The Kinematics of a New Schönflies Motion Generator Parallel Manipulator Using Screw Theory

Abstract

1. Introduction

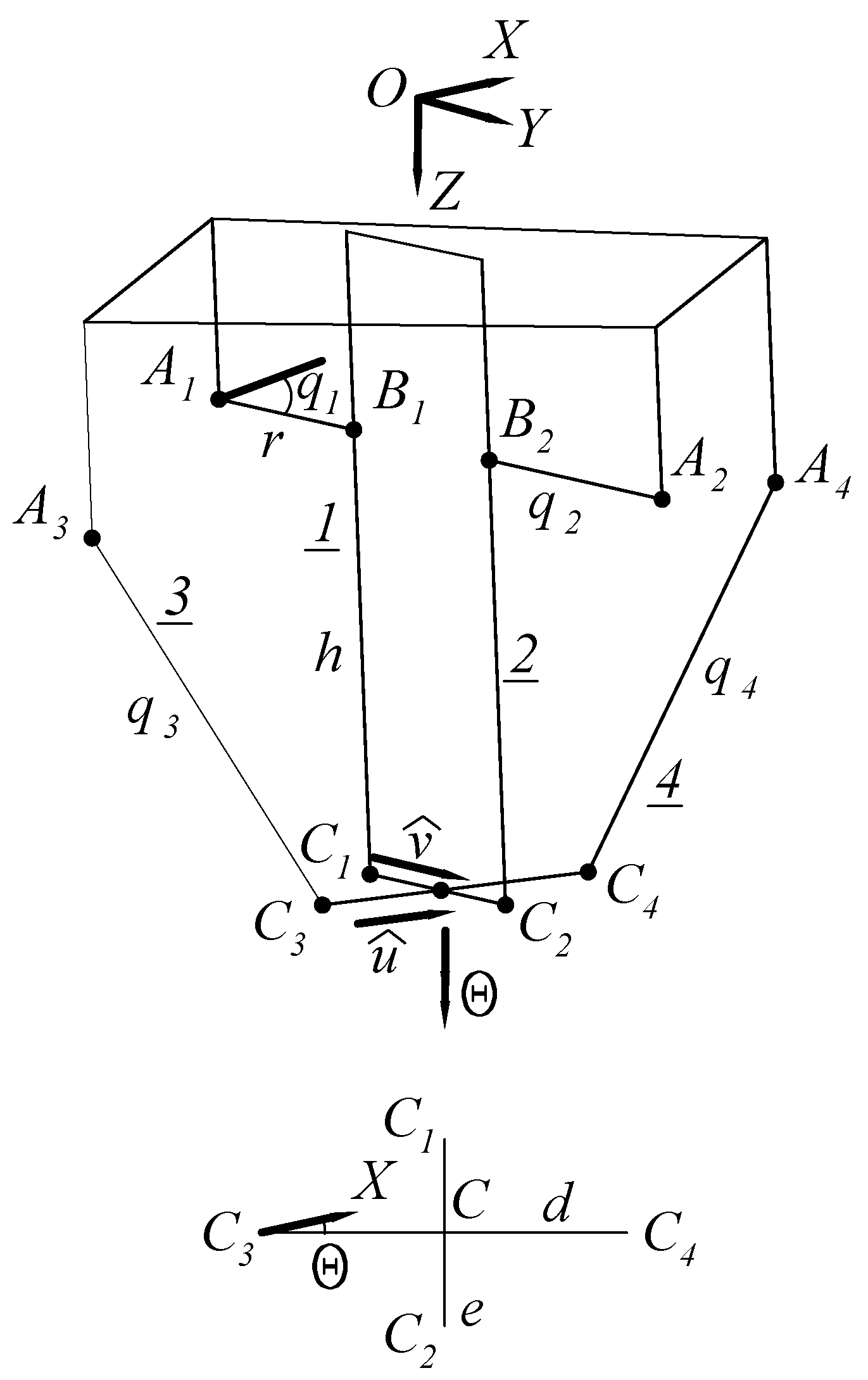

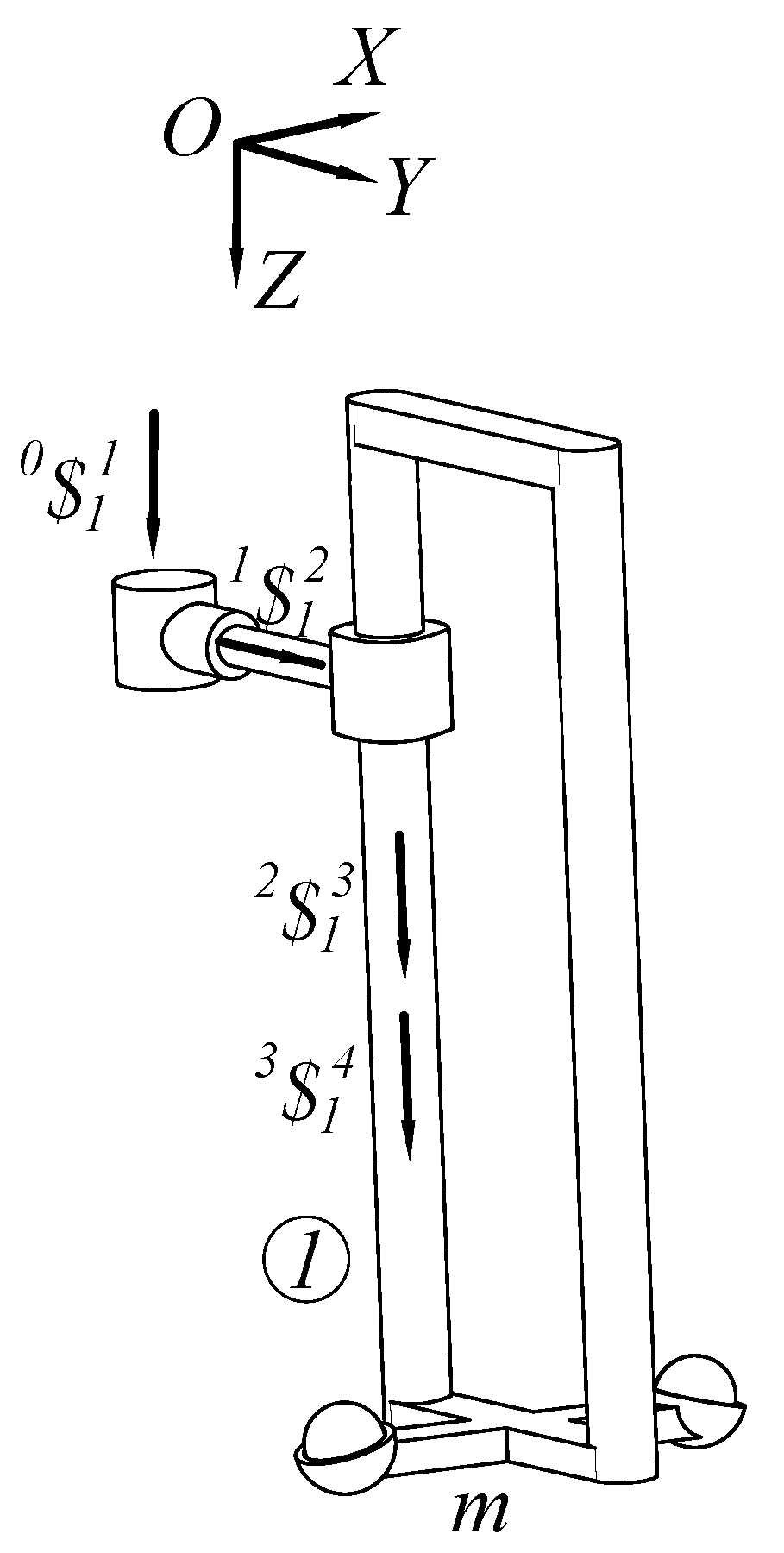

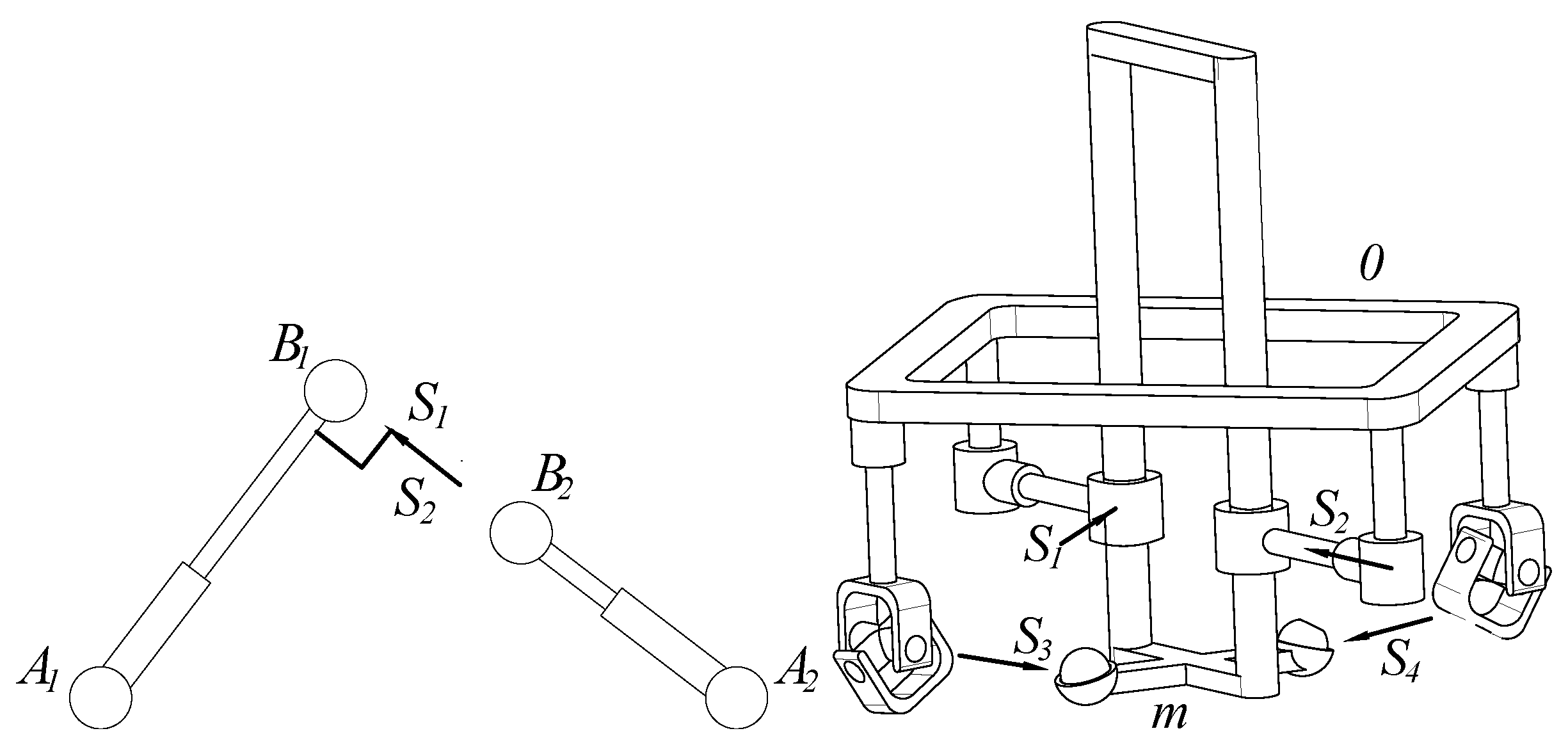

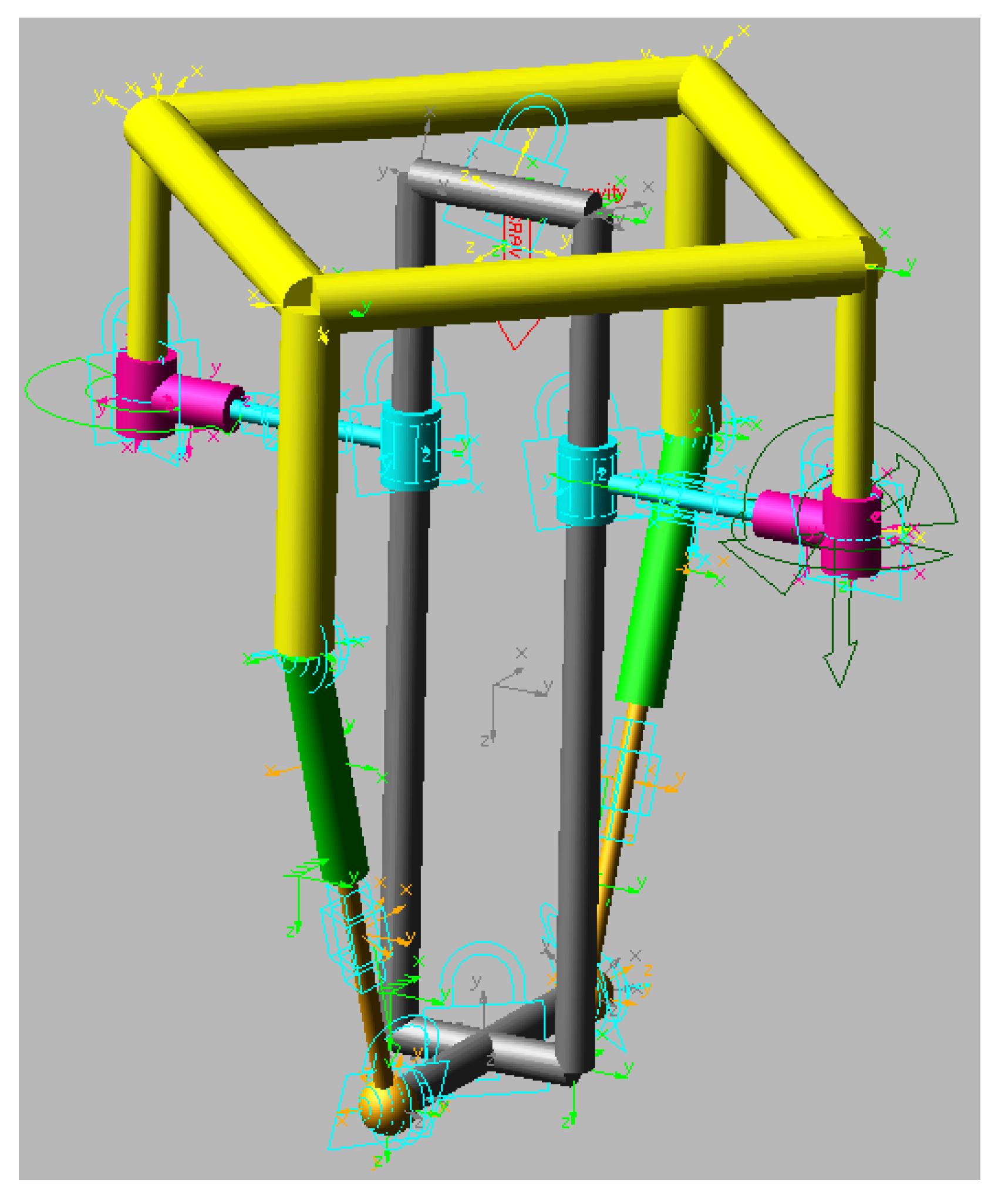

2. Description of the Robot Manipulator

Mobility Analysis

3. Displacement Analysis

3.1. Closure Equations

3.2. Forward Displacement Analysis

- Define a known set of generalized coordinates .

- Express and in terms of the tangent half-angle ; see Equation (3).

- Define and according to Equation (2).

- From Equation (13), formulate three quadratic equations in the unknowns r, h, and as follows

- Solve the three quadratic equations by applying the Sylvester dialytic method of elimination; for details, see [19].

- Determine the center C of the moving platform based on Equation (8).

- Determine the angle , see Equation (4), as

3.3. Inverse Displacement Analysis

- Define the pose of the moving platform providing the vector and the angle .

- Compute the unit vectors and ; see Equation (2).

- Compute the vertices of the moving platform; see Equation (5).

- Compute the generalized coordinates and by resorting to Equation (13). Indeed

- Determine h as follows

- Compute the position vector by applying Equation (11).

- Calculate the generalized coordinate considering that from Equation (9) it follows that

- Compute the position vector by applying Equation (12).

- Compute the generalized coordinate taking into account that from Equation (13a) it follows that

4. Instantaneous Kinematics

4.1. Velocity

- is the Jacobian matrix of the parallel manipulator. This is a matrix formed with the reciprocal screws that maps the input joint velocity rates or generalized speeds of the parallel manipulator to the instantaneous velocity state of the moving platform.

- is the six-dimensional operator of polarity. This is a matrix formed with the identity matrix and the zero matrix .

- is the first-order coefficients matrix of the parallel manipulator. This is a near identical matrix to the matrix of order six. The inclusion of a rotary actuator is the reason why not all the elements of the diagonal of the matrix satisfy the condition of an identity matrix.

- is the first-order driver matrix of the parallel manipulator. This matrix is composed of the generalized speeds. Considering this, and are hypothetical joint velocity rates and therefore it must be considered that .

4.2. Singularity

4.2.1. Forward Kinematic Singularities

4.2.2. Inverse Kinematic Singularities

4.2.3. Combined Singularities

4.3. Acceleration

- is the second-order driver matrix of the parallel manipulator. This matrix is composed of the generalized accelerations. Considering this, and are hypothetical joint acceleration rates and therefore it must be considered that . These fictitious joint acceleration rates are included with the purpose to satisfy an algebraic requisite.

- is the Coriolis matrix. This matrix collects the “Coriolis” and “centripetal” terms that arise from the computation of the Lie screws of acceleration.

5. Numerical Simulation

5.1. Displacement

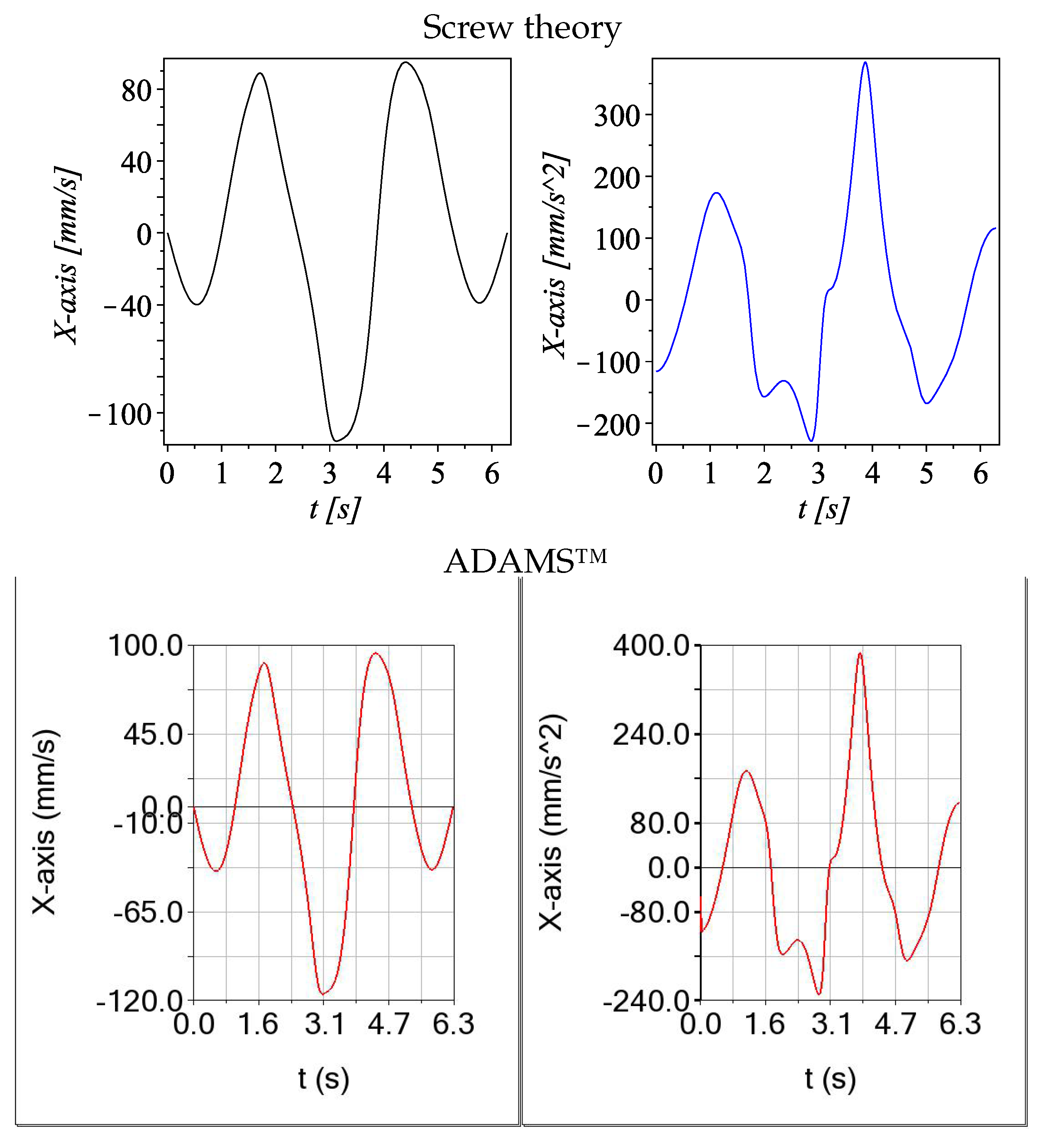

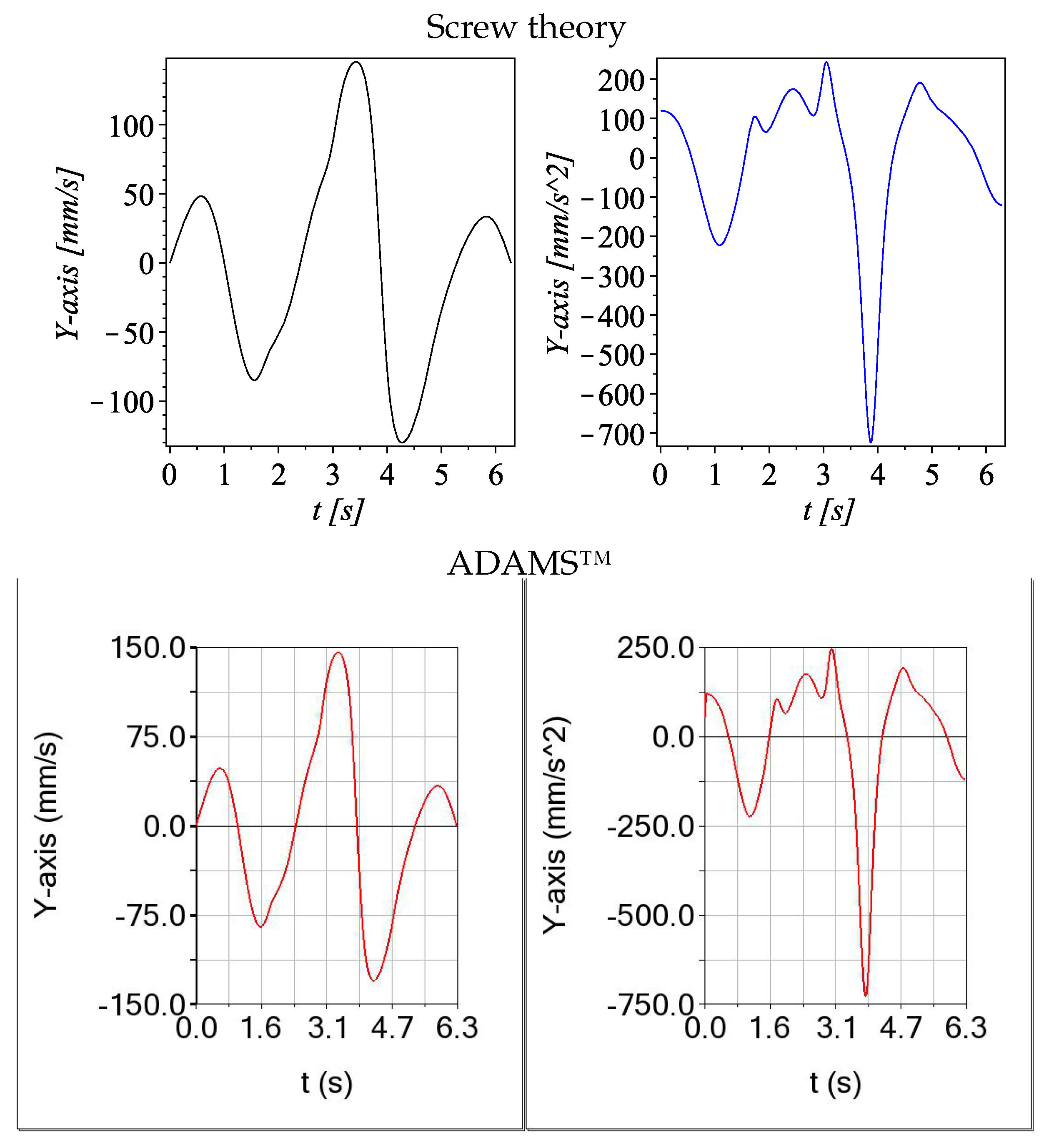

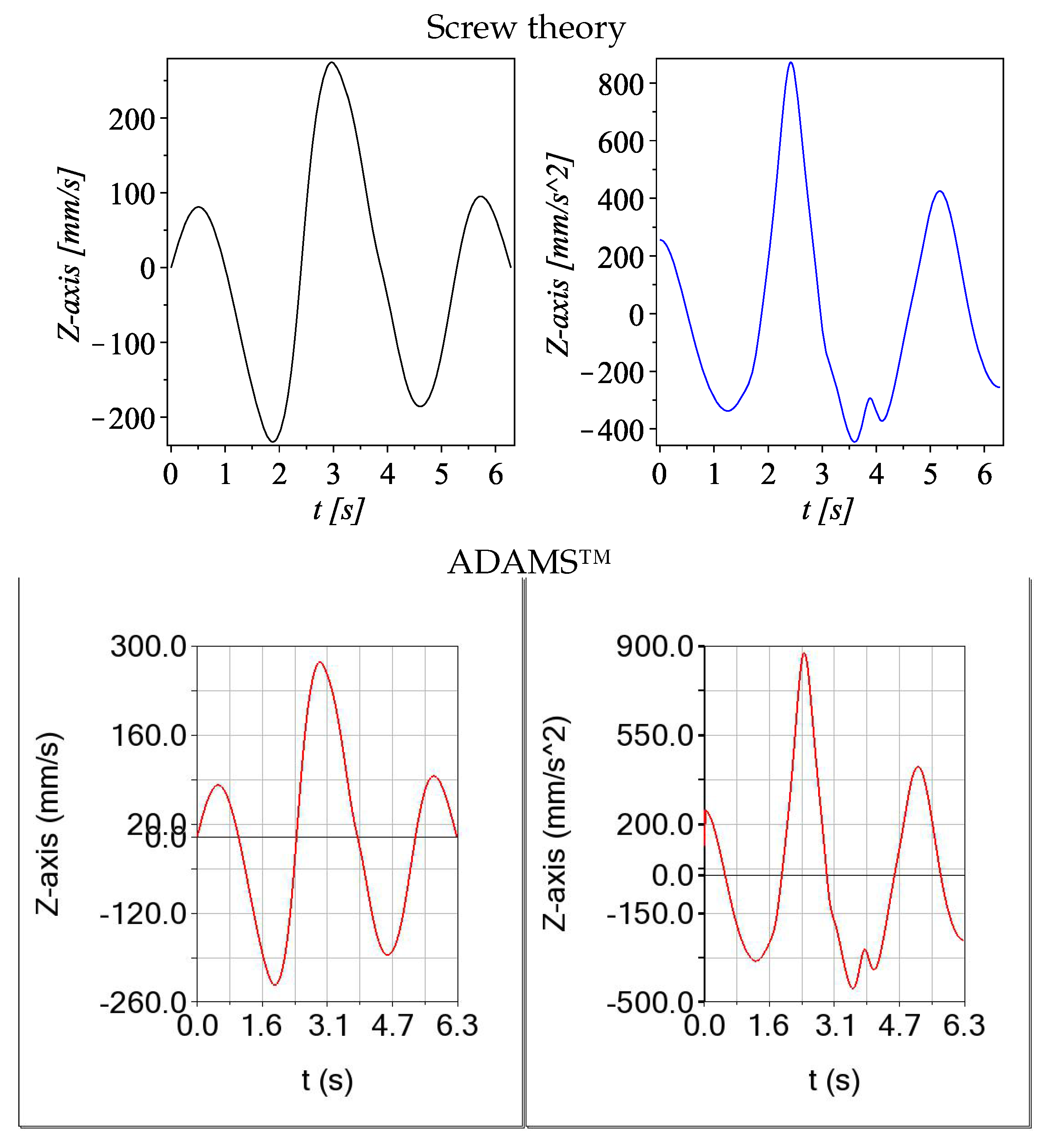

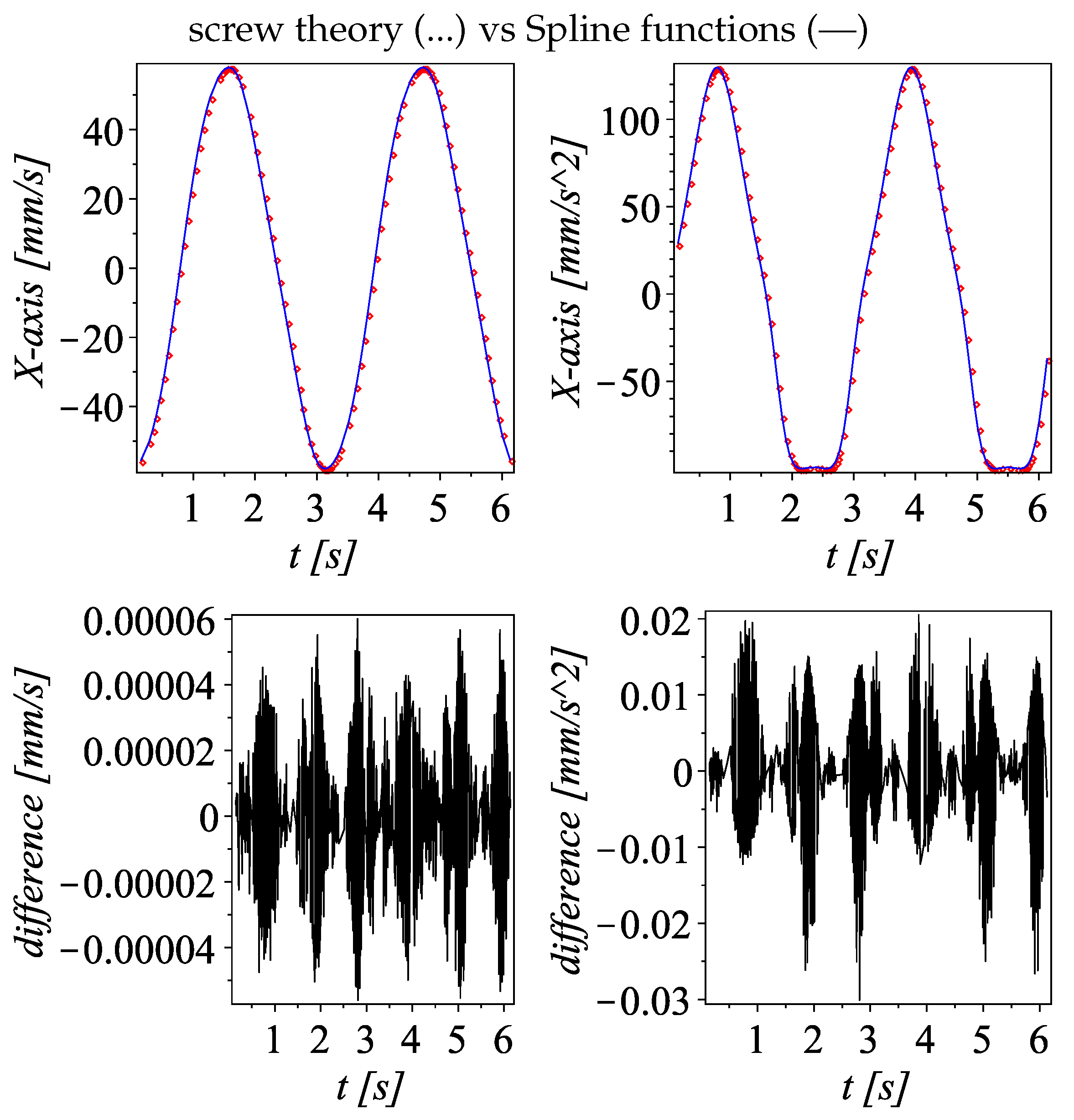

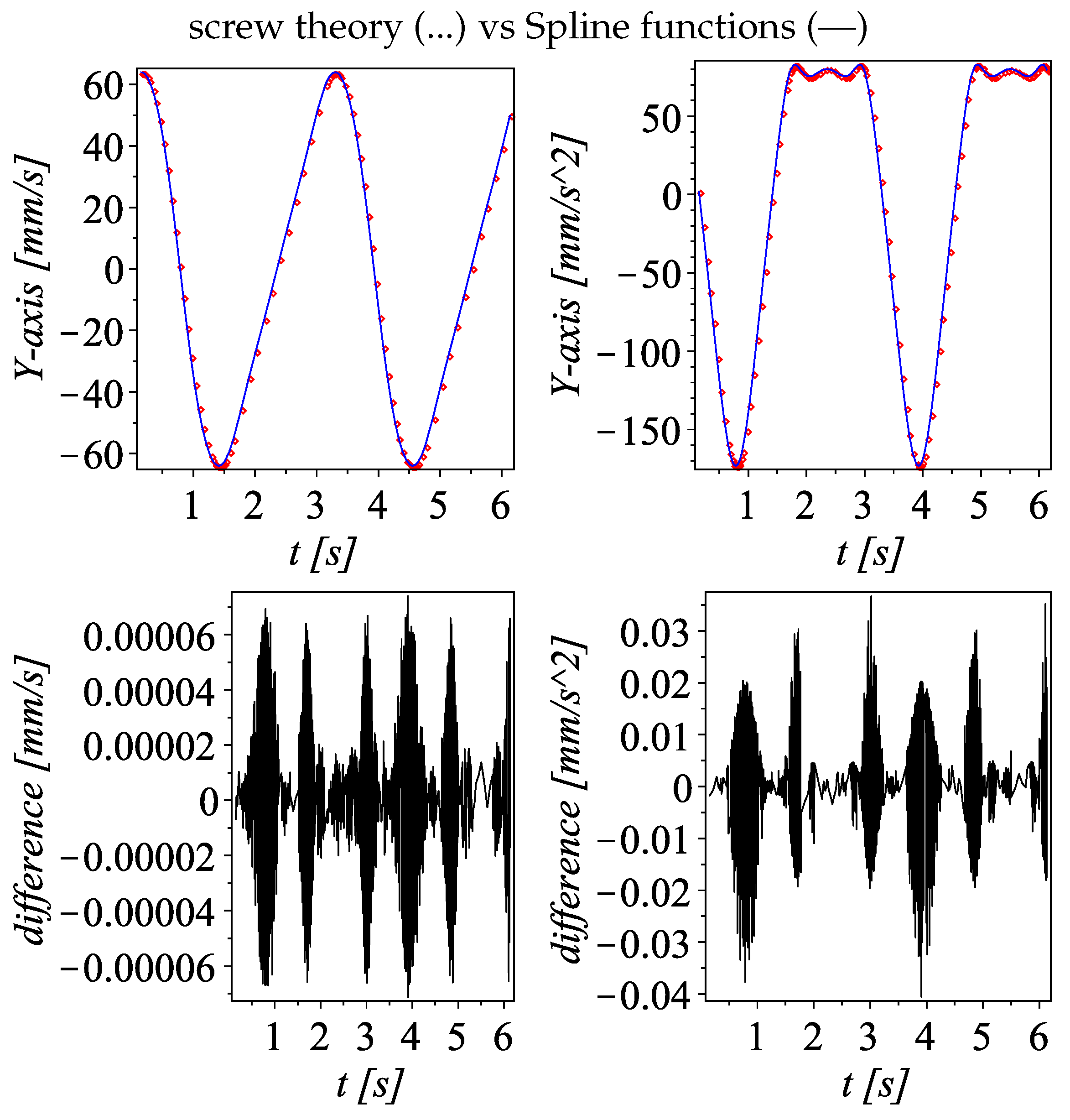

5.2. Velocity and Acceleration—Example 1

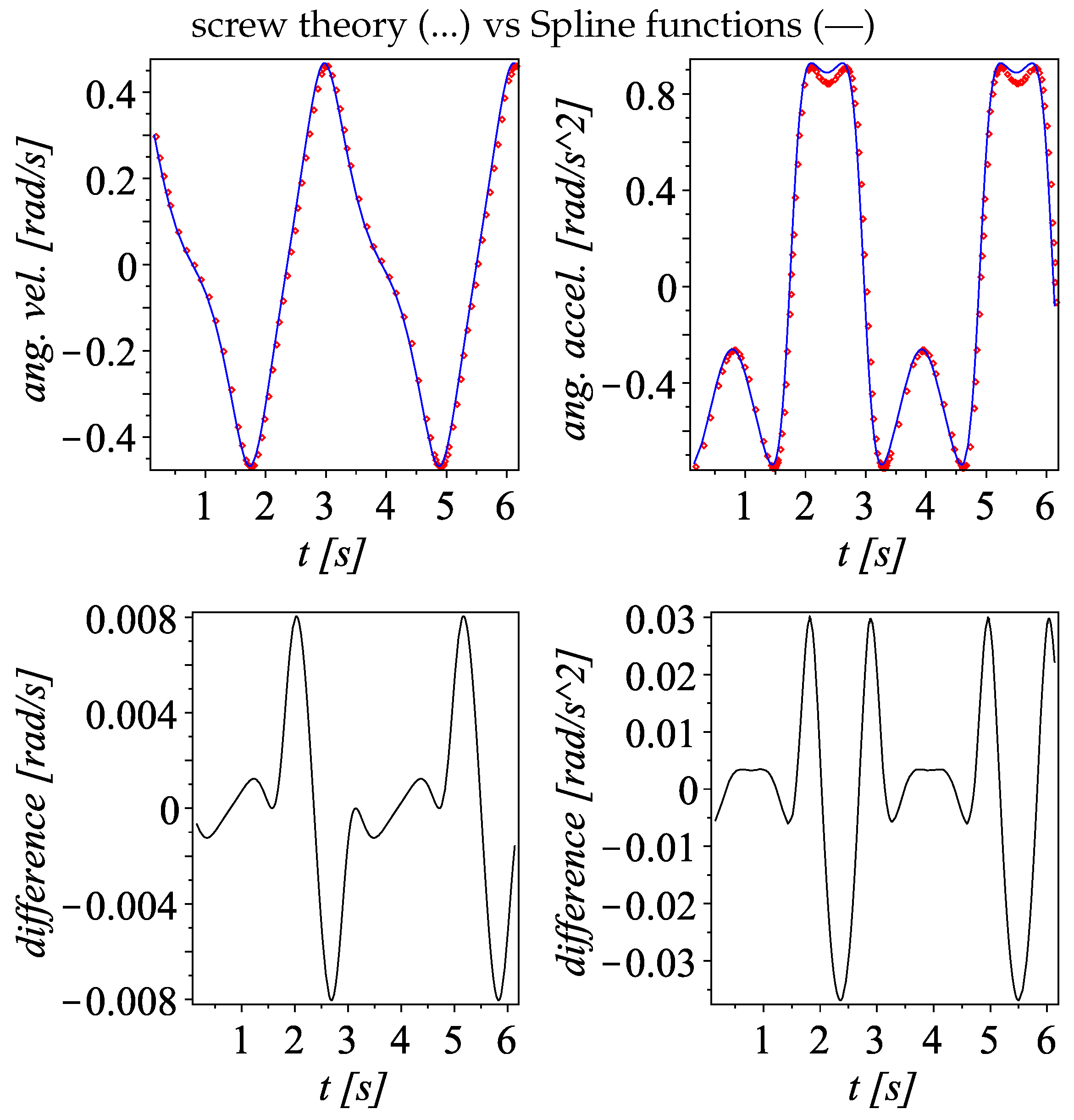

5.3. Velocity and Acceleration—Example 2

- Formulate the equations of the direct position analysis according to the algorithm described in Section 3.2.

- Since only one solution of the direct position analysis is required, apply a numerical technique such as the Newton–Raphson method to compute the solution for each time step. In the example, it was considered with .

- Obtain time-dependent angular and linear displacement functions of the moving platform using a numerical data fitting method. The Spline command from the (CurveFitting) library of the symbolic mathematics software Maple is particularly efficient for this task due to its ability to smoothly approximate data points.

- Obtain the velocity expressions by applying the time derivatives to the displacement functions generated in the previous point.

- Obtain the acceleration expressions by applying the time derivatives to the velocity functions generated in the previous point.

- Plot the velocity and acceleration expressions to observe trends, periodic behavior, or critical points.

6. Conclusions

- Mobility. The global mobility of the mechanism was determined using screw theory, with emphasis on the standard basis that facilitates the 3T1R motion characteristic of Schönflies motion generator mechanisms. This analysis revealed how the constraint systems inherent to each limited-DOF limb govern the interaction of joints and links, which is essential for understanding and computing the effective degrees of freedom available to the robot.

- Displacement analysis. Both forward and inverse position analyses were conducted based on the closure equations of the parallel manipulator. A key observation is the complexity difference between these analyses: the direct position analysis requires solving a system of three quadratic equations, an algebraically demanding task that may yield multiple solutions, whereas the inverse position analysis leads to a single, straightforward solution, making it more suitable for practical implementation.

- Instantaneous kinematics. Compact input–output expressions for velocity and acceleration were derived using screw theory, relating the robot’s input variables (instantaneous generalized coordinates) to the velocity and acceleration of the moving platform relative to the fixed base. This kinematic analysis was complemented by a singularity assessment, which revealed that the proposed manipulator is practically free from singular configurations—an important advantage in robotic applications.

- Numerical examples. Numerical simulations were provided to support the theoretical development. These examples demonstrated the practical applicability of the proposed kinematic methodology. The results were validated by comparison with outputs from alternative tools, including ADAMS™software and data fitting using spline algorithms.

- Although a physical prototype was not constructed, the mechanical design depicted in Figure 1, and validated in ADAMS™, demonstrates feasibility and supports the consideration of realistic scenarios for implementation. The manipulator is well-suited to tasks typically performed by conventional SCARA-type robots, such as the Adept Quattro, and more broadly, Delta-type manipulators.

- Compared to traditional SCARA serial robots, the proposed parallel manipulator demonstrates potential advantages, including greater structural rigidity, improved positioning accuracy, and enhanced robustness. These features make it well-suited for high precision and reliability applications such as electronic component handling, surgical tool positioning, and aeronautical assembly.

- Unlike Delta-type manipulators, which depend on articulated parallelograms and multiple passive links, the proposed 3T1R parallel manipulator employs four serial kinematic chains and eliminates the need for a closed internal loop. This results in a simpler and potentially more efficient mechanical structure, ideal for tasks requiring high stiffness, accurate alignment, and compact rotational motion such as laser cutting, engraving, and other orientation sensitive processes.

- The proposed robot architecture does not include passive limbs; all four limbs are actuated, simplifying control and improving motion precision.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Clavel, R. Device for the Movement and Positioning of an Element in Space. U.S. Patent No. 4,976,582, 11 December 1990. [Google Scholar]

- Altuzarra, O.; Şandru, B.; Pinto, C.; Petuya, V. A symmetric parallel Schönflies-motion manipulator for pick-and-place operations. Robotica 2011, 29, 853–862. [Google Scholar] [CrossRef]

- Cervantes-Sanchez, J.; Rico-Martinez, J.; Perez-Munoz, V. Angularity and axiality of a Schönflies parallel manipulator. Robotica 2016, 34, 2415–2439. [Google Scholar] [CrossRef]

- Isaksson, M.; Gosselin, C.; Marlow, K. Singularity analysis of a class of kinematically redundant parallel Schönflies motion generators. Mech. Mach. Theory 2017, 112, 172–191. [Google Scholar] [CrossRef]

- Cao, W.; Yang, D.; Ding, H. A method for stiffness analysis of overconstrained parallel robotic mechanisms with Scara motion. Robot. Comput.-Integr. Manuf. 2018, 49, 426–435. [Google Scholar] [CrossRef]

- Gallardo-Alvarado, J.; Rodriguez-Castro, R.; Delossantos-Lara, P. Kinematics and dynamics of a 4-PRUR Schönflies parallel manipulator by means of screw theory and the principle of virtual work. Mech. Mach. Theory 2018, 122, 347–360. [Google Scholar] [CrossRef]

- Kong, X.; Gosselin, C. Type synthesis of 3T1R 4-DOF parallel manipulators based on screw theory. IEEE Trans. Robot. Autom. 2004, 20, 181–190. [Google Scholar] [CrossRef]

- Guo, S.; Fang, Y.; Qu, H. Type synthesis of 4-DOF nonoverconstrained parallel mechanisms based on screw theory. Robotica 2012, 30, 31–37. [Google Scholar] [CrossRef]

- Guo, S.; Ye, W.; Qu, H.; Zhang, D.; Fang, Y. A serial of novel four degrees of freedom parallel mechanisms with large rotational workspace. Robotica 2016, 34, 764–776. [Google Scholar] [CrossRef]

- Zhao, J.S.; Sun, H.L.; Li, H.Y.; Zhao, D.J. Screw Dynamics of a Multibody System by a Schoenflies Manipulator. Appl. Sci. 2023, 13, 9732. [Google Scholar] [CrossRef]

- Arian, A.; Isaksson, M.; Gosselin, C. Kinematic and dynamic analysis of a novel parallel kinematic Schönflies motion generator. Mech. Mach. Theory 2020, 147, 103629. [Google Scholar] [CrossRef]

- Wu, G.; Lin, Z.; Zhao, W.; Zhang, S.; Shen, H.; Caro, S. A four-limb parallel Schönflies motion generator with full-circle end-effector rotation. Mech. Mach. Theory 2020, 146, 103711. [Google Scholar] [CrossRef]

- Meng, Q.; Liu, X.J.; Xie, F. Design and development of a Schönflies-motion parallel robot with articulated platforms and closed-loop passive limbs. Robot. Comput.-Integr. Manuf. 2022, 77, 102352. [Google Scholar] [CrossRef]

- Urrea, C.; Dominguez, C.; Kern, J. Modeling, design and control of a 4-arm delta parallel manipulator employing type-1 and interval type-2 fuzzy logic-based techniques for precision applications. Robot. Auton. Syst. 2024, 175, 104661. [Google Scholar] [CrossRef]

- Sanchez-Alonso, R.; Gonzalez-Barbosa, J.J.; Castillo-Castaneda, E.; Gallardo-Alvarado, J. Kinematic analysis of a novel 2(3-RUS) parallel manipulator. Robotica 2016, 34, 2241–2256. [Google Scholar] [CrossRef]

- Li, Q.; Huang, Z. Mobility Analysis of a Novel 3-5R Parallel Mechanism Family. J. Mech. Des. 2004, 126, 79–82. [Google Scholar] [CrossRef]

- Dai, J.; Huang, Z.; Lipkin, H. Mobility of Overconstrained Parallel Mechanisms. J. Mech. Des. 2004, 128, 220–229. [Google Scholar] [CrossRef]

- Lynch, K.; Park, F. Modern Robotics: Mechanics, Planning, and Control; Cambridge University Press: Cambridge, UK, 2017. [Google Scholar]

- Gallardo-Alvarado, J.; Rodriguez-Castro, R.; Islam, M. Analytical Solution of the Forward Position Analysis of Parallel Manipulators That Generate 3-RS Structures. Adv. Robot. 2008, 22, 215–234. [Google Scholar] [CrossRef]

- Gallardo-Alvarado, J.; Gallardo-Razo, J. Mechanisms: Kinematic Analysis and Applications in Robotics; Emerging Methodologies and Applications in Modelling, Identification and Control; Academic Press: Cambridge, MA, USA; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Gallardo-Alvarado, J.; Rico, J. Screw Theory and Helicoidal Fields. In Proceedings of the 25th Biennial Mechanisms Conference, International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Atlanta, GA, USA, 13–16 September 1998; Volume 1B, p. V01BT01A007. [Google Scholar] [CrossRef]

| i | [mm] | [mm] | [mm] | |

|---|---|---|---|---|

| 1 | [rad] | (0, −200, 140) | (0, −50, 140) | (0, −50, 448.994) |

| 2 | 150 [mm] | (0, 200, 140) | (0, 50, 140) | (0, 50, 448.994) |

| 3 | 286.631 [mm] | (−200, 0, 180) | — | (−100, 0, 448.994) |

| 4 | 286.631 [mm] | (200, 0, 180) | — | (100, 0, 448.994) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gallardo-Alvarado, J.; Orozco-Mendoza, H.; Rodriguez-Castro, R.; Sanchez-Rodriguez, A.; Alcaraz-Caracheo, L.A. The Kinematics of a New Schönflies Motion Generator Parallel Manipulator Using Screw Theory. Mathematics 2025, 13, 2291. https://doi.org/10.3390/math13142291

Gallardo-Alvarado J, Orozco-Mendoza H, Rodriguez-Castro R, Sanchez-Rodriguez A, Alcaraz-Caracheo LA. The Kinematics of a New Schönflies Motion Generator Parallel Manipulator Using Screw Theory. Mathematics. 2025; 13(14):2291. https://doi.org/10.3390/math13142291

Chicago/Turabian StyleGallardo-Alvarado, Jaime, Horacio Orozco-Mendoza, Ramon Rodriguez-Castro, Alvaro Sanchez-Rodriguez, and Luis A. Alcaraz-Caracheo. 2025. "The Kinematics of a New Schönflies Motion Generator Parallel Manipulator Using Screw Theory" Mathematics 13, no. 14: 2291. https://doi.org/10.3390/math13142291

APA StyleGallardo-Alvarado, J., Orozco-Mendoza, H., Rodriguez-Castro, R., Sanchez-Rodriguez, A., & Alcaraz-Caracheo, L. A. (2025). The Kinematics of a New Schönflies Motion Generator Parallel Manipulator Using Screw Theory. Mathematics, 13(14), 2291. https://doi.org/10.3390/math13142291