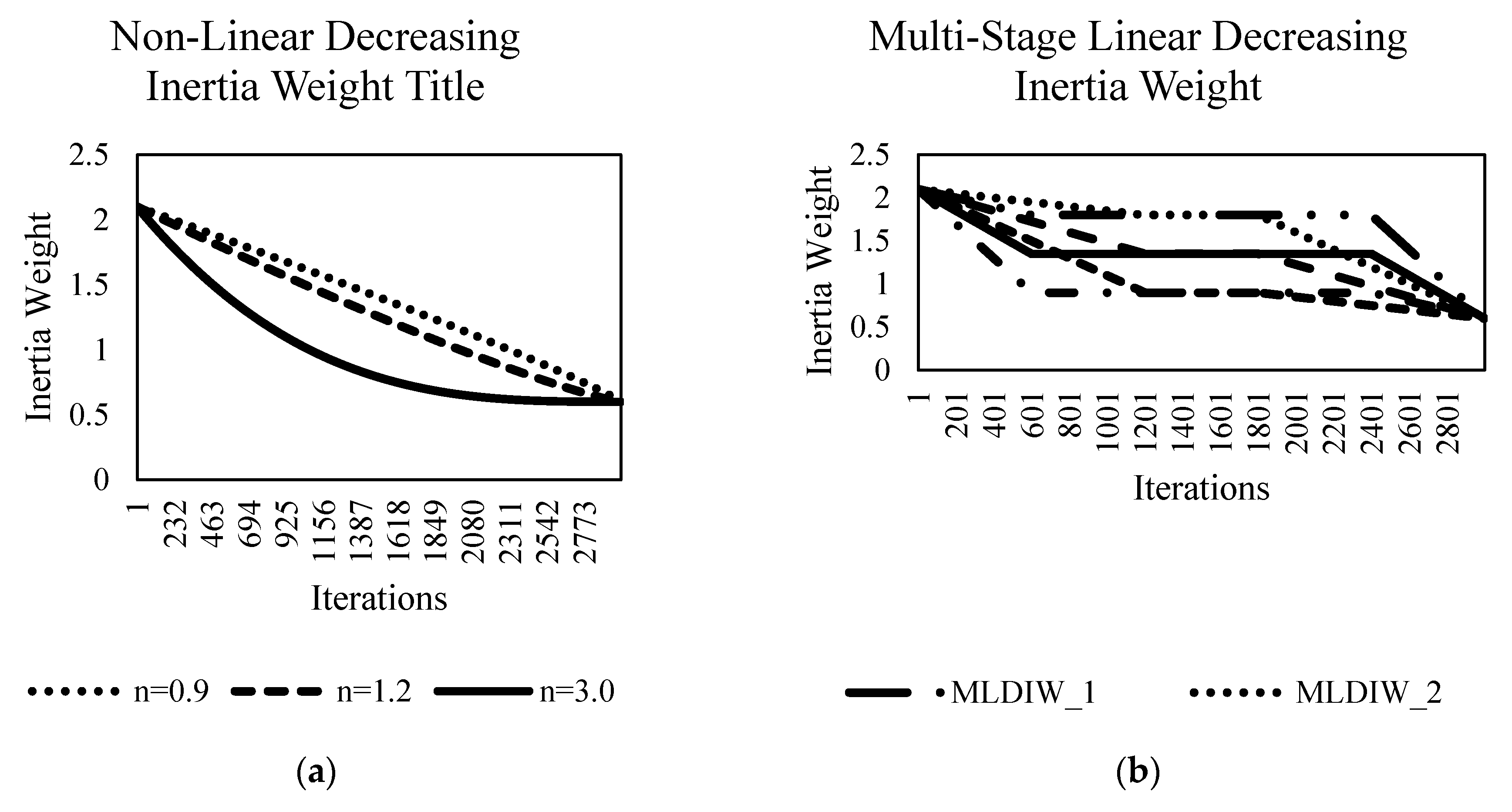

- PSO2–3: A non-linear decreasing inertia weight was also reported in [50] with w decreasing linearly from 0.9 to 0.4. The governing equation for updating the inertia weight isObserve that when n = 1, the inertia weight would be linearly decreasing as shown in Figure 7a, where n is a constant ranging from 0.9 to 1.3, the value n = 1.2 was reported as the recommended value for n in [50] but n = 3 was found to be more suitable for robot analysis. Therefore, the results for the two values n = 1.2 and n = 3.0 shall be presented in this experiment as PSO2 and PSO3, respectively.

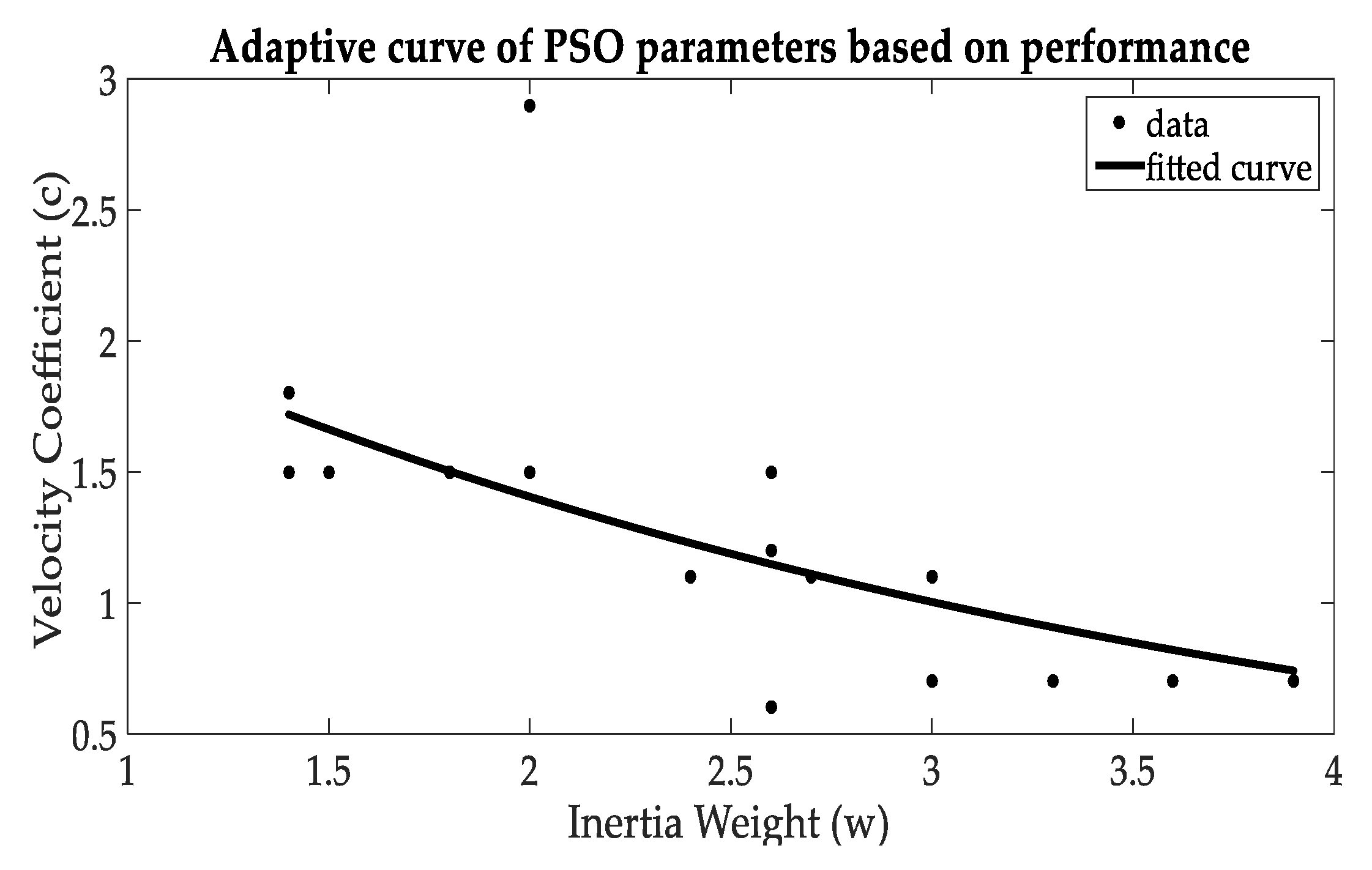

- PSO4: A novel non-linear decreasing w and non-linear increasing c is hereby proposed. The parameters recorded for the best performance of PSO from the previous experiment were plotted and a fitted curve generated as shown in Figure 8. The non-linear technique presented in (15)–(17) exploits the experimental range of values for w and c, where n and m are problem dependent variables.If the maximum number of iterations is 3000, then the values of the coefficients n and m can be easily determined. The parameter w in PSO4 shall be updated according on Equation (15) while c1 and c2 are updated according to Equation (16), where the learning coefficients are not adaptive therefore a reduced computation cost can be achieved, while the parameters in PSO11 shall be updated according to Equations (15)–(17) as originally proposed.

- PSO5–6: The concept of multi-stage decreasing inertia weight was introduced in [51], where w was decreased linearly from 0.9 to 0.4 in three distinct stages. The inertia weight first decreases from the initial value to a predetermined value wm where it remains constant for a while before decreasing further to the final value. As shown in Figure 7b, five different scenarios were presented, and the governing equation for updating the value of the inertia weight in each of the scenarios is given in Equations (18)–(22)The parameter for MLDIW5 was recommended in [51] for inertia weight but the parameters of MLDIW3 were found to be more suitable for the robot analysis. The results for the two values MLDIW5 and MLDIW3 shall also be presented as PSO4 and PSO5 respectively.

- PSO7: All the aforementioned algorithms exploited only the inertia weight, leaving the learning factor constantly at 2.05. In [52] and [36], a linear decreasing and linear increasing inertia weights were proposed respectively, both with decreasing cognitive component and increasing social component, thereby these techniques exploited both the inertia weight and learning coefficients. The technique reported in [52] shall be utilized in this experiment as it incorporates a linear decreasing inertia weight which is in line with our objectives and its parameters are updated according to Equation (12) above while the cognitive and social components shall be updated asThe inertia weight of PSO8–13 shall be updated according to the equations for PSO1–6 respectively, while the learning coefficients shall be updated according to Equations (16) and (17). For the sake of fair comparison, the adaptive values of w for all the aforementioned techniques shall decrease from the initial value of 2.1 to a final value of 0.6, the cognitive component remains at 2.24 while the social component is nonlinearly increasing from 1.8 to 3.9.

5. Results

- Most algorithms stagnate above 1 × 10−3, also most of the algorithms tested were found to either find the global minimum solution or run into stagnation. Accuracy is an important criterion for robot analysis and control, some algorithms were found to sometimes avoid stagnation but still incapable of finding the global minimum result even after 3000 iterations. This is an anomaly that was unfavorable in this analysis because when taking averages, these solutions gave competitive results, which is capable of confusing the algorithm. Therefore, another penalty was introduced such that if a solution is found to escape stagnation yet incapable of finding the global minimum solution, then the best solution for that run is recorded as 5.5. This signifies that the run gave bad results, and this problem is easily captured when taking averages.

- It can be seen from Table 15 that using the parameters derived from the previous experiment in place of the parameters of the PSO enhances the results as all the adaptive PSO techniques implemented so far found the global minimum solution except in PSO5 and PSO12. When the robot configuration has more than 4DOF PSO5 was not capable of finding the global minimum solution while PSO12 could not find the global minimum for the 6DOF Stanford robot configuration. Since almost all the algorithms were capable of finding the minimum solution, the quest was therefore reduced to finding the algorithm with the least computations and less likely to fall into stagnation.

- The proposed algorithm in PSO11 was found to produce better results than the PSO techniques reported in other works of literature and was only surpassed by PSO13 which is a modification of PSO6 and contested keenly with PSO10 which is also a modification of PSO3.

- From the results presented in Table 16, it can also be deduced that varying both the inertia weight and learning coefficient produces better results in adaptive PSO algorithms compared to only varying the inertia weight.

- It would also be observed that the proposed algorithm (PSO11) does not perform well at lower DOFs but performed better than PSO10 at higher DOF configurations. PSO13 perform well across all robot configurations. producing the best result for all techniques tested in this experiment.

- Modifying the adaptive PSO techniques presented in literature (PSO1–6) with a non-linear increasing learning coefficient as defined in Equations (16) and (17) greatly improved the performance of the PSO algorithm as it can be seen that the modified algorithms in PSO8–13 performed better than their counterparts with constant learning factors (PSO1–6).

6. Mutation Function

7. Conclusions

8. Future Thrust

Author Contributions

Funding

Conflicts of Interest

References

- Umar, A.; Shi, Z.; Wang, W.; Farouk, Z.I.B. A Novel Mutating PSO Based Solution for Inverse Kinematic Analysis of Multi Degree-Of-Freedom Robot Manipulators. In Proceedings of the 2019 IEEE International Conference on Artificial Intelligence and Computer Applications, Dalian, China, 29–31 March 2019; pp. 554–559. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R.C. Particle Swarm Optimization. In Proceeding of International Conference on Neural Networks; IEEE Press: Perth, Australia, 1995; pp. 1942–1948. [Google Scholar] [CrossRef]

- Zhu, L.; Feng, R.; Li, X.; Xi, J.; Wei, X. A Tree-Shaped Support Structure for Additive Manufacturing Generated by Using a Hybrid of Particle Swarm Optimization and Greedy Algorithm. J. Comput. Inf. Sci. Eng. 2019, 19, 1–12. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, D.; Zhang, X.; Wang, Y. Antenna Array Design by a Contraction Adaptive Particle Swarm Optimization Algorithm. EURASIP J. Wirel. Commun. Netw. 2019, 2019, 1–7. [Google Scholar] [CrossRef]

- Cai, X.; Cui, Z.; Zeng, J.; Tan, Y. Self-adaptive PID-controlled Particle Swarm Optimization. In Proceedings of the Chinese Control Conference, Hunan, China, 26–31 July 2007; pp. 799–803. [Google Scholar] [CrossRef]

- Cui, Z.; Cai, X.; Zeng, J.; Yin, Y. PID-Controlled Particle Swarm Optimization. Mult. Valued Log. Soft Comput. 2010, 16, 585–609. [Google Scholar]

- Lu, Y.; Yan, D.; Zhang, J.; Levy, D. A Variant with a Time Varying PID Controller of Particle Swarm Optimizers. Inf. Sci. 2015, 297, 21–49. [Google Scholar] [CrossRef]

- Xiang, Z.; Ji, D.; Zhang, H.; Wu, H.; Li, Y. A Simple PID-based Strategy for Particle Swarm Optimization Algorithm. Inf. Sci. 2019, 502, 558–574. [Google Scholar] [CrossRef]

- Chang, C.; Wu, X. An Improved Particle Swarm Optimization Algorithm. Adv. Intell. Sys. Comp. 2020, 928, 1406–1410. [Google Scholar] [CrossRef]

- Zidan, A.; Tappe, S.; Ortmaier, T. Auto-tuning of PID Controllers for Robotic Manipulators using PSO and MOPSO. Lect. Notes Electr. Eng. 2020, 495, 339–354. [Google Scholar] [CrossRef]

- Peng, Z.; Al Chami, Z.; Manier, H.; Manier, M.-A. A Hybrid Particle Swarm Optimization for the Selective Pickup and Delivery Problem with Transfers. Eng. Appl. Artif. Intell. 2019, 85, 99–111. [Google Scholar] [CrossRef]

- Jiang, G.; Luo, M.; Bai, K.; Chen, S. A Precise Positioning Method for a Puncture Robot Based on a PSO-Optimized BP Neural Network Algorithm. Appl. Sci. 2017, 7, 969. [Google Scholar] [CrossRef]

- Iacca, G.; Caraffini, F.; Neri, F. Compact Differential Evolution Light: High Performance Despite Limited Memory Requirement and Modest Computational Overhead. J. Comput. Sci. Technol. 2012, 27, 1056–1076. [Google Scholar] [CrossRef]

- Li, J.; Zhang, J.; Jiang, C.; Zhou, M. Composite Particle Swarm Optimizer with Historical Memory for Function Optimization. IEEE Trans. Cybern. 2015, 45, 2350–2363. [Google Scholar] [CrossRef] [PubMed]

- Santucci, V.; Milani, A.; Caraffini, F. An Optimisation-Driven Prediction Method for Automated Diagnosis and Prognosis. Mathematics 2019, 7, 1051. [Google Scholar] [CrossRef]

- Hu, J.; Chen, D.; Liang, P. A Novel Interval Three-Way Concept Lattice Model with Its Application in Medical Diagnosis. Mathematics 2019, 7, 103. [Google Scholar] [CrossRef]

- Hu, J.; Yang, Y.; Chen, X. A Novel TODIM Method-based Three-Way Decision Model for Medical Treatment Selection. Int. J. Fuzzy Syst. 2017, 33, 3405–3417. [Google Scholar] [CrossRef]

- Yao, J.T.; Azam, N. Web-based Medical Decision Support Systems for Three-Way Medical Decision Making with Game-theoretic Rough Sets. IEEE Trans. Fuzzy Syst. 2015, 23, 3–15. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, J.; Liu, D.; Lin, Y.; Zhao, Y.; Lin, Z.; Zhao, T.; Lei, Y. Parameter Identification with the Random Perturbation Particle Swarm Optimization Method and Sensitivity Analysis of an Advanced Pressurized Water Reactor Nuclear Power Plant Model for Power Systems. Energies 2017, 10, 173. [Google Scholar] [CrossRef]

- Clerc, M.; Kennedy, J. The Particle Swarm—Explosion, Stability, and Convergence in a Multi-Dimensional Complex Space. IEEE Trans. Evol. Comput. 2002, 6, 58–73. [Google Scholar] [CrossRef]

- Reynolds, W.C. Flocks, Herds, and Schools: A Distributed Behavioral Model; ACM: New York, NY, USA, 1987; Volume 21, pp. 25–34. [Google Scholar] [CrossRef]

- Cui, Z.; Shi, Z. Boids Particle Swarm Optimization. Int. J. Innov. Comput. Appl. 2009, 2, 78–85. [Google Scholar] [CrossRef]

- Kennedy, J. Small Worlds and Mega-Minds: Effects of Neighborhood Topology on Particle Swarm Performance. In Proceedings of the 1999 Congress on Evolutionary Computation-CEC99 (Cat. No. 99TH8406), Washington, DC, USA, 6–9 July 1999; Volume 3, pp. 1931–1938. [Google Scholar] [CrossRef]

- Kennedy, J. The Particle Swarm: Social Adaptation of Knowledge. In Proceedings of the 1997 International Conference on Evolutionary Computation, Indianapolis, IN, USA, 13–16 April 1997; pp. 303–308. [Google Scholar] [CrossRef]

- Mendes, R.; Kennedy, J.; Neves, J. Watch Thy Neighbor or How the Swarm Can Learn from Its Environment. In Proceedings of the 2003 IEEE Swarm Intelligence Symposium, Indianapolis, IN, USA, 24–26 April 2003; pp. 88–94. [Google Scholar] [CrossRef]

- Qteish, A.; Hamdan, M. Hybrid Particle Swarm and Conjugate Gradient Optimization Algorithm. In Advances in Swarm Intelligence; ICSI 2010; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2010; Volume 6145, pp. 582–588. [Google Scholar] [CrossRef]

- Qin, J.; Yin, Y.; Ban, X. A Hybrid of Particle Swarm Optimization and Local Search for Multimodal Functions. In Advances in Swarm Intelligence; ICSI 2010; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2010; Volume 6145, pp. 589–596. [Google Scholar] [CrossRef]

- De-los-Cobos-Silva, S.G.; Andrade, M.Á.G.; Lara-Velázquez, P.; García, E.A.R.; Mora-Gutiérrez, R.A.; Ponsich, A. ABC-PSO: An Efficient Bioinspired Metaheuristic for Parameter Estimation in Nonlinear Regression. In Advances in Soft Computing, Mexican International Conference on Artificial Intelligence MICAI 2016; Pichardo-Lagunas, O., Miranda-Jiménez, S., Eds.; Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2016; Volume 10062, pp. 388–400. [Google Scholar] [CrossRef]

- Marinakis, Y.; Marinaki, M. Particle Swarm Optimization with Expanding Neighborhood Topology for the Permutation Flowshop Scheduling Problem. Soft Comput. 2013, 17, 1159–1173. [Google Scholar] [CrossRef]

- Guo, W.; Zhu, L.; Wang, L.; Wu, Q.; Kong, F. An Entropy-Assisted Particle Swarm Optimizer for Large-Scale Optimization Problem. Mathematics 2019, 7, 414. [Google Scholar] [CrossRef]

- Kong, F.; Jiang, J.; Huang, Y. An Adaptive Multi-Swarm Competition Particle Swarm Optimizer for Large-Scale Optimization. Mathematics 2019, 7, 521. [Google Scholar] [CrossRef]

- Ahmad, N.; Mohammed, M.E.; Reza, S. DNPSO: A Dynamic Niching Particle Swarm Optimization for Multi-Modal Optimization. In Proceedings of the 2008 IEEE Congress on Evolutionary Computation, Hong Kong, China, 1–6 June 2008; pp. 26–32. [Google Scholar] [CrossRef]

- Seo, J.H.; Im, C.H.; Heo, C.G.; Kim, J.K.; Jung, H.K.; Lee, C.G. Multimodal Function Optimization Based on Particle Swarm Optimization. IEEE Trans. Magn. 2006, 42, 1095–1098. [Google Scholar] [CrossRef]

- Blackwell, T.M. Particle swarms and population diversity. Soft Comput. 2005, 9, 793–802. [Google Scholar] [CrossRef]

- Blackwell, T.; Branke, J. Multi-swarm Optimization in Dynamic Environments. In Applications of Evolutionary Computing; Springer: Berlin/Heidelberg, Germany, 2004; Volume 3005, pp. 489–500. [Google Scholar] [CrossRef]

- Ratnaweera, A.; Halgamuge, S.K.; Watson, H.C. Self-Organizing Hierarchical Particle Swarm Optimizer with Time-Varying Acceleration Coefficients. IEEE Trans. Evol. Comput. 2004, 8, 240–255. [Google Scholar] [CrossRef]

- Qin, Z.; Yu, F.; Shi, Z.; Wang, Y. Adaptive Inertia Weight Particle Swarm Optimization. In Artificial Intelligence and Soft Computing—ICAISC 2006; Rutkowski, L., Tadeusiewicz, R., Zadeh, L.A., Żurada, J.M., Eds.; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2006; Volume 4029, pp. 450–459. [Google Scholar] [CrossRef]

- Yang, X.; Yuan, J.; Mao, H. A Modified Particle Swarm Optimizer with Dynamic Adaptation. Appl. Math. Comput. 2007, 189, 1205–1213. [Google Scholar] [CrossRef]

- Arumugam, M.S.; Rao, M.V.C. On the Improved Performances of the Particle Swarm Optimization Algorithms with Adaptive Parameters, Cross-over Operators and Root Mean Square (RMS) Variants for Computing Optimal Control of a Class of Hybrid Systems. Appl. Soft Comput. 2008, 8, 324–336. [Google Scholar] [CrossRef]

- Pandey, B.B.; Debbarma, S.; Bhardwaji, P. Particle Swarm Optimization with varying Inertia Weight for solving nonlinear optimization problem. In Proceedings of the International Conference on Electrical, Electronics, Signals, Communication and Optimization, EESCO, Visakhapatnam, India, 24–25 January 2015. [Google Scholar] [CrossRef]

- Bingul, Z.; Karahan, O. Dynamic identification of Staubli RX-60 Robot using PSO and LS Methods. Expert Syst. Appl. 2011, 38, 4136–4149. [Google Scholar] [CrossRef]

- Xue-qian, W.; Hou-de, L.; Ye, S.; Bin, L.; Ying-chun, Z. Research on Identification Method of Kinematics for Space Robot. Procedia Eng. 2012, 29, 3381–3386. [Google Scholar] [CrossRef][Green Version]

- Feng, F.; Hu, H.; Guo, Z. Application of Genetic Algorithm PSO in Parameter Identification of SCARA Robot. In Proceedings of the Chinese Automation Congress, CAC, Jinan, China, 20–22 October 2017; pp. 923–927. [Google Scholar] [CrossRef]

- Gao, G.; Lin, F.; San, H.; Wu, X.; Wang, W. Hybrid Optimal Kinematic Parameter Identification for an Industrial Robot Based on BPNN-PSO. Complexity 2018, 1–11. [Google Scholar] [CrossRef]

- Nizar, R.; Adel, M.A. Inverse Kinematics using Particle Swarm Optimization, a Statistical Analysis. Procedia Eng. 2013, 64, 1602–1611. [Google Scholar] [CrossRef]

- Sarosh, P.; Tarek, S. Task Based Synthesis of Serial Manipulators. J. Adv. Res. 2015, 6, 479–492. [Google Scholar] [CrossRef]

- Sarosh, P.; Tarek, S. Using Task Descriptions for Designing Optimal Task Specific Manipulators. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 29 September–3 October 2015; pp. 3544–3551. [Google Scholar] [CrossRef]

- Mizuno, N.; Nguyen, C.H. Parameters Identification of Robot Manipulator based on Particle Swarm. In Proceedings of the 13th IEEE International Conference on Control and Automation, ICCA, Ohrid, Macedonia, 3–6 July 2017; pp. 307–312. [Google Scholar] [CrossRef]

- Fang, L.; Dang, P. A step identification method of joint parameters of robots based on the measured pose of end-effector. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 3218–3233. [Google Scholar] [CrossRef]

- Chatterjee, A.; Siarry, P. Nonlinear Inertia Weight Variation for Dynamic Adaption in Particle Swarm Optimization. Comput. Oper. Res. 2006, 33, 859–871. [Google Scholar] [CrossRef]

- Xin, J.; Chen, G.; Hai, Y. A Particle Swarm Optimizer with Multi-Stage Linearly-Decreasing Inertia Weight. In Proceedings of the International Joint Conference on Computational Sciences and Optimization, Sanya, China, 24–26 April 2009; Volume 1, pp. 505–508. [Google Scholar] [CrossRef]

- Wang, H.; Qian, F. Improved PSO-based Multi-Objective Optimization using Inertia Weight and Acceleration Coefficients Dynamic Changing, Crowding and Mutation. In Proceedings of the 7th World Congress on Intelligent Control and Automation, Chongqing, China, 25–27 June 2008; pp. 4473–4478. [Google Scholar] [CrossRef]

- Kononova, A.V.; Corne, D.W.; Wilde, P.D.; Shneer, V.; Caraffini, F. Structural Bias in Population-based Algorithms. Inf. Sci. 2015, 298, 468–490. [Google Scholar] [CrossRef]

| Joint | Link | Off-Set | Joint Displacement 1 | Off-Set Displacement 2 |

|---|---|---|---|---|

| 1 | 0 | Variable (0–300) | 0 | 0 |

| 2 | 350 | 0 | Variable (−pi/2–pi/2) | 0 |

| 3 | 350 | 0 | Variable (−pi/2–pi/2) | 0 |

| 4 | 0 | 200 | Variable (−pi/2–pi/2) | 0 |

| Joint | Link | Off-Set | Joint Displacement | Off-Set Displacement |

|---|---|---|---|---|

| 1 | 70 | 200 | Variable (−pi/2–pi/2) | −pi/2 |

| 2 | 150 | 0 | Variable (−pi/2–pi/2) | 0 |

| 3 | 150 | 0 | Variable (−pi/2–pi/2) | 0 |

| Joint | Link | Off-Set | Joint Displacement | Off-Set Displacement |

|---|---|---|---|---|

| 1 | 64.5 | 170 | Variable (−pi/2–pi/2) | −pi/2 |

| 2 | 305 | 0 | Variable (−pi/2–pi/2) | 0 |

| 3 | 0 | 0 | Variable (−pi/2–pi/2) | pi/2 |

| 4 | 0 | −220 | Variable (−pi/2–pi/2) | −pi/2 |

| 5 | 0 | 0 | Variable (−pi/2–pi/2) | pi/2 |

| 6 | 0 | −36 | Variable (−pi/2–pi/2) | 0 |

| Joint | Link | Off-Set | Joint Displacement | Off-Set Displacement |

|---|---|---|---|---|

| 1 | 300 | 320 | Variable (−pi/2–pi/2) | −pi/2 |

| 2 | 700 | 0 | Variable (−pi/2–pi/2) | 0 |

| 3 | 0 | 0 | Variable (−pi/2–pi/2) | −pi/2 |

| 4 | 0 | 697.5 | Variable (−pi/2–pi/2) | pi/2 |

| 5 | 0 | 0 | Variable (−pi/2–pi/2) | −pi/2 |

| 6 | 0 | 127.5 | Variable (−pi/2–pi/2) | 0 |

| Joint | Link | Off-Set | Joint Displacement | Off-Set Displacement |

|---|---|---|---|---|

| 1 | 154 | 412 | Variable (−pi/2–pi/2) | −pi/2 |

| 2 | 0 | 0 | Variable (−pi/2–pi/2) | 0 |

| 3 | 0 | Variable (50–154) | −pi/2 | −pi/2 |

| 4 | 0 | 0 | Variable (−pi/2–pi/2) | pi/2 |

| 5 | 0 | 0 | Variable (−pi/2–pi/2) | −pi/2 |

| 6 | 0 | 263 | Variable (−pi/2–pi/2) | 0 |

| Joint | Link | Off-Set | Joint Displacement | Off-Set Displacement |

|---|---|---|---|---|

| 1 | 0 | 400 | th1 | pi/2 |

| 2 | 0 | 200 | Variable (−pi/2–pi/2) (a) | pi/2 |

| −200 | Variable (−pi/2–pi/2) (b) | −pi/2 | ||

| 3 | 0 | 0 | pi/2) (a) | 0 |

| 0 | −pi/2) (b) | 0 | ||

| 4 | 0 | 0 | Variable (−pi/2–pi/2) (a) | −pi/2 |

| 0 | Variable (−pi/2–pi/2) (b) | pi/2 | ||

| 5 | 0 | 150 | Variable (−pi/2–pi/2) (a) | pi/2 |

| −150 | Variable (−pi/2–pi/2) (b) | −pi/2 | ||

| 6 | 0 | 0 | Variable (−pi/2–pi/2) (a) | −pi/2 |

| 0 | Variable (−pi/2–pi/2) (b) | pi/2 | ||

| 7 | 0 | 150 | Variable (−pi/2–pi/2) (a) | pi/2 |

| −150 | Variable (−pi/2–pi/2) (b) | −pi/2 | ||

| 8 | 0 | 0 | Variable (−pi/2–pi/2) (a) | −pi/2 |

| 0 | Variable (−pi/2–pi/2) (b) | pi/2 | ||

| 9 | 0 | 150 | Variable (−pi/2–pi/2) (a) | 0 |

| −150 | Variable (−pi/2–pi/2) (b) | 0 |

| Robot Configuration | PSO Parameters @ w = 0.7 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| c = 1.5 | c = 1.8 | c = 2.1 | c = 2.4 | c = 2.7 | c = 3.0 | c = 3.3 | c = 3.6 | c = 3.9 | ||

| 3DOF Articulate Robot Arm | Average (Std) | 1.1999 (0.996) | 0.66662 (0.958) | 0.99993 (1.017) | 0.99993 (1.017) | 0.8666 (1.008) | 1.0666 (1.015) | 0.99993 (1.017) | 0.79994 (0.996) | 0.8666 (1.008) |

| Minimum | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | |

| Iteration | 74.8 | 74.1 | 74.333 | 74.4 | 75.233 | 75.867 | 77.133 | 78.4 | 81.333 | |

| 4DOF SCARA Robot Arm | Average (Std) | 2.1333 (2.029) | 1.7333 (2.016) | 1.4667 (1.960) | 2.1333 (2.029) | 2.1333 (2.029) | 2.2667 (2.016) | 2.2667 (2.016) | 1.7333 (2.02) | 1.3333 (1.918) |

| Minimum | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | |

| Iteration | 78.967 | 78.067 | 78.467 | 79.233 | 79.5 | 81.233 | 82.733 | 85.433 | 87.267 | |

| 6DOF Stanford Robot Arm | Average (Std) | 2.4859 (2.145) | 1.2563 (0.992) | 1.2951 (1.049) | 0.85651 (1.123) | 0.28667 (0.751) | 0.18892 (0.590) | 0.10886 (0.509) | 0.08696 (0.388) | 0.015589 (0.0401) |

| Minimum | 4.67 × 10−4 | 3.21 × 10−2 | 1.05 × 10−4 | 4.31 × 10−7 | 1.68 × 10−6 | 1.32 × 10−6 | 5.80 × 10−9 | 5.80 × 10−9 | 5.80 × 10−9 | |

| Iteration | 533.4 | 508.3 | 554.1 | 511.8 | 417.4 | 601.4 | 567.6 | 651.57 | 643.47 | |

| 6DOF Articulate Robot Arm (small) | Average (Std) | 3.7837 (1.759) | 1.5927 (1.237) | 1.1403 (0.633) | 0.80981 (0.506) | 0.59953 (0.780) | 0.24822 (0.412) | 0.27092 (0.457) | 0.17026 (0.385) | 0.31949 (0.596) |

| Minimum | 1.11 × 100 | 3.48 × 10−1 | 9.21 × 10−2 | 8.27 × 10−2 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | |

| Iteration | 261.87 | 235.43 | 265.87 | 260.93 | 296.7 | 214.53 | 166.63 | 170.67 | 157.63 | |

| 6DOF Articulate Robot Arm (big) | Average (Std) | 3.4266 (1.732) | 2.9774 (1.649) | 1.5511 (0.902) | 1.3035 (1.180) | 0.86441 (1.095) | 0.43759 (0.784) | 0.30934 (0.458) | 0.35057 (0.680) | 0.35187 (0.456) |

| Minimum | 6.53 × 10−1 | 7.02 × 10−1 | 5.70 × 10−2 | 7.09 × 10−2 | 6.98 × 10−4 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | |

| Iteration | 244.33 | 230.5 | 285.63 | 343.43 | 416.5 | 375.47 | 327.27 | 323.77 | 377.8 | |

| 17DOF Dual-Arm Robot Arm | Average (Std) | 2.873 (2.307) | 1.7774 (1.672) | 0.71947 (0.803) | 0.51867 (0.569) | 0.25626 (0.425) | 0.13317 (0.388) | 0.14343 (0.469) | 0.14844 (0.678) | 0.13608 (0.419) |

| Minimum | 2.35 × 10−2 | 1.81 × 10−2 | 3.90 × 10−3 | 1.99 × 10−4 | 4.43 × 10−5 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | |

| Iteration | 326.07 | 378.17 | 364.87 | 390.77 | 451.3 | 437.33 | 447.07 | 457.43 | 468.83 | |

| Robot Configuration | PSO Parameters @ w = 1.1 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| c = 1.5 | c = 1.8 | c = 2.1 | c = 2.4 | c = 2.7 | c = 3.0 | c = 3.3 | c = 3.6 | c = 3.9 | ||

| 3DOF Articulate Robot Arm | Average (Std) | 1.0666 (1.015) | 1.1999 (0.996) | 0.79994 (0.996) | 0.99993 (1.017) | 0.66662 (0.959) | 1.3332 (0.959) | 1.2666 (0.980) | 1.1333 (1.008) | 1.0666 (1.015) |

| Minimum | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | |

| Iteration | 81.6 | 81.7 | 81.267 | 82.267 | 83.9 | 85.733 | 87.667 | 91.1 | 96.533 | |

| 4DOF SCARA Robot Arm | Average (Std) | 2 (2.034) | 2.2667 (2.016) | 1.7333 (2.016) | 2.1333 (2.03) | 2.2667 (2.016) | 1.8667 (2.03) | 2.2667 (2.016) | 2 (2.034) | 2.2667 (2.016) |

| Minimum | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | |

| Iteration | 88.667 | 87.7 | 88.633 | 90.133 | 91.6 | 93.367 | 97.767 | 101.97 | 106 | |

| 6DOF Stanford Robot Arm | Average (Std) | 0.75869 (1.099) | 0.71229 (1.079) | 0.37784 (1.009) | 0.27387 (0.758) | 0.28313 (0.852) | 0.02518 (0.059) | 0.53394 (1.008) | 0.19628 (0.561) | 0.17413 (0.519) |

| Minimum | 7.02 × 10−5 | 1.06 × 10−5 | 4.14 × 10−6 | 5.80 × 10−9 | 5.80 × 10−9 | 5.80 × 10−9 | 5.80 × 10−9 | 5.80 × 10−9 | 5.80 × 10−9 | |

| Iteration | 661.17 | 637.47 | 581.6 | 590.93 | 548.53 | 648.57 | 585.13 | 648.67 | 810.17 | |

| 6DOF Articulate Robot Arm (small) | Average (Std) | 1.3059 (1.047) | 0.71658 (0.695) | 0.27506 (0.580) | 0.46958 (0.945) | 0.22999 (0.387) | 0.32675 (0.611) | 0.30032 (0.452) | 0.46418 (0.779) | 0.22069 (0.412) |

| Minimum | 9.23 × 10−3 | 3.23 × 10−3 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | |

| Iteration | 375.67 | 385.77 | 367.23 | 193.1 | 186.47 | 162.57 | 178.2 | 190.97 | 246.33 | |

| 6DOF Articulate Robot Arm (big) | Average (Std) | 1.5539 (1.113) | 0.82201 (0.625) | 0.46599 (0.473) | 0.30729 (0.433) | 0.52439 (1.167) | 0.49672 (0.635) | 0.33982 (0.588) | 0.48452 (0.488) | 0.70028 (1.07) |

| Minimum | 6.30 × 10−2 | 2.71 × 10−2 | 3.28 × 10−7 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | |

| Iteration | 341.5 | 532.1 | 553.77 | 405.8 | 311.9 | 293.23 | 352.83 | 315.17 | 483.03 | |

| 17DOF Dual-Arm Robot Arm | Average (Std) | 0.4248 (0.48) | 0.09798 (0.131) | 0.14656 (0.316) | 0.11974 (0.248) | 875.8 (4796.4) | 0.068428 (0.151) | 723.89 (3964.6) | 0.18718 (0.324) | 0.12041 (0.269) |

| Minimum | 5.31 × 10−3 | 3.60 × 10−4 | 5.10 × 10−5 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | |

| Iteration | 501.6 | 562.43 | 483.93 | 444.2 | 432 | 422.9 | 422.1 | 440 | 611.93 | |

| Robot Configuration | PSO Parameters @ w = 1.5 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| c = 1.5 | c = 1.8 | c = 2.1 | c = 2.4 | c = 2.7 | c = 3.0 | c = 3.3 | c = 3.6 | c = 3.9 | ||

| 3DOF Articulate Robot Arm | Average (Std) | 0.8666 (1.008) | 0.9999 (1.017) | 0.9333 (1.015) | 1.0666 (1.015) | 0.7999 (0.996) | 1.3999 (0.932) | 1.0666 (1.015) | 0.7333 (0.980) | 1.1999 (0.996) |

| Minimum | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | |

| Iteration | 93.633 | 94.333 | 95.1 | 97.6 | 101.53 | 104.93 | 111.3 | 119.9 | 130.03 | |

| 4DOF SCARA Robot Arm | Average (Std) | 2.4 (1.993) | 1.8667 (2.03) | 2.1333 (2.03) | 2 (2.034) | 2.2667 (2.016) | 2.5333 (1.960) | 1.6 (1.993) | 1.7333 (2.016) | 2 (2.034) |

| Minimum | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | |

| Iteration | 103.9 | 103.9 | 105.03 | 110.07 | 113.53 | 117 | 126.2 | 139.67 | 156.7 | |

| 6DOF Stanford Robot Arm | Average (Std) | 0.0169 (0.048) | 0.1762 (0.58) | 0.0927 (0.387) | 0.0793 (0.382) | 0.2655 (0.69) | 0.1456 (0.462) | 0.1750 (0.603) | 0.2623 (0.748) | 0.0996 (0.241) |

| Minimum | 5.80 × 10−9 | 5.80 × 10−9 | 5.80 × 10−9 | 5.80 × 10−9 | 5.80 × 10−9 | 5.80 × 10−9 | 5.86 × 10−9 | 6.77 × 10−9 | 6.72 × 10−7 | |

| Iteration | 784.03 | 764.1 | 728.07 | 689.4 | 664.9 | 839.4 | 1143.2 | 1273.1 | 1667.7 | |

| 6DOF Articulate Robot Arm (small) | Average (Std) | 0.4613 (0.735) | 0.2363 (0.411) | 0.3917 (0.629) | 0.27185 (0.456) | 0.7003 (0.841) | 0.29195 (0.6) | 0.38275 (0.474) | 0.24172 (0.434) | 0.42294 (0.499) |

| Minimum | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.90 × 10−9 | |

| Iteration | 235.23 | 236.67 | 208.27 | 213.37 | 208.53 | 251.27 | 331.77 | 377.17 | 558.5 | |

| 6DOF Articulate Robot Arm (big) | Average (Std) | 0.3755 (0.616) | 0.3122 (0.429) | 0.2982 (0.602) | 0.54127 (0.736) | 0.24539 (0.422) | 0.33632 (0.472) | 0.33908 (0.666) | 0.54117 (0.492) | 0.60112 (0.79) |

| Minimum | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 5.56 × 10−9 | 6.22 × 10−9 | |

| Iteration | 490.57 | 434.43 | 405.5 | 375.57 | 438.6 | 509.8 | 695.57 | 935.57 | 1374.1 | |

| 17DOF Dual-Arm Robot Arm | Average (Std) | 0.03969 (0.091) | 0.1555 (0.349) | 0.58298 (1.275) | 0.12749 (0.280) | 0.24011 (0.726) | 0.25313 (0.850) | 0.089832 (0.219) | 0.31591 (0.629) | 0.27926 (0.494) |

| Minimum | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | 3.84 × 10−9 | 4.09 × 10−9 | |

| Iteration | 566.6 | 419.9 | 412.63 | 538.6 | 571.17 | 587.53 | 911.87 | 945.53 | 1338 | |

| Robot Configuration | PSO Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| c = 1.5 | c = 1.8 | c = 2.1 | c = 2.4 | c = 2.7 | c = 3.0 | c = 3.3 | c = 3.6 | c = 3.9 | ||

| 3DOF Articulate Robot Arm | w = 0.7 | 0.02513 | 0.14763 | 0.06318 | 0.06297 | 0.09043 | 0.04511 | 0.05457 | 0.09739 | 0.07168 |

| w = 1.1 | 0.08921 | 0.06846 | 0.14458 | 0.09944 | 0.17200 | 0.04226 | 0.04449 | 0.05379 | 0.05053 | |

| w = 1.5 | 0.16746 | 0.14006 | 0.15103 | 0.12242 | 0.16699 | 0.06913 | 0.09608 | 0.14758 | 0.04076 | |

| 4DOF SCARA Robot Arm | w = 0.7 | 0.03849 | 0.08687 | 0.12197 | 0.03773 | 0.03696 | 0.01897 | 0.01468 | 0.06577 | 0.11672 |

| w = 1.1 | 0.07029 | 0.04539 | 0.10203 | 0.05269 | 0.03619 | 0.07446 | 0.02166 | 0.0389 | 0.00224 | |

| w = 1.5 | 0.10249 | 0.15062 | 0.12251 | 0.12707 | 0.09746 | 0.07244 | 0.14586 | 0.10839 | 0.05263 | |

| 6DOF Stanford Robot Arm | w = 0.7 | 0.29170 | 0.31301 | 0.53404 | 0.58656 | 0.72349 | 0.68145 | 0.71189 | 0.69607 | 0.74687 |

| w = 1.1 | 0.04599 | 0.28527 | 0.45162 | 0.55492 | 0.54350 | 0.77809 | 0.41407 | 0.60752 | 0.57449 | |

| w = 1.5 | 0.84829 | 0.52364 | 0.67211 | 0.69225 | 0.41774 | 0.58066 | 0.46007 | 0.30967 | 0.32558 | |

| 6DOF Articulate Robot Arm (small) | w = 0.7 | 0.02935 | 0.44219 | 0.58987 | 0.63601 | 0.59946 | 0.74424 | 0.77674 | 0.79026 | 0.76129 |

| w = 1.1 | 0.00654 | 0.35941 | 0.57088 | 0.55936 | 0.74264 | 0.68628 | 0.71899 | 0.60129 | 0.69970 | |

| w = 1.5 | 0.26829 | 0.44414 | 0.33662 | 0.42852 | 0.16347 | 0.36172 | 0.33072 | 0.37207 | 0.20066 | |

| 6DOF Articulate Robot Arm (big) | w = 0.7 | 0.12076 | 0.15641 | 0.56486 | 0.50314 | 0.52856 | 0.62945 | 0.71490 | 0.68191 | 0.68178 |

| w = 1.1 | 0.10744 | 0.38614 | 0.57372 | 0.67457 | 0.52483 | 0.65161 | 0.65997 | 0.67519 | 0.44003 | |

| w = 1.5 | 0.33744 | 0.43315 | 0.38945 | 0.25154 | 0.46242 | 0.39587 | 0.29945 | 0.22558 | 0 | |

| 17DOF Dual-Arm Robot Arm | w = 0.7 | 0.07612 | 0.26993 | 0.61418 | 0.68276 | 0.69043 | 0.71311 | 0.69829 | 0.66969 | 0.69280 |

| w = 1.1 | 0.54493 | 0.75326 | 0.79984 | 0.81848 | 0.32351 | 0.82719 | 0.41427 | 0.82017 | 0.74995 | |

| w = 1.5 | 0.62593 | 0.55313 | 0.18953 | 0.55625 | 0.41449 | 0.38161 | 0.51477 | 0.33042 | 0.28333 | |

| Robot Configuration | PSO Parameters @ c = 1.4 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| w = 0.6 | w = 0.9 | w = 1.2 | w = 1.5 | w = 1.8 | w = 2.1 | w = 2.4 | w = 2.7 | w = 3.0 | ||

| 3DOF Articulate Robot Arm | Average (Std) | 0.73328 (0.980) | 0.79994 (0.996) | 0.66662 (0.959) | 1.2666 (0.980) | 0.73328 (0.980) | 0.93327 (1.015) | 0.99994 (1.017) | 0.73819 (0.978) | 1.0239 (1.018) |

| Minimum | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 1.31 × 10−8 | 3.26 × 10−5 | 7.19 × 10−4 | |

| Iteration | 74.3 | 78.033 | 83.933 | 93.667 | 111.1 | 163.37 | 232.83 | 194.1 | 148.43 | |

| 4DOF SCARA Robot Arm | Average (Std) | 1.8667 (2.03) | 1.7333 (2.016) | 2.2667 (2.016) | 2.2667 (2.016) | 2 (2.034) | 1.7333 (2.016) | 2.1337 (2.03) | 2.0962 (2.004) | 3.1436 (2.001) |

| Minimum | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.75 × 10−10 | 1.55 × 10−6 | 1.79 × 10−3 | 1.40 × 10−2 | |

| Iteration | 79.5 | 83.367 | 91 | 105.17 | 130.5 | 206.57 | 308.47 | 187.27 | 157.93 | |

| 6DOF Stanford Robot Arm | Average (Std) | 2.5438 (1.583) | 1.2003 (0.786) | 0.52798 (0.625) | 0.097716 (0.141) | 0.35949 (0.813) | 0.32893 (0.483) | 0.77691 (0.806) | 1.7795 (1.523) | 2.3766 (1.732) |

| Minimum | 1.51 × 10−1 | 9.36 × 10−2 | 3.03 × 10−4 | 5.80 × 10−9 | 5.91 × 10−9 | 3.63 × 10−7 | 4.73 × 10−2 | 3.86 × 10−3 | 5.43 × 10−2 | |

| Iteration | 262.63 | 306.27 | 642.43 | 435.93 | 499.73 | 1470.9 | 1207.9 | 310.93 | 248.13 | |

| 6DOF Articulate Robot Arm (small) | Average (Std) | 4.6704 (1.794) | 2.1154 (1.661) | 0.82515 (0.557) | 0.22069 (0.412) | 0.4114 (1.166) | 0.51296 (0.829) | 1.2454 (1.115) | 4.4305 (2.404) | 4.6366 (1.966) |

| Minimum | 1.21 × 10−1 | 3.65 × 10−1 | 1.47 × 10−3 | 2.83 × 10−9 | 2.83 × 10−9 | 2.99 × 10−9 | 2.33 × 10−2 | 4.50 × 10−1 | 1.44 × 100 | |

| Iteration | 235.63 | 275.37 | 484.83 | 287.63 | 285.87 | 966.1 | 958.5 | 195.5 | 149.53 | |

| 6DOF Articulate Robot Arm (big) | Average (Std) | 4.1872 (1.933) | 3.1769 (1.566) | 1.2053 (0.941) | 0.33989 (0.610) | 0.44367 (0.68) | 0.68313 (1.127) | 4.4449 (2.091) | 4.6878 (2.046) | 5.856 (2.395) |

| Minimum | 1.64 × 10−1 | 2.00 × 10−1 | 2.27 × 10−2 | 5.53 × 10−9 | 5.53 × 10−9 | 8.06 × 10−8 | 2.35 × 10−1 | 1.87 × 100 | 1.89 × 100 | |

| Iteration | 215.27 | 302.93 | 744.57 | 518.87 | 555.8 | 1648.6 | 316.07 | 177.73 | 153.57 | |

| 17DOF Dual-Arm Robot Arm | Average (Std) | 3.498 (2.36) | 1.446 (1.482) | 0.57004 (1.077) | 0.32323 (1.048) | 0.1926 (0.663) | 0.31277 (0.748) | 1.253 (1.894) | 3.564 (2.658) | 3.7033 (2.702) |

| Minimum | 3.11 × 10−1 | 9.79 × 10−2 | 1.88 × 10−4 | 3.82 × 10−9 | 3.82 × 10−9 | 3.76 × 10−8 | 4.11 × 10−3 | 1.56 × 10−1 | 6.29 × 10−2 | |

| Iteration | 372.1 | 390.1 | 749.33 | 641.27 | 717.17 | 1487.3 | 840.23 | 222.47 | 167.8 | |

| Robot Configuration | PSO Parameters @ c = 2.0 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| w = 0.6 | w = 0.9 | w = 1.2 | w = 1.5 | w = 1.8 | w = 2.1 | w = 2.4 | w = 2.7 | w = 3.0 | ||

| 3DOF Articulate Robot Arm | Average (Std) | 1.2666 (0.980) | 1.0666 (1.015) | 0.79994 (0.996) | 1.1333 (1.008) | 1.2666 (0.980) | 1.1333 (1.008) | 1.0668 (1.015) | 0.87109 (1.009) | 1.2906 (0.996) |

| Minimum | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.14 × 10−9 | 4.64 × 10−6 | 3.20 × 10−4 | 2.23 × 10−4 | |

| Iteration | 72.2 | 77.133 | 83.2 | 94.767 | 116.83 | 188.97 | 234.67 | 177.8 | 160.8 | |

| 4DOF SCARA Robot Arm | Average (Std) | 2.5333 (1.960) | 1.6 (1.993) | 1.4667 (1.960) | 1.4667 (1.960) | 1.3333 (1.918) | 2.1333 (2.03) | 1.7349 (2.017) | 2.3599 (2.030) | 2.766 (2.038) |

| Minimum | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 1.09 × 10−9 | 3.84 × 10−7 | 3.16 × 10−3 | 2.99 × 10−2 | |

| Iteration | 76.533 | 82.733 | 91.7 | 105.2 | 135.63 | 241.73 | 241.67 | 168.1 | 172 | |

| 6DOF Stanford Robot Arm | Average (Std) | 1.3284 (1.109) | 0.81005 (0.726) | 0.21514 (0.525) | 0.14129 (0.178) | 0.18694 (0.239) | 0.35786 (0.465) | 1.0369 (0.939) | 3.3027 (8.697) | 2.3353 (1.637) |

| Minimum | 1.11 × 10−4 | 2.88 × 10−4 | 6.62 × 10−7 | 5.80 × 10−9 | 2.84 × 10−8 | 4.72 × 10−7 | 5.75 × 10−2 | 3.22 × 10−1 | 2.23 × 10−1 | |

| Iteration | 262.17 | 343.6 | 482.7 | 407.93 | 686.8 | 1528.3 | 922.13 | 433.7 | 230.27 | |

| 6DOF Articulate Robot Arm (small) | Average (Std) | 1.8589 (1.261) | 0.77962 (0.727) | 0.47691 (0.630) | 0.29102 (0.703) | 0.42741 (0.633) | 0.37187 (0.476) | 2.0606 (1.968) | 4.4253 (1.984) | 4.2691 (1.984) |

| Minimum | 3.62 × 10−1 | 4.90 × 10−2 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 4.88 × 10−9 | 3.23 × 10−2 | 2.99 × 10−1 | 6.28 × 10−1 | |

| Iteration | 274.63 | 288.7 | 248.77 | 224.4 | 302.47 | 1291.5 | 698.8 | 222.47 | 170.67 | |

| 6DOF Articulate Robot Arm (big) | Average (Std) | 2.791 (1.543) | 1.018 (0.532) | 0.41474 (0.622) | 0.34059 (0.61) | 0.36141 (0.621) | 1.1712 (1.458) | 3.9099 (2.242) | 4.9021 (2.015) | 5.8541 (2.339) |

| Minimum | 7.32 × 10−1 | 1.39 × 10−2 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 3.10 × 10−2 | 5.18 × 10−1 | 1.41 × 100 | 1.28 × 100 | |

| Iteration | 217.1 | 339.4 | 518.1 | 430.33 | 600.13 | 1428.2 | 293.03 | 185 | 157.67 | |

| 17DOF Dual-Arm Robot Arm | Average (Std) | 725.92 (3965.7) | 0.56706 (0.482) | 0.12174 (0.205) | 0.10393 (0.219) | 0.1511 (0.329) | 0.28911 (0.646) | 0.84244 (1.004) | 3.791 (2.441) | 3.6224 (2.501) |

| Minimum | 1.03 × 10−1 | 2.38 × 10−3 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | 2.09 × 10−4 | 7.55 × 10−3 | 5.07 × 10−1 | 9.86 × 10−2 | |

| Iteration | 343.93 | 426.93 | 486.23 | 500.5 | 787.8 | 1574.7 | 676.1 | 205.9 | 172.47 | |

| Robot Configuration | PSO Parameters @ c = 2.6 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| w = 0.6 | w = 0.9 | w = 1.2 | w = 1.5 | w = 1.8 | w = 2.1 | w = 2.4 | w = 2.7 | w = 3.0 | ||

| 3DOF Articulate Robot Arm | Average (Std) | 1.1333 (1.008) | 0.66662 (0.959) | 0.93327 (1.015) | 0.93327 (1.015) | 0.8666 (1.008) | 0.9333 (1.015) | 1.0005 (1.017) | 0.9414 (1.012) | 0.74984 (0.980) |

| Minimum | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.48 × 10−9 | 8.80 × 10−7 | 1.47 × 10−3 | 7.17 × 10−7 | |

| Iteration | 72.833 | 79.533 | 86.8 | 99.633 | 132.5 | 240.2 | 178.6 | 139.67 | 126.83 | |

| 4DOF SCARA Robot Arm | Average (Std) | 2.6667 (1.918) | 1.4667 (1.960) | 2.2667 (2.016) | 2.2667 (2.016) | 2.4 (1.993) | 1.8667 (2.03) | 1.8716 (2.03) | 2.3128 (2.103) | 2.5558 (1.99) |

| Minimum | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.75 × 10−10 | 9.97 × 10−10 | 4.60 × 10−6 | 1.37 × 10−4 | 9.94 × 10−3 | |

| Iteration | 77.867 | 84.367 | 93.467 | 110.87 | 149.87 | 276.57 | 225.33 | 153.43 | 158.63 | |

| 6DOF Stanford Robot Arm | Average (Std) | 0.4103 (0.361) | 0.1916 (0.253) | 0.1814 (0.25) | 0.1011 (0.164) | 0.3338 (0.887) | 0.5239 (0.755) | 1.2597 (0.836) | 2.2256 (2.137) | 2.3583 (1.831) |

| Minimum | 5.62 × 10−5 | 2.36 × 10−8 | 5.80 × 10−9 | 5.80 × 10−9 | 4.34 × 10−6 | 1.70 × 10−2 | 7.80 × 10−2 | 1.55 × 10−1 | 7.98 × 10−2 | |

| Iteration | 263.4 | 394.53 | 381.87 | 493.23 | 1202.9 | 1434.6 | 672.2 | 388.73 | 202.37 | |

| 6DOF Articulate Robot Arm (small) | Average (Std) | 0.5845 (0.664) | 0.39707 (0.609) | 0.39503 (1.16) | 0.23352 (0.413) | 0.56577 (0.935) | 0.66547 (0.888) | 2.8483 (2.109) | 4.8635 (2.095) | 4.2852 (2.107) |

| Minimum | 7.65 × 10−3 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 1.02 × 10−3 | 2.51 × 10−1 | 3.28 × 10−1 | 1.27 × 100 | |

| Iteration | 321.03 | 240.93 | 174.77 | 233.2 | 407.57 | 1274.5 | 379.97 | 186.7 | 162.97 | |

| 6DOF Articulate Robot Arm (big) | Average (Std) | 1.4178 (1.265) | 0.42641 (0.437) | 0.38365 (0.686) | 0.41372 (0.678) | 0.41043 (1.08) | 1.603 (1.249) | 4.4837 (2.419) | 5.165 (1.76) | 6.3959 (2.660) |

| Minimum | 2.18 × 10−2 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 5.55 × 10−9 | 3.18 × 10−1 | 4.05 × 10−1 | 1.42 × 100 | 1.22 × 100 | |

| Iteration | 233.9 | 473.1 | 344.93 | 443.6 | 1276.8 | 1122 | 225.47 | 181.97 | 139.43 | |

| 17DOF Dual-Arm Robot Arm | Average (Std) | 0.2944 (0.450) | 0.0372 (0.081) | 0.0088 (0.035) | 875.85 (4796.4) | 0.2173 (0.630) | 0.6797 (1.129) | 1449.2 (5508.9) | 3.3124 (2.753) | 3.3555 (2.487) |

| Minimum | 6.63 × 10−4 | 1.06 × 10−6 | 3.82 × 10−9 | 3.82 × 10−9 | 4.53 × 10−9 | 1.33 × 10−3 | 1.55 × 10−2 | 1.05 × 10−1 | 1.86 × 10−1 | |

| Iteration | 335.73 | 496.2 | 504.8 | 536.53 | 1252.9 | 1246.7 | 434.8 | 209.63 | 162.83 | |

| Robot Configuration | PSO Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| w = 0.6 | w = 0.9 | w = 1.2 | w = 1.5 | w = 1.8 | w = 2.1 | w = 2.4 | w = 2.7 | w = 3.0 | ||

| 3DOF Articulate Robot Arm | c = 1.4 | 0.5347464 | 0.513582 | 0.542799 | 0.4086851 | 0.4952326 | 0.3911338 | 0.3028495 | 0.3943838 | 0.138528 |

| c = 2.0 | 0.436254 | 0.461214 | 0.5109207 | 0.4312077 | 0.3887085 | 0.3308507 | 0.28977 | 0.1432765 | 0.158528 | |

| c = 2.6 | 0.4264314 | 0.53446 | 0.454324 | 0.4409674 | 0.4231626 | 0.2946653 | 0.3432588 | 0.1481972 | 0.461408 | |

| 4DOF SCARA Robot Arm | c = 1.4 | 0.5376697 | 0.546828 | 0.4982226 | 0.4867385 | 0.4851827 | 0.4469782 | 0.3308146 | 0.4031722 | 0.126061 |

| c = 2.0 | 0.4513523 | 0.525295 | 0.5320692 | 0.5181073 | 0.5039198 | 0.308167 | 0.3458049 | 0.3372666 | 0.072116 | |

| c = 2.6 | 0.4515854 | 0.553144 | 0.46332 | 0.4475889 | 0.4025616 | 0.3336784 | 0.3793495 | 0.3910511 | 0.130394 | |

| 6DOF Stanford Robot Arm | c = 1.4 | 0.226814 | 0.561708 | 0.7481638 | 0.8958934 | 0.7622983 | 0.6479014 | 0.5237504 | 0.5460761 | 0.384375 |

| c = 2.0 | 0.8245952 | 0.861384 | 0.889674 | 0.9174587 | 0.866636 | 0.7095383 | 0.6990268 | 0.1790552 | 0.565292 | |

| c = 2.6 | 0.8682516 | 0.881334 | 0.8852368 | 0.8841414 | 0.6511562 | 0.5787048 | 0.525432 | 0.1963255 | 0.371534 | |

| 6DOF Articulate Robot Arm (small) | c = 1.4 | 0.4815013 | 0.579652 | 0.77219 | 0.8708856 | 0.7827311 | 0.6363195 | 0.565344 | 0.3842927 | 0.258683 |

| c = 2.0 | 0.5388443 | 0.788992 | 0.8455001 | 0.8515363 | 0.8375048 | 0.6689601 | 0.4875258 | 0.3378529 | 0.225812 | |

| c = 2.6 | 0.8267822 | 0.860148 | 0.8079613 | 0.8933018 | 0.7801186 | 0.6103401 | 0.4797442 | 0.400593 | 0.248079 | |

| 6DOF Articulate Robot Arm (big) | c = 1.4 | 0.5651641 | 0.628611 | 0.7344366 | 0.8431123 | 0.8258427 | 0.6031733 | 0.5129578 | 0.3123379 | 0.226712 |

| c = 2.0 | 0.548103 | 0.837771 | 0.8250971 | 0.8449657 | 0.8131663 | 0.5386513 | 0.4502542 | 0.2929035 | 0.245574 | |

| c = 2.6 | 0.7761238 | 0.849648 | 0.8529644 | 0.8332735 | 0.6324973 | 0.5443506 | 0.4819496 | 0.3473131 | 0.257056 | |

| 17DOF Dual-Arm Robot Arm | c = 1.4 | 0.233272 | 0.621082 | 0.7357603 | 0.7733828 | 0.8050895 | 0.6597047 | 0.5956085 | 0.3511421 | 0.421283 |

| c = 2.0 | 0.394751 | 0.93082 | 0.9227511 | 0.9204908 | 0.8748558 | 0.7497568 | 0.8885874 | 0.7158518 | 0.922621 | |

| c = 2.6 | 0.9320448 | 0.900978 | 0.8992706 | 0.5241844 | 0.7499339 | 0.7492772 | 0.3923669 | 0.8158875 | 0.716818 | |

| Robot Configuration | PSO Algorithms | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PSO1 | PSO2 | PSO3 | PSO4 | PSO5 | PSO6 | PSO7 | PSO8 | PSO9 | PSO10 | PSO11 | PSO12 | PSO13 | ||

| 3DOF Articulate Robot Arm | Minimum | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 |

| Average | 1.0221 | 0.91104 | 0.9555 | 1.0666 | 1.0222 | 1.0444 | 1.0833 | 0.88883 | 0.89991 | 0.82216 | 1.0444 | 1.0888 | 0.84438 | |

| Std | 1.0087 | 0.99104 | 1.0079 | 1.0132 | 1.0102 | 1.0017 | 1.104 | 1.001 | 1.0012 | 0.99385 | 1.0125 | 0.99689 | 0.99459 | |

| Iteration | 342.95 | 337.83 | 314.22 | 329.42 | 222.5 | 222.63 | 427.43 | 330.79 | 323.28 | 305.74 | 320.52 | 300.66 | 312.12 | |

| 4DOF SCARA Robot Arm | Minimum | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 |

| Average | 1.8222 | 1.5555 | 2.1333 | 1.8222 | 2 | 1.9111 | 1.9556 | 2.1333 | 1.9111 | 1.7778 | 1.4667 | 1.5556 | 1.7333 | |

| Std | 2.0066 | 1.9757 | 2.0175 | 2.019 | 1.9975 | 2.0129 | 2.0053 | 2.0205 | 2.0312 | 2.0206 | 1.9605 | 1.9822 | 2.0068 | |

| Iteration | 383.48 | 377.17 | 343.6 | 363.21 | 226.72 | 227.24 | 526.11 | 371.67 | 357.73 | 337.02 | 352.49 | 326.02 | 346.79 | |

| 6DOF Stanford Robot Arm | Minimum | 5.80 × 10−9 | 5.80 × 10−9 | 5.80 × 10−9 | 5.80 × 10−9 | 0.00503 | 5.80 × 10−9 | 5.80 × 10−9 | 5.80 × 10−9 | 5.80 × 10−9 | 5.80 × 10−9 | 5.80 × 10−9 | 6.85 × 10−5 | 5.80 × 10−9 |

| Average | 0.73517 | 0.56363 | 1.4628 | 1.0201 | 1.4391 | 0.80209 | 0.57368 | 0.66049 | 0.7891 | 0.89401 | 0.48719 | 1.3465 | 0.36397 | |

| Std | 1.501 | 1.4168 | 2.2052 | 1.7473 | 3.1713 | 1.228 | 1.3985 | 2.881 | 3.3545 | 1.7495 | 1.2585 | 2.2116 | 0.87091 | |

| Iteration | 1296.4 | 1336.9 | 992.82 | 1216.1 | 612.91 | 746.29 | 1593.2 | 1355.6 | 1247.6 | 999.88 | 1187.5 | 1201.9 | 960.5 | |

| 6DOF Articulate Robot Arm | Minimum | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 0.05314 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 |

| Average | 0.40148 | 0.46231 | 0.40928 | 0.41159 | 1.1148 | 0.84461 | 0.32191 | 0.41798 | 0.37357 | 0.34845 | 0.50466 | 0.34546 | 0.47359 | |

| Std | 0.54642 | 0.7966 | 0.66896 | 0.53455 | 0.85375 | 1.0268 | 0.55764 | 0.57991 | 0.77192 | 0.55917 | 0.97798 | 0.72753 | 0.65956 | |

| Iteration | 730.8 | 683.83 | 530.39 | 643.9 | 541.98 | 590.92 | 1030.6 | 710.09 | 689.53 | 534.81 | 618.8 | 510.45 | 547.89 | |

| 6DOF Articulate Robot Arm | Minimum | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 0.07665 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 | 5.53 × 10−9 |

| Average | 0.57103 | 0.58342 | 0.4679 | 0.63143 | 1.5126 | 1.2445 | 0.59572 | 0.46228 | 0.52115 | 0.52637 | 0.47206 | 0.8547 | 0.47416 | |

| Std | 0.77659 | 0.92347 | 0.64328 | 1.0937 | 1.1692 | 0.9791 | 0.72651 | 0.79572 | 0.9415 | 0.8635 | 0.87465 | 1.3579 | 0.7217 | |

| Iteration | 1160.2 | 1083.9 | 938.25 | 966.36 | 604.29 | 548.72 | 1508.2 | 1175.9 | 1092.1 | 975.23 | 987.9 | 980.3 | 853.53 | |

| 17DOF Dual-Arm Robot Arm | Minimum | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | 0.00432 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 | 3.82 × 10−9 |

| Average | 0.32223 | 241.76 | 0.4961 | 0.36216 | 0.54445 | 1016 | 0.33813 | 0.238 | 0.24413 | 0.75383 | 0.36512 | 0.67878 | 0.27086 | |

| Std | 0.73876 | 1322.3 | 1.1388 | 0.88827 | 0.62487 | 3807.8 | 0.8389 | 0.48422 | 0.65331 | 1.4823 | 1.0622 | 1.5277 | 0.66004 | |

| Iteration | 1156.6 | 1101.9 | 909.2 | 1021.2 | 721.7 | 947.77 | 1526.4 | 1162.5 | 1118.4 | 1038 | 1020.4 | 1042.9 | 926.02 | |

| Rank PSO Algorithms | 3DOF Articulate Robot | 4DOF SCARA Robot | 6DOF Stanford Robot | 6DOF Articulate Robot | 6DOF Articulate Robot | 17DOF Dual-Arm Robot | Sum of Ranks |

|---|---|---|---|---|---|---|---|

| PSO13 | 4 | 7 | 1 | 4 | 1 | 1 | 18 |

| PSO10 | 3 | 6 | 4 | 2 | 4 | 9 | 28 |

| PSO11 | 10 | 4 | 3 | 7 | 3 | 2 | 29 |

| PSO9 | 5 | 9 | 8 | 6 | 6 | 3 | 37 |

| PSO6 | 2 | 1 | 2 | 12 | 10 | 12 | 39 |

| PSO3 | 7 | 11 | 11 | 3 | 2 | 7 | 41 |

| PSO12 | 9 | 3 | 12 | 1 | 11 | 6 | 42 |

| PSO4 | 12 | 8 | 10 | 5 | 5 | 4 | 44 |

| PSO2 | 8 | 5 | 5 | 10 | 8 | 11 | 47 |

| PSO8 | 6 | 12 | 7 | 8 | 7 | 8 | 48 |

| PSO1 | 11 | 10 | 6 | 9 | 9 | 5 | 50 |

| PSO5 | 1 | 2 | 13 | 13 | 13 | 13 | 55 |

| PSO7 | 13 | 13 | 9 | 11 | 12 | 10 | 68 |

| Robot Configuration | PSO Algorithms | ||||||

|---|---|---|---|---|---|---|---|

| MuPSO | PSO | Mu-MLDIW | MLDIW | Mu-NLDIW | NLDIW | ||

| 3 DOF Articulate Robot Arm | Min | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 | 6.10 × 10−9 |

| Average | 6.78 × 10−9 | 6.10 × 10−9 | 6.93 × 10−9 | 6.10 × 10−9 | 6.23 × 10−9 | 6.10 × 10−9 | |

| std | 1.21 × 10−9 | 7.90 × 10−21 | 1.37 × 10−9 | 7.48 × 10−21 | 3.15 × 10−10 | 6.45 × 10−21 | |

| Iteratn | 354.83 | 169.03 | 271.93 | 122.8 | 333.83 | 160.07 | |

| 4 DOF SCARA Robot Arm | Min | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 | 9.73 × 10−10 |

| Average | 1.78 × 10−9 | 9.73 × 10−10 | 1.48 × 10−9 | 9.73 × 10−10 | 1.07 × 10−9 | 9.73 × 10−10 | |

| std | 2.07 × 10−9 | 2.90 × 10−21 | 1.55 × 10−9 | 1.57 × 10−21 | 2.94 × 10−10 | 2.19 × 10−21 | |

| Iteratn | 375.1 | 144.2 | 375.9 | 193.13 | 344.27 | 108.67 | |

| 6 DOF Stanford Robot Arm | Min | 5.80 × 10−9 | 0.002297 | 5.80 × 10−9 | 0.042038 | 5.80 × 10−9 | 0.22311 |

| Average | 0.18333 | 3.6594 | 2.74 × 10−5 | 36.556 | 3.6698 | 2.8953 | |

| std | 1.0042 | 2.4823 | 0.00015 | 191.83 | 2.6327 | 5.7772 | |

| Iteratn | 1893.9 | 3000 | 1615.7 | 3000 | 2577.1 | 3000 | |

| 6 DOF Articulate Robot Arm (small) | Min | 2.83 × 10−9 | 2.83 × 10−9 | 2.83 × 10−9 | 0.3014 | 2.83 × 10−9 | 0.78448 |

| Average | 2.84 × 10−9 | 22.959 | 2.83 × 10−9 | 3.1822 | 2.83 × 10−9 | 2.9146 | |

| std | 2.13 × 10−11 | 119.19 | 1.36 × 10−12 | 2.6104 | 2.76 × 10−13 | 1.9617 | |

| Iteratn | 641.47 | 2907.5 | 613.8 | 3000 | 540.97 | 3000 | |

| 6 DOF Articulate Robot Arm (big) | Min | 5.53 × 10−9 | 0.002899 | 5.53 × 10−9 | 0.9546 | 5.53 × 10−9 | 0.66512 |

| Average | 5.53 × 10−9 | 1.021 | 5.61 × 10−9 | 621.59 | 0.44417 | 5538.1 | |

| std | 4.36 × 10−12 | 0.93764 | 4.43 × 10−10 | 2520.5 | 1.4376 | 29995 | |

| Iteratn | 1136.6 | 3000 | 1020.1 | 3000 | 1574.9 | 3000 | |

| 17 DOF Dual-Arm Robot | Min | 3.82 × 10−9 | 0.006624 | 3.82 × 10−9 | 0.10807 | 3.82 × 10−9 | 0.00634 |

| Average | 0.000172 | 0.50215 | 0.18333 | 1212.1 | 0.5695 | Inf | |

| std | 0.000942 | 1.1307 | 1.0042 | 5014.6 | 1.6748 | NaN | |

| Iteratn | 1222.8 | 3000 | 1315 | 3000 | 1621.9 | 3000 | |

| Robot Configurations | Identified Joint Parameters | ||||||

|---|---|---|---|---|---|---|---|

| Joint 1 | Joint 2 | Joint 3 | Joint 4 | Joint 5 | Joint 6 | ||

| Ideal Parameters | 80°/(200 mm) | 20° | −60°/(60 mm) | 270° | 50° | 10° | |

| 3DOF Articulate | MuPSO (PSO) | 80° (80) | 20° (20°) | −60° (−60°) | NA | NA | NA |

| 4DOF SCARA | MuPSO (PSO) | 200 mm (200 mm) | −17.124° (−57.156°) | −34.876° (17.146°) | −30° (−66.000°) | NA | NA |

| 6DOF Stanford | MuPSO (PSO) | 73.633° (52.043°) | 3.260° (−0.661°) | 60.396 mm (34.905 mm) | −72.909° (−43.846°) | 56.575° (40.649°) | −8.424° (−19.521°) |

| 6DOF Articulate (small) | MuPSO (PSO) | 80.000° (80.903°) | 20.000° (18.656°) | −60.001° (−57.726°) | −89.998° (−54.286°) | 50.001° (27.956°) | 9.9983° (−16.874°) |

| 6DOF Articulate (big) | MuPSO (PSO) | 80.000° (77.829°) | 20.002° (17.475°) | −60.004° (−56.446°) | −89.997° (−46.180°) | 50.001° (20.163°) | 9.9959° (−15.677°) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Umar, A.; Shi, Z.; Khlil, A.; Farouk, Z.I.B. Developing a New Robust Swarm-Based Algorithm for Robot Analysis. Mathematics 2020, 8, 158. https://doi.org/10.3390/math8020158

Umar A, Shi Z, Khlil A, Farouk ZIB. Developing a New Robust Swarm-Based Algorithm for Robot Analysis. Mathematics. 2020; 8(2):158. https://doi.org/10.3390/math8020158

Chicago/Turabian StyleUmar, Abubakar, Zhanqun Shi, Alhadi Khlil, and Zulfiqar I. B. Farouk. 2020. "Developing a New Robust Swarm-Based Algorithm for Robot Analysis" Mathematics 8, no. 2: 158. https://doi.org/10.3390/math8020158

APA StyleUmar, A., Shi, Z., Khlil, A., & Farouk, Z. I. B. (2020). Developing a New Robust Swarm-Based Algorithm for Robot Analysis. Mathematics, 8(2), 158. https://doi.org/10.3390/math8020158