Abstract

The simulation of damage in composite materials is an important research area that impacts different engineering applications from aerospace structures to renewable energy systems. This review provides a comprehensive analysis of current damage modeling approaches, including intra-layer and inter-layer failures. Various numerical strategies, such as continuum damage mechanics (CDM), cohesive zone models (CZM), extended finite element methods (XFEM), phase-field models (PFM), and peridynamics (PD), are examined to assess their efficiency in predicting crack initiation, propagation, and interaction. Additionally, the role of data-assisted (driven) techniques, such as machine learning, in enhancing predictive capabilities is explored. This review highlights the strengths and limitations of each approach, underscoring the need for further advancements in computational efficiency, multiscale modeling, and integration with experimental data. The findings serve as a foundation for future research into optimizing damage prediction techniques to improve the reliability and durability of composite structures.

MSC:

74-10

1. Introduction

Damage in materials is a critical aspect of structural integrity, influencing the performance, safety, and lifespan of engineering systems. It encompasses the initiation, accumulation, and progression of defects within a material leading to that material’s eventual failure under various loading conditions [,]. Unlike singular catastrophic failures, damage manifests progressively, beginning at microscopic scales with phenomena such as microcracking, void formation, and interface debonding. These processes interact and evolve, often culminating in macroscopic failures. In composite materials, the complexity is magnified due to their heterogeneous and anisotropic nature, where damage mechanisms such as fiber breakage, matrix cracking, and delamination occur simultaneously or sequentially [,]. Understanding and accurately modeling these damage phenomena is essential for designing durable and reliable composite structures, especially in critical applications such as aerospace, automotive, and renewable energy.

Damage mechanisms in composite materials encompass a wide range of phenomena, spanning from intra-layer failures—such as matrix cracking, fiber tensile failure, fiber kinking, and fiber–matrix debonding—to inter-layer failure, commonly known as delamination [,]. Intra-layer damage typically initiates within the matrix or at the fiber–matrix interface, with cracks propagating under various loading conditions [,]. Fiber breakage or buckling may follow, particularly under tensile or compressive loads, further exacerbating the damage []. Delamination, a critical concern in laminated composites, arises due to the lack of reinforcement in the through-thickness direction, resulting in the separation of adjacent layers [,,,,]. This inter-layer failure can be triggered by service life loads such as fatigue, impact events, or even thermal cycling, as well as manufacturing-induced residual stresses []. Beyond these, other notable damage mechanisms include void formation, micro-buckling, and shear-induced failure, all of which can compromise structural integrity [,]. Given the potential for these mechanisms to interact and coalesce, leading to catastrophic failure, the development of robust predictive tools for damage progression remains a critical need in the design and analysis of composite structures.

Given the diverse range of damage mechanisms in composite materials and their profound influence on overall structural integrity, the implementation of progressive damage analysis (PDA) is essential. PDA provides a systematic framework for simulating the initiation, evolution, and interaction of damage within the composite medium. Typically, two distinct regions—intra-layer damage and delamination damage—are identified and formulated independently []. Intra-layer damage involves phenomena such as matrix cracking, fiber breakage, and fiber–matrix debonding, while delamination refers to inter-layer separation. However, advanced studies have explored the coupling of these regions to achieve a more accurate representation of composite behavior under various loading conditions [,,,,].

For the modeling of intra-layer damage mechanisms, continuum damage mechanics (CDM) approaches have been widely utilized, enabling the representation of the progressive degradation of material stiffness due to cracking and other localized phenomena [,,,]. On the other hand, cohesive zone models (CZMs) have proven to be effective in simulating delamination by capturing the separation and sliding between layers with cohesive laws calibrated for energy dissipation and fracture toughness [,,].

On the other hand, fracture mechanics plays a pivotal role in understanding and predicting damage in composite materials. Unlike continuum damage mechanics, which focuses on the progressive degradation of material properties, fracture mechanics provides a framework for quantifying the energy required for crack growth and the conditions under which failure occurs. In composites, fracture mechanics is applied at multiple scales, addressing both intra-layer cracks [] and inter-layer delamination []. Key approaches include linear elastic fracture mechanics (LEFM) and non-linear fracture mechanics, which accounts for plasticity or large-scale damage zones near the crack tip []. Parameters such as the stress intensity factor (SIF), strain energy release rate (SERR), and fracture toughness are critical in these analyses [], providing insights into the resistance of the material to crack growth under various loading conditions.

This review aims to provide a comprehensive analysis of the current advancements in damage simulation methods for composite materials, with a focus on both intra-layer and inter-layer (delamination) damage mechanisms. It seeks to consolidate existing modeling approaches, spanning micro-mechanical frameworks and macroscale analyses, to provide a holistic understanding of damage progression. The study investigates the impact of various loading conditions, such as cyclic loading, impact events, and static overloading, on the initiation and evolution of damage. Emphasis is placed on advanced simulation techniques capable of capturing the complexities of crack initiation, growth, and interaction. Moreover, the integration of computational models with experimental data is highlighted as a pivotal factor in enhancing predictive accuracy and reliability. This review also explores the growing role of data-assisted approaches in uncovering connections between microscale damage phenomena and their macroscopic structural consequences. By synthesizing these insights, it identifies critical gaps in the current methodologies and suggests avenues for future research and development.

The scope of this review encompasses a thorough exploration of damage simulation approaches for composite materials, addressing both intra-layer mechanisms, such as matrix cracking and fiber failure, and inter-layer mechanisms like delamination. The review aims to integrate micro-mechanical and macroscale modeling techniques while also incorporating data-assisted approaches. The structure is organized to first introduce general modeling concepts and frameworks, then delve into specific methodologies for intra-layer and delamination damage modeling. Subsequent sections will examine coupled damage scenarios and highlight the emerging trends. The review concludes with a discussion of current challenges and potential directions for future research in this domain.

2. General Overview of Modeling Schemes

2.1. Mathematical Approaches

Accurate modeling of composite laminates is a critical precursor to simulating damage evolution, as it governs the stress and strain fields that ultimately influence intralaminar and interlaminar damage initiation and progression. Broadly speaking, modeling strategies for laminated composites can be categorized into three-dimensional (3D) continuum models and two-dimensional (2D) theories, each with their specific trade-offs in terms of computational efficiency and accuracy.

Three-dimensional solid finite element models offer the highest level of detail by explicitly representing the full geometry and anisotropic behavior of each ply, including inter-ply interfaces. These models can capture complex stress states, including out-of-plane stresses that are critical for predicting delamination []. However, they are computationally expensive, particularly for large structures or when fine meshes are needed to resolve local effects like matrix cracks or fiber–matrix debonding []. Moreover, modeling the entire laminate stack-up with full 3D elements can lead to ill-conditioned problems due to the extreme aspect ratios between in-plane and thickness dimensions [].

To reduce computational costs while maintaining reasonable accuracy, various 2D laminated plate and shell theories have been developed. These include equivalent single layer (ESL), layer-wise, and zigzag theories. ESL theories can be further classified into three main categories: classical plate theory (CPT), first-order shear deformation theory (FSDT), and higher-order shear deformation theory (HSDT) [].

Within ESL theory, the laminated composite is assumed to be equivalent to a single-layer medium []. CPT is the simplest ESL method in which the core assumption is that normals to the mid-plane before deformation remain straight and perpendicular to the plane after deformation, which neglects transverse shear strains and reduces the model to a single degree of freedom. This simplification leads to ease in deriving closed-form solutions and significant computational savings, making CPT widely used for quick predictions in thin, symmetric, and balanced laminates under pure bending or tension []. However, it disregards important boundary conditions—normal force, bending moment, and twisting couple []—and introduces errors for thick composite plates, particularly those with high longitudinal-to-transverse shear modulus ratios, by underpredicting deflections and overestimating natural frequencies and buckling loads [,]. Consequently, more-refined theories have been proposed to address these limitations and improve accuracy for composite structures [,,].

FSDT, also known as Reissner–Mindlin theory, was developed as an improvement over CPT to account for transverse shear effects in thicker laminated composite plates [,,]. FSDT assumes that the transverse displacement w remains constant through the thickness while the in-plane displacements u and v vary linearly, resulting in straight but not necessarily perpendicular lines to the mid-plane after deformation. Unlike CPT, it includes transverse shear strains but assumes them to be constant through the thickness, necessitating the use of a shear correction factor to properly satisfy the expected elastic energy of the parabolic analytical solution and improve result accuracy [,]. The effectiveness of FSDT heavily depends on this correction factor, and research has been conducted to refine the theory without invoking higher-order models that increase complexity [,,]. Bhaskar and Varadan [] applied Navier’s method with Laplace transforms, showing significant dynamic amplification and interlaminar stress sensitivity based on geometry and loading []. Onsy et al. [] introduced a finite strip model using FSDT that better captures cross-sectional warping and discontinuous shear strains at layer interfaces, representing an improvement over CPT for thick laminated composites. Nonetheless, for more accurate shear stress predictions and complex loading scenarios, higher-order shear deformation theories (HOSDTs) are ultimately required.

HSDT was developed to overcome the limitations of CPT and FSDT by incorporating nonlinear stress variation through the plate thickness and enabling a more accurate representation of section warping in the deformed configuration[]. Unlike discrete layer theories, which can handle interlaminar continuity more precisely but are computationally expensive and scale with the number of layers [], HSDT models are more efficient while offering improved accuracy. Some early notable contributions include Whitney and Pagano’s works on interlaminar stresses [,], Tang’s boundary layer theory [,], and Pipes and Pagano’s elasticity-based solutions []. Further improvements came from Wang and Choi, who used Lekhnitskii’s stress potential and anisotropic elasticity theory to explore stress singularities at laminate edges through a collocation-based eigenfunction technique, albeit with limited applicability to thin laminates [,].

First-order discrete layer theories, also known as zigzag or layer-wise theories, improve upon single-layer formulations by introducing a piecewise linear (zigzag) displacement function superimposed on a linear field to more accurately capture the in-plane displacement variation through the thickness of laminated composites [,,,,]. These theories incorporate zigzag functions or Heaviside unit functions to reflect the discontinuous displacement field across interfaces, a behavior consistent with the exact elasticity solutions of thick laminates given by Pagano [,]. By doing so, they provide a better approximation of the interlaminar stress field, especially in thick laminates. However, due to the first-order nature of their displacement assumptions, transverse shear stresses remain constant through the thickness, similar to first-order shear deformation theories. Zigzag theories thus serve as a layerwise counterpart to FSDT, offering improved in-plane accuracy while maintaining relatively simple mathematical formulations.

2.2. Simulation Methods

The simulation of damage in materials, particularly composites, demands sophisticated numerical techniques capable of capturing the initiation, growth, and interaction of damage phenomena across scales. Over the years, various general simulation methods have been developed to address these challenges, offering unique advantages in modeling discontinuities and complex material behaviors. This section explores these approaches in detail, discussing their foundational principles, capabilities, and limitations. These tools collectively form the backbone of modern damage simulation strategies, providing insights that are crucial for addressing real-world engineering problems.

Generally, cracks are introduced into the finite element simulations within either smeared or explicit representations. Smeared crack models deal with the damage phenomenon in a distributed manner where material degradation is represented through continuous field variables across the material domain []. On the other hand, explicit methods directly consider sharp discontinuities within the structure []. Each category will be explored in detail in the following section, with a focus on introducing the most significant methods within each group.

Continuum damage models (CDMs) are categorized as the smeared methods in which the property degradation is treated by reducing the stiffness of the engaged material. This degradation can be either instantaneous or gradual based on the damage behavior after initiation []. Instantaneous softening methods immediately reduce the material’s strength and stiffness in the directions corresponding to the failure mechanism as soon as damage is initiated [,,,,,]. As a result, it is demonstrated that these models underestimate the structural performance as a result of neglecting the residual strength after damage initiation []. These models can be found in commercial software as well, such as *MAT_COMPOSITE_DAMAGE (MAT_22) based on Chang–Chang’s [] failure model in LS-DYNA []. Alternatively, gradual softening methods have been proposed in which a controlled pace of decay is considered in the stiffness and strength once the damage is initiated [,,,]. A damage variable is introduced to the formulation, and its value varies between 0 for the intact material and 1 for the completely damaged medium []. This method has also been extended to fatigue models for the analysis of steel and composite structures [,,,].

One of the major drawbacks of the CDM approach is the localization of damage and the creation of singular points in terms of the damage variable, which can lead to a mesh-dependent solution [,]. Nonlocal regularization remedies mesh sensitivity in CDM by introducing a material length scale that spreads damage over a finite zone instead of a sharp localization. In practice, this is achieved by either averaging (integral-type nonlocal damage) or by adding gradient-dependent terms so that the damage (or strain) field is smoothed over a finite width [,].

One alternative method to CDM is the phase-field model (PFM) [,,,,]. PFM, rooted in a variational approach to fracture mechanics, represents a specific form of smeared or diffusive gradient damage modeling taking into account energy minimization principles. The approach considers cracks in a diffused manner without the explicit representation of discontinuities [,]. The method facilitates the incorporation of cracks within the simulation without ad hoc procedures for determining the crack path []. Single or multiple scalar parameters are defined in the medium to account for the transition between intact and completely damaged regions, as depicted in Figure 1. With this method, crack-tracking algorithms will no longer be required [].

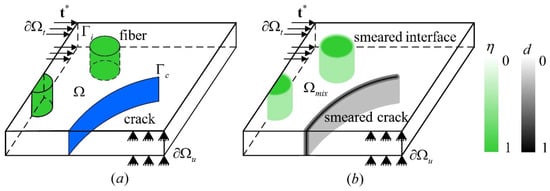

Figure 1.

Representation of the crack in an (a) explicit and (b) diffused manner [].

The phase-field model leads to a system of coupled partial differential equations (PDEs) governing the evolution of displacement and the phase field which are typically solved using numerical techniques []. However, a generalized phase-field model applicable to a wide range of constitutive laws has yet to be established. Additionally, the need for extremely fine meshes in the localization zone makes this method computationally demanding []. Adaptive mesh refinement (AMR) techniques alleviate this cost by concentrating the fine mesh resolution only in the narrow damage (process) zone while maintaining a much coarser mesh elsewhere []. These methods refine the mesh dynamically where the phase field or crack-driving energy is high, e.g., in the vicinity of an evolving crack, and leave the mesh coarse in relatively undisturbed regions. Common strategies include h-adaptivity, p-adaptivity, and combinations thereof (hp-adaptivity) [,,]. In many schemes, a two-stage (global/local) process is used: a coarse global solution identifies active crack regions which are then refined and resolved on a finer mesh []. As a result, AMR preserves accuracy in the fracture zone while drastically reducing total degrees of freedom.

In contrast to the phase-field model, the mixed strain/displacement finite element method (MFEM) [] offers a more efficient and versatile alternative. Unlike PFM, which requires highly refined meshes—typically 10 to 30 elements across a crack—to accurately capture fracture behavior, MFEM achieves comparable accuracy with only about three elements across the crack. This substantially reduces computational expense, making 3D applications more feasible. Additionally, MFEM maintains full generality in constitutive modeling, allowing straightforward incorporation of orthotropic behavior and irreversible strains, whereas PFM relies on a single isotropic damage index with limited constitutive capabilities. As computational demands continue to shape the practicality of fracture modeling techniques, the efficiency and flexibility of MFEM position it as a superior approach, particularly for large-scale and complex structural applications.

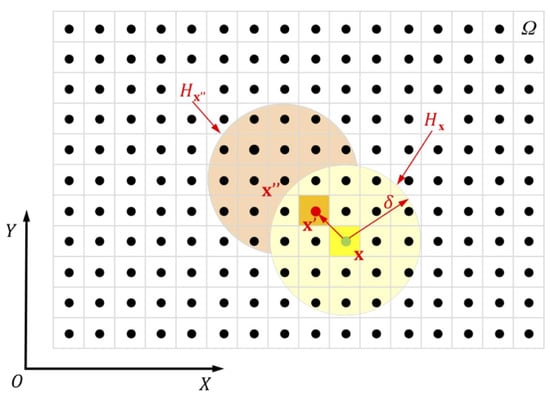

To represent discontinuities in materials without relying on spatial derivatives, an alternative approach involves reformulating the equation of motion as an integro-differential []. This concept, introduced by Silling [] under the framework of peridynamics (PD), provides a robust method for addressing mechanical problems involving discontinuities, such as cracks and interfaces. Unlike classical continuum mechanics, PD theory enables each material point to interact with its neighbors within a defined horizon through bonds [,,]. These bonds capture internal force densities and inherently accommodate damage within the medium. Figure 2 briefly represents how the PD method works. If an object occupies a spatial domain at a given time t, the the peridynamic theory assumes that every material point within interacts with other material points located within a certain neighborhood, denoted as . This interaction region, commonly referred to as the horizon, is typically a circular or spherical area characterized by a radius . All material points within this horizon are called the family points of . The interactions between these points form the foundation for defining mechanical behavior under the peridynamics framework [].

Figure 2.

Discretization of the medium in the PD method considering a specific horizon [,].

PD has been successfully applied to different mechanical problems, including plasticity [,], viscoelasticity [], and thermomechanics [], and its evolution has introduced multiple formulations to address the limitations of the original formulation, which is constrained by a fixed Poisson’s ratio and inability to separate distortional and volumetric deformations. State-based PD (SBPD) generalizes the framework to overcome these challenges by incorporating a modulus state to handle nonlinear and incremental deformations [,]. For greater flexibility, the nonordinary state-based PD (NOSBPD) approach integrates traditional constitutive models into the PD framework, though it faces unresolved issues related to material stability [,]. These advancements highlight the continuous effort to refine PD models for diverse material behaviors.

Within the explicit simulation schemes, the extended finite element method (XFEM) can be considered a procedure that does not require any re-meshing processes []. In the XFEM, the effect of the crack on the strain and displacement field is reflected in the element formulation, and hence, the geometry and mesh remain unchanged. The method builds upon the traditional finite element method, distinguished by its ability to accommodate discontinuities within an element by enhancing the degrees of freedom with specialized displacement functions []. Several techniques, regarded as variations or equivalents of XFEM, have been proposed using the principles of discontinuous functions []. Examples include the phantom node method (PNM) [,,], the augmented finite element method (A-FEM) [,], and the floating node method (FNM) [,]. Although XFEM is widely acknowledged to be a sophisticated technique with a clear advantage in modeling the initiation and progression of cracks along arbitrary, solution-dependent paths [], it does have certain limitations. These include a relatively high computational run-time, challenges with convergence, and the need for significant modifications to the finite element code, such as the incorporation of tracking techniques. Additionally, it struggles to effectively handle scenarios involving crack branching and merging [,].

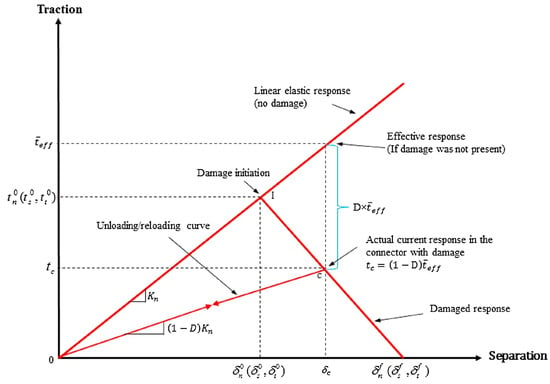

The cohesive zone model (CZM) is a widely used explicit meso-scale approach for simulating intra-layer damage through a cohesive formulation which captures the nonlinear interfacial softening behavior through a traction–separation law (TSL), as depicted in Figure 3, and mitigates issues with high-stress gradients at the delamination front []. CZMs effectively handle the nonlinear zone ahead of the crack tip, accommodating phenomena like plasticity and micro-cracking without requiring refined mesh configurations []. Initially developed to model energy dissipation rates [], CZMs are capable of simulating damage initiation, propagation, and interactions, such as delamination coupled with matrix cracking []. By modeling the fracture process as a transition from an intact material to a completely broken one, CZMs operate independently of the bulk material’s mechanical behavior [] and are easily implemented in conventional finite element codes []. They provide a simplified and effective means to define crack growth paths by applying the traction–separation law to cohesive elements along the crack path.

Figure 3.

Traction–separation law within the cohesive zone model [].

CZMs, while effective, face several limitations that affect their applicability. A key challenge is the need for dedicated surface or volume elements at ply interfaces, which can complicate implementation and increase computational runtime due to potential convergence issues. The thickness of the cohesive layer also critically influences the results []. Additionally, CZMs require the crack path to be predetermined and aligned with the fiber direction, which complicates mesh generation []. For composites with numerous layers, incorporating cohesive elements at every interface becomes time consuming and impractical. The traction–separation law used by CZMs can introduce artificial stiffness reductions in the elastic domain, altering the bulk structural response before any damage occurs []. Moreover, the penalty stiffness parameter in TSLs often requires ad hoc calibration, making it problem dependent and nontrivial to determine [,].

In addition to the simulation methods, various computational tools have been employed, each offering distinct capabilities and levels of feasibility depending on the complexity of the modeled phenomena. MATLAB, for instance, is widely used for prototyping numerical algorithms and implementing reduced-order models (ROM) due to its high-level programming environment and integration with toolboxes such as Partial Differential Equation Toolbox and Simulink []. However, for high-fidelity simulations of damage evolution in composites, especially those involving progressive failure, mesh dependency, and nonlinear constitutive models, finite element packages such as ABAQUS (Version 2022), ANSYS (Version 2023 R1), and LS-DYNA (Version R13.0) are more frequently utilized. ABAQUS, in particular, has proven effective due to its user subroutine capabilities, e.g., UMAT, VUMAT, which allow for custom material modeling, such as CZM and CDM [,]. LS-DYNA is also frequently employed for dynamic damage simulations due to its explicit solver, which handles high strain-rate problems and complex contact interactions effectively []. Moreover, emerging data-driven methods and hybrid approaches are increasingly being integrated into simulation workflows using Python (Version 3.9), TensorFlow (Version 2.8), or MATLAB (R2022b), enhancing model calibration and uncertainty quantification []. The feasibility of these tools is not only demonstrated by their widespread use in academia and industry but also by extensive validation through experimental correlation and peer-reviewed benchmarking studies [,,,].

In summary, the simulation of damage in materials, particularly composites, requires advanced numerical techniques capable of capturing complex failure mechanisms. Various modeling approaches, including smeared and explicit representations, have been explored to address the challenges of crack initiation, propagation, and interaction. While smeared methods like CDM and PFM provide a distributed representation of material degradation, explicit methods such as peridynamics (PD), XFEM, and CZM enable the direct modeling of discontinuities. Each technique offers unique advantages and limitations, necessitating careful selection based on the problem at hand. Future advancements will likely focus on improving computational efficiency, enhancing model accuracy, and integrating multiscale approaches to better capture real-world material behavior.

3. Damage Modeling in Composites

Composite materials exhibit distinct damage mechanisms under varying loading conditions, necessitating tailored simulation approaches. Under monotonic loading, damage typically initiates with matrix cracking in off-axis plies followed by fiber breakage and delamination. Daniel and Lee [] identified three characteristic stiffness ranges in cross-ply graphite/epoxy laminates: an initial linear elastic phase, a stiffness degradation phase due to transverse matrix cracking, and a final phase leading to ultimate failure governed by fiber breakage. Under cyclic loading conditions, however, fatigue damage in fiber-reinforced composites initiates with matrix microcracking, fiber/matrix interface debonding, and fiber breakage, progressing to delamination and eventual structural failure. This degradation typically follows a three-stage stiffness reduction: an initial phase with minor stiffness loss due to microcrack formation, a gradual degradation phase with slow damage accumulation, and a final phase characterized by rapid stiffness decline leading to catastrophic failure [,,]. Numerical models, such as CDM and CZM, have been developed to simulate these fatigue processes, incorporating factors like stress amplitude, mean stress, and residual stresses to predict damage initiation and progression [].

In addition, impact loading also introduces complex damage patterns due to high strain rates. Low-velocity impacts, for instance, can cause matrix cracking, fiber breakage, and interlaminar delamination [,,,,,], while high-velocity impacts, such as ballistic strikes, can result in severe damage, including penetration and extensive delamination [].

In contrast, creep damage arises under sustained loads at elevated temperatures, leading to time-dependent deformation. In fiber-reinforced composites, creep mechanisms include longitudinal matrix cracks, transverse shear failure, and local twisting of the fibers []. Modeling creep behavior often employs viscoelastic constitutive models, micromechanical approaches, and homogenization techniques to capture the time-dependent response accurately [,].

3.1. Intra-Layer Damage Modeling

The study of intra-layer damage in composite materials can be approached from different scales, primarily categorized into micro-mechanical and macromechanical models. The fundamental difference between these approaches lies in how the composite is treated. Micro-mechanical models analyze the composite at the level of its constituent materials, focusing on the inherent heterogeneity of the resulting material. In contrast, macromechanical models treat the composite as a homogeneous, orthotropic continuum, capturing the global response rather than local heterogeneities. This duality in composite modeling results in a variety of techniques, each with specific strengths and limitations in terms of accuracy, computational cost, and applicability range.

3.1.1. Micro-Mechanical Models

Intralaminar damage modeling is pivotal for understanding failure mechanisms in composite materials, which are integral to high-performance applications in aerospace, automotive, renewable energy, and structural engineering.

In the last five years, several studies have been published in this direction with varying levels of complexity.

Specifically, the study proposed by Chen and He [] introduces a hierarchical homogenization framework combining finite-volume direct averaging micromechanics (FVDAM) with ABAQUS/CAE to simulate elastoplastic and ductile damage in unidirectional B/Al composite laminates under tensile and shear loading. The model uses plasticity and continuum damage mechanics, implemented as a user material subroutine (Meta-UMAT), to predict nonlinear behavior and microscale stress/damage distributions. Validation against experimental data shows accurate stress–strain responses and computational efficiency, with potential for design applications. The approach is achieving simulations in 13–78 s.

Targeting dynamic effects, Larsson [] and Singh []’s work employs computational homogenization with a VUMAT subroutine in ABAQUS to study dynamic compression failure in UD composites. It models a viscoelastic–viscoplastic matrix with elastic fibers, focusing on shear and kinking. Validated against dynamic stress–strain data, it targets crash simulation applications. The approach captures rate-dependent behavior effectively, balancing efficiency with dynamic detail.

An interesting perspective is the one proposed by Hu et al. []. This paper develops a 3D peridynamic model to study damage in short-fiber and woven composites, supporting mixed stress–strain boundary conditions. Applied to short-fiber (15% fiber volume) and woven (51.97% fiber volume) microstructures, it predicts elastic properties and progressive failure, e.g., debonding, fiber pull-out, and trellising, and is validated against FEA and DIC experiments. The model’s single-load-case capability enhances multiscale efficiency, revealing detailed crack propagation.

Hessman et al. [] proposes a mean field homogenization model for high cycle fatigue (HCF) in short glass fiber reinforced PA66, incorporating fiber and matrix damage. Fiber damage uses a Weibull–Tsai–Wu criterion, while matrix damage includes a novel fiber-coupled progressive law, implemented in a cycle-based FEA framework. Validated with tensile and fatigue tests across fiber fractions (15–50%), it captures orientation-dependent failure and stress concentrations, suitable for industrial applications.

Naderi and Iyyer’s study [] targets the mechanisms governing damage evolution in thin-ply carbon fiber-reinforced laminates subjected to transverse tensile loading, focusing on the influence of 90° ply thickness—spanning 30 m to 120 m—within a [0//0] configuration. Utilizing a three-dimensional micromechanical framework integrated with the augmented finite element method (AFEM), they model a 90° ply constrained between two 50 m 0° plies, where fibers and matrix exhibit isotropic elastic behavior, and fiber–matrix interfaces are governed by a cohesive traction–separation response. Their analysis reveals that damage initiates predominantly through fiber–matrix debonding, subsequently triggering matrix crack propagation and kinking, with visualizations of damage contours and crack trajectories elucidating these processes over precise numerical quantification. Thinner 90° plies demonstrate a pronounced suppression of matrix cracking, attributed to in situ constraint effects, while stochastic fiber arrangements, variable interface toughness, and the presence of voids introduce heterogeneity, altering stress distributions and crack initiation loci in a manner resistant to strict empirical measurement. Emphasizing qualitative insights into failure progression, the authors underscore the need for future investigations incorporating experimental validation, process-induced residual stresses, and additional loading regimes such as compression and shear to further elucidate thin-ply laminate degradation mechanisms.

Kovačević et al. [] develops an analytical micromechanical model for unidirectional (UD) carbon/PEEK composites under cyclic loading, unifying creep and fatigue behavior. It uses a two-scale temporal framework with time homogenization, incorporating matrix viscoplasticity (via the Eindhoven glassy polymer model) and cohesive microcracking, while treating fibers as elastic. Validated against S–N and S–t curves, it captures frequency-dependent failure transitions but struggles with load ratio (R) and off-axis angle effects.

Khansari et al. [] presents the Damage Zone Micro-Mechanical Criterion (DZMC) for orthotropic UD composites under mixed mode I/II loading. It models the damage zone as randomly oriented elliptical microcracks using a probabilistic, semi-empirical image processing approach. Validated with epoxy resin tensile tests, it excels in predicting quasi-brittle fracture but faces mesh sensitivity at certain angles.

The work by Zheng et al. [] introduces a multiscale damage model for 3D woven composites with angle-interlock architecture under warp tension. Using microscale and mesoscale RVEs, it employs the micromechanics of failure Mori–Tanaka mean field (MMF) theory and incorporates Weibull-distributed fiber strength. It focuses on matrix cracking and tortuosity, validated with stress–strain curves. Implemented in ABAQUS, it predicts stiffness and strength accurately (errors 3–5%) but overlooks microstructural imperfections.

Employing the parametric high-fidelity generalized method of cells (PHFGMC) with phase-field damage, Meshi et al. [] model UD CFRP under static loading. Their study focuses on flexible crack paths calibrated against experimental stress–strain curves. The study captures brittle failure and interface debonding but notes RVE size–toughness discrepancies.

The study by Wu et al. [] models SiCp/AZ91 metal matrix composites (MMCs) under tensile loading using the conventional theory of mechanism-based strain gradient (CMSG) plasticity. It couples matrix damage, interface debonding, and particle fracture in a 2D FEA framework (ABAQUS/Explicit). Validated with tensile tests, it highlights interface-dominated failure and strain gradient effects, suggesting 3D extensions.

Qu et al. [] explores the impact of ply orientation and loading conditions on intralaminar and interlaminar damage in composite laminates, integrating 3D two-layer representative volume elements (RVEs) with in situ experimental validation to improve failure mechanism understanding for material design. Using RVEs (RVE00, RVE45, RVE90), they model elastic fibers, elastic–plastic matrices with ductile damage, and cohesive interfaces under transverse tension, through-thickness compression, and out-of-plane shear, validated by force–displacement curves and SEM/optical imaging of orthotropic laminates. Findings reveal that transverse tension initiates interfacial microcracks evolving into fiber-parallel matrix cracks, with RVE45 delaying delamination via fiber rotation and RVE90 showing extensive matrix damage. Compression induces ductile matrix damage and angled fracture planes in RVE00, redirected intralaminarily in RVE45/RVE90, and shear causes delamination from intralaminar cracks migrating to resin-rich zones. Key insights highlight ply orientation’s role in microcrack-triggered delamination, introducing the “delamination plane” concept, with simulations matching experimental fracture patterns, demonstrating the multi-layer RVE’s efficacy in guiding multiscale modeling and enhancing crack resistance through interfacial bonding optimization.

Varandas et al. [] propose a 3D micromechanical framework to estimate the mode I through-thickness intralaminar R-curve of unidirectional CFRPs, focusing on fracture toughness and fracture process zone length using finite element models of geometrically scaled single-edge notch tension specimens combined with the size effect method. The FE models integrate microscale regions: elastic fibers, elasto-plastic matrix damage via VUMAT in ABAQUS/Explicit, and cohesive fiber–matrix interfaces and mesoscale homogenized outer plies, incorporating ±30% variability in matrix/interface properties to simulate 3D effects, with peak loads across specimen sizes (5–40 mm) and fiber volume fractions (35–71%) analyzed to derive steady-state toughness and fracture process zone length. Results show steady-state toughness (exceeding that of neat epoxy due to fiber bridging) and fracture process zone length both increasing with interface toughness and fiber volume fraction, driven by matrix plasticity, interface debonding, and bridging, as validated by SEM. The study underscores the matrix-dominated crack propagation and the significant influence of interface properties and fiber content, though it lacks fiber damage modeling and relies on macromechanical matrix assumptions, offering a robust tool for R-curve prediction and damage model calibration while highlighting the need for improved interface characterization.

In their work, Wani and Daggumati [] explore damage initiation and progression in a unidirectional non-crimp fabric (NCF) glass fiber-reinforced polymer (GFRP) composite ply under transverse tension and compression and use a detailed computational micromechanical model to reveal how microscale features shape macroscopic behavior. They propose a 3D RVE that weaves together axial and backing fiber bundles, an epoxy matrix, small voids, and subtle fiber waviness, portraying fibers as elastic yet breakable. The matrix is flexible with a pressure-sensitive twist, and interfaces are fragile bonds governed by cohesive rules, all validated through hands-on experiments with digital image correlation (DIC). Their findings show that, under tension, damage initiates at the fiber–matrix boundary, propagates through peeling interfaces and a yielding matrix, and ends with the snapping of backing fibers, where voids and waviness noticeably weaken the material. Under compression, it initiates with interface cracks, followed by matrix softening and the formation of shear bands, and ends with backing fiber collapse, again tempered by defects. This work underscores the role of interface breakdown and microstructural particularities such as voids and waviness in driving damage.

Sagar et al. [] propose a thermodynamically consistent PFM for elastoplastic continua, specifically targeting the micromechanical analysis of ductile fracture within the epoxy matrix of FRP composites with an emphasis on elucidating pressure-sensitive plastic deformation and stress-state-dependent failure mechanisms. The methodology integrates a novel phase-field driving energy formulation incorporating a local damage propagation indicator and an energy barrier associated with damage initiation and regularization. Fibers are modeled as linear elastic, the epoxy matrix employs a Drucker–Prager plasticity framework with isotropic hardening, and fiber–matrix interfaces are governed by CZM utilizing Benzeggagh–Kenane (BK) criteria. This is implemented within a 3D microstructural volume element (MVE) featuring stochastic fiber distribution, subjected to transverse tensile loading via FEA, and is validated through analytical 1D studies and numerical benchmarks against established literature. Findings delineate a sequential damage evolution under transverse tension: initial interface debonding post-elastoplastic deformation precipitates matrix cracking, coalescing debonded regions into a primary vertical crack accompanied by secondary microcracks, with crack morphology modulated by fiber spatial arrangement and MVE dimensions, corroborated by homogenized stress–strain responses aligning with reference data. The model’s efficacy lies in its capacity to capture the epoxy’s ductile fracture characteristics, leveraging pressure sensitivity and stress-state dependency to enhance predictive fidelity without necessitating discrete crack tracking, thus surpassing conventional methodologies such as CZM or XFEM and offering a robust computational tool for FRP strength prognosis and broader elastoplastic fracture investigations.

When looking at the global picture across all these studies, matrix cracking and fiber–matrix interface failure are universal, reflecting the intralaminar focus in composite failure. Chen and He [] model elastoplastic matrix damage, Singh et al. [] emphasize matrix shear and kink-band formation, and Sagar et al. [] focus on ductile fracture. This consistency spans UD, e.g., [,], NCF [], and FRP [] systems, underscoring a shared foundation.

With respect to constituent-level material modeling, fibers are typically elastic, e.g., [,,], while matrices vary: elastic [], elastoplastic [,,,], viscoelastic–viscoplastic [,,], pressure-dependent [,,], or strain gradient-dependent []. Damage evolution is a shared focus, with mechanisms like fiber bridging [], shear bands [], crack linking [], or kink-bands [] enhancing resistance.

The recent works analyzed collectively affirm the pivotal role of micromechanical modeling in elucidating intralaminar damage mechanisms within composite materials. These studies converge on a unified approach: employing constituent-scale analyses via RVEs or microstructural volume elements (MVEs) to dissect the complex interactions of matrix cracking, fiber–matrix interfacial decohesion, and progressive damage under a spectrum of mechanical stimuli, including static tension, dynamic compression, and cyclic fatigue. Methodological diversity is pronounced, spanning finite element methodologies—e.g., the augmented finite element method, phase-field fracture, and computational homogenization—analytical formulations, and peridynamic simulations together with probabilistic frameworks, each tailored to specific composite architectures—unidirectional (UD), non-crimp fabric (NCF), woven, or metal matrix composites (MMCs)—and damage modalities, such as kink-band formation, ductile matrix failure, or fiber bridging.

Validation approaches integrate qualitative assessments, such as crack trajectory visualization [], with quantitative metrics, including stress-strain responses [,] and in situ imaging data [], achieving error margins of 2–10% where robust experimental benchmarks exist, though limitations in direct experimental corroboration, e.g., [], and computational scalability, e.g., [,], persist.

These models collectively demonstrate that intralaminar damage is intricately governed by microstructural heterogeneities such as fiber spatial distribution, interfacial constitutive properties, and inherent defects. Unresolved challenges include the incorporation of process-induced residual stresses, fiber rupture mechanics, and standardized validation protocols across loading regimes.

3.1.2. Macromechanical Models

In macromechanical modeling, the composite material is represented by a RVE []. This unit cell concept allows for the description of the composite as a homogeneous material, whose behavior replicates that of the heterogeneous composite structure when repeated in space. Consequently, macromechanical approaches are commonly referred to as homogenization models, as they focus on the equivalent material properties derived from the RVE.

Under elastic conditions, the characterization of this equivalent material involves determining the nine independent components of the orthotropic constitutive tensor. Experimentally, this is achieved by measuring the elastic moduli (, , ), shear moduli (, , ), and Poisson’s ratios (, , ) that define the composite’s mechanical response. These properties correspond to a specific composite configuration, meaning that variations in fiber orientation, volume fraction, or constituent materials result in different material properties. This is particularly important, as manufacturing processes can introduce deviations in fiber orientation or volume fraction [,], making laboratory-measured properties potentially non-representative of the final composite structure. Consequently, while macromechanical models offer simplicity compared to micromechanical approaches, they are often rigid, requiring recalibration when material composition changes.

The experimental determination of these mechanical properties is typically performed following standardized testing procedures outlined in guidelines such as those provided by ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization). For example, ASTM D3039 [] describes the tensile testing of polymer matrix composites, ASTM D3518 [] focuses on in-plane shear response, and ASTM D5379 [] provides guidelines for measuring shear properties using the V-notched beam method. These standardized protocols ensure the reliability and repeatability of material characterization, which is critical for accurately defining input parameters in macromechanical models [].

Numerous studies have employed macromechanical models to simulate the elastic and inelastic behavior of fiber-reinforced polymers (FRPs). Following this approach, several models have been developed to incorporate effects such as loading rate dependency [,], which is critical for thermoplastic-matrix composites and cyclic loading responses [,], including frequency and stress ratio effects.

To address the rigidity associated with macromechanical models, some researchers have adopted meso-scale modeling approaches [,,,]. These models share the philosophy of macromechanical homogenization but focus on the response of individual laminate plies rather than the composite as a whole. In this framework, material behavior is defined phenomenologically based on strain distribution rules among the plies. As with macromechanical models, extensive experimental data are required to characterize ply behavior accurately. For instance, Llobet et al. [] introduced a meso-scale model for studying damage evolution in laminates under cyclic loading. Their approach required the identification of 14 parameters to characterize intralaminar damage under both elastic and inelastic conditions, including stiffness, strength, and fracture toughness. However, just as in macromechanical modeling, changes in laminate composition necessitate recharacterization, incurring significant experimental costs.

Another important category within homogenization models is based on mixture theories. Originally formulated by Truesdell and Toupin [] and later adapted by Reuss and Voigt for composite materials [], these homogenization rules serve as constitutive frameworks to define the overall response of the composite. In some cases, these models are coupled with meso-scale formulations to phenomenologically describe the interaction between different layers of the composite []. Alternatively, they can be employed as standalone models to derive the macroscopic response directly from the behavior of the constituent materials [,,,,,].

One notable development in this area is the series-parallel mixing theory, introduced by Oller [,] for modeling fiber-reinforced composites. This model captures the orthotropic response of the composite by assuming iso-deformation along the fiber direction and iso-stress in the transverse direction. A key advantage of this approach is that its calibration is directly linked to the properties of the constituent homogeneous materials, making it less sensitive to variations in fiber volume fraction or orientation. This significantly reduces the experimental effort required for material characterization, offering a flexible alternative to conventional homogenization methods.

3.1.3. Multiscale Models

The previous phenomenological approaches describe the mechanical response of composite materials only at the macroscopic level. This is really efficient from a computational point of view, enabling the analysis of large-scale structures. However, its accuracy is compromised when complex interactions between the different components of a composite material take place. The introduction of more complex composites, such as CFRP’s [,,,,], nanofibers [,,], carbon nanotubes (CNTs) [,], short fiber reinforced concrete [], or masonry [,,], or composites that are additively manufactured [,,] required the development of more sophisticated numerical techniques for their analysis.

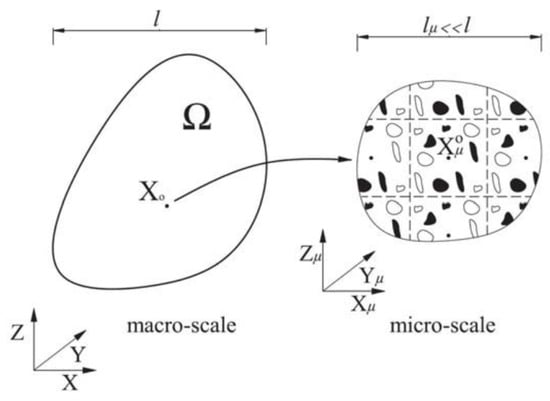

With the advancement of computational power, multiscale homogenization methods have emerged as a viable approach for analyzing composite materials. These methods compute the stress–strain response at each macroscopic integration point by solving an RVE or unit cell, which is modeled as an independent subproblem. To ensure the validity of this approach, a clear scale separation between the macrostructure and microstructure must be maintained (see Figure 4), as well as its periodicity [].

Figure 4.

Separation of scales in a multiscale approach. Source: Otero [].

The RVE serves as a geometric and mechanical representation of the microstructure subjected to the macroscopic deformation gradient. Among the various multiscale techniques, the first-order multiscale method () [,,,,,,,,,] is the most widely adopted. In this framework, the macroscopic behavior is determined solely by the first gradient of the displacement field, allowing for the homogenization of material properties based on microscale computations. This multiscale method leverages the macroscopic strain tensor as an input of the microscale problem. The overall composite behavior is expressed as the macroscopic stress–strain relationship through an explicit representation of the internal heterogeneous structure within an RVE. A key advantage of this approach is that it does not rely on predefined constitutive assumptions or compatibility equations for the composite material. Instead, the macroscopic response naturally emerges from the microscale solution after a proper up-scaling is performed. Additionally, this method imposes no restrictions on the constitutive laws governing the individual constituents, allowing for the inclusion of non-linear behaviors and time-dependent effects such as damage, viscoelasticity, or plasticity. This flexibility makes the approach particularly suitable for studying composites with complex and evolving material properties.

The fundamental principles of classical first-order computational homogenization can be described using the four-step homogenization scheme introduced by []:

- Define an RVE of the microstructure, where the constitutive behavior of each individual constituent is known.

- Apply the macroscopic strain as displacement boundary conditions on the RVE, establishing the macro-to-micro transition.

- Compute the macroscopic stress by analyzing the deformed microstructural RVE, enabling the micro-to-macro transition.

- Derive the numerical relationship between the macroscopic input and output variables, effectively linking the microscale and macroscale behaviors.

Numerous studies have demonstrated that can effectively model both linear and nonlinear RVEs, enabling the simulation of complex material behaviors. The computational homogenization technique offers several key advantages []:

- No explicit assumptions about the macroscopic local constitutive response are required, as it is naturally accounted for by the resolution of the microscale boundary value problem (BVP).

- The macroscopic constitutive tangent operator is directly obtained from the microscopic stiffness matrix via static condensation.

- The scale transition ensures consistency throughout the analysis and in terms of energy dissipation.

- The method seamlessly accommodates large strains and large rotations, provided that the microstructural constituents can be modeled with a geometrically nonlinear framework.

However, this methodology comes with a significant computational burden, as a microscale problem must be solved at each macroscopic integration point. Consequently, efficient numerical strategies, parallel computing, and reduced-order modeling [,] techniques are often employed to mitigate the computational cost while maintaining accuracy. In this regard, several ROM techniques have been developed, such as the response surface models (RSM) [] and proper orthogonal decomposition (POD) [], among others [,].

In problems involving localized deformations, fracture typically affects only a small region of the structure (i.e., strain localization), while most of the material remains in the linear-elastic regime. This observation suggests that solving a full RVE problem at every macroscopic integration point may be unnecessary, leading to the development of more efficient multiscale strategies. One such approach is the use of nonlinear activation functions, as proposed by Otero et al. []. This method defines an activation criterion based on the maximum elastic energy density that an RVE can sustain before failure. When the material remains within the elastic threshold, homogenized properties can be used directly, bypassing computationally expensive RVE calculations. This results in a substantial reduction in computational cost while maintaining accuracy in critical regions. However, a key limitation of this approach is that any modification at the macroscopic level necessitates a re-evaluation of the nonlinear activation function, even when using the same RVE. This introduces additional computational overhead in cases where frequent updates are required, making it less efficient for simulations with evolving boundary conditions or progressive damage.

As a natural extension of the first-order homogenization method, second-order computational homogenization [,] was introduced in the last decade to address regions of intense deformation. This approach is particularly relevant when the characteristic wavelength of the macroscopic deformation field is comparable to the microstructural length scale. Unlike first-order homogenization, where only the macroscopic strain is passed to the RVE, the second-order method also incorporates the macroscopic gradient of the strain into the microscale equations. Consequently, while the first-order equilibrium problem remains unchanged at the microscale, a higher-order equilibrium problem emerges at the macroscale. Despite its advantages in capturing localization effects and nonlinear behavior, second-order homogenization has seen limited widespread application due to its complex FE implementation. In contrast, first-order homogenization retains first-order equilibrium equations at both scales, making it computationally more efficient and easier to implement. As a compromise between these two approaches, an enhanced first-order method [] could provide a practical alternative. By incorporating macroscopic second-order deformation measures into the microscale boundary value problem, this approach aims to account for second-order effects while maintaining the relative simplicity of first-order formulations.

In conclusion, while multiscale methods offer an accurate and rigorous framework for capturing the behavior of heterogeneous composite materials, their high computational cost poses a significant challenge, particularly for large-scale geometries. Nevertheless, continuous advancements in computational power, enhanced parallelization strategies, and the integration of machine learning or surrogate modeling techniques for microscale computations are progressively alleviating these limitations (see Section 4). These developments pave the way for a broader and more efficient application of multiscale approaches in engineering practice.

3.2. Inter-Layer (Delamination) Damage Modeling

Delamination in laminated composite materials represents a critical failure mode that significantly influences structural integrity and load-bearing capacity [,,,,]. This damage mechanism arises due to the weak bonding between adjacent plies, as composites generally lack through-thickness reinforcement [,]. Delamination can be triggered by various factors, including cyclic loading (fatigue), impact damage, and residual stresses generated during the manufacturing process []. If left unaddressed, delamination can propagate through the structure, ultimately leading to loss of stiffness and potential failure.

Traditionally, the modeling of delamination progression is divided into two main stages: initiation and propagation. Several numerical techniques have been developed to capture these phenomena. One of the earliest and least computationally expensive methods is the element erosion approach in which elements are removed from the mesh once their failure threshold is reached [,]. This method ensures numerical stability by gradually reducing the load-bearing capacity of elements over multiple load increments rather than removing them instantly. Often employed in conjunction with CDMs, element erosion is particularly useful for simulating ductile fracture []. However, some implementations rely solely on a failure criterion without incorporating the softening behavior of materials. While straightforward to implement, this technique is sensitive to mesh size and element shape, potentially leading to non-physical results.

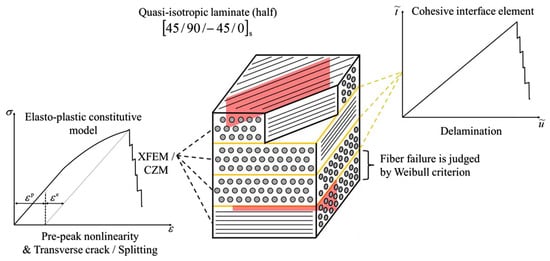

A more advanced technique that addresses some of these limitations is the XFEM, which allows cracks to initiate and propagate along solution-dependent paths without requiring predefined crack locations []. Several studies have integrated XFEM with other modeling approaches to enhance accuracy and computational efficiency. For instance, XFEM has been coupled with the CZM to simulate the interactive progression of matrix cracks and delamination, enabling a more comprehensive representation of failure mechanisms in composite structures [,]. This combination is particularly effective in modeling progressive damage, as XFEM captures matrix cracking, while CZM handles delamination propagation [], as illustrated in Figure 5. Additionally, a crack-leading model implemented in ABAQUS successfully characterized different delamination morphologies and interactions with matrix cracks, yielding numerical results that closely align with experimental observations []. Further improvements include XFEM-based models designed to capture the zigzag delamination growth path using quadratic crack initiation criteria and principal stress-based propagation direction, making them suitable for accurately predicting complex delamination behavior [].

Figure 5.

Coupling XFEM with CZM for the modeling of matrix cracking and delamination, respectively [].

XFEM has also been applied to various material systems and test configurations, demonstrating its versatility. For example, it has been utilized to analyze delamination in fiber–metal laminates, marking one of the first instances of its application in GLARE composites []. Similarly, the method has been evaluated in traditional carbon fiber-reinforced polymer (CFRP) laminates, where it showed high accuracy in mode I fracture predictions but required fine meshing to address convergence issues []. XFEM has further been employed in fatigue modeling, where it has been combined with VCCT to predict energy release rates at disbond crack tips in bonded composite-metal joints []. The method has proven effective in high cycle fatigue simulations, incorporating a phantom node approach for mesh-independent crack insertion and integrating fatigue-cohesive zone formulations for progressive failure analysis [,,]. Moreover, a coupled XFEM-VCCT approach has been proposed for mode I fatigue delamination modeling, demonstrating reduced computational costs compared to conventional techniques while maintaining high accuracy []. The integration of XFEM with cohesive elements has also enabled the prediction of fatigue-driven multi-crack evolution in laminated composites under mixed-mode loading, further enhancing its capability in damage modeling [].

The XFEM approach enhances modeling flexibility but introduces challenges related to computational cost, convergence difficulties, and complex tracking algorithms. Additionally, XFEM struggles to handle crack branching and merging, further limiting its applicability in highly dynamic failure scenarios [,].

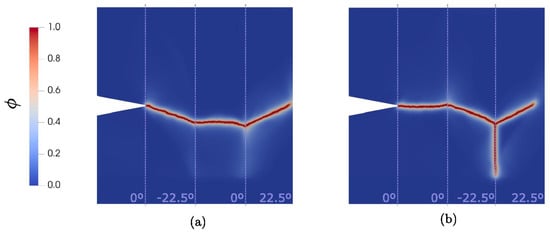

Another emerging approach for delamination modeling is the PFM, which formulates crack propagation as a diffused interface problem based on energy minimization principles []. PFM has gained significant attention for modeling delamination in composite laminates due to its ability to capture complex crack paths without requiring predefined crack surfaces or tracking algorithms. Unlike conventional methods, PFM modeling introduces a gradient-enhanced damage formulation based on Griffith’s theory of fracture, allowing for the simulation of intralaminar and translaminar fracture in long fiber composites [], as depicted in Figure 6. This approach provides robust predictions under quasi-static loading while minimizing mesh dependency, making it a compelling alternative to classical fracture mechanics models [].

Figure 6.

The failure pattern obtained through the PF approach in two different configurations of (a) and (b) [].

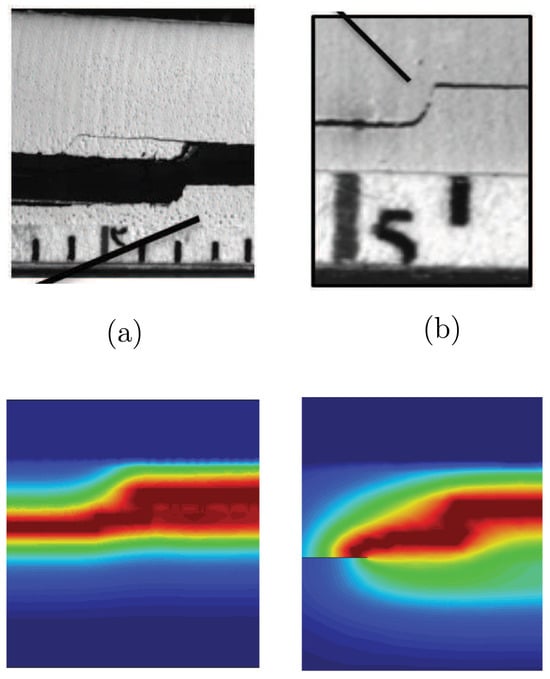

To address delamination migration and mixed-mode failure, a mixed-mode phase-field formulation has been developed, incorporating volumetric and deviatoric effects along with a power law-based delamination criterion. This formulation has demonstrated accuracy in predicting delamination kinking, migration, and crack path evolution, closely matching experimental observations [], as presented in Figure 7.

Figure 7.

Interfacial crack migration in experiments and obtained phase field results in two different geometrical configurations where the point of load application is (a) on the right side and (b) on the left side of the notch [].

Moreover, a unified phase-field-cohesive zone model (PF-CZM) has been introduced to predict bulk fracture and interfacial delamination in CFRP composites, enabling quasi-brittle failure predictions without requiring an explicit traction–separation law for interfacial cracks. The PF-CZM approach simplifies delamination modeling while inherently capturing material strength, offering an efficient framework for simulating failure in fiber-reinforced composites [].

The integration of PF with advanced numerical techniques has further enhanced its applicability. An isogeometric phase-field model (IGA-PFM) has been proposed to improve computational efficiency and accuracy in delamination simulations, leveraging smooth geometric representations to provide higher sensitivity to laminate stacking configurations []. Additionally, hybrid modeling frameworks combining PF with CZM have been explored to address the intricate interactions between intralaminar and interlaminar failure mechanisms, ensuring thermodynamic consistency and reducing computational complexity []. A phase-field-augmented peridynamics model has also been introduced, eliminating the need for empirical interaction laws and conventional traction–separation models while providing a general framework for delamination tracking under varying boundary conditions []. This PD-PF model offers additional advantages, including the elimination of artificial crack tracking algorithms, enhanced physical realism in fracture propagation, and a natural treatment of different delamination modes without special constraints. Collectively, these advancements highlight the phase-field approach as a versatile and powerful tool for delamination modeling in composite laminates, capable of capturing complex crack interactions, improving numerical stability, and reducing reliance on empirical formulations.

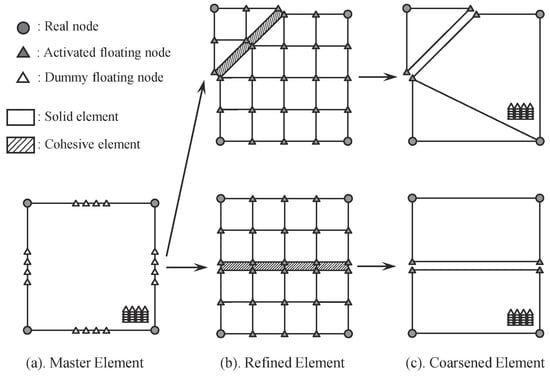

Alongside PFM, FNM has gained attention for its capability to model both matrix cracks and delamination within the same framework []. Unlike traditional finite element-based methods, FNM introduces additional degrees of freedom to capture discontinuities within an element. This method has been integrated into enriched shell finite elements to efficiently simulate delamination migration, combining FNM with VCCT for damage propagation prediction []. The enriched element formulation enables the modeling of arbitrary delamination growth paths and transverse matrix cracking while reducing computational complexity compared to traditional techniques. Furthermore, an alternative approach using virtual embedded cohesive elements has been introduced, where floating nodes automatically generate cohesive elements at the crack tip, allowing for more flexible delamination migration modeling without severe mesh distortions [].

To further enhance computational efficiency, an adaptive floating node method (A-FNM) has been developed, featuring elements that transition between different configurations—refined, coarsened, or master elements—based on the crack propagation state [], as illustrated in Figure 8. This approach allows for local refinement without requiring global remeshing, significantly reducing computational effort while maintaining accuracy in progressive damage simulations.

Figure 8.

Adaptive floating node element (a) master element configuration, (b) refined element configuration, (c) coarsened element configuration [].

The fundamental architecture of FNM closely resembles the phantom node method used in XFEM, but it eliminates issues related to crack geometry mapping and integration errors, making it well-suited for modeling complex crack networks in composite laminates []. Additionally, the ability to represent multiple plies, interfaces, and damage interactions within a single element enhances the method’s applicability for composite failure analysis [].

In the context of multiple delaminations, an adaptive floating node formulation coupled with an adaptive refinement scheme (ARS) has been proposed to accurately simulate quasi-static delamination growth while reducing the computational costs associated with cohesive element-based models []. By adaptively updating element interface discretizations, this formulation ensures efficient convergence and improved solution times. Similarly, a hybrid approach that combines FNM with VCCT has been introduced for modeling delamination migration in cross-ply tape laminates, capturing both delamination and matrix cracking within a single element while determining migration onset and path in a mesh-independent manner [].

Beyond quasi-static loading scenarios, FNM has been applied to impact simulations, where enriched shell elements incorporating the method have been used to simulate low-velocity impact damage in composites []. While the current implementation requires a pre-seeded initial crack and is limited to capturing delamination at a single ply interface per element, it demonstrates the potential for computationally efficient impact damage modeling.

The CZM is another widely used approach for modeling delamination in composite materials, addressing damage initiation and propagation through traction–separation laws. One key challenge in CZM implementation is accurately characterizing the traction–separation response (TSR) for mode I delamination. Experimental advancements, such as the composite rigid double cantilever beam (cRDCB) method, now allow direct TSR measurement from a single specimen. However, these TSRs also capture the stiffness contribution of adjacent laminae, introducing artificial compliance in numerical models. To address this, a two-stage analysis procedure incorporating a crack tip compensation function has been proposed, refining TSRs for more accurate mode I delamination modeling []. Similarly, an energy-based CZM approach has been developed for fully uncoupled multi-directional (FUMD) laminates, introducing a single internal variable to govern damage evolution. This method provides a more general constitutive response, ensuring thermodynamic consistency and improving agreement with experimental results [].

Various modifications to CZM have been proposed to enhance its accuracy in different scenarios. For instance, a trapezoidal TSL has been introduced for high-cycle fatigue loading in fiber–metal laminates (FMLs), proving more efficient in predicting delamination growth in ductile adhesives than traditional bilinear CZM []. Similarly, a three-linear CZM, integrating two bilinear laws, has been designed to model mixed-mode delamination with large-scale fiber bridging. This model applies varying bridging strengths along the fracture process zone (FPZ), accounting for geometry-dependent effects []. In fatigue delamination, a novel cyclic cohesive zone model (CCZM) has been proposed, incorporating trilinear traction–separation laws based on the Turon et al. [] and Kawashita–Hallett [] models. This approach enhances accuracy and computational efficiency, particularly in glass/epoxy laminates exhibiting significant fiber bridging []. Additionally, recent advancements in mixed-mode CZM have led to the development of a hybrid approach using linear and torsional spring elements to simulate fracture process zone effects. This method integrates R-curve behavior estimation, allowing accurate prediction of fracture toughness evolution without costly experiments []. These innovations highlight the versatility and ongoing development of CZM in delamination modeling, making it a crucial tool for composite material analysis.

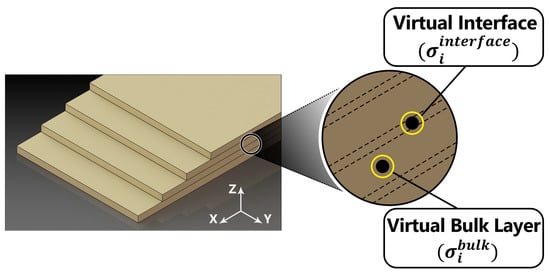

An alternative to explicitly modeling individual cracks is the use of homogenization techniques, which aim to incorporate delamination effects into the bulk composite response without discretizing each ply interface. This method has been developed recently based on a classical mixing theory [], and it is matured by incorporating virtual interfaces and virtual bulk layers, as presented in Figure 9.

Figure 9.

Virtual bulk layers and virtual interfaces through the homogenized medium [].

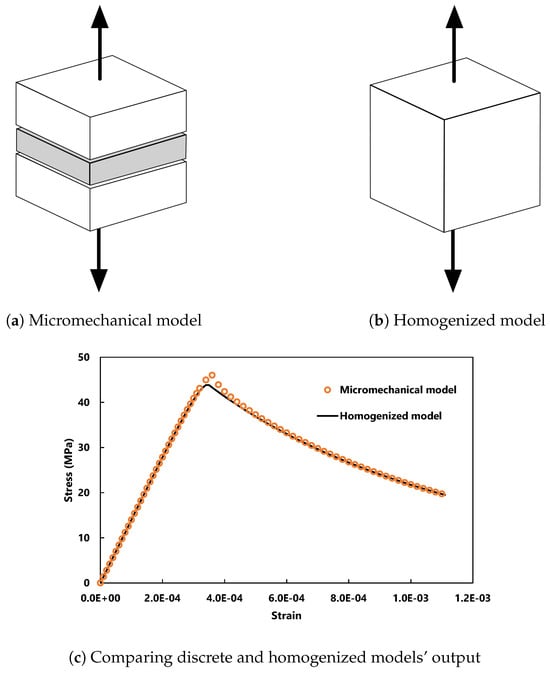

Mode I and mode II delamination damages are accounted for independently, and their corresponding interfacial stresses are computed by employing an averaging scheme. A stress-based damage model [] is then considered to compute the inter-layer damage values at each interface. The material behavior in macroscale is well-captured by affecting the associated mode I and mode II stress components at each bulk layer. Figure 10 illustrates the discrete and homogenized configurations along with their corresponding behaviors.

Figure 10.

Modeling debonding between two blocks in (a) micromechanical and (b) homogenized approaches and (c) their corresponding behavior [].

This method has been applied to different loading configurations using standard test specimens, including double cantilever beam (DCB), end notch flexure (ENF), and mixed mode bending (MMB), and good accuracy was obtained compared to other numerical methods and experimental data.

The homogenization method eliminates the need for explicit cohesive elements, thereby reducing artificial stiffness effects and facilitating implementation in large-scale structural simulations. Moreover, the homogenized approach enables the consideration of intra-layer failure mechanisms such as plasticity and matrix cracking, further improving the predictive capability of composite damage models.

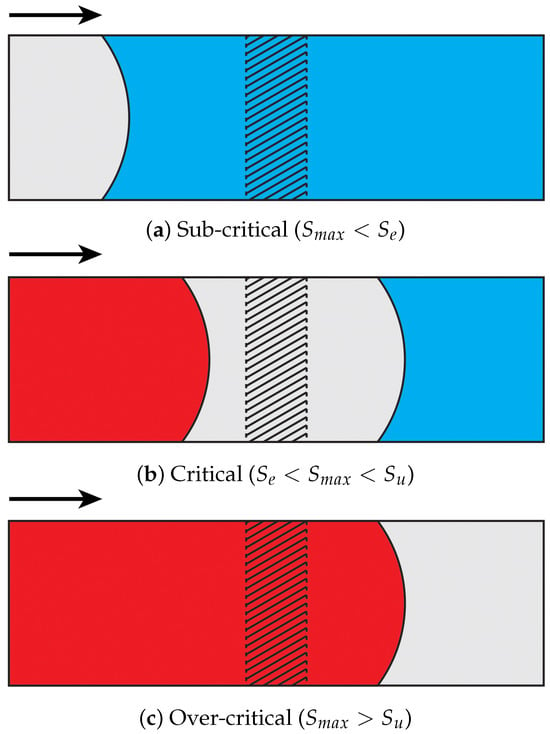

The homogenization theory has been further developed into the cyclic loading regime as an efficient way to simulate structural behavior in fatigue conditions []. To achieve this, the crack propagation regime is divided into three distinct stages determined by the maximum stress at the crack tip () relative to the fatigue limit () and the ultimate strength (), as illustrated in Figure 11.

Figure 11.

Different stages experienced by a band of elements in (a) sub-critical (blue), (b) critical (gray), and (c) over-critical (red) regions as a fatigue crack propagates in the direction illustrated by arrows [].

A fatigue reduction function () is incorporated into the formulation to address the effects of cyclic loading, and it is independently developed for each stage of crack propagation. The model can be calibrated by employing the available Wöhler diagrams. A set of standard test procedures has been conducted to evaluate the model performance in both damage initiation and damage propagation stages.

The incorporation of virtual layers and interfaces enhances the efficiency of the proposed model, making it well suited to simulating large-scale structures with multiple layers. This approach also streamlines the preprocessing stage by eliminating the need for a layer-by-layer representation. Furthermore, by calibrating fatigue parameters at a single interface, the model can accommodate various stacking sequences and fiber orientations [].

In summary, while several numerical methods exist to model delamination, each presents its own advantages and challenges. The trade-off between accuracy and computational efficiency remains a key consideration, particularly for large-scale structures with multiple layers. Advances in homogenization techniques offer a promising direction by providing an efficient means of addressing delamination without the complexities associated with explicit interfacial modeling.

Among the methods discussed, continuum damage mechanics (CDM), cohesive zone models (CZM), extended finite element method (XFEM), phase-field models (PFM), and peridynamics (PD) are evaluated for their accuracy in predicting these phenomena. CDM excels in modeling intra-layer damage by representing progressive stiffness degradation through smeared crack approaches, making it effective for capturing crack initiation and propagation under monotonic and cyclic loading. However, its mesh dependency can lead to inaccuracies in crack interaction due to localization issues. PFM addresses this by using a diffused crack representation, offering high accuracy in predicting crack initiation and propagation without requiring explicit crack tracking, as it relies on energy minimization principles. Yet, PFM struggles with crack interaction due to its computational intensity and the need for extremely fine meshes, which can miss complex crack branching scenarios.

XFEM and CZM are explicit methods that directly model discontinuities, providing robust frameworks for crack propagation and interaction. XFEM is particularly accurate for crack propagation along arbitrary paths, as it enhances finite element formulations to accommodate discontinuities without re-meshing, making it suitable for capturing crack initiation and growth in composites. However, its limitations in handling crack branching and merging reduce its accuracy for crack interaction, and it incurs high computational costs due to convergence challenges. CZM, on the other hand, is highly effective for delamination and crack interaction, using traction–separation laws to model the nonlinear behavior at interfaces. It accurately predicts crack initiation and propagation, especially in scenarios involving delamination coupled with matrix cracking, but its accuracy depends on predefined crack paths, which can be a limitation for complex crack interactions. PD offers a unique advantage by reformulating the equation of motion in an integro-differential form, enabling accurate prediction of crack initiation, propagation, and interaction, including complex scenarios like branching, due to its bond-based approach. However, PD’s computational cost is significant, particularly for large-scale problems, as it requires interactions to be modeled within a defined horizon.