Decision Support System to Solve Single-Container Loading Problem Considering Practical Constraints

Abstract

1. Introduction

- RQ1: How can a decision support system (DSS) be designed to efficiently assist in packing problems with practical delivery constraints, ensuring both operational feasibility and high container space utilization?

- RQ2: How can the strict multi-drop constraint be relaxed through penalty mechanisms to balance container space optimization with practical unloading requirements, and how can this trade-off be made transparent to the end-user?

2. Problem Definition and Related Work

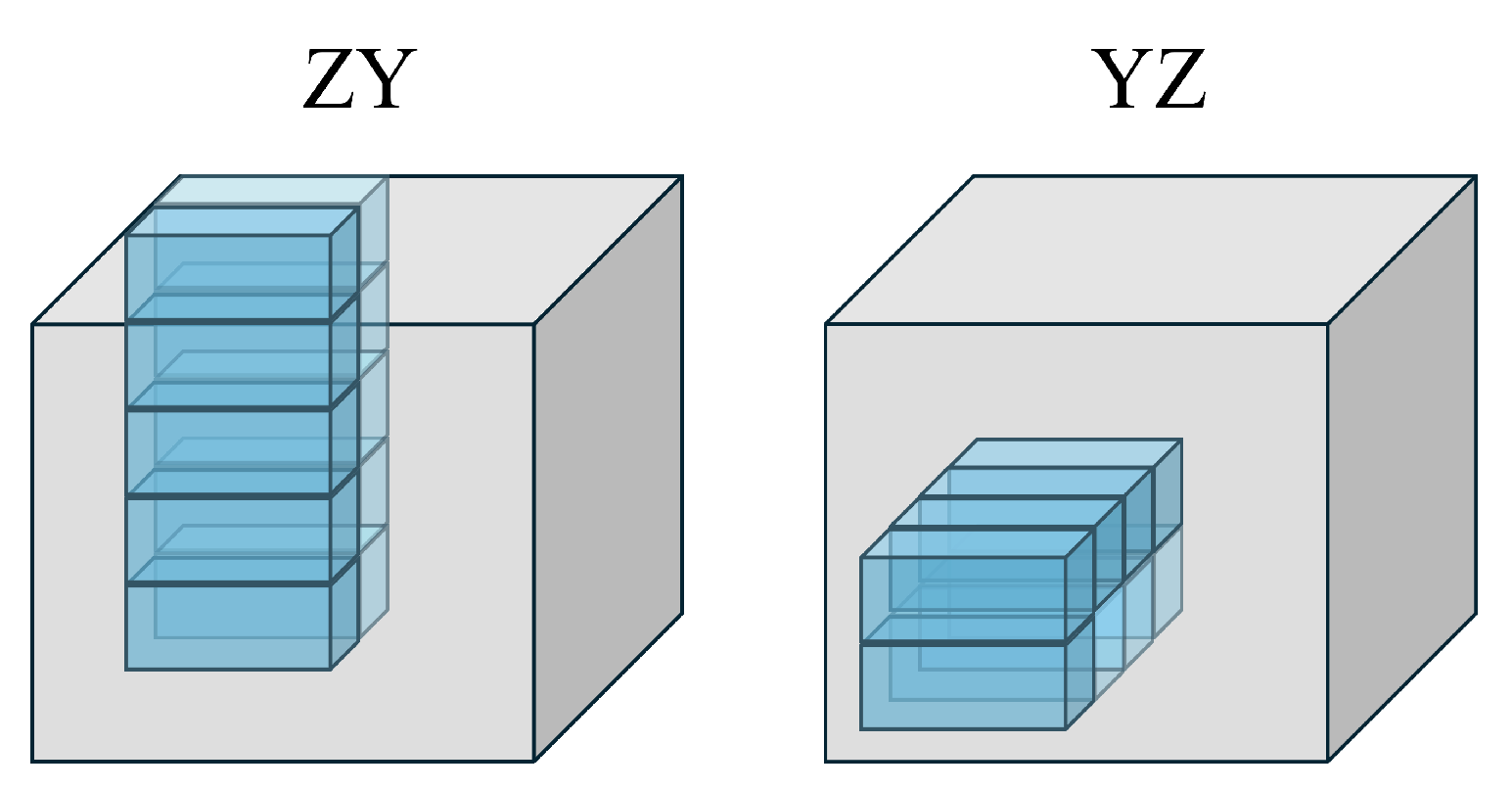

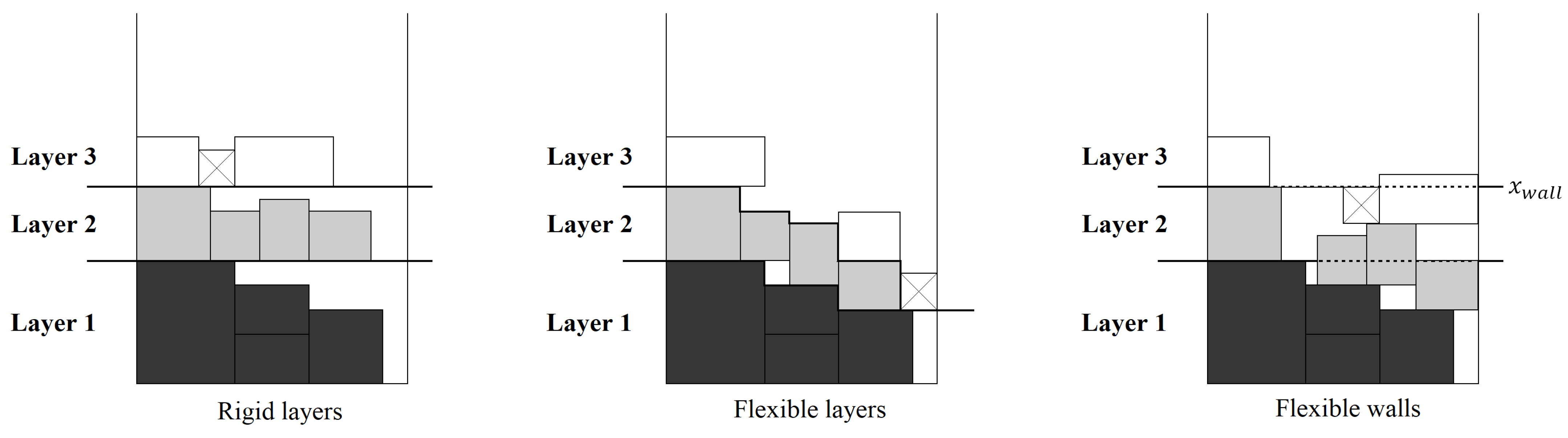

2.1. Multi-Drop Constraints

2.2. Related Work

3. Proposed Methodology

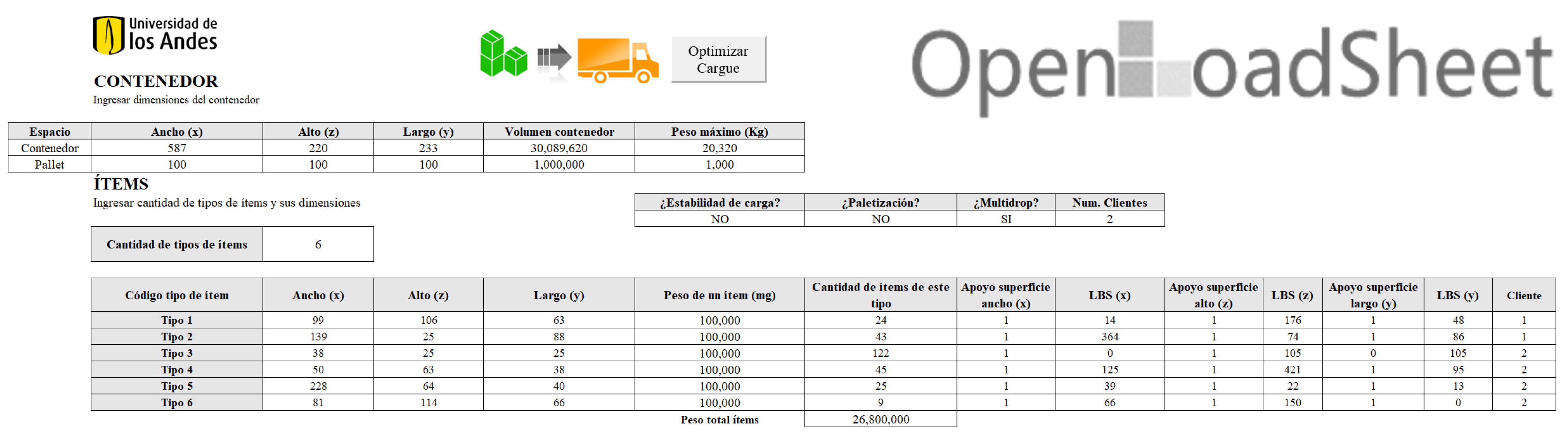

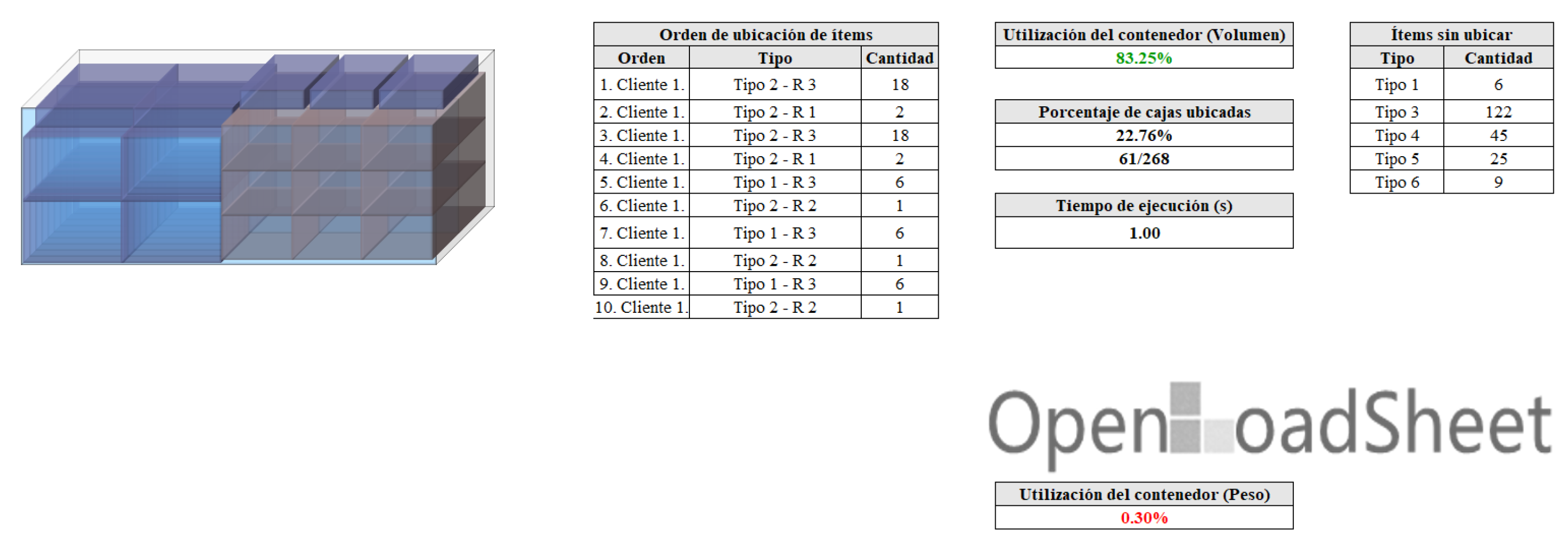

3.1. Decision Support System (DSS)

3.2. Optimization Algorithm

| Algorithm 1 Multi-start randomized constructive algorithm for container loading. |

|

3.3. Complexity Analysis of Multi-Start Randomized Constructive Algorithm

- Initialization: Initializing the set of packed boxes and creating the initial empty space representing the container are considered constant-time operations ().

- Loop over customers: The algorithm processes each customer sequentially, implying iterations at this level.

- Loop over boxes and spaces: For each customer, the algorithm iterates while there are remaining boxes and available spaces.

- Selecting a space: Scanning or selecting a feasible space requires time, where is the number of current empty spaces.

- Layer selection: Building and randomly selecting a packing layer may involve checking all remaining boxes of the customer, costing operations.

- Packing and updating spaces: Each packing operation removes a space and may create up to three new spaces. Hence, the number of spaces grows linearly with the number of boxes, leading to in the worst case.

- Updating box lists: Removing packed boxes is per box.

Consequently, each box incurs a cost of , and processing all n boxes gives a total cost of for this stage. - Virtual wall insertion and space adjustment: After finishing the packing for each customer, the algorithm updates the list by checking each available space. As there are spaces at most, and this check happens m times (once per customer), this step has a total cost of .

- Best incumbent update: Comparing volumes and updating the incumbent solution is considered a constant-time operation ( per construction).

4. Computational Experiments and Analysis of Results

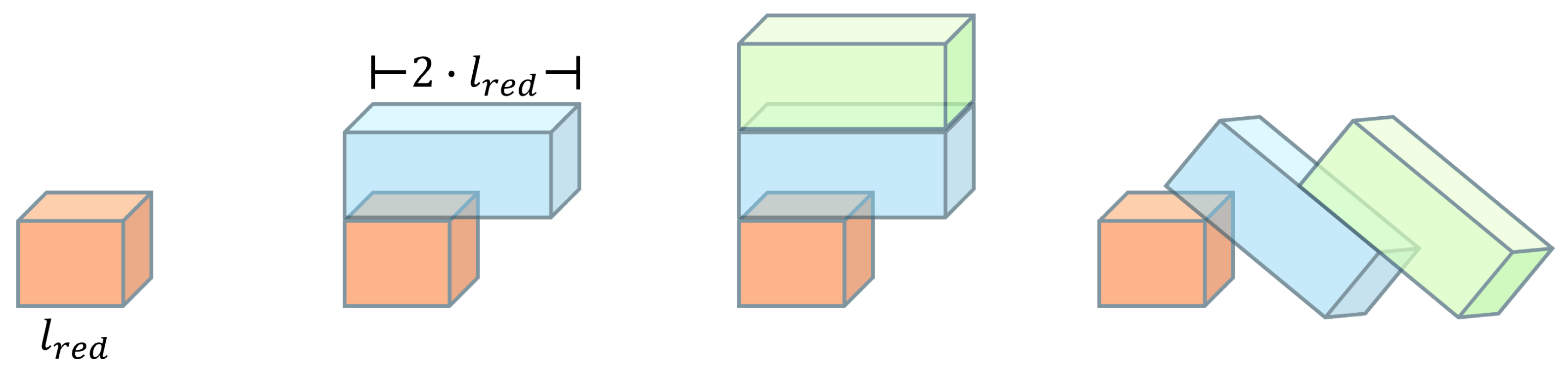

4.1. Comparison with [19,26]

4.2. Comparison with [41]

4.3. Comparison of a Relaxed and Penalized Model Versus the Virtual Wall Model When

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Filella, G.B.; Trivella, A.; Corman, F. Modeling soft unloading constraints in the multi-drop container loading problem. Eur. J. Oper. Res. 2023, 308, 336–352. [Google Scholar] [CrossRef]

- Pitney Bowes. Parcel Shipping Index 2022 (Annual Report). Pitney Bowes Inc. 2022. Available online: https://www.pitneybowes.com/us/shipping-index.html (accessed on 10 March 2025).

- Mikele, G.; Trivella, A.; Mansini, R.; Pisinger, D. An optimization approach for a complex real-life container loading problem. Omega 2022, 107, 102559. [Google Scholar]

- Montes-Franco, A.M.; Martinez-Franco, J.C.; Tabares, A.; Álvarez-Martínez, D. A Hybrid Approach for the Container Loading Problem for Enhancing the Dynamic Stability Representation. Mathematics 2025, 13, 869. [Google Scholar] [CrossRef]

- Wäscher, G.; Haußner, H.; Schumann, H. An improved typology of cutting and packing problems. Eur. J. Oper. Res. 2007, 183, 1109–1130. [Google Scholar] [CrossRef]

- Pachón, J.C.; Martínez-Franco, J.; Álvarez-Martínez, D. SIC: An intelligent packing system with industry-grade features. SoftwareX 2022, 20, 101241. [Google Scholar] [CrossRef]

- Bischoff, E.E.; Ratcliff, M.S.W. Issues in the development of approaches to container loading. Omeg 1995, 23, 377–390. [Google Scholar] [CrossRef]

- Bortfeldt, A.; Wäscher, G. Constraints in container loading—A state-of-the-art review. Eur. J. Oper. Res. 2013, 229, 1–20. [Google Scholar] [CrossRef]

- Ratcliff, M.S.W.; Bischoff, E.E. Allowing for weight considerations in container loading. Oper. Res. Spektrum 1998, 20, 65–71. [Google Scholar] [CrossRef]

- Bischoff, E.E.; Janetz, F.; Ratcliff, M.S.W. Loading pallets with non-identical items. EJOR (Europ. J. OR) 1995, 84, 681–692. [Google Scholar] [CrossRef]

- Ali, S.; Ramos, A.G.; Carravilla, M.A.; Oliveira, J.F. On-line three-dimensional packing problems: A review of off-line and on-line solution approaches. Comput. Ind. Eng. 2022, 168, 108122. [Google Scholar] [CrossRef]

- Christensen, S.G.; Rousøe, D.M. Container loading with multi-drop constraints. Int. Trans. Oper. Res. 2009, 16, 727–743. [Google Scholar] [CrossRef]

- Gendreau, M.; Iori, M.; Laporte, G.; Martello, S. A tabu search algorithm for a routing and container loading problem. Transp. Sci. 2006, 40, 342–350. [Google Scholar] [CrossRef]

- Iori, M.; Salazar-González, J.J.; Vigo, D. An exact approach for the vehicle routing problem with two-dimensional loading constraints. Transp. Sci. 2007, 41, 253–264. [Google Scholar] [CrossRef]

- Pan, L.; Chu, S.C.K.; Han, G.; Huang, J.Z. A tree-based wall-building algorithm for solving container loading problem with multi-drop constraints. In Proceedings of the 2009 IEEE International Conference on Industrial Engineering and Engineering Management, Hong Kong, China, 8–11 December 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 538–542. [Google Scholar]

- Fuellerer, G.; Doerner, K.F.; Hartl, R.F.; Iori, M. Metaheuristics for vehicle routing problems with three-dimensional loading constraints. Eur. J. Oper. Res. 2010, 201, 751–759. [Google Scholar] [CrossRef]

- Iori, M.; Martello, S. Routing problems with loading constraints. Top 2010, 18, 4–27. [Google Scholar] [CrossRef]

- de Queiroz, T.A.; Miyazawa, F.K. Two-dimensional strip packing problem with load balancing, load bearing and multi-drop constraints. Int. J. Prod. Econ. 2013, 145, 511–530. [Google Scholar] [CrossRef]

- Alvarez-Martinez, D.; Alvarez-Valdes, R.; Parreño, F. A GRASP algorithm for the container loading problem with multi-drop constraints. Pesqui. Oper. 2015, 35, 1–24. [Google Scholar] [CrossRef]

- Hokama, P.; Miyazawa, F.K.; Xavier, E.C. A branch-and-cut approach for the vehicle routing problem with loading constraints. Expert Syst. Appl. 2016, 47, 1–13. [Google Scholar] [CrossRef]

- Pollaris, H.; Braekers, K.; Caris, A.; Janssens, G.K.; Limbourg, S. Capacitated vehicle routing problem with sequence-based pallet loading and axle weight constraints. EURO J. Transp. Logist. 2016, 5, 231–255. [Google Scholar] [CrossRef]

- Iori, M.; Locatelli, M.; Moreira, M.C.; Silveira, T. Reactive GRASP-based algorithm for pallet building problem with visibility and contiguity constraints. In Proceedings of the International Conference on Computational Logistics, Enschede, The Netherlands, 28–30 September 2020; Springer International Publishing: Cham, Switzerland, 2020; pp. 651–665. [Google Scholar]

- Ferreira, K.M.; de Queiroz, T.A.; Toledo, F.M.B. An exact approach for the green vehicle routing problem with two-dimensional loading constraints and split delivery. Comput. Oper. Res. 2021, 136, 105452. [Google Scholar] [CrossRef]

- do Nascimento, O.X.; de Queiroz, T.A.; Junqueira, L. Practical constraints in the container loading problem: Comprehensive formulations and exact algorithm. Comput. Oper. Res. 2021, 128, 105186. [Google Scholar] [CrossRef]

- Liu, W.Y.; Lin, C.C.; Yu, C.S. On the three-dimensional container packing problem under home delivery service. Asia-Pac. J. Oper. Res. 2011, 28, 601–621. [Google Scholar] [CrossRef]

- Junqueira, L.; Morabito, R.; Sato Yamashita, D. MIP-based approaches for the container loading problem with multi-drop constraints. Ann. Oper. Res. 2012, 199, 51–75. [Google Scholar] [CrossRef]

- Delorme, M.; Wagenaar, J. Exact decomposition approaches for a single container loading problem with stacking constraints and medium-sized weakly heterogeneous items. Omega 2024, 125, 103039. [Google Scholar] [CrossRef]

- Huertas Arango, J.M.; Pantoja-Benavides, G.; Valero, S.; Álvarez-Martínez, D. Approaches for the On-Line Three-Dimensional Knapsack Problem with Buffering and Repacking. Mathematics 2024, 12, 3223. [Google Scholar] [CrossRef]

- Mazur, P.G.; Melsbach, J.W.; Schoder, D. Physical question, virtual answer: Optimized real-time physical simulations and physics-informed learning approaches for cargo loading stability. Oper. Res. Perspect. 2025, 14, 100329. [Google Scholar] [CrossRef]

- Kurpel, D.V.; Scarpin, C.T.; Junior, J.E.P.; Schenekemberg, C.M.; Coelho, L.C. The exact solutions of several types of container loading problems. Eur. J. Oper. Res. 2020, 284, 87–107. [Google Scholar] [CrossRef]

- Ananno, A.A.; Ribeiro, L. A multi-heuristic algorithm for multi-container 3-d bin packing problem optimization using real world constraints. IEEE Access 2024, 12, 42105–42130. [Google Scholar] [CrossRef]

- da Silva, E.F.; Leão, A.A.S.; Toledo, F.M.B.; Wauters, T. A matheuristic framework for the three-dimensional single large object placement problem with practical constraints. Comput. Oper. Res. 2020, 124, 105058. [Google Scholar] [CrossRef]

- Ocloo, V.E.; Fügenschuh, A.; Pamen, O.M. A New Mathematical Model for a 3D Container Packing Problem; Fakultät 1/MINT; Brandenburgische Technische Universität Cottbus-Senftenberg: Senftenberg, Germany, 2020. [Google Scholar]

- de Azevedo Oliveira, L.; de Lima, V.L.; de Queiroz, T.A.; Miyazawa, F.K. The container loading problem with cargo stability: A study on support factors, mechanical equilibrium and grids. Eng. Optim. 2021, 53, 1192–1211. [Google Scholar] [CrossRef]

- de Azevedo Oliveira, L.; de Lima, V.L.; de Queiroz, T.A.; Miyazawa, F.K. Comparing a static equilibrium-based method with the support factor for horizontal cargo stability in the container loading problem. Pesquisa Oper. 2021, 41, e240379. [Google Scholar] [CrossRef]

- Martínez, J.C.; Cuellar, D.; Álvarez-Martínez, D. Review of dynamic stability metrics and a mechanical model integrated with open source tools for the container loading problem. Electron. Notes Discret. Math. 2018, 69, 325–332. [Google Scholar] [CrossRef]

- Martínez-Franco, J.C.; Álvarez-Martínez, D. Physx as a middleware for dynamic simulations in the container loading problem. In Proceedings of the 2018 Winter Simulation Conference (WSC), Gothenburg, Sweden, 9–12 December 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 2933–2940. [Google Scholar]

- Safak, Y.; Bortfeldt, A.; Çetinkaya, S.; Ölckers, A. A Large Neighbourhood Search algorithm for solving container loading problems. Expert Syst. Appl. 2023, 212, 118689. [Google Scholar]

- Gimenez-Palacios, I.; Alonso, M.T.; Alvarez-Valdés, R.; Parreño, F. Multi-container loading problems with multidrop and split delivery conditions. Comput. Ind. Eng. 2023, 175, 108844. [Google Scholar] [CrossRef]

- Romero, N. Restricciones de Fuerza de carga Máxima en el Problema de Carga en único Contenedor. Unpublished Bachelor’s Thesis, Universidad de los Andes, Bogotá, Colombia, 2020. [Google Scholar]

- Ceschia, S.; Schaerf, A. Local search for a multi-drop multi-container loading problem. J. Heuristics 2013, 19, 275–294. [Google Scholar] [CrossRef]

- Davies, A.P.; Bischoff, E.E. Weight distribution considerations in container loading. Eur. J. Oper. Res. 1999, 114, 509–527. [Google Scholar] [CrossRef]

| Id | Container Length | Type of Boxes | Number of Boxes | Percentage of Located Boxes (%) | |||

|---|---|---|---|---|---|---|---|

|

MILP [26] |

GRASP [19] | MSRCA |

MSRCA

Without FS | ||||

| A1 | 15 | 1 | 20 | 100 | 100 | 100 | 100 |

| 12 | 1 | 20 | 95 | 95 | 80 | 95 | |

| A5 | 15 | 5 | 41 | 100 | 100 | 100 | 100 |

| 12 | 5 | 41 | 77.9 | 96 | 97.6 | 97.6 | |

| A10 | 15 | 10 | 99 | 100 | 100 | 100 | 100 |

| A20 | 15 | 20 | 89 | 100 | 100 | 100 | 100 |

| 12 | 20 | 89 | 92.8 | 98.4 | 96.6 | 96.6 | |

| B1 | 15 | 1 | 500 | 100 | 100 | 100 | 100 |

| B5 | 15 | 5 | 813 | 100 | 100 | 100 | 100 |

| B10 | 15 | 10 | 1000 | 100 | 100 | 100 | 100 |

| B20 | 15 | 20 | 674 | 100 | 100 | 100 | 100 |

| Average | 96.88 | 99.04 | 97.65 | 99.02 | |||

| L | Vol (%) | Boxes Left Out | |||||

|---|---|---|---|---|---|---|---|

| A1 | 15 | 4 | 8 | 14 | 14 | 100 | 0 |

| 12 | 2 | 6 | 12 | 12 | 95 | 1 |

| Id | Percentage of Used Volume (%) | ||

|---|---|---|---|

|

SA

[41] | MSRCA |

MSRCA

with Flexible Wall | |

| ceschia_CS2000 | 79.08 | 81.15 | 81.15 |

| ceschia_CS2805 | 67.37 | 52.97 | 75.14 |

| ceschia_CS2822 | 73.03 | 71.16 | 71.16 |

| ceschia_CS2843 | 44.54 | 44.54 | 44.54 |

| ceschia_CS2899 | 79 | 68.62 | 79.67 |

| ceschia_CS3048 | 48.37 | 48.37 | 48.37 |

| ceschia_CS3056 | 50.17 | 58.1 | 58.1 |

| ceschia_CS3074 | 71 | 66.7 | 66.7 |

| ceschia_CS3122 | 67.31 | 54.34 | 54.34 |

| ceschia_CS3142 | 71.66 | 57.75 | 57.75 |

| ceschia_CS3151 | 65.02 | 56.37 | 78.37 |

| ceschia_CS3152 | 69.85 | 60.21 | 69.85 |

| ceschia_CS3182 | 77.15 | 52.34 | 77.15 |

| ceschia_CS3203 | 83.72 | 70.75 | 70.75 |

| ceschia_CS3207 | 67.59 | 66.12 | 80.88 |

| ceschia_CS3291 | 69.81 | 64.55 | 69.81 |

| ceschia_CS3314 | 80.42 | 71.74 | 71.74 |

| ceschia_CS3388 | 36.38 | 36.38 | 36.38 |

| ceschia_CS3432 | 75.6 | 70.11 | 76.51 |

| ceschia_CS3556 | 42.83 | 42.83 | 42.83 |

| ceschia_CS3695 | 41.49 | 41.5 | 41.49 |

| ceschia_CS3915 | 49.58 | 44.04 | 62.02 |

| ceschia_CS3941 | 70.25 | 63.41 | 70.25 |

| Average | 64.40 | 58.44 | 64.56 |

| Data | Penalty Level | |||

|---|---|---|---|---|

| P-1 | Low | |||

| P-2 | Medium | |||

| P-3 | High | |||

| P-4 | Very high |

| Instances | Average Percentage of Used Volume (%) | Average Utilization After Penalties (%) | ||||

|---|---|---|---|---|---|---|

| Relaxed | P-1 | P-2 | P-3 | P-4 | ||

| BR1 | 76.16 | 80.31 | 73.63 | 69.05 | 66.47 | 65.09 |

| BR2 | 74.50 | 77.30 | 69.95 | 64.50 | 61.51 | 60.18 |

| BR3 | 71.75 | 74.46 | 66.26 | 59.17 | 56.93 | 55.00 |

| BR4 | 70.43 | 72.24 | 63.10 | 55.64 | 50.67 | 48.23 |

| BR5 | 67.30 | 68.83 | 59.72 | 54.61 | 51.42 | 49.28 |

| BR6 | 63.79 | 65.68 | 58.85 | 53.69 | 51.58 | 50.14 |

| BR7 | 57.16 | 59.69 | 51.89 | 47.52 | 44.61 | 43.03 |

| Instances | Average Percentage of Used Volume (%) | Average Utilization After Penalties (%) | ||||

|---|---|---|---|---|---|---|

| Relaxed | P-1 | P-2 | P-3 | P-4 | ||

| BR1 | 61.55 | 71.24 | 62.21 | 56.27 | 53.46 | 51.06 |

| BR2 | 56.33 | 65.57 | 56.78 | 52.65 | 50.75 | 49.04 |

| BR3 | 51.32 | 56.92 | 48.62 | 43.15 | 39.75 | 37.34 |

| BR4 | 50.72 | 54.78 | 48.95 | 42.83 | 39.59 | 37.30 |

| BR5 | 47.94 | 50.61 | 44.69 | 37.74 | 34.08 | 31.73 |

| BR6 | 45.62 | 46.56 | 39.22 | 34.33 | 32.03 | 30.63 |

| BR7 | 57.16 | 59.69 | 51.89 | 47.52 | 44.61 | 43.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romero-Olarte , N.; Amézquita-Ortiz, S.; Escobar, J.W.; Álvarez-Martínez, D. Decision Support System to Solve Single-Container Loading Problem Considering Practical Constraints. Mathematics 2025, 13, 1668. https://doi.org/10.3390/math13101668

Romero-Olarte N, Amézquita-Ortiz S, Escobar JW, Álvarez-Martínez D. Decision Support System to Solve Single-Container Loading Problem Considering Practical Constraints. Mathematics. 2025; 13(10):1668. https://doi.org/10.3390/math13101668

Chicago/Turabian StyleRomero-Olarte , Natalia, Santiago Amézquita-Ortiz, John Willmer Escobar, and David Álvarez-Martínez. 2025. "Decision Support System to Solve Single-Container Loading Problem Considering Practical Constraints" Mathematics 13, no. 10: 1668. https://doi.org/10.3390/math13101668

APA StyleRomero-Olarte , N., Amézquita-Ortiz, S., Escobar, J. W., & Álvarez-Martínez, D. (2025). Decision Support System to Solve Single-Container Loading Problem Considering Practical Constraints. Mathematics, 13(10), 1668. https://doi.org/10.3390/math13101668