Design and Analysis of Modular Reconfigurable Manipulator System

Abstract

1. Introduction

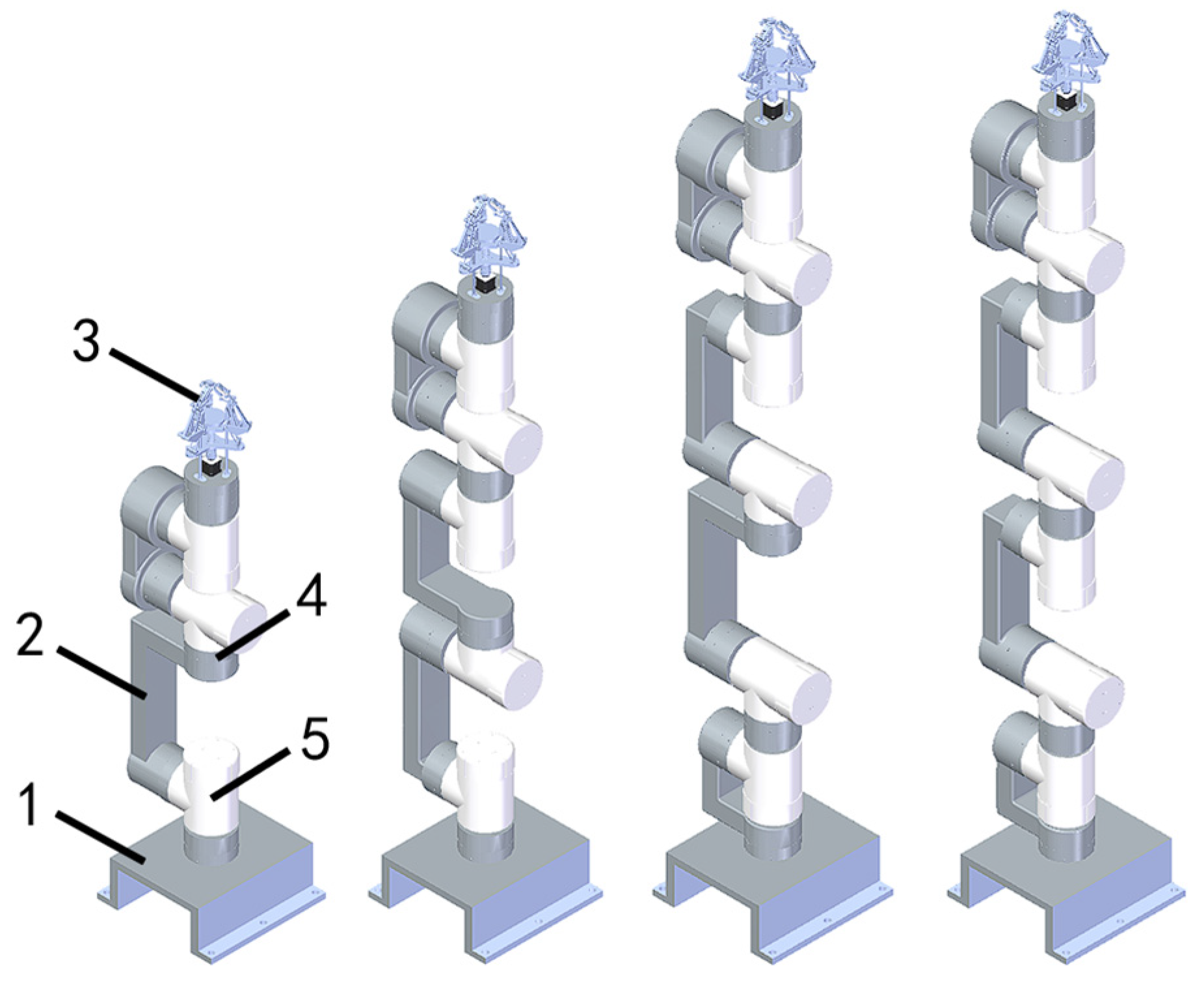

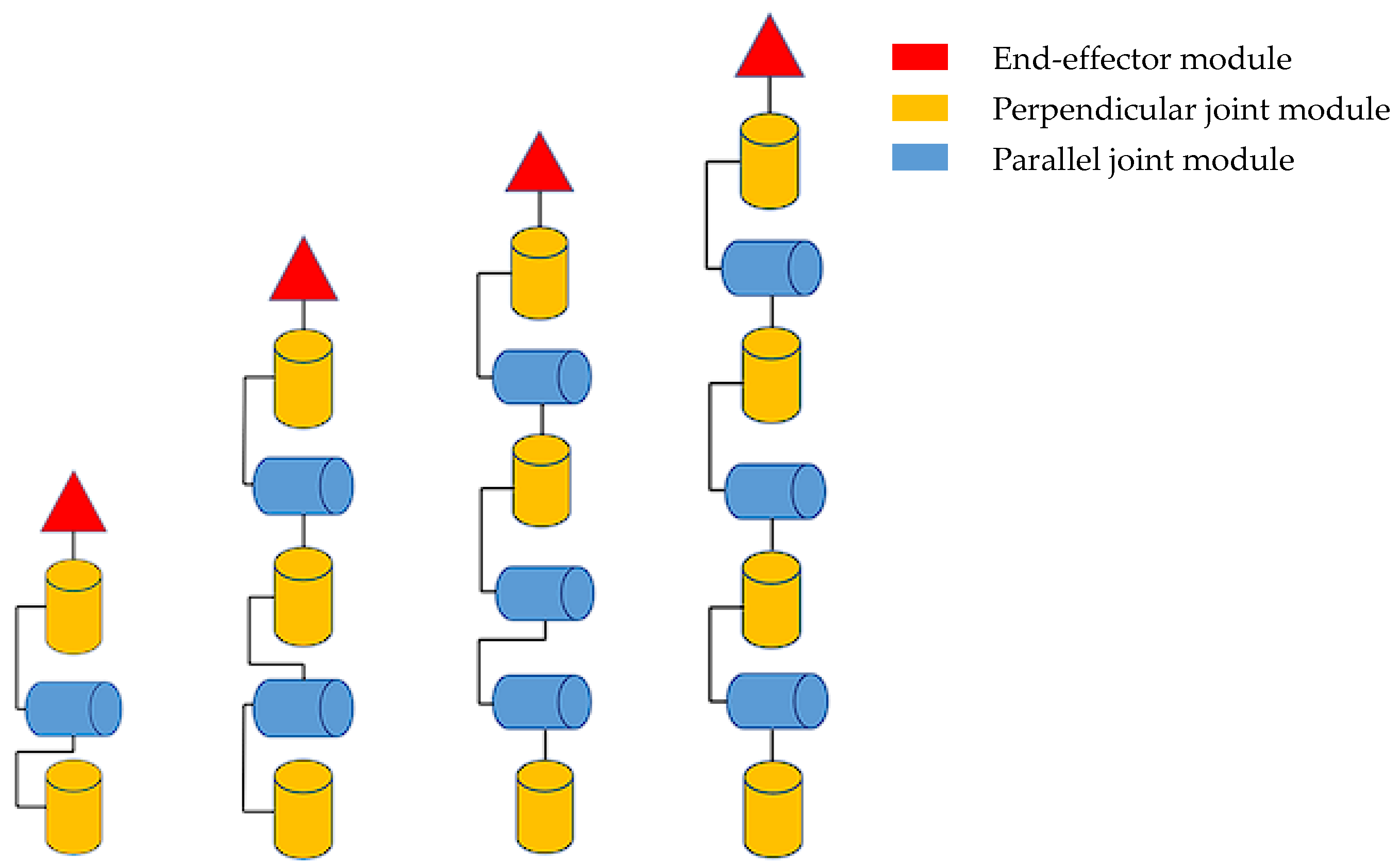

2. Modular Reconfigurable Manipulator: Overall Design

2.1. Overall Design Objectives

- All the components of the manipulator are modularized, allowing the assembly of various configurations with different degrees of freedom using existing modular joints, linkages, and end-effectors to meet diverse task requirements;

- The joint module features a highly integrated design, incorporating motors, brakes, reducers, and encoders within the joint. This ensures full functionality while achieving a compact and lightweight structure;

- The modular docking mechanism is designed to connect each module, including its fixation to the base, through a specially designed docking interface. This enhances the assembly and disassembly efficiency while facilitating the maintenance and upkeep of the manipulator;

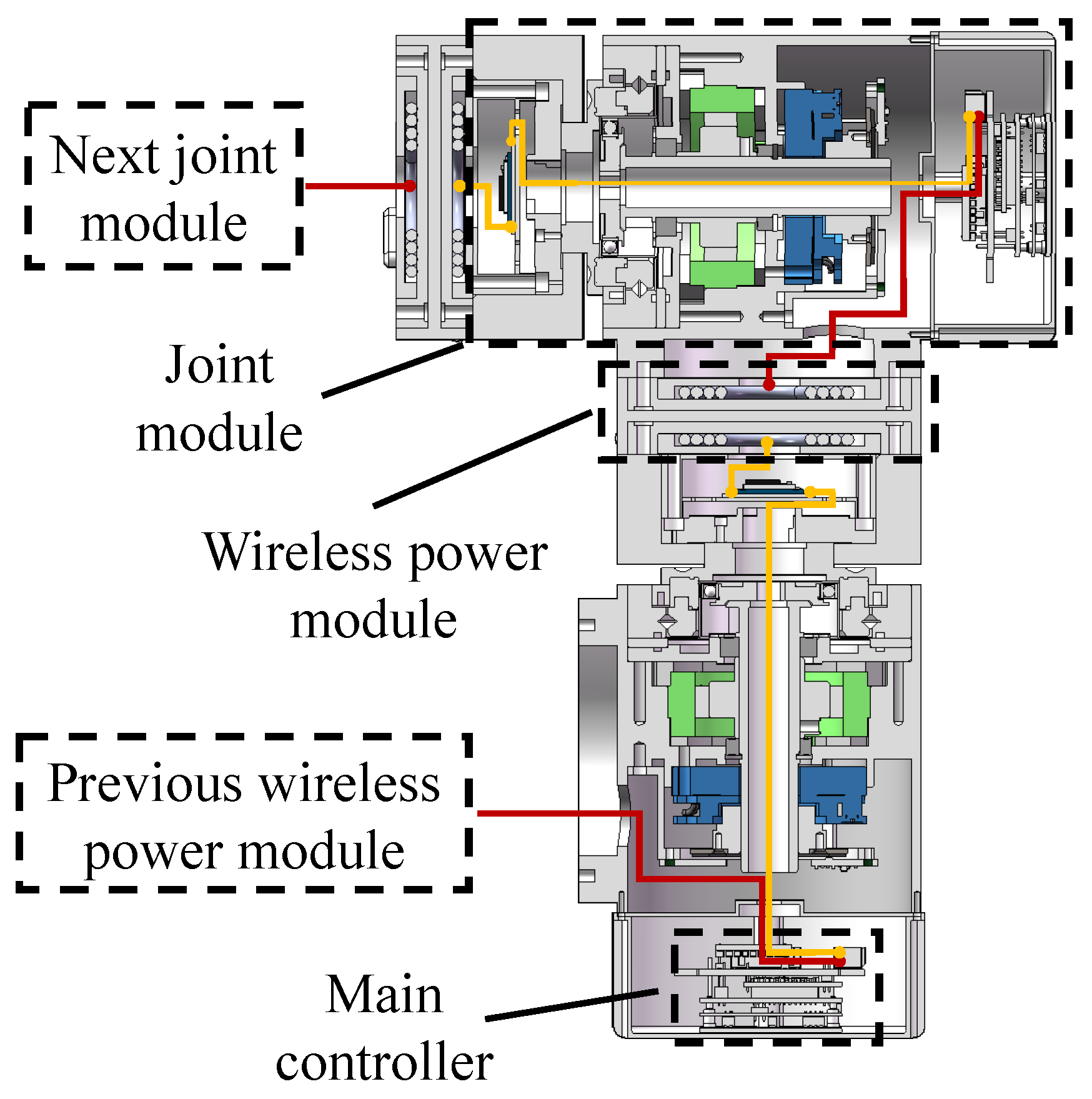

- The integrated wireless energy transfer module is designed to be embedded in the docking mechanism, enabling plug-and-play functionality for each module and eliminating the need for electrical interface design. Additionally, each module features a hollow routing structure to prevent wire entanglement and related issues during manipulator operation;

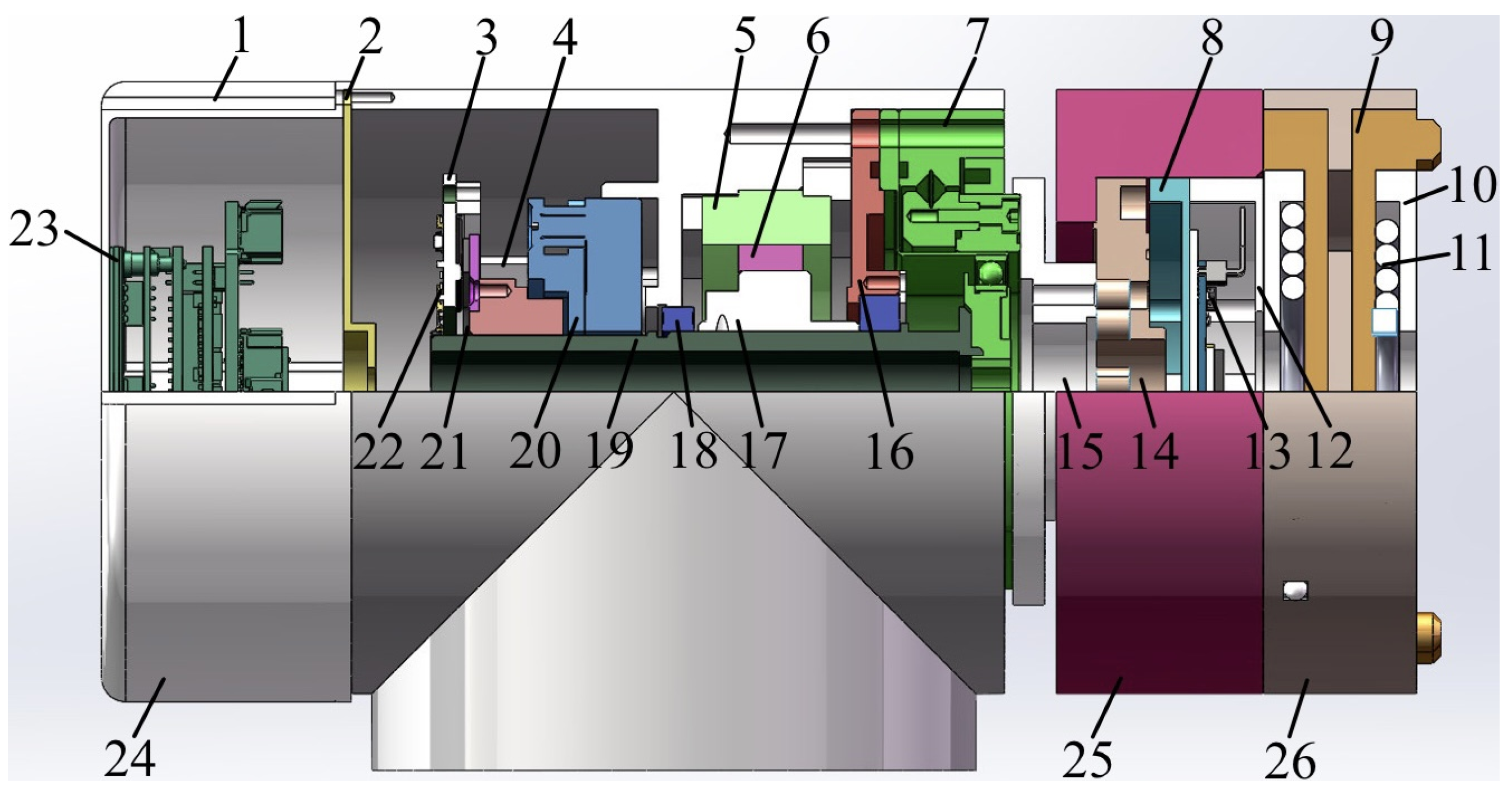

2.2. Structural Design

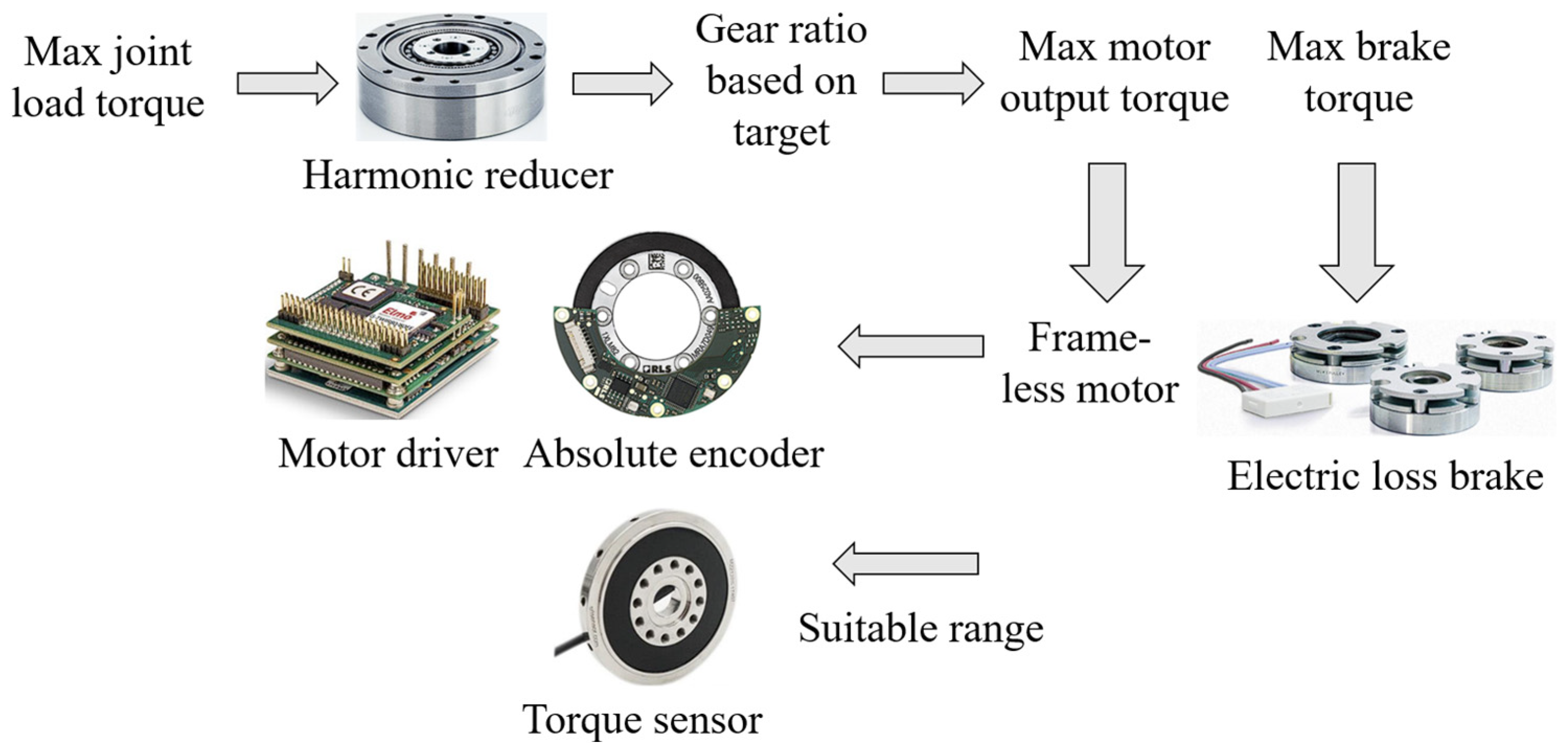

3. Design of Joint Module

3.1. Structural Design of the Joint Module

3.2. Force Analysis

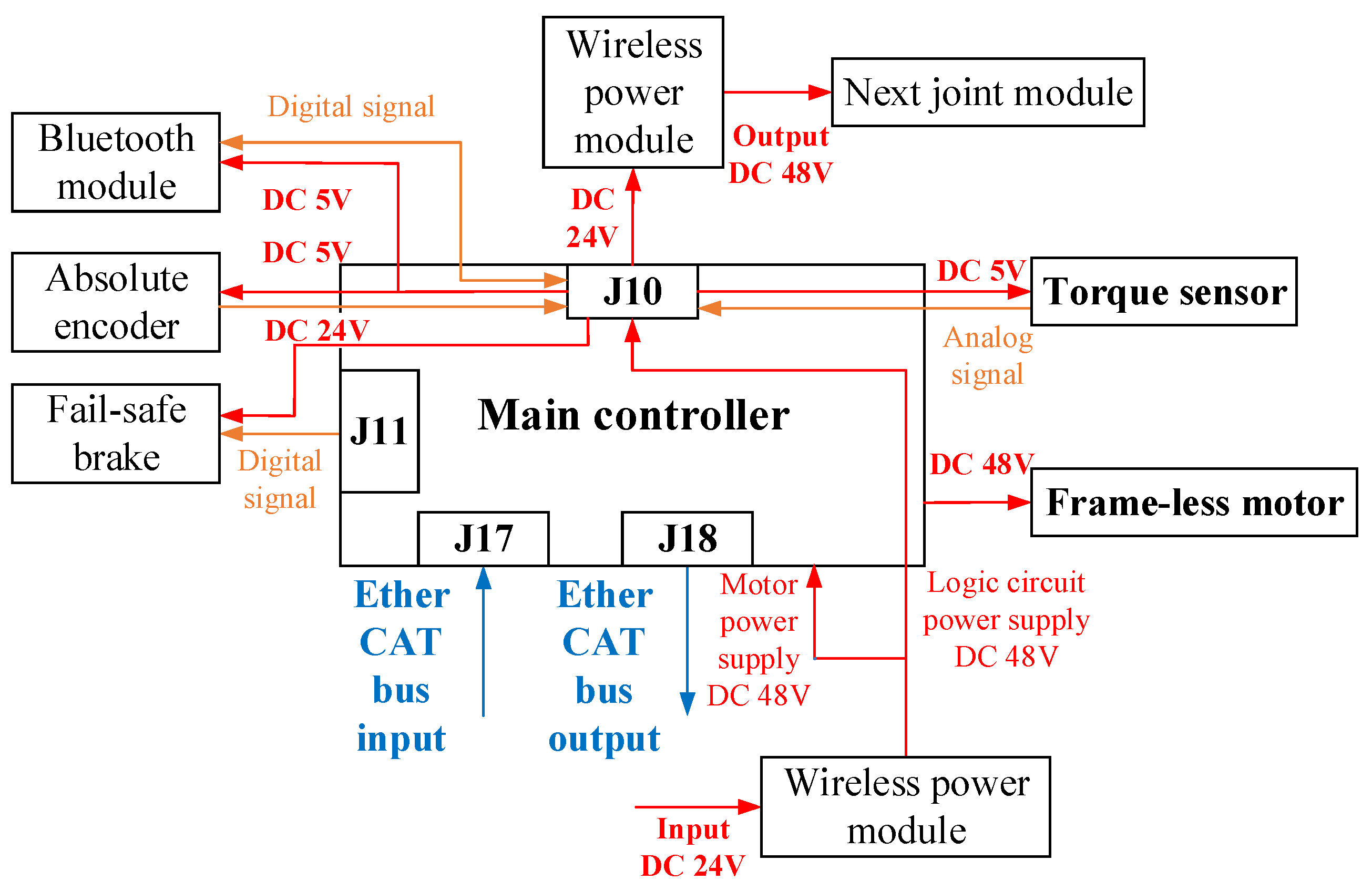

3.3. Electrical Connection and Wiring Layout of the Joint Module

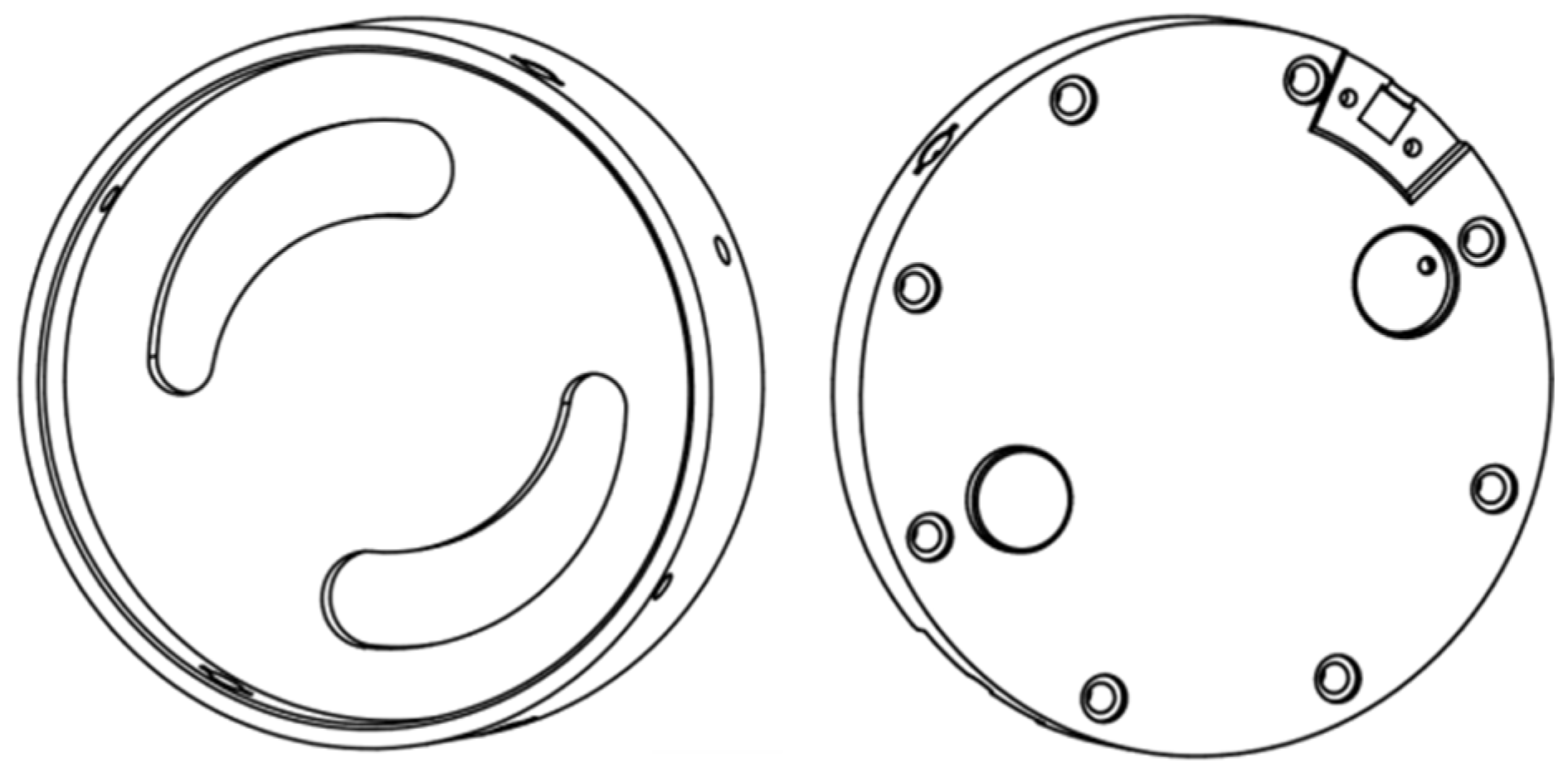

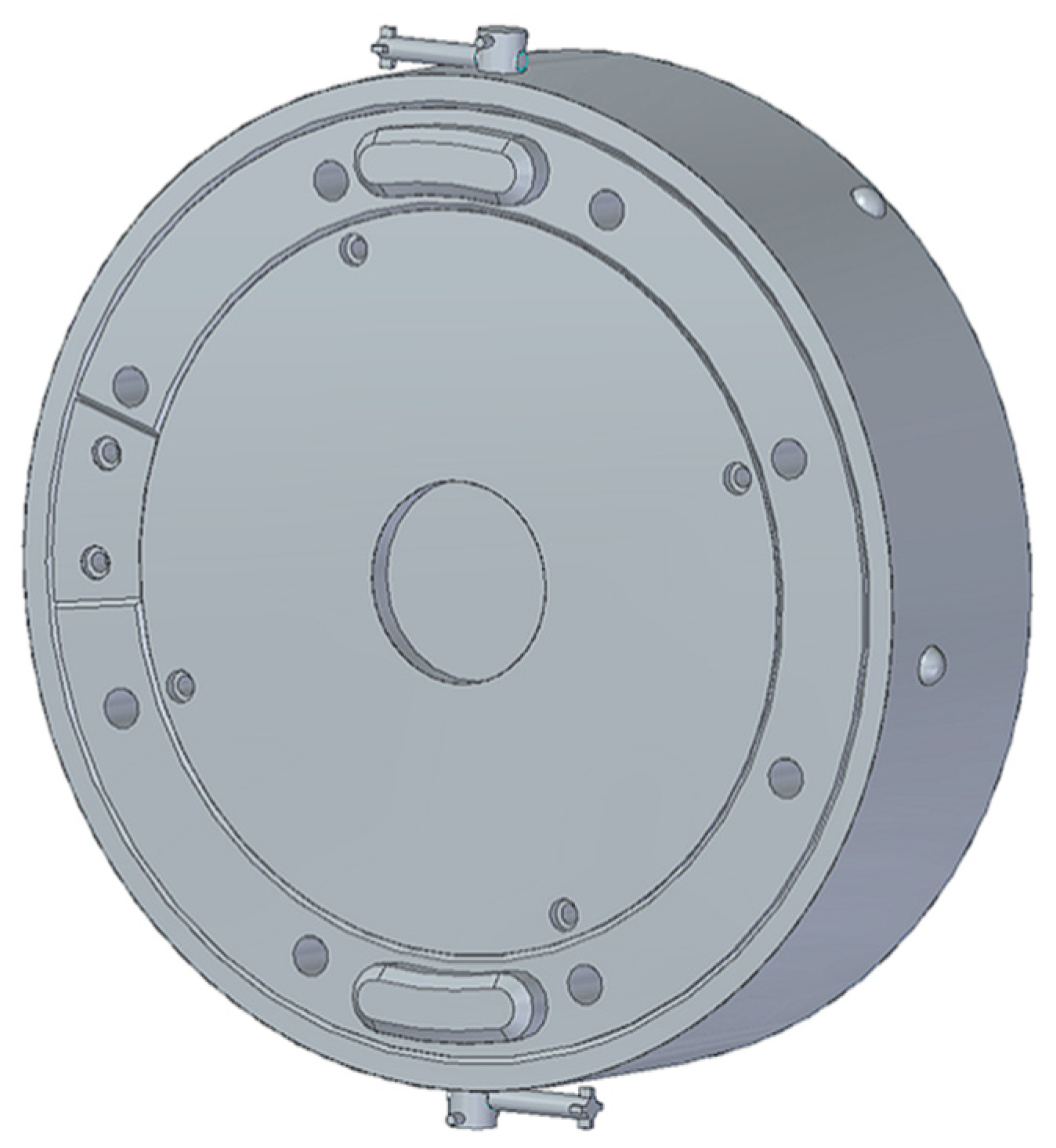

4. Design of the Docking Mechanism Module

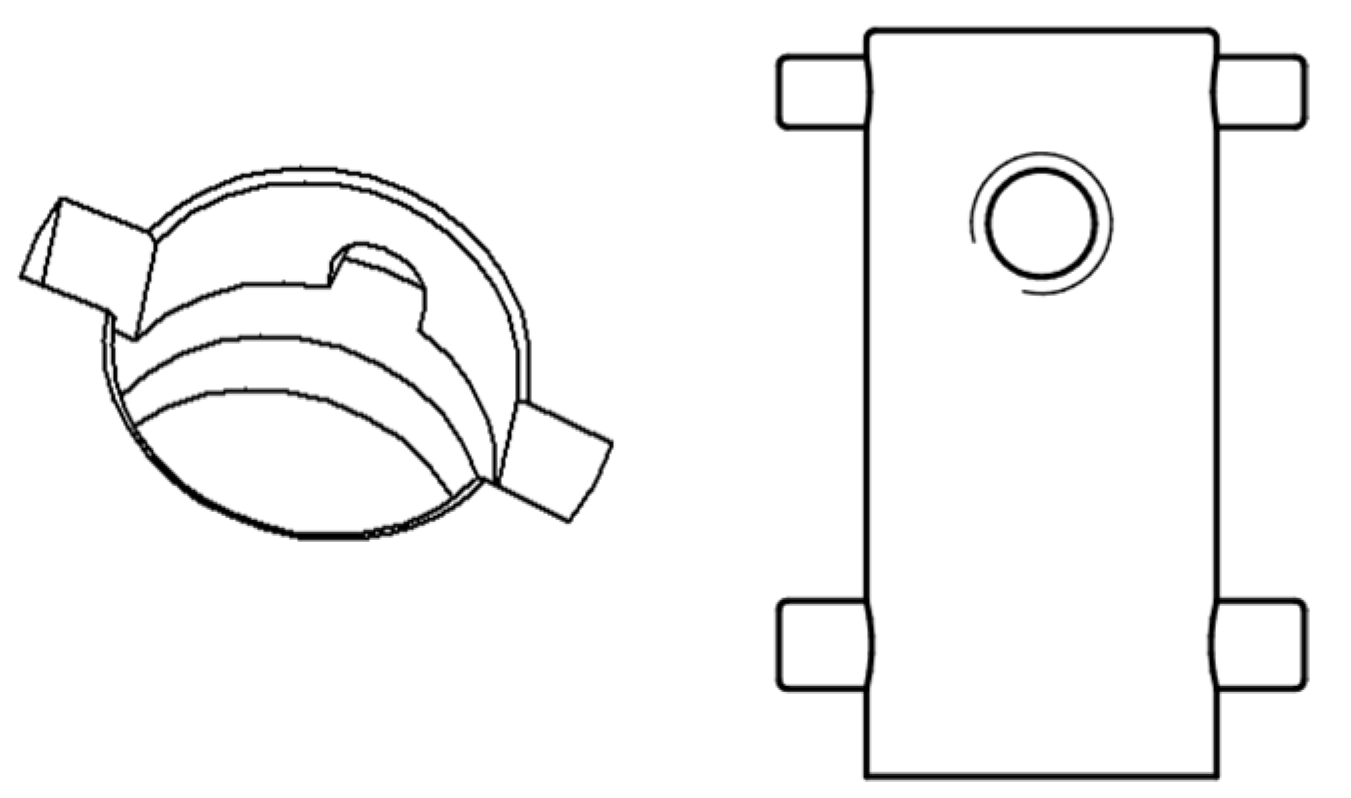

4.1. Structural Design of the Docking Mechanism Module

- The magnetic coil for wireless energy transmission is placed inside the coil guard, and the power transmission cable is threaded through the hole in the guard. The cable then connects to the main control board via the hollow drive shaft, enabling power transfer to the next joint module via wireless energy. The coil guard is then bolted to the fixed head of the docking mechanism module.

- The fixed head of the docking mechanism module is first inserted into the correct position via the guiding groove at the connection end, then bolted to the corresponding connection end of each module, preparing the system for the docking operation. If the fixed head is not damaged or the joint module does not require internal maintenance, disassembly is not necessary.

- The spring and spring pin are placed into the spring pin grooves of the fixed head, one set on each side. The bottom of the spring and the spring pin of the locking head are glued to the corresponding end face using an adhesive. When the docking mechanism is not locked, the limit holes of the movable and fixed heads do not overlap. The spring is compressed with a larger deformation, and the spring pin does not push out of the limit holes of the movable head. As a result, the axial and circumferential movements of both heads are not constrained. When the docking mechanism is locked, the limit holes of the movable and fixed heads overlap. Spring compresses with a smaller deformation compared to when the mechanism is unlocked, and the spring pin passes through the limit holes of the movable head to restrain both the fixed and movable heads. A single movable head has two sets of spring pins.

- 1.

- To connect the modules, the two fixed heads at the connection ends of the modules are inserted into the positioning groove of the other fixed head through the large end of the circular groove on the active head of the docking mechanism module, using the upper tab on the fixed head. At this point, the limit holes of both the active and fixed heads do not overlap, and the spring pins remain in place.

- 2.

- Manually rotate the movable head so that the tab on the fixed head moves from the large end to the small end of the movable head’s circular groove, locking it in place. This creates an axial constraint between the fixed and active movable heads. At this point, the limit holes of both heads overlap, causing the spring pins to eject and constraining the circumferential movement of both heads.

- 3.

- The locking holes of the fixed head and the active head align. The locking head is inserted into the fixed head’s locking hole via the guiding groove on the active head and rotated 90°. Due to the spring’s force, the locking head is pushed upwards. The outwardly protruding cylinders on either side of the locking head’s front end are pushed into the locking slot. Next, manually lift the locking head until its lower end cylinder tightly fits in the locking slot. Then, using a simple hand screw or a knurled bolt, screw it into the locking head’s upper limit through-hole to secure the locking head axially. This prevents the locking head from being compressed by external force and exiting the locking slot. This completes the docking mechanism module’s connection process. The locking holes on the main dynamic head and fixed head, as well as the locking head assembly section, are shown in Figure 11 and Figure 12.

- 4.

- To separate the docking mechanism module, first loosen the hand-screwed bolt, rotate the locking head by 90°, and remove it. Then, simultaneously press the spring pin and rotate the movable head, so that the tab on the fixed head moves from the small end to the large end of the movable head’s circular groove. This will separate the modules connected by the two fixed heads, completing the separation of the docking mechanism module.

4.2. Calibration of the Docking Mechanism Module

- 1.

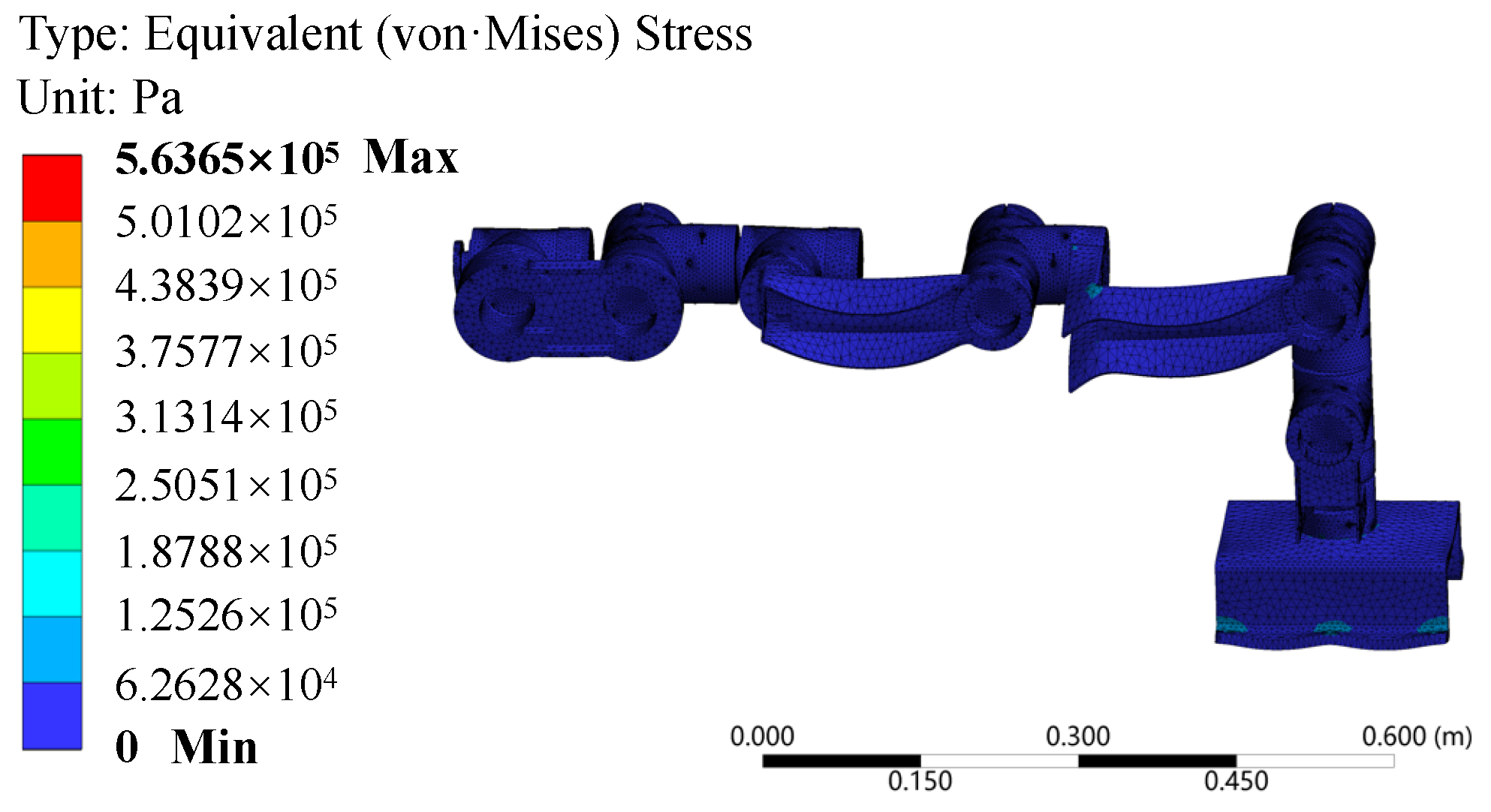

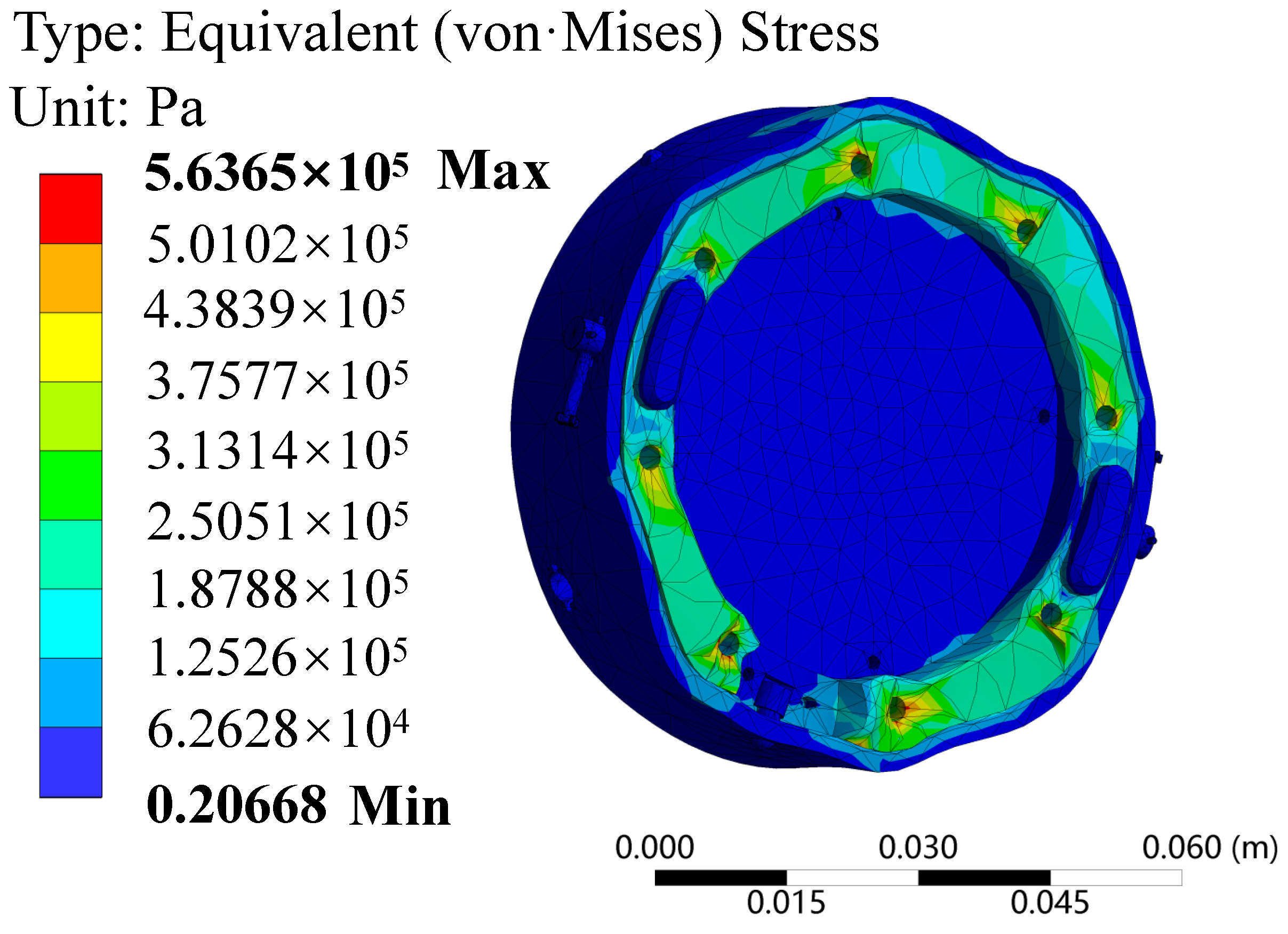

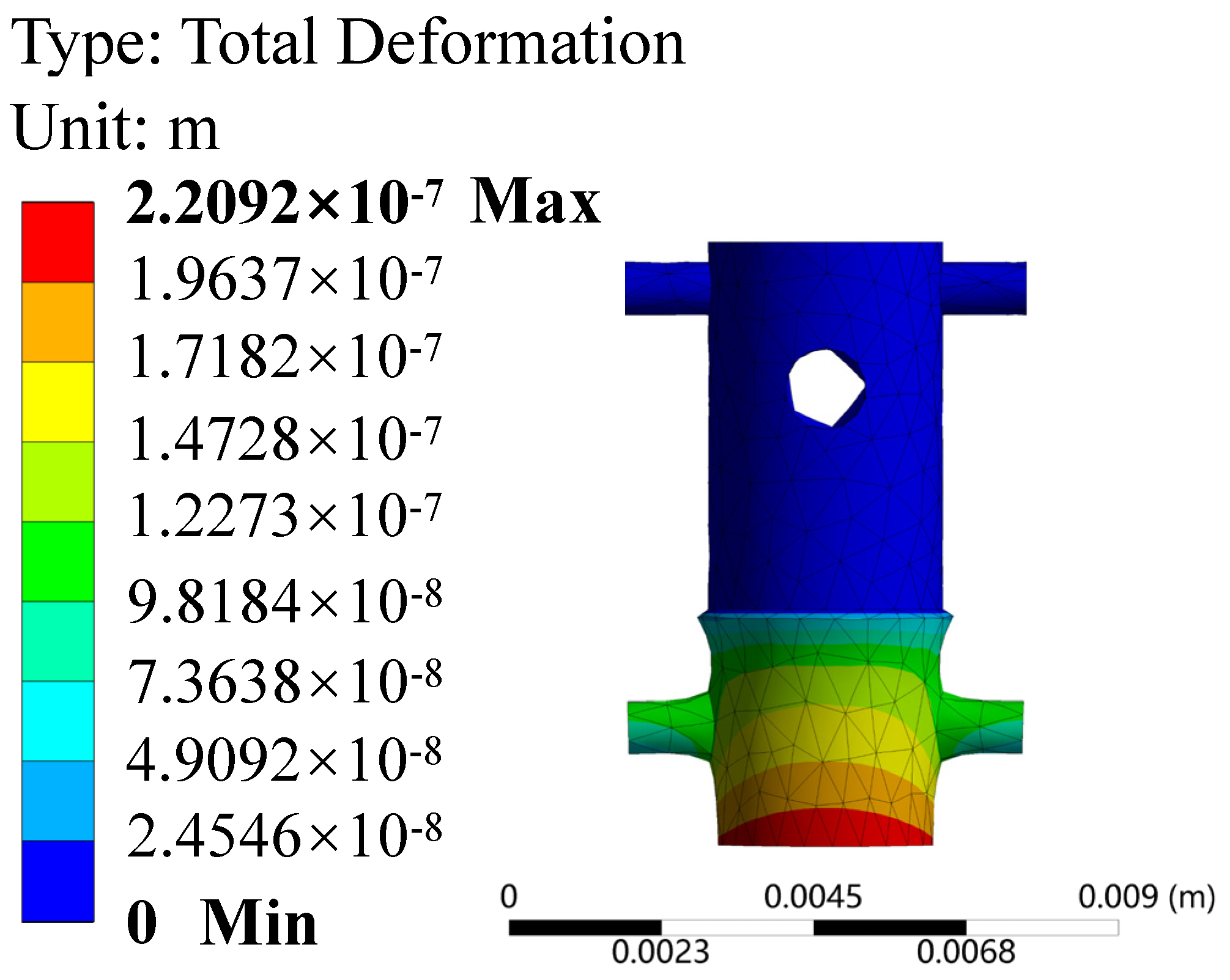

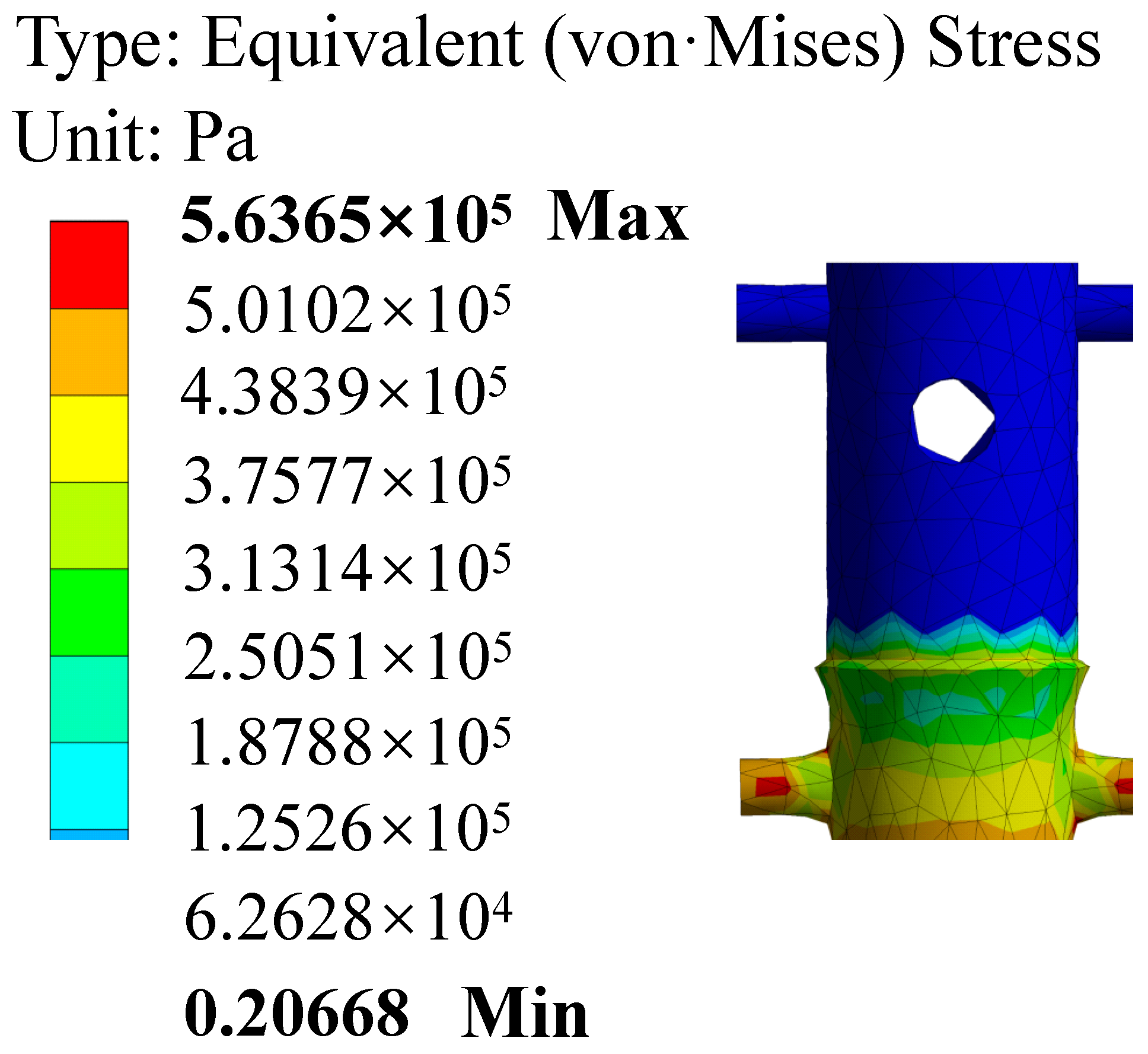

- After completing the structural design and force analysis of each module, the deformation and stress are compared against the allowable strength and stiffness values of the selected materials, optimizing and improving any unreasonable structures. Therefore, a finite element analysis must be performed based on the maximum torque calculated from the design parameters, with corresponding external loads and constraints applied. Relevant stress-strain diagrams are generated to analyze the deformation and force state, completing the static analysis and calculation of the entire manipulator and docking mechanism module Define the material properties of each major component.

- 2.

- Apply external loads and constraints to them respectively

- 3.

- Model solving and result analysis

5. Mathematical Modeling and Analysis

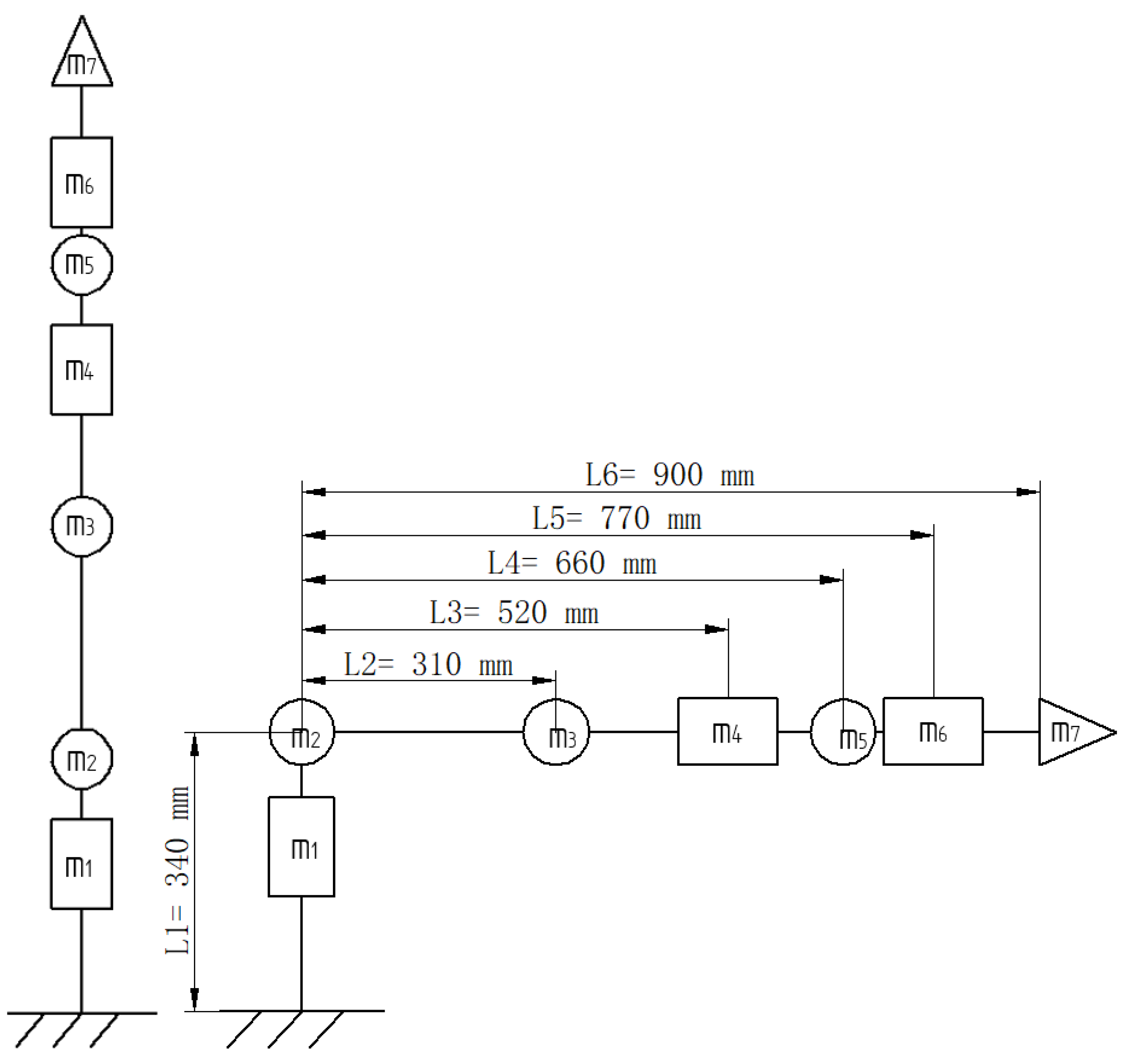

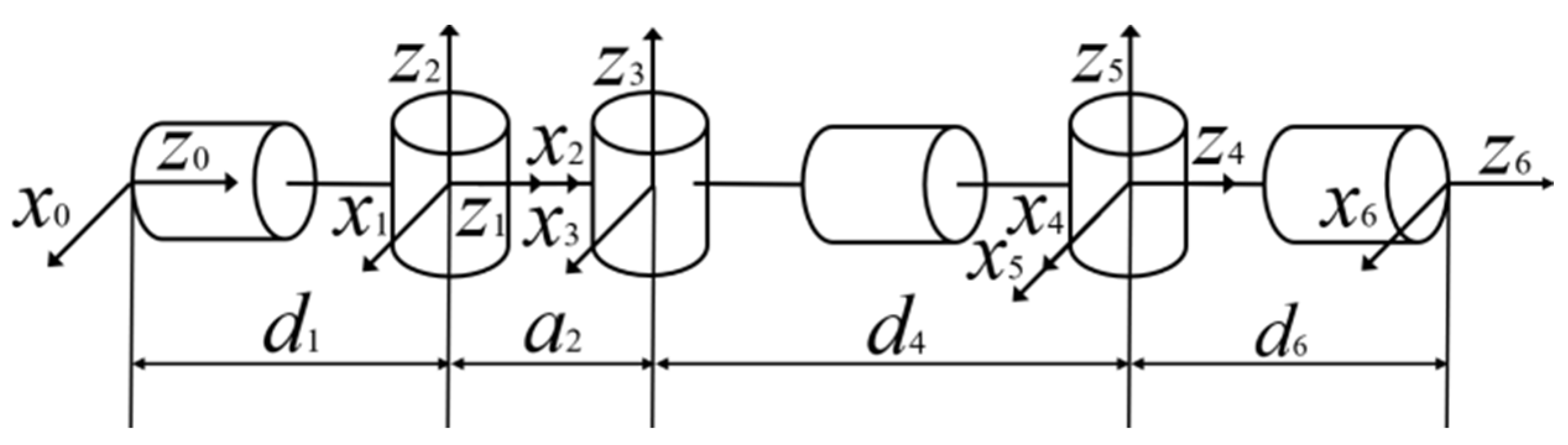

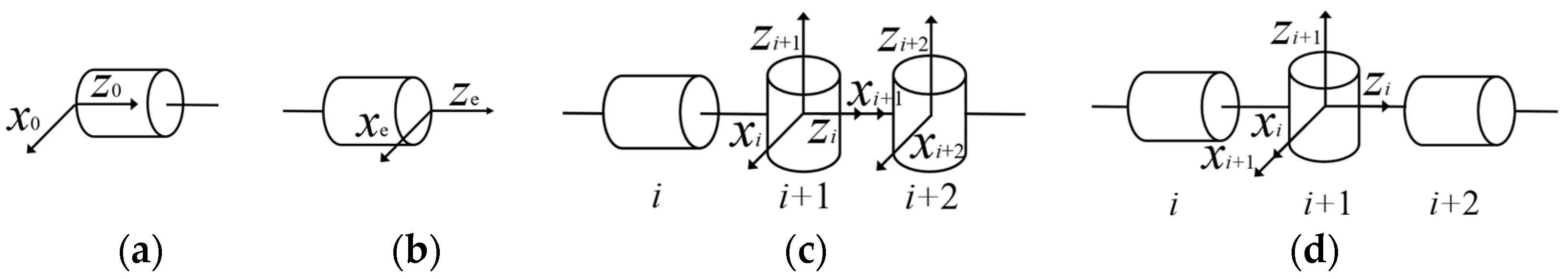

5.1. Kinematic Analysis of a Modular Reconfigurable Manipulator

5.1.1. Kinematic Modeling

5.1.2. Forward Kinematics Solution

5.1.3. Inverse Kinematics Solution

- 1.

- Solve for θ1

- 2.

- Solve for θ2

- 3.

- Solve for θ3

- 4.

- Solve for θ5

- 5.

- Solve for θ4

- 6.

- Solve for θ6

- When = 180°, has a unique solution.

- When has no solution. When and , = 180°, has a unique solution.

- When has no solution.

- When S5 = 0, i.e., = 180° or 180°, has no solution.

- When has no solution. When and , = 180°, has a unique solution.

5.2. Analysis of the Manipulator’s Workspace and Dexterity

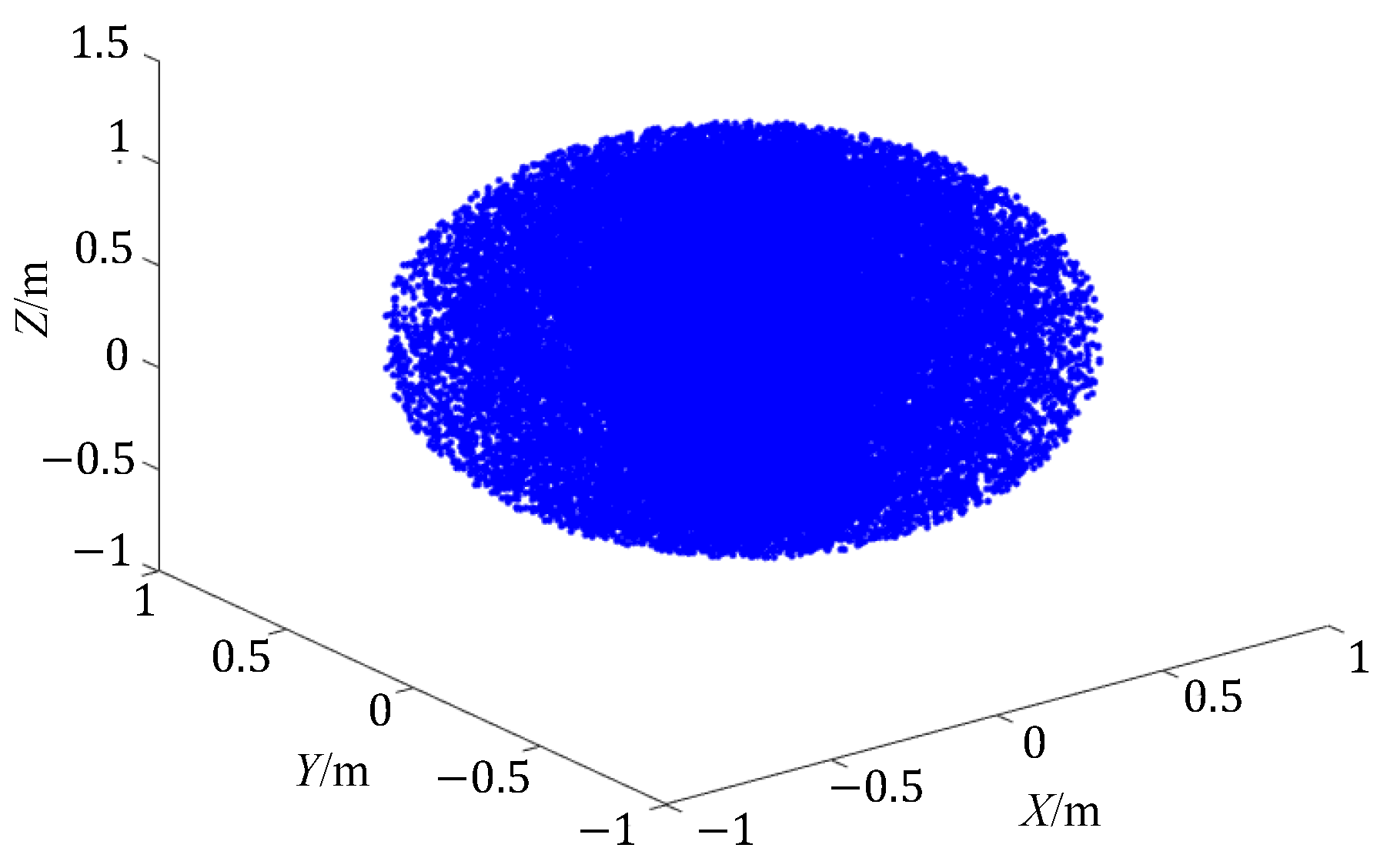

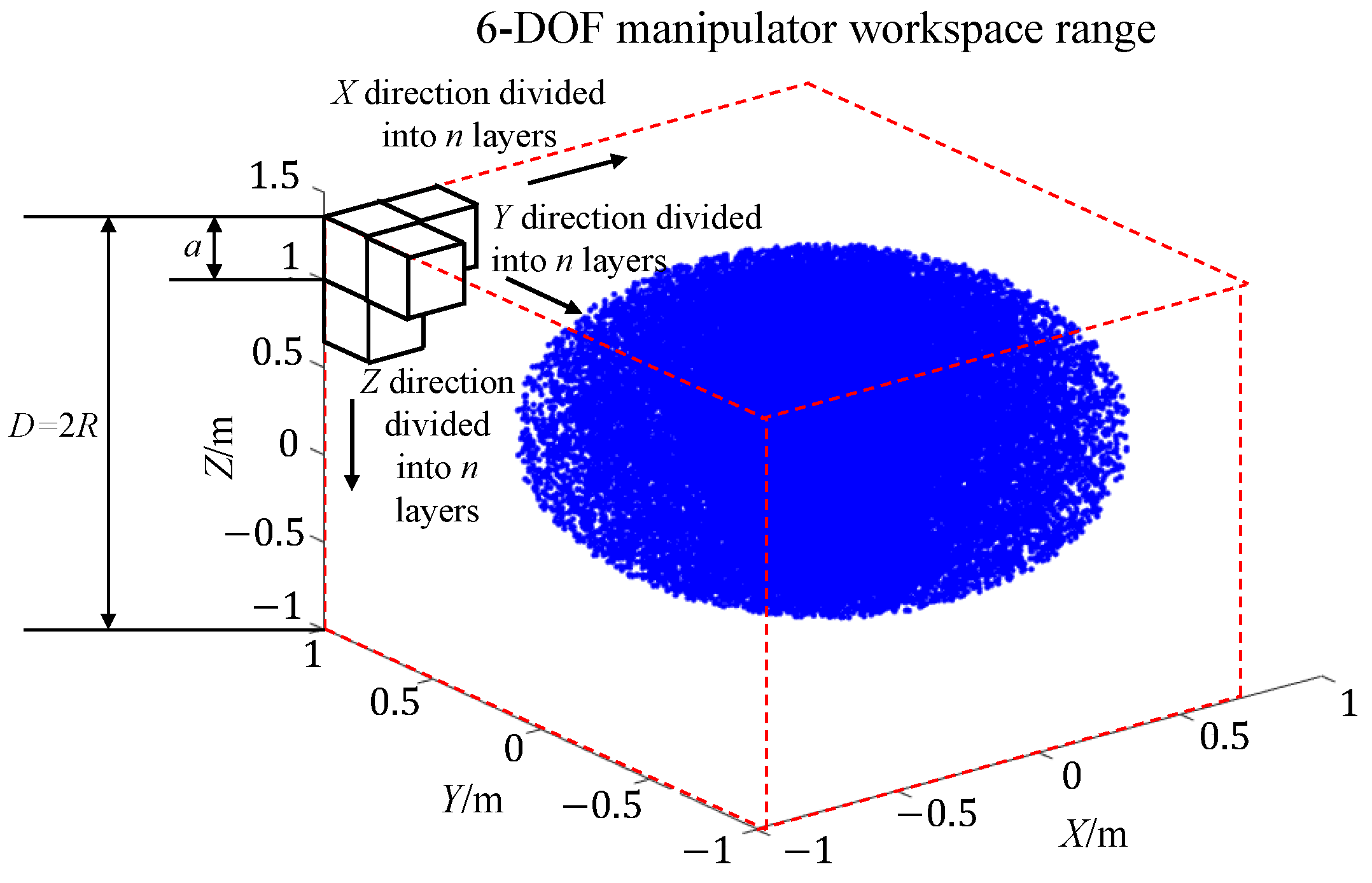

5.2.1. Workspace Analysis

- A set of joint angles is randomly generated within the specified range, based on the joint angle limits for each joint.

- The generated joint angles undergo kinematic orthogonal computation, and the resulting position of the end-effector is then represented as a point in the Cartesian coordinate system.

- Repeat steps 1 and 2 until the specified number of target sampling points is reached. Finally, plot the resulting set of reachable workspace points, representing the manipulator’s entire workspace.

- The joint angle limits for the designed 6-degree-of-freedom modular reconfigurable manipulator are provided in Table 4.

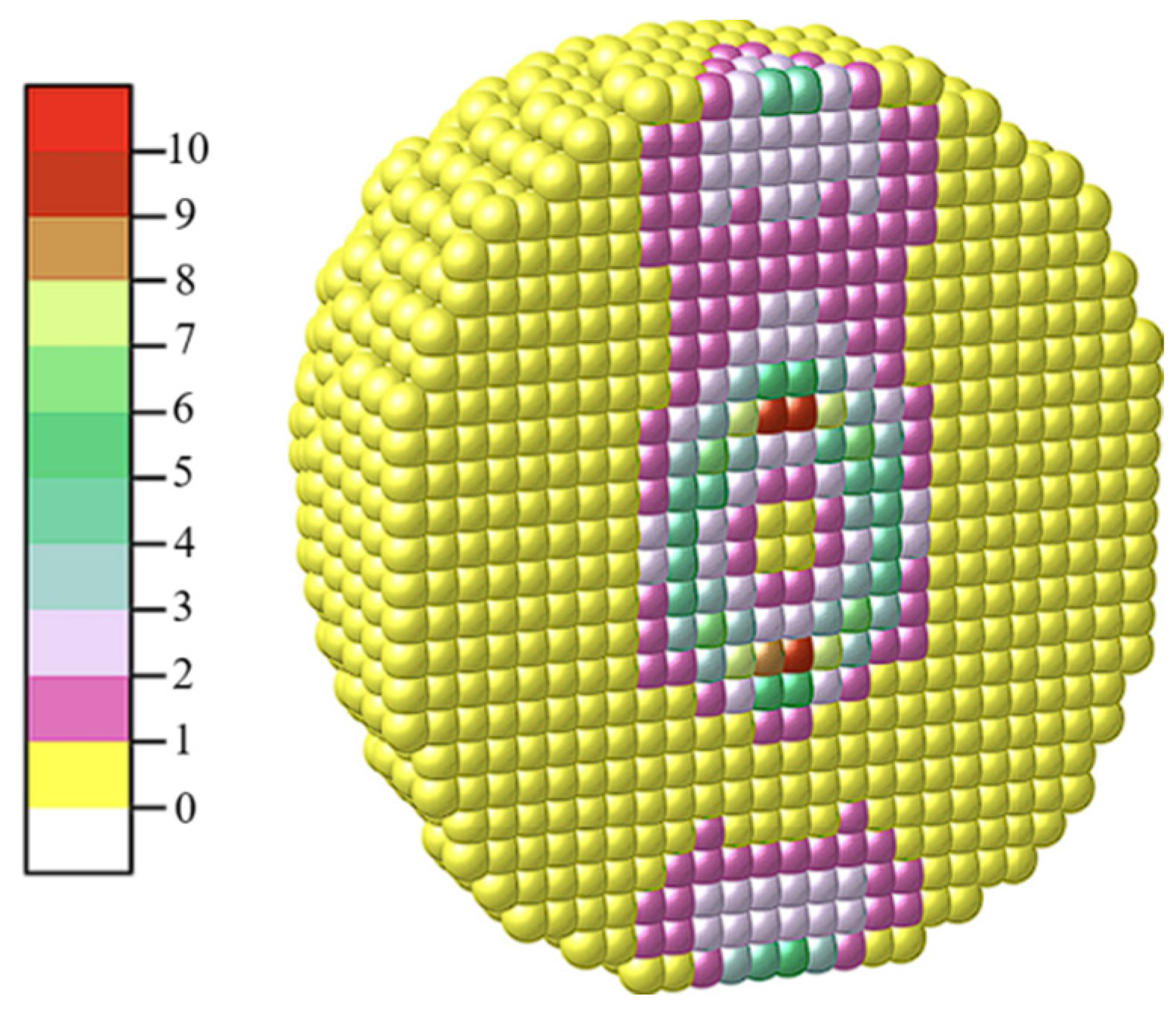

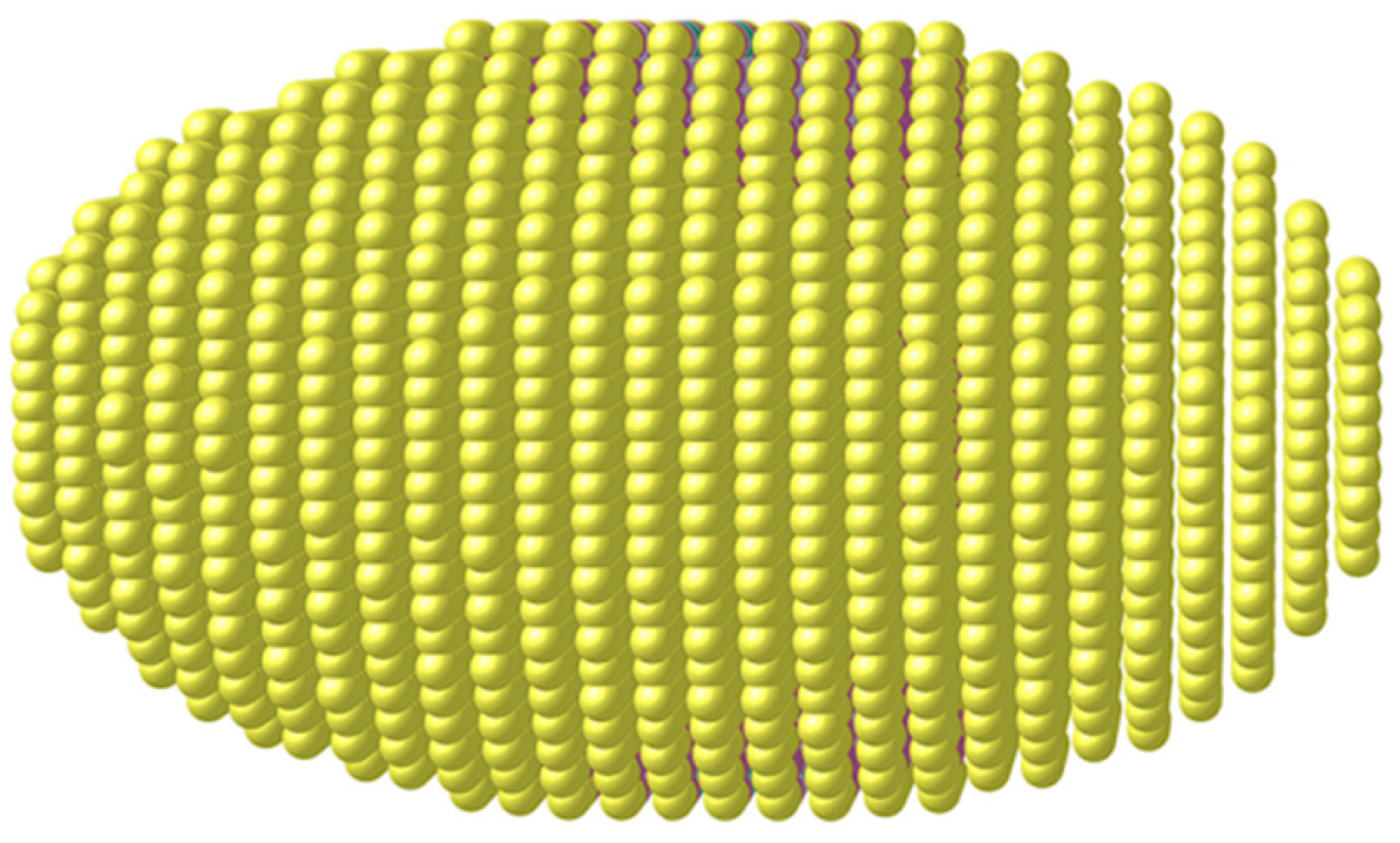

5.2.2. Spatial Dexterity Analysis

- The obtained workspace is divided into subspaces of equal volume. For the manipulator workspace determined using the Monte Carlo method, a cube is used to fully enclose the workspace, which is then further subdivided into smaller subspaces.

- 2.

- Determine the workspace density of the manipulator. First, find the Cartesian coordinates of each random sample point and identify the corresponding subspace along x, y, z. Next, assign the appropriate subspace label i, j, k, and increment the count of the points in that labeled subspace by one. After counting all the points in each subspace, divide the point count by the volume of the subspace to calculate its density [19]. The calculation follows this equation:

- 3.

- Classify the workspace density distribution. First, determine the maximum workspace density in each subspace. Then, categorize the density values into intervals using 10% equal divisions, assigning different colors to each range. Finally, generate a visual representation of the manipulator’s workspace density distribution.

- The gripping workspace distribution of this 6-degree-of-freedom manipulator follows an ellipsoidal shape;

- Starting from the origin of the base coordinate system, the reachable dexterity along the x-axis is greater than along the y-axes and z-axes. This manipulator demonstrates a high dexterity in tasks involving grasping positions and motion trajectories along the x-axis but is slightly less efficient in the y-axis and z-axis directions;

- The trend of dexterity along the x-axis follows a minimum-increasing-maximum-decreasing-increasing pattern, while along the y-axes and z-axes, it follows a minimum-increasing-higher-decreasing-lowest pattern;

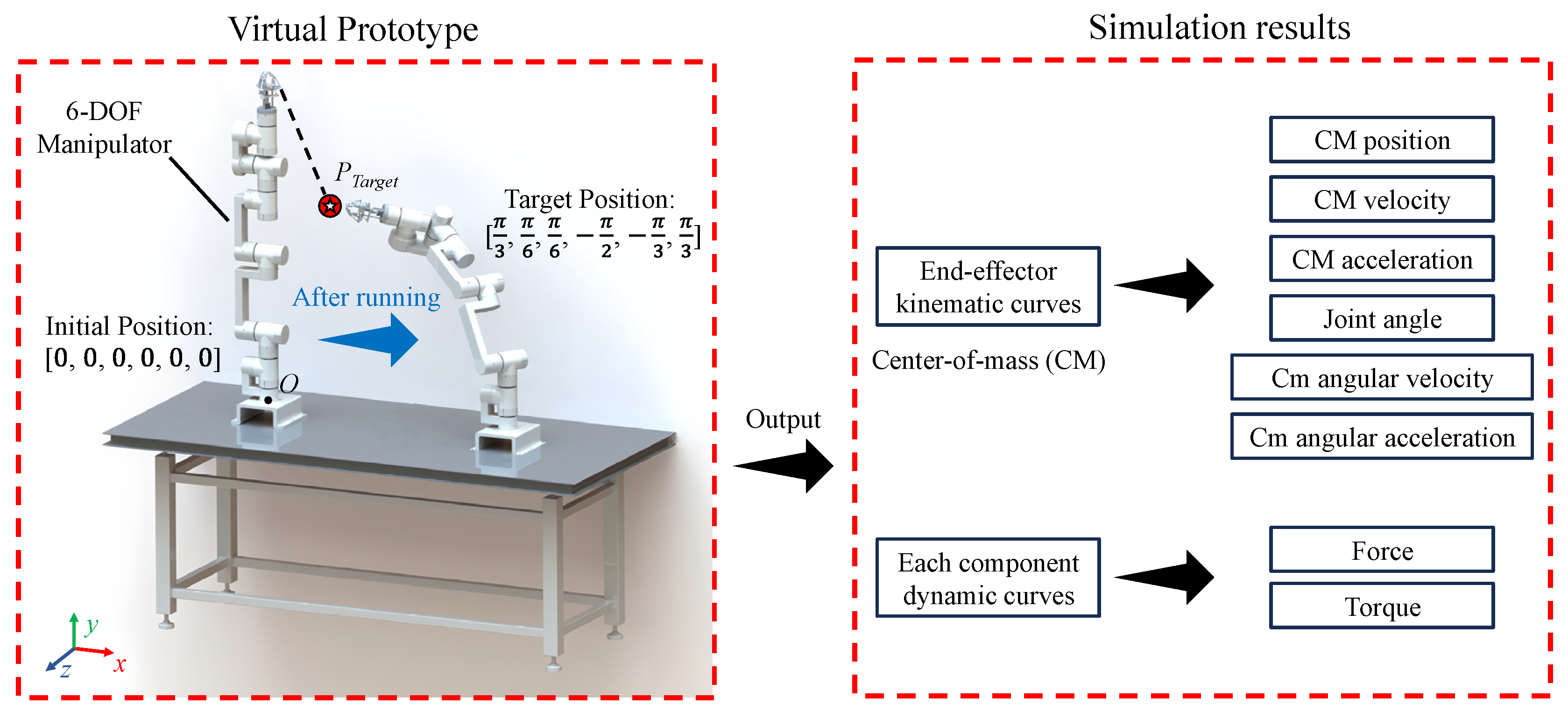

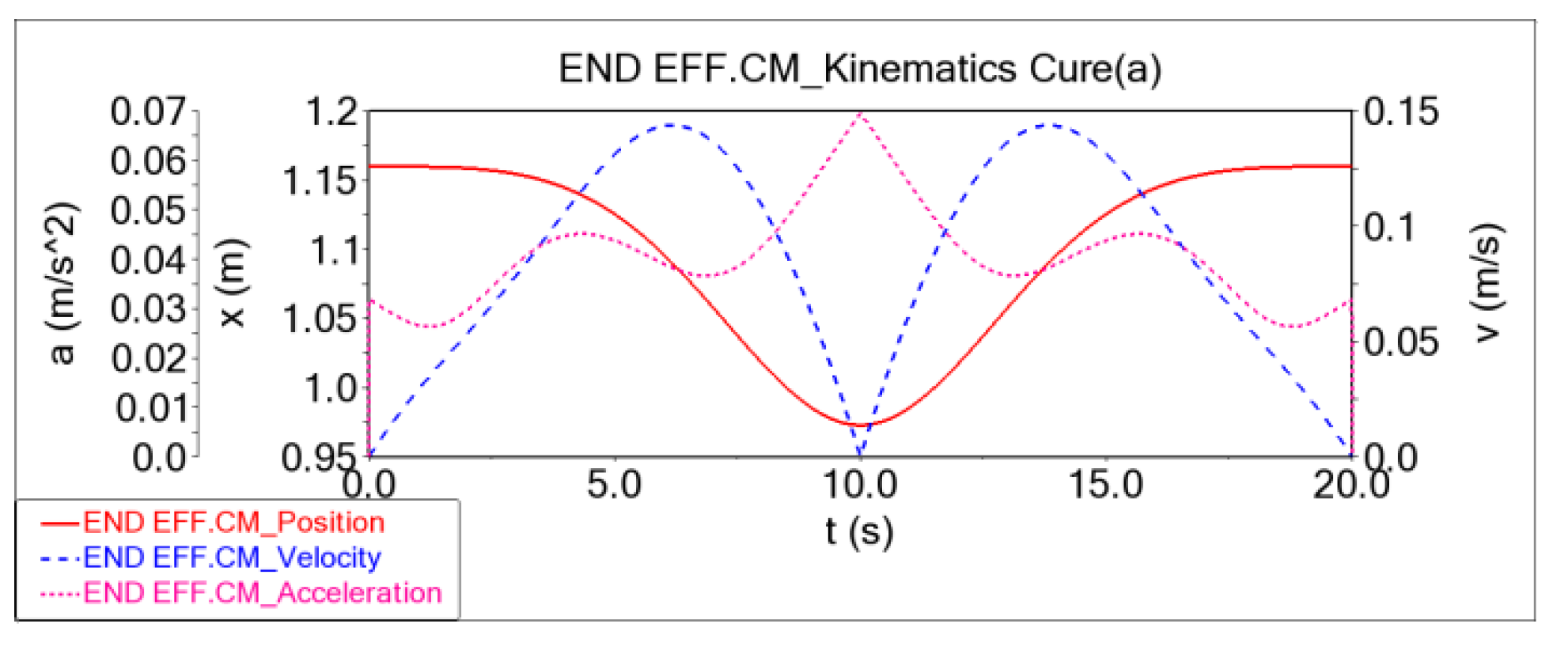

5.3. Modular Reconfigurable Manipulator Trajectory Planning and Simulation

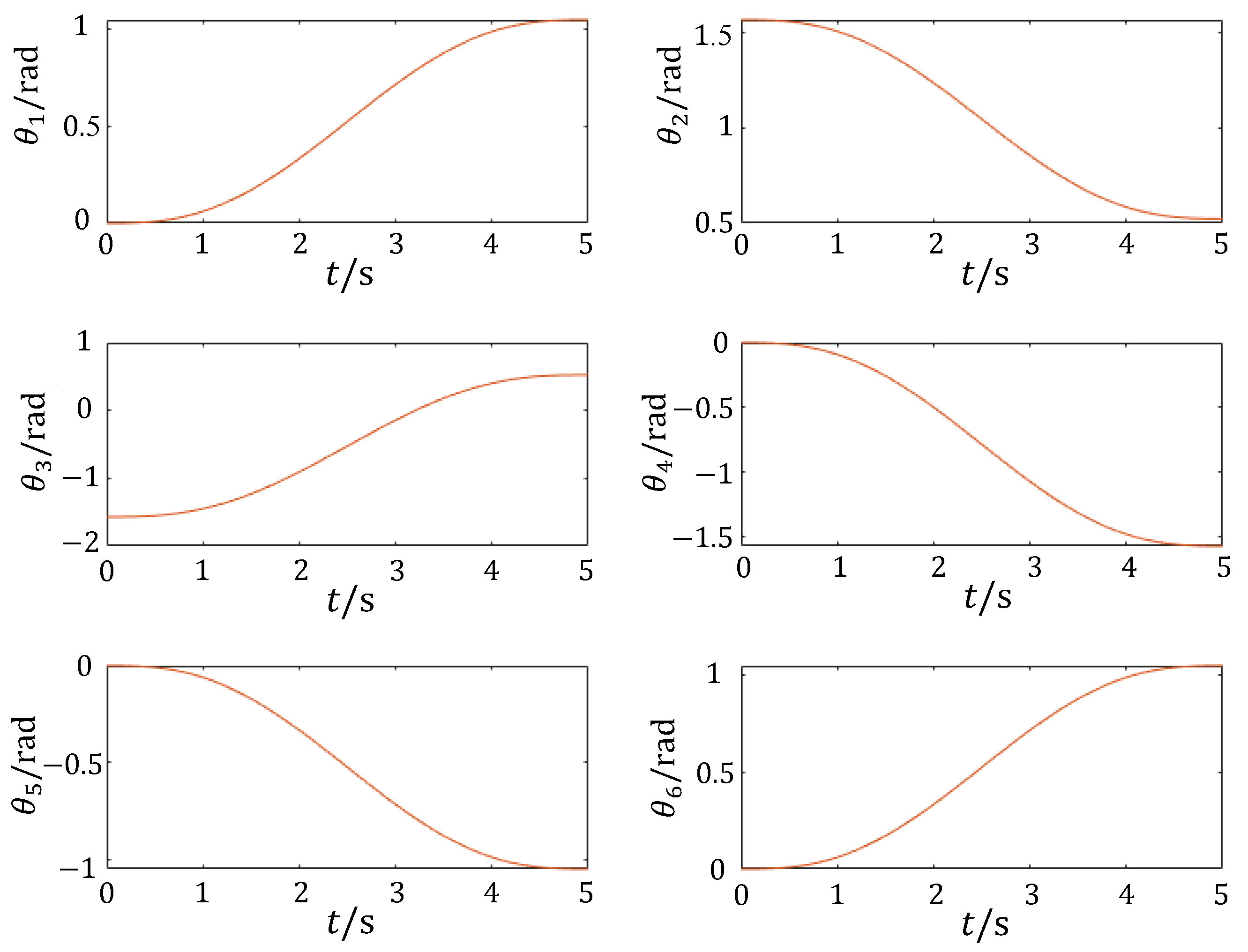

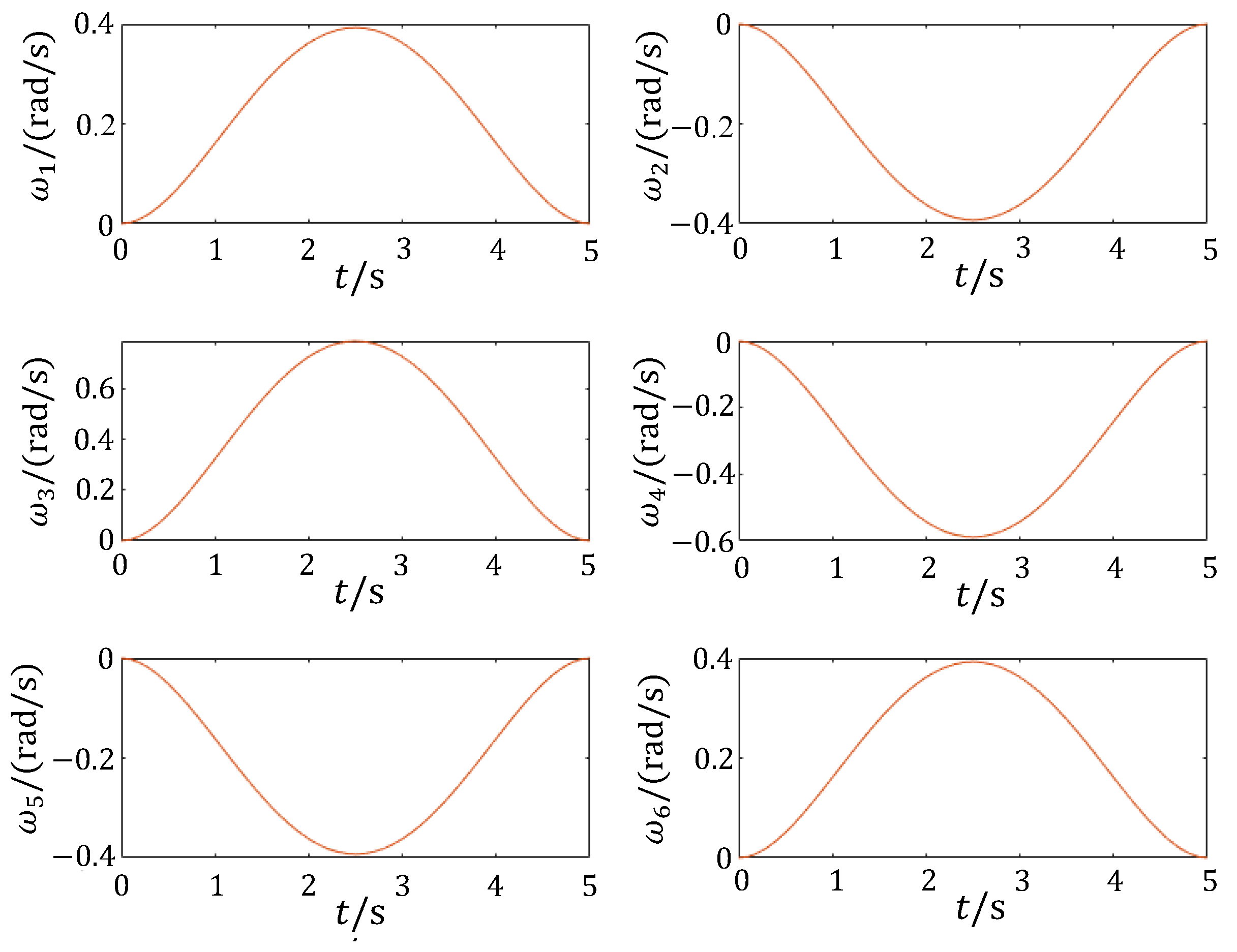

5.3.1. Joint Space Trajectory Planning

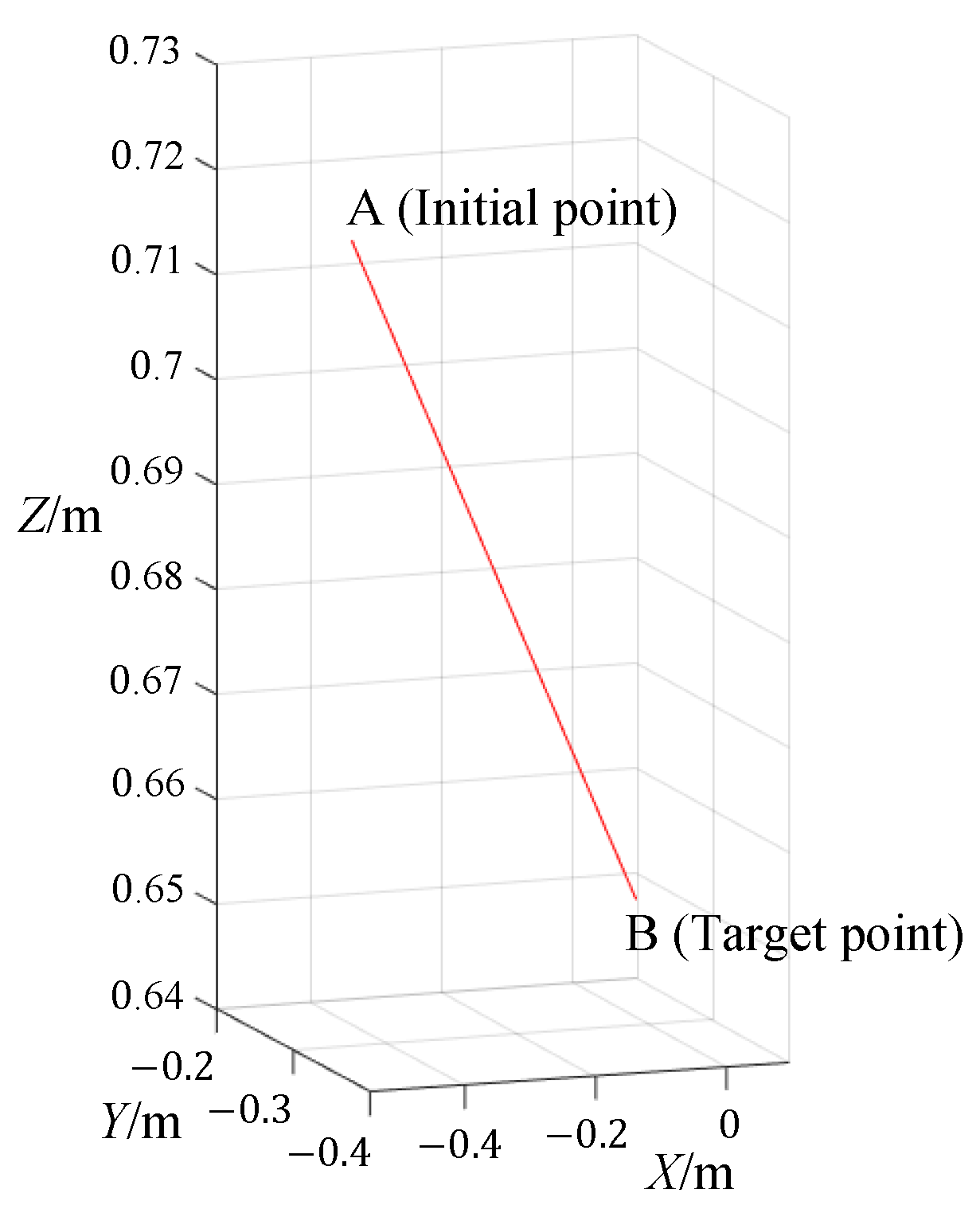

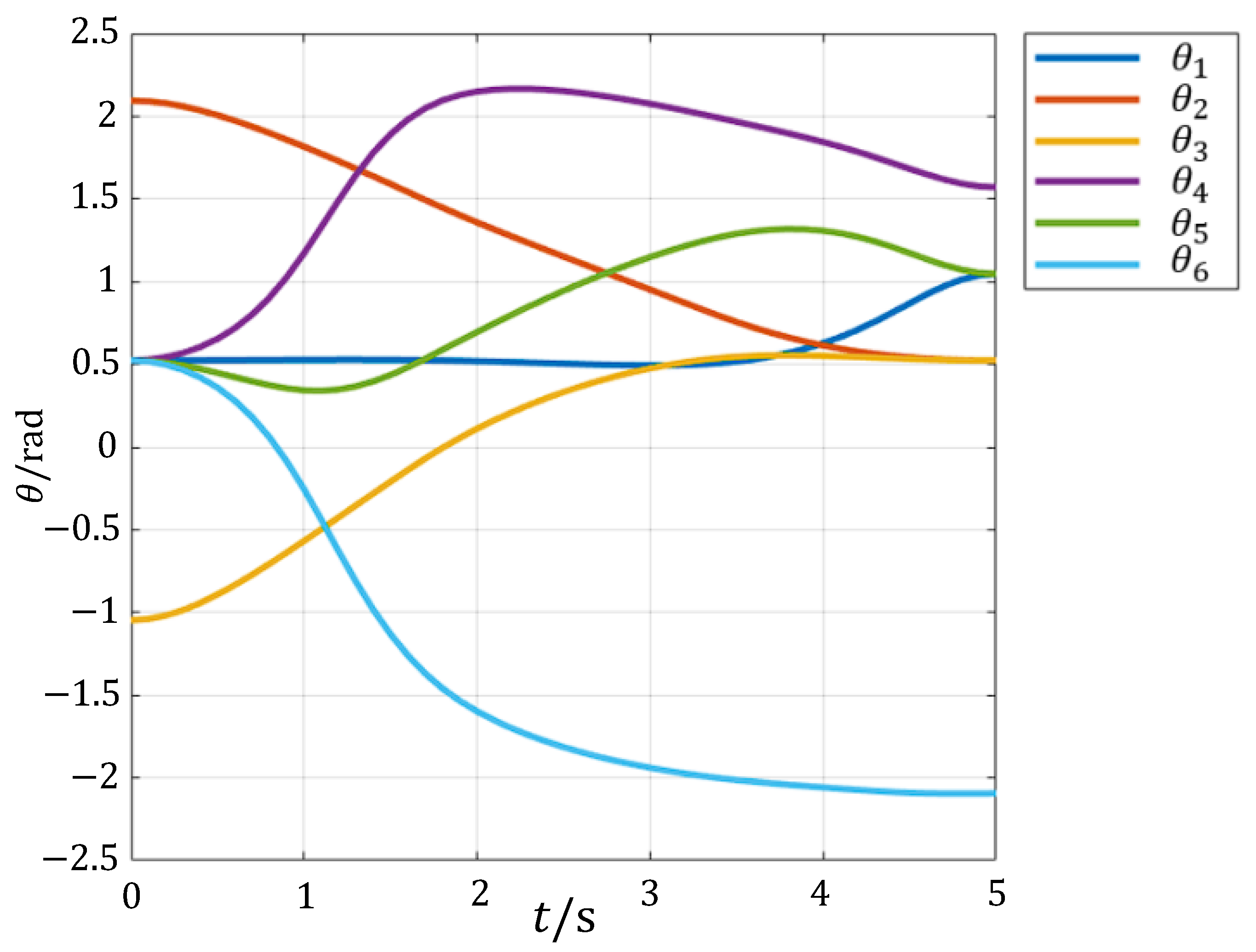

5.3.2. Cartesian Spatial Trajectory Planning

- Defining the positions of the start and end points;

- Assume that the velocity v at the output of the end-effector and the time interval between each interpolation is t;

- Calculate the distance L between the start point and end point;

- 4.

- Calculate the total interpolation time T;

- 5.

- Calculate the total number of interpolation steps N (rounded);

- 6.

- Calculate the increment for each interpolation step;

- 7.

- Based on the increment of each interpolation, the Cartesian coordinates of each point along the line are calculated;

- 8.

- Finally, the position of each interpolation point is substituted into the manipulator’s inverse kinematics for calculation, yielding a set of joint angles to complete the linear interpolation path planning.

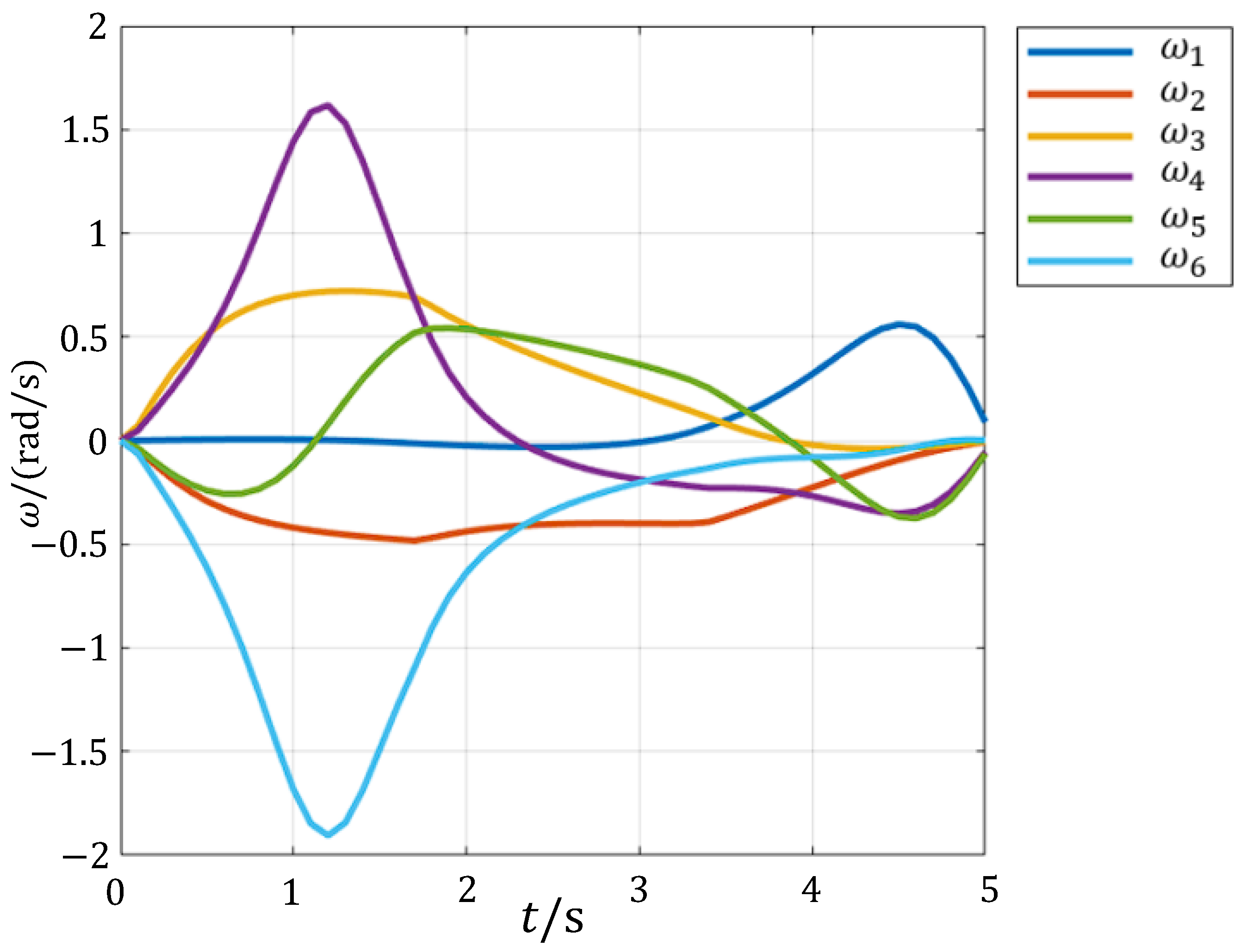

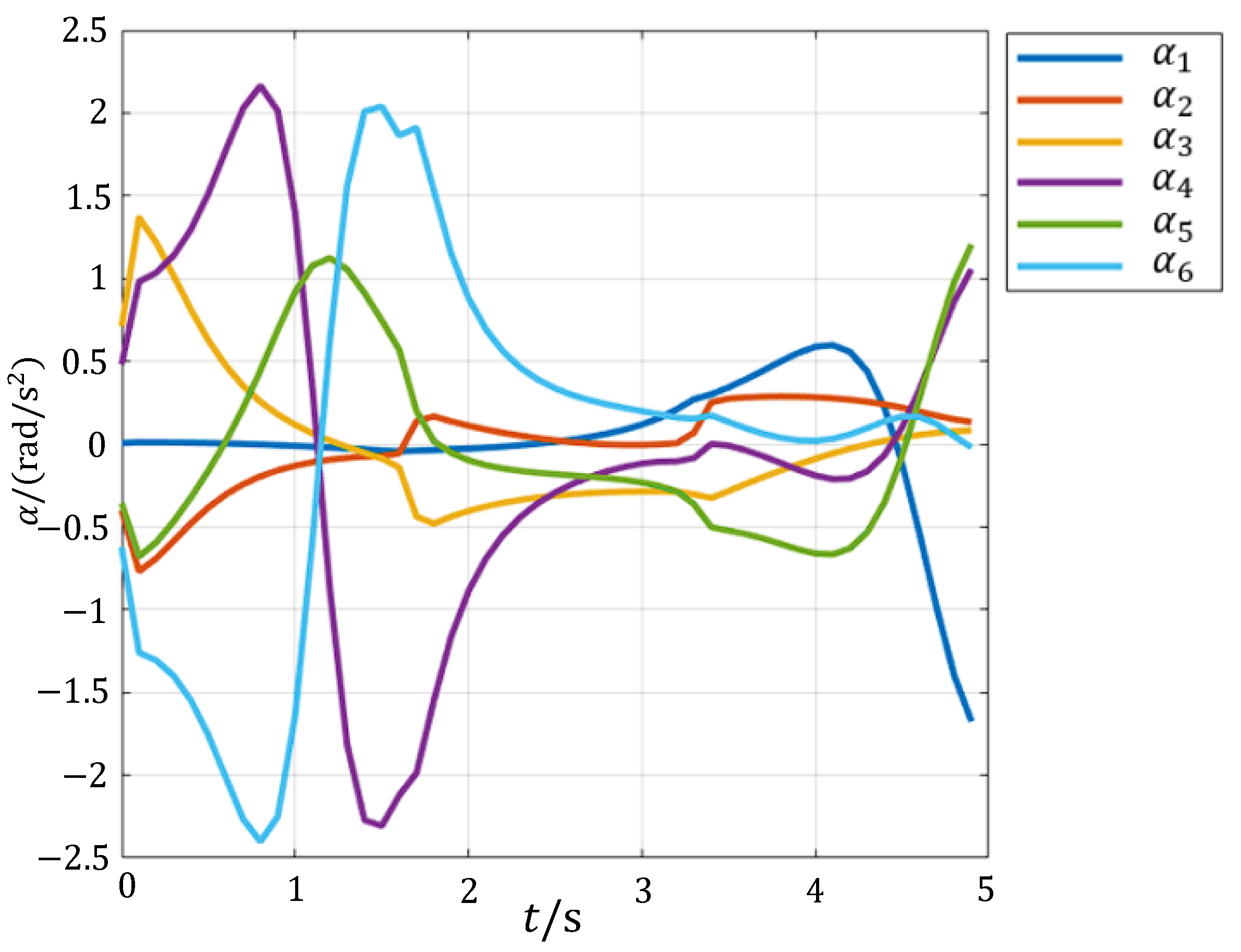

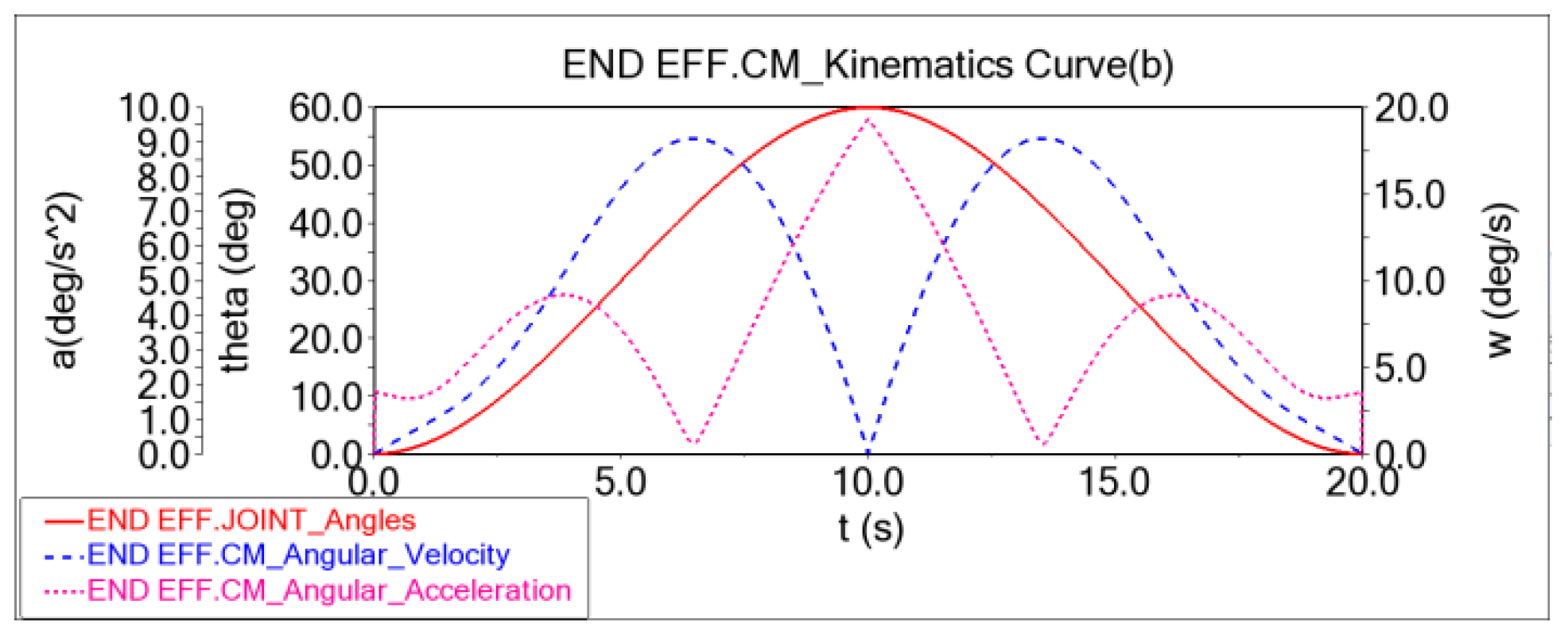

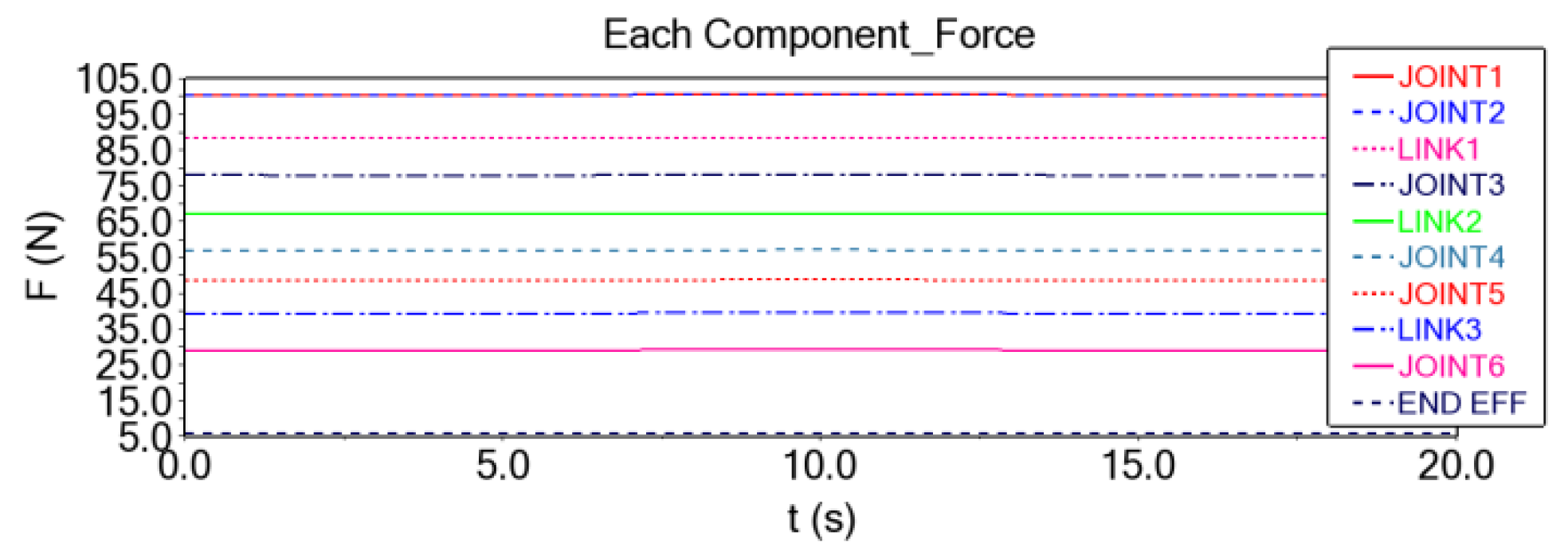

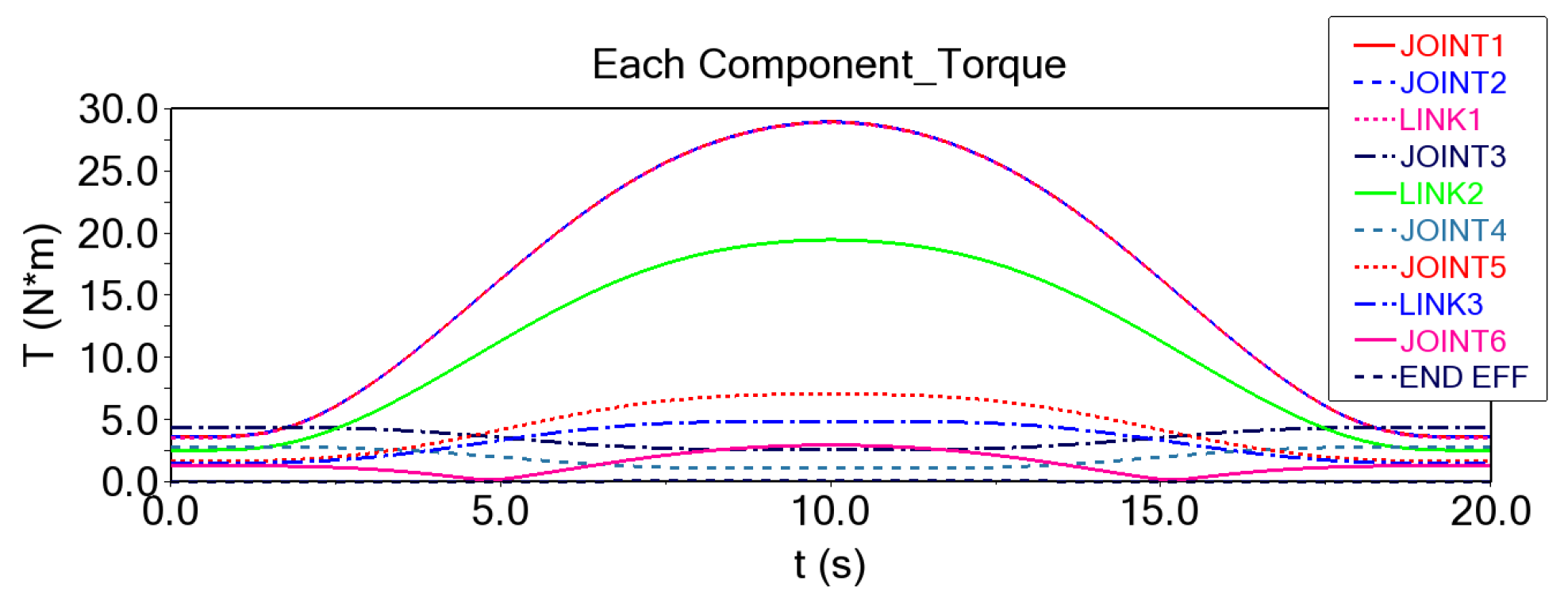

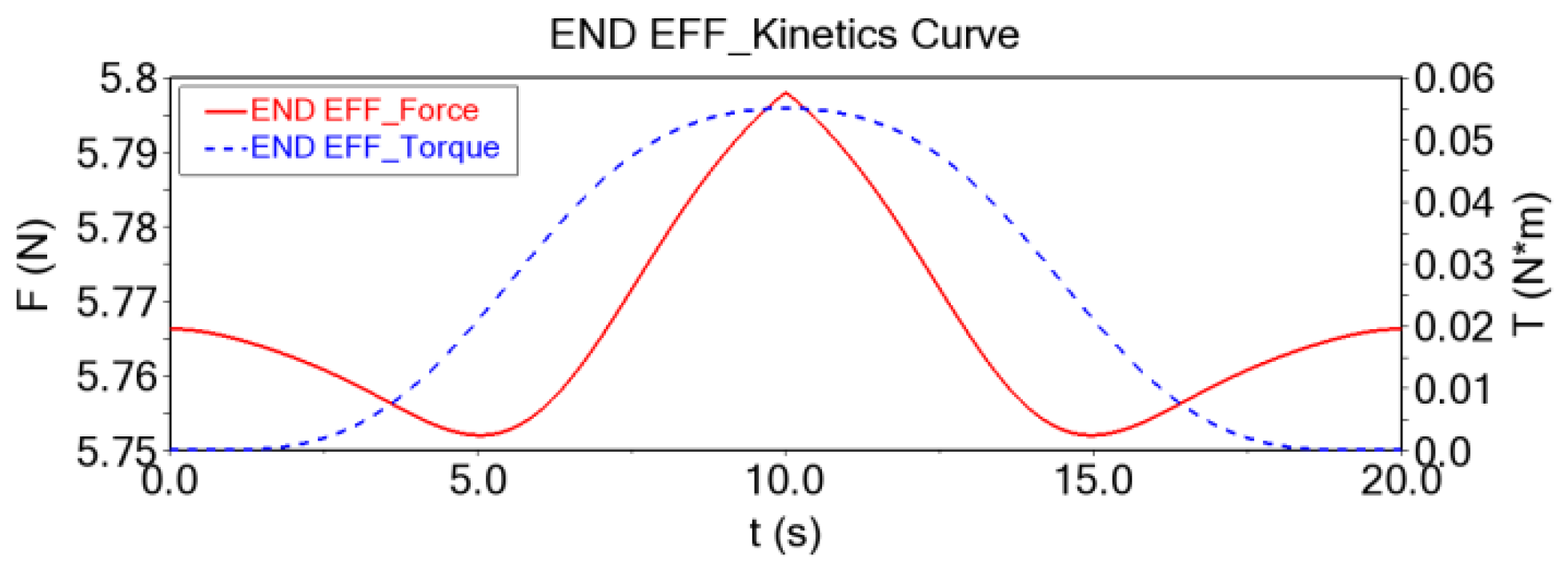

5.4. Dynamic Analysis and Simulation of Modular Reconfigurable Manipulator

6. Conclusions

- This paper proposes the creation of a modular reconfigurable manipulator module library and the structural design of a new modular docking mechanism, based on the target design requirements. The modules are connected via the docking mechanism, which has been verified to enable rapid assembly and disassembly while ensuring the strength and stiffness of the connection. This enhances the reconfigurability and flexibility of the manipulator.

- This paper proposes a fast kinematic model for a modular reconfigurable manipulator that satisfies the Pieper criterion configuration and provides a method for solving both forward and inverse kinematics. The workspace is further subdivided into smaller subspaces to conduct a spatial analysis of the manipulator’s dexterity using the workspace density method. Two methods—joint space planning and Cartesian space planning—are used to generate and simulate the motion paths, successfully verifying the rationality of the manipulator’s kinematics. Finally, the dynamic simulation provides the force and moment change curves for each component during movement under gravity alone, corresponding to the kinematic curves obtained from the path planning. This also serves as a reference for strength calibration and further verifies the reasonableness of the manipulator’s kinematics while completing the dynamics analysis. The results of this paper provide valuable guidance and a reference for the design and research of plug-and-play, highly integrated modular reconfigurable manipulators.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Surappa, S.; Pavagada, S.; Akin, D.; Wei, C.; Degertekin, F.L.; Demirci, U. Dynamically reconfigurable acoustofluidic metasurface for subwavelength particle manipulation and assembly. Nat. Commun. 2025, 16, 494. [Google Scholar] [CrossRef] [PubMed]

- Song, S.; Gong, D.; Zhu, M.; Zhao, Y.; Huang, C. Data-Driven Optimal Tracking Control for Discrete-Time Nonlinear Systems with Unknown Dynamics Using Deterministic ADP. IEEE Trans. Neural Netw. Learn. Syst. 2023, 36, 1184–1198. [Google Scholar] [CrossRef] [PubMed]

- Seo, J.; Paik, J.; Yim, M. Modular reconfigurable robotics. Annu. Rev. Control Robot. Auton. Syst. 2019, 2, 63–88. [Google Scholar] [CrossRef]

- Zhu, M.; Briot, S.; Chriette, A. Sensor-based design of a delta parallel robot. Mechatronics 2022, 87, 102893. [Google Scholar] [CrossRef]

- Dai, Y.; He, S.; Nie, X.; Rui, X.; Li, S.; He, S. Research on reconfiguration strategies for self-reconfiguring modular robots: A review. J. Intell. Robot. Syst. 2024, 110, 47. [Google Scholar] [CrossRef]

- Liang, G.; Wu, D.; Tu, Y.; Lam, T.L. Decoding modular reconfigurable robots: A survey on mechanisms and design. Int. J. Robot. Res. 2024, 02783649241283847. [Google Scholar] [CrossRef]

- Sarker, A.; Islam, T.U.; Islam, R. A Review on Recent Trends of Bioinspired Soft Robotics: Actuators, Control Methods, Materials Selection, Sensors, Challenges, and Future Prospects. Adv. Intell. Syst. 2024, 7, 2400414. [Google Scholar] [CrossRef]

- Dokuyucu, H.İ.; Özmen, N.G. Achievements and future directions in self-reconfigurable modular robotic systems. J. Field Robot. 2023, 40, 701–746. [Google Scholar] [CrossRef]

- Zhu, M.; Huang, C.; Song, S.; Xu, S.; Gong, D. Vision-admittance-based adaptive RBFNN control with a SMC robust compensator for collaborative parallel robots. J. Frankl. Inst. 2024, 361, 106538. [Google Scholar] [CrossRef]

- Tang, S.; Huang, R.; Zhao, G.; Wang, G. Cone–hole docking mechanism for a modular reconfigurable mobile robot and its characteristic analysis. Ind. Robot. Int. J. Robot. Res. Appl. 2023, 50, 781–792. [Google Scholar] [CrossRef]

- Xue, Z.; Liu, J.; Wu, C.; Tong, Y. Review of in-space assembly technologies. Chin. J. Aeronaut. 2021, 34, 21–47. [Google Scholar]

- Jiang, Z.; Cao, X.; Huang, X.; Li, H.; Ceccarelli, M. Progress and development trend of space intelligent robot technology. Space Sci. Technol. 2022, 2022, 9832053. [Google Scholar]

- Post, M.A.; Yan, X.T.; Letier, P. Modularity for the future in space robotics: A review. Acta Astronaut. 2021, 189, 530–547. [Google Scholar]

- Zhang, Z.; Li, X.; Li, Y.; Hu, G.; Wang, X.; Zhang, G.; Tao, H. Modularity, reconfigurability, and autonomy for the future in spacecraft: A review. Chin. J. Aeronaut. 2023, 36, 282–315. [Google Scholar]

- Li, B.; Qiu, S.; Ye, H.; Guo, Y.; Wang, H.; Bai, J. Motion planning for 7-degree-of-freedom bionic arm: Deep deterministic policy gradient algorithm based on imitation of human action. Eng. Appl. Artif. Intell. 2025, 140, 109673. [Google Scholar]

- Blatnický, M.; Dižo, J.; Gerlici, J.; Sága, M.; Lack, T.; Kuba, E. Design of a robotic manipulator for handling products of automotive industry. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420906290. [Google Scholar] [CrossRef]

- Quan, Y.; Zhao, C.; Lv, C.; Wang, K.; Zhou, Y. The dexterity capability map for a seven-degree-of-freedom manipulator. Machines 2022, 10, 1038. [Google Scholar] [CrossRef]

- Zhao, X.; Zhao, Z.; Liu, Y.; Su, C.; Meng, J. Analysis of workspace boundary for multi-robot coordinated lifting system with rolling base. Robotica 2024, 42, 3657–3674. [Google Scholar]

- Cao, W.; Li, S.; Cheng, P.; Ge, M.; Ding, H.; Lai, J. Design and development of a new 4 DOF hybrid robot with Scara motion for high-speed operations in large workspace. Mech. Mach. Theory 2024, 198, 105656. [Google Scholar]

- Ye, L.; Xiong, G.; Zeng, C.; Zhang, H. Trajectory tracking control of 7-DOF redundant robot based on estimation of intention in physical human-robot interaction. Sci. Prog. 2020, 103, 0036850420953642. [Google Scholar]

- Wei, Y.; Zheng, Z.; Li, Q.; He, J. A trajectory planning method for the redundant manipulator based on configuration plane. Int. J. Adv. Robot. Syst. 2021, 18, 17298814211058558. [Google Scholar]

- Zhao, J.; Xu, Z.; Zhao, L.; Li, Y.; Ma, L.; Liu, H. A novel inverse kinematics for solving repetitive motion planning of 7-DOF SRS manipulator. Robotica 2023, 41, 392–409. [Google Scholar]

- Wang, H.; Zhao, Q.; Li, H.; Zhao, R. Polynomial-based smooth trajectory planning for fruit-picking robot manipulator. Inf. Process. Agric. 2022, 9, 112–122. [Google Scholar]

- Potter, H.; Kern, J.; Gonzalez, G.; Urrea, C. Energetically optimal trajectory for a redundant planar robot by means of a nested loop algorithm. Elektron. Elektrotech. 2022, 28, 4–17. [Google Scholar]

- Zeng, C.; Yang, C.; Jin, Z.; Zhang, J. Hierarchical impedance, force, and manipulability control for robot learning of skills. IEEE/ASME Trans. Mechatron. 2024. [Google Scholar] [CrossRef]

- Fan, Z.; Jia, K.; Zhang, L.; Zou, F.; Du, Z.; Liu, M.; Cao, Y.; Zhang, Q. A cartesian-based trajectory optimization with jerk constraints for a robot. Entropy 2023, 25, 610. [Google Scholar] [CrossRef]

- Li, X.; Zhao, H.; He, X.; Ding, H. A novel cartesian trajectory planning method by using triple NURBS curves for industrial robots. Robot. Comput. Integr. Manuf. 2023, 83, 102576. [Google Scholar]

- Ekrem, Ö.; Aksoy, B. Trajectory planning for a 6-axis robotic arm with particle swarm optimization algorithm. Eng. Appl. Artif. Intell. 2023, 122, 106099. [Google Scholar]

| Technical Indicators | Parameters |

|---|---|

| Overall quality of the manipulator | ≤12 kg |

| Manipulator span length | ≤1.3 m |

| Acceleration of each joint | |

| Angular velocity of each joint | 0.3 rad/s |

| Manipulator load | ≤1 kg |

| Degrees of freedom | 3–7 |

| Degrees of Freedom | Mass Estimation (kg) | Manipulator Length (m) | Number of Connecting Rod Modules |

|---|---|---|---|

| 3 | 5 | 0.78 | 2 |

| 5 | 8 | 1.13 | 3 |

| 6 | 9 | ||

| 7 | 11 | 1.33 | 4 |

| i | ||||

|---|---|---|---|---|

| 1 | 0 | 0 | ||

| 2 | 0 | 0 | ||

| 3 | 0 | 0 | ||

| 4 | 0 | |||

| 5 | 0 | 0 | ||

| 6 | 0 |

| Joint | Angle Range |

|---|---|

| 1 | −180°~180° |

| 2 | −150°~150° |

| 3 | −125°~125° |

| 4 | −180°~180° |

| 5 | −100°~100° |

| 6 | −180°~180° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Li, J.; Wang, K.; Wang, S. Design and Analysis of Modular Reconfigurable Manipulator System. Mathematics 2025, 13, 1103. https://doi.org/10.3390/math13071103

Wang Y, Li J, Wang K, Wang S. Design and Analysis of Modular Reconfigurable Manipulator System. Mathematics. 2025; 13(7):1103. https://doi.org/10.3390/math13071103

Chicago/Turabian StyleWang, Yutong, Junjie Li, Ke Wang, and Shaokun Wang. 2025. "Design and Analysis of Modular Reconfigurable Manipulator System" Mathematics 13, no. 7: 1103. https://doi.org/10.3390/math13071103

APA StyleWang, Y., Li, J., Wang, K., & Wang, S. (2025). Design and Analysis of Modular Reconfigurable Manipulator System. Mathematics, 13(7), 1103. https://doi.org/10.3390/math13071103