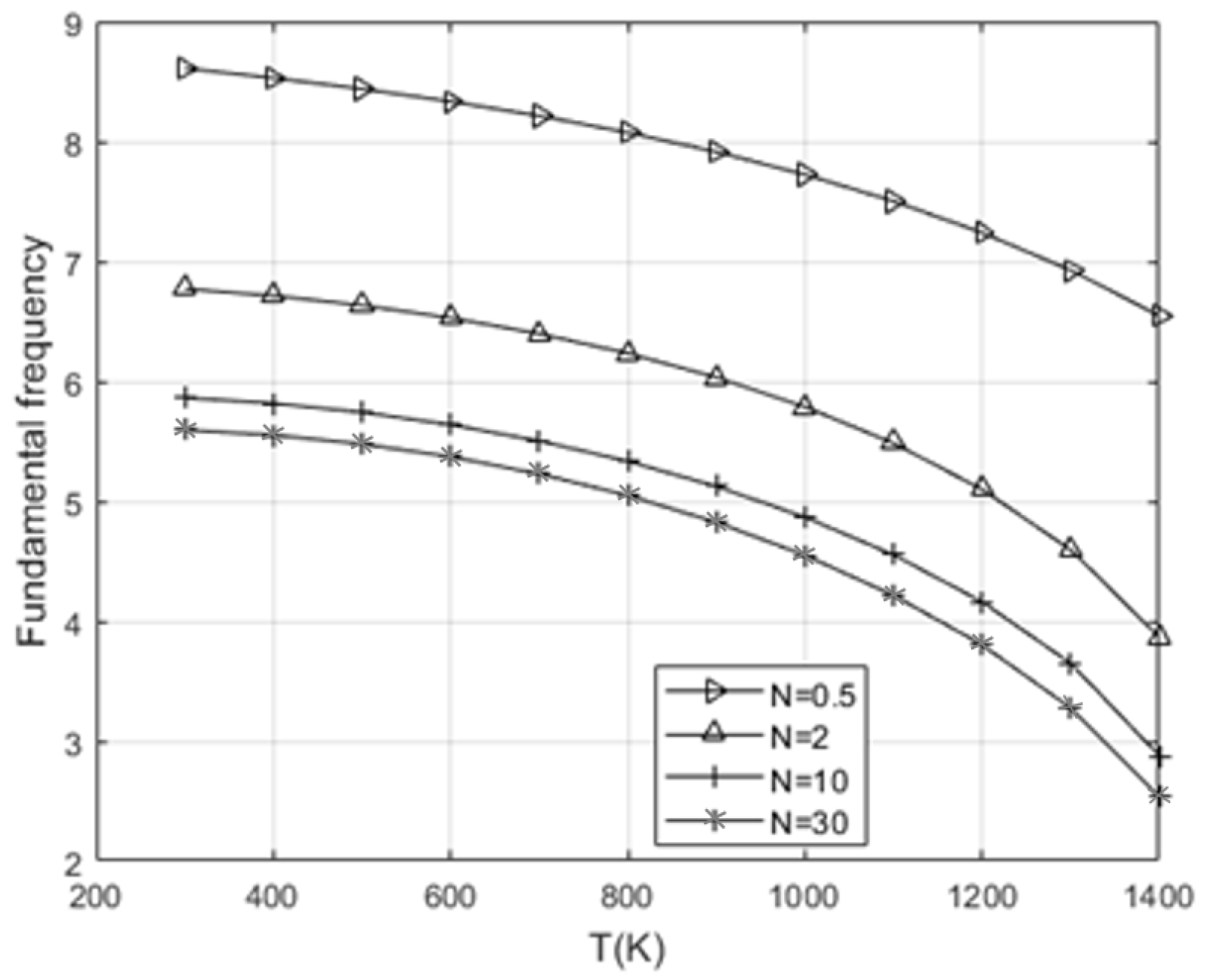

6.2. Effect of Gradient Index, Geometric Ratios, and Temperature

The systematic decrease in natural frequencies with increasing N clearly reflects the transition in material distribution from ceramic to metal composition, aligning with the known mechanical behavior of FGM structures. This confirms that the proposed shape functions not only provide accurate results but also enable physically consistent modelling of gradient effects without the need for additional correction parameters, making them well-suited for vibration analysis of composite systems.

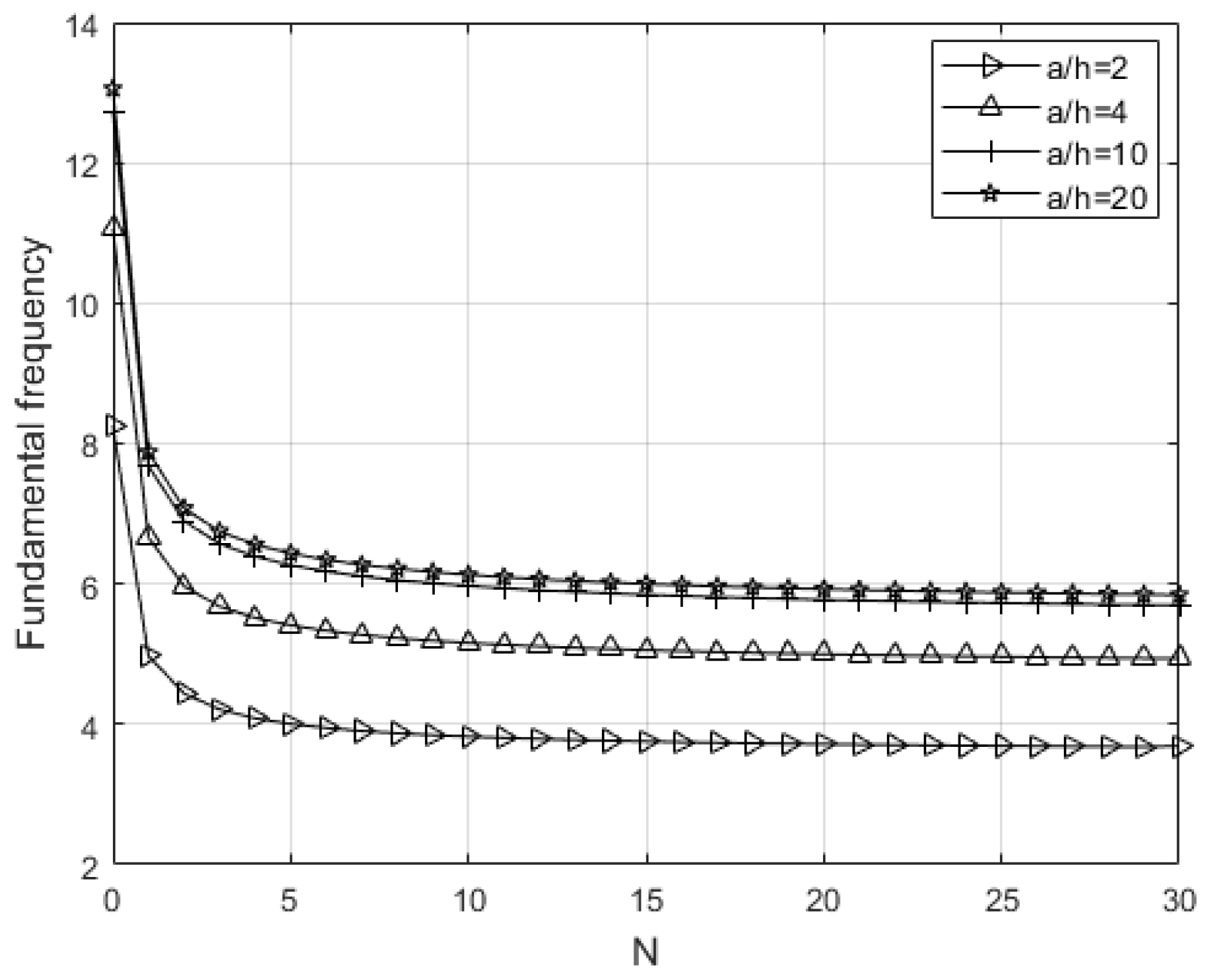

Based on the results shown in

Figure 6 and

Figure 7, a pronounced influence of temperature effects, as well as the material gradient exponent, on the fundamental nondimensional frequency of square

FGM plates is observed. An increase in temperature leads to a systematic reduction in the fundamental frequency, which is a direct consequence of the degradation of the material’s mechanical properties due to thermal softening. This effect is more pronounced for higher values of the gradient exponent

N, indicating that structures with more pronounced heterogeneity, i.e., with a higher metal content, are more susceptible to thermal loading.

On the other hand, the analysis of the frequency dependence on the gradient exponent N, which characterizes the distribution of material properties, shows an initial sharp decrease in frequency at low values of N, followed by stabilization. This saturation suggests that within a certain range of N values, the effect of the gradient on the dynamic response practically saturates, especially pronounced in thicker plates (with smaller a/h ratios).

Such behavior confirms that by proper selection of the material property distribution, the dynamic response of FGM structures under thermal loading can be effectively controlled, representing a key prerequisite for the optimization of these systems in engineering applications.

The influence of geometrical aspect ratios on the fundamental frequencies of

FGM plates is illustrated in

Figure 8 and

Figure 9. The shape function labelled Present 1 was used in the analysis.

Figure 8 shows the variation in the nondimensional fundamental frequency as a function of the

a/

h ratio at a constant temperature of

T = 300 K, for different values of the material gradient exponent

N. A clear increase in frequency is observed with increasing

a/

h ratio, which is physically expected, as a reduction in relative thickness (i.e., an increase in width aa relative to height

h) results in greater stiffness per unit mass.

However, the rate of this increase depends on the value of the parameter N, higher values of N (indicating a greater concentration of material with weaker mechanical properties in the lower region of the plate) are associated with lower values of fundamental frequency. This highlights the significant effect of material distribution on the dynamic response of the plate, further confirming the importance of incorporating functionally graded materials in engineering applications.

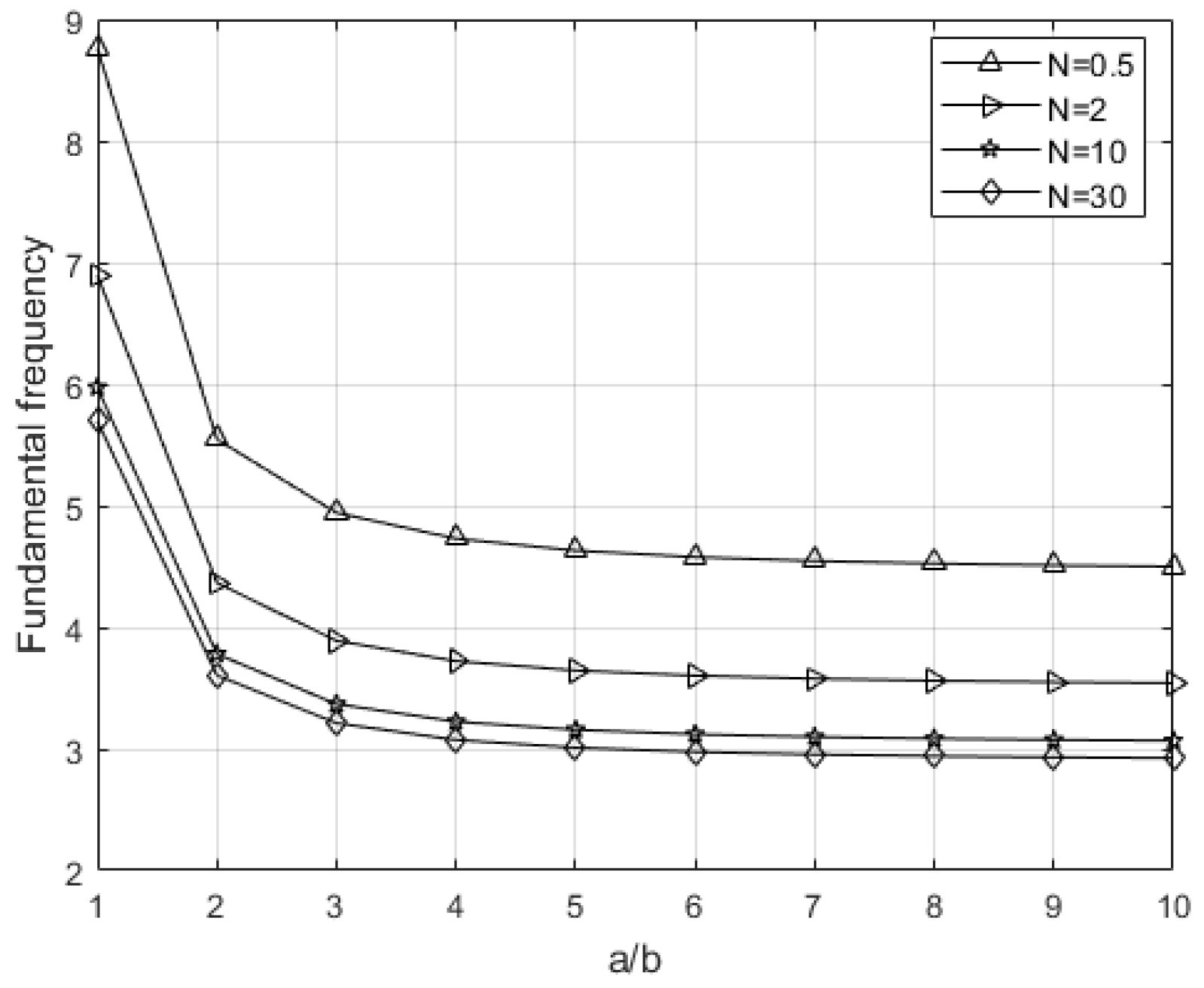

Figure 9 shows the effect of the

a/

b ratio (length-to-width ratio of the plate) on the fundamental frequencies at the same temperature and for different values of the gradient exponent

N. A significant drop in frequency is observed at low

a/

b values, followed by stabilization or saturation at higher

a/

b ratios. This phenomenon results from a shift in the plate’s mode shape, were for more elongated geometries, the dominant vibration modes transition from two-dimensional to nearly one-dimensional.

The values of the exponent N continue to exert influence, higher N values reduce the overall structural stiffness and thus lower the frequency, but this effect becomes less pronounced as the geometry approaches the saturation region.

Overall, these results confirm that both geometric parameters and the material gradient exponent are key factors defining the dynamic behavior of FGM plates. Such dependencies provide an important basis for optimizing structural design in terms of mass, stiffness, and resonant response, thereby justifying the need for accurate modelling of functional gradation in analysis and engineering design.

6.3. Effect of Elastic Foundation and Porosity Distributions

Table 4 presents the non-dimensional fundamental frequencies of an aluminium functionally graded (FGM) plate for different values of the gradient parameter

N, and four sets of Kerr-type elastic foundation parameters: (100, 0, 100), (100, 100, 100), (100, 100, 200), and (100, 200, 200). All results correspond to a geometric ratio of

a/

h = 20, which represents a typical case of a thin plate subjected to bending and shear deformations.

The objective of this analysis is to verify the numerical results obtained using the newly proposed shape functions (Present1 and Present2) by comparing them with data from the literature (Refs. [

19,

40,

48]).

In all analyzed cases, the results obtained using the Present1 and Present2 models perfectly match the values from Ref. [

19], which was used as the primary benchmark example. Deviations from the results reported in Refs. [

40,

48] are less than 0.3%, confirming the exceptional accuracy of the proposed models.

For the foundation configuration (100, 0, 100), the Present1 and Present2 results for the gradient parameter

N in the range of 0 to 5 precisely reproduce the reference values from Ref. [

19], with virtually negligible numerical error. Deviations from Refs. [

40,

48] for

N = 1 and

N = 5 are in the range of 0.002 to 0.004.

A similar level of accuracy is observed for more complex Kerr foundation configurations: for (100, 100, 100) and (100, 100, 200), the Present1 and Present2 models achieve exact agreement with Ref. [

19] up to the third decimal place, while the differences compared to Refs. [

40,

48] remain below 0.2%.

In the most demanding case, (100, 200, 200), the proposed models maintain high precision and consistency across all three references, with the maximum recorded deviation being 0.002 for N = 1.

In addition to their high accuracy, the results exhibit a consistent trend of decreasing nondimensional fundamental frequencies with increasing values of the gradient parameter N, which corresponds to a higher content of the metallic component in the FGM structure and reflects the overall reduction in system stiffness due to the lower elastic modulus of the metal. This outcome fully aligns with physical expectations and further confirms the validity of the proposed model.

The observed trends in gradient exponent, metallic content, and porosity distribution also carry important implications for engineering design. The systematic reduction in fundamental frequencies with increasing gradient exponent and metallic content highlights the need for careful control of these parameters in applications where dynamic stability is critical. At the same time, tailoring the porosity distribution provides opportunities for structural weight optimization. This allows for a compromise between mass reduction and preservation of vibration performance. The present findings therefore offer guidelines that can serve as a basis for preliminary optimization strategies in future studies.

It is important to emphasize that the shape functions in the Present1 and Present2 models are carefully constructed to satisfy physically realistic shear deformation distributions through the thickness without the need for shear correction factors. Their mathematical structure enables efficient integration into the Navier method while maintaining numerical stability under variations in substrate and material parameters.

Based on the data presented in

Table 4, it can be confidently confirmed that the proposed shape functions enable a high level of accuracy and predictability of results across a wide range of mechanical and geometrical conditions. This consistency with renowned results from the literature serves as clear evidence of the validity and scientific relevance of the proposed model in the analysis of free vibrations of FGM plates resting on elastic foundations.

Table 5 presents the fundamental dimensionless frequencies

of square

FGM solar plates resting on elastic Kerr-type foundations with parameters (50, 50, 50), (100, 100, 100), and (200, 200, 200), for various geometric ratios

a/

h = 2, 4, 10 and power-law index values

N = 0, 0.5, 2, 10. The results obtained using the newly proposed shape functions, Present1 and Present2, are compared with the reference values reported in the literature (Ref. [

19]).

The analysis indicates that the frequencies computed using the Present1 and Present2 models exhibit near-perfect agreement, yielding results that closely match the reference values with minimal deviations. Specifically, for all three Kerr foundation configurations and all examined geometric ratios, the Present models consistently reproduce the reference frequencies for N = 0, thereby confirming the accurate implementation of the initial boundary conditions.

As the parameter N increases, representing a higher proportion of the metallic phase within the FGM structure, a clear trend of decreasing fundamental frequencies is observed. This behavior is attributed to the reduction in overall stiffness due to the lower elastic modulus of the metallic component. This trend is evident across all investigated cases, and the results from the Present models follow it with a high degree of accuracy.

More specifically, for

a/

h = 2, the differences between the Present models and Ref. [

19] are negligible, particularly for higher values of

N, where the deviations are on the order of 10

−3. For larger geometric ratios,

a/

h = 4 and

a/

h = 10, the agreement remains exceptionally high, with differences that are virtually imperceptible and do not exceed a few thousandths. This indicates the stability and robustness of the proposed shape functions across different deformation regimes and foundation configurations.

Furthermore, the Present1 and Present2 models produce practically identical results, which further confirms the consistency and reliability of their mathematical formulations. Such alignment demonstrates the successful integration of the shape functions into the numerical methods used for analyzing the free vibration behavior of FGM plates resting on elastic foundations.

In conclusion, based on the results presented in

Table 5, it can be affirmed that the proposed Present1 and Present2 models offer a high level of accuracy and reliability in predicting the fundamental frequencies of FGM plates with varying Kerr foundation parameters and geometric ratios. This analysis further strengthens confidence in the applicability of these shape functions for comprehensive dynamic analyses of functionally graded materials.

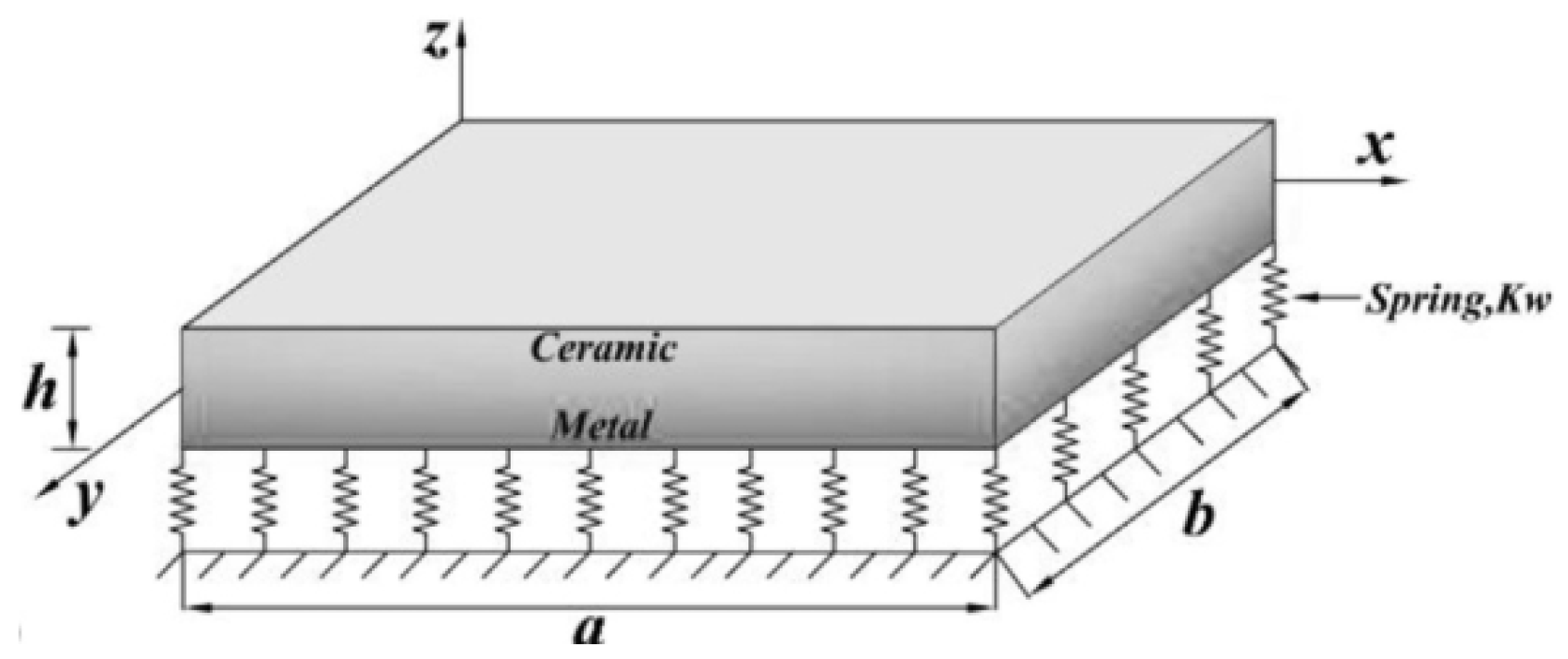

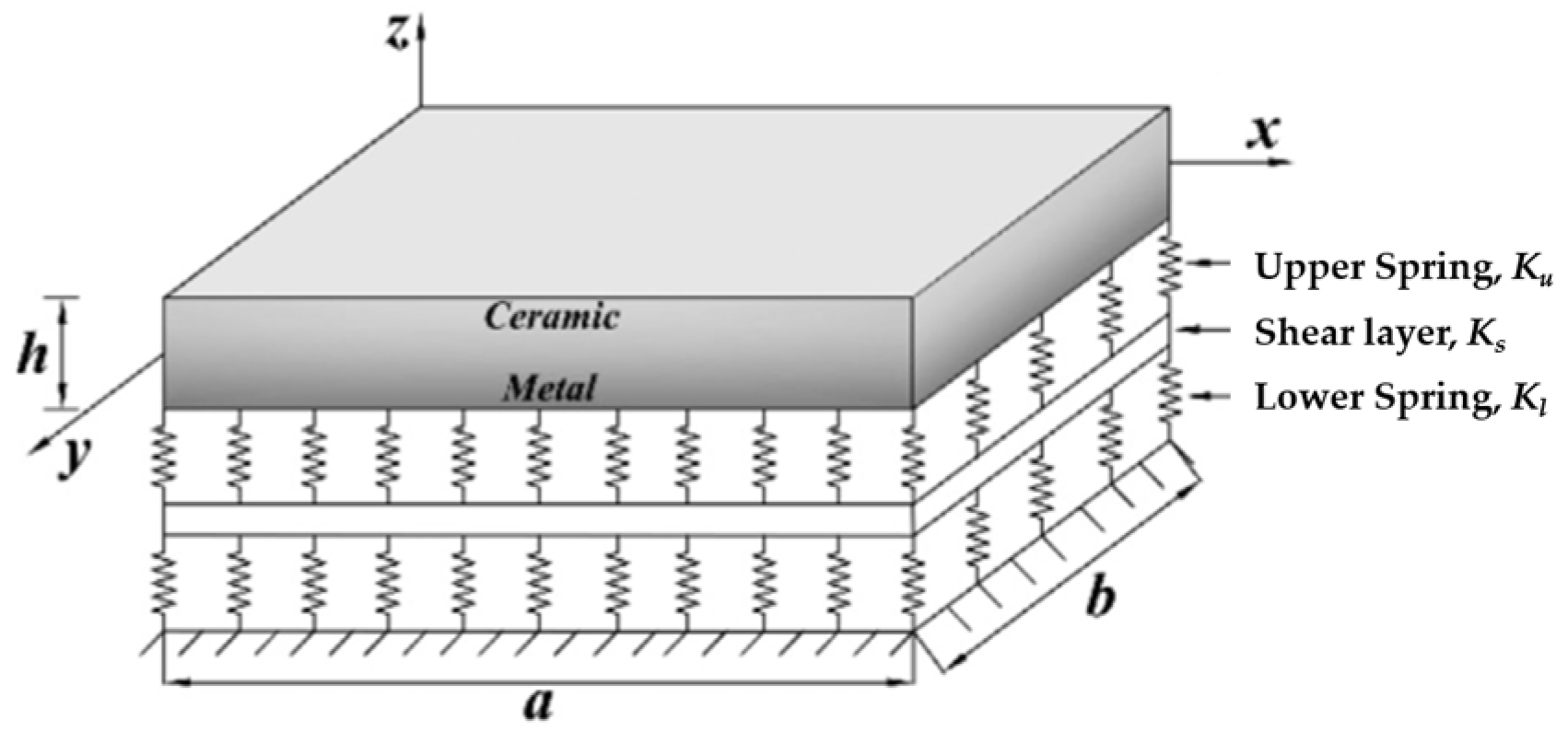

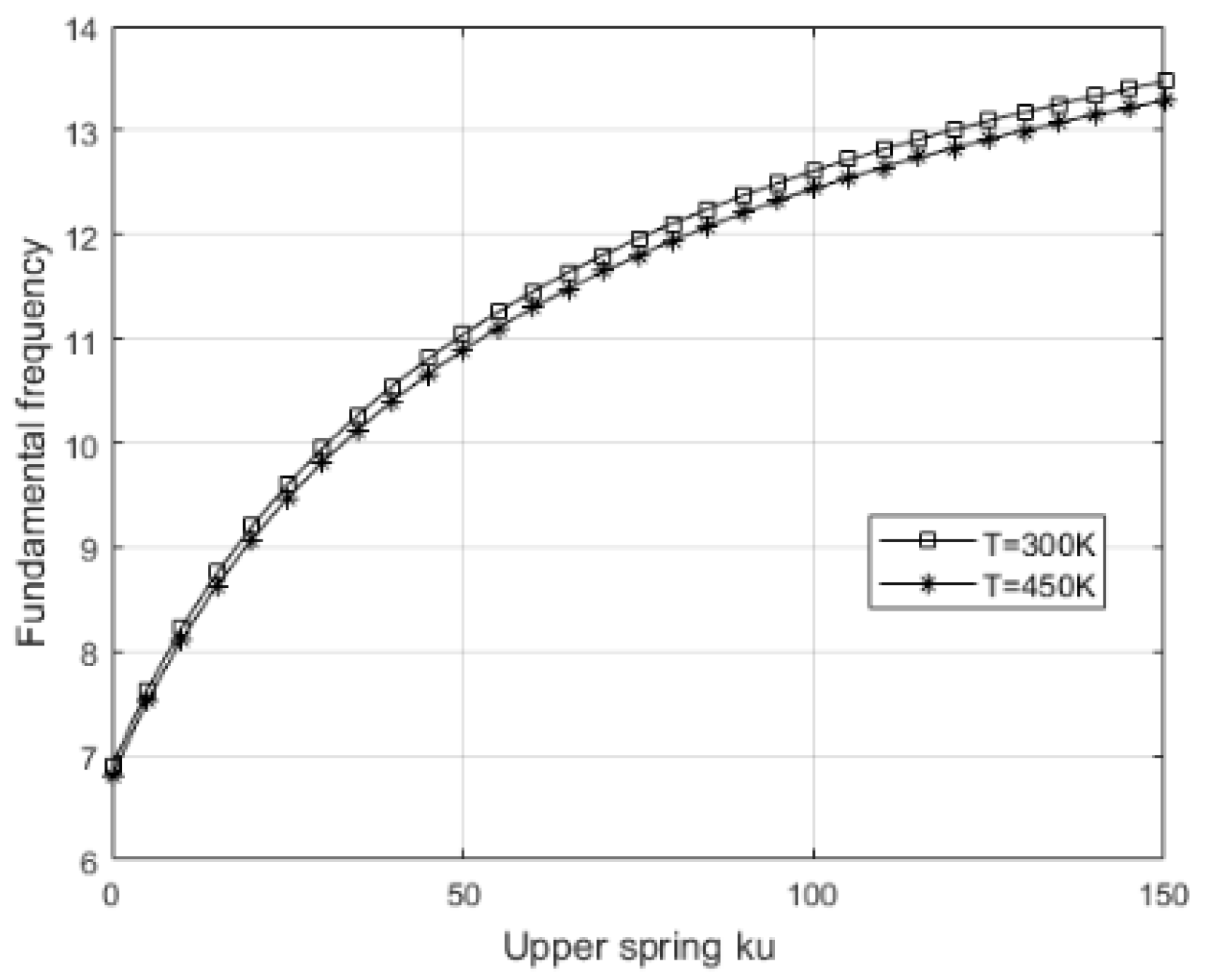

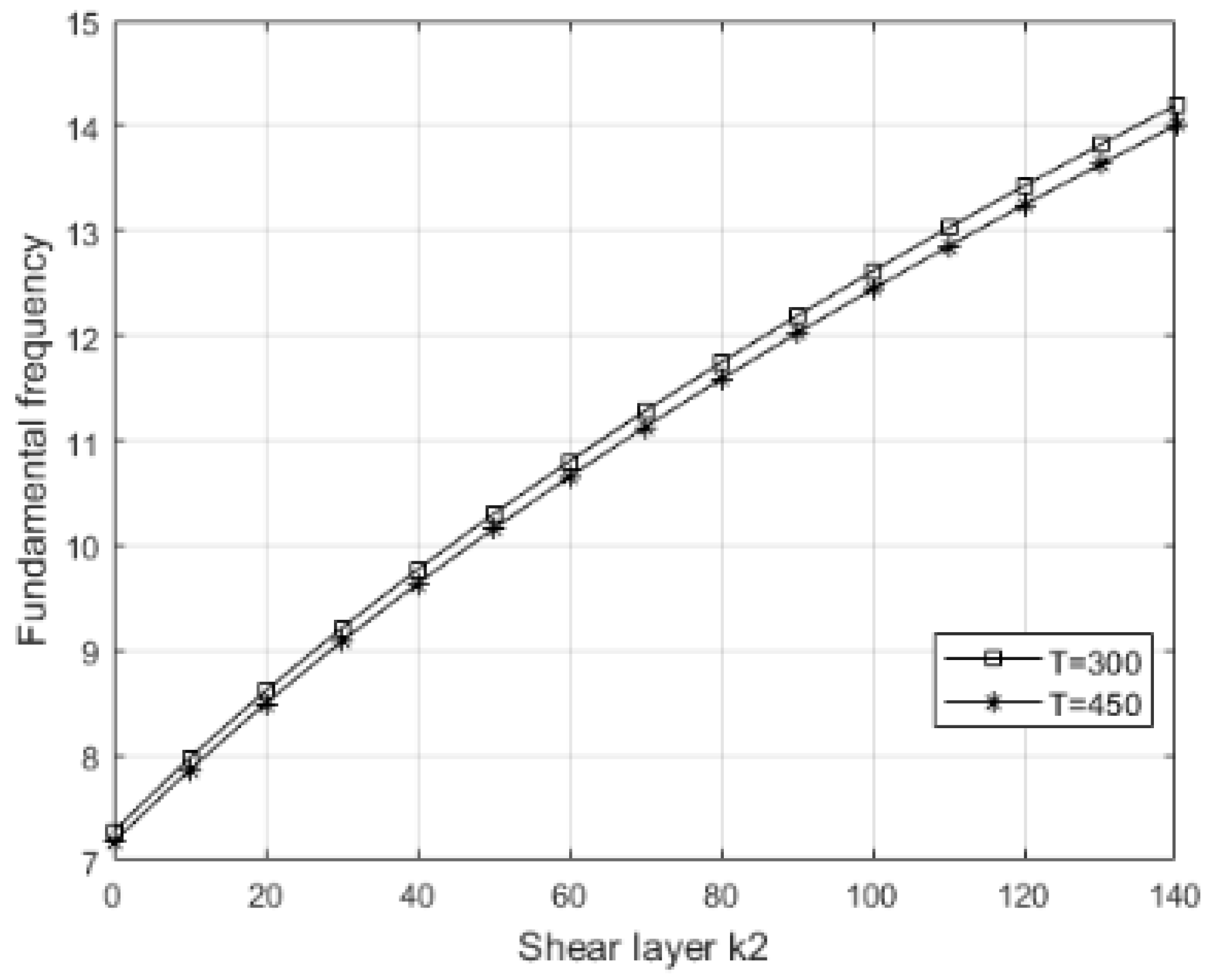

The study of the influence of the elastic foundation modelled according to the Kerr approach reveals a pronounced dependence of the fundamental nondimensional frequency

on the individual foundation components: the upper spring stiffness

ku, the lower spring stiffness

kl, and the shear layer stiffness

ks. An increase in

ku (

Figure 10) results in a systematic rise in

, which can be attributed to the additional support provided in the upper zone of the plate. This component acts as an active constraint against bending, increasing the effective flexural stiffness and reducing amplitudes in the fundamental vibration mode. Such behavior highlights the importance of introducing vertical reactive forces at the surface layer of the foundation, especially in thin FGM plates with a pronounced gradient in material properties.

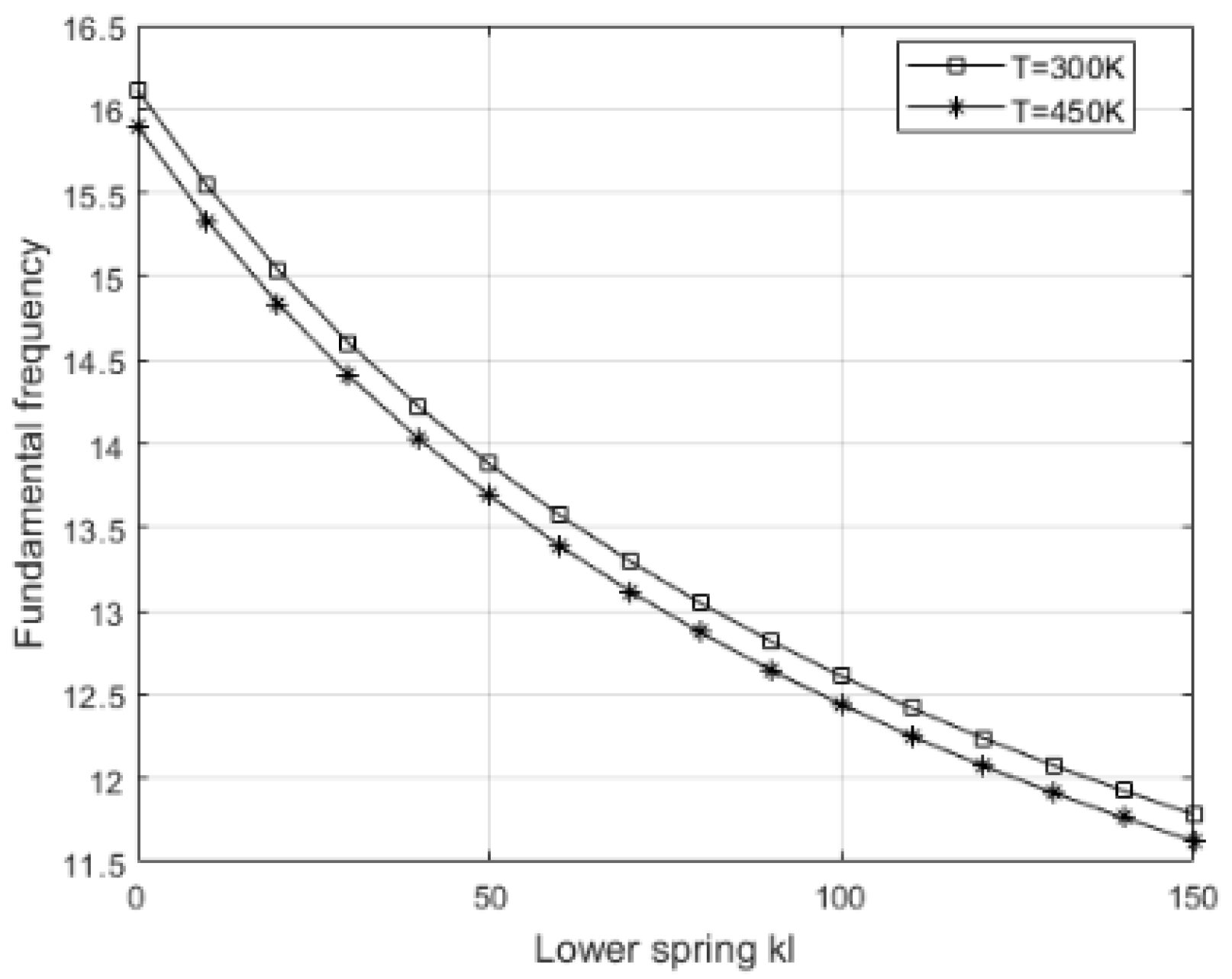

In contrast, an increase in

kl (

Figure 11) leads to a reduction in

, indicating a redistribution of deformations and energy dissipation in the lower zone. Rather than enhancing stability, a high lower spring stiffness creates localized system behavior and limits the efficient transfer of energy, thereby reducing the global dynamic stiffness. This result reveals the delicate balance between support and deformability, where the lower layer may exert a destabilizing effect if not properly coordinated with the rest of the system.

Finally, an increase in

ks (

Figure 12) consistently has a positive effect on

, underscoring the importance of shear rigidity in limiting relative displacements between layers. This parameter further homogenizes the dynamic response of the system, particularly in the presence of thermal variations and material gradation. Comparative analysis shows that

ku is the most effective in increasing frequency,

kl can be potentially counterproductive, while

ks acts as a stabilizing factor across a wide range of configurations.

These findings emphasize the need for an integrated design approach to elastic foundations in FGM structures, where the optimization of individual parameters must be aligned with the goals of vibration control and mechanical stability.

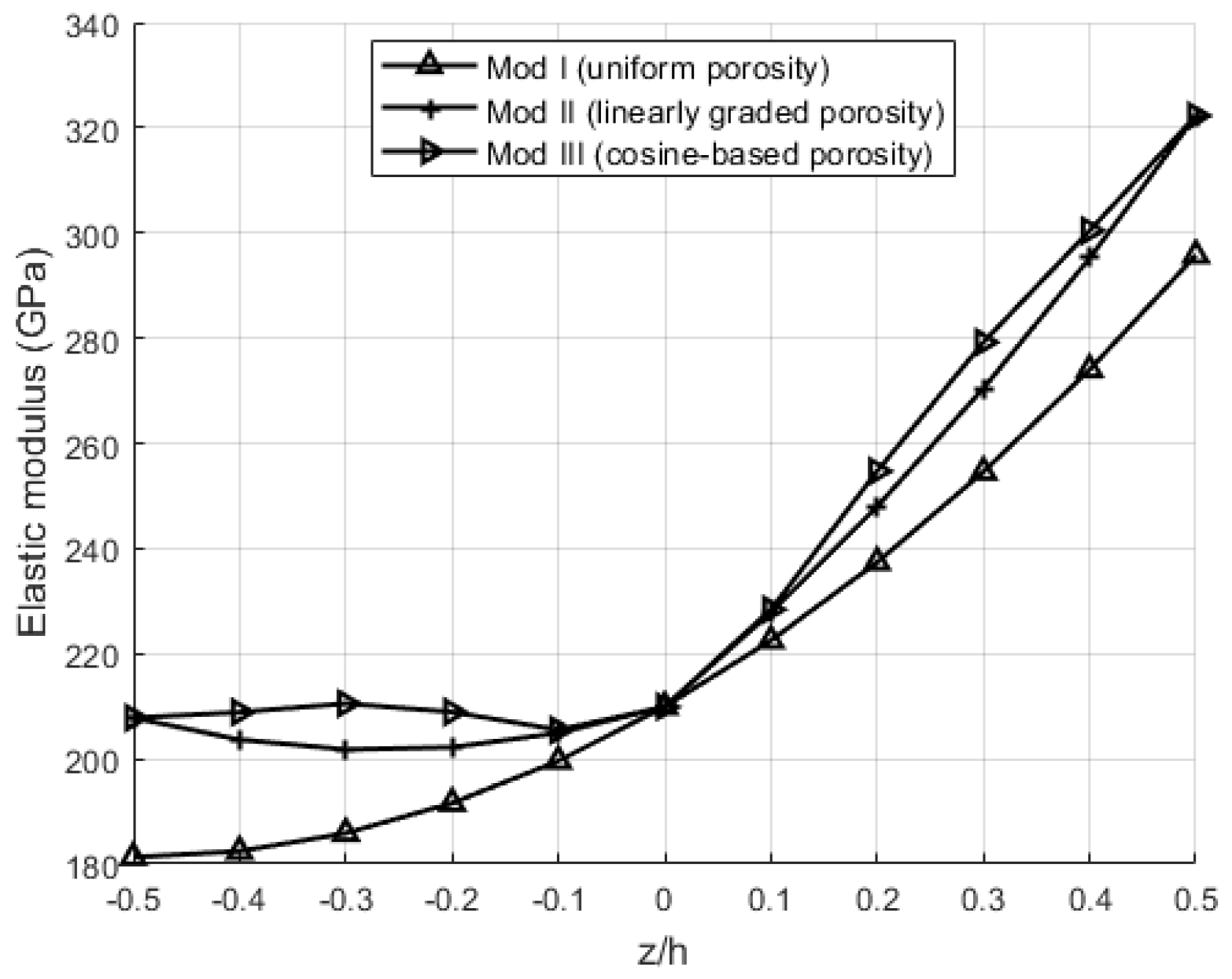

Table 6 presents the influence of different porosity distributions (Types I, II, and III), the porosity coefficient

β, and the material gradient exponent

N on the dimensionless fundamental frequencies

of a square FGM plate with a side-to-thickness ratio

a/

h = 5, evaluated at room temperature (Δ

T = 0 K). Special emphasis is placed on comparing the reference results from the literature [

19] with those obtained using the newly proposed porosity functions Present1 and Present 2.

By introducing these new functions, a quantitatively almost identical response is achieved compared to the reference models for all parameter combinations, with frequency deviations ranging from 10−4 to 10−2. This consistency confirms the accuracy and reliability of the new models, along with the added flexibility and improved numerical stability they offer for subsequent implementation in higher-dimensional simulations.

The contribution of the Present1 and Present2 shape functions is primarily reflected in their ability to accurately approximate complex porosity distributions with minimal error, making them suitable for application in nonlinear analyses and optimization tasks, where traditional models often exhibit limitations.

An analysis of the results clearly shows that an increase in the porosity parameter β leads to a reduction in the fundamental frequencies for all porosity distribution types, which can be attributed to the decrease in the material’s effective stiffness due to increased porosity. Conversely, increasing the material gradient exponent N results in a continuous decline in frequencies, because of the redistribution of mass and elastic modulus across the plate thickness.

It is noteworthy that Present1 and Present2 yield virtually identical values in most cases, indicating the numerical consistency of both formulations. The minor deviations observed at higher values of β, and N further confirm the robustness of the proposed models under more demanding engineering conditions.

In conclusion, the proposed porosity models represent a valid alternative to existing approaches, exhibiting extremely small deviations and strong potential for improving analytical and numerical models in engineering applications involving functionally graded materials with porous structures.

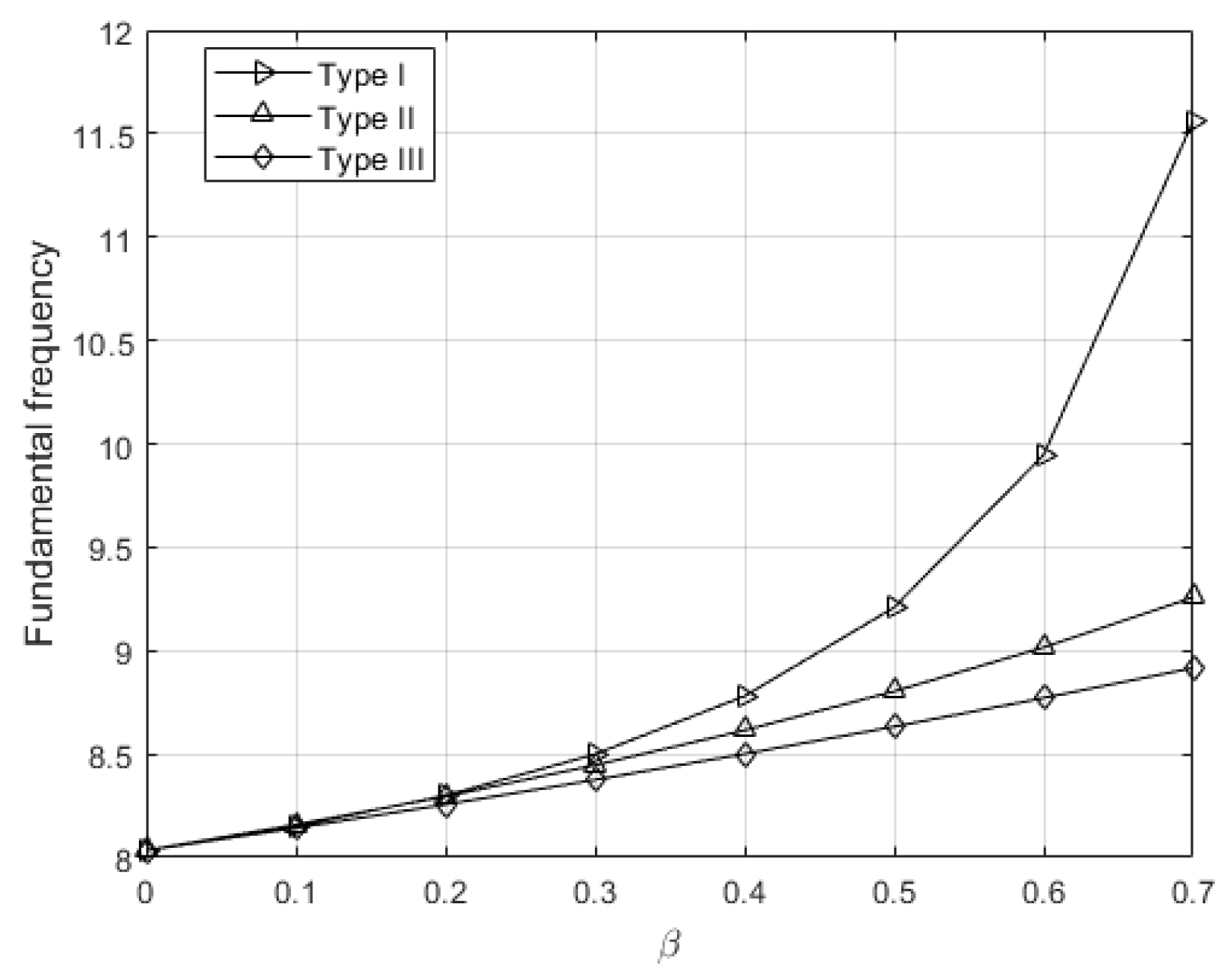

The influence of the porosity volume fraction

β and porosity distribution on the fundamental dimensionless natural frequency of a square FGM plate is presented in

Figure 13, while

Figure 14 illustrates the effect of the gradient exponent

N for different porosity distributions.

In

Figure 13, the dependence of the frequency ω on the porosity

β is analyzed at a fixed

N = 0.5. Three different functional porosity distributions are considered: uniform (Type I), linear (Type II), and trigonometric (Type III). The results show that an increase in

β leads to a rise in the natural frequency for all distributions, with the most pronounced effect observed in the Type III distribution.

This behavior can be explained by the fact that the trigonometric distribution concentrates a larger amount of the solid (ceramic) component near the plate surfaces, contributing to greater bending stiffness. The increase in despite higher porosity is a result of the nonuniform distribution of stiff and porous zones, where the effective mass decreases while stiffness is maintained or even locally enhanced in critical bending regions. It should be emphasized, however, that this trend is not universal; for different porosity models or boundary conditions, stiffness degradation may dominate over mass reduction, leading to decreasing frequencies with increasing β.

Figure 14 shows the dependence of ω on the gradient exponent

N at a constant porosity

β = 0.2. An increase in frequency is observed with the rise in

N, which is explained by the greater presence of the ceramic component in the upper region of the plate as

N increases. However, at higher values of

N (e.g.,

N > 1.2), the curves reach a plateau, indicating saturation of the effect of mass and stiffness redistribution. The trigonometric distribution (Type III) consistently results in the highest frequency values across the entire range of

N, confirming its efficiency in localizing stiffness in regions of dominant deformation. In contrast, uniform porosity (Type I) produces the lowest ω values because the evenly distributed porosity degrades stiffness throughout the plate thickness without local optimization of bending resistance.

Overall, the results show that besides the porosity value β itself, the distribution of the porous material has a dominant influence on the dynamic behavior. An appropriate distribution (especially Type III), combined with a higher exponent N, enables achieving an optimal balance between mass reduction and increased dynamic stability. These findings can directly contribute to the development of FGM structures with improved vibration performance in high-precision engineering applications.

Table 7 clearly demonstrates the high level of accuracy of the proposed shape functions Present1 and Present2 within the HSDT formulation. The obtained non-dimensional frequencies for higher modes show an almost perfect agreement with the reference 3D exact solutions and existing HSDT models, with deviations consistently below 0.3% and practically negligible.

Importantly, both functions yield identical results, confirming their numerical stability and robustness. Compared to classical HSDT approaches, the Present functions provide an accurate description of transverse shear deformation without the need for additional correction factors, while retaining a simple expression structure. This makes them well-suited for further analytical and numerical applications.

Their use is therefore not only justified but also highly desirable, as they enhance the accuracy of the model without increasing computational complexity.

Table 8 presents the non-dimensional fundamental frequencies of a square FGM plate for various values of the material distribution parameter

N. The results obtained using the shape functions Present1 and Present2 show complete agreement. For all analyzed values of

N, these results closely match the existing HSDT models available in the literature.

A stable performance of the proposed functions is observed with increasing nonlinearity in the material gradient, which becomes especially evident at higher values of N, where the ceramic component is more significantly concentrated toward the surfaces. The deviation from the FSDT model increases with rising N, indicating the limitations of simplified theories in capturing the more complex transverse response. In contrast, the results based on the Present functions remain within expected bounds when compared with higher-order theories.

This consistency suggests that the proposed shape functions enable an accurate representation of the influence of variable material property distributions within the analytical model.

Table 9 presents the influence of different porosity distributions on the non-dimensional fundamental frequencies of an FGM plate, considering three values of the power-law exponent

N and three levels of total porosity, represented by the parameter

β. The results across all porosity types (Type I—uniform, Type II—linear, and Type III—cosine) demonstrate that the Present1 and Present2 shape functions yield solutions in full agreement with the reference values, maintaining consistency regardless of porosity level or distribution profile.

Notably, with increasing β, the frequency values for Type I distribution exhibit a more pronounced decline compared to Type II and Type III, indicating a higher sensitivity of uniform porosity to reductions in the system’s mechanical stiffness. In the domain of higher N values, where the ceramic component is more concentrated near the surface, the distinctions between the porosity types become more significant.

The presence of more complex porosity distributions (Type II and Type III) is clearly reflected in the frequency behavior due to the mass and stiffness redistribution, with the Present functions accurately capturing these effects. This confirms the validated applicability of the proposed model even in scenarios where porosity effects are nonlinearly distributed through the plate thickness.

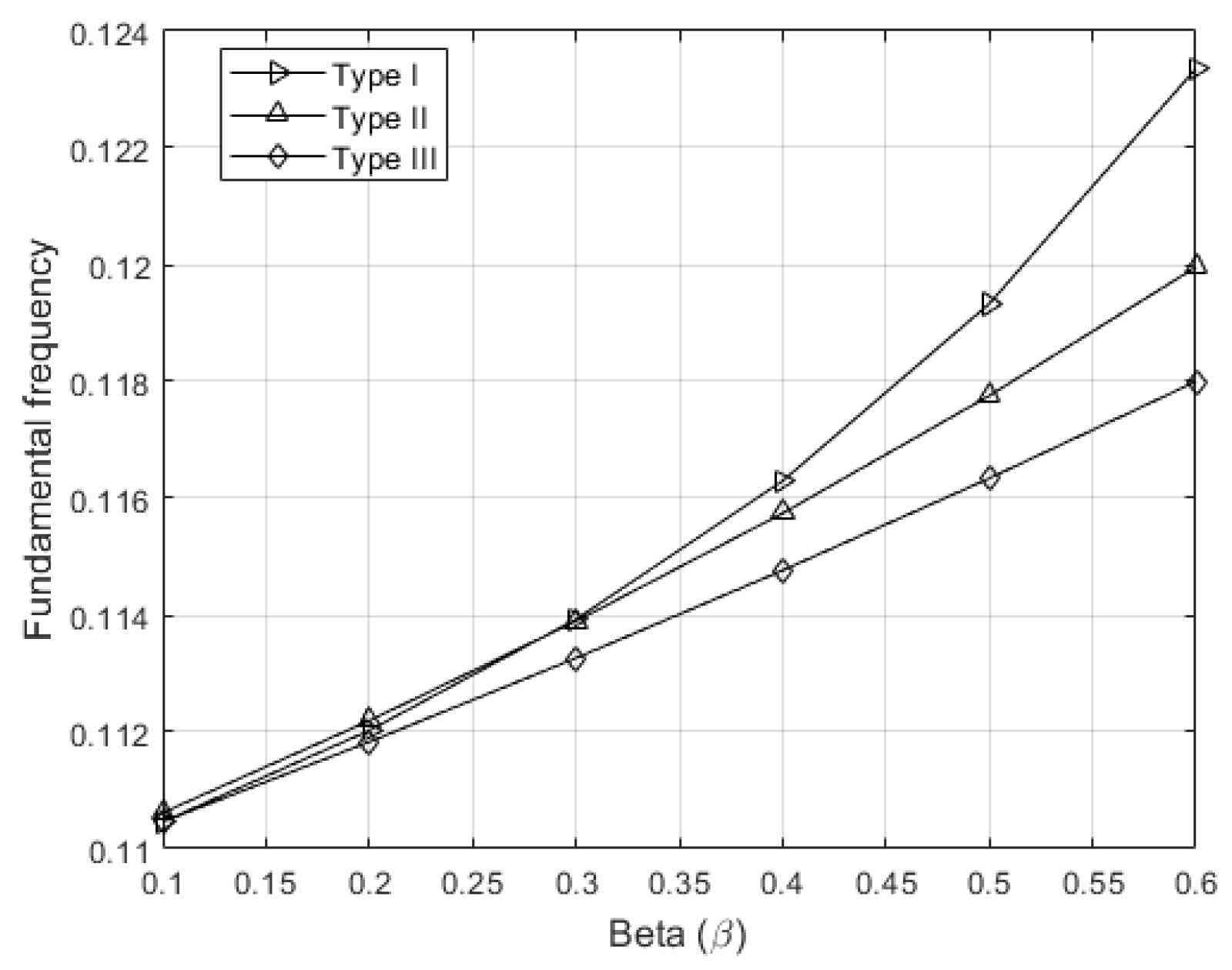

Figure 15 illustrates the dependence of the non-dimensional fundamental frequency on the porosity volume fraction

β for three different porosity distributions (Type I, II, and III), at a constant aspect ratio of

a/

h = 10 and a fixed power-law index of

N = 0.1. The diagram clearly confirms that the frequency increases with rising β for all distribution types, which is a direct consequence of the reduction in effective material mass due to porosity, while the stiffness remains the dominant factor. The differences among the distributions become more pronounced at higher

β values, with Type II and Type III showing higher frequencies compared to Type I, implying a more favorable pore arrangement in terms of dynamic response. This behavior should be interpreted in the context of the present modeling assumptions; under different porosity patterns or boundary conditions, the reduction in stiffness may become more dominant, in which case the natural frequencies could decrease with increasing β.

This diagram not only validates the mechanical sensitivity of FGM plates to the porosity distribution profile but also highlights the potential for design optimization through controlled pore allocation, thereby enabling the development of structures with tailored dynamic characteristics.

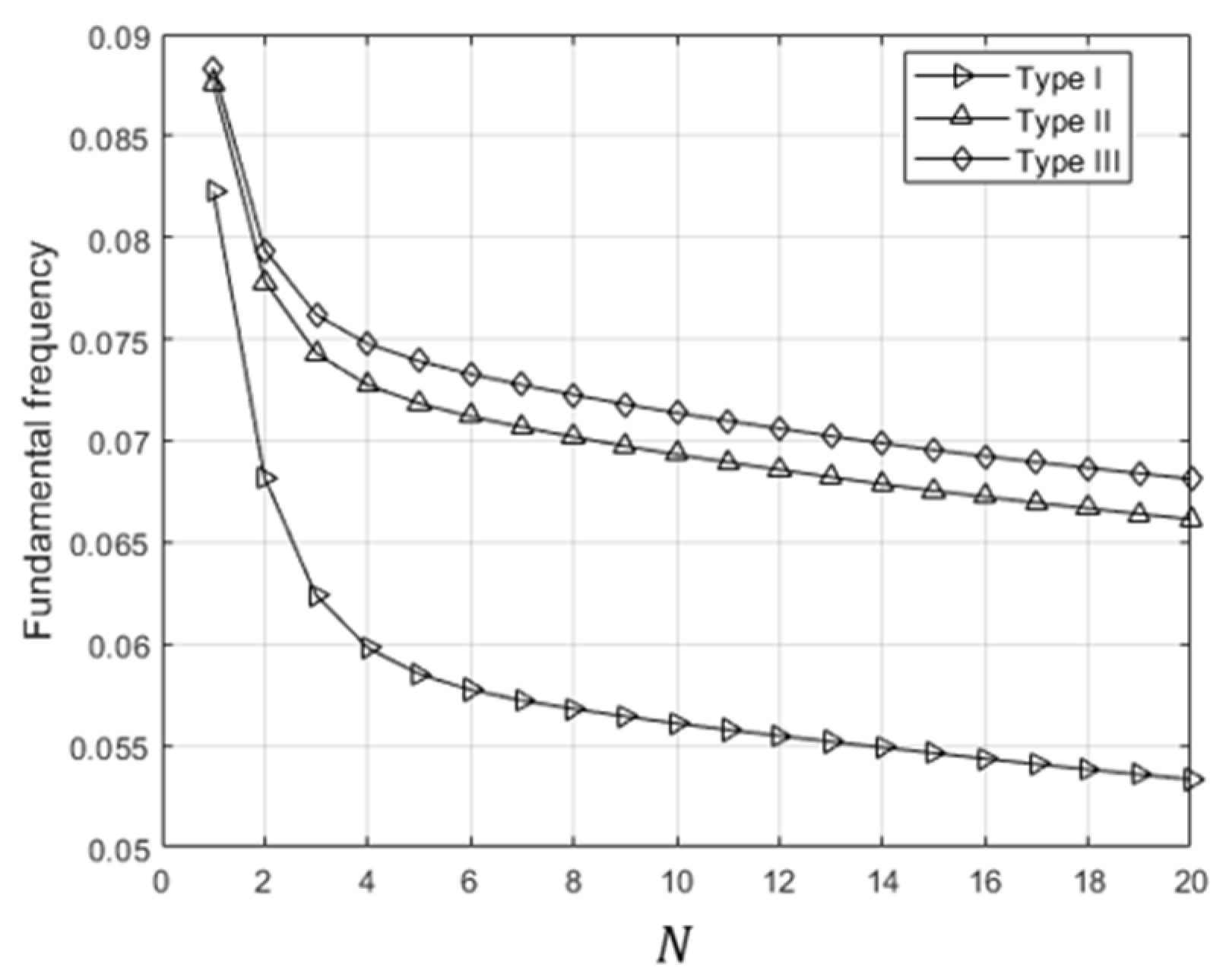

Figure 16 analyses the influence of the power-law index

N on the fundamental frequency under a fixed porosity volume fraction of

β = 0.2. For all porosity types, a distinct nonlinear decrease in frequency is observed as the material transitions from a homogeneous to a highly graded distribution (from low to high

N values), which gradually stabilizes beyond

N > 10. This effect can be attributed to the redistribution of mass and stiffness within the FGM plate: higher

N values lead to a dominant metallic phase (

Al) toward the mid-thickness, reducing overall stiffness and thus lowering the resonant frequency.

Type III distribution exhibits slightly elevated frequency values across the entire N range, indicating that a specific porosity profile can mitigate the adverse effect of stiffness degradation at high gradient levels. The diagram provides a quantitative insight into the interrelationship between material gradient index and porosity distribution, which is of critical importance for the design of advanced FGM systems subjected to dynamic loading.

The bar chart shown in

Figure 17 illustrates the influence of different porosity distributions (Type I, II, and III) on the non-dimensional fundamental frequency of a functionally graded

Al-

Al2O3 plate, for a fixed aspect ratio of

a/

h = 10, a constant porosity volume fraction

β = 0.4, and three characteristic material gradient indices (

N = 0.1, 0.5, 1). It is clear that an increase in the gradient parameter

N, which models a progressive transition from the ceramic to the metallic component through the thickness of the plate, leads to a systematic decrease in the natural frequency for all porosity distribution types.

The most significant frequency reduction is observed for Type I distribution, suggesting that a uniform distribution of porous defects through the thickness further amplifies the degradation of the effective stiffness as the metallic phase becomes more dominant. In contrast, Type II and especially Type III distributions, which introduce linear and trigonometric non-uniformity in the porosity profile, respectively, demonstrate a more stable frequency response with changes in N. Type III exhibits the smallest frequency reduction gradient with increasing N, indicating potentially more favorable mechanical performance in terms of vibrational stability. This behavior can be attributed to the redistribution of mass and stiffness that mitigates localized zones of reduced rigidity.

Such analysis provides both quantitative and qualitative insight into the complex interdependence between porosity distribution, material gradient profile, and vibrational characteristics of FGM structures. Consequently, it can serve as a foundation for design optimization in engineering applications where dynamic performance is of critical importance.

The present study has been restricted to linear free vibration analysis, which is appropriate for small amplitude oscillations where linear kinematics provide accurate predictions. However, in applications involving large deflections, high mechanical loads, or severe thermal environments, nonlinear effects such as geometric nonlinearity and material plasticity may become significant. A systematic extension of the present formulation to nonlinear vibration analysis, including amplitude-dependent frequency shifts and stability considerations, represents a natural direction for future research.

_Constantinou_Generalis.png)