Mixed-Integer Linear Programming Models for the Vehicle Routing Problem with Release Times and Reloading at Mobile Satellites

Abstract

1. Introduction

- We propose a new variant of the Vehicle Routing Problem, the Vehicle Routing Problem with Release Times and Reloading at Mobile Satellites (VRP-RT-RMS), which jointly integrates late product availability and en-route reloading operations.

- The models explicitly incorporate synchronization between the reloading vehicle and the delivery vehicles at customer nodes that act as mobile satellites.

- A realistic instance generation procedure is designed based on real-world last-mile delivery data from Santiago, Chile, preserving spatial and demand distributions.

- Comprehensive computational experiments are conducted to evaluate the models’ performance, and solution quality, showing that MILP-2 achieves higher efficiency and smaller optimality gaps.

- The results show operational benefits over the classical VRP, including reduced total distance, fleet utilization, and idle time, highlighting the practical value of integrating in-route reloading.

2. Literature Review

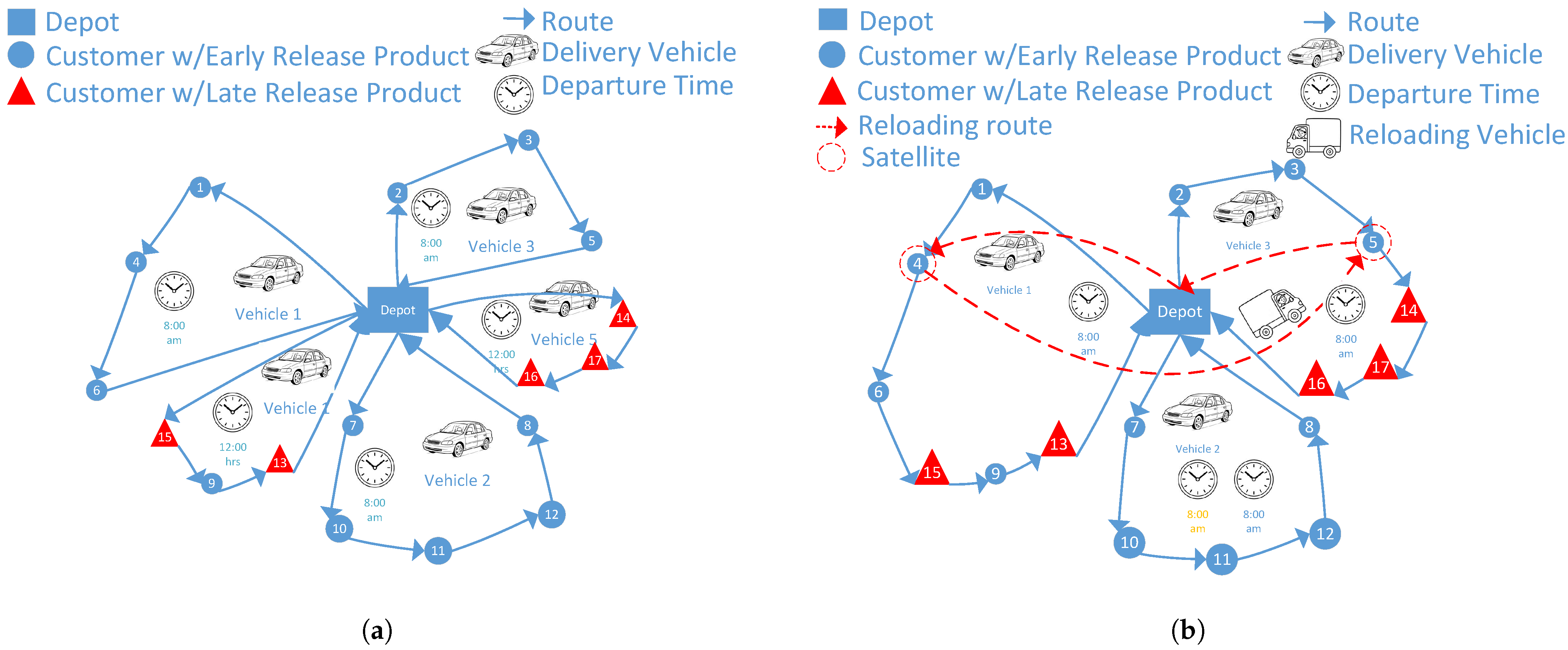

3. Description of the Problem

- : customers requesting early-release products , available at the depot from the start of the planning horizon .

- : customers requesting late-release products , available only after the release time .

- All demands for products and are satisfied;

- Vehicle capacities are respected;

- Each customer is visited exactly once by a single delivery vehicle;

- Mobile satellites are selected among ER/LR customers at feasible nodes occurring after , enabling reloading before or at the first type-2 delivery; multiple reloads per route are permitted;

- Synchronization at reloading points is guaranteed;

- The total distance traveled by all vehicles (delivery and reloading) is minimized.

4. Proposed Mathematical Models

- All vehicles start and end their routes at the central depot.

- The delivery vehicle fleet has a limited capacity , while the reloading vehicle has a sufficiently large capacity to satisfy the total demand for type-2 products.

- Products are classified into two non-interchangeable types: early-release (type-1) and late-release (type-2).

- Travel times, service times, and reloading times are deterministic and known.

- Mobile satellite points coincide with customer locations and operate as temporary cross-docking points without storage capacity.

- Synchronization between the reloading vehicle and the delivery vehicle at a mobile satellite is assumed to be perfect; both must coincide spatially and temporally for the reloading operation to occur.

- Each customer is served exactly once by a single delivery vehicle.

- The reloading vehicle does not deliver directly to customers.

- The release time is the same for all type-2 products.

- All routes must be completed within a maximum time horizon .

- Sets

- : Set of nodes of all customers, including both early-release and late-release customers. Includes the depot (0).

- : Set of customers requesting only early-release products.

- : Set of customers requesting only early-release products, including the depot.

- : Set of customers requesting late-release products.

- : Set containing all customers.

- : Set of the total delivery vehicles available.

- : Set including early-release products (type-1) and late-release products (type-2).

- Parameters

- : Number of customers with early product release time (u).

- : Number of customers with late product release time (u).

- : Number of delivery vehicles (u).

- : Distance between nodes and (m).

- : Travel time from to (min).

- : Demand of node for product (u).

- : Reloading vehicle capacity (u).

- : Delivery vehicle capacity (u).

- : Maximum route duration time (min).

- : Service time (min).

- : Reloading time (min).

- : Late product release time (min).

4.1. Mathematical Model of Three Index

- Decision Variables

- : freight transported of product by delivery vehicle before visiting node (u).

- : time of arrival of the reloading vehicle at node (min).

- : time of arrival of the delivery vehicle at node (min).

- : departure time of vehicle from the depot (min)

- Objective Function

- Subject to

- Flow of Reloading reloading vehicle

- Flow of Delivery Vehicles

- Reloading NodesConstraint (9) ensures that if node j is designated as a reloading satellite for some delivery vehicle k, then the reloading vehicle must travel to node j from some preceding node i.Constraint (10) ensures that if node j is selected as a reloading satellite, then it must be visited by a delivery vehicle.

- ReloadingConstraint (13) ensures that, before visiting any node i, the sum of the freight carried by delivery vehicle k across both product types never exceeds the maximum delivery vehicle capacity .Constraint (14) ensures load conservation for product type-2 while accounting for both deliveries and possible en-route reloads. When and , vehicle k travels from node i to node j, so the load before visiting j () must be less than or equal to the load before visiting i () minus the demand served at i (). However, if node i operates as a satellite , the term allows the load to increase up to the reloading vehicle’s capacity, representing a reloading operation. Thus, the constraint distinguishes three situations: normal unloading , reloading at a satellite , and inactive arcs , ensuring a consistent and physically feasible load flow throughout the route.Constraint (15) establishes the analogous conservation rule for product type-1 (early release), where no reloading is permitted along the route. Thus, if an arc is used, the load before visiting j must not exceed the load before visiting i minus the demand at i. The parameter , similarly to in Constraint (14), acts as a constant, ensuring that the constraint is relaxed whenever the arc is not part of the route ().

- Reloading Vehicle Time Constraints

- Delivery Vehicle Time ConstraintsConstraints (16)–(18) control the routing time of the reloading vehicle, ensuring that the maximum route duration is not exceeded and that the temporal sequence of visits between nodes, including reloading times, is preserved. Similarly, constraints (19)–(21) regulate the accumulated time of the delivery vehicles, also accounting for customer service times.

- Synchronization

- Release TimeConstraint (24) ensures that the reloading vehicle does not reach a customer before the product release time plus the travel time from the depot to the first customer. Specifically, if j is the first customer (i.e., , the constraint enforces ; otherwise, it reduces to ), thus preventing any visit prior to the release.Constraints (25) and (26) form a pair of dichotomous constraints that regulate the departure time of delivery vehicle k with respect to the product release time . Only one of them is active depending on the value of the binary variable . When , Constraint (25) becomes active, resulting in ; this indicates that the delivery vehicle departs at or after the release time, corresponding to a late-departure scenario. Conversely, when , Constraint (26) is activated, yielding ; in this case, the delivery vehicle departs before the release time, representing an early-departure scenario. The parameter prevents numerical ambiguities between the two cases, while T acts as a constant that deactivates the constraint not applicable for the given value of .Constraints (27) and (28) link the departure time of vehicle k from the depot with its arrival time at customer j. Specifically, Constraint (27) provides a lower bound and Constraint (28) provides an upper bound for . When customer j is the first node visited by delivery vehicle k (), both constraints become active, enforcing . Otherwise (), both constraints are relaxed through the constant with T.Constraint (29) links the load of late-release products with the departure time of delivery vehicle k, ensuring that the delivery vehicle can only transport these products if it departs at or after the release time. Specifically, when , meaning that customer j is the first node visited by delivery vehicle k, the constraint enforces that the delivery vehicle can carry type-2 products only if ; otherwise (), it must depart without any type-2 load (). Conversely, when , the delivery vehicle does not depart directly from the depot toward j, and the constraint becomes non-binding through the term , allowing the load to be positive if the products were received via an en-route reload rather than loaded at the depot.

- Domain of variablesFinally, constraints (30) define the nature of the decision variables.

4.2. Mathematical Model of Two Index

- Decision Variables

- : freight transported of product before visiting node (u).

- : time of arrival of the reloading vehicle at node i (min).

- : time of arrival of the delivery vehicle at node i (min).

- Objective Function

- Subject to

- Flow of Reloading TruckConstraint (32) ensures that the reloading vehicle can depart from each node i at most once. This means that only one outgoing arc from each node can be active in the route, preventing multiple departures from the same location.Constraint (33) enforces flow conservation for the reloading vehicle at every node l. It requires that the number of arcs entering a node equals the number of arcs leaving it, so that the vehicle cannot appear or disappear at any node, preserving route continuity.Constraint (34) limits the reloading vehicle to depart from the depot at most once, thereby allowing the existence of only a single reloading route starting from the depot.

- Flow of Delivery VehiclesConstraint (35) ensures that each customer i is visited exactly once by one delivery vehicle. It enforces that only one outgoing arc from each customer node is active in the delivery network, thus guaranteeing a single service per customer.Constraint (36) limits the number of delivery vehicles that can depart from the depot. It ensures that no more than vehicles initiate routes from the depot, thereby preventing the use of additional vehicles beyond the available fleet.Constraint (37) guarantees that each customer j receives exactly one arrival from a delivery vehicle. This avoids multiple visits to the same customer and ensures that every customer is assigned to only one route.Constraint (38) enforces flow conservation for each delivery vehicle at every node l. It requires that, if a vehicle arrives at a node, it must also depart from it, thereby maintaining route continuity and preventing disconnected paths.

- Reloading NodesConstraint (39) ensures that if the reloading truck visits a node j, that node can be considered as a potential reloading satellite. In other words, for a node j to act as a satellite, the reloading truck must visit it at least once. If the truck does not travel through that node, it cannot be activated as a reloading point.Constraint (40) guarantees that if a node j is designated as a reloading satellite, then it must be visited by at least one delivery vehicle. This ensures consistency between the selection of satellites and the delivery routes, so that a node cannot be declared as a satellite unless it is also visited by a delivery vehicle.Constraint (41) states that a node j becomes a satellite () if and only if both vehicle types (the reloading truck and at least one delivery vehicle) coincide at that node. This synchronization prevents the model from activating a satellite without the simultaneous presence of both.

- ReloadingConstraint (42), states that the sum of the quantities of both product types (early- and late-release) loaded before visiting any node i cannot exceed the vehicle capacity .Constraint (43) models load conservation for type-2 (late-release) products and allows the possibility of in-route reloading. If a vehicle travels from node i to node j (), the load before visiting node j must be less than or equal to the load before visiting node i minus the demand served at i. However, if node i operates as a reloading satellite (), the vehicle can increase its load up to the reloading truck capacity , representing an en-route reloading operation. The term differentiates between normal travel, reloading events, and inactive arcs.Constraint (44) represents load conservation for type-1 (early-release) products, which cannot be reloaded during the route. If a vehicle moves from node i to node j (), the load before visiting node j must be less than or equal to the load before visiting node i minus the demand delivered at i. The term acts as a Big-M parameter that relaxes the constraint when the arc is not part of the active route.

- Truck Time ConstraintsConstraint (45) limits the arrival time of the reloading truck at any node so that it does not exceed the maximum allowed route duration T.Constraint (46) enforces the temporal sequence between two consecutive nodes i and j on the reloading truck’s route. If the truck travels from node i to node j (), the arrival time at node j must be at least the arrival time at node i plus the travel time and the reloading time . The Big-M term deactivates the constraint when the arc is not part of the truck’s route.Constraint (47) defines the temporal condition for the truck’s first leg departing from the depot. If the reloading truck travels directly from the depot (node 0) to node j (), its arrival time at node j must be at least equal to the travel time from the depot to that node. Otherwise, the Big-M term relaxes the constraint when the corresponding arc is inactive.

- Delivery Vehicle Time ConstraintsConstraint (48) limits the arrival time of each delivery vehicle at any node so that it does not exceed the maximum route duration T. This ensures that all delivery routes are completed within the planning time horizon defined for the operation.Constraint (49) enforces the temporal sequence between two consecutive nodes i and j visited by a delivery vehicle. If the vehicle travels from node i to node j (), the arrival time at node j must be at least equal to the arrival time at node i plus the travel time and the service time at node i. The Big-M term relaxes the constraint when the arc is not part of the vehicle’s active route.Constraint (50) defines the temporal condition for the first leg of each delivery route departing from the depot. If the delivery vehicle travels directly from the depot (node 0) to node j (), the arrival time at node j must be at least equal to the travel time from the depot to that node. Otherwise, the Big-M term deactivates the constraint when the corresponding arc is not used in the route.

- SynchronizationConstraint (51) ensures temporal synchronization between the reloading truck and the delivery vehicles at nodes functioning as reloading satellites. If a node i is designated as a satellite (), the reloading truck must arrive at that node before or at the same time as the delivery vehicle, so that the reloading operation can take place. The Big-M term relaxes the constraint when the node is not a satellite.Constraint (52) complements the previous one by ensuring that the arrival time of the delivery vehicle at the satellite node is not significantly earlier than that of the reloading truck. Thus, both vehicles must coincide temporally at the node to allow the load transfer to occur. The Big-M term again relaxes the constraint when the node is not a satellite.

- Release TimeConstraint (53) ensures that the reloading truck cannot reach any customer j before the release time of type-2 products. If the truck travels directly from the depot to j (), it must arrive no earlier than the release time plus the travel time (); otherwise (), it simply cannot arrive before . This guarantees that late-release products are never available to the delivery fleet before their official release.Constraint (54) relates the amount of type-2 load carried by the delivery vehicle with the departure condition from the depot. If customer j is the first node visited (, which implies ), the vehicle can only carry type-2 products if it departs late (); otherwise (), it must leave the depot without any type-2 load (). Moreover, if a reload occurs at this first node, the vehicle must also have departed late, since a reload at the initial customer is only possible once type-2 products become available (i.e., after the release time ). Therefore, the case of an early departure with type-2 load due to reloading cannot occur. Conversely, if j is not the first node on the route (), the constraint becomes non-binding due to the Big-M term , allowing a positive load that may have been acquired through an en-route reload at a satellite node. Thus, this constraint distinguishes whether type-2 products are loaded directly at the depot or obtained through a mobile reloading operation along the route.Constraint (55) defines the binary relationship between early and late departures. When customer j is the first node visited (), the vehicle can depart either early () or late (), but not both simultaneously. If , neither variable is active, since j is not reached directly from the depot. This constraint enforces the mutually exclusive activation of early and late departure variables.Constraints (56) and (57) link the arrival time at the first visited node with the product release time. When the departure is late (), both constraints are simultaneously active: (56) provides a lower bound ensuring arrival after the release time, while (57) provides an upper bound consistent with feasible travel time. When , both constraints are relaxed through the Big-M constant T, having no effect. These two constraints act simultaneously—not as dichotomous conditions—to ensure temporal consistency between the vehicle’s departure time, travel time, and the release time of type-2 products.

- Domain of variablesIn summary, constraints (53)–(57) jointly regulate the timing of vehicle departures from the depot, the conditions under which late-release products can be carried, and the alignment between arrival times and product availability, ensuring logical and feasible synchronization among release times, reloading, and routing operations. Finally, constraints (58) define the domains of the decision variables, specifying the binary nature of routing and departure indicators and the non-negativity of load and time-related variables.

5. Results

5.1. Instances Generation

- Data extraction and cleaning: the initial dataset was obtained from the company’s historical records. Atypical periods such as Cyberday, Black Friday, Christmas, Mother’s Day, and other holidays were excluded in order to capture the regular operational pattern.

- Geographic and demand analysis: Customer locations were grouped by municipality, obtaining for each customer the historical ordering frequency and quantities by product type (early-release and late-release), as well as the historical percentage frequency by municipality. This resulted in an empirical distribution derived from real data. Addresses located outside the defined urban coverage area were removed.

- For each customer, a municipality was selected according to the empirical distribution function obtained in the previous step. To achieve this, a random value was drawn from a continuous uniform distribution in , which located the customer within a municipality based on the historical behavior observed in the real data. A fixed random seed was used to ensure reproducibility of the instances

- Demand assignment: Using a fixed random seed, each customer was assigned independent integer demands, sampled from an empirical distribution obtained from real data, between 1 and 6 units for both product types. Early-release (type-1) and late-release (type-2) products were treated separately and considered non-substitutable.

- Distance matrix construction: distances were computed from UTM coordinates obtained from latitude and longitude.

- The central depot was defined as the origin.

- From a file containing municipality, address, latitude, and longitude, the and coordinates of each customer were calculated.

- The Manhattan distance between any two points was computed as shown in Equation (59):

- The complete distance matrix was generated for all pairs of nodes, including the depot.

- Travel time matrix construction: based on the distance matrix (expressed in meters), travel times were computed assuming an average vehicle speed of 31.6 km/h (526.67 m per minute), derived from the company’s operational data, as shown in Equation (60).

- Output parameters and storage: the generated data were stored in files including:

- Number Early-release customers (),

- Number Late-release customers (),

- Assigned demand for each customer and product type,

- Reloading vehicle capacity (), calculated as the total demand for type-2 products,

- Delivery vehicle capacity (), set as the maximum demand among all customers plus one, to prevent infeasibility,

- Number of available delivery vehicles (), computed as is shown in Equation (61).

- Service time per customer (),

- Reloading time (),

- Maximum route duration (T),

- Release time (),

- Average travel speed (),

- Number of available reloading vehicles (),

- UTM coordinates of depot and customers,

- Manhattan distance matrix (),

- Travel time matrix (t).

5.2. Analysis of Computational Results

- Relative Gap.For , MILP-3 reaches optimality in all instances; in contrast, for it returns only feasible solutions, with gaps between 11.35% and 35.13%. For it likewise yields only feasible solutions, with an average gap of 42.54%; the same holds for , with an average gap of 56.20%, and it fails to find a feasible solution for 25_6.For MILP-2, at it matches MILP-3 (optimal in all instances), but it outperforms it as N increases: at it attains optimality in instances and, for those that hit the time limit 15_2 and 15_3, it returns feasible solutions with gaps of and . For it is optimal in instances and reports an average gap of ; at it yields only feasible solutions with an average gap of .

- Computational Time (CPU (s)).For , MILP-3 records an average time of and a maximum of (in 10_7). For , it reaches the time limit in all instances, as it does for and . It is also shown that in 25_6 MILP-3 does not report a feasible solution.For MILP-2 , the average solution time is , with a maximum of in 10_7. At , the solution time averages and it reaches the limit only in 15_2 and 15_3. For , MILP-2 reaches optimal status in 2 out of 10 instances 20_0 and 20_2, whereas for , as with MILP-3, it reaches the time limit. Overall, the results show that MILP-2 shows greater efficiency.

- Efficiency .For , MILP-3 records an average of and a maximum of (in 10_3). For , the average is and the maximum (in 15_6). For larger instances, such as , the average reaches with a maximum of (in 20_2), and for the average is with a maximum of (in 25_8). Note that in 25_6 no feasible solution is reported, and it is not included in the average.Now, for MILP-2, at the average is with a maximum of (in 10_1). At , the average is and the maximum (in 15_2). For , the average is with a maximum of (in 20_4). For , the average is with a maximum of (in 25_8). Overall, the results indicate that the average value of MILP-2 is lower than that of MILP-3 by factors of approximately 1.85, 5.92, 4.56, and 2.98 for instance sizes , 15, 20, and 25, respectively, which demonstrates the superior computational efficiency of MILP-2.

5.3. Fleet Usage and Reloading Analysis

- Available Fleet (K) vs. Used Fleet .MILP-3 shows a used fleet between 3 and 4, with an average of 1–2 idle vehicles and a maximum of 4 (10_3) for , where the status is optimal in all 10 instances (see Table 6). For (Table 7), where feasible solutions are obtained in all ten instances, the used fleet lies between and 6, with between 1 and 5 idle delivery vehicles (maximum in 15_4). As shown in Table 8, for , feasible solutions indicate between 4 and 8, with up to 7 idle vehicles, as in 20_5. For (As shown in Table 9), feasible solutions indicate that in instances (no feasible solution in 25_6), the model uses between and 9 delivery vehicles, with between 2 and 5 idle vehicles (maximum idle capacity in 25_7).For MILP-2, in the instances, availability K ranges from 3 to 8, the used fleet is between 3 and 4, with a maximum of 4 idle vehicles in 10_3. All delivery vehicles are used in instances (10_0, 10_5, 10_6, 10_9). For , K ranges from 6 to 8, from 3 to 6, and idle vehicles range from a minimum of 1 to a maximum of 5 (maximum in 15_4) (see Table 6 and Table 7).

- Reload Satellites (w) vs. Route Reloading (r).For the use of reload satellites (w) and route reloading (r), in MILP-3 satellites are used in instances for . 10_3 stands out with and only , hence , implying that at least one route was reloaded more than once. For the same instance in MILP-2, , which also indicates that at least one route is reloaded more than once. Note that MILP-2 reaches the same solutions as MILP-3 except for the aforementioned instance and for 10_7, where MILP-3 has whereas MILP-2 has (Table 6).For MILP-3 with , the average w lies between 3 and 4, while per instance between and 4 routes are reloaded. 15_1 and 15_2 stand out (each with and ) as well as 15_9 (, ). In these cases , indicating multiple reloads on at least one route. For MILP-2, w ranges from 2 to 6, while r ranges from 1 to 5. There is in instances (15_0, 15_1, 15_2, 15_4, 15_6, 15_7, 15_9) and in (15_3, 15_5, 15_8). The maximum difference is in 15_1 and 15_2 (Table 7).For , in MILP-3 the average w lies between 3 and 4; 20_5 stands out with over routes (), implying multiple reloads on at least one route. For MILP-2, w ranges from 3 to 6 and r from 1 to 5. We have in cases (20_0, 20_1, 20_2, 20_3, 20_4, 20_5, 20_7, 20_8) and in (20_6, 20_9). The maximum difference is in 20_5 (Table 8).With , in MILP-3 25_4, 25_5, and 25_9 stand out, where more satellites than routes are used (), hence , indicating that at least one route is reloaded more than once. In contrast, for MILP-2, w ranges from 3 to 7 with r between 3 and 6; there is in instances (25_2, 25_3, 25_4, 25_7, 25_8, 25_9) and in (25_0, 25_1, 25_5, 25_6), with a maximum difference of in 25_7 (Table 9).As shown in Table 10 and Table 11, both models exhibit exponential growth in computation time as the number of nodes increases, which is consistent with the NP-hard nature of the vehicle routing problem. Nevertheless, the MILP-2 formulation demonstrates better scalability than MILP-3. This can be observed in the data from the tables, where the number of variables and constraints in MILP-2 depends only on the number of nodes and remains constant for a given instance size, whereas in MILP-3 these values increase with the number of vehicles. The inclusion of the vehicle index k in MILP-3 results in a larger model, negatively impacting its computational performance. Consequently, MILP-2 can handle larger fleets without increasing computation time, thus achieving greater efficiency and scalability.

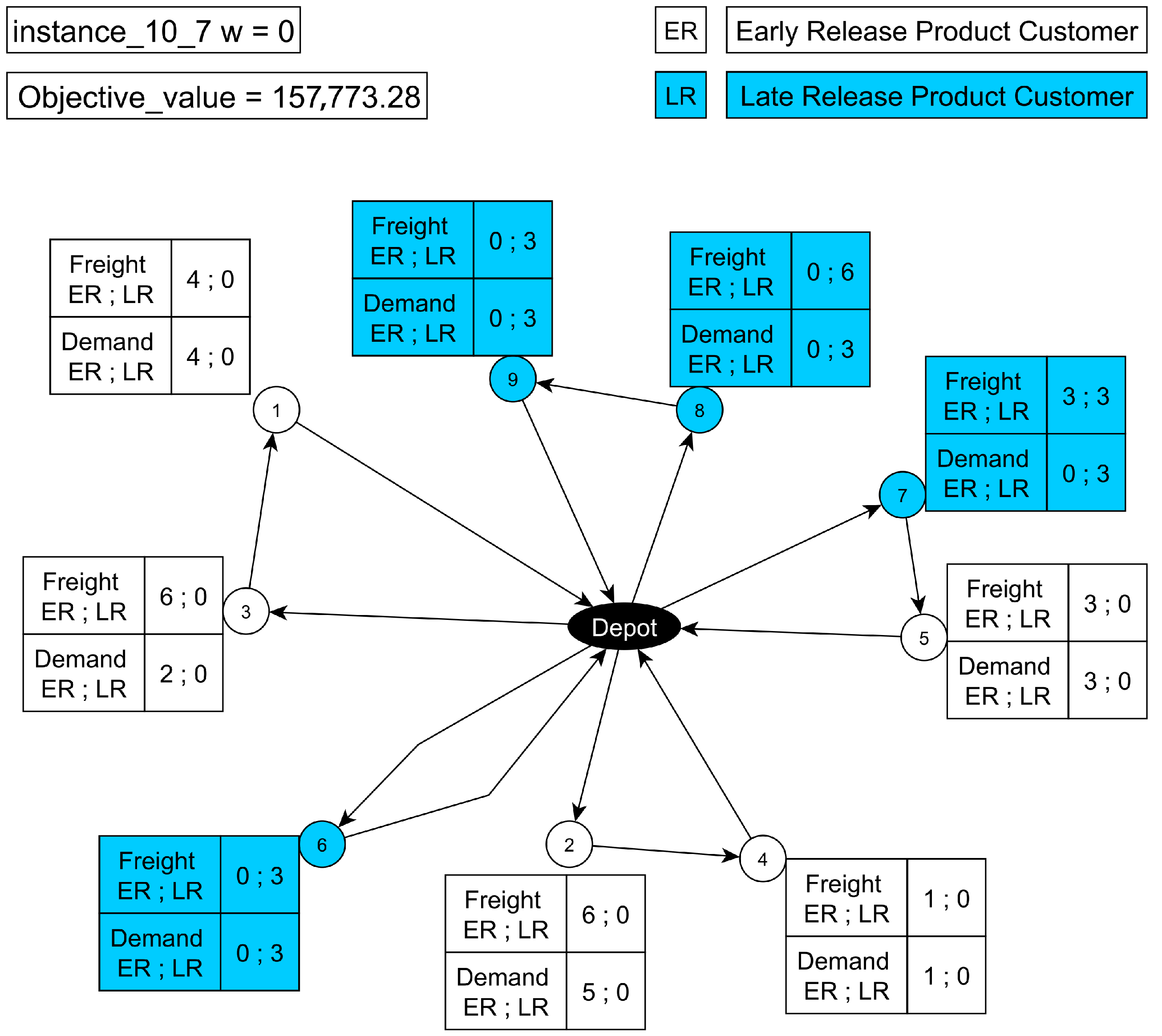

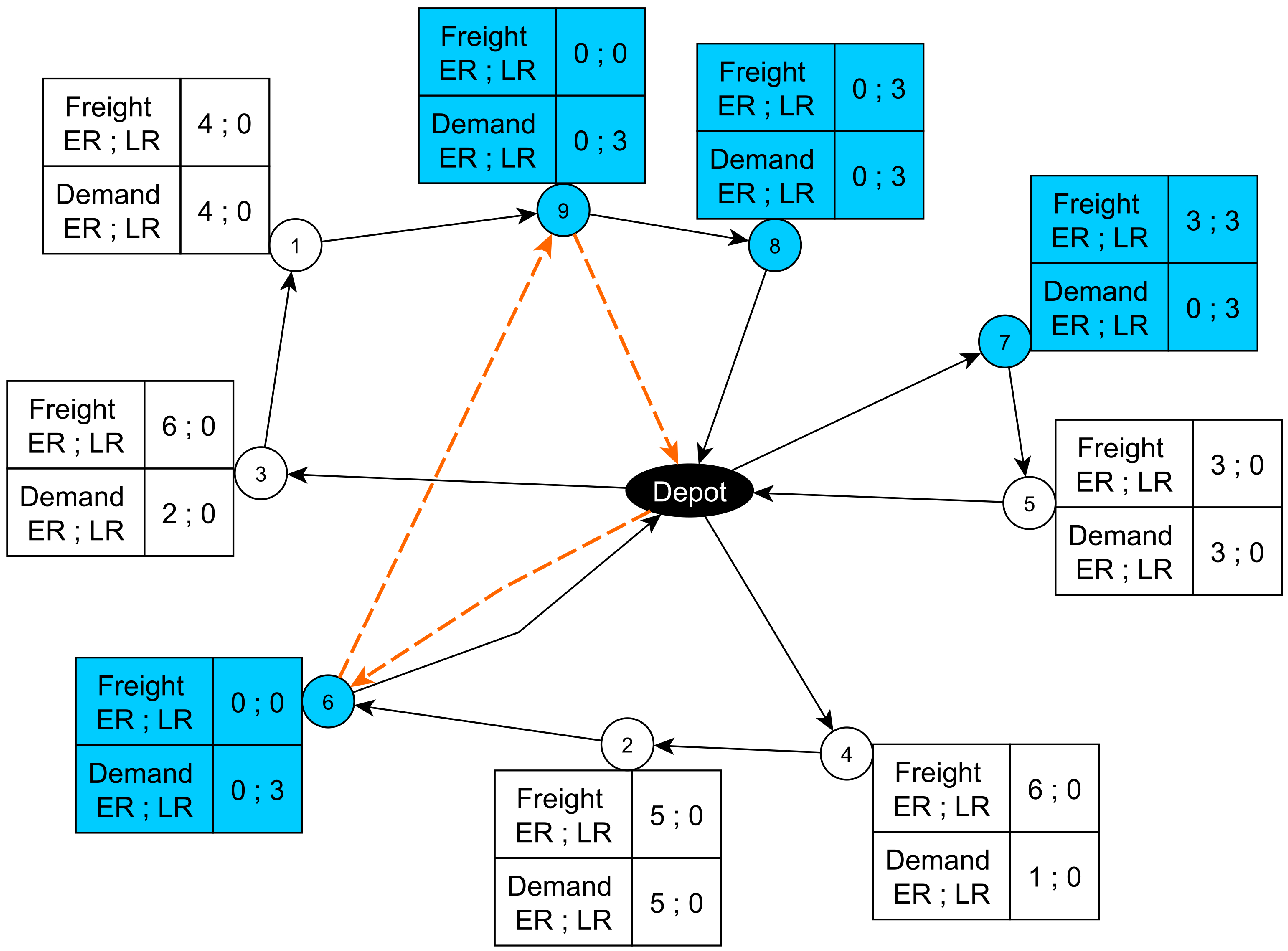

- Results of the Proposed VRP-RT-RMS Model.Figure 4 shows the model solution for instance 15_1. The dashed line indicates the tour of the reload vehicle, which follows the route [0, 12, 9, 11, 14, 8, 0] as depicted. Reloads occur across different delivery routes and, in particular, multiple reloads within a single route (Node_12, Node_15, Node_9). This behavior is consistent with the vehicle capacity () and with the cumulative demand, which exceeds what can be carried in a single trip; therefore, the delivery vehicle must be assisted several times by the reload tour.Figure 5 presents the model behavior for instance 15_6. The reload vehicle tour according to the table is [0, 3, 1, 5, 14, 12, 2, 0]. In this solution, the same delivery vehicle is reloaded twice along its route, but not at consecutive nodes. This occurs on route [0, 5, 13, 7, 12, 0]: the reloads take place at nodes 5 and 12, with two intermediate visits (13 and 7). This pattern is consistent with the delivery vehicle capacity () and with the cumulative demand and product mix, which require reloading at different points of the tour. The reload vehicle serves multiple delivery routes; between the two reloads of the same route (at 5 and 12), it reloads another vehicle at node 14 before returning to complete the second reload.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Salehi Sarbijan, M.; Behnamian, J. Emerging research fields in vehicle routing problem: A short review. Arch. Comput. Methods Eng. 2023, 30, 2473–2491. [Google Scholar] [CrossRef]

- Lo, S.C.; Chuang, Y.L. Vehicle routing optimization with cross-docking based on an artificial immune system in logistics management. Mathematics 2023, 11, 811. [Google Scholar] [CrossRef]

- Yu, V.F.; Lin, C.H.; Maglasang, R.S.; Lin, S.W.; Chen, K.F. An Efficient Simulated Annealing Algorithm for the Vehicle Routing Problem in Omnichannel Distribution. Mathematics 2024, 12, 3664. [Google Scholar] [CrossRef]

- Mardešić, N.; Erdelić, T.; Carić, T.; Đurasević, M. Review of stochastic dynamic vehicle routing in the evolving urban logistics environment. Mathematics 2023, 12, 28. [Google Scholar] [CrossRef]

- Ambrosino, D.; Cerrone, C. A Rich Vehicle Routing Problem for a City Logistics Problem. Mathematics 2022, 10, 191. [Google Scholar] [CrossRef]

- Huang, Y.H.; Blazquez, C.A.; Huang, S.H.; Paredes-Belmar, G.; Latorre-Nuñez, G. Solving the feeder vehicle routing problem using ant colony optimization. Comput. Ind. Eng. 2019, 127, 520–535. [Google Scholar] [CrossRef]

- Pillac, V.; Gendreau, M.; Guéret, C.; Medaglia, A.L. A review of dynamic vehicle routing problems. Eur. J. Oper. Res. 2013, 225, 1–11. [Google Scholar] [CrossRef]

- Cruijssen, F.; Bräysy, O.; Dullaert, W.; Fleuren, H.; Salomon, M. Joint route planning under varying market conditions. Int. J. Phys. Distrib. Logist. Manag. 2007, 37, 287–304. [Google Scholar] [CrossRef]

- Yousefikhoshbakht, M.; Chaharmahali, M.; Ahmed, Z.H. The Line-Haul Feeder Vehicle Routing Problem: A Classification and Review. Complexity 2023, 2023, 9902545. [Google Scholar] [CrossRef]

- Torres-Tapia, W.; Montoya-Torres, J.; Ruiz-Meza, J. Hybrid ils-vnd algorithm for the vehicle routing problem with release times. In Applied Computer Sciences in Engineering; Springer: Cham, Switzerland, 2022; pp. 222–233. [Google Scholar] [CrossRef]

- Bard, J.F.; Huang, L.; Jaillet, P.; Dror, M. A decomposition approach to the inventory routing problem with satellite facilities. Transp. Sci. 1998, 32, 189–203. [Google Scholar] [CrossRef]

- Lan, Y.L.; Liu, F.G.; Huang, Z.; Ng, W.W.; Zhong, J. Two-echelon dispatching problem with mobile satellites in city logistics. IEEE Trans. Intell. Transp. Syst. 2020, 23, 84–96. [Google Scholar] [CrossRef]

- Ancele, Y.; Hà, M.H.; Lersteau, C.; Matellini, D.B.; Nguyen, T.T. Toward a more flexible VRP with pickup and delivery allowing consolidations. Transp. Res. Part C Emerg. Technol. 2021, 128, 103077. [Google Scholar] [CrossRef]

- Soto-Concha, R.; Escobar, J.W.; Morillo-Torres, D.; Linfati, R. The Vehicle-Routing Problem with Satellites Utilization: A Systematic Review of the Literature. Mathematics 2025, 13, 1092. [Google Scholar] [CrossRef]

- Sarbijan, M.S.; Behnamian, J. Multi-fleet feeder vehicle routing problem using hybrid metaheuristic. Comput. Oper. Res. 2022, 141, 105696. [Google Scholar] [CrossRef]

- Chen, H.K.; Chou, H.W.; Hsueh, C.F.; Ho, T.Y. The linehaul-feeder vehicle routing problem with virtual depots. IEEE Trans. Autom. Sci. Eng. 2011, 8, 694–704. [Google Scholar] [CrossRef]

- Chen, H.K.; Chou, H.W.; Hsu, C.Y. The Linehaul-Feeder Vehicle Routing Problem with Virtual Depots and Time Windows. Math. Probl. Eng. 2011, 2011, 759418. [Google Scholar] [CrossRef]

- Brandstätter, C.; Reimann, M. The line-haul feeder vehicle routing problem: Mathematical model formulation and heuristic approaches. Eur. J. Oper. Res. 2018, 270, 157–170. [Google Scholar] [CrossRef]

- Brandstätter, C. A metaheuristic algorithm and structured analysis for the line-haul feeder vehicle routing problem with time windows. Cent. Eur. J. Oper. Res. 2021, 29, 247–289. [Google Scholar] [CrossRef]

- Chen, H.K.; Wang, H. A two-stage algorithm for the extended linehaul-feeder vehicle routing problem with time windows. Int. J. Shipp. Transp. Logist. 2012, 4, 339–356. [Google Scholar] [CrossRef]

- Sarbijan, M.S.; Behnamian, J. A mathematical model and metaheuristic approach to solve the real-time feeder vehicle routing problem. Comput. Ind. Eng. 2023, 185, 109684. [Google Scholar] [CrossRef]

- Sarbijan, M.S.; Behnamian, J. Real-time collaborative feeder vehicle routing problem with flexible time windows. Swarm Evol. Comput. 2022, 75, 101201. [Google Scholar] [CrossRef]

- Salehi Sarbijan, M.; Behnamian, J. Feeder vehicle routing problem in a collaborative environment using hybrid particle swarm optimization and adaptive learning strategy. Environ. Dev. Sustain. 2023, 27, 6165–6205. [Google Scholar] [CrossRef]

- Bevilaqua, A.; Bevilaqua, D.; Yamanaka, K. Parallel island based Memetic Algorithm with Lin–Kernighan local search for a real-life Two-Echelon Heterogeneous Vehicle Routing Problem based on Brazilian wholesale companies. Appl. Soft Comput. 2019, 76, 697–711. [Google Scholar] [CrossRef]

- Maknoon, M.; Kone, O.; Baptiste, P. A sequential priority-based heuristic for scheduling material handling in a satellite cross-dock. Comput. Ind. Eng. 2014, 72, 43–49. [Google Scholar] [CrossRef]

- Li, H.; Zhang, L.; Lv, T.; Chang, X. The two-echelon time-constrained vehicle routing problem in linehaul-delivery systems. Transp. Res. Part B Methodol. 2016, 94, 169–188. [Google Scholar] [CrossRef]

- Mühlbauer, F.; Fontaine, P. A parallelised large neighbourhood search heuristic for the asymmetric two-echelon vehicle routing problem with swap containers for cargo-bicycles. Eur. J. Oper. Res. 2021, 289, 742–757. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J. A Hybrid Method Combing Reinforcement Learning and Heuristics in Solving Two-Echelon Vehicle Routing Problem with Backhauls. In Knowledge Science, Engineering and Management; Springer: Singapore, 2024; pp. 241–253. [Google Scholar] [CrossRef]

- Babagolzadeh, M.; Zhang, Y.; Abbasi, B.; Shrestha, A.; Zhang, A. Promoting Australian regional airports with subsidy schemes: Optimised downstream logistics using vehicle routing problem. Transp. Policy 2022, 128, 38–51. [Google Scholar] [CrossRef]

- Xue, G.; Wang, Z. Order acceptance and scheduling in the instant delivery system. Comput. Ind. Eng. 2023, 182, 109395. [Google Scholar] [CrossRef]

- Ransikarbum, K.; Wattanasaeng, N.; Madathil, S.C. Analysis of multi-objective vehicle routing problem with flexible time windows: The implication for open innovation dynamics. J. Open Innov. Technol. Mark. Complex. 2023, 9, 100024. [Google Scholar] [CrossRef]

| Authors | Problem | Reloading | Release Time | Fleet | Satellite | Solution Method |

|---|---|---|---|---|---|---|

| [6] | FVRP | Yes | No | Heterogeneous | No | ACO |

| [15] | Multi-Fleet FVRP | Yes | No | Heterogeneous | No | PSO PSO–SA |

| [18] | LFVRP | Yes | No | Heterogeneous | No | Linkage/ Split |

| [16] | LFVRP-VD | Yes | No | Heterogeneous | No | Cost-sharing Threshold |

| [19] | LFVRPTW | Yes | No | Heterogeneous | No | Linkage-based matheuristic (multi-start + local search) |

| [17] | LFVRPTW | Yes | No | Heterogeneous | No | Tabu Search |

| [20] | ELFVRPTW | Yes | No | Heterogeneous | No | Two-stage |

| [21] | RTFVRP | Yes | No | Heterogeneous | No | DIWPSO |

| [22] | RTCFVRP | Yes | No | Heterogeneous | No | MOPSO MOPSO-VNS |

| [23] | CFVRPFlexTW | Yes | No | Heterogeneous | No | WMOPSO LAMOPSO |

| [11] | IRPSF | Yes | No | Homogeneous | Yes | Randomized Clarke–Wright GRASP Modified sweep |

| [25] | satellite cross-dock | Yes | No | Homogeneous | Yes | Sequential priority-based heuristic |

| [26] | 2E-TVRP | Yes | No | Homogeneous | Yes | Clarke–Wright Local Search phase |

| [24] | 2E-HVRP | Yes | No | Heterogeneous | Yes | Parallel island based Memetic Algorithm Lin–Kernighan local search |

| [27] | 2E-CVRP | Yes | No | Heterogeneous | Yes | Parallelised large neighbourhood search |

| [28] | 2E-CVRP-B | Yes | No | Heterogeneous | Yes | RePart-DRL (DRL + LNS) |

| [29] | OVRP | No | Yes | Heterogeneous | No | Exact |

| [10] | VRP-RT | No | Yes | Homogeneous | No | Hybrid ILS–VND |

| [30] | OAS-IDS MT-PCPDP- RT&DT | No | Yes | Homogeneous | No | Online insertion OIB-TSO |

| Current Study | VRP-RT-RMS | Yes | Yes | Heterogeneous | Yes | Exact |

| MILP-2 | MILP-3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Instance | Objective Value | Best Bound | CPU (s) | Relative Gap | Ef | Objective Value | Best Bound | CPU (s) | Relative Gap | Ef |

| 10_0 | 107,847.24 | 107,847.24 | 0.28 | 0.00% | 3.94 | 107,847.24 | 107,847.24 | 3.54 | 0.00% | 4.60 |

| 10_1 | 128,668.62 | 128,668.62 | 0.47 | 0.00% | 6.41 | 128,668.62 | 128,668.62 | 11.00 | 0.00% | 4.12 |

| 10_2 | 141,662.08 | 141,662.08 | 0.41 | 0.00% | 1.55 | 141,662.08 | 141,662.08 | 94.53 | 0.00% | 7.09 |

| 10_3 | 131,745.42 | 131,745.42 | 0.32 | 0.00% | 1.97 | 131,745.42 | 131,745.42 | 11.85 | 0.00% | 9.90 |

| 10_4 | 143,910.84 | 143,910.84 | 3.31 | 0.00% | 1.43 | 143,910.84 | 143,910.84 | 124.85 | 0.00% | 4.92 |

| 10_5 | 84,885.96 | 84,885.96 | 0.24 | 0.00% | 3.93 | 84,885.96 | 84,885.96 | 0.65 | 0.00% | 3.49 |

| 10_6 | 94,354.90 | 94,354.90 | 0.29 | 0.00% | 5.15 | 94,354.90 | 94,354.90 | 0.50 | 0.00% | 2.85 |

| 10_7 | 146,313.14 | 146,313.14 | 8.58 | 0.00% | 1.44 | 146,313.14 | 146,313.14 | 2420.57 | 0.00% | 5.44 |

| 10_8 | 181,688.34 | 181,688.34 | 0.50 | 0.00% | 1.43 | 181,688.34 | 181,688.34 | 90.60 | 0.00% | 6.97 |

| 10_9 | 135,284.02 | 135,284.02 | 0.31 | 0.00% | 1.13 | 135,284.02 | 135,284.02 | 3.38 | 0.00% | 3.11 |

| MILP-2 | MILP-3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Instance | Objective Value | Best Bound | CPU (s) | Relative Gap | Ef | Objective Value | Best Bound | CPU (s) | Relative Gap | Ef |

| 15_0 | 178,631.62 | 178,631.62 | 955.12 | 0.00% | 4.06 | 181,343.54 | 120,750.79 | 3600.00 | 33.41% | 9.51 |

| 15_1 | 147,447.00 | 147,447.00 | 10.70 | 0.00% | 4.05 | 147,446.99 | 130,713.82 | 3600.02 | 11.35% | 33.13 |

| 15_2 | 135,517.23 | 129,513.59 | 3600.00 | 4.43% | 5.47 | 137,009.06 | 88,879.03 | 3600.02 | 35.13% | 18.73 |

| 15_3 | 149,502.96 | 130,724.18 | 3600.00 | 12.56% | 2.68 | 149,502.96 | 105,187.63 | 3600.00 | 29.64% | 14.30 |

| 15_4 | 145,325.80 | 145,325.80 | 2297.69 | 0.00% | 3.63 | 145,325.82 | 107,827.68 | 3600.01 | 25.80% | 21.64 |

| 15_5 | 159,148.10 | 159,148.10 | 9.07 | 0.00% | 4.02 | 159,148.10 | 119,917.96 | 3600.01 | 24.65% | 33.58 |

| 15_6 | 186,483.06 | 186,483.06 | 22.64 | 0.00% | 3.92 | 186,483.06 | 152,015.60 | 3600.02 | 18.48% | 45.83 |

| 15_7 | 179,994.24 | 179,994.24 | 1419.13 | 0.00% | 4.35 | 179,994.24 | 124,638.66 | 3600.01 | 30.75% | 18.80 |

| 15_8 | 176,316.78 | 176,316.78 | 265.67 | 0.00% | 3.27 | 179,247.32 | 138,258.97 | 3600.01 | 22.87% | 14.51 |

| 15_9 | 167,197.14 | 167,197.14 | 62.13 | 0.00% | 3.19 | 167,197.14 | 135,033.02 | 3600.01 | 19.24% | 18.86 |

| MILP-2 | MILP-3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Instance | Objective Value | Best Bound | CPU (s) | Relative Gap | Ef | Objective Value | Best Bound | CPU (s) | Relative Gap | Ef |

| 20_0 | 239,160.56 | 239,139.89 | 1715.85 | 0.00% | 8.86 | 240,946.02 | 139,164.12 | 3600.01 | 42.24% | 18.74 |

| 20_1 | 211,358.56 | 181,571.15 | 3600.00 | 14.09% | 6.69 | 215,540.30 | 126,090.73 | 3600.01 | 41.50% | 18.00 |

| 20_2 | 172,203.41 | 172,203.41 | 3432.54 | 0.00% | 7.42 | 173,735.78 | 111,185.35 | 3600.03 | 36.00% | 88.96 |

| 20_3 | 232,695.73 | 174,208.35 | 3600.01 | 25.13% | 8.76 | 238,922.20 | 101,468.01 | 3600.01 | 57.53% | 45.80 |

| 20_4 | 189,382.08 | 167,021.26 | 3600.00 | 11.81% | 10.12 | 206,518.38 | 122,864.44 | 3600.01 | 40.51% | 53.58 |

| 20_5 | 202,338.14 | 174,009.48 | 3600.00 | 14.00% | 8.33 | 197,597.70 | 122,877.04 | 3600.01 | 37.81% | 23.12 |

| 20_6 | 192,692.28 | 153,943.86 | 3600.01 | 20.11% | 8.43 | 199,772.78 | 118,777.13 | 3600.03 | 40.54% | 32.34 |

| 20_7 | 261,591.00 | 237,461.96 | 3600.01 | 9.22% | 8.49 | 265,056.60 | 173,350.43 | 3600.01 | 34.60% | 24.95 |

| 20_8 | 184,828.21 | 158,246.41 | 3600.00 | 14.38% | 8.85 | 185,345.62 | 93,097.90 | 3600.02 | 49.77% | 52.10 |

| 20_9 | 224,869.34 | 196,671.83 | 3600.00 | 12.54% | 7.09 | 229,875.42 | 126,535.69 | 3600.01 | 44.95% | 20.77 |

| MILP-2 | MILP-3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Instance | Objective Value | Best Bound | CPU (s) | Relative Gap | Ef | Objective Value | Best Bound | CPU (s) | Relative Gap | Ef |

| 25_0 | 256,587.42 | 174,463.48 | 3600.00 | 32.01% | 8.47 | 269,513.80 | 112,222.05 | 3600.04 | 58.36% | 23.99 |

| 25_1 | 265,842.89 | 218,669.80 | 3600.01 | 17.74% | 13.91 | 269,041.20 | 112,715.27 | 3600.01 | 58.10% | 38.44 |

| 25_2 | 220,234.34 | 179,000.34 | 3600.01 | 18.72% | 9.74 | 235,070.72 | 112,761.82 | 3600.02 | 52.03% | 26.04 |

| 25_3 | 298,452.78 | 212,708.83 | 3600.00 | 28.73% | 11.27 | 305,607.50 | 145,382.67 | 3600.02 | 52.43% | 51.03 |

| 25_4 | 204,914.88 | 141,279.89 | 3600.00 | 31.05% | 9.88 | 211,211.88 | 87,465.78 | 3600.01 | 58.59% | 24.49 |

| 25_5 | 264,082.98 | 137,642.25 | 3600.01 | 47.88% | 11.01 | 285,276.14 | 88,400.18 | 3600.01 | 69.01% | 24.49 |

| 25_6 | 346,155.68 | 227,715.12 | 3600.01 | 34.22% | 8.54 | - | - | - | - | - |

| 25_7 | 239,082.58 | 178,997.61 | 3600.01 | 25.13% | 13.04 | 242,536.24 | 115,110.88 | 3600.01 | 52.54% | 27.35 |

| 25_8 | 268,228.52 | 201,062.98 | 3600.01 | 25.04% | 17.70 | 273,273.80 | 128,698.12 | 3600.01 | 52.91% | 61.64 |

| 25_9 | 255,763.96 | 185,736.29 | 3600.00 | 27.38% | 10.19 | 278,945.30 | 134,119.43 | 3600.02 | 51.92% | 27.65 |

| MILP-2 | MILP-3 | |||||||

|---|---|---|---|---|---|---|---|---|

| Instance | ||||||||

| 10_0 | 4 | 4 | 0 | 0 | 4 | 4 | 0 | 0 |

| 10_1 | 5 | 3 | 2 | 2 | 5 | 3 | 2 | 2 |

| 10_2 | 6 | 4 | 2 | 2 | 6 | 4 | 2 | 2 |

| 10_3 | 8 | 4 | 4 | 3 | 8 | 4 | 4 | 2 |

| 10_4 | 5 | 3 | 1 | 1 | 5 | 3 | 1 | 1 |

| 10_5 | 3 | 3 | 0 | 0 | 3 | 3 | 0 | 0 |

| 10_6 | 3 | 3 | 0 | 0 | 3 | 3 | 0 | 0 |

| 10_7 | 5 | 3 | 2 | 2 | 5 | 3 | 1 | 1 |

| 10_8 | 5 | 4 | 2 | 2 | 5 | 4 | 2 | 2 |

| 10_9 | 4 | 4 | 1 | 1 | 4 | 4 | 1 | 1 |

| MILP-2 | MILP-3 | |||||||

|---|---|---|---|---|---|---|---|---|

| Instance | ||||||||

| 15_0 | 7 | 4 | 3 | 2 | 7 | 4 | 3 | 2 |

| 15_1 | 8 | 4 | 5 | 3 | 8 | 4 | 5 | 3 |

| 15_2 | 7 | 3 | 5 | 3 | 7 | 3 | 5 | 3 |

| 15_3 | 7 | 3 | 3 | 3 | 7 | 3 | 3 | 3 |

| 15_4 | 8 | 3 | 4 | 3 | 8 | 3 | 5 | 3 |

| 15_5 | 8 | 6 | 3 | 3 | 8 | 6 | 3 | 3 |

| 15_6 | 8 | 5 | 6 | 5 | 8 | 5 | 4 | 4 |

| 15_7 | 6 | 5 | 2 | 1 | 6 | 5 | 2 | 1 |

| 15_8 | 7 | 5 | 2 | 2 | 7 | 4 | 2 | 2 |

| 15_9 | 6 | 4 | 2 | 1 | 6 | 4 | 3 | 1 |

| MILP-2 | MILP-3 | |||||||

|---|---|---|---|---|---|---|---|---|

| Instance | ||||||||

| 20_0 | 10 | 7 | 4 | 3 | 10 | 7 | 4 | 3 |

| 20_1 | 8 | 7 | 3 | 2 | 8 | 8 | 1 | 1 |

| 20_2 | 9 | 6 | 3 | 1 | 9 | 8 | 0 | 0 |

| 20_3 | 9 | 6 | 3 | 2 | 9 | 6 | 2 | 2 |

| 20_4 | 8 | 5 | 4 | 3 | 8 | 6 | 2 | 2 |

| 20_5 | 11 | 5 | 6 | 3 | 11 | 4 | 6 | 3 |

| 20_6 | 9 | 5 | 4 | 4 | 9 | 5 | 4 | 4 |

| 20_7 | 10 | 8 | 5 | 4 | 10 | 7 | 4 | 3 |

| 20_8 | 9 | 6 | 6 | 5 | 9 | 6 | 5 | 3 |

| 20_9 | 8 | 6 | 3 | 3 | 8 | 6 | 3 | 3 |

| MILP-2 | MILP-3 | |||||||

|---|---|---|---|---|---|---|---|---|

| Instance | ||||||||

| 25_0 | 10 | 6 | 4 | 4 | 10 | 7 | 3 | 3 |

| 25_1 | 11 | 9 | 4 | 4 | 11 | 9 | 2 | 2 |

| 25_2 | 11 | 8 | 4 | 3 | 11 | 8 | 3 | 3 |

| 25_3 | 12 | 8 | 6 | 4 | 12 | 8 | 4 | 4 |

| 25_4 | 11 | 6 | 6 | 4 | 11 | 7 | 5 | 4 |

| 25_5 | 10 | 7 | 3 | 3 | 10 | 7 | 4 | 3 |

| 25_6 | 10 | 8 | 3 | 3 | – | – | – | – |

| 25_7 | 11 | 7 | 6 | 3 | 11 | 6 | 4 | 4 |

| 25_8 | 12 | 7 | 7 | 6 | 12 | 8 | 6 | 6 |

| 25_9 | 9 | 6 | 5 | 3 | 9 | 7 | 4 | 3 |

| K = 1–10 | ||

|---|---|---|

| Instance | Var | Constr |

| 10 | 247 | 512 |

| 15 | 522 | 1072 |

| 20 | 897 | 1832 |

| 25 | 1372 | 2792 |

| 50 | 5247 | 10,592 |

| 75 | 11,622 | 23,392 |

| 100 | 20,497 | 41,192 |

| Instance | K Range | Var’s | Constr’s | Var’s | Constr’s | Var’s | Constr’s | Var’s | Constr’s | Var’s | Constr’s |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 1–5 | 231 | 522 | 362 | 887 | 493 | 1252 | 624 | 1617 | 755 | 1982 |

| 6–10 | 886 | 2347 | 1017 | 2712 | 1148 | 3077 | 1279 | 3442 | 1410 | 3807 | |

| 15 | 1–5 | 496 | 1087 | 767 | 1862 | 1038 | 2637 | 1309 | 3412 | 1580 | 4187 |

| 6–10 | 1851 | 4962 | 2122 | 5737 | 2393 | 6512 | 2664 | 7287 | 2935 | 8062 | |

| 20 | 1–5 | 861 | 1852 | 1322 | 3187 | 1783 | 4522 | 2244 | 5857 | 2705 | 7192 |

| 6–10 | 3166 | 8527 | 3627 | 9862 | 4088 | 11,197 | 4549 | 12,532 | 5010 | 13,867 | |

| 25 | 1–5 | 1326 | 2817 | 2027 | 4862 | 2728 | 6907 | 3429 | 8952 | 4130 | 10,997 |

| 6–10 | 4831 | 13,042 | 5532 | 15,087 | 6233 | 17,132 | 6934 | 19,177 | 7635 | 21,222 | |

| 50 | 1–5 | 5151 | 10,642 | 7802 | 18,487 | 10,453 | 26,332 | 13,104 | 34,177 | 15,755 | 42,022 |

| 6–10 | 18,406 | 49,867 | 21,057 | 57,712 | 23,708 | 65,557 | 26,359 | 73,402 | 29,010 | 81,247 | |

| 75 | 1–5 | 11,476 | 23,467 | 17,327 | 40,862 | 23,178 | 58,257 | 29,029 | 75,652 | 34,880 | 93,047 |

| 6–10 | 40,731 | 110,442 | 46,582 | 127,837 | 52,433 | 145,232 | 58,284 | 162,627 | 64,135 | 180,022 | |

| 100 | 1–5 | 20,301 | 41,292 | 30,602 | 71,987 | 40,903 | 102,682 | 51,204 | 133,377 | 61,505 | 164,072 |

| 6–10 | 71,806 | 194,767 | 82,107 | 225,462 | 92,408 | 256,157 | 102,709 | 286,852 | 113,010 | 317,547 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soto-Concha, R.; Morillo-Torres, D.; Escobar, J.W.; Mena-Reyes, J.F.; Linfati, R. Mixed-Integer Linear Programming Models for the Vehicle Routing Problem with Release Times and Reloading at Mobile Satellites. Mathematics 2025, 13, 3638. https://doi.org/10.3390/math13223638

Soto-Concha R, Morillo-Torres D, Escobar JW, Mena-Reyes JF, Linfati R. Mixed-Integer Linear Programming Models for the Vehicle Routing Problem with Release Times and Reloading at Mobile Satellites. Mathematics. 2025; 13(22):3638. https://doi.org/10.3390/math13223638

Chicago/Turabian StyleSoto-Concha, Raúl, Daniel Morillo-Torres, John Willmer Escobar, Jorge Félix Mena-Reyes, and Rodrigo Linfati. 2025. "Mixed-Integer Linear Programming Models for the Vehicle Routing Problem with Release Times and Reloading at Mobile Satellites" Mathematics 13, no. 22: 3638. https://doi.org/10.3390/math13223638

APA StyleSoto-Concha, R., Morillo-Torres, D., Escobar, J. W., Mena-Reyes, J. F., & Linfati, R. (2025). Mixed-Integer Linear Programming Models for the Vehicle Routing Problem with Release Times and Reloading at Mobile Satellites. Mathematics, 13(22), 3638. https://doi.org/10.3390/math13223638