A Mathematical Method for Predicting Tunnel Pressure Waves Based on Train Wave Signature and Graph Theory

Abstract

1. Introduction

2. Mathematical Model

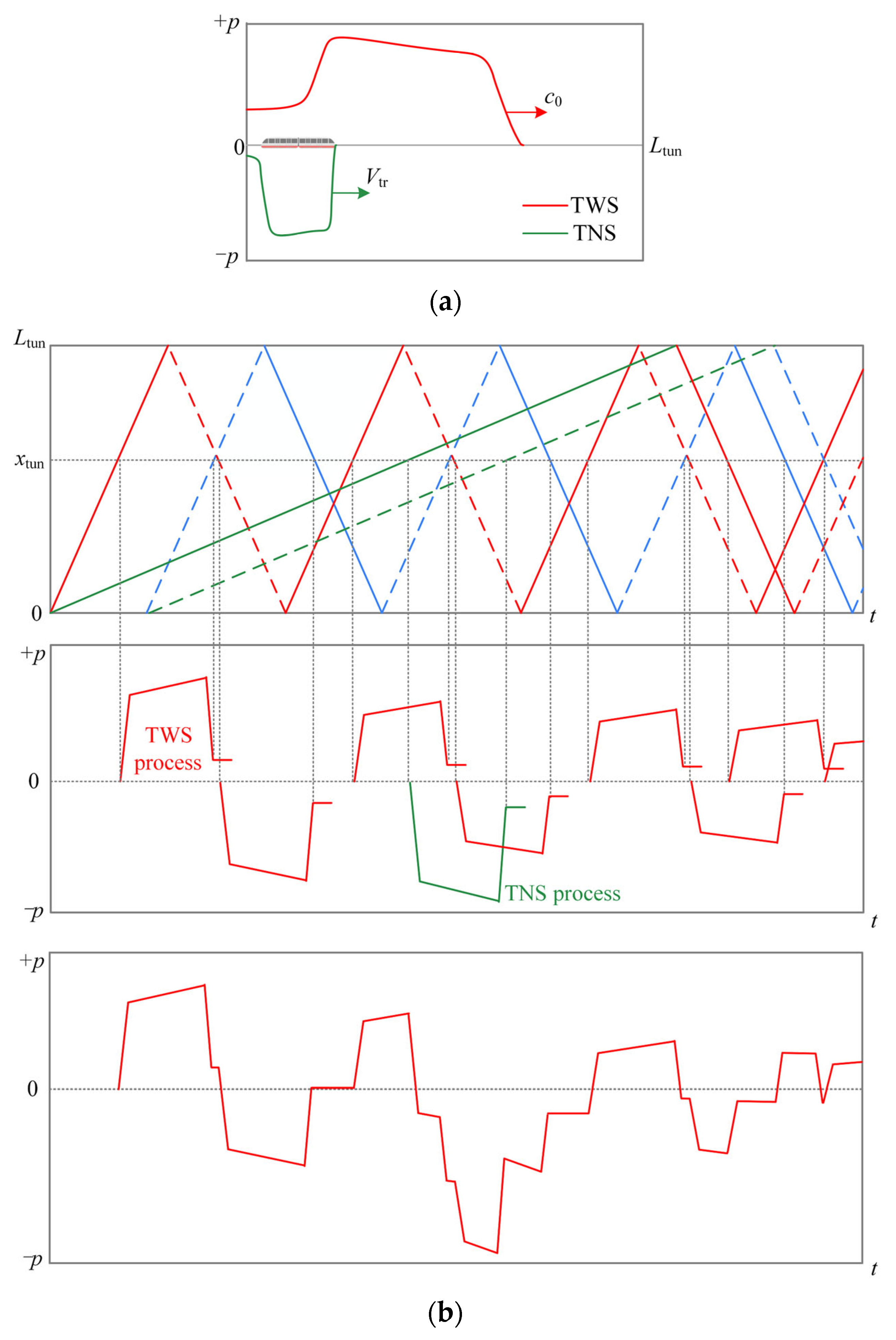

2.1. Initial TWS Model

2.2. TWS Propagation and Attenuation Model

2.3. TWS Reflection and Transmission Model

2.4. Passing TWS Generation Model

2.5. TWS Superposition Model

3. Discretization

3.1. Time Discretization

3.2. Space Discretization

4. Implementation

5. Results and Discussion

5.1. Field Measurements

5.2. Computational Accuracy

5.2.1. Time Interval

5.2.2. TWS Definitions

5.3. Computational Efficiency

5.3.1. Weak TWS

5.3.2. Reflected TWS from Train

5.4. Pressure Signature

6. Conclusions

- (1)

- The method’s accuracy is sensitive to the time interval. A larger time interval leads to positional deviation of both the TWS and TNS, while a smaller interval does not necessarily improve accuracy but substantially increases computation time.

- (2)

- The TWS definition affects only the pressure gradient prediction, not the extreme pressure. The sin-type definition performs better than the line-type, improving pressure gradient prediction accuracy by 60%.

- (3)

- Weak TWS events have minimal influence on the overall pressure time history. If the maximum pressure of a TWS is within ±1 Pa, it can be neglected, reducing total computation time by up to 78.8%.

- (4)

- The influence of reflected TWSs from the train is significantly diminished in tunnels with shafts. In such cases, a slight reduction in accuracy may be acceptable in exchange for a substantial decrease in computational cost.

- (5)

- Pressure signatures must be determined prior to applying the TWS method. Key influencing factors include the streamlined shape of the train nose, blockage ratio, and train speed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations/Nomenclature

| TWS | Train Wave Signature |

| TNS | Train Nearfield Signature |

| rw | reflected wave |

| iw | incident wave |

| tw | transmitted wave |

| ps | passing wave |

| MPP | maximum positive pressure |

| MNP | maximum negative pressure |

| CFL | Courant-Friedrichs-Lewy |

| c0 | speed of sound (m/s) |

| Vtr | speed of train (m/s) |

| Ltun | tunnel length (m) |

| Ltr | train length (m) |

| Lnose | train nose length (m) |

| Lbody | train body length (m) |

| xtun | position of measured point (m) |

| Lc | position of tunnel structural changes (m) |

| t | time (s) |

| t0 | initial time (s) |

| Δt | time interval (s) |

| p | pressure (Pa) |

| Δw | mathematical model of TWS |

| ΔtrTNS | mathematical model of TNS |

| α | coefficient of pressure attenuation |

| k | coefficient of new pressure wave |

| ε | eplison |

| CP | dimensionless pressure coefficient |

| ρ | air density (kg/m3) |

| G | directed graph |

| V | vertice set |

| E | edge set |

| v | vertice |

| NV | quantity of vertices |

| A | adjacency matrix |

| aij | element in adjacency matrix |

Appendix A

Appendix B

| Parameter or Coefficient | Value |

|---|---|

| Δpnose | 580 Pa |

| Δpbody | 320 Pa |

| Δprear | −417 Pa |

| ΔpTNSnose | −580 Pa |

| ΔpTNSbody | −380 Pa |

| ΔpTNSrear | 487 Pa |

| c0 | 343 m/s |

| kps: train passing tunnel exit | 0.35 |

| kps: train passing shaft 1 | 0.4 |

| kps: train passing shaft 2 | 0.3 |

| kre: tunnel portal (v1, v4) | −0.8 |

| kre: shaft portal (v5, v6) | −0.8 |

| kre: tunnel junction (v2, v3, waves in tunnel) | −0.325 |

| kre: tunnel junction (v2, v3, waves in shaft) | −0.54 |

| ktr: tunnel junction (v2, v3, waves in tunnel) | 0.675 |

| ktr: tunnel junction (v2, v3, waves in shaft) | 0.46 |

| α | 0.00003 |

References

- Zhou, Y.; Wang, H.; Bi, H.; Wang, J. Experimental and Numerical Study of Aerodynamic Pressures on Platform Screen Doors at the Overtaking Station of a High-Speed Subway. Build. Environ. 2021, 191, 107582. [Google Scholar] [CrossRef]

- Weng, M.; Xiong, K.; Liu, F. Influence of the Door Opening on the Pressure Transient Caused by the High-Speed Subway Train Passing Through the Double-Track Tunnel with the Mid-Partition Wall. Tunn. Undergr. Space Technol. 2023, 142, 105417. [Google Scholar] [CrossRef]

- Yang, C.; Huo, Y.; Meng, K.; Zhou, W.; Yang, J.; Nan, Z. Fatigue Failure Analysis of Platform Screen Doors Under Subway Aerodynamic Loads Using Finite Element Modeling. Eng. Fail. Anal. 2025, 174, 109502. [Google Scholar] [CrossRef]

- Yuan, H.; Zhou, D.; Meng, S. Study of the Unsteady Aerodynamic Performance of an Inter-City Train Passing Through a Station in a Tunnel. Tunn. Undergr. Space Technol. 2019, 86, 1–9. [Google Scholar] [CrossRef]

- Niu, J.; Sui, Y.; Yu, Q.; Cao, X.; Yuan, Y. Aerodynamics of Railway Train/Tunnel System: A Review of Recent Research. Energy Built Environ. 2020, 1, 351–375. [Google Scholar] [CrossRef]

- Ouyang, D.; Yang, W.; Deng, E.; Wang, Y.; He, X.; Tang, L. Comparison of Aerodynamic Performance of Moving Train Model at Bridge–Tunnel Section in Wind Tunnel with or Without Tunnel Portal. Tunn. Undergr. Space Technol. 2023, 135, 105030. [Google Scholar] [CrossRef]

- William-Louis, M.; Tournier, C. A Wave Signature Based Method for the Prediction of Pressure Transients in Railway Tunnels. J. Wind. Eng. Ind. Aerodyn. 2005, 93, 521–531. [Google Scholar] [CrossRef]

- Liu, T.; Chen, X.; Li, W.; Xie, T.; Chen, Z. Field Study on the Interior Pressure Variations in High-Speed Trains Passing Through Tunnels of Different Lengths. J. Wind Eng. Ind. Aerodyn. 2017, 169, 54–66. [Google Scholar] [CrossRef]

- Xiong, K.; Weng, M.; Zou, Z.; Liu, F. A Simple Method for Predicting Pressure Transients in High-Speed Subway Tunnel Based on Train Reflected Waves. J. Wind. Eng. Ind. Aerodyn. 2023, 241, 105546. [Google Scholar] [CrossRef]

- Ricco, P.; Baron, A.; Molteni, P. Nature of Pressure Waves Induced by a High-Speed Train Travelling Through a Tunnel. J. Wind. Eng. Ind. Aerodyn. 2007, 95, 781–808. [Google Scholar] [CrossRef]

- Jia, Y.; Mei, Y. Numerical Simulation of Pressure Waves Induced by High-Speed Maglev Trains Passing Through Tunnels. Int. J. Heat Technol. 2018, 36, 687–696. [Google Scholar] [CrossRef]

- Xue, X.; Song, Y.; Zhang, D.; Ren, S.; Kang, Y. Investigation of Critical Tunnel Length Based on the Maximum Positive Pressure on the Trailing Carriage of a High-Speed Train. AIP Adv. 2025, 15, 025216. [Google Scholar] [CrossRef]

- Xiong, K.; Weng, M.; Liu, F. Theoretical Study on the Most Unfavorable Tunnel Length (MUTL) Based on the Interior Pressure Variations of High-Speed Subway Trains. Tunn. Undergr. Space Technol. 2024, 148, 105774. [Google Scholar] [CrossRef]

- Howe, M. Review of the Theory of the Compression Wave Generated When a High-Speed Train Enters a Tunnel. Proc. Inst. Mech. Eng. Part F-J. Rail Rapid Transit 1999, 213, 89–104. [Google Scholar] [CrossRef]

- Baron, A.; Mossi, M.; Sililla, S. The Alleviation of the Aerodynamic Drag and Wave Effects of High-Speed Trains in Very Long Tunnels. J. Wind. Eng. Ind. Aerodyn. 2001, 89, 365–401. [Google Scholar] [CrossRef]

- Saito, S.; Iida, M.; Kajiyama, H. Numerical Simulation of 1-D Unsteady Compressible Flow in Railway Tunnels. J. Environ. Eng. 2011, 6, 723–738. [Google Scholar] [CrossRef]

- Howe, M.; Iida, M.; Maeda, T.; Sakuma, Y. Rapid Calculation of the Compression Wave Generated by a Train Entering a Tunnel with a Vented Hood. J. Sound Vib. 2006, 297, 267–292. [Google Scholar] [CrossRef]

- Lv, W.; Li, A.; Cui, H.; Chen, L. General Analytical Method to Predict the Spatial–Temporal Distribution of Extreme Pressure in High-Speed Railway Tunnels in the Post-Train Stage. Appl. Sci. 2023, 13, 1350. [Google Scholar] [CrossRef]

- Fukuda, T.; Masanobu, I.; Murata, K. Distortion of Compression Wave Propagating Through Slab Track Tunnel with Side Branches. Q. Rep. RTRI 2001, 42, 71–76. [Google Scholar] [CrossRef]

- Li, X.; Wu, Z.; Yang, J.; Zhang, L.; Zhou, D.; Hu, T. Experimental Study on Transient Pressure Induced by High-Speed Train Passing Through an Underground Station with Adjoining Tunnels. J. Wind. Eng. Ind. Aerodyn. 2022, 224, 104984. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, H.; Bi, H.; Zhou, Y.; Yu, N.; Fang, Y. Model Test Research on Pressure Wave in the Subway Tunnel. In Computational and Experimental Simulations in Engineering; ICCES(2023); Springer: Berlin/Heidelberg, Germany; Volume 145, pp. 327–352. [CrossRef]

- Saito, S.; Miyachi, T.; Iida, M. Reduction of Micro-pressure Wave Emitted from Portal of Side Branch of High-speed Railway Tunnel. Q. Rep. RTRI 2010, 51, 146–150. [Google Scholar] [CrossRef]

- Luo, J.; Li, Z.; Wang, L.; Zhang, D.; Wu, Y. Aerodynamic Effect of Cross Passages at the Entrance Section of a High-Speed Railway Tunnel in a Region with Mountains and Canyons. J. Wind. Eng. Ind. Aerodyn. 2020, 204, 104268. [Google Scholar] [CrossRef]

- Miyachi, T.; Fukuda, T.; Saito, S. Model Experiment and Analysis of Pressure Waves Emitted from Portals of a Tunnel with a Branch. J. Sound Vib. 2014, 333, 6156–6169. [Google Scholar] [CrossRef]

- Okubo, H.; Miyachi, T.; Sugiyama, K. Pressure Fluctuation and a Micro-pressure Wave in a High-Speed Railway Tunnel with Large Branch Shaft. J. Wind. Eng. Ind. Aerodyn. 2021, 217, 104751. [Google Scholar] [CrossRef]

- Yang, X.; Shou, A.; Zhang, R.; Quan, J.; Li, X.; Niu, J. Numerical Study on Transient Aerodynamic Behaviors in a Subway Tunnel Caused by a Metro Train Running Between Adjacent Platforms. Tunn. Undergr. Space Technol. 2021, 117, 104152. [Google Scholar] [CrossRef]

- Liu, T.; Jiang, Z.; Chen, X.; Zhang, J.; Liang, X. Wave Effects in a Realistic Tunnel Induced by the Passage of High-Speed Trains. Tunn. Undergr. Space Technol. 2019, 86, 224–235. [Google Scholar] [CrossRef]

- Ko, Y.; Chen, C.; Hoe, I.; Wang, S. Field Measurements of Aerodynamic Pressures in Tunnels Induced by High Speed Trains. J. Wind. Eng. Ind. Aerodyn. 2012, 100, 19–29. [Google Scholar] [CrossRef]

- Colella, F.; Rein, G.; Borchiellini, R.; Carvel, R.; Torero, J.L.; Verda, V. Calculation and Design of Tunnel Ventilation Systems Using a Two-Scale Modelling Approach. Build. Environ. 2009, 44, 2357–2367. [Google Scholar] [CrossRef]

- Wei, L. Topology Theory of Mine Ventilation Network. Procedia Earth Planet. Sci. 2009, 1, 354–360. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Z.; Gao, K.; Huang, Y.; Zhu, C. Efficient Graphical Algorithm of Sensor Distribution and Air Volume Reconstruction for a Smart Mine Ventilation Network. Sensors 2022, 22, 2096. [Google Scholar] [CrossRef]

- William-Louis, M.; Tournier, C. Non-Homentropic Flow Generated by Trains in Tunnels with Side Branches. Int. J. Numer. Methods Heat Fluid Flow 1998, 8, 183–198. [Google Scholar] [CrossRef]

- Iyer, R.S.; Kim, D.H.; Kim, H.D. Propagation Characteristics of Compression Wave in a High-Speed Railway Tunnel. Phys. Fluids 2021, 33, 086104. [Google Scholar] [CrossRef]

- Zhang, L.; Thurow, K.; Stoll, N.; Liu, H. Influence of the Geometry of Equal-Transect Oblique Tunnel Portal on Compression Wave and Micro-Pressure Wave Generated by High-Speed Trains Entering Tunnels. J. Wind. Eng. Ind. Aerodyn. 2018, 178, 1–17. [Google Scholar] [CrossRef]

- Liu, F.; Lei, H.; Wei, M.; Sun, H.; Iqbal, M.; Chen, D. Improving the Effect of Air Chambers on Micro-Pressure Waves from Tunnel Portals: Moderate Underdamping. Tunn. Undergr. Space Technol. 2024, 153, 106016. [Google Scholar] [CrossRef]

- Mei, Y. A Generalized Numerical Simulation Method for Pressure Waves Generated by High-Speed Trains Passing through Tunnels. Adv. Struct. Eng. 2013, 16, 1427–1436. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, M.; Niu, J.; Liang, X.; Zhang, J. Moving Model Tests on Transient Pressure and Micro-pressure Wave Distribution Induced by Train Passing through Tunnel. J. Wind. Eng. Ind. Aerodyn. 2019, 191, 1–21. [Google Scholar] [CrossRef]

- Xiong, K.; Weng, M.; Zou, Z.; Zhu, X.; Liu, F. Field Measurements of Aerodynamic Pressures Induced by Suburban Rail Transit Train Passing Through Double-Track Tunnel with Mid-Partition Wall. Int. J. Rail Transp. 2024, 13, 120–150. [Google Scholar] [CrossRef]

- Yun, S.; Kwak, M.; Lee, D.; Kwon, H.; Ko, T. Passive Reduction of Large Pressure Variation for a High-speed Express Train in a Narrow Tunnel Using an Extra Dummy Tunnel Duct. J. Mech. Sci. Technol. 2010, 24, 1433–1440. [Google Scholar] [CrossRef]

- Somaschini, C.; Argentini, T.; Brambilla, E.; Rocchi, D.; Schito, P.; Tomasini, G. Full-Scale Experimental Investigation of the Interaction between Trains and Tunnels. Appl. Sci. 2020, 10, 7189. [Google Scholar] [CrossRef]

- Wu, K. Aerodynamic Aspects of High-Speed Railway Underground Station with Adjoining Tunnels. Ph.D. Thesis, Hong Kong University of Science and Technology, Hong Kong, China, 2008. [Google Scholar] [CrossRef]

- Niu, J.; Zhou, D.; Liang, X.; Liu, T.; Liu, S. Numerical Study on the Aerodynamic Pressure of a Metro Train Running Between Two Adjacent Platforms. Tunn. Undergr. Space Technol. 2017, 65, 187–199. [Google Scholar] [CrossRef]

| Evaluation Index | Field Measurement | TWS Δt = 0.01 s | TWS Δt = 0.03 s | TWS Δt = 0.05 s | TWS Δt = 0.07 s | |

|---|---|---|---|---|---|---|

| MPP | Pressure (Pa) | 528.4 | 527.0 | 524.9 | 523.6 | 498.7 |

| Pressure deviation (%) | - | −0.26 | −0.66 | −0.91 | −5.62 | |

| Time (s) | 85.8765 | 85.93 | 85.92 | 85.6 | 85.19 | |

| Time deviation (%) | - | 0.06 | 0.05 | −0.32 | −0.8 | |

| MNP | Pressure (Pa) | −358.1 | −360.6 | −358.9 | −343.7 | −370.6 |

| Pressure deviation (%) | - | 0.7 | 0.22 | −4.02 | 3.49 | |

| Time (s) | 90.63 | 90.56 | 90.57 | 90.45 | 89.81 | |

| Time deviation (%) | - | −0.08 | −0.07 | −0.2 | −0.9 | |

| Evaluation Index | ε = 10 | ε = 5 | ε = 1 | ε = 0.1 | Without ε |

|---|---|---|---|---|---|

| MPP (Pa)/deviation (%) | 493.2/−6.7 | 511.3/−3.2 | 523.6/−0.9 | 521.1/−1.3 | 524.9/−0.7 |

| MNP (Pa)/deviation (%) | −390.2/8.9 | −366.1/2.2 | −354.3/−1.1 | −357.3/−0.2 | −358.9/0.2 |

| Total computation time (s) | 93.8 | 151.5 | 543.1 | 1127.7 | 2561.1 |

| Maximum number of TWS | 167 | 291 | 991 | 2013 | 3943 |

| Cumulative distance (×104) | 483.14 | 391.96 | 366.02 | 364.58 | 364.21 |

| Evaluation Index | Case 1 | Case 2 | Case 3 |

|---|---|---|---|

| MPP (Pa)/deviation (%) | 526.4/−0.4 | 523.6/−0.9 | 518.6/−1.9 |

| MNP (Pa)/deviation (%) | −355.7/−0.7 | −354.3/−1.1 | −350.2/−2.2 |

| Total computation time (s) | 1966 | 543.1 | 218 |

| Maximum number of TWS | 1471 | 991 | 308 |

| Cumulative distance (×104) | 362.18 | 366.02 | 367.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Bi, H.; Wang, H.; Zhou, Y.; Yu, N.; Yang, J.; Jiang, Y. A Mathematical Method for Predicting Tunnel Pressure Waves Based on Train Wave Signature and Graph Theory. Mathematics 2025, 13, 2360. https://doi.org/10.3390/math13152360

Zhang X, Bi H, Wang H, Zhou Y, Yu N, Yang J, Jiang Y. A Mathematical Method for Predicting Tunnel Pressure Waves Based on Train Wave Signature and Graph Theory. Mathematics. 2025; 13(15):2360. https://doi.org/10.3390/math13152360

Chicago/Turabian StyleZhang, Xu, Haiquan Bi, Honglin Wang, Yuanlong Zhou, Nanyang Yu, Jizhong Yang, and Yao Jiang. 2025. "A Mathematical Method for Predicting Tunnel Pressure Waves Based on Train Wave Signature and Graph Theory" Mathematics 13, no. 15: 2360. https://doi.org/10.3390/math13152360

APA StyleZhang, X., Bi, H., Wang, H., Zhou, Y., Yu, N., Yang, J., & Jiang, Y. (2025). A Mathematical Method for Predicting Tunnel Pressure Waves Based on Train Wave Signature and Graph Theory. Mathematics, 13(15), 2360. https://doi.org/10.3390/math13152360