A Fast Integration Method of Analysis and Optimization for the Contact Performance Design of a Face Gear Split-Torque Transmission

Abstract

1. Introduction

2. The Proposed Analysis and Optimization Integration Algorithm Framework

2.1. Description of the FGST System

2.2. The Proposed Analysis and Optimization Integration Method Framework

3. The Parameterized Mapping Method of the FGST System

3.1. Comprehensive Modification of Face Gears

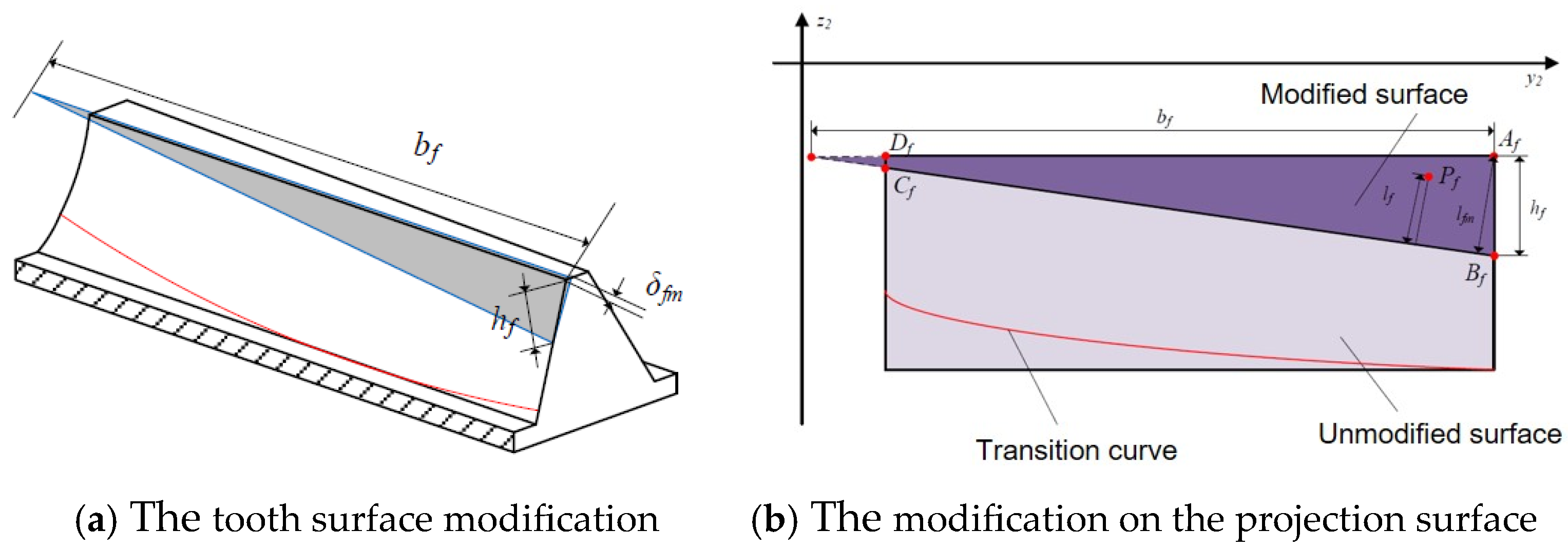

3.1.1. Modification Parameters of Tooth Surface for Upper and Lower Face Gears

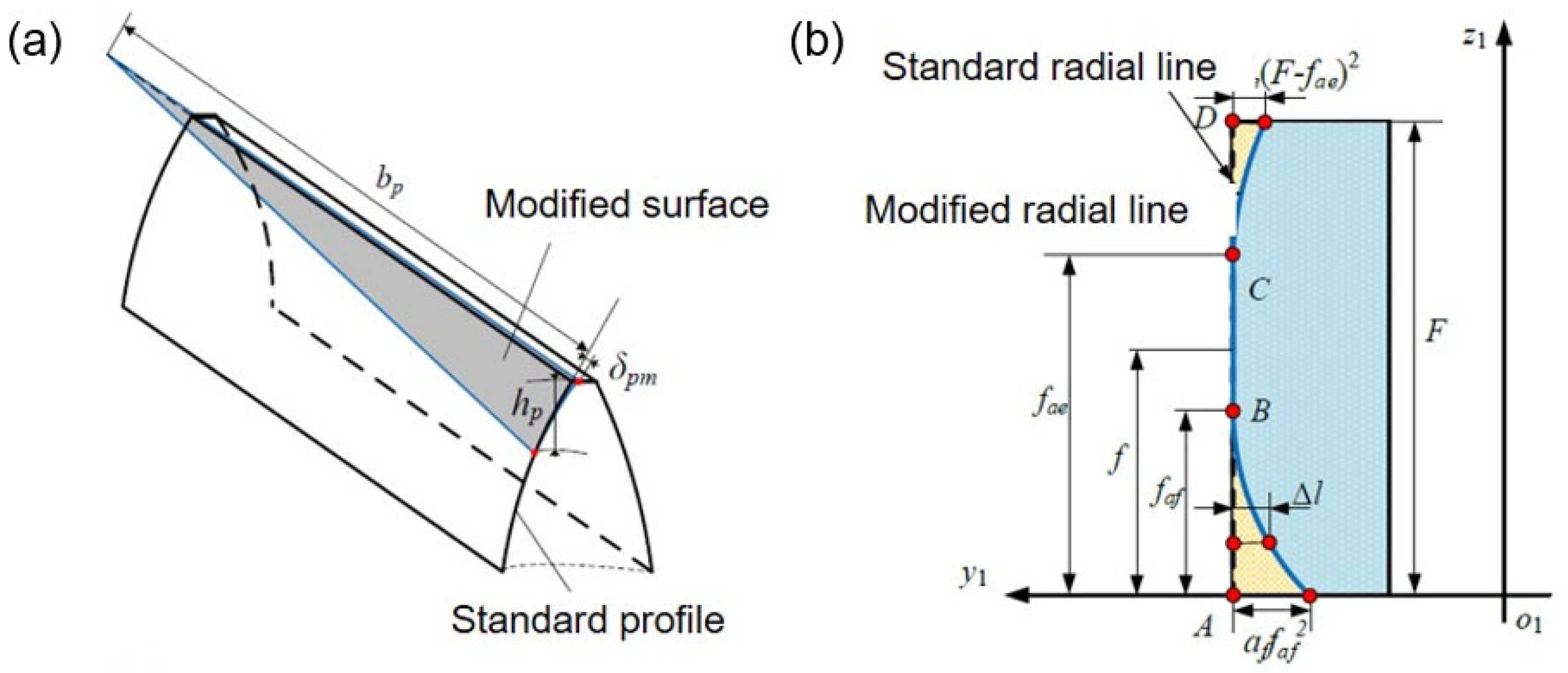

3.1.2. Modification Parameters of Tooth Surface for Pinion

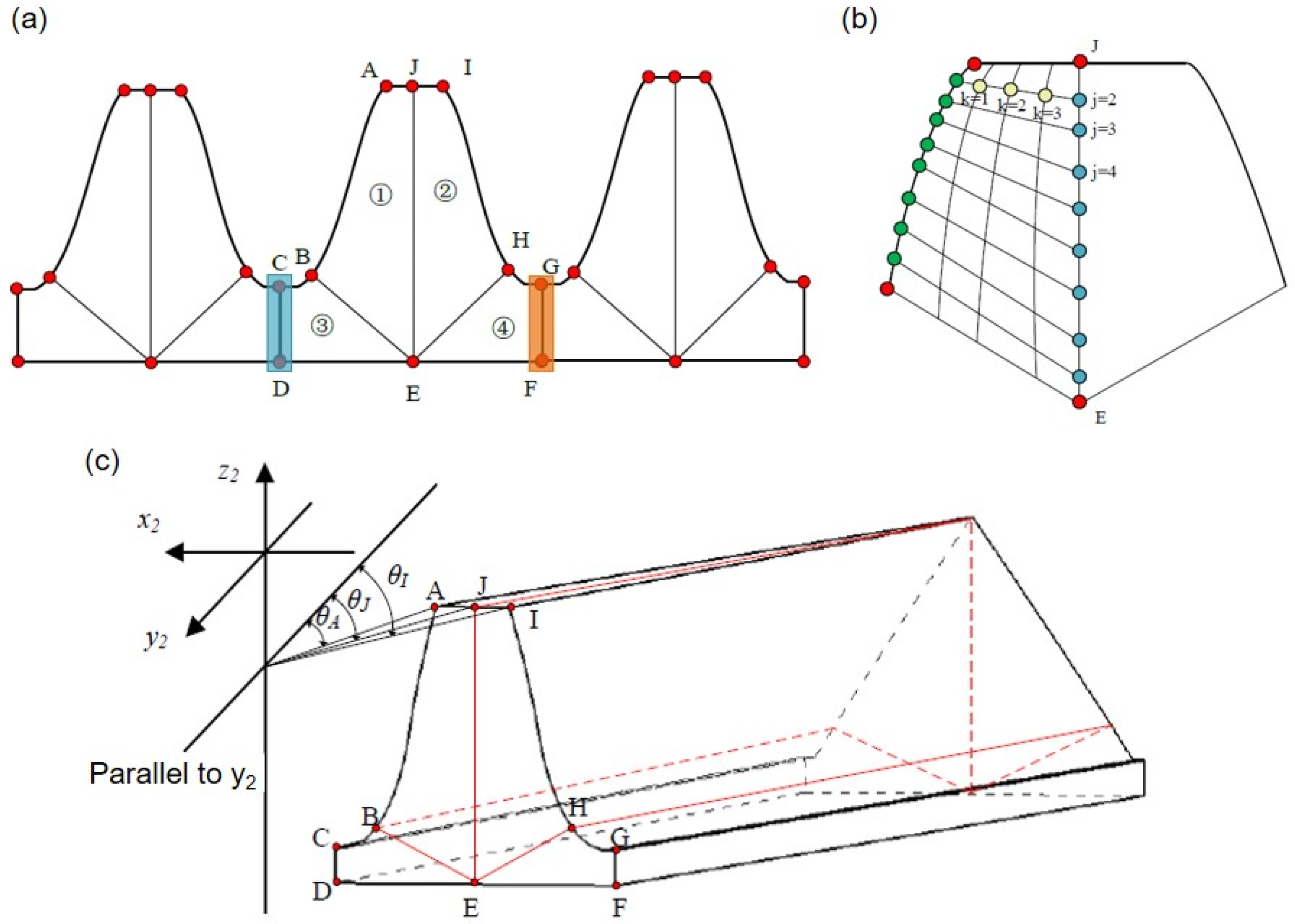

3.2. Mapping Method for the Tooth Surface Modification Parameters to Mesh for Face Gears and Pinion

3.3. Modeling of Split Torque Transmission System

4. A Fast Optimization Model Based on Kriging

4.1. Optimization Model of Tooth Surface Contact Performance

4.1.1. Image-Based Method of Contact Performance Index

4.1.2. Optimization Variables

4.1.3. Constrained Condition

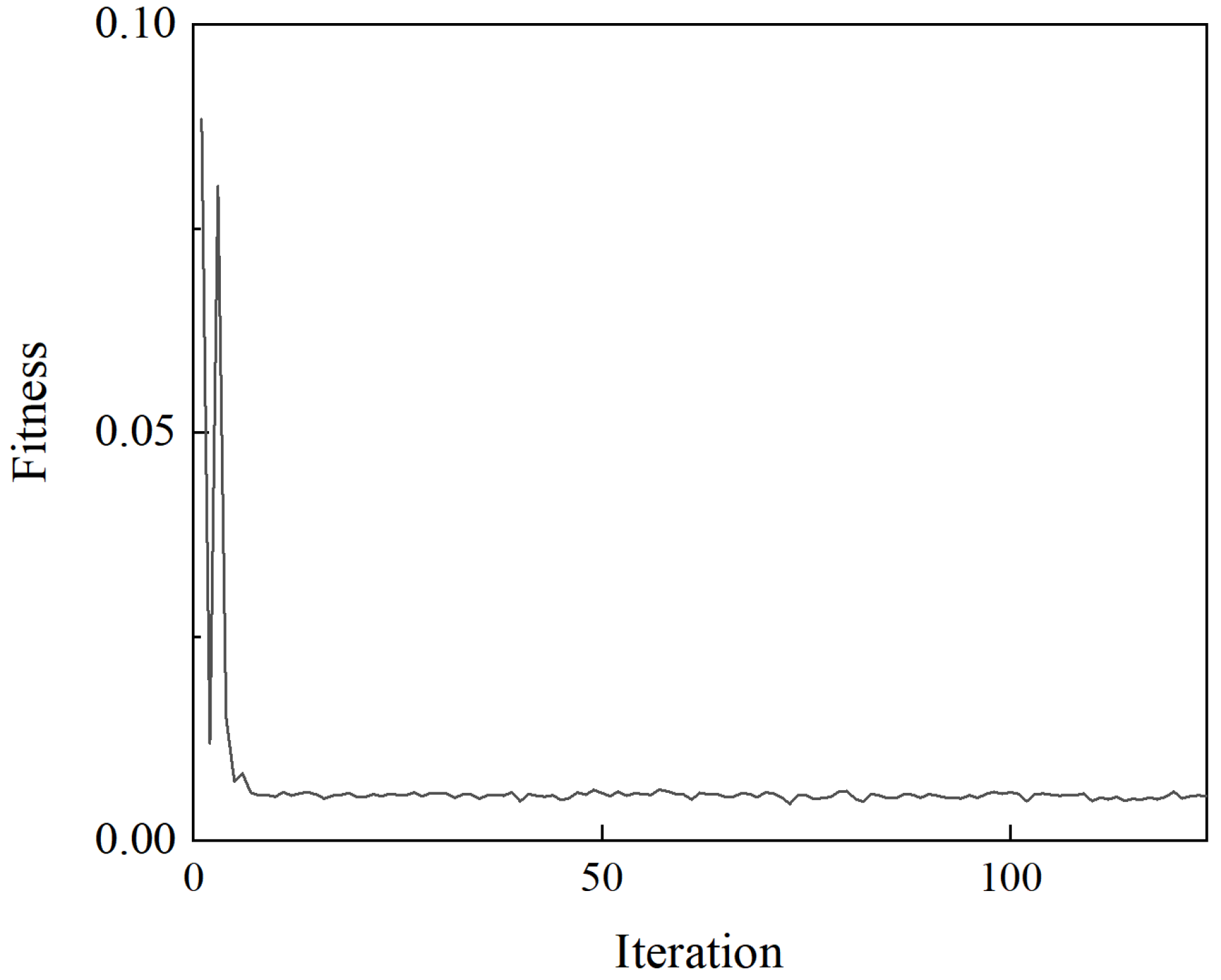

4.2. An Improved Optimization Method

4.2.1. Kriging Model

4.2.2. Adding Points Criteria

4.2.3. Optimization Termination Conditions

- (1)

- The difference between the newly added sample points and the response values, i.e.,

- (2)

- The difference between the objective function value of the newly added sample points and the predicted value of the surrogate model, i.e.,

- (3)

- The number of iterations is greater than the maximum number of iterations.

5. Case Study

5.1. Contact Performance Analysis of the FGST System

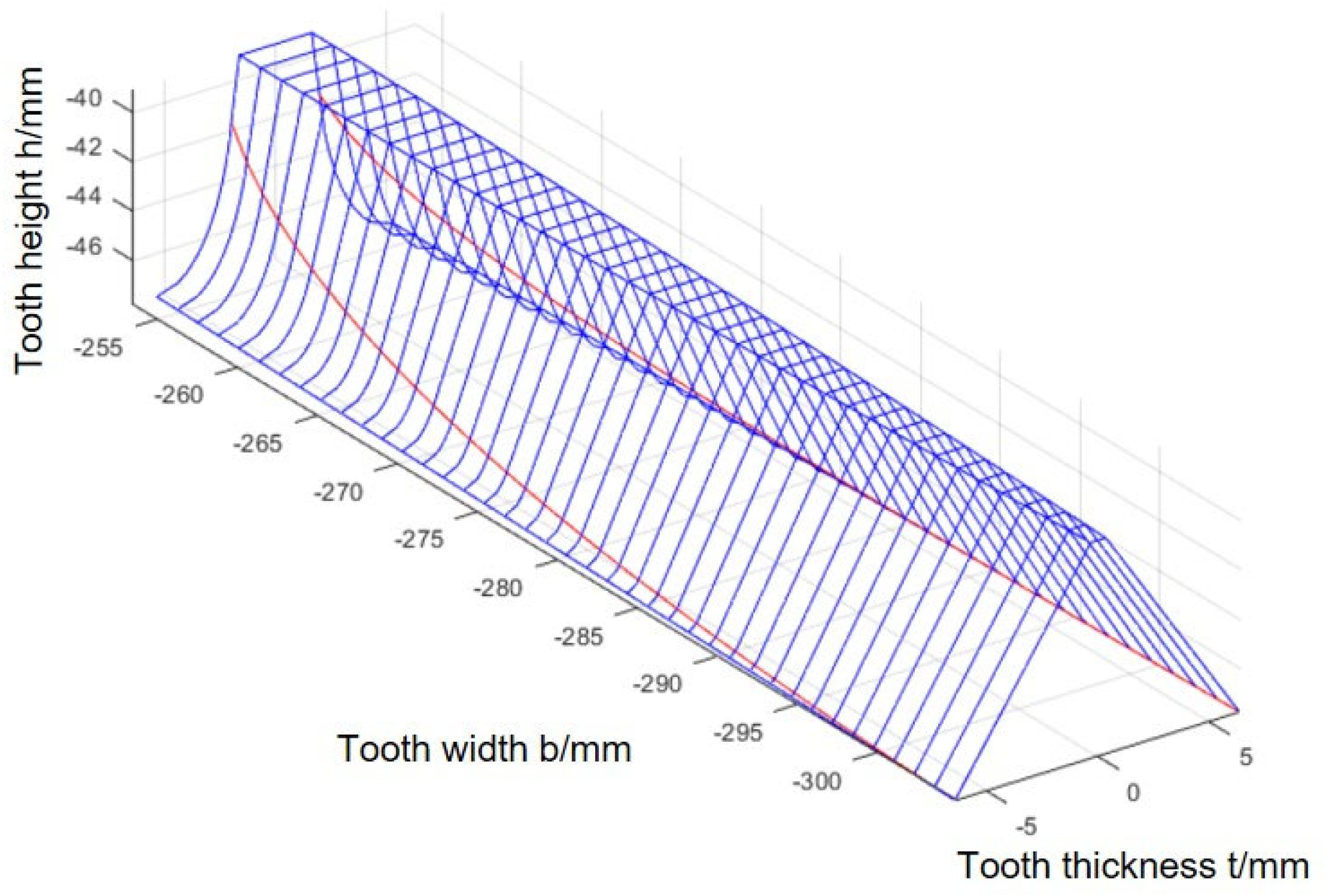

5.1.1. Accurate 3D Geometric Modeling

5.1.2. Finite Element Modeling and Analysis

5.2. Contact Area Test and Its Verification

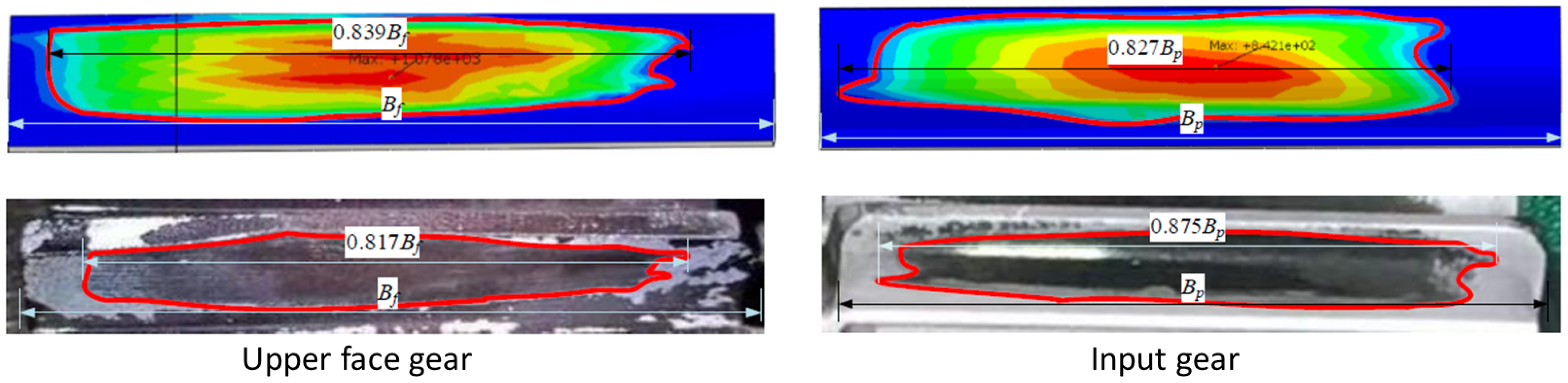

- (1)

- The simulation results of the upper face gear show that the ratio of the length of the tooth contact imprint in the tooth width direction to the entire tooth width of the face gear is 0.839. The value obtained by test is 0.817. The deviation between the simulation and the experimental results is 2.69%.

- (2)

- The contact simulation results of the input gear show that the ratio of the length of the tooth surface contact imprint in the tooth width direction to the width of the entire tooth surface is 0.827. The value obtained by test is 0.875. The deviation between simulation and experimental results is 5.49%.

- (3)

- Comparing the simulation and experimental results of the upper face gear and input gear, the position, shape, and size of the tooth surface contact imprint are basically the same, and they have consistent imprint characteristics (such as the sharp corners of the imprint).

5.3. Optimization Design and Result Analysis

6. Conclusions

- (1)

- A method for automatic modeling considering the modification parameters of face gears has been proposed to achieve the modeling and optimization for the FGST system. The time required for manual participation in modeling is shortened to less than 0.5 h, which greatly improved design efficiency.

- (2)

- An image-based method for quantifying the contact characteristics of face gears was proposed, and an objective function for optimizing the contact characteristics was established, achieving the optimization of the contact characteristics. The maximum tooth surface contact stress is reduced by 77.30%.

- (3)

- Considering the load differences of different power paths, the balanced design of different contact pairs (including input gears and upper and lower gears, face gears and idler gears) has been achieved, improving the overall contact performance of the system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lin, Y.; Huang, Y.; Huang, T.; Yin, Z. Open-hole tensile behaviour and failure prediction of carbon fibre reinforced aluminium laminates. Polym. Compos. 2018, 39, 4123–4138. [Google Scholar] [CrossRef]

- Le, K.Q.; Wu, Y.R.; Luu, T.T. A Mathematical Modeling of Computer Numerical Control Skiving Process for Manufacturing Helical Face Gears Using Sensitivity Matrix Combined with Levenberg–Marquardt Algorithm. J. Manuf. Sci. Eng. 2024, 146, 091007. [Google Scholar] [CrossRef]

- Jiang, C.; Shang, Y.; Wang, Z.; Han, Z.; Deng, J. Optimal calculation and experimental study on cutting force of low-angle straight tooth face gear by power skiving. Int. J. Adv. Manuf. Technol. 2024, 135, 3961–3982. [Google Scholar] [CrossRef]

- Han, Z.; Jiang, C.; Deng, X.; Zhang, C.; Geng, L.; Feng, Y. The Grinding and Correction of Face Gears Based on an Internal Gear Grinding Machine. Machines 2024, 12, 496. [Google Scholar] [CrossRef]

- Sheng, W.; Li, Z.; Yu, X. Research on the top cutting features on face gears using normal to tooth profile method. Eng. Sci. Technol. Int. J. 2024, 59, 101849. [Google Scholar] [CrossRef]

- Huang, K.; Yu, J.; Luo, H.; Shang, Z.; Huang, S.; Fu, L. An efficient vectorization solution to cutting dynamics modeling for face-hobbing of hypoid gears. Mech. Mach. Theory 2024, 191, 105504. [Google Scholar] [CrossRef]

- Zanzi, C.; Pedrero, J.I. Application of modified geometry of face gear drive. Comput. Methods Appl. Mech. Eng. 2005, 194, 3047–3066. [Google Scholar] [CrossRef]

- Litvin, F.; Zhang, Y.; Kuan, C.; Handschuh, R. Computerized inspection of real surfaces and minimization of their deviations. Int. J. Mach. Tools Manuf. 1992, 32, 141–145. [Google Scholar] [CrossRef]

- Tao, J.; Zhou, J.; Wang, S.; Dong, J.; Ma, C.; Xiao, Y.; Xia, M. An efficient and accurate measurement method of tooth flank variations for face gears. Measurement 2023, 221, 113486. [Google Scholar] [CrossRef]

- Dong, J.; Wang, Q.; Tang, J.; Hu, Z.; Li, X. Dynamic characteristics and load-sharing performance of concentric face gear split-torque transmission systems with time-varying mesh stiffness, flexible supports and deformable shafts. Meccanica 2021, 56, 2893–2918. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, P.; Min, X.; Li, N.; Deng, Z. Study on power split characteristics of planetary multistage face gear transmission device and its effect to drive efficiency under variable speed working condition. Mech. Sci. 2020, 11, 173–182. [Google Scholar] [CrossRef]

- Lewicki, D.G.; Heath, G.F.; Filler, R.R.; Slaughter, S.C.; Fetty, J. RDS-21 face-gear surface durability tests. In Proceedings of the American Helicoptr Society 63rd Annual Forum, Virginia Beach, VA, USA, 1–3 May 2007. [Google Scholar]

- Guingand, M.; De Vaujany, J.P.; Jacquin, C.Y. Quasi-static analysis of a face gear under torque. Comput. Methods Appl. Mech. Eng. 2005, 194, 4301–4318. [Google Scholar] [CrossRef]

- Handschuh, R.F.; Lewicki, D.G.; Bossler, R.B. Experimental testing of prototype face gears for helicopter transmissions. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 1994, 208, 129–136. [Google Scholar] [CrossRef]

- Lewicki, D.G.; Handschuh, R.F.; Heath, G.F.; Sheth, V. Evaluation of carburized and ground face gears. J. Am. Helicopter Soc. 2000, 45, 118–124. [Google Scholar] [CrossRef]

- White, G. Design study of a split-torque helicopter transmission. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 1998, 212, 117–123. [Google Scholar] [CrossRef]

- Peng, X.; Zhou, J. Optimization design for dynamic characteristics of face gear drive with surface-active modification. Mech. Mach. Theory 2022, 176, 105007. [Google Scholar] [CrossRef]

- Chen, Y.; Bossler, R. Design, analysis, and testing methods for a split-torque face-gear transmission. In Proceedings of the 31st Joint Propulsion Conference and Exhibit, San Diego, CA, USA, 10–12 July 1995; p. 3051. [Google Scholar]

- Hu, Z.; Tang, J.; Wang, Q.; Chen, S.; Qian, L. Investigation of nonlinear dynamics and load sharing characteristics of a two-path split torque transmission system. Mech. Mach. Theory 2020, 152, 103955. [Google Scholar] [CrossRef]

- Filler, R.R.; Heath, G.F.; Slaughter, S.C.; Lewicki, D.G. Torque splitting by a concentric face gear transmission. In Proceedings of the American Helicopter Society 58th Annual Forum, Montreal, QC, Canada, 11–13 June 2002. [Google Scholar]

- Heath, G.F.; Filler, R.R.; Tan, J. Development of face gear technology for industrial and aerospace power transmission. 2002. Available online: https://ntrs.nasa.gov/api/citations/20020062003/downloads/20020062003.pdf (accessed on 22 September 2025).

- Dong, J.; Tang, J.; Hu, Z. Investigation of assembly, power direction and load sharing in concentric face gear split-torque transmission system. Meccanica 2019, 54, 2485–2506. [Google Scholar] [CrossRef]

- Aydoğan, M.Ö.; Sarıbay, Z.B.; Özgüven, H.N. Non-Linear Dynamic Modeling and Analysis of Split-Torque Face-Gear Drive Systems. J. Vib. Acoust. 2023, 145, 031003. [Google Scholar] [CrossRef]

- Gong, F.; Zhu, R.; Li, P.; Jin, G. Analysis of load-sharing and contact characteristics of the concentric face gear split-torque transmission system with elastic supports. Appl. Sci. 2022, 12, 4894. [Google Scholar] [CrossRef]

- Gong, F.; Zhu, R.; Wang, Q. Dynamics Modeling and Load-Sharing Performance Optimization of Concentric Face Gear Split-Torque Transmission Systems. Appl. Sci. 2023, 13, 4352. [Google Scholar] [CrossRef]

- Dong, H.; Zhang, D.-b.; Cao, Z.-X.; Hu, X.-R.; Zhao, X.-l.; Liu, X.-y. Optimization design of load-sharing and light weight of the twin rotors concentric face gear power-split transmission system based on gear tooth matching condition. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2024, 238, 09544062231218785. [Google Scholar]

- Zhao, N.; Wang, R.F.; Tao, L.; Jia, Q.J. Load sharing of parallel shaft split torque transmission system. Adv. Mater. Res. 2012, 490, 2231–2235. [Google Scholar] [CrossRef]

| Parameter | Number of Teeth | Modulus | Pressure Angle | Inner Radius | Outer Radius | |

|---|---|---|---|---|---|---|

| Value | 138 | 4 mm | 25° | 255 mm | 305 mm | |

| Parameter | Axis angle | Helix angle | Number of teeth of shaper (upper) | Number of teeth of shaper (lower) | ||

| Value | 90° | 0 | 24 | 23 | ||

| Parameter | Number of Teeth | Modulus | Pressure Angle | Tooth Width |

|---|---|---|---|---|

| Value | 22 | 4 mm | 25° | 52 mm |

| Parameters | Upper/Lower Face Gears | Cylindrical Gear | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| bfu | hfu | bp | hp | faf | fae | |||||

| values | 40 | 400 | 2.5 | 40 | 200 | 2.5 | 41.25 | 8 | 41.25 | 65 |

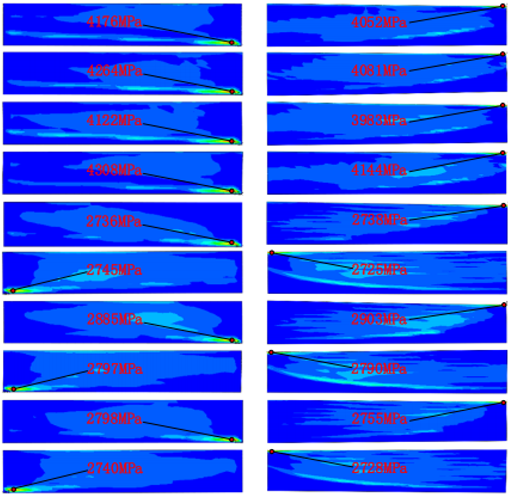

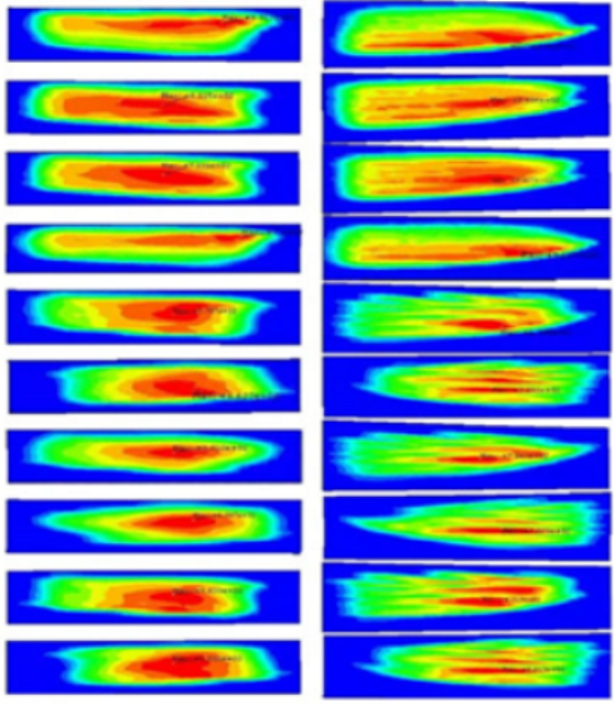

| Position | Pinion | Face Gear |

|---|---|---|

| LI-UF |  | |

| LI-BF | ||

| RI-UF | ||

| RI-BF | ||

| LIG-UF | ||

| LIG-BF | ||

| RIG-UF | ||

| RIG-BF | ||

| TG-UF | ||

| TG-BF | ||

| Parameters | Upper/Lower Face Gears | Input Gears | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ) | bfu(mm) | hfu(mm) | bp(mm) | hp(mm) | faf(mm) | fae(mm) | ||||

| Upper bound | 200 | 400 | 3.9 | 100 | 400 | 3.9 | 52 | 100 | 52 | 100 |

| Lower bound | 0 | 50 | 1.56 | 0 | 52 | 1.56 | 0 | 0 | 0 | 0 |

| Initial values | 100 | 100 | 2 | 50 | 104 | 2 | 26 | 50 | 26 | 50 |

| Components | Optimization Variables | Optimal Value |

|---|---|---|

| Upper face gears | ) | 185.19 |

| bfu (mm) | 98.39 | |

| hfu (mm) | 2.76 | |

| Lower face gears | () | 140.74 |

| bfl (mm) | 106.64 | |

| hfl (mm) | 2.64 | |

| Input gears | 65.56 | |

| bp (mm) | 105.11 | |

| hp (mm) | 2.61 | |

| faf (mm) | 11.78 | |

| 59.29 | ||

| fae (mm) | 16.86 | |

| 86.02 |

| Position | Before Optimization | After Optimization | ||

|---|---|---|---|---|

| Pinion | Face Gear | Pinion | Face Gear | |

| LI-UF |  |  | ||

| LI-BF | ||||

| RI-UF | ||||

| RI-BF | ||||

| LIG-UF | ||||

| LIG-BF | ||||

| RIG-UF | ||||

| RIG-BF | ||||

| TG-UF | ||||

| TG-BF | ||||

| Position | ΔD, mm | The Maximum Contact Stress (Face Gear), MPa | ||||

|---|---|---|---|---|---|---|

| Before Opt. | After Opt. | Decreased | Before Opt. | After Opt. | Decreased | |

| LI-UF | 2.91 | 0.34 | 88% | 997.3 | 848.4 | 14.9% |

| LI-BF | 0.94 | 0.70 | 26% | 1079.0 | 940.7 | 12.8% |

| RI-UF | 2.64 | 1.59 | 40% | 1021.2 | 921.7 | 9.7% |

| RI-BF | 1.44 | 0.61 | 58% | 885.1 | 729.3 | 17.6% |

| LIG-UF | 1.36 | 0.11 | 92% | 901.7 | 764.7 | 15.2% |

| LIG-BF | 0.40 | 1.28 | −224% | 853.2 | 707.9 | 17.0% |

| RIG-UF | 1.13 | 0.15 | 87% | 820.1 | 621.9 | 24.2% |

| RIG-BF | 0.22 | 0.70 | −218% | 796.8 | 661.3 | 17.0% |

| TG-UF | 2.06 | 1.60 | 22% | 760.0 | 633.5 | 16.6% |

| TG-BF | 0.34 | 1.19 | −255% | 758.4 | 627.1 | 17.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Z.; Tang, Z.; Zhou, Y.; Tang, W.; Tang, J.; Lu, B.; Wu, Z.; Hong, X. A Fast Integration Method of Analysis and Optimization for the Contact Performance Design of a Face Gear Split-Torque Transmission. Mathematics 2025, 13, 3519. https://doi.org/10.3390/math13213519

Yu Z, Tang Z, Zhou Y, Tang W, Tang J, Lu B, Wu Z, Hong X. A Fast Integration Method of Analysis and Optimization for the Contact Performance Design of a Face Gear Split-Torque Transmission. Mathematics. 2025; 13(21):3519. https://doi.org/10.3390/math13213519

Chicago/Turabian StyleYu, Zhen, Zhongwei Tang, Yuansheng Zhou, Weichen Tang, Jinyuan Tang, Bingquan Lu, Ziheng Wu, and Xiao Hong. 2025. "A Fast Integration Method of Analysis and Optimization for the Contact Performance Design of a Face Gear Split-Torque Transmission" Mathematics 13, no. 21: 3519. https://doi.org/10.3390/math13213519

APA StyleYu, Z., Tang, Z., Zhou, Y., Tang, W., Tang, J., Lu, B., Wu, Z., & Hong, X. (2025). A Fast Integration Method of Analysis and Optimization for the Contact Performance Design of a Face Gear Split-Torque Transmission. Mathematics, 13(21), 3519. https://doi.org/10.3390/math13213519