Abstract

Compliant force control is a fundamental capability for enabling robots to interact safely and effectively with dynamic and uncertain environments. This paper presents a comprehensive survey of compliant force control strategies, intending to enhance safety, adaptability, and precision in applications such as physical human–robot interaction, robotic manipulation, and collaborative tasks. The review begins with a classification of compliant control methods into passive and active approaches, followed by a detailed examination of direct force control techniques—including hybrid and parallel force/position control—and indirect methods such as impedance and admittance control. Special emphasis is placed on advanced compliant control strategies applied to structurally complex robotic systems, including aerial, mobile, cable-driven, and bionic robots. In addition, intelligent compliant control approaches are systematically analyzed, encompassing neural networks, fuzzy logic, sliding mode control, and reinforcement learning. Sensorless compliance techniques are also discussed, along with emerging trends in hardware design and intelligent control methodologies. This survey provides a holistic view of the current landscape, identifies key technical challenges, and outlines future research directions for achieving more robust, intelligent, and adaptive compliant force control in robotic systems.

MSC:

70K40

1. Introduction

In recent years, robotic systems have progressively evolved from operating exclusively in structured industrial environments to performing complex tasks in dynamic, unstructured, and human-centered settings. These emerging applications include collaborative manufacturing, medical assistance, service robotics, teleoperation, and exploration in hazardous or remote areas. In such contexts, robots are required not only to manipulate objects with high precision but also to interact safely, adaptively, and effectively with their environments and human users. A key enabler of such interactions is compliant force control—the capability of a robot to regulate interaction forces during physical contact while maintaining overall task performance and operational stability.

Compliant force control plays a crucial role in ensuring that robots do not exert excessive or unstable forces during physical interaction, thereby preventing potential damage, instability, or safety risks. In contrast to traditional rigid position control, which prioritizes precise trajectory tracking, and high stiffness, compliant force control emphasizes adaptability, flexibility, and safety by allowing the robot to modulate its response in the presence of external forces or disturbances. This capability is particularly vital in applications such as surgical robotics, physical human–robot interaction (pHRI), rehabilitation robotics, robotic assembly, and the manipulation of soft or fragile objects.

In contrast to rigid industrial robots that operate in highly structured environments with predictable contact conditions, compliant robotic systems often operate in dynamic, uncertain, and unstructured environments where human safety and environmental adaptability are critical. The fundamental characteristics of such robots include physical compliance, real-time adaptability, dynamic interaction with uncertain external forces, and the necessity for multi-modal perception. Compared to conventional control systems, compliant force control presents multiple challenges such as nonlinear dynamics, model uncertainties, safety-critical constraints, and the need for rapid real-time computation to ensure safe human–robot collaboration. These aspects make compliant force control a multidisciplinary research frontier integrating control theory, machine learning, biomechanics, and robotic morphology co-design.

Historically, compliant force control originated with passive strategies, which introduced mechanical compliance through physical elements such as springs or Remote Center Compliance (RCC) devices [1,2,3]. These components enabled basic force accommodation without requiring active sensing or feedback, offering simplicity and cost-effectiveness. However, passive methods are inherently limited in terms of tunability and adaptability to varying task conditions [4]. In contrast, active compliant control strategies utilize sensory feedback, typically from force/torque sensors or joint torque estimates, to modulate control inputs in real time based on interaction forces [5,6]. Active strategies can be broadly categorized into direct force control and indirect force control, each offering different levels of responsiveness and robustness in handling dynamic environments.

Direct force control approaches, such as hybrid and parallel position/force control, explicitly regulate the contact forces by incorporating the force error directly into the control loop [7,8,9,10,11,12,13,14,15,16,17,18,19,19]. These methods aim to maintain desired force levels by continuously adjusting actuator commands based on real-time force measurements, enabling precise force tracking during interaction tasks. In contrast, indirect force control methods, primarily impedance and admittance control, do not regulate force directly. Instead, they modulate the robot’s dynamic behavior, such as stiffness, damping, or reference trajectories, to achieve a compliant interaction indirectly [20,21,22,23,24,25,26,27,28,29,30,31,32,33,34]. By shaping the mechanical impedance or admittance of the system, these strategies allow the robot to respond flexibly to external forces, ensuring stable and adaptive contact with the environment.

Beyond these foundational methods, the field has progressed toward more advanced intelligent force control strategies that integrate artificial intelligence and learning-based techniques. Approaches leveraging neural networks, fuzzy logic, sliding mode control, and reinforcement learning enable robots to adapt effectively in highly nonlinear, uncertain, and dynamic environments scenarios where traditional model-based control methods often fall short [35,36,37,38,39,40,41,42,43,44]. These intelligent methods offer improved robustness, real-time learning, and the ability to handle unmodeled dynamics, making them particularly suited for complex compliant force control tasks.

Moreover, the emergence of advanced robotic platforms such as flying robots, mobile manipulators, cable-driven systems, and bionic robots has introduced both new challenges and opportunities in compliant force control [45,46,47,48,49,50,51]. These sophisticated systems often demand innovative integrations of sensing, actuation, and control strategies to maintain stability and adaptability, particularly when faced with issues like underactuation, high degrees of freedom, and uncertain, dynamic environments. Additionally, sensorless force control has emerged as a practical alternative to reduce hardware complexity and cost, particularly in scenarios where integrating physical force sensors is impractical. These techniques estimate interaction forces using motor currents, joint torques, or dynamic model-based observers. Alongside advancements in algorithms and control architectures, there is a growing trend toward the co-design of control systems and mechanical structures [52,53,54,55,56,57,58,59,60,61,62,63,64,65,66]. Modern approaches emphasize optimizing robot morphology, incorporating compliant actuators, refining transmission mechanisms, and integrating soft materials into end effectors. By physically embedding compliance, these designs reduce computational demands and enhance overall control robustness [67,68,69,70,71,72,73,74,75].

This survey aims to provide a comprehensive and structured overview of the current state of compliant force control in robotics. The main contributions of this paper include:

- A taxonomy and comparative review of passive, direct, and indirect force control methods.

- An in-depth analysis of advanced compliant force control strategies, emphasizing.

- Robots with complex mechanical structures (e.g., aerial, mobile, cable-driven, and bioinspired platforms).

- Intelligent control algorithms that integrate artificial intelligence, learning, and robust control techniques.

- A detailed discussion of sensorless force control approaches and the challenges associated with their implementation.

- A synthesis of emerging trends, including the evolution of robot morphology and the integration of multi-modal sensing and control methodologies.

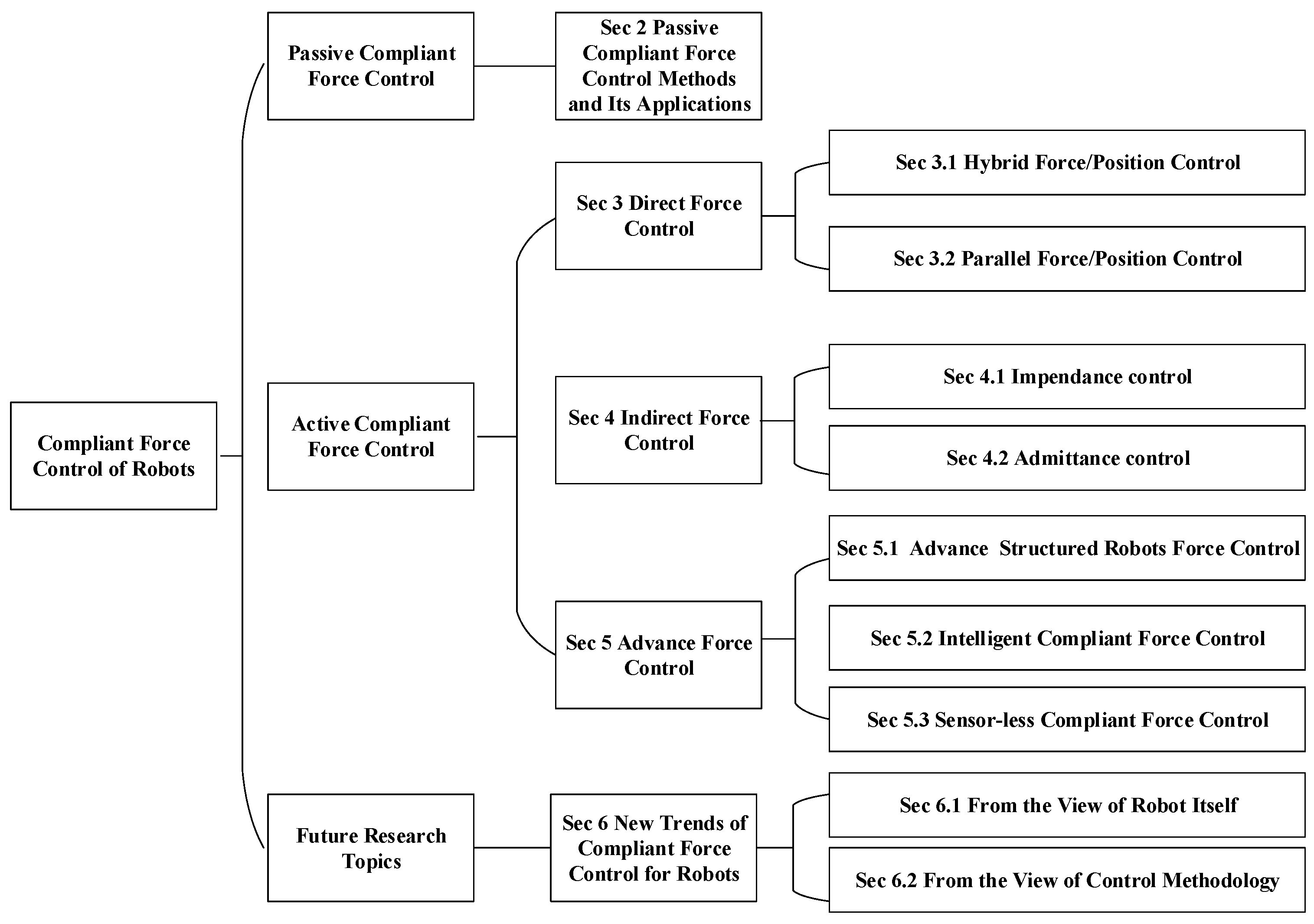

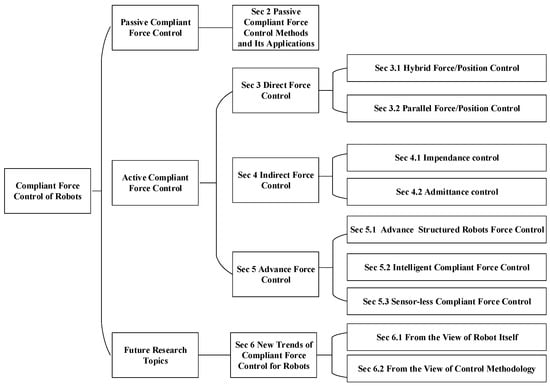

The remainder of this paper is organized as follows (Figure 1): Section 2 introduces passive compliant force control and its historical evolution. In Section 3 and Section 4, we present the direct and indirect control strategies in detail, respectively. Section 5 examines advanced force control approaches, categorized by robot structure and intelligent methodologies. The presentation of new trends from both the perspective of robot hardware and control theory is given in Section 6. The conclusion is drawn in Section 8.

Figure 1.

Organization of the survey.

2. Passive Compliant Force Control Methods and Applications

The passive compliant control of robotic manipulators involves installing a mechanical elastic structure (e.g., springs or dampers) at the end effector or in the interaction environment to achieve force control through the inherent elasticity of the system. This approach offers advantages such as simplicity, low cost, and minimal requirements for the manipulator itself. However, its force control accuracy is limited due to the complex structure of robotic manipulators, which exhibit nonlinear friction, transmission backlash, and other uncertainties. As a result, the desired stiffness cannot be precisely achieved, making this method suitable for applications with relatively low force control precision requirements.

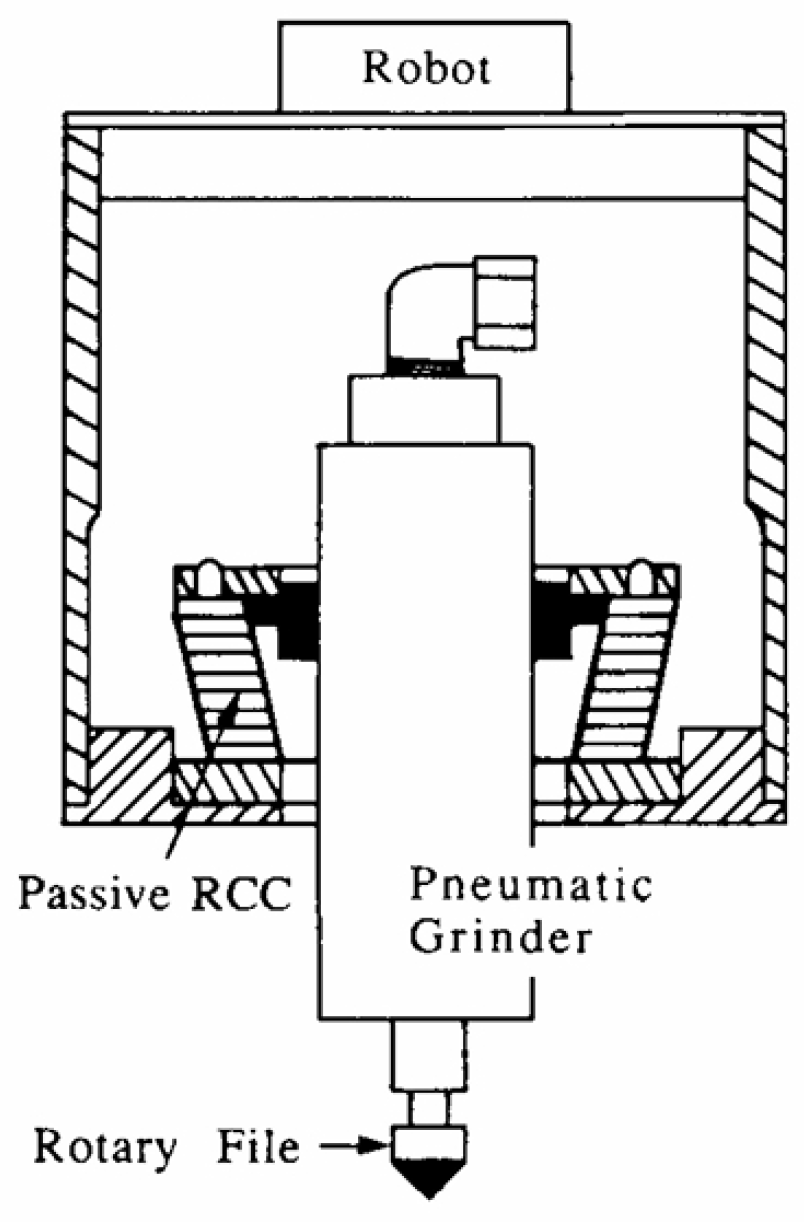

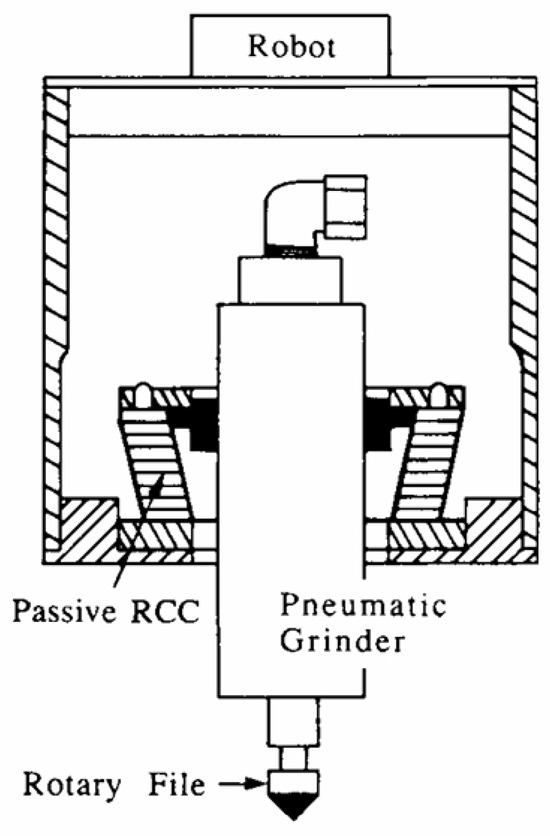

The first passive mechanical device, possibly a wrist, was developed in 1976 by Charles Stark Draper Laboratory, Inc. to assist with assembly tasks. This device, known as the Remote Center Compliance (RCC), was specifically designed to facilitate precise alignment during assembly operations (see Figure 2). Subsequently, in [1], a refined RCC wrist was introduced, demonstrating success in peg-in-hole assembly. This robotic system featured three fingers, each driven by an individual motor through coil springs, enhancing its compliance capabilities. Further advances in RCC technology were explored in [2], where a mechanical calculation method was proposed to enable a wider range of force control applications for RCC devices. However, conventional RCC mechanisms exhibit certain limitations when applied to flexible precision assembly automation, particularly due to the lack of the precise characterization of key parameters such as the position of the remote compliance center and local compliance properties. To address these challenges, a more cost-effective, compact, and lightweight variable RCC (VRCC) was developed in [76]. Moreover, a novel soft RCC device featuring pneumatic regulation was introduced in [3]. This device incorporated a specialized structural design that enabled stiffness modulation in non-actuated directions, further expanding the potential applications of RCC-based compliance mechanisms.

Figure 2.

Structure of the passive compliant force control (RCC) [77].

In addition to modifications and enhancements of passive compliant mechanisms, research on passive compliant force control has also been conducted from the perspectives of design theory and control theory. In [4], a comprehensive analysis was provided on the specification of robot end-effector compliance, the properties of the compliance matrix at the end effector, as well as a detailed discussion and comparison between passive and active compliance. Given the inherent limitation of passive compliance, which lacks tunability, a hybrid compliance approach was proposed in [5], where active compliance was utilized in the low-frequency domain, while passive compliance was relied upon in the high-frequency domain. This method was successfully applied to the shoulder mechanism of a humanoid torso robot, demonstrating effective results. Furthermore, ref. [6] introduced a parallel composition of active and passive compliance to ensure safe interaction with the environment. In this scheme, passive compliance was achieved by limiting the currents to the joint motors based on an identified model of the studied robotic system.

In conclusion, passive compliant force control heavily depends on the design of the mechanical elastic structure and the tuning of its parameters. However, due to its inherent limitations in achieving precise interaction force control, its application scope remains restricted. Consequently, passive force control is rarely considered a primary research focus in the field of compliant control.

3. Direct Force Control

Direct force control method aims at achieving force regulation when the manipulator is in contact with a compliant environment, and this control method directly operates on a force error between the desired and the measured values from the force sensor. The force sensing error is a directly closed loop to the robot’s motion control. It can be divided into two directions: the hybrid force/position control, and the parallel force/position control.

3.1. Hybrid Force/Position Control

The “Hybrid” method aims at combining the force and robot torque information with position data to satisfy the simultaneous position and force trajectory constraints in the specified task. In this methodology, the position control loop and the force control loop can be considered separately. This concept was proposed in [78] for the first time. It formally partitions the six task space DOF into purely position-controlled and purely force-controlled directions, and the selection of these directions is made a priori based on a detailed description of the environment geometry. A diagonal selection matrix is employed to define which DOFs are force-controlled and which are position-controlled. Subsequently, two independent controllers are designed for each subspace, ensuring the orthogonality of the position and force control subspaces within this control architecture.

Based on this methodology, other related work has been proceeded. Ref. [7] proposed a hybrid position/force control for the coordination of a two-arm robot. It defined a unique system of workspace coordinates and, corresponding to the unique workspace, introduced a unique joint space vector consisting of joint vectors of the two arms. Similarly, in [8], a hybrid symmetric position/force control scheme was proposed for the coordination of two robots to manipulate a single object jointly. Ref. [79] aimed to fill the gap between theory and industrial applications and developed an implicit hybrid control scheme. The experimental validation of the strategy was performed on an industrial robot with a six-DOF force/torque sensor. The hybrid position/force controller was successfully applied not only to the industrial robot but to other robots with different structures, such as flexible robots [9,10,11], joint robots [12], continuum robots [80,81], and soft robots [13]. Meanwhile, researchers focused on combining this control theory with intelligent control methodologies, such as neural network control [14,15], fuzzy control [16,17], and sliding mode control [82]. In order to avoid the knowledge of the environment geometry, some sensors are used in this kind of controller. Ref. [83] used a single camera to measure the unknown contact surface. Ref. [84] applied a charge-coupled device (CCD) camera and a laser distance sensor to provide global relative position information. Meanwhile, the position control loop can also be replaced with other sensor-based control loops, such as visual servoing [13,18,19] and laser endomicroscopy [85].

However, even though hybrid position/force control is a powerful technique, it still has some limitations, such as accurate environment geometrical information, poor tuning between position loop and force loop, environmental uncertainties, limited adaptability, etc. These drawbacks make it difficult to consider the implications in practice. The hybrid position/force control is not the dominant control method in the field of compliant control nowadays.

3.2. Parallel Force/Position Control

Another direct force control methodology is parallel position force control. Unlike the hybrid position force controller, it offers an effective framework for tasks that involve interaction with the environment. This approach operates within a full-dimensional task space without the need for a selection matrix. Conflicting situations between position and force tasks are managed through a priority strategy, where the force control loop is designed to take precedence over the position control loop. This ensures that the force constraints are respected even if they conflict with the objectives of position control [86]. It offers good performance in the face of uncertainty in the geometry of the contact surface. Ref. [87] developed an adaptive controller for the uncertainty in contact stiffness. In [88], the parallel force and position control was applied to the control of flexible manipulators, and the simulation results were presented for a two-link planar manipulator under gravity in contact with an elastically compliant surface. Ref. [89] proposed the controller for the control of loads through the wave zone in marine operations. In [90], a parallel force/position control was developed to ensure the stability of the grasp task with a novel biomechatronic hand prosthesis. In addition to its implementation on industrial robots, this control method was also applied to aerial robots. In [91], the problem of unilateral contact by an under-actuated quadrotor UAV equipped with a passive tool in a bilateral teleoperation scheme was presented.

Similarly, to address the model-based control in the position control loop, vision was utilized for motion tracking in parallel position-force control, referred to as parallel vision-force control [92,93,94,95]. Since visual servo can bypass the complexities of the robot’s mechanical structure, including clearance, it enhances position accuracy. Furthermore, this controller enables simultaneous contact force and position control within a single dedicated degree of freedom (DOF). In particular, when applied, the dynamic parameters of the environment are not indispensable.

4. Indirect Force Control

Different from direct force control, indirect force control is a strategy employed in robotic systems where force regulation is achieved indirectly by modulating position, velocity, or impedance rather than directly controlling force. This approach is particularly advantageous when direct force measurement is challenging or when compliance with an external wrench is required. Generally, indirect force control can be categorized into two main approaches: impedance control and admittance control. These two control methods are fundamentally opposite: impedance control establishes a dynamic mass-spring-damper relationship between force and motion, enabling adaptability in contact tasks, whereas admittance control adjusts position in response to force inputs.

4.1. Impedance Control

Compliance force control is designed to achieve a desired static interaction behavior. To achieve a desired dynamic behavior, it is necessary to consider not only stiffness but also the actual mass and damping at the contact point, leading to impedance control.

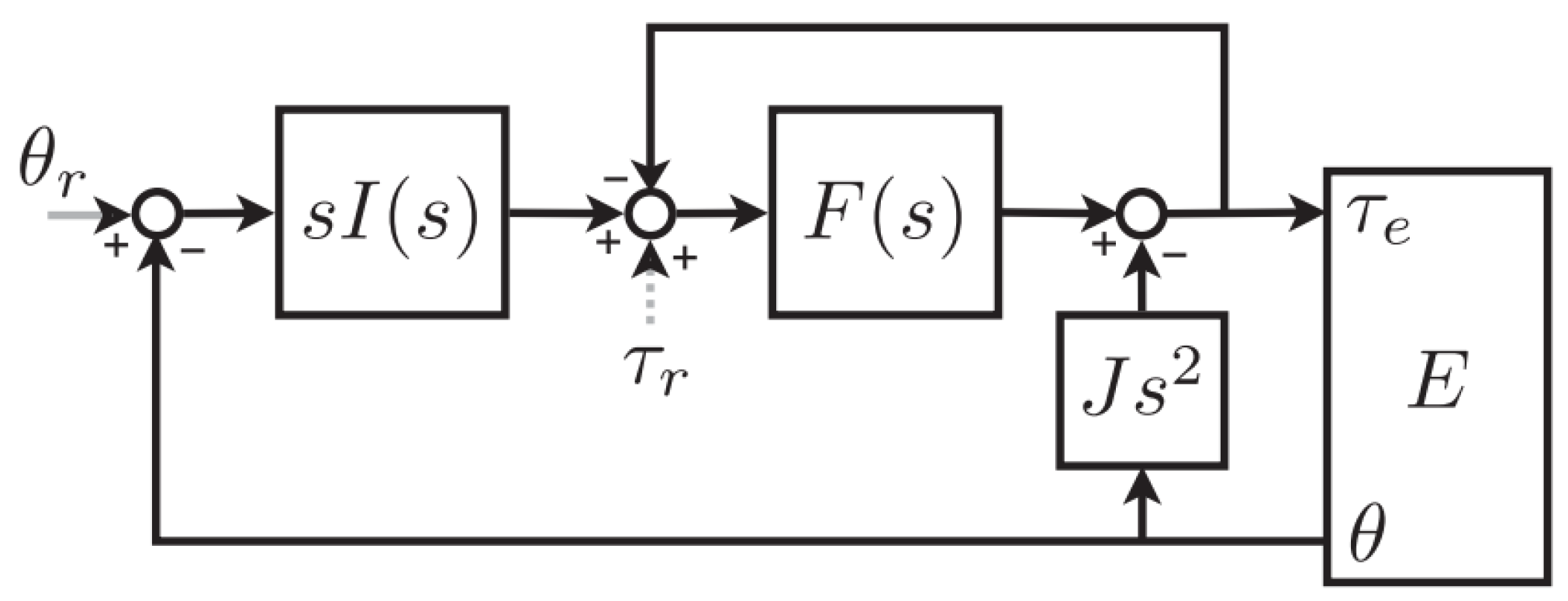

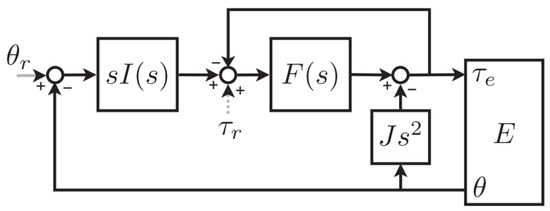

The concept of “impedance control” was first introduced in [20]. Since manipulation inherently involves mechanical interaction between systems, this approach focuses on characterizing and controlling these interactions. This method defines a virtual mechanical impedance (mass, damping, and stiffness) to shape the robot’s response to an external wrench (see Figure 3). The desired mechanical impedance is expressed as

where , , and represent the desired position, velocity, and acceleration, respectively, and , , and are the virtual inertia, damping, and stiffness parameters. The goal is to shape the robot’s dynamic response so that the actual motion follows the desired trajectory while maintaining a compliant interaction with the environment. The impedance represents a measure of the dynamic compliance of the manipulator. The fundamental principle of impedance control is to generate different levels of compliance to regulate the interaction forces. Consequently, well-designed impedance parameters significantly influence control performance.

Figure 3.

Impedance control schema [96].

Traditional constant impedance control is a simple yet effective approach widely used in various fields, including contact force tracking. This method requires prior knowledge of the relative position and stiffness of the environment and typically assumes a desired constant force. However, its lack of adaptability limits its applicability to different tasks. To address this limitation, researchers have explored adaptive variable impedance control for contact force regulation. In [21], the direct adaptive impedance controller was first proposed, incorporating a simple “filter”, an adaptive controller, and an algorithm to map Cartesian space control input to physically realizable joint-space control torques. In [22], a novel impedance controller was introduced that can track desired dynamic forces while compensating for uncertainties in unknown geometric and mechanical properties of the environment. Similarly, Ref. [23] investigated impedance control from the perspective of the actuator, proposing an optimal impedance control strategy for a variable stiffness actuator, where a variable stiffness mechanism is aligned in series with the actuator. With the development of intelligent control methods, an increasing number of studies have focused on learning-based adaptive impedance control. These include approaches such as using barrier functions [24], employing adaptive neural networks (NNs) to compensate for uncertain dynamics and unknown disturbances online [97], applying observers for nonlinear time-delay disturbances [98], performing online stiffness estimation [99], using neural network synchronization methods [25], and incorporating cooperative differential game theory [100].

The impedance control can also be divided into three types: position-based impedance control [26,27], torque-based impedance control [101], and model-based impedance control.

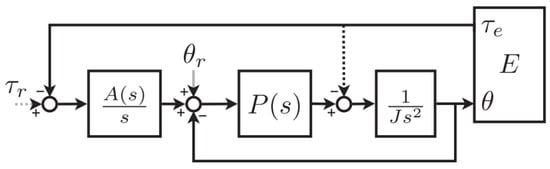

4.2. Admittance Control

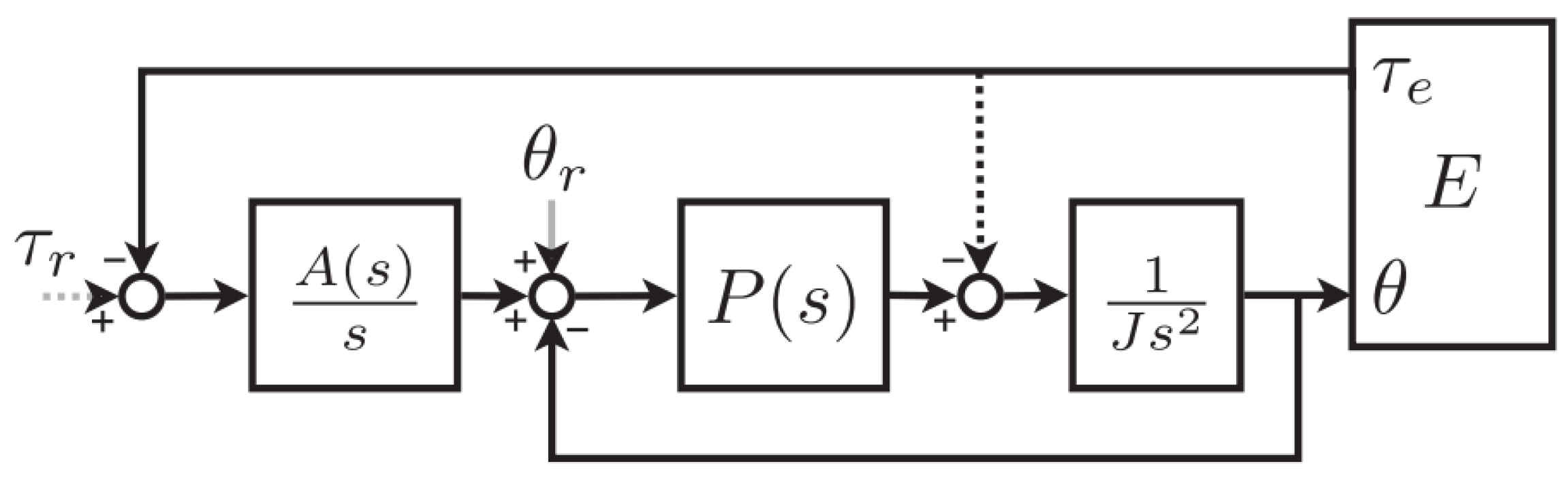

Admittance control is the inverse of impedance control. Instead of directly controlling position and velocity, it focuses on managing how a system responds to an external wrench. This control law establishes the relationship between the external force and the desired movement, often referred to as the interaction environment admittance model [28,29] (see Figure 4). As a method that uses motion to compensate for force errors, admittance control is highly dependent on precise position control to achieve accurate force regulation. In admittance control, the desired mechanical behavior of the robot is modeled as a virtual admittance system, typically using a second-order mass-spring-damper model:

where , , and are the desired inertia, damping, and stiffness matrices, respectively, and is the measured external force or torque. The solution of this differential equation provides a desired trajectory or velocity command that is then executed by the robot’s low-level controller.

Figure 4.

Admittance control schema [96].

Admittance control can provide very good performance in soft environments but results in contact instability in stiff environments [29]. In the admittance model, a large number of studies have focused on the adaptive adjustment of the parameters of the admittance model. In [102,103], reinforcement learning is integrated with admittance control, where neural networks are employed to predict changes in environmental parameters, leading to improved adaptability. In [30,31], admittance control is implemented to allow effective human–robot interaction. In [104], visual servoing is combined with admittance control to enhance robot interaction capabilities. These developments offer novel solutions to implement admittance control in complex and unstructured environments. Fixed-parameter admittance controllers may not suffice in environments with time-varying dynamics or task uncertainties. To address this limitation, researchers have proposed adaptive [39,105] and variable admittance control schemes that update the admittance parameters in real time based on sensory feedback or interaction metrics [32,33,34].

Despite its advantages, admittance control also poses several challenges. These include the accurate measurement and filtering of external forces, the tuning of dynamic parameters for stability and responsiveness, and the risk of instability in the presence of high interaction forces or delays. Moreover, in the absence of direct force sensing, implementing admittance control requires accurate estimation techniques or observer-based approaches.

5. Advance Force Control

Advanced force control refers to the use of advanced algorithms and technologies to enable robots to achieve precise and stable coordination of force and position in dynamic and uncertain environments. It is mainly categorized into three types: advanced-structure-based force control, intelligent compliant force control, and sensorless compliant force control.

5.1. Advance Structured Robots Force Control

Compliant force control is essential for enabling robots to interact safely and effectively with complex, dynamic environments. Advanced robotic platforms—such as flying robots, mobile robots, cable-driven systems, and bionic robots—pose distinct challenges and offer unique opportunities for the implementation of compliant control strategies. This section explores the specific considerations, design methodologies, and control approaches tailored to these advanced robotic structures [45].

Flying robots, or aerial drones, demand highly precise force control to ensure stability during flight and to enable interaction-based tasks such as manipulation, inspection, or perching. The integration of compliant mechanisms into these systems allows them to engage with their environments adaptively, without adversely affecting their flight dynamics. For example, the Astrobee robotic system incorporates a compliant, detachable arm that enables the robot to perch on surfaces, thereby conserving energy during prolonged operations [46]. Similarly, the Morphy robot represents a morphologically adaptive aerial platform that leverages compliant design principles to navigate and interact with cluttered or constrained environments safely and effectively [47].

Mobile robots operating in dynamic and unstructured environments greatly benefit from compliant force control to ensure safe navigation and effective interaction with objects or humans. By implementing impedance or admittance control strategies, these robots can adapt their motion in response to external forces, improving both safety and task performance [48]. For instance, current-based impedance control has been applied to mobile manipulators, enabling compliant interaction without the need for dedicated force/torque sensors. Additionally, hybrid velocity/force control methods have been proposed to facilitate navigation in unknown, compliant environments. These approaches integrate force sensing with dynamic control laws to maintain system stability and enhance adaptability in real-time interactions [49].

Cable-driven robots offer significant advantages, such as expansive workspaces, lightweight structures, and high-speed operation. However, they present inherent challenges for compliant force control due to cable elasticity, backlash, and the unidirectional nature of cable actuation. To address these limitations, compliance control strategies based on force–position hybrid drive schemes have been proposed. These methods involve accurately mapping the relationship between the cable space and the joint space to enable precise regulation of interaction forces. Furthermore, recent advancements in modular, cable-driven, snake-like manipulators have demonstrated improved active compliance through impedance control. These developments have enhanced the robots’ ability to perform complex manipulation tasks in constrained or cluttered environments [50].

Bionic robots, inspired by the structure and function of biological organisms, utilize compliant actuators to replicate natural movement and interaction patterns [106,107]. The integration of compliant mechanisms—such as spiral springs, tendon-driven systems, or variable stiffness actuators—enables these robots to achieve energy-efficient, adaptive, and resilient motion. For example, bionic robotic arms equipped with compliant actuators have demonstrated the ability to perform manipulation tasks with human-like dexterity and responsiveness, accommodating external disturbances with minimal control effort. Recent advances in actuator design that emulate the properties of biological muscles—such as nonlinear stiffness [51], damping, and force generation—have further improved the ability of bionic robots to safely and effectively interact with complex and dynamic environments [108].

5.2. Intelligent Compliant Force Control

Intelligent control methods have been increasingly integrated into compliant force control systems to enhance adaptability, robustness, and autonomy. Traditional model-based force control strategies often struggle with nonlinearities, uncertainties, and dynamic interactions in unstructured environments. To address these limitations, intelligent control paradigms, such as neural networks, fuzzy logic, sliding mode control, and reinforcement learning, have been employed in impedance and admittance control frameworks to achieve compliant interaction with greater flexibility and generalization capability.

Neural networks (NNs) are well-suited for approximating complex nonlinear mappings and compensating for unknown dynamics in robotic systems. In the context of compliant control, NNs have been extensively employed to estimate system uncertainties and adapt control parameters in real time. For example, adaptive NN-based controllers have been integrated into impedance control frameworks to enhance compliance and maintain stability under varying environmental conditions [36]. In [35], a neural network-adaptive impedance control strategy was proposed for robotic manipulators interacting with unknown environments, wherein the NN effectively learned the nonlinear interaction forces without requiring an accurate system model. Common implementations include radial basis function (RBF) networks and recurrent neural networks, which are capable of learning the system’s dynamic properties and ensuring smooth force tracking performance [37,38,39].

Fuzzy logic offers a robust framework for managing uncertainty and imprecision in control systems, making it particularly suitable for force interaction tasks where accurate modeling of the environment is challenging. Fuzzy impedance control strategies have been applied in scenarios involving uncertain or time-varying contact conditions [40,41]. One of the key advantages of fuzzy logic lies in the interpretability of its rule base, which can be formulated using expert knowledge to dynamically adjust impedance parameters. For instance, fuzzy-PID-based impedance control has proven effective in regulating contact forces during surface polishing and human–robot interaction tasks, delivering both flexibility and stability in unstructured environments [109].

Sliding mode control (SMC) is renowned for its robustness against system uncertainties and external disturbances. It has been widely applied to impedance or admittance control frameworks to achieve stable compliant motion. The integration of intelligent features, such as adaptive laws or observers, further improves the performance of conventional SMC [42,43]. For example, a leakage-type adaptive sliding mode impedance control approach was proposed in [44], which combines auxiliary dynamics compensation and sliding surfaces to suppress chattering while maintaining robustness. Such methods have been successfully applied in polishing, assembly, and rehabilitation robotics.

Reinforcement learning (RL), especially deep reinforcement learning (DRL), has demonstrated considerable potential in acquiring compliant behaviors through direct interaction with the environment. RL-based compliant control approaches enable robots to autonomously learn force interaction policies, allowing for adaptive behavior in complex and unstructured tasks [110,111]. For example, Zhang et al. [112] proposed a residual reinforcement learning framework for contact-rich manipulation tasks, which integrates prior model knowledge with learned policies to enhance both safety and compliance. Despite these promising advancements, several challenges remain, including sample inefficiency, limited safety guarantees during training, and poor generalization across varying tasks or environments. These issues continue to be active areas of research in applying RL techniques to real-world compliant force control systems.

Recent developments, such as meta-learning and few-shot learning, provide promising approaches for enabling robots to rapidly adapt force control policies to novel tasks with limited training data. Residual reinforcement learning facilitates the integration of prior model knowledge with learning-based adaptation, thereby enhancing sample efficiency and ensuring safety during training. Furthermore, biologically inspired spiking neural networks and physics-informed neural networks have emerged as effective frameworks for real-time compliant force control in complex environments, offering advantages in energy-efficient computation and improved interpretability.

Despite the superior adaptability and control performance of intelligent approaches, challenges remain in terms of computational load, convergence stability, and safety guarantees. Future research should focus on lightweight implementation and enhancing interpretability to facilitate real-world deployment.

5.3. Sensorless Compliant Force Control

Sensorless compliant force control enables robots to interact compliantly with their environments without relying on external force/torque sensors, using only internal measurements such as joint positions, velocities, and actuator torques. The main strategies in this domain include model-based methods, observer-based techniques (e.g., disturbance observers, sliding mode observers, and state observers), and data-driven approaches.

Model-based methods estimate external interaction forces indirectly by leveraging the robot’s dynamic model in combination with parameter identification. For example, Villagrossi et al. [113] proposed a “virtual” force sensing method that computes the residual between measured actuator torques and those predicted by the dynamic model. While such methods are effective under accurate modeling conditions, they are highly sensitive to parameter uncertainties and unmodeled dynamics. To improve robustness, observer-based techniques have been widely adopted. Disturbance observers treat unknown external forces as lumped disturbances and estimate them in real time, achieving fast response with relatively simple implementations [114,115]. However, these methods typically involve a trade-off between estimation bandwidth and accuracy. Sliding mode observers exploit the robustness of sliding mode control to estimate external forces [116], although the inherent switching nature can lead to undesirable chattering. Alternatively, state observers extend the system state space to include external forces as observable variables [117], but their performance still depends heavily on the accuracy of the underlying dynamic model.

In recent years, data-driven approaches have emerged as promising alternatives for sensorless force estimation. Techniques such as Gaussian Process Regression (GPR) [118] and deep neural networks [119] have been applied to learn mappings from motion states to interaction forces without explicit modeling. These methods are particularly advantageous in highly nonlinear and complex environments but often require extensive training data and may suffer from limited generalization or real-time performance constraints.

6. New Trends of Compliant Force Control for Robots

6.1. From the View of Robot Itself

Advancements in robot design have significantly influenced the evolution of compliant force control strategies. By optimizing physical characteristics—such as configuration, actuation methods, transmission mechanisms, and the compliance of interaction interfaces—engineers have enhanced the ability of robots to perform safe and effective interactions in dynamic and uncertain environments.

Modern robotic systems increasingly adopt modular and reconfigurable architectures to improve adaptability and compliance. These configurations allow robots to morphologically adjust to task-specific requirements, facilitating safer and more efficient interactions in unstructured environments. Incorporating compliant joints and flexible structures into robotic arms further enhances safety by absorbing unexpected contact forces and minimizing the risk of mechanical damage or failure during interaction [52,53,54,55,56].

The choice of actuation plays a pivotal role in achieving compliant behavior. While traditional rigid actuators offer high precision and force output, they lack inherent compliance. As a result, variable stiffness actuators (VSAs) and series elastic actuators (SEAs) have gained popularity in compliant force control. VSAs dynamically adjust stiffness to match task demands, offering adaptability in physical interactions [57,58,59]. SEAs, which incorporate elastic elements between the actuator and load, are widely used in human–robot collaboration and rehabilitation robotics for their ability to safely manage contact forces through passive compliance and accurate force sensing [60,61].

Transmission mechanisms also influence compliance characteristics. Cable-driven transmission systems, known for their low weight and flexibility, enable more responsive and compliant end-effector control [62,63]. These systems can decouple the actuator location from the end effector, reducing inertia and allowing finer force modulation. Similarly, tendon-driven mechanisms often inspired by human musculoskeletal systems have been employed in robotic limbs and hands to achieve smooth, adaptive movements, particularly in dexterous manipulation tasks [64,65].

The design of end effectors, or interaction interfaces, is central to compliant force control. Incorporating soft and deformable materials such as silicone or elastomer composites into grippers allows for shape conformance during contact, effectively distributing forces and minimizing the risk of damaging fragile objects [66]. Soft robotic end effectors are especially effective in applications such as object handling, prosthetics, and service robotics. Moreover, embedding tactile or pressure sensors into these soft structures provides real-time feedback for adaptive force regulation, enhancing both control precision and interaction safety.

6.2. From the View of Control Methodology

Recent advancements in artificial intelligence (AI) and machine learning (ML) have significantly shaped the evolution of compliant force control strategies. Traditional model-based control methods, while effective in structured environments, often struggle with the nonlinearities, uncertainties, and dynamic interactions encountered in real-world scenarios. To address these limitations, researchers have increasingly turned to intelligent control approaches, which offer adaptability, learning capabilities, and robustness. This subsection highlights emerging control methodologies that reflect the ongoing shift toward intelligent compliant force control.

Data-driven modeling has become a central component in the development of sensorless compliant force control [67,68]. Rather than relying exclusively on accurate dynamic models, data-driven techniques such as Gaussian Process Regression (GPR), deep neural networks (DNNs), and recurrent neural networks are employed to estimate interaction forces and dynamically adjust control policies [69,70]. These models can generalize from historical data and adapt to novel environmental conditions, enabling more flexible and robust compliance. Nonetheless, challenges persist, including data efficiency, real-time adaptation, and the interpretability of learned models.

A particularly promising direction involves hybrid control approaches that integrate physical models with intelligent learning systems. For instance, physics-informed neural networks and residual learning techniques have been developed to complement model-based control with data-driven corrections. This fusion leverages the reliability of physical models and the adaptability of learning-based components, thereby improving generalization, safety, and robustness in compliant force control tasks.

To tackle the issue of generalization across tasks and environments, meta-learning and few-shot learning techniques are gaining traction [71]. These methods allow robotic systems to quickly adapt their force control policies with minimal training data, which is especially advantageous in contact-rich applications where large datasets are difficult to obtain [120,121]. Meta-learning frameworks can, for example, enable the fast adaptation of impedance parameters or compliance behaviors to novel manipulation or interaction scenarios.

With the increasing deployment of robots in safety-critical domains such as human–robot collaboration and healthcare, there is growing emphasis on safe and explainable intelligent control. Safe reinforcement learning frameworks, constrained optimization algorithms, and explainable AI (XAI) methodologies are being incorporated into compliant control systems to ensure predictability and transparency in physical interactions [72,73]. These developments aim to provide robust performance while maintaining trust and accountability in autonomous systems.

Another key trend is the integration of multi-modal perception and sensor fusion into intelligent compliant force control [74]. By combining data from vision, proprioception, tactile sensing, and auditory signals, robots can gain a deeper understanding of their environment [75]. Advanced fusion techniques, including attention mechanisms and graph neural networks, are being investigated to harmonize these sensory inputs within unified control frameworks, enhancing situational awareness and interaction precision.

The advancement of compliant force control necessitates the integration of novel methodologies capable of addressing the complexities of dynamic and uncertain environments. A promising direction in this regard is the application of Hydrocarbon Networks (HCNs)—a class of biologically inspired neural architectures characterized by modular, graph-based connectivity and local adaptive learning. HCNs exhibit strong capabilities in approximating highly nonlinear system dynamics and are notably robust in high-dimensional control spaces, making them well-suited for real-time adaptation in robot–environment interactions [122,123]. Moreover, their energy-efficient computation and reliance on localized plasticity mechanisms render them ideal for deployment in resource-constrained platforms, such as soft robotic systems or embedded robotic controllers. By leveraging the structural and functional properties of HCNs, future compliant force control systems could achieve greater adaptability, scalability, and autonomy in complex unstructured environments.

In addition to algorithmic innovations, future compliant control frameworks should be designed with several key characteristics:

- Multi-modal Perception Fusion: Integrating data from force sensors, tactile arrays, vision systems, and proprioceptive feedback is essential for robust and context-aware interaction. This sensor fusion enhances the control system’s situational understanding and responsiveness.

- Real-time Learning and Adaptation: The ability to adapt on-the-fly to changing task requirements, user intentions, or environmental uncertainties is becoming increasingly critical, especially for human–robot collaboration scenarios. Techniques such as reinforcement learning, meta-learning, and adaptive observers are expected to play major roles.

- Physical and Energy-aware Behavior: Control strategies should account for energy consumption, thermal dynamics, and mechanical stress, enabling more sustainable and long-term deployment of robots, especially in mission-critical settings.

- Hardware-aware Control Design: Future methods must be co-designed with the physical structure of the robot, leveraging characteristics such as variable stiffness actuators, flexible joints, and series elastic elements to enhance compliance and robustness.

Despite the notable progress, several challenges and limitations still hinder the development of more robust and generalizable compliant control strategies:

- Many current methods assume accurate dynamic models or rely heavily on offline-trained models that lack generalizability in novel conditions.

- Ensuring closed-loop stability while enabling rapid adaptation to disturbances and unstructured environments remains a fundamental research bottleneck.

- The absence of standardized benchmarks and reproducible testing scenarios makes it difficult to quantitatively compare the performance of different methods.

- Most compliant control strategies are still designed for single-robot, single-contact settings. Expanding them to multi-robot cooperative manipulation or whole-body interaction requires more sophisticated control architectures and coordination strategies.

To address these challenges, future research should seek to integrate insights from control theory, machine learning, biomechanics, and cognitive science to develop more adaptive and robust compliant force control frameworks. A particularly promising avenue lies in the neural-symbolic integration of model-based control strategies with adaptive learning models, such as hierarchical compositional networks (HCNs) and spiking neural networks, which can offer interpretable and biologically inspired adaptation mechanisms. Furthermore, system-level co-design—where control algorithms and robotic morphology are developed in tandem—may pave the way toward embodied intelligence, enabling the emergence of behaviors that are jointly optimized through both mechanical structure and control policy. Such interdisciplinary and co-adaptive approaches are expected to significantly enhance the autonomy, safety, and versatility of compliant robotic systems in complex real-world environments.

In addition, future research may explore neural-symbolic learning architectures that combine interpretable symbolic reasoning with data-driven adaptability, enabling real-time decision-making in unstructured environments. Embodied intelligence, where control policy co-evolves with robot morphology through co-design optimization, offers another promising direction. Moreover, developing safety-aware adaptive control frameworks that incorporate formal verification, constrained optimization, and risk-aware reinforcement learning will be essential for deployment in human-centered applications.

In summary, the field of compliant force control is undergoing a paradigm shift from rigid, model-dependent architectures to intelligent, adaptive, and data-driven control paradigms. These emerging methodologies promise to greatly expand the operational capability and autonomy of robots in complex, dynamic, and unstructured environments. Future research will likely focus on improving sample efficiency, real-time learning, interpretability, and safety, paving the way toward truly intelligent physical interaction systems.

7. Comparative Analysis, Application Guidelines, and Case Study of Compliant Force Control Strategies

7.1. Comparison and Guidelines for Compliant Force Control Strategies

The key characteristics, advantages, limitations, and typical applications of these methods are concluded in Table 1. To assist researchers in selecting compliant force control strategies, we synthesize the following recommendations based on experimental results from prior studies. For high-precision tasks in structured environments, hybrid position/force control is recommended due to its capability to achieve force tracking errors below 0.5 N in constrained settings. However, this approach requires accurate modeling of the environment’s geometry, which limits its applicability in more dynamic contexts. In human–robot collaboration scenarios, such as rehabilitation robotics, adaptive admittance control enhanced with reinforcement learning (RL) proves effective, as RL enables real-time stiffness adaptation to accommodate individual human motion variability. For unstructured or unknown environments, neural network-based impedance control is preferred, given its ability to reduce force tracking errors by 30–50% compared to fixed-parameter impedance control under uncertain contact conditions. Nonetheless, this benefit comes at the cost of increased computational complexity. In contrast, for low-cost and robust applications, such as basic industrial manipulation, passive compliance mechanisms or PID-based force control strategies offer a practical alternative by eliminating the need for force sensors while still maintaining fundamental safety in interactions.

Table 1.

Comparative analysis of compliant force control strategies.

7.2. Illustrative Case Study: Comparative Analysis of Compliant Force Control Methods in Peg-in-Hole Assembly

To further illustrate the practical differences among various compliant force control strategies, we consider a widely adopted benchmark task: the peg-in-hole assembly using a 6-DOF industrial robotic manipulator. This task exemplifies the challenges of contact-rich manipulation, where precise positioning, compliance with uncertainties, and safe interaction forces are critical for successful execution.

- Hybrid Force/Position Control: This method partitions the task space into orthogonal force and position subspaces. For the peg-in-hole task, axial insertion along the hole direction is governed by force control, while lateral alignment is handled by position control. When accurate environmental models are available (e.g., hole geometry and insertion depth), hybrid control can achieve submillimeter precision and force tracking errors below 0.5 N [124,125,126]. However, it is sensitive to geometric uncertainties or surface deformation, limiting its adaptability in unstructured environments.

- Parallel Force/Position Control: Unlike hybrid control, parallel controllers handle both force and position commands simultaneously within the same task space. In peg-in-hole tasks that involve flexible components or unknown compliance, this strategy can prioritize force control to ensure safe contact while allowing the position controller to adjust accordingly. Its strength lies in reduced dependency on accurate environmental modeling, but tuning priorities between force and position loops becomes more complex, particularly when high-stiffness contacts occur.

- Impedance Control: By regulating the manipulator’s dynamic stiffness and damping, impedance control allows natural interaction with uncertain contact forces during insertion. In cases where hole tolerances are variable or slight misalignments exist, adaptive impedance control can absorb insertion errors, reducing insertion force peaks and avoiding excessive binding [127,128]. The challenge lies in selecting appropriate impedance parameters in real-time to balance compliance and stability.

- Admittance Control: For scenarios where position sensing is highly accurate and force feedback is reliable, admittance control enables the robot to modulate its motion directly based on external forces. This is particularly useful in human-supervised or teleoperated insertion tasks, where the operator indirectly guides the robot through contact forces [129,130]. However, stiff environments with abrupt contact transitions may induce instability if the dynamic parameters are not appropriately tuned.

- Intelligent Control Approaches (Neural Networks, Reinforcement Learning, Fuzzy Logic): Emerging intelligent control methods offer adaptive learning capabilities to handle unmodeled dynamics, contact uncertainty, and real-time disturbance compensation. For example, reinforcement learning-based compliant control can iteratively optimize insertion policies through direct interaction, even when hole positions or contact forces are unknown. Neural network-augmented impedance controllers can compensate for nonlinear contact dynamics without requiring explicit physical models [131,132]. Despite their promise, intelligent methods face challenges related to training data efficiency, safety assurance during learning, and computational load.

This case study highlights that no single compliant force control strategy universally dominates across all conditions. Instead, method selection must balance task complexity, environmental uncertainty, computational resources, safety requirements, and available prior knowledge. Future compliant robotic systems may benefit from hybrid control frameworks that leverage the complementary strengths of these methods within unified architectures.

8. Conclusions

This paper has presented a comprehensive survey of compliant force control methods for robots, encompassing both classical techniques and emerging approaches. We reviewed passive, direct, and indirect control strategies and emphasized recent developments in intelligent algorithms, sensorless methods, and structurally adaptive robotic platforms. In addition, we analyzed the current trends in robot design and control methodologies from a holistic, system-level perspective. Despite substantial progress, significant challenges persist in ensuring robustness, adaptability, and generalization, particularly in unstructured and dynamic environments. Future research is expected to focus on the deeper integration of learning-based methods, advanced sensor fusion, and the co-design of mechanical structures and control architectures, paving the way for the next generation of safe, intelligent, and compliant robotic systems.

Author Contributions

Conceptualization, M.Z. and S.S.; methodology, M.Z.; software, D.G.; validation, D.G. and Y.Z.; formal analysis, J.C. and J.Q.; investigation, J.Q.; resources, M.Z.; data curation, M.Z.; writing—original draft preparation, M.Z.; writing—review and editing, M.Z.; visualization, S.S.; supervision, S.S.; project administration, D.G.; funding acquisition, M.Z. and J.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (Grant No. 62303095), Fundamental Research Funds for the Central Universities 2682025CX080, and the Natural Science Foundation of Sichuan (NO: 2024NSFSC0141).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to thank the reviewers for their valuable comments and suggestions.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Hanafusa, H.; Asada, H. A Robot Hand with Elastic Fingers and Its Application to Assembly Process. IFAC Proc. Vol. 1977, 10, 127–138. [Google Scholar] [CrossRef]

- Goswami, A.; Peshkin, M. Mechanical computation for passive force control. In Proceedings of the [1993] Proceedings IEEE International Conference on Robotics and Automation, Atlanta, GA, USA, 2–6 May 1993; Volume 1, pp. 476–483. [Google Scholar] [CrossRef]

- Bottero, S.; Muscolo, G.G.; Ferraresi, C. A New Soft RCC Device with Pneumatic Regulation. Robotics 2020, 9, 98. [Google Scholar] [CrossRef]

- Wang, W.; Loh, R.N.; Gu, E.Y. Passive compliance versus active compliance in robot-based automated assembly systems. Ind. Robot. Int. J. 1998, 25, 48–57. [Google Scholar] [CrossRef]

- Okada, M.; Nakamura, Y.; Hoshino, S. Design of active/passive hybrid compliance in the frequency domain-shaping dynamic compliance of humanoid shoulder mechanism. In Proceedings of the Proceedings 2000 ICRA. Millennium Conference. IEEE International Conference on Robotics and Automation. Symposia Proceedings (Cat. No.00CH37065), San Francisco, CA, USA, 24–28 April 2000; Volume 3, pp. 2250–2257. [Google Scholar] [CrossRef]

- Udai, A.D.; Hayat, A.A.; Saha, S.K. Parallel active/passive force control of industrial robots with joint compliance. In Proceedings of the 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems, Chicago, IL, USA , 14–18 September 2014; pp. 4511–4516. [Google Scholar] [CrossRef]

- Uchiyama, M.; Iwasawa, N.; Hakomori, K. Hybrid position/Force control for coordination of a two-arm robot. In Proceedings of the 1987 IEEE International Conference on Robotics and Automation, Raleigh, NC, USA, 31 March–3 April 1987; Volume 4, pp. 1242–1247. [Google Scholar] [CrossRef]

- Uchiyama, M.; Dauchez, P. A symmetric hybrid position/force control scheme for the coordination of two robots. In Proceedings of the 1988 IEEE International Conference on Robotics and Automation, Philadelphia, PA, USA, 24–29 April 1988; Volume 1, pp. 350–356. [Google Scholar] [CrossRef]

- Goldsmith, P.; Francis, B.; Goldenberg, A. Stability of hybrid position/force control applied to manipulators with flexible joints. Int. J. Robot. Autom. 1999, 14, 146–160. [Google Scholar]

- Madani, M.; Moallem, M. Hybrid position/force control of a flexible parallel manipulator. J. Frankl. Inst. 2011, 348, 999–1012. [Google Scholar] [CrossRef]

- Matsuno, F.; Yamamoto, K. Dynamic hybrid position/force control of a two degree-of-freedom flexible manipulator. J. Robot. Syst. 1994, 11, 355–366. [Google Scholar] [CrossRef]

- Xie, S.; Ren, J. A hybrid position/force controller for joint robots. In Proceedings of the 2021 IEEE International Conference on Robotics and Automation (ICRA), Xi’an, China, 30 May–5 June 2021; pp. 6415–6421. [Google Scholar]

- Wang, H.; Ni, H.; Wang, J.; Chen, W. Hybrid vision/force control of soft robot based on a deformation model. IEEE Trans. Control Syst. Technol. 2019, 29, 661–671. [Google Scholar] [CrossRef]

- Connolly, T.H.; Pfeiffer, F. Neural network hybrid position/force control. In Proceedings of the 1993 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS’93), Yokohama, Japan, 26–30 July 1993; Volume 1, pp. 240–244. [Google Scholar]

- Li, Y.; Wang, G.; Dong, B.; Zhao, B. Hybrid position–force control for constrained reconfigurable manipulators based on adaptive neural network. Adv. Mech. Eng. 2015, 7, 1687814015602409. [Google Scholar] [CrossRef]

- Lin, J.; Lin, C.; Lo, H.S. Hybrid position/force control of robot manipulators mounted on oscillatory bases using adaptive fuzzy control. In Proceedings of the 2010 IEEE International Symposium on Intelligent Control, Yokohama, Japan, 8–10 September 2010; pp. 487–492. [Google Scholar]

- Hsu, F.Y.; Fu, L.C. Intelligent robot deburring using adaptive fuzzy hybrid position/force control. IEEE Trans. Robot. Autom. 2000, 16, 325–335. [Google Scholar] [CrossRef]

- Leite, A.C.; Lizarralde, F.; Hsu, L. Hybrid adaptive vision—Force control for robot manipulators interacting with unknown surfaces. Int. J. Robot. Res. 2009, 28, 911–926. [Google Scholar] [CrossRef]

- Liu, J.; Yan, W.; Gao, J.; Chen, Y. Hybrid vision/force control for underwater vehicles landing on unknown surfaces. Ocean. Eng. 2022, 253, 111233. [Google Scholar] [CrossRef]

- Hogan, N. Impedance control: An approach to manipulation. In Proceedings of the 1984 American Control Conference, San Diego, CA, USA, 6–8 June 1984; pp. 304–313. [Google Scholar]

- Colbaugh, R.; Seraji, H.; Glass, K. Direct Adaptive Impedance Control of Robot Manipulators. J. Robot. Syst. 1993, 10, 217–248. [Google Scholar] [CrossRef]

- Duan, J.; Gan, Y.; Chen, M.; Dai, X. Adaptive variable impedance control for dynamic contact force tracking in uncertain environment. Robot. Auton. Syst. 2018, 102, 54–65. [Google Scholar] [CrossRef]

- Ozawa, R.; Kobayashi, H.; Ishibashi, R. Adaptive impedance control of a variable stiffness actuator. Adv. Robot. 2015, 29, 273–286. [Google Scholar] [CrossRef]

- Liang, J.; Zhong, H.; Wang, Y.; Chen, Y.; Zeng, J.; Mao, J. Adaptive Force Tracking Impedance Control for Aerial Interaction in Uncertain Contact Environment Using Barrier Function. IEEE Trans. Autom. Sci. Eng. 2024, 21, 4720–4731. [Google Scholar] [CrossRef]

- Zhai, A.; Zhang, H.; Wang, J.; Lu, G.; Li, J.; Chen, S. Adaptive neural synchronized impedance control for cooperative manipulators processing under uncertain environments. Robot. Comput.-Integr. Manuf. 2022, 75, 102291. [Google Scholar] [CrossRef]

- Lawrence, D.; Stoughton, R. Position-based impedance control-Achieving stability in practice. In Proceedings of the Guidance, Navigation and Control Conference, New Orleans, LA, USA, 17–19 August 1987; p. 2265. [Google Scholar]

- Heinrichs, B.; Sepehri, N.; Thornton-Trump, A. Position-based impedance control of an industrial hydraulic manipulator. IEEE Control Syst. Mag. 1997, 17, 46–52. [Google Scholar]

- Seraji, H. Adaptive admittance control: An approach to explicit force control in compliant motion. In Proceedings of the 1994 IEEE International Conference on Robotics and Automation, San Diego, CA, USA, 8–13 May 1994; Volume 4, pp. 2705–2712. [Google Scholar] [CrossRef]

- Ott, C.; Mukherjee, R.; Nakamura, Y. Unified impedance and admittance control. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010; pp. 554–561. [Google Scholar]

- Keemink, A.Q.; Herman, V.D.K.; Stienen, A.H. Admittance control for physical human–robot interaction. Int. J. Robot. Res. 2018, 22, 027836491876895. [Google Scholar] [CrossRef]

- Dimeas, F.; Aspragathos, N. Online Stability in Human-Robot Cooperation with Admittance Control. IEEE Trans. Haptics 2016, 9, 267–278. [Google Scholar] [CrossRef]

- Ferraguti, F.; Talignani Landi, C.; Sabattini, L.; Bonfe, M.; Fantuzzi, C.; Secchi, C. A variable admittance control strategy for stable physical human–robot interaction. Int. J. Robot. Res. 2019, 38, 747–765. [Google Scholar] [CrossRef]

- Kang, G.; Oh, H.S.; Seo, J.K.; Kim, U.; Choi, H.R. Variable admittance control of robot manipulators based on human intention. IEEE/ASME Trans. Mechatronics 2019, 24, 1023–1032. [Google Scholar] [CrossRef]

- Mujica, M.; Crespo, M.; Benoussaad, M.; Junco, S.; Fourquet, J.Y. Robust variable admittance control for human–robot co-manipulation of objects with unknown load. Robot. Comput.-Integr. Manuf. 2023, 79, 102408. [Google Scholar] [CrossRef]

- An, H.; Ye, C.; Yin, Z.; Lin, W. Neural Adaptive impedance control for force tracking in uncertain environment. Electronics 2023, 12, 640. [Google Scholar] [CrossRef]

- He, W.; Dong, Y.; Sun, C. Adaptive neural impedance control of a robotic manipulator with input saturation. IEEE Trans. Syst. Man, Cybern. Syst. 2015, 46, 334–344. [Google Scholar] [CrossRef]

- Zhu, M.; Huang, C.; Song, S.; Xu, S.; Gong, D. Vision-admittance-based adaptive RBFNN control with a SMC robust compensator for collaborative parallel robots. J. Frankl. Inst. 2024, 361, 106538. [Google Scholar] [CrossRef]

- Xiao, M.; Li, L.; Jin, H.; Bao, D.; Huang, F. Research on robot force control based on RBF neural network stiffness prediction and reinforcement learning. Ind. Robot. Int. J. Robot. Res. Appl. 2025, 12, 18270–18279. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, Z.; Chen, Y.; Wu, H. Barrier Lyapunov Function-Based Fuzzy Adaptive Admittance Control of an Upper Limb Exoskeleton Using RBFNN Compensation. IEEE/ASME Trans. Mechatronics 2025, 30, 3–14. [Google Scholar] [CrossRef]

- Kong, D.; Huang, Q. Impedance force control of manipulator based on variable universe fuzzy control. Actuators 2023, 12, 305. [Google Scholar] [CrossRef]

- Nguyen, T.V.; Huynh, N.T.; Vu, N.C.; Kieu, V.N.; Huang, S.C. Optimizing compliant gripper mechanism design by employing an effective bi-algorithm: Fuzzy logic and ANFIS. Microsyst. Technol. 2021, 27, 3389–3412. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, Z.; Huang, P.; Kuang, Z. Adaptive fractional-order sliding mode control for admittance-based telerobotic system with optimized order and force estimation. IEEE Trans. Ind. Electron. 2021, 69, 5165–5174. [Google Scholar] [CrossRef]

- Gao, H.; Ma, C.; Zhang, X.; Zhou, C. Compliant variable admittance adaptive fixed-time sliding mode control for trajectory tracking of robotic manipulators. Robotica 2024, 42, 1731–1760. [Google Scholar] [CrossRef]

- Huang, C.; Zhu, M.; Song, S.; Zhao, Y.; Jiang, J. Vision-based adaptive LT sliding mode admittance control for collaborative robots with actuator saturation. Robotica 2024, 42, 1986–2003. [Google Scholar] [CrossRef]

- Xue, X.; Huang, H.; Zuo, L.; Wang, N. A compliant force control scheme for industrial robot interactive operation. Front. Neurorobotics 2022, 16, 865187. [Google Scholar] [CrossRef]

- Park, I.W.; Smith, T.; Sanchez, H.; Wong, S.W.; Piacenza, P.; Ciocarlie, M. Developing a 3-DOF compliant perching arm for a free-flying robot on the International Space Station. In Proceedings of the 2017 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), 3–7 July 2017; pp. 1135–1141. [Google Scholar]

- De Petris, P.; Nissov, M.; Alexis, K. Morphy: A Compliant and Morphologically Aware Flying Robot. Adv. Intell. Syst. 2024, 2400493. [Google Scholar] [CrossRef]

- De Wolde, J.; Knoedler, L.; Garofalo, G.; Alonso-Mora, J. Current-Based Impedance Control for Interacting with Mobile Manipulators. In Proceedings of the 2024 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Abu Dhabi, United Arab Emirates, 14–18 October 2024; pp. 753–760. [Google Scholar]

- Palejiya, D.; Tanner, H.G. Hybrid velocity/force control for robot navigation in compliant unknown environments. Robotica 2006, 24, 745–758. [Google Scholar] [CrossRef]

- Xiang, R.; Xu, H.; Li, X.; Zhu, X.; Meng, D.; Xu, W. Compliance Control of a Cable-Driven Space Manipulator Based on Force–Position Hybrid Drive Mode. Aerospace 2025, 12, 69. [Google Scholar] [CrossRef]

- Dong, H.; Figueroa, N.; El Saddik, A. Muscle force control of a kinematically redundant bionic arm with real-time parameter update. In Proceedings of the 2013 IEEE International Conference on Systems, Man, and Cybernetics, Manchester, UK, 13–16 October 2013; pp. 1640–1647. [Google Scholar]

- Kim, H.S.; Kim, I.M.; Cho, C.N.; Song, J.B. Safe joint module for safe robot arm based on passive and active compliance method. Mechatronics 2012, 22, 1023–1030. [Google Scholar] [CrossRef]

- Yin, S.; Yao, D.R.; Song, Y.; Heng, W.; Ma, X.; Han, H.; Gao, W. Wearable and Implantable Soft Robots. Chem. Rev. 2024, 124, 11585–11636. [Google Scholar] [CrossRef]

- Li, W.; Hu, Y.; Zhou, Y.; Pham, D.T. Safe human–robot collaboration for industrial settings: A survey. J. Intell. Manuf. 2024, 35, 2235–2261. [Google Scholar] [CrossRef]

- Bang, J.; Choi, S.H.; Pyun, K.R.; Jung, Y.; Hong, S.; Kim, D.; Lee, Y.; Won, D.; Jeong, S.; Shin, W.; et al. Bioinspired electronics for intelligent soft robots. Nat. Rev. Electr. Eng. 2024, 1, 597–613. [Google Scholar] [CrossRef]

- Yang, H.; Wei, G.; Ren, L. Development and Characteristics of a Highly Biomimetic Robotic Shoulder Inspired by Musculoskeletal Mechanical Intelligence. IEEE Trans. Robot. 2024, 40, 2672–2691. [Google Scholar] [CrossRef]

- Han, S.; Wang, H.; Yu, H. Human–robot interaction evaluation-based AAN control for upper limb rehabilitation robots driven by series elastic actuators. IEEE Trans. Robot. 2023, 39, 3437–3451. [Google Scholar] [CrossRef]

- Tiboni, M.; Borboni, A.; Vérité, F.; Bregoli, C.; Amici, C. Sensors and actuation technologies in exoskeletons: A review. Sensors 2022, 22, 884. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, B.; Tan, X.; Zhao, Y.; Liu, L.; Zhao, X. Hip–Knee–Ankle Rehabilitation Exoskeleton with Compliant Actuators: From Human–Robot Interaction Control to Clinical Evaluation. IEEE Trans. Robot. 2024, 41, 269–288. [Google Scholar] [CrossRef]

- Sariyildiz, E.; Mutlu, R.; Roberts, J.; Kuo, C.H.; Ugurlu, B. Design and control of a novel variable stiffness series elastic actuator. IEEE/ASME Trans. Mechatronics 2023, 28, 1534–1545. [Google Scholar] [CrossRef]

- Toubar, H.; Awad, M.I.; Boushaki, M.N.; Niu, Z.; Khalaf, K.; Hussain, I. Design, modeling, and control of a series elastic actuator with discretely adjustable stiffness (seadas). Mechatronics 2022, 86, 102863. [Google Scholar] [CrossRef]

- Mattioni, V.; Idà, E.; Carricato, M. Force-distribution sensitivity to cable-tension errors in overconstrained cable-driven parallel robots. Mech. Mach. Theory 2022, 175, 104940. [Google Scholar] [CrossRef]

- Li, W.; Huang, X.; Yan, L.; Cheng, H.; Liang, B.; Xu, W. Force sensing and compliance control for a cable-driven redundant manipulator. IEEE/ASME Trans. Mechatronics 2023, 29, 777–788. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, W.; Yang, J.; Pu, W. Bioinspired soft robotic fingers with sequential motion based on tendon-driven mechanisms. Soft Robot. 2022, 9, 531–541. [Google Scholar] [CrossRef]

- Lin, B.; Wang, J.; Song, S.; Li, B.; Meng, M.Q.H. A modular lockable mechanism for tendon-driven robots: Design, modeling and characterization. IEEE Robot. Autom. Lett. 2022, 7, 2023–2030. [Google Scholar] [CrossRef]

- AboZaid, Y.A.; Aboelrayat, M.T.; Fahim, I.S.; Radwan, A.G. Soft robotic grippers: A review on technologies, materials, and applications. Sens. Actuators Phys. 2024, 372, 115380. [Google Scholar] [CrossRef]

- Polverini, M.P.; Formentin, S.; Merzagora, L.; Rocco, P. Mixed data-driven and model-based robot implicit force control: A hierarchical approach. IEEE Trans. Control Syst. Technol. 2019, 28, 1258–1271. [Google Scholar] [CrossRef]

- Carron, A.; Arcari, E.; Wermelinger, M.; Hewing, L.; Hutter, M.; Zeilinger, M.N. Data-driven model predictive control for trajectory tracking with a robotic arm. IEEE Robot. Autom. Lett. 2019, 4, 3758–3765. [Google Scholar] [CrossRef]

- Polverini, M.P.; Formentin, S.; Dao, L.A.; Rocco, P. Data-driven design of implicit force control for industrial robots. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), 29 May–3 June 2017; pp. 2322–2327. [Google Scholar]

- Kwon, H.; Kim, S.W.; Joe, H.M. Learning-Based Force Control of Twisted String Actuators Using a Neural Network-Based Inverse Model. IEEE Robot. Autom. Lett. 2024, 9, 8170–8177. [Google Scholar] [CrossRef]

- Johannsmeier, L.; Gerchow, M.; Haddadin, S. A framework for robot manipulation: Skill formalism, meta learning and adaptive control. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 5844–5850. [Google Scholar]

- Hanchate, A.; Bukkapatnam, S.T.; Lee, K.H.; Srivastava, A.; Kumara, S. Explainable AI (XAI)-driven vibration sensing scheme for surface quality monitoring in a smart surface grinding process. J. Manuf. Processes 2023, 99, 184–194. [Google Scholar] [CrossRef]

- Olivas-Padilla, B.E.; Manitsaris, S.; Glushkova, A. Explainable AI in human motion: A comprehensive approach to analysis, modeling, and generation. Pattern Recognit. 2024, 151, 110418. [Google Scholar] [CrossRef]

- Xue, Y.; Yu, Y.; Yin, K.; Li, P.; Xie, S.; Ju, Z. Human in-hand motion recognition based on multi-modal perception information fusion. IEEE Sens. J. 2022, 22, 6793–6805. [Google Scholar] [CrossRef]

- Donato, E.; Falotico, E.; Thuruthel, T.G. Multi-modal perception for soft robotic interactions using generative models. In Proceedings of the 2024 IEEE 7th International Conference on Soft Robotics (RoboSoft), San Diego, CA, USA, 14–17 April 2024; pp. 311–318. [Google Scholar]

- Joo, S.; Miyazaki, F. Development of variable RCC and its application. In Proceedings of the 1998 IEEE/RSJ International Conference on Intelligent Robots and Systems. Innovations in Theory, Practice and Applications (Cat. No.98CH36190), Victoria, BC, Canada, 17 October 1998; Volume 2, pp. 1326–1332. [Google Scholar] [CrossRef]

- Kazerooni, H. Direct-drive active compliant end effector (active RCC). IEEE J. Robot. Autom. 1988, 4, 324–333. [Google Scholar] [CrossRef]

- Raibert, M.H.; Craig, J.J. Hybrid position/force control of manipulators. J. Dyn. Sys., Meas. Control. 1981, 103, 126–133. [Google Scholar] [CrossRef]

- Ferretti, G.; Magnani, G.; Rocco, P. Toward the implementation of hybrid position/force control in industrial robots. IEEE Trans. Robot. Autom. 1997, 13, 838–845. [Google Scholar] [CrossRef]

- Xu, S.; He, B.; Zhou, Y.; Wang, Z.; Zhang, C. A Hybrid Position/Force Control Method for a Continuum Robot With Robotic and Environmental Compliance. IEEE Access 2019, 7, 100467–100479. [Google Scholar] [CrossRef]

- Yip, M.C.; Camarillo, D.B. Model-less hybrid position/force control: A minimalist approach for continuum manipulators in unknown, constrained environments. IEEE Robot. Autom. Lett. 2016, 1, 844–851. [Google Scholar] [CrossRef]

- Bassi, E.; Benzi, F.; Capisani, L.M.; Cuppone, D.; Ferrara, A. Hybrid position/force sliding mode control of a class of robotic manipulators. In Proceedings of the 48h IEEE Conference on Decision and Control (CDC) held jointly with 2009 28th Chinese Control Conference, Shanghai, China, 15–18 December 2009; pp. 2966–2971. [Google Scholar] [CrossRef]

- Xiao, D.; Ghosh, B.K.; Xi, N.; Tarn, T.J. Sensor-based hybrid position/force control of a robot manipulator in an uncalibrated environment. IEEE Trans. Control Syst. Technol. 2000, 8, 635–645. [Google Scholar] [CrossRef]

- Gao, C.; Cong, D.; Liu, X.; Yang, Z.; Tao, H. Hybrid position/force control of 6-dof hydraulic parallel manipulator using force and vision. Ind. Robot. Int. J. 2016, 43, 274–283. [Google Scholar] [CrossRef]

- Choi, I.; Kim, E.; Sungwook. A Hybrid Vision/Force Control Strategy for Handheld Robotic Devices Enhancing Probe-Based Confocal Laser Endomicroscopy. In Proceedings of the 2024 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Abu Dhabi, United Arab Emirates, 14–18 October 2024; pp. 10642–10649. [Google Scholar]

- Chiaverini, S.; Sciavicco, L. The parallel approach to force/position control of robotic manipulators. IEEE Trans. Robot. Autom. 1993, 9, 361–373. [Google Scholar] [CrossRef]

- Chiaverini, S.; Siciliano, B.; Villani, L. Force and position tracking: Parallel control with stiffness adaptation. IEEE Control Syst. Mag. 1998, 18, 27–33. [Google Scholar] [CrossRef]

- Siciliano, B.; Villani, L. Parallel force and position control of flexible manipulators. IEE Proc. Control Theory Appl. 2000, 147, 605–612. [Google Scholar] [CrossRef]

- Skaare, B.; Egeland, O. Parallel Force/Position Crane Control in Marine Operations. IEEE J. Ocean. Eng. 2006, 31, 599–613. [Google Scholar] [CrossRef]

- Scherillo, P.; Siciliano, B.; Zollo, L.; Carrozza, M.; Guglielmelli, E.; Dario, P. Parallel force/position control of a novel biomechatronic hand prosthesis. In Proceedings of the 2003 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM 2003), Kobe, Japan, 20–24 July 2003; Volume 2, pp. 920–925. [Google Scholar] [CrossRef]

- Mohammadi, M.; Bicego, D.; Franchi, A.; Barcelli, D.; Prattichizzo, D. Aerial tele-manipulation with passive tool via parallel position/force control. Appl. Sci. 2021, 11, 8955. [Google Scholar] [CrossRef]

- Paccot, F.; Andreff, N.; Martinet, P. A review on the dynamic control of parallel kinematic machines: Theory and experiments. Int. J. Robot. Res. 2009, 28, 395–416. [Google Scholar] [CrossRef]

- Bellakehal, S.; Andreff, N.; Mezouar, Y.; Tadjine, M. Vision/force control of parallel robots. Mech. Mach. Theory 2011, 46, 1376–1395. [Google Scholar] [CrossRef]

- Zhu, M.; Huang, C.; Qiu, Z.; Zheng, W.; Gong, D. Parallel image-based visual servoing/force control of a collaborative delta robot. Front. Neurorobotics 2022, 16, 922704. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; Huang, C.; Qi, J.; Du, Y. Model Predictive Control for Parallel Vision/Force Control of the Collaborative Robot. In Proceedings of the 2023 42nd Chinese Control Conference (CCC), Tianjin, China, 24–26 July 2023; pp. 2658–2663. [Google Scholar]

- Calanca, A.; Muradore, R.; Fiorini, P. A Review of Algorithms for Compliant Control of Stiff and Fixed-Compliance Robots. IEEE/ASME Trans. Mechatronics 2016, 21, 613–624. [Google Scholar] [CrossRef]

- Huo, Y.; Li, P.; Chen, D.; Liu, Y.H.; Li, X. Model-Free Adaptive Impedance Control for Autonomous Robotic Sanding. IEEE Trans. Autom. Sci. Eng. 2022, 19, 3601–3611. [Google Scholar] [CrossRef]

- Brahmi, B.; Driscoll, M.; El Bojairami, I.K.; Saad, M.; Brahmi, A. Novel adaptive impedance control for exoskeleton robot for rehabilitation using a nonlinear time-delay disturbance observer. ISA Trans. 2021, 108, 381–392. [Google Scholar] [CrossRef]

- Marković, L.; Car, M.; Orsag, M.; Bogdan, S. Adaptive stiffness estimation impedance control for achieving sustained contact in aerial manipulation. In Proceedings of the 2021 IEEE International Conference on Robotics and Automation (ICRA), Xi’an, China, 30 May–5 June 2021; pp. 117–123. [Google Scholar] [CrossRef]

- Franceschi, P.; Pedrocchi, N.; Beschi, M. Adaptive Impedance Controller for Human-Robot Arbitration based on Cooperative Differential Game Theory. In Proceedings of the 2022 International Conference on Robotics and Automation (ICRA), Philadelphia, PA, USA, 23–27 May 2022; pp. 7881–7887. [Google Scholar] [CrossRef]

- Khan, H.; Lee, M.C.; Lee, J.W.; Li, C.; Salman, M. Force/torque-based impedance control with perturbation observer—Toward high payload system robust trajectory tracking. IEEE Access 2022, 10, 119150–119161. [Google Scholar] [CrossRef]