Optimization Method for Reliability–Redundancy Allocation Problem in Large Hybrid Binary Systems

Abstract

1. Introduction

- where the solution directly or indirectly reflects component reliability for each subsystem;

- () where the solution concerns the number of components for each subsystem;

- where the decision variables reflect both component reliability and the level of redundancy for each subsystem.

- The number of subsystems () as a measure of system complexity;

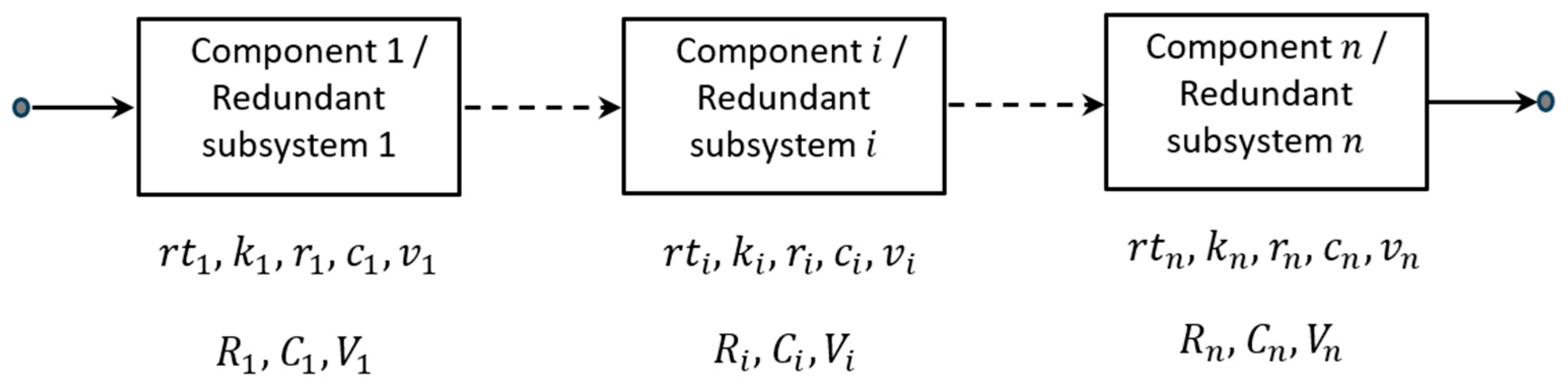

2. Problem Description

- (a)

- Maximizing system reliability under cost and volume constraints;

- (b)

- Achieving the required reliability at the lowest possible cost and possibly under volume constraints.

| Algorithm 1: The computation of the reliability of a subsystem with direct reliability allocation steps. |

for do ∟ |

| Algorithm 2: The computation of the cost of a subsystem with direct reliability allocation steps (alternative 2). |

for do ∟ |

3. Types of Redundancy

- Active redundancy ;

- Passive redundancy (or cold standby redundancy) ;

- Hybrid standby redundancy with a hot spare or a warm one;

- and possibly other CSCs;

- Hybrid redundancy consisting of a TMR structure with control facilities and possibly other CSCs

- Static redundancy structure implementing an out of majority logic: TMR or 5MR

- Reconfigurable TMR/Simplex structure with possibly other CSCs .

3.1. Active Redundancy ()

3.2. Passive Redundancy ()

3.3. Hybrid Standby Redundancy with a Hot () Spare and Possibly Other CSCs

3.4. TMR Structure with Control Facilities and Optionally Other CSCs ()

- Case 1. TMR structure without standby redundancy

- Case 2. TMR structure and one CSC

- Case 3. TMR structure and two CSCs

3.5. Static Redundancy: TMR or 5MR ()

- Case 1. TMR structure

- Case 2. 5MR structure

3.6. TMR/Simplex and Optionally Other CSCs ()

- Case 1. TMR/Simplex without standby redundancy

- Case 2. TMR/Simplex with one CSC

- Case 3. TMR/Simplex with two CSCs

4. Related Work

5. The Optimization Approach

Examples

+ 5 · x7 + 10 · x8 + 15 · x9 ≤ 30

x4 + x5 + x6 = 1

x7 + x8 + x9 = 1

+ 5 · x7 + 10 · x8 + 15 · x9 + 8 · x10 + 15 · x11 + 23 · x12

+ 5 · x13 + 10 · x14 + 15 · x15 + 8 · x16 + 15 · x17 + 23 · x18 ≤ 30

+ 1 · x7 + 2 · x8 + 3 · x9 + 1 · x10 + 3 · x11 + 3 · x12

+ 1 · x13 + 2 · x14 + 3 · x15 + 1 · x16 + 2 · x17 + 3 · x18 ≤ 5

x7 + x8 + x9 + x10 + x11 + x12 = 1

x13 + x14 + x15 + x16 + x17 + x18 = 1

6. Experimental Results

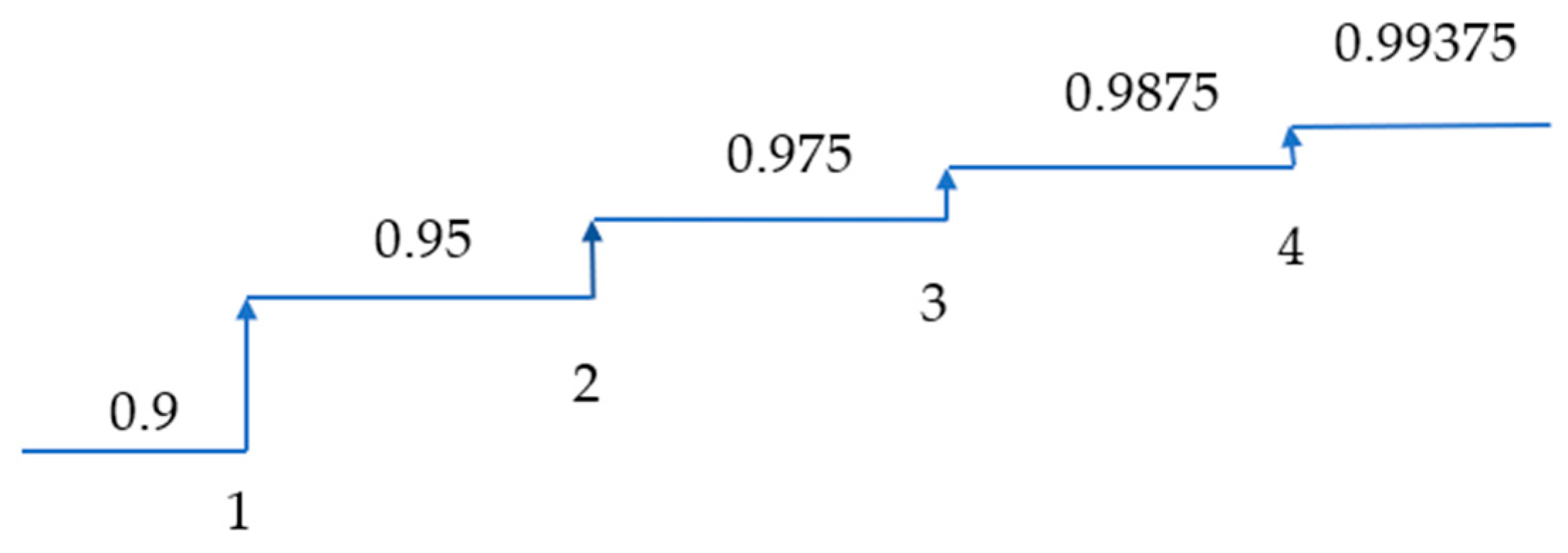

6.1. Example of an RRAP Optimization Problem

6.2. Discussion

7. Conclusions

8. Assumptions

| A1. In any redundant system, the spare components are considered identical to the basic ones; with this assumption, the assessment of subsystem reliability is simplified, but the optimization problem remains as complex. |

| A2. For the components in operating mode and for the spares kept in warm conditions, the random variable expressing the time to failure has a negative-exponential distribution law—a widely accepted assumption in the study of the reliability of electronic systems and necessary for the use of Markov chains in the assessment of the reliability of reconfigurable redundant structures. |

| A3. Faults occurring in the system are independent events, not correlated in any way with one another. |

| A4. When increasing the reliability of a component by direct allocation, the volume does not change. |

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Reliability | The probability that a component or system in initial good operating condition will operate successfully within a given period of time |

| A system in which only two states are considered for each component, normal operating or failed—the state of a component can thus be described by a logic variable | |

| A system in which for a complete description, for some components, the state of failure must be detailed/refined, thus resulting in several states | |

| A reliability model that reflects a system with a redundant structure, composed of several subsystems in which some may be non-redundant and others redundant, possibly provided with other spare components kept in a passive state | |

| TMR | Triple-modular redundancy structure implementing 2 out of 3 majority logic |

| TMR/Simplex | Reconfigurable redundant structure that includes an initial TMR arrangement and then, when one component fails, continues operation with one of the two remaining functional components |

| 5MR | structure implementing 3 out of 5 majority logic |

Notations

| The number of components in the non-redundant system or the number of subsystems in the redundant system, as appropriate | |

| The given time period for which reliability is assessed (system mission time) | |

| The initial reliability of a component of type for the given period of time | |

| The initial cost of a component of type | |

| Number of steps to improve/increase reliability by direct allocation for a component of type ; | |

| Cost increase factor for a direct reliability allocation step for a component of type ; | |

| The additional cost for a reliability improvement/enhancement step by direct allocation to a component of type | |

| The current reliability of a component of type after reliability enhancement steps | |

| The current cost of a component of type after reliability enhancement steps | |

| The volume of a component of type ; | |

| The failure rate of a component of type | |

| Redundancy type for subsystem | |

| The number of components allocated to subsystem ; | |

| The reliability of subsystem | |

| The cost of subsystem | |

| The volume of subsystem | |

| Reduction coefficient (load factor) used to express the failure rate for a warm-spare component compared to the failure rate of the component in operation (active component) | |

| A factor used to express the failure rate of the voter in a structure based on the failure rate of the basic components | |

| A factor used to express the failure rate of the voter in a 5MR structure based on the failure rate of the basic components | |

| A factor used to express the failure rate of the decision, control and reconfiguration logic of a TMR/Simplex structure based on the failure rate of the basic components | |

| The non-redundant system reliability (system with series reliability model) | |

| The non-redundant system cost | |

| The non-redundant system volume | |

| The redundant system reliability (system with series-redundant reliability model) | |

| The redundant system cost | |

| The redundant system volume | |

| The level of reliability required for the system | |

| The maximum budget allowed for the system (upper limit of cost) | |

| The maximum volume accepted for the system (upper limit of volume) | |

| The maximum number of components allocated to a subsystem | |

| The maximum number of steps to increase the reliability of a component by direct reliability allocation | |

| A component in operation (an active component) | |

| A warm-maintained spare component | |

| A cold-maintained spare component | |

| : For notations to , when the subsystem is not indicated, the index is not necessary; therefore, the notations used are , , and so on. | |

References

- Patil, R.B.; Kyeong, S.; Pecht, M.; Gujar, R.A.; Mane, S. Assessment of Reliability Allocation Methods for Electronic Systems: A Systematic and Bibliometric Analysis. Stats 2025, 8, 11. [Google Scholar] [CrossRef]

- Devi, S.; Garg, H.; Garg, D. A review of redundancy allocation problem for two decades: Bibliometrics and future directions. Artif. Intell. Rev. 2023, 56, 7457–7548. [Google Scholar] [CrossRef]

- Ashraf, Z.; Shahid, M.; Ahamd, F.; Sajid, M.; Kotecha, K.; Patil, S. A generalized multi-objective reliability redundancy allocation with uncertainties. IEEE Access 2023, 11, 21575–21599. [Google Scholar] [CrossRef]

- Hsieh, T.J. A simple hybrid redundancy strategy accompanied by simplified swarm optimization for the reliability–redundancy allocation problem. Eng. Optim. 2022, 54, 369–386. [Google Scholar] [CrossRef]

- Garcia, P.A.A.; Neves, T.A.; Jacinto, C.M.C.; Alvarez, G.B.; Garcia, V.S.; Motta, G.S. Proposal of an optimal redundancy and reliability allocation approach for designing complex systems. Pesqui. Oper. 2022, 42, e263499. [Google Scholar] [CrossRef]

- Cașcaval, P.; Leon, F. Optimization Methods for Redundancy Allocation in Hybrid Structure Large Binary Systems. Mathematics 2022, 10, 3698. [Google Scholar] [CrossRef]

- Soltani, R. Reliability optimization of binary state non-repairable systems: A state of the art survey. Int. J. Ind. Eng. Comput. 2014, 5, 339–364. [Google Scholar] [CrossRef][Green Version]

- Forcina, A.; Silvestri, L.; Di Bona, G.; Silvestri, A. Reliability allocation methods: A systematic literature review. Qual. Reliab. Eng. Int. 2020, 36, 2085–2107. [Google Scholar] [CrossRef]

- Coit, D.W.; Zio, E. The evolution of system reliability optimization. Reliab. Eng. Syst. Saf. 2018, 192, 106259. [Google Scholar] [CrossRef]

- Kuo, W.; Prasad, R. System Reliability Optimization: An Overview, Mathematical Reliability: An Expository Perspective; Springer: New York, NY, USA, 2004; pp. 31–54. [Google Scholar] [CrossRef]

- Ali Najmi, K.B.; Ardakan, M.A.; Javid, A.Y. Optimization of reliability redundancy allocation problem with component mixing and strategy selection for subsystems. J. Stat. Comput. Simul. 2021, 91, 1935–1959. [Google Scholar] [CrossRef]

- Peiravi, A.; Karbasian, M.; Ardakan, M.A.; Coit, D.W. Reliability optimization of series-parallel systems with K-mixed redundancy strategy. Reliab. Eng. Syst. Saf. 2019, 183, 17–28. [Google Scholar] [CrossRef]

- Gholinezhad, H.; Hamadani, A.Z. A new model for the redundancy allocation problem with component mixing and mixed redundancy strategy. Reliab. Eng. Syst. Saf. 2017, 164, 66–73. [Google Scholar] [CrossRef]

- Wang, S.M.; Li, Y.F.; Jia, T. Distributionally Robust Design for Redundancy Allocation. Inf. J. Comput. 2020, 32, 620–640. [Google Scholar] [CrossRef]

- Feizollahi, M.J.; Soltani, R.; Feyzollahi, H. The robust cold standby redundancy allocation in series-parallel systems with budgeted uncertainty. IEEE Trans. Reliab. 2015, 64, 799–806. [Google Scholar] [CrossRef]

- Dobani, E.R.; Ardakan, M.A.; Davari-Ardakani, H.; Juybari, M.N. RRAP-CM: A new reliability-redundancy allocation problem with heterogeneous components. Reliab. Eng. Syst. Saf. 2019, 191, 106–563. [Google Scholar] [CrossRef]

- Feizabadi, M.; Jahromi, A.E. A new model for reliability optimization of series-parallel systems with non-homogeneous components. Reliab. Eng. Syst. Saf. 2017, 157, 101–112. [Google Scholar] [CrossRef]

- Kim, H.; Kim, P. Reliability models for a nonrepairable system with heterogeneous components having a phase-type time-to-failure distribution. Reliab. Eng. Syst. Saf. 2017, 159, 37–46. [Google Scholar] [CrossRef]

- Leon, F.; Cașcaval, P.; Bădică, C. Optimization Methods for Redundancy Allocation in Large Systems. Vietnam. J. Comput. Sci. 2020, 7, 281–299. [Google Scholar] [CrossRef]

- Khalili-Damghani, K.; Abtahi, A.-R.; Tavana, M. A new multi-objective particle swarm optimization method for solving reliability redundancy allocation problems. Reliab. Eng. Syst. Saf. 2013, 111, 58–75. [Google Scholar] [CrossRef]

- Kulturel-Konak, S.; Coit, D.W.; Baheranwala, F. Pruned Pareto-optimal sets for the system redundancy allocation problem based on multiple prioritized objectives. J. Heuristics 2008, 14, 335–357. [Google Scholar] [CrossRef]

- Coit, D.W.; Konak, A. Multiple weighted objectives heuristic for the redundancy allocation problem. IEEE Trans. Reliab. 2006, 55, 551–558. [Google Scholar] [CrossRef]

- Tavana, M.; Khalili-Damghani, K.; Di Caprio, D.; Oveisi, Z. An evolutionary computation approach to solving repairable multi-state multi-objective redundancy allocation problems. Neural Comput. Appl. 2018, 30, 127–139. [Google Scholar] [CrossRef]

- Ramirez-Marquez, J.E.; Coit, D.W.; Konak, A. Redundancy allocation for series-parallel systems using a max-min approach. IIE Trans. 2004, 36, 891–898. [Google Scholar] [CrossRef]

- Misra, K.B. (Ed.) Handbook of Performability Engineering; Springer: London, UK, 2008; pp. 499–532. [Google Scholar]

- Shooman, M. Reliability of Computer Systems and Networks; John Wiley & Sons: New York, NY, USA, 2002. [Google Scholar]

- El-Neweihi, E.; Proschan, F.; Sethuraman, J. Optimal Allocation of Components in Parallel-Series and Series-Parallel Systems. J. Appl. Probab. 1986, 23, 770–777. [Google Scholar] [CrossRef]

- Cașcaval, P.; Leon, F. Active Redundancy Allocation in Complex Systems by Using Different Optimization Methods. In Computational Collective Intelligence 11th International Conference, ICCCI 2019, Hendaye, France, September 4–6, 2019, Proceedings, Part I; Nguyen, N., Chbeir, R., Exposito, E., Aniorte, P., Trawinski, B., Eds.; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2019; Volume 11683, pp. 625–637. [Google Scholar] [CrossRef]

- Kuo, W.; Lin, H.H.; Xu, Z.; Zhang, W. Reliability optimization with the Lagrange-multiplier and branch-and-bound technique. IEEE Trans. Reliab. 1987, 36, 624–630. [Google Scholar] [CrossRef]

- Misra, K.B. Reliability Optimization of a Series-Parallel System. IEEE Trans. Reliab. 1972, R-21, 230–238. [Google Scholar] [CrossRef]

- Misra, K.B. Dynamic programming formulation of the redundancy allocation problem. Int. J. Math. Educ. Sci. Technol. 1971, 2, 207–215. [Google Scholar] [CrossRef]

- Yalaoui, A.; Châtelet, E.; Chu, C. A new dynamic programming method for reliability & redundancy allocation in a parallel-series system. IEEE Trans. Reliab. 2005, 54, 254–261. [Google Scholar] [CrossRef]

- Prasad, V.R.; Aneja, Y.P.; Nair, K.P.K. A Heuristic Approach to Optimal Assignment of Components to Parallel-Series Network. IEEE Trans. Reliab. 1992, 40, 555–558. [Google Scholar] [CrossRef]

- Nakagawa, Y.; Miyazaki, S. An experimental comparison of the heuristic methods for solving reliability optimization problems. IEEE Trans. Reliab. 1981, 30, 181–184. [Google Scholar] [CrossRef]

- Nakagawa, Y.; Nakashima, K. A heuristic method for determining optimal reliability allocation. IEEE Trans. Reliab. 1977, 26, 156–161. [Google Scholar] [CrossRef]

- Shi, D.H. A new heuristic algorithm for constrained redundancy optimization in complex system. IEEE Trans. Reliab. 1987, R-36, 621–623. [Google Scholar] [CrossRef]

- He, Q.; Hu, X.; Ren, H.; Zhang, H. A novel artificial fish swarm algorithm for solving large-scale reliability–redundancy application problem. ISA Trans. 2015, 59, 105–113. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, L.; Bhunia, A.K.; Roy, D. Reliability optimization with high and low level redundancies in interval environment via genetic algorithm. Int. J. Syst. Assur. Eng. Manag. 2014, 5, 513–523. [Google Scholar] [CrossRef]

- Coelho, L.D.S. Self-organizing migrating strategies applied to reliability-redundancy optimization of systems. IEEE Trans. Reliab. 2009, 58, 501–510. [Google Scholar] [CrossRef]

- Agarwal, M.; Gupta, R. Genetic Search for Redundancy Optimization in Complex Systems. J. Qual. Maint. Eng. 2006, 12, 338–353. [Google Scholar] [CrossRef]

- Marseguerra, M.; Zio, E. System Design Optimization by Genetic Algorithms. In Proceedings of the Annual Reliability and Maintainability Symposium 2000, Los Angeles, CA, USA, 24–27 January 2000; pp. 222–227. [Google Scholar] [CrossRef]

- Coit, D.W.; Smith, A.E. Reliability Optimization of Series-Parallel Systems Using a Genetic Algorithm. IEEE Trans. Reliab. 1996, 45, 254–260. [Google Scholar] [CrossRef]

- Leon, F.; Cașcaval, P. 01LP and QUBO: Optimization Methods for Redundancy Allocation in Complex Systems. In Proceedings of the 2019 23rd International Conference on System Theory, Control and Computing (ICSTCC), Sinaia, Romania, 9–11 October 2019; pp. 877–882. [Google Scholar] [CrossRef]

- Misra, K.B.; Sharma, U. An efficient algorithm to solve integer-programming problems arising in system-reliability design. IEEE Trans. Reliab. 1991, 40, 81–91. [Google Scholar] [CrossRef]

- Trivedi, K.S. Probability and Statistics with Reliability, Queueing, and Computer Science Applications; John Wiley & Sons: New York, NY, USA, 2002. [Google Scholar]

- Punia, P.; Raj, A.; Kumar, P. Enhanced Zebra Optimization Algorithm for Reliability Redundancy Allocation and Engineering Optimization Problems. Cluster Comput. 2025, 28, 267. [Google Scholar] [CrossRef]

- Zio, E.; Gholinezhad, H. Redundancy Allocation of Components with Time-Dependent Failure Rates. Mathematics 2023, 11, 3534. [Google Scholar] [CrossRef]

- Todinov, M. Improving the Reliability of Parallel and Series–Parallel Systems by Reverse Engineering of Algebraic Inequalities. Mathematics 2025, 13, 1381. [Google Scholar] [CrossRef]

- Dui, H.; Xu, H.; Zhang, Y.A. Reliability Analysis and Redundancy Optimization of a Command Post Phased-Mission System. Mathematics 2022, 10, 4180. [Google Scholar] [CrossRef]

- Ma, L.; Li, N.; Zhu, P.; Tang, K.; Khan, A.; Wang, F.; Yu, G. A Novel Fuzzy Neural Network Architecture Search Framework for Defect Recognition with Uncertainties. IEEE Trans. Fuzzy Syst. 2024, 32, 3274–3285. [Google Scholar] [CrossRef]

- Zhao, L.; Feng, Y.; Hawbani, A.; Xu, L.; Liu, Z.; Bi, Y. Optimized Resource Allocation in Vehicle Edge Computing Through Platoon Collaboration. IEEE Internet Things J. 2025, 2, 16129–16141. [Google Scholar] [CrossRef]

- McGeoch, C.C.; Harris, R.; Reinhardt, S.P.; Bunyk, P. Practical Annealing-Based Quantum Computing, Whitepaper, D-Wave Systems. Available online: https://www.dwavesys.com/media/vh5jmyka/14-1036a-b_wp_practical_annealing-based_quantum_computing_0.pdf (accessed on 25 March 2025).

- Berkelaar, M.; Eikland, K.; Notebaert, P. lpsolve, Mixed Integer Linear Programming (MILP) Solver. 2021. Available online: https://sourceforge.net/projects/lpsolve (accessed on 20 March 2025).

- Huang, T.; Ferber, A.M.; Tian, Y.; Dilkina, B.; Steiner, B. Local Branching Relaxation Heuristics for Integer Linear Programs. In Integration of Constraint Programming, Artificial Intelligence, and Operations Research 20th International Conference, CPAIOR 2023, Nice, France, May 29–June 1, 2023, Proceedings; Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2023; Volume 13884, pp. 96–113. [Google Scholar] [CrossRef]

- Cai, J.; Kadıoğlu, S.; Dilkina, B. BALANS: Multi-Armed Bandits-based Adaptive Large Neighborhood Search for Mixed-Integer Programming Problems. arXiv 2024, arXiv:2412.14382v2. [Google Scholar] [CrossRef]

- Luteberget, B.S.; Sartor, G. Feasibility Jump: An LP-Free Lagrangian MIP Heuristic. Math. Program. Comput. 2023, 15, 365–388. [Google Scholar] [CrossRef]

| 0.800, 0.000, 0.000 | −2.23144 · 10−1 · x1 |

| 0.960, 0.000, 0.000 | −4.08220 · 10−2 · x2 |

| 0.992, 0.000, 0.000 | −8.03217 · 10−3 · x3 |

| 0.000, 0.950, 0.000 | −5.12933 · 10−2 · x4 |

| 0.000, 0.998, 0.000 | −2.50313 · 10−3 · x5 |

| 0.000, 1.000, 0.000 | −1.25008 · 10−4 · x6 |

| 0.000, 0.000, 0.990 | −1.00503 · 10−2 · x7 |

| 0.000, 0.000, 1.000 | −1.00005 · 10−4 · x8 |

| 0.000, 0.000, 1.000 | −1.00000 · 10−6 · x9 |

| Type of redundancy | A, B, C, D, E, G | F |

| Weight |

| Type of redundancy | A, B, C, D | E, F, G |

| Value ranges |

| Structural details: tuples of ) extended with parameters , , or as appropriate, |

| (1: B, 0.921, 4, 16; 0.358), (2: A, 0.800, 47, 15; 0.347), (3: B, 0.861, 6, 14; 0.568), (4: B, 0.924, 2, 4; 0.637), (5: D, 0.838, 17, 9, 0.420; α = 0.183), (6: G, 0.931, 37, 17, 0.704; δ = 47), (7: A, 0.880, 33, 4, 0.327), (8: A, 0.889, 6, 7, 0.718), (9: D, 0.810, 15, 8, 0.734; α = 0.481), (10: G, 0.904, 18, 5, 0.563; δ = 42), (11: C, 0.849, 9, 0.412), (12: D, 0.894, 15, 8, 0.346, α = 0.625), (13: D, 0.807, 40, 6, 0.424; α = 0.611), (14: G, 0.920, 41, 18, 0.433; δ = 72), (15: D, 0.812, 12, 17, 0.365; α = 0.397), (16: A, 0.826, 47, 2, 0.649), (17: F, 0.918, 13, 5, 0.485; β = 69, γ = 34), (18: G, 0.940, 36, 3, 0.367; δ = 46), (19: G, 0.947, 44, 15, 0.519; δ = 50), (20: E, 0.969, 30, 15, 0.383; β = 90), (21: F, 0.974, 48, 13, 0.327; β = 97, γ = 48), (22: G, 0.965, 11, 7, 0.484; δ = 54), (23: D, 0.960, 38, 9, 0.519; α = 0.139), (24: F, 0.934, 38, 4, 0.508; β = 83, γ = 41), (25: A, 0.930, 31, 13, 0.489), (26: D, 0.909, 6, 6, 0.745; α = 0.881), (27: E, 0.902, 35, 6, ρ = 0.617; β = 85), (28: D, 0.843, 13, 13, 0.674; α = 0.499), (29: G, 0.910, 41, 4, 0.319; δ = 62), (30: C, 0.930, 19, 6, 0.317), (31: F, 0.974, 25, 17, 0.450; β = 52, γ = 26), (32: C, 0.887, 6, 15, 0.439), (33: C, 0.805, 5, 4, 0.716), (34: A, 0.953, 34, 2, 0.562), (35: C, 0.929, 3, 11, 0.484), (36: E, 0.971, 23, 15, 0.563; β = 52), (37: C, 0.986, 14, 8, 0.662), (38: A, 0.940, 45, 18, 0.375), (39: A, 0.973, 15, 5, 0.483), (40: D, 0.801, 36, 4, 0.638; α = 0.958), (41: A, 0.854, 48, 6, 0.572), (42: B, 0.958, 35, 18, 0.272), (43: G, 0.989, 47, 10, 0.634; δ = 73), (44: C, 0.989, 6, 2, 0.392), (45: E, 0.922, 30, 13, 0.592; β = 88), (46: C, 0.905, 17, 11, 0.298), (47: E, 0.915, 13, 8, 0.494; β = 81), (48: B, 0.922, 46, 1, 0.564), (49: D, 0.856, 3, 6, 0.632; α = 0.410), (50: B, 0.893, 37, 11, 0.474). |

| , , |

| Optimal allocation: , , …, | ||||

| 4, 5, 5, 5, 4, 5, 4, 5, 4, 5, 5, 4, 4, 5, 4, 5, 3, 5, 4, 4, 3, 5, 3, 3, 4, 4, 5, 4, 5, 4, 3, 5, 5, 3, 5, 4, 3, 3, 3, 4, 5, 3, 3, 3, 5, 4, 5, 3, 4, 3 | 4960 | 1857 | 0.976633 | 42.51 |

| Steps of increasing reliability: , , …, | ||||

| 10, 8, 9, 10, 8, 5, 7, 9, 8, 7, 9, 8, 7, 6, 9, 6, 8, 6, 5, 5, 5, 6, 5, 6, 6, 8, 6, 8, 7, 7, 5, 9, 10, 5, 9, 5, 5, 6, 6, 7, 6, 6, 3, 6, 6, 8, 8, 6, 10, 7 | 4959.91 | 455 | 0.959565 | 24.57 |

| Value pairs: (, (, …, ( | ||||

| (4, 0), (1, 9), (4, 0), (4, 0), (4, 0), (1, 7), (4, 0), (5, 0), (4, 0), (1, 9), (5, 0), (4, 0), (4, 0), (1, 8), (4, 0), (5, 0), (1, 9), (1, 8), (1, 7), (1, 7), (3, 0), (1, 8), (3, 0), (1, 8), (3, 0), (4, 0), (1, 8), (4, 0), (1, 9), (3, 0), (3, 0), (4, 0), (5, 0), (3, 0), (4, 0), (1, 7), (3, 0), (3, 0), (3, 0), (4, 0), (4, 0), (3, 0), (3, 0), (3, 0), (1, 8), (4, 0), (1, 9), (3, 0), (4, 0), (3, 0) | 4959.09 | 1251 | 0.990937 | 109.61 |

| Value pairs: (, (, …, ( | ||||

| (1, 10), (1, 9), (1, 10), (1, 10), (1, 10), (1, 7), (1, 9), (1, 10),(4, 0), (1, 9), (4, 0), (1, 10), (4, 0), (1, 7), (1, 10), (4, 0), (1, 9), (1, 7), (1, 7), (1, 7), (1, 6), (1, 8), (3, 0), (1, 7), (3, 0), (4, 0), (1, 7), (1, 9), (1, 8), (1, 9), (1, 6), (1, 10), (5, 0), (3, 0), (1, 10), (1, 6), (2, 0), (1, 7), (3, 0), (4, 0), (4, 0), (1, 7), (3, 0), (2, 0), (1, 7), (1, 9), (1, 9), (3, 0), (1, 10), (3, 0). | 4959.79 | 682 | 0.986308 | 72.55 |

| Value pairs: (, (, …, ( | ||||

| (1, 10), (1, 9), (1, 10), (1, 10), (1, 10), (1, 7), (1, 9), (1, 10), (4, 0), (1, 9), (4, 0), (1, 10), (4, 0), (1, 7), (1, 10), (4, 0), (1, 9), (1, 7), (1, 7), (1, 7), (1, 6), (1, 8), (3, 0), (1, 7), (3, 0), (4, 0), (1, 7), (1, 9), (1, 8), (1, 9), (1, 6), (1, 10), (5, 0), (3, 0), (1, 10), (1, 6), (2, 0), (1, 7), (3, 0), (4, 0), (4, 0), (1, 7), (3, 0), (2, 0), (1, 7), (1, 9), (1, 9), (3, 0), (1, 10), (3, 0). | 4959.79 | 682 | 0.986308 | 72.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leon, F.; Cașcaval, P. Optimization Method for Reliability–Redundancy Allocation Problem in Large Hybrid Binary Systems. Mathematics 2025, 13, 2450. https://doi.org/10.3390/math13152450

Leon F, Cașcaval P. Optimization Method for Reliability–Redundancy Allocation Problem in Large Hybrid Binary Systems. Mathematics. 2025; 13(15):2450. https://doi.org/10.3390/math13152450

Chicago/Turabian StyleLeon, Florin, and Petru Cașcaval. 2025. "Optimization Method for Reliability–Redundancy Allocation Problem in Large Hybrid Binary Systems" Mathematics 13, no. 15: 2450. https://doi.org/10.3390/math13152450

APA StyleLeon, F., & Cașcaval, P. (2025). Optimization Method for Reliability–Redundancy Allocation Problem in Large Hybrid Binary Systems. Mathematics, 13(15), 2450. https://doi.org/10.3390/math13152450