A Novel Model-Free Nonsingular Fixed-Time Sliding Mode Control Method for Robotic Arm Systems

Abstract

1. Introduction

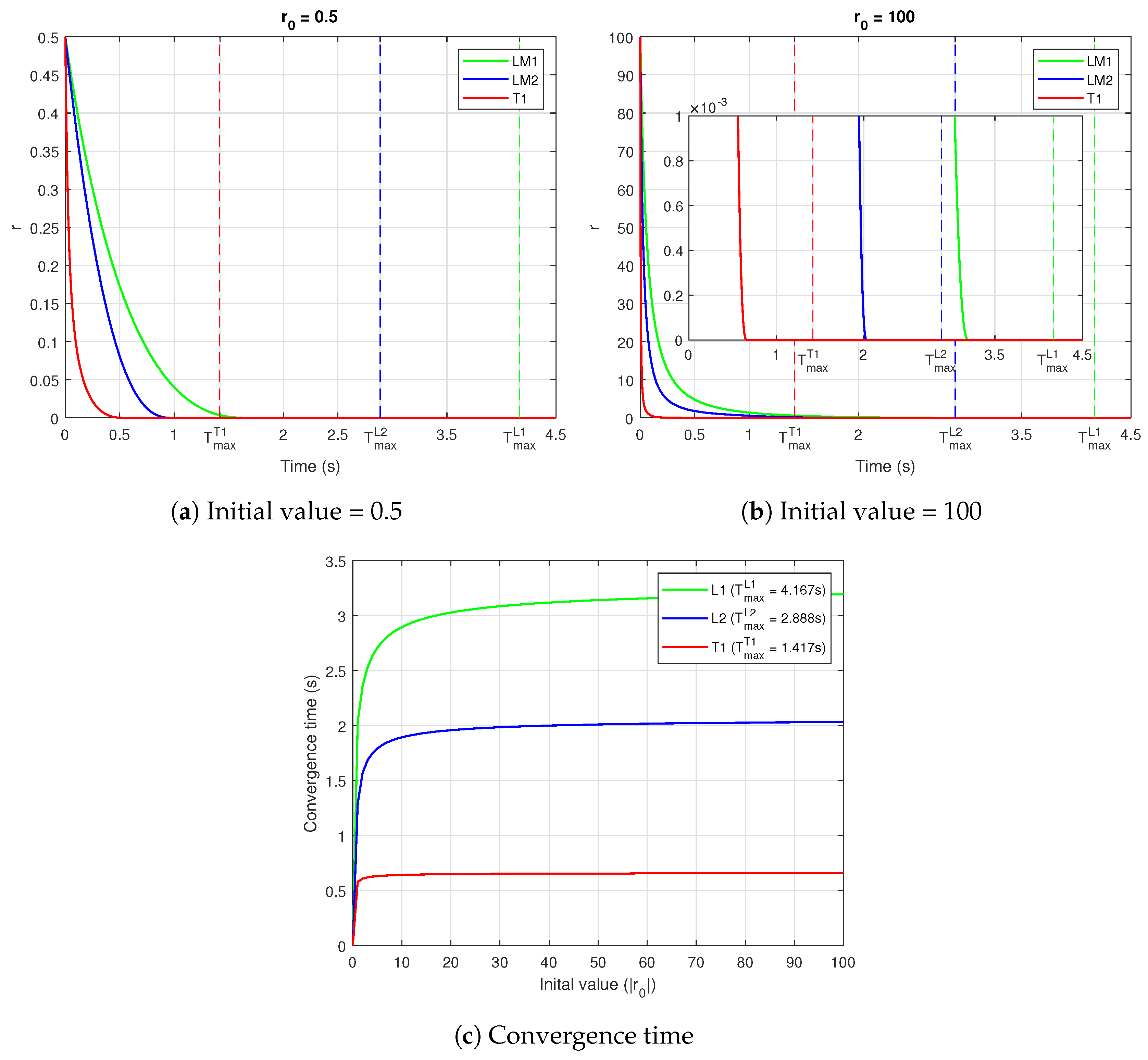

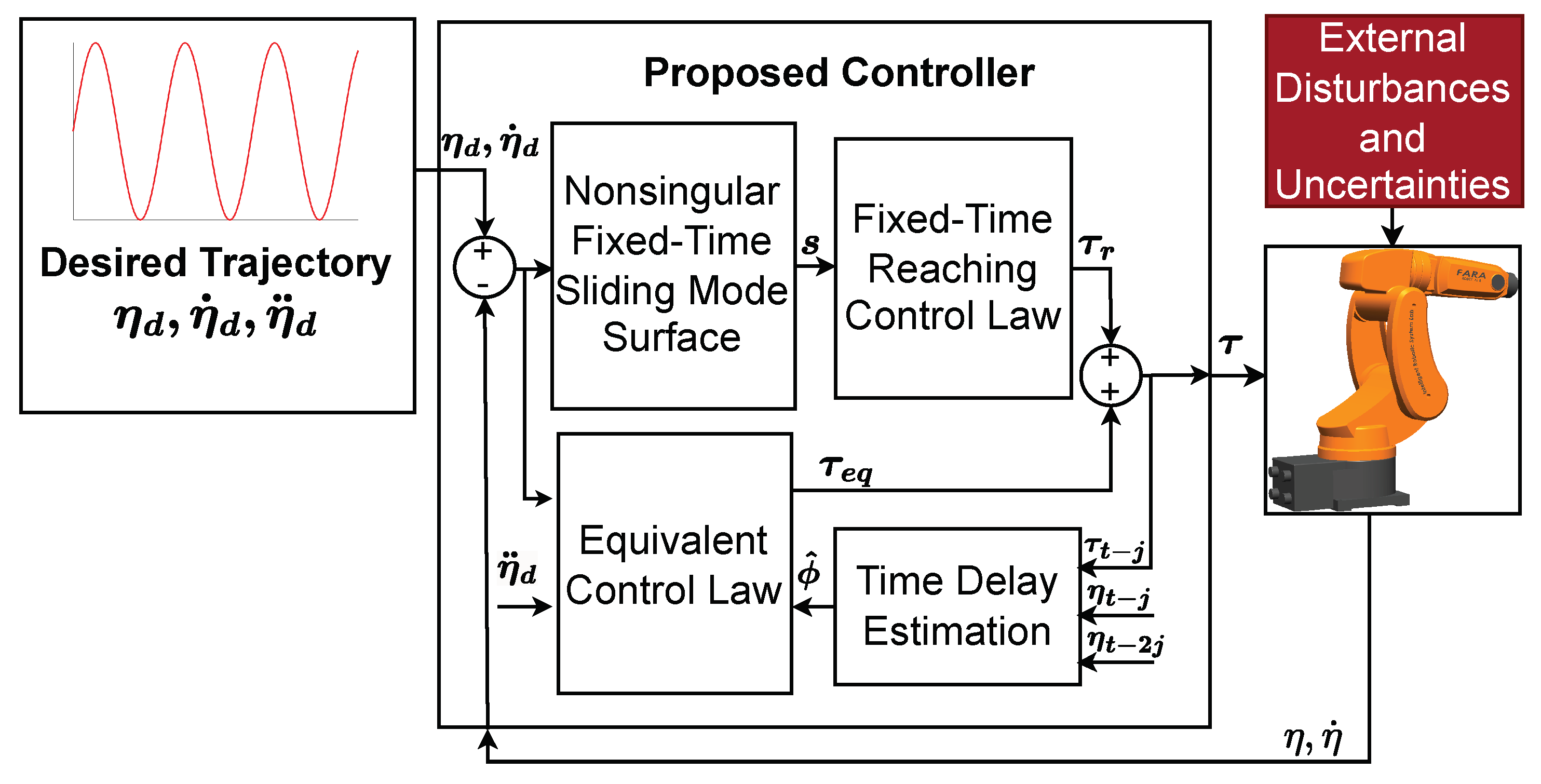

- A new fixed-time control theorem is proposed, offering faster convergence than conventional fixed-time approaches. Building on this theorem, an SF-FxTSS and an FxTRL are developed. The SF-FxTSS ensures fixed-time convergence of tracking errors without singularity issues, while the FxTRL provides rapid fixed-time convergence of the sliding surface and effectively suppresses chattering. This design enhances smooth control actions, improving practical applicability and reducing mechanical wear.

- A MF-NFxTSMC method is introduced, leveraging a TDE mechanism for real-time estimation of unknown dynamics and disturbances. The novelty lies in seamlessly integrating TDE into the nonsingular fixed-time SMC framework with the newly designed SF-FxTSS and FxTRL, enabling robust, model-independent control.

- The fixed-time stability of the closed-loop system is rigorously established using Lyapunov-based analysis, ensuring that convergence time is strictly bounded and independent of initial conditions.

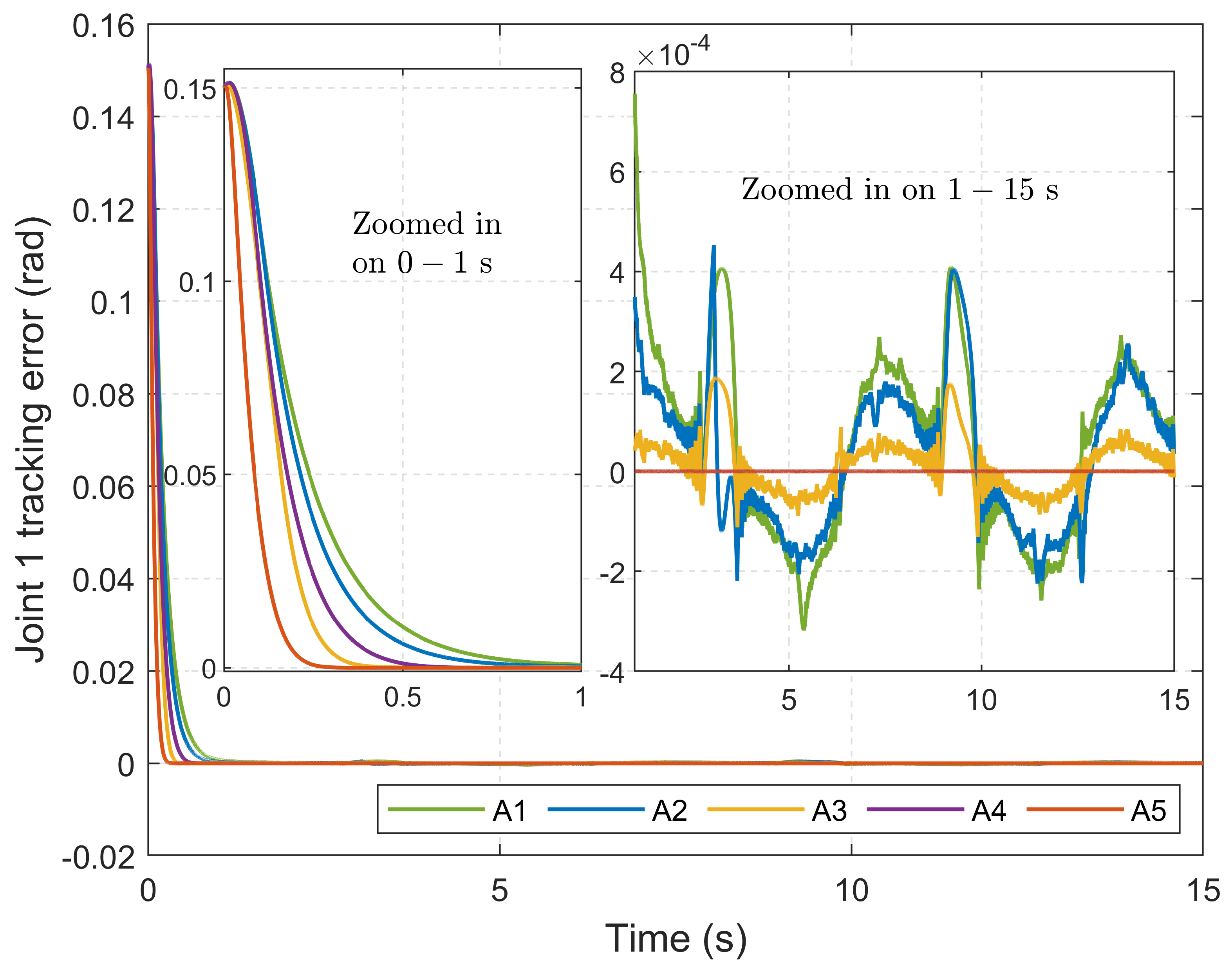

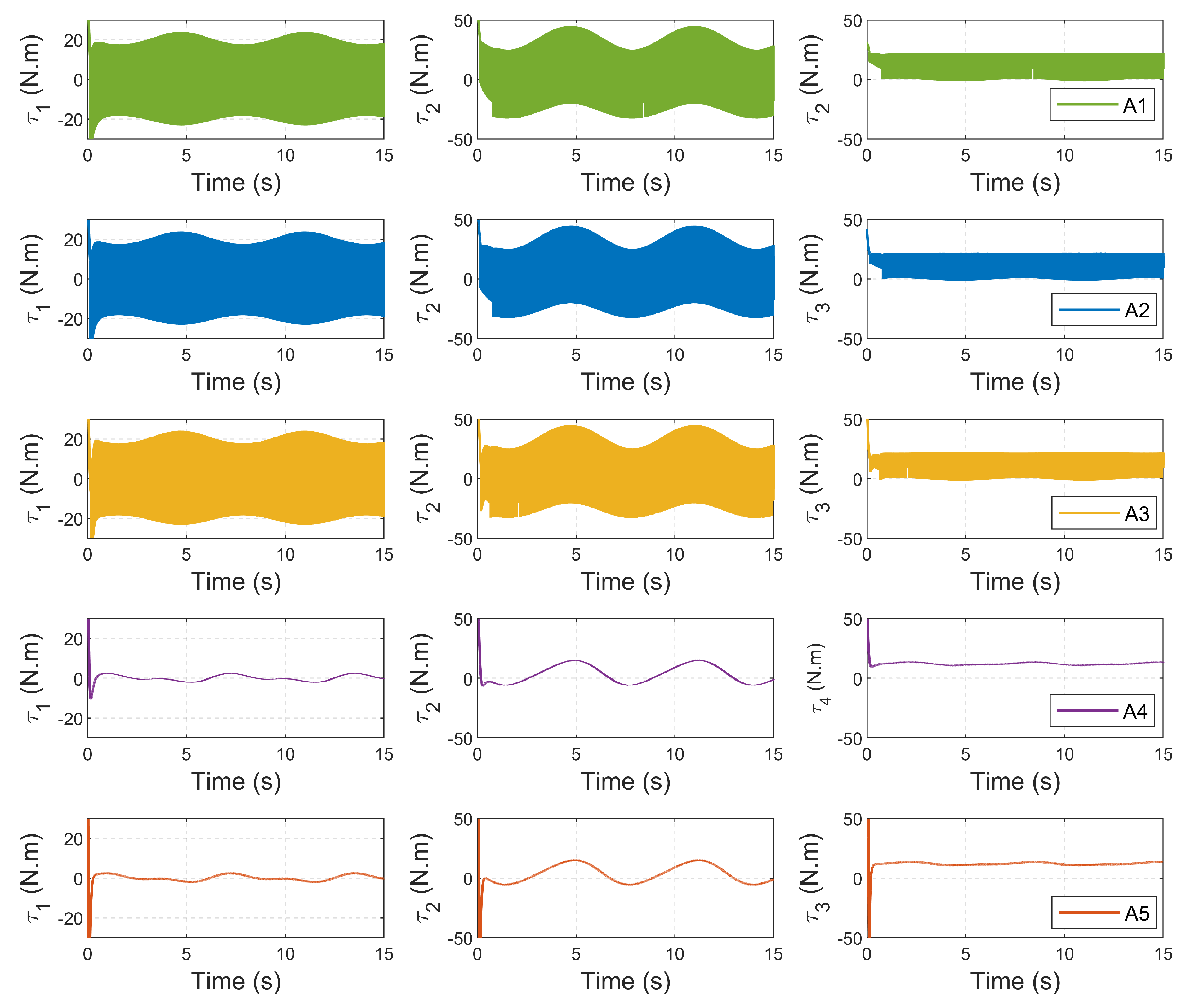

- Extensive simulations on a three-DOF SAMSUNG FARA AT2 robotic manipulator validate the effectiveness of the proposed method. The results demonstrate superior performance in terms of tracking accuracy, convergence speed, and control smoothness compared to conventional SMC, finite-time SMC, approximate fixed-time SMC, and global fixed-time NTSMC methods.

- Model-free operation through real-time estimation, eliminating reliance on physical parameter identification;

- Fixed-time convergence performance, which outperforms finite-time or asymptotic counterparts by ensuring fast convergence even from large initial errors;

- A nonsingular and smooth control structure that avoids singularities and mitigates chattering;

- Practical applicability to real-world manipulators with scalability to higher DOF systems.

2. System Model and Preliminaries

2.1. Mathematical Notations

2.2. Robotic Arm System Description

2.3. Preliminaries

3. Design of the Proposed Control Method

3.1. Novel Fixed-Time Control System

3.2. Novel Nonsingular Fixed-Time Sliding Mode Surface

3.3. Novel Model-Free Nonsingular Fixed-Time Sliding Mode Control

4. Simulation Setup and Performance Evaluation

4.1. Simulation Environment and System Configuration

4.2. Control Methods for Comparison

4.3. Simulation Settings

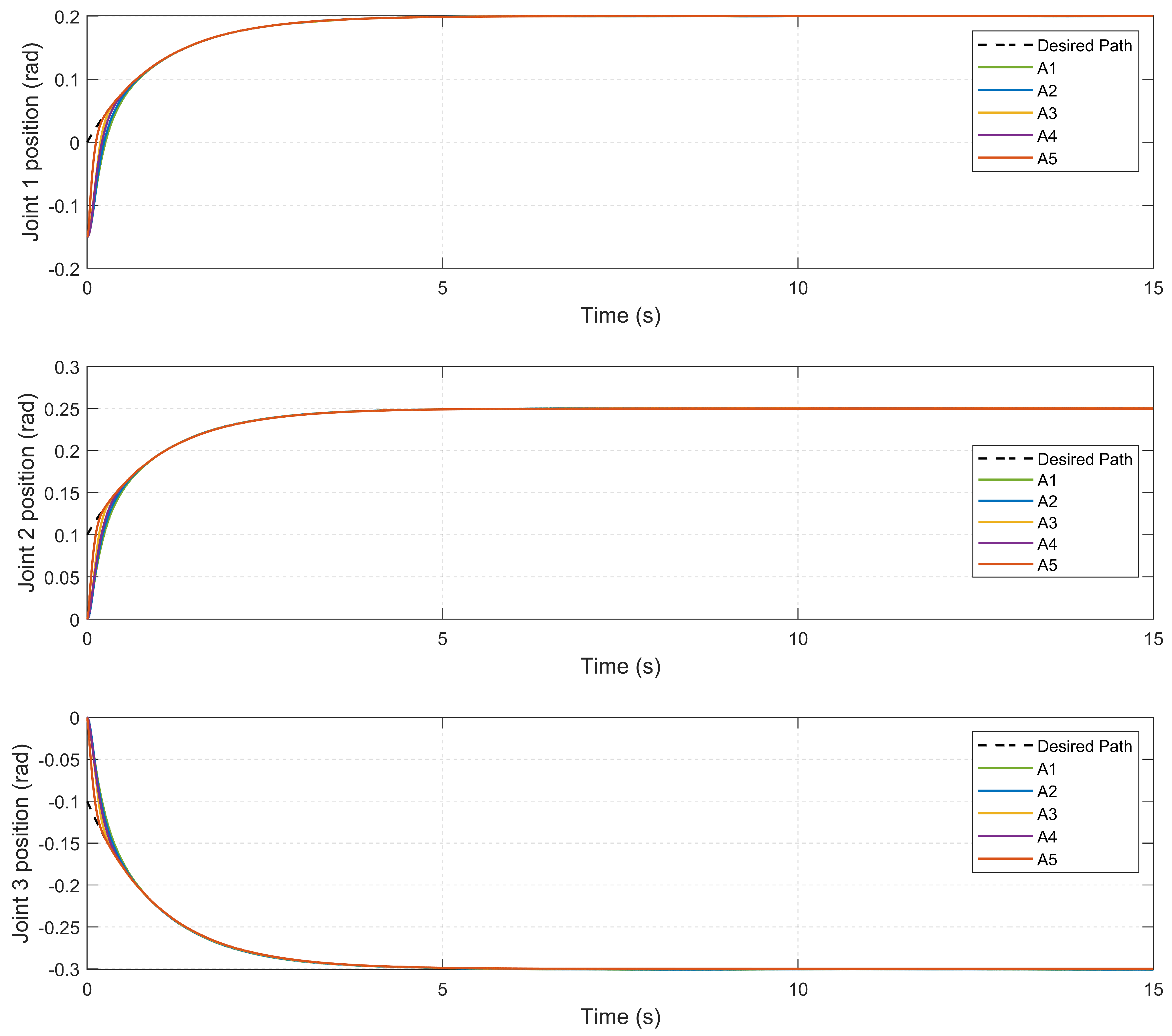

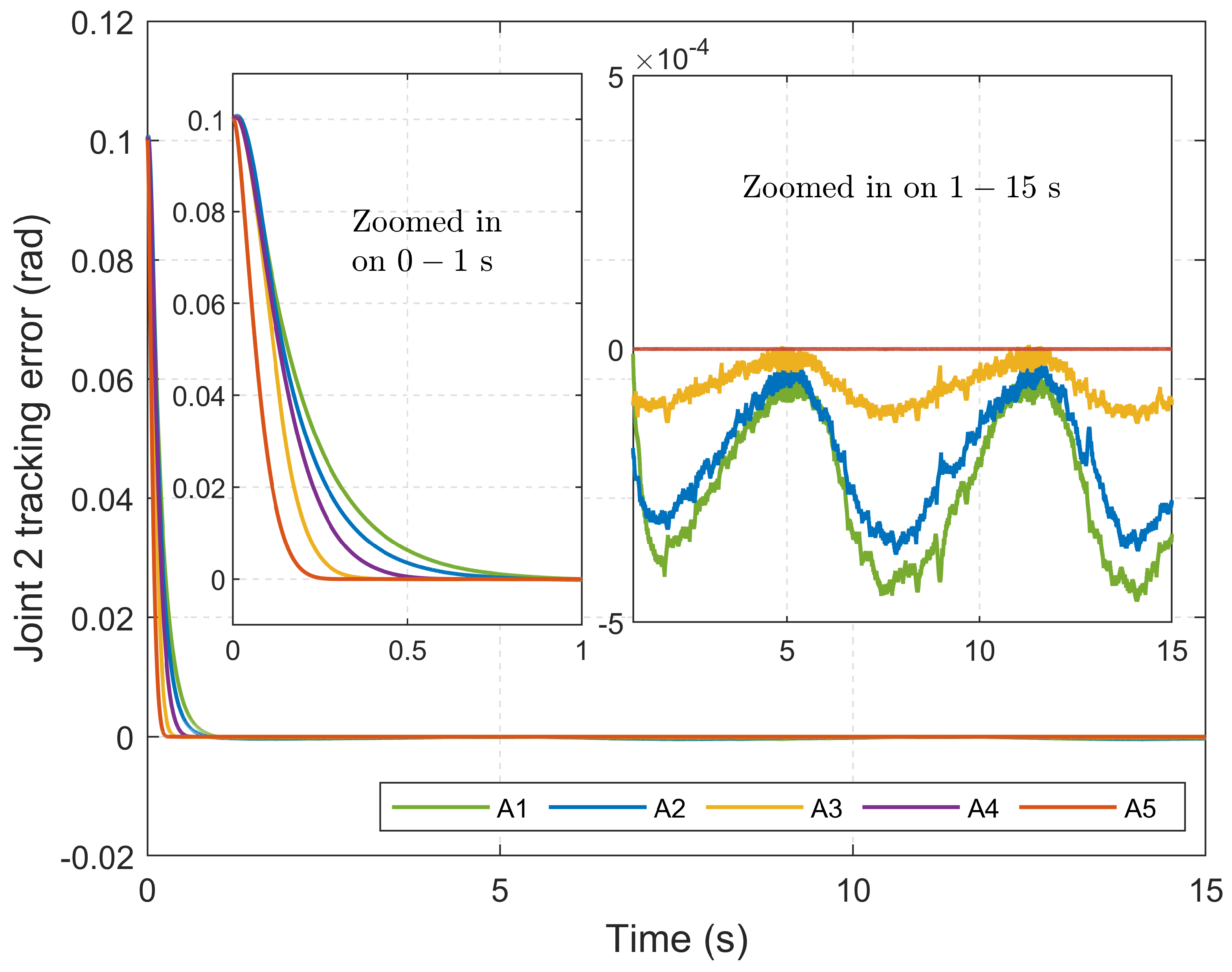

- Case 1: Exponential Trajectory.In this scenario, the initial joint configuration of the manipulator is set as (rad), corresponding to an initial tracking error of approximately , which is typical in real-world applications due to pre-positioning or task transitions.

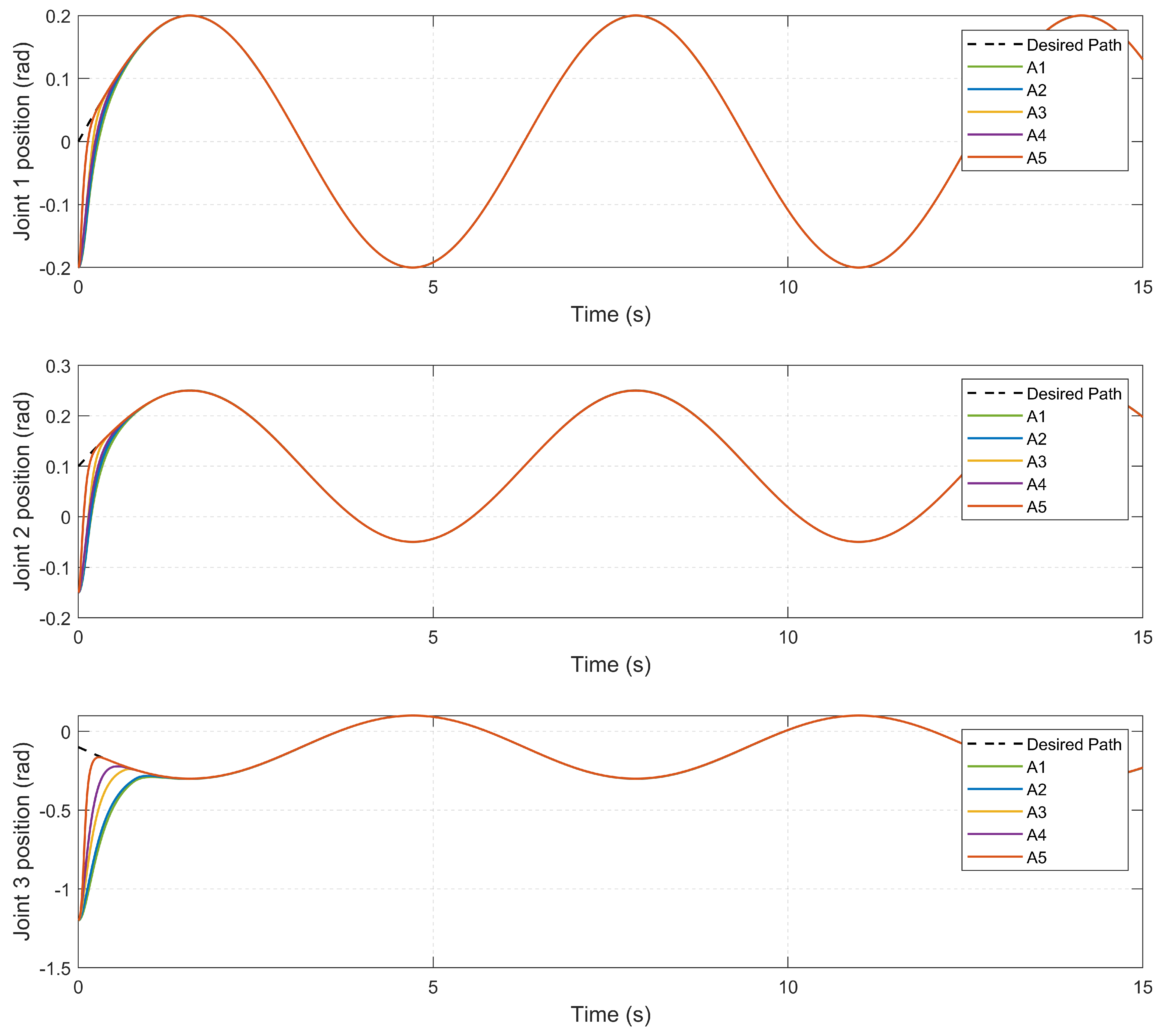

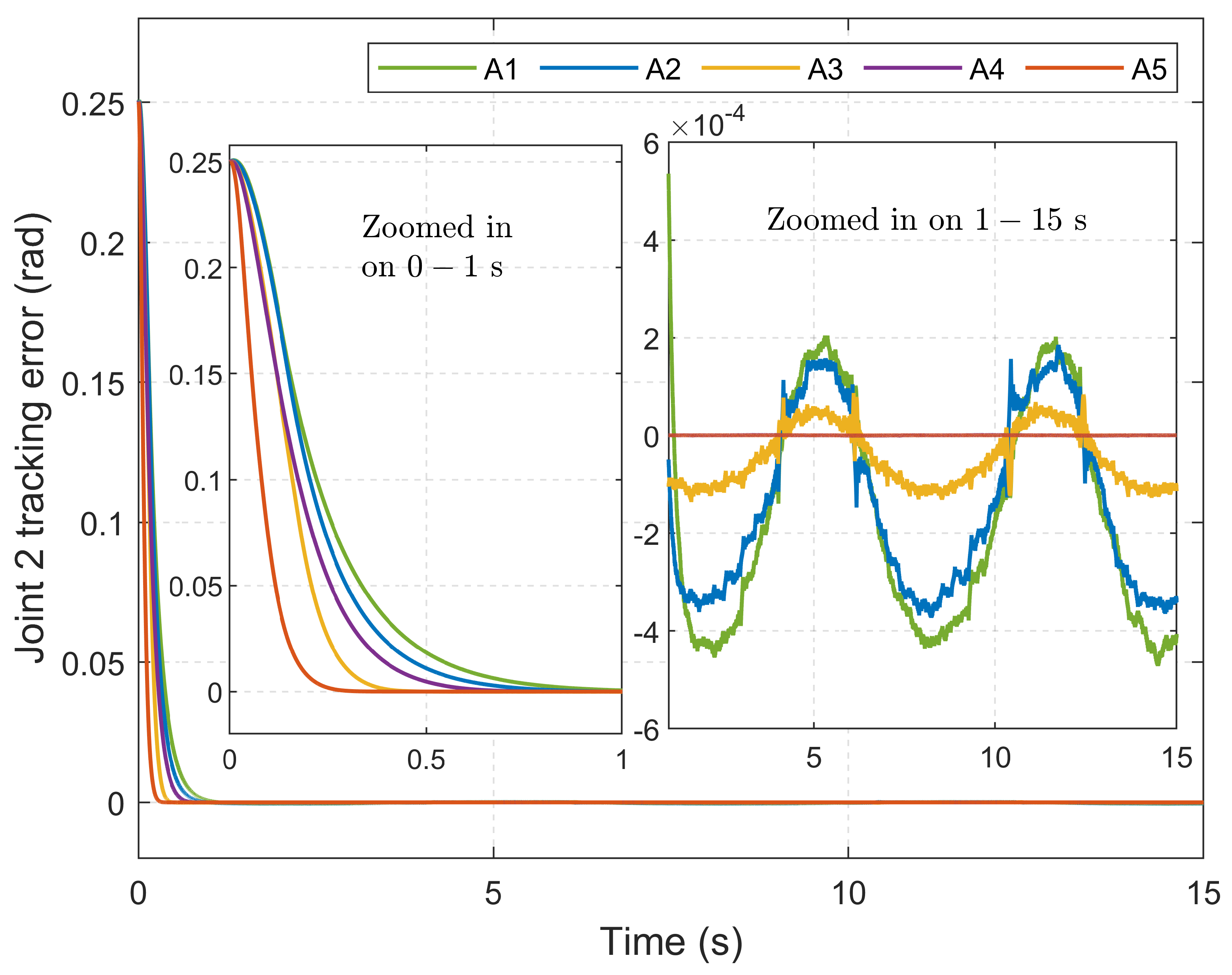

- Case 2: Sinusoidal Trajectory.To assess robustness against more significant deviations, this scenario uses a larger initial condition (rad), introducing an initial tracking error of approximately , which is particularly challenging at joint 3. This configuration is intended to rigorously test the controller’s performance under harsh initial conditions.

- Root mean square error (RMSE): Used to assess tracking accuracy after the system has converged, specifically in the interval from 1.5 s to 15 s.

- Integral of absolute error (IAE): Used to evaluate the overall accumulated tracking error over time.

4.4. Tracking Performance: Exponential Reference Trajectory

4.5. Tracking Performance: Sinusoidal Reference Trajectory

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jin, M.; Kang, S.H.; Chang, P.H.; Lee, J. Robust control of robot manipulators using inclusive and enhanced time delay control. IEEE/ASME Trans. Mechatron. 2017, 22, 2141–2152. [Google Scholar] [CrossRef]

- Kali, Y.; Saad, M.; Boland, J.F.; Fortin, J.; Girardeau, V. Walking task space control using time delay estimation based sliding mode of position controlled nao biped robot. Int. J. Dyn. Control 2021, 9, 679–688. [Google Scholar] [CrossRef]

- Lee, J.E.; Kim, B.W. Research on Direct Yaw Moment Control Based on Neural Sliding Mode Control for Four-Wheel Actuated Electric Vehicles. In Proceedings of the 2023 IEEE 6th International Conference on Knowledge Innovation and Invention (ICKII), Sapporo, Japan, 11–13 August 2023; pp. 736–740. [Google Scholar]

- Kali, Y.; Saad, M.; Benjelloun, K.; Benbrahim, M. Sliding mode with time delay control for robot manipulators. In Applications of Sliding Mode Control; Springer: Berlin/Heidelberg, Germany, 2017; pp. 135–156. [Google Scholar]

- Taheri, E.; Ferdowsi, M.H.; Danesh, M. Design boundary layer thickness and switching gain in SMC algorithm for AUV motion control. Robotica 2019, 37, 1785–1803. [Google Scholar] [CrossRef]

- Fateh, A.; Momeni, H. Time delay control of a robotic manipulator using an enhanced adaptive sliding mode control switching gain. Int. J. Dyn. Control 2025, 13, 91. [Google Scholar] [CrossRef]

- Truong, T.N.; Vo, A.T.; Kang, H.J. A Novel Time Delay Nonsingular Fast Terminal Sliding Mode Control for Robot Manipulators with Input Saturation. Mathematics 2024, 13, 119. [Google Scholar] [CrossRef]

- Song, T.; Fang, L.; Wang, H. Model-free finite-time terminal sliding mode control with a novel adaptive sliding mode observer of uncertain robot systems. Asian J. Control 2022, 24, 1437–1451. [Google Scholar] [CrossRef]

- Ahmed, S.; Wang, H.; Tian, Y. Adaptive high-order terminal sliding mode control based on time delay estimation for the robotic manipulators with backlash hysteresis. IEEE Trans. Syst. Man, Cybern. Syst. 2019, 51, 1128–1137. [Google Scholar] [CrossRef]

- Brahmi, B.; Driscoll, M.; Laraki, M.H.; Brahmi, A. Adaptive high-order sliding mode control based on quasi-time delay estimation for uncertain robot manipulator. Control Theory Technol. 2020, 18, 279–292. [Google Scholar] [CrossRef]

- Boudjedir, C.E.; Bouri, M.; Boukhetala, D. An enhanced adaptive time delay control-based integral sliding mode for trajectory tracking of robot manipulators. IEEE Trans. Control Syst. Technol. 2022, 31, 1042–1050. [Google Scholar] [CrossRef]

- Park, J.; Kwon, W.; Park, P. An improved adaptive sliding mode control based on time-delay control for robot manipulators. IEEE Trans. Ind. Electron. 2022, 70, 10363–10373. [Google Scholar] [CrossRef]

- Meng, D.; Xu, H.; Xu, H.; Sun, H.; Liang, B. Trajectory tracking control for a cable-driven space manipulator using time-delay estimation and nonsingular terminal sliding mode. Control Eng. Pract. 2023, 139, 105649. [Google Scholar] [CrossRef]

- Truong, T.N.; Vo, A.T.; Kang, H.J. Real-time implementation of the prescribed performance tracking control for magnetic levitation systems. Sensors 2022, 22, 9132. [Google Scholar] [CrossRef]

- Yu, X.; Feng, Y.; Man, Z. Terminal sliding mode control–an overview. IEEE Open J. Ind. Electron. Soc. 2020, 2, 36–52. [Google Scholar] [CrossRef]

- Sun, C.; Huang, Z.; Wu, H. Adaptive super-twisting global nonsingular terminal sliding mode control for robotic manipulators. Nonlinear Dyn. 2024, 112, 5379–5389. [Google Scholar] [CrossRef]

- Hu, S.; Wan, Y.; Liang, X. Adaptive nonsingular fast terminal sliding mode trajectory tracking control for robotic manipulators with model feedforward compensation. Nonlinear Dyn. 2025, 113, 16893–16911. [Google Scholar] [CrossRef]

- Lee, J.E.; Kim, B.W. A Novel Adaptive Non-Singular Fast Terminal Sliding Mode Control for Direct Yaw Moment Control in 4WID Electric Vehicles. Sensors 2025, 25, 941. [Google Scholar] [CrossRef]

- Vo, A.T.; Truong, T.N.; Kang, H.J.; Le, T.D. A fixed-time sliding mode control for uncertain magnetic levitation systems with prescribed performance and anti-saturation input. Eng. Appl. Artif. Intell. 2024, 133, 108373. [Google Scholar] [CrossRef]

- Lee, J.E.; Kim, B.W. Improving Direct Yaw-Moment Control via Neural-Network-Based Non-Singular Fast Terminal Sliding Mode Control for Electric Vehicles. Sensors 2024, 24, 4079. [Google Scholar] [CrossRef]

- Lee, J.E.; Kim, B.W. A DYC system for 4WID Electric Vehicles via Fuzzy-Nonsingular Fast Terminal Sliding Mode Control. In Proceedings of the 2025 IEEE International Conference on Mechatronics (ICM), Wollongong, Australia, 28 February–2 March 2025; pp. 1–6. [Google Scholar]

- Zhang, Y.; Yang, X.; Wei, P.; Liu, P.X. Fractional-order adaptive non-singular fast terminal sliding mode control with time delay estimation for robotic manipulators. IET Control Theory Appl. 2020, 14, 2556–2565. [Google Scholar] [CrossRef]

- Labbadi, M.; Muñoz-Vázquez, A.; Djemai, M.; Boukal, Y.; Zerrougui, M.; Cherkaoui, M. Fractional-order nonsingular terminal sliding mode controller for a quadrotor with disturbances. Appl. Math. Model. 2022, 111, 753–776. [Google Scholar] [CrossRef]

- Liu, Y.; Li, H.; Lu, R.; Zuo, Z.; Li, X. An overview of finite/fixed-time control and its application in engineering systems. IEEE/CAA J. Autom. Sin. 2022, 9, 2106–2120. [Google Scholar] [CrossRef]

- Sai, H.; Xu, Z.; He, S.; Zhang, E.; Zhu, L. Adaptive nonsingular fixed-time sliding mode control for uncertain robotic manipulators under actuator saturation. ISA Trans. 2022, 123, 46–60. [Google Scholar] [CrossRef]

- Zhang, D.; Hu, J.; Cheng, J.; Wu, Z.G.; Yan, H. A novel disturbance observer based fixed-time sliding mode control for robotic manipulators with global fast convergence. IEEE/CAA J. Autom. Sin. 2024, 11, 661–672. [Google Scholar] [CrossRef]

- Khodaverdian, M.; Hajshirmohamadi, S.; Hakobyan, A.; Ijaz, S. Predictor-based constrained fixed-time sliding mode control of multi-UAV formation flight. Aerosp. Sci. Technol. 2024, 148, 109113. [Google Scholar] [CrossRef]

- Xu, R.; Tian, D.; Wang, Z. Adaptive disturbance observer-based local fixed-time sliding mode control with an improved approach law for motion tracking of piezo-driven microscanning system. IEEE Trans. Ind. Electron. 2024, 71, 12824–12834. [Google Scholar] [CrossRef]

- Anjum, Z.; Zhou, H.; Ahmed, S.; Guo, Y. Fixed time sliding mode control for disturbed robotic manipulator. J. Vib. Control 2024, 30, 1580–1593. [Google Scholar] [CrossRef]

- Truong, T.N.; Vo, A.T.; Kang, H.J. Neural network-based sliding mode controllers applied to robot manipulators: A review. Neurocomputing 2023, 562, 126896. [Google Scholar] [CrossRef]

- Levant, A. Chattering analysis. IEEE Trans. Autom. Control 2010, 55, 1380–1389. [Google Scholar] [CrossRef]

- Zuo, Z. Non-singular fixed-time terminal sliding mode control of non-linear systems. IET Control Theory Appl. 2015, 9, 545–552. [Google Scholar] [CrossRef]

- Gao, Z.; Zhang, Y.; Guo, G. Fixed-Time Prescribed Performance Adaptive Fixed-Time Sliding Mode Control for Vehicular Platoons with Actuator Saturation. IEEE Trans. Intell. Transp. Syst. 2022, 23, 24176–24189. [Google Scholar] [CrossRef]

- Su, Y.; Zheng, C.; Mercorelli, P. Robust approximate fixed-time tracking control for uncertain robot manipulators. Mech. Syst. Signal Process. 2020, 135, 106379. [Google Scholar] [CrossRef]

- Yu, L.; He, G.; Wang, X.; Shen, L. A novel fixed-time sliding mode control of quadrotor with experiments and comparisons. IEEE Control Syst. Lett. 2021, 6, 770–775. [Google Scholar] [CrossRef]

- Li, H.; Cai, Y. Fixed-time non-singular terminal sliding mode control with globally fast convergence. IET Control Theory Appl. 2022, 16, 1227–1241. [Google Scholar] [CrossRef]

- Lee, J.; Chang, P.H.; Jin, M. Adaptive integral sliding mode control with time-delay estimation for robot manipulators. IEEE Trans. Ind. Electron. 2017, 64, 6796–6804. [Google Scholar] [CrossRef]

- Truong, T.N.; Vo, A.T.; Kang, H.J. A model-free terminal sliding mode control for robots: Achieving fixed-time prescribed performance and convergence. ISA Trans. 2024, 144, 330–341. [Google Scholar] [CrossRef]

- Sun, G.; Zeng, Q. A Finite-Time Sliding Mode Control Approach for Constrained Euler–Lagrange System. Mathematics 2023, 11, 2788. [Google Scholar] [CrossRef]

| Method | Parameter | Value |

|---|---|---|

| A1 | , , | 6, 10, 6 |

| A2 | , , , , , | 6, 0.8, 1.1, 1.08, 10, 6 |

| A3 | , , , , , , , | 6, 6, , , , 10, 6, |

| A4 | , , , , , l, , , , , , , , , , , o | 6, 6, 6, , , , , 3, 3, 3, , , , 5, , , |

| A5 | , , , , , , , , , j, P | 6, , 6, , , 6, , 6, , , |

| Method | Joint 1 (rad) | Joint 2 (rad) | Joint 3 (rad) |

|---|---|---|---|

| A1 | |||

| A2 | |||

| A3 | |||

| A4 | |||

| A5 |

| Method | Joint 1 (rad) | Joint 2 (rad) | Joint 3 (rad) |

|---|---|---|---|

| A1 | |||

| A2 | |||

| A3 | |||

| A4 | |||

| A5 |

| Method | Joint 1 (rad) | Joint 2 (rad) | Joint 3 (rad) |

|---|---|---|---|

| A1 | |||

| A2 | |||

| A3 | |||

| A4 | |||

| A5 |

| Method | Joint 1 (rad) | Joint 2 (rad) | Joint 3 (rad) |

|---|---|---|---|

| A1 | |||

| A2 | |||

| A3 | |||

| A4 | |||

| A5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Truong, T.N.; Vo, A.T.; Kang, H.-J.; Hong, I.-P. A Novel Model-Free Nonsingular Fixed-Time Sliding Mode Control Method for Robotic Arm Systems. Mathematics 2025, 13, 1579. https://doi.org/10.3390/math13101579

Truong TN, Vo AT, Kang H-J, Hong I-P. A Novel Model-Free Nonsingular Fixed-Time Sliding Mode Control Method for Robotic Arm Systems. Mathematics. 2025; 13(10):1579. https://doi.org/10.3390/math13101579

Chicago/Turabian StyleTruong, Thanh Nguyen, Anh Tuan Vo, Hee-Jun Kang, and Ic-Pyo Hong. 2025. "A Novel Model-Free Nonsingular Fixed-Time Sliding Mode Control Method for Robotic Arm Systems" Mathematics 13, no. 10: 1579. https://doi.org/10.3390/math13101579

APA StyleTruong, T. N., Vo, A. T., Kang, H.-J., & Hong, I.-P. (2025). A Novel Model-Free Nonsingular Fixed-Time Sliding Mode Control Method for Robotic Arm Systems. Mathematics, 13(10), 1579. https://doi.org/10.3390/math13101579