Estimation of Sporulated Cell Concentration of Bacillus thuringiensis in a Batch Biochemical Reactor via Simple State Observers

Abstract

1. Introduction

2. Benchmark Model

Plant Model for Batch Process Model Using Bacillus thuringiensis Production

3. Linear Model of the System in Equations (1a–d)–(2a–c)

Observability Properties of the System in Equations (1a–d)–(2a–c)

4. Nonlinear Observability Analysis

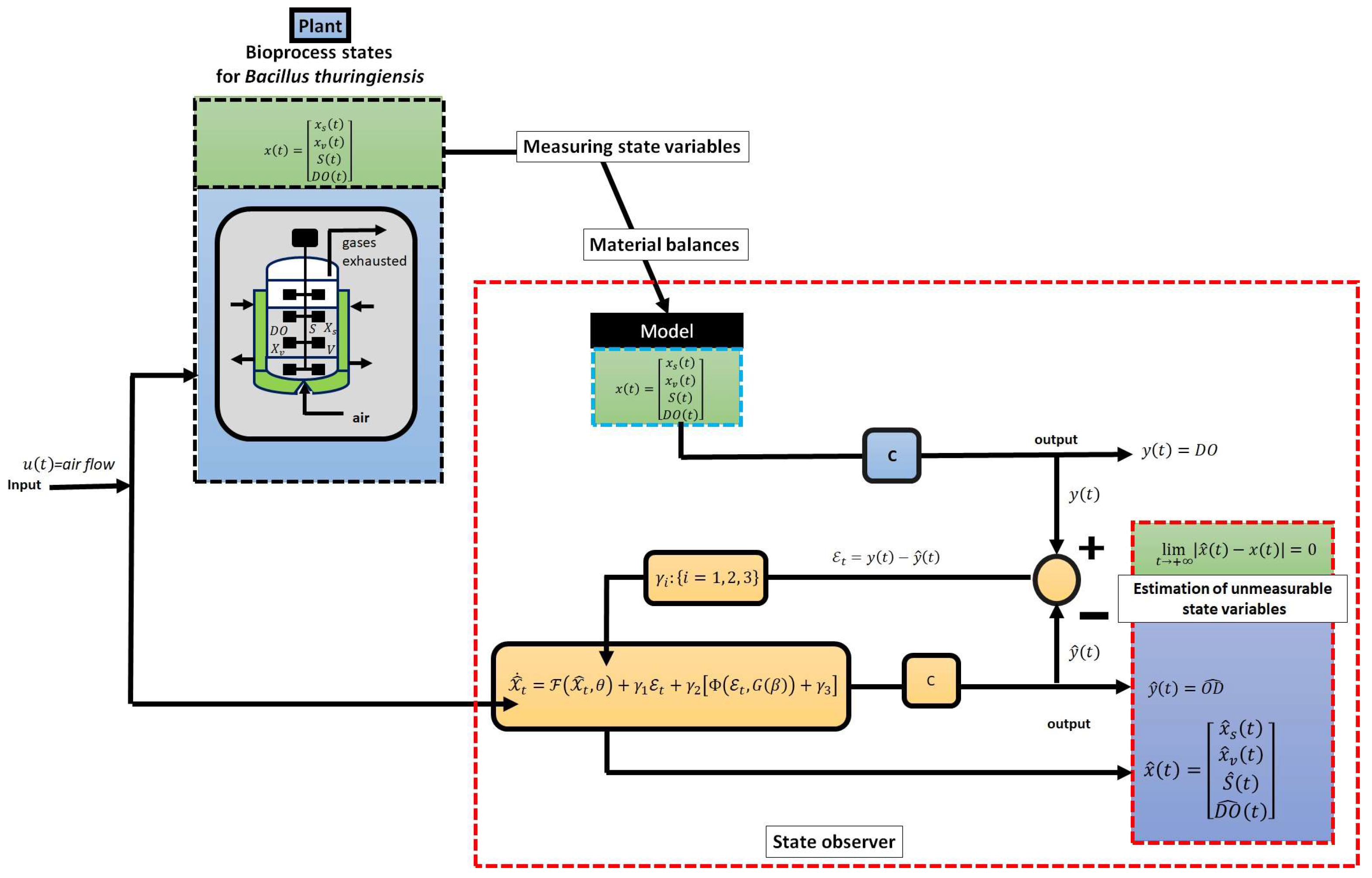

5. Observer Design

Proposed Observer Algorithm for B. thuringiensis Bioreactor

- (i)

- The first stage involves the proper definition of a model bioreactor, which involves process modeling and, hence, the general state–space dynamical model or the plant model.

- (ii)

- The observer must then be formulated in mathematical terms (Equation (14)).

6. Sketch of Proof of Proposition 2 (Equation (15))

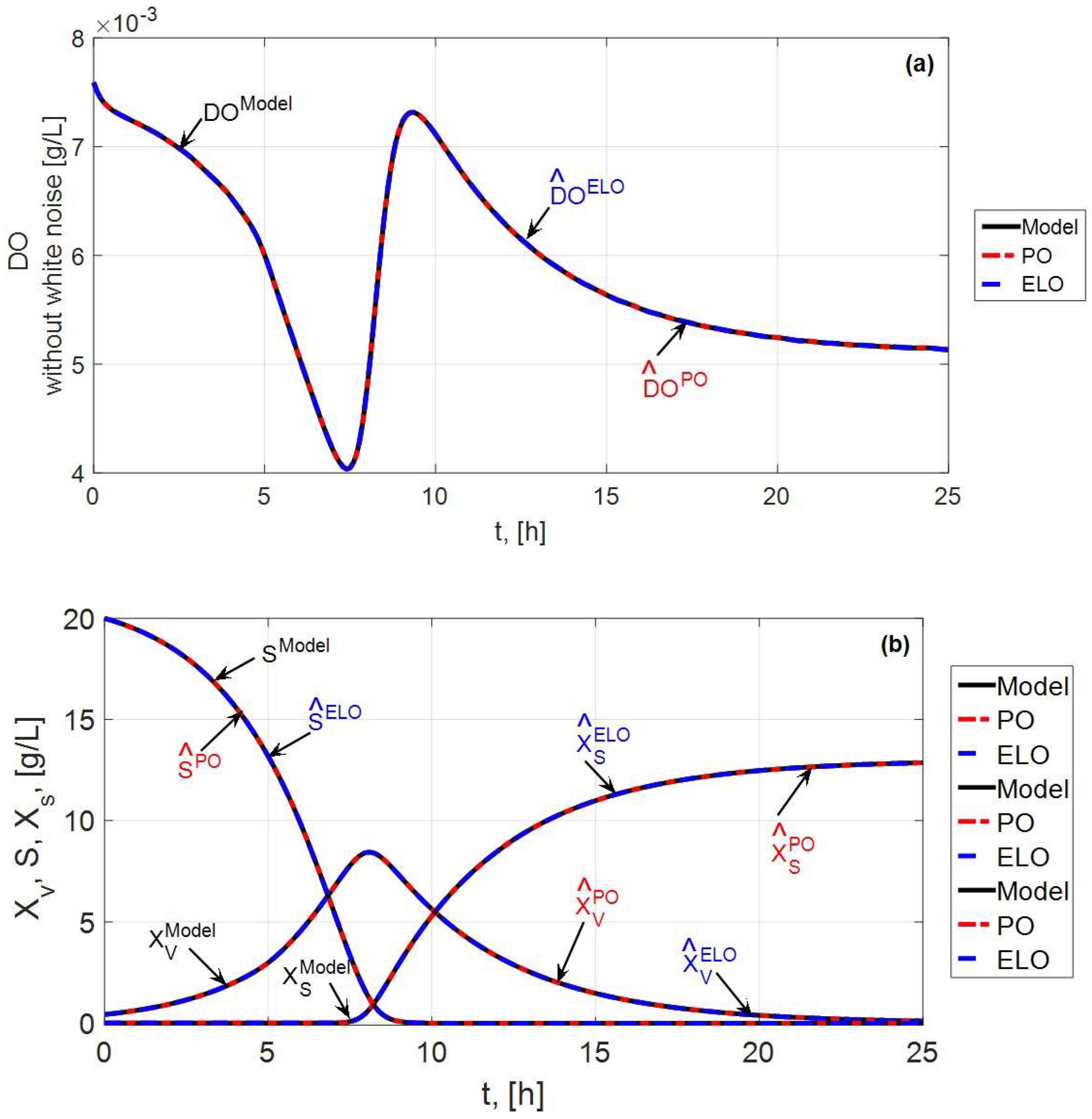

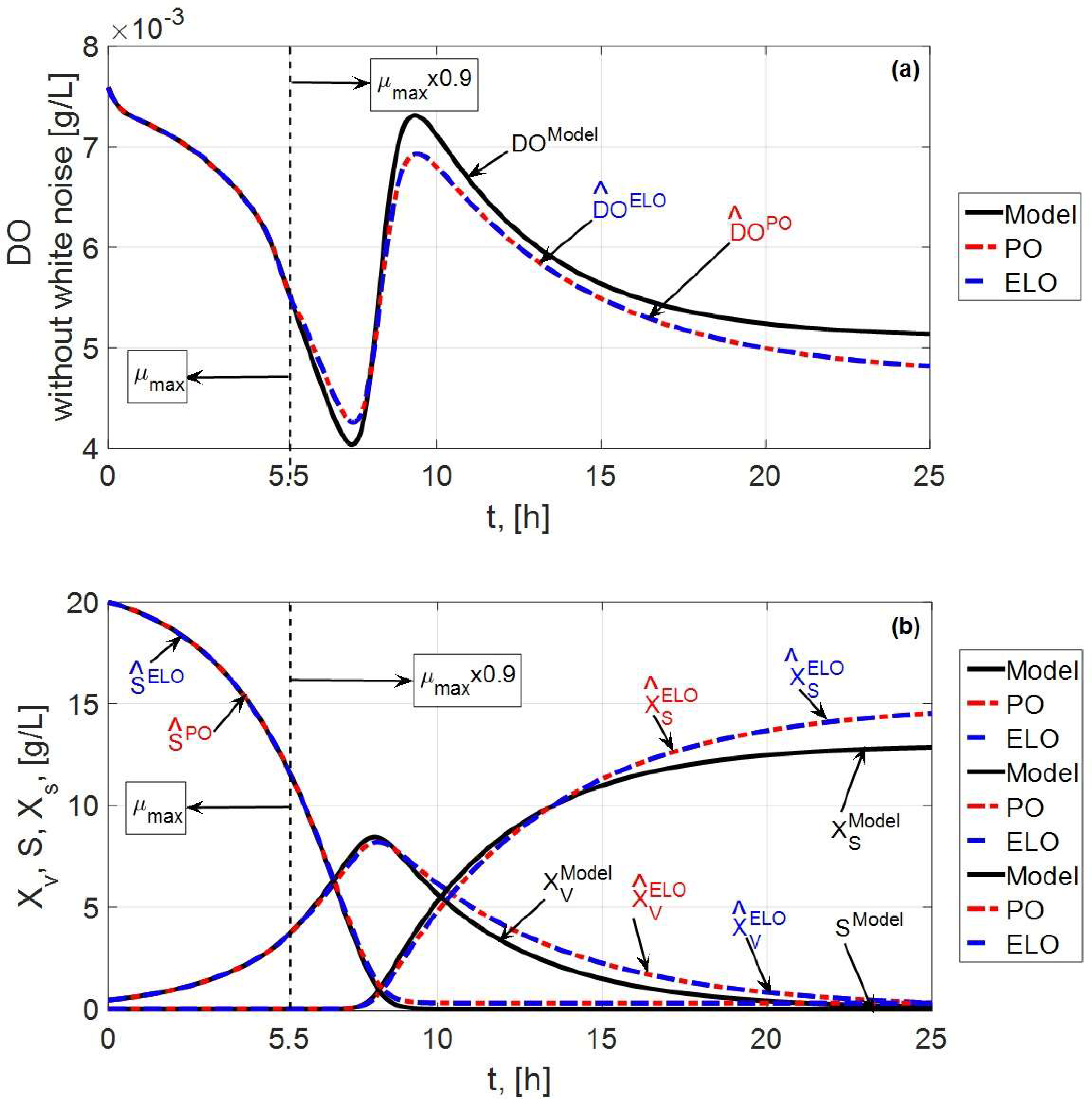

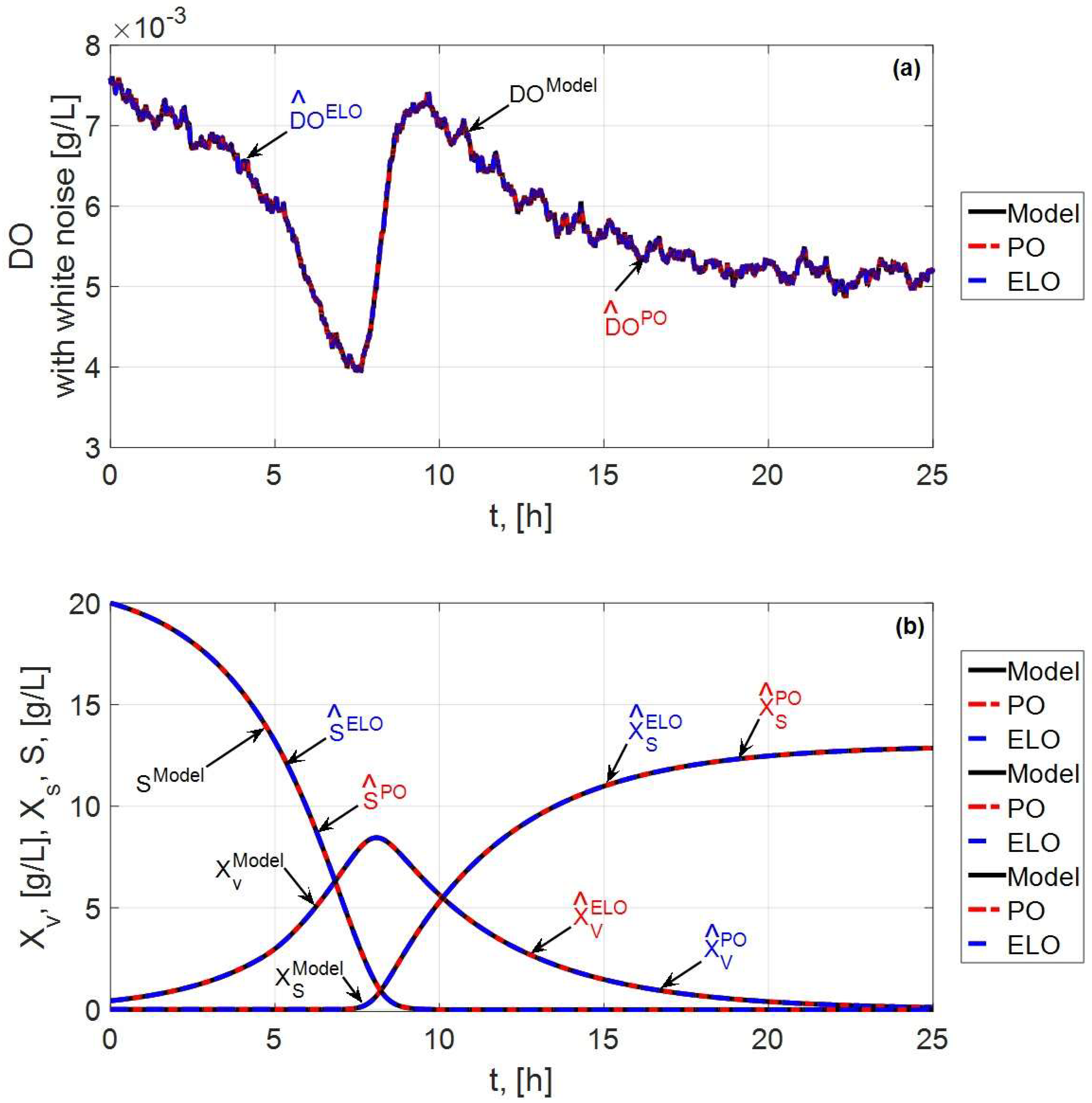

7. Numerical Results and Simulation Research

7.1. Dynamics of Bacillus thuringiensis Production Culture in a Batch Bioreactor

7.2. Observability Properties

7.3. Observer Design: Application to Bioreactor System for B. thuringiensis Production

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Nonlinear Observability Analysis

References

- Aguilar-López, R.; Alvarado-Santos, E.; Thalasso, F.; López-Pérez, P.A. Monitoring Ethanol Fermentation in Real Time by a Robust State Observer for Uncertainties. Chem. Eng. Technol. 2024, 47, 779–790. [Google Scholar] [CrossRef]

- Aguilar-López, R.; González-Viveros, I.; López-Pérez, P.A. Sinusoidal control strategy applied to continuous stirred-tank reactors: Asymptotic and exponential convergence. Can. J. Chem. Eng. 2024. [Google Scholar] [CrossRef]

- Aguilar-López, R.; Mata-Machuca, J.; Martinez-Guerra, R. On the Observability for a Class of Nonlinear (Bio)chemical Systems. Int. J. Chem. React. Eng. 2010, 8. [Google Scholar] [CrossRef]

- Alford, J.S. Bioprocess control: Advances and challenges. Comput. Chem. Eng. 2006, 30, 1464–1475. [Google Scholar] [CrossRef]

- Alvarez-Ramirez, J.; Meraz, M.; Monroy, O. Mathematical analysis of proportional-integral control for fixed bed bioreactors. J. Chem. Technol. Biotechnol. 1999, 74, 78–84. [Google Scholar] [CrossRef]

- Amicarelli, A.; di Sciascio, F.; Toibero, J.M.; Alvarez, H. Including dissolved oxygen dynamics into the Bt δ-endotoxins production process model and its application to process control. Braz. J. Chem. Eng. 2010, 27, 41–62. [Google Scholar] [CrossRef]

- Amicarelli, A.; Quintero, O.; di Sciascio, F. Behavior comparison for biomass observers in batch processes. Asia-Pac. J. Chem. Eng. 2014, 9, 81–92. [Google Scholar] [CrossRef]

- Arsov, A.; Gerginova, M.; Paunova-Krasteva, T.; Petrov, K.; Petrova, P. Multiple cry Genes in Bacillus thuringiensis Strain BTG Suggest a Broad-Spectrum Insecticidal Activity. Int. J. Mol. Sci. 2023, 24, 11137. [Google Scholar] [CrossRef]

- Belmonte-Izquierdo, R.; Carlos-Hernandez, S.; Sanchez, E.N. A new neural observer for an anaerobic bioreactor. Int. J. Neural Syst. 2010, 20, 75–86. [Google Scholar] [CrossRef] [PubMed]

- Bolton, L.; Smith, R. On the Role of Material Balances in the Synthesis of Overall Process Control Systems. Process Integr. Optim. Sustain. 2023, 7, 971–987. [Google Scholar] [CrossRef]

- Boniolo, F.S.; Rodrigues, R.C.; Prata, A.M.R.; López, M.L.; Jacinto, T.; da Silveira, M.M.; Berbert-Molina, M.A. Oxygen supply in Bacillus thuringiensis fermentations: Bringing new insights on their impact on sporulation and δ-endotoxin production. Appl. Microbiol. Biotechnol. 2012, 94, 625–636. [Google Scholar] [CrossRef] [PubMed]

- Bouraoui, I.; Farza, M.; Ménard, T.; Ben Abdennour, R.; M’Saad, M.; Mosrati, H. Observer design for a class of uncertain nonlinear systems with sampled outputs—Application to the estimation of kinetic rates in bioreactors. Automatica 2015, 55, 78–87. [Google Scholar] [CrossRef]

- Brunner, V.; Siegl, M.; Geier, D.; Becker, T. Challenges in the Development of Soft Sensors for Bioprocesses: A Critical Review. Front. Bioeng. Biotechnol. 2021, 9. [Google Scholar] [CrossRef] [PubMed]

- Caraballo, T.; López-de-la-Cruz, J.; Caraballo-Romero, V. Effects of real random perturbations on Monod and Haldane consumption functions in the chemostat model. Math. Comput. Simul. 2024, 218, 482–497. [Google Scholar] [CrossRef]

- Chandra, K.P.B.; Gu, D.-W. Control Systems and State Estimation. In Nonlinear Filtering; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 1–11. [Google Scholar] [CrossRef]

- Christie, L.; Rutherford, S.; Palmer, D.S.; Baker, M.J.; Butler, H.J. Bioprocess monitoring applications of an innovative ATR-FTIR spectroscopy platform. Front. Bioeng. Biotechnol. 2024, 12, 1349473. [Google Scholar] [CrossRef] [PubMed]

- Czyżniewski, M.; Łangowski, R. Robust asymptotic super twisting sliding mode observer for non-linear uncertain biochemical systems. J. Process Control. 2024, 136, 103192. [Google Scholar] [CrossRef]

- da Costa, A.C.; Lima, E.L.; Alves, T.L.M. Start-up Strategy for Continuous Bioreactors. Braz. J. Chem. Eng. 1997, 14, 167–177. [Google Scholar] [CrossRef]

- de Assis, A.J.; Filho, R.M. Soft sensors development for on-line bioreactor state estimation. Comput. Chem. Eng. 2000, 24, 1099–1103. [Google Scholar] [CrossRef]

- Demirtas, M.U.; Kolhatkar, A.; Kilbane Ii, J.J. Effect of Aeration and Agitation on Growth Rate of Thermus thermophilus in Batch Mode. J. Biosci. Bioeng. 2003, 95, 113–117. [Google Scholar] [CrossRef]

- Díaz Pacheco, A.; Dinorín-Téllez-Girón, J.; Martínez Montes, F.J.; Martínez Tolibia, S.E.; López y López, V.E. On-line monitoring of industrial interest Bacillus fermentations, using impedance spectroscopy. J. Biotechnol. 2022, 343, 52–61. [Google Scholar] [CrossRef] [PubMed]

- Du, S.; Wang, W.; Fu, H.; Wan, X. Fault Detection and State Estimation in Automatic Control. Appl. Sci. 2023, 13, 12936. [Google Scholar] [CrossRef]

- García-Mañas, F.; Guzmán, J.L.; Berenguel, M.; Acién, F.G. Biomass estimation of an industrial raceway photobioreactor using an extended Kalman filter and a dynamic model for microalgae production. Algal Res. 2019, 37, 103–114. [Google Scholar] [CrossRef]

- Grijalva-Hernández, F.; Peña-Caballero, V.; López-Pérez, P.A.; Aguilar-López, R. Estimation of plasmid concentration in batch culture of Escherichia coli DH5α via simple state observer. Chem. Pap. 2018, 72, 2589–2598. [Google Scholar] [CrossRef]

- Gu, J.; Ye, R.; Xu, Y.; Yin, Y.; Li, S.; Chen, H. A historical overview of analysis systems for Bacillus thuringiensis (Bt) Cry proteins. Microchem. J. 2021, 165, 106137. [Google Scholar] [CrossRef]

- Gupta, V.; Agarwal, R.P. Convergence Estimates in Approximation Theory; Springer: Cham, Switzerland, 2014; Volume 13. [Google Scholar]

- Gupta, M.; Kumar, H.; Kaur, S. Vegetative Insecticidal Protein (Vip): A Potential Contender from Bacillus thuringiensis for Efficient Management of Various Detrimental Agricultural Pests. Front. Microbiol. 2021, 12. [Google Scholar] [CrossRef]

- Hrnčiřík, P.; Kohout, J. A MATLAB-based simulator for the study of process control of fed-batch yeast fermentations. Educ. Chem. Eng. 2024, 49, 67–77. [Google Scholar] [CrossRef]

- Jin, X.-B.; Robert Jeremiah, R.J.; Su, T.-L.; Bai, Y.-T.; Kong, J.-L. The New Trend of State Estimation: From Model-Driven to Hybrid-Driven Methods. Sensors 2021, 21, 2085. [Google Scholar] [CrossRef] [PubMed]

- Joshi, H.; Jha, B.K. Generalized Diffusion Characteristics of Calcium Model with Concentration and Memory of Cells: A Spatiotemporal Approach. Iran. J. Sci. Technol. Trans. Sci. 2022, 46, 309–322. [Google Scholar] [CrossRef]

- Jurat-Fuentes, J.L.; Crickmore, N. Specificity determinants for Cry insecticidal proteins: Insights from their mode of action. J. Invertebr. Pathol. 2017, 142, 5–10. [Google Scholar] [CrossRef]

- Kazantzis, N.; Wright, R.A. Nonlinear observer design in the presence of delayed output measurements. Syst. Control. Lett. 2005, 54, 877–886. [Google Scholar] [CrossRef]

- Kemmer, A.; Fischer, N.; Wilms, T.; Cai, L.; Groß, S.; King, R.; Neubauer, P.; Cruz Bournazou, M.N. Nonlinear state estimation as tool for online monitoring and adaptive feed in high throughput cultivations. Biotechnol. Bioeng. 2023, 120, 3261–3275. [Google Scholar] [CrossRef] [PubMed]

- Koilybayeva, M.; Shynykul, Z.; Ustenova, G.; Abzaliyeva, S.; Alimzhanova, M.; Amirkhanova, A.; Turgumbayeva, A.; Mustafina, K.; Yeleken, G.; Raganina, K.; et al. Molecular Characterization of Some Bacillus Species from Vegetables and Evaluation of Their Antimicrobial and Antibiotic Potency. Molecules 2023, 28, 3210. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Kamle, M.; Borah, R.; Mahato, D.K.; Sharma, B. Bacillus thuringiensis as microbial biopesticide: Uses and application for sustainable agriculture. Egypt. J. Biol. Pest Control 2021, 31, 95. [Google Scholar] [CrossRef]

- Lim, H.C.; Shin, H.S. 6- Models Based on Mass Balance Equations. In Fed-Batch Cultures Principles and Application of Semi-Batch Bioreactors; Lim, H.C., Shin, H.S., Eds.; Cambridge University Press: Cambridge, UK, 2013; pp. 85–120. [Google Scholar] [CrossRef]

- Longhi, L.G.S.; Marcon, S.M.; Trierweiler, J.O.; Secchi, A.R. State estimation of an experimental bioreactor using the extended kalman filtering technology. IFAC Proc. Vol. 2002, 35, 379–382. [Google Scholar] [CrossRef]

- López-Pérez, P.A.; López-López, M.; Núñez-Colín, C.A.; Mukhtar, H.; Aguilar-López, R.; Peña-Caballero, V. A novel nonlinear sliding mode observer to estimate biomass for lactic acid production. Chem. Prod. Process Model. 2023, 18, 565–580. [Google Scholar] [CrossRef]

- Lyubenova, V.; Ignatova, M.; Zoteva, D.; Roeva, O. Model-Based Adaptive Control of Bioreactors—A Brief Review. Mathematics 2024, 12, 2205. [Google Scholar] [CrossRef]

- Mandenius, C.; Gustavsson, R. Mini-review: Soft sensors as means for PAT in the manufacture of bio-therapeutics. J. Chem. Technol. Biotechnol. 2015, 90, 215–227. [Google Scholar] [CrossRef]

- Marafioti, G.; Tebbani, S.; Beauvois, D.; Becerra, G.; Isambert, A.; Hovd, M. Unscented Kalman Filter state and parameter estimation in a photobioreactor for microalgae production. IFAC Proc. Vol. 2009, 42, 804–809. [Google Scholar] [CrossRef]

- Maschke, R.W.; John, G.T.; Eibl, D. Monitoring of Oxygen, pH, CO2, and Biomass in Smart Single-Use Shake Flasks. Chem. Ing. Tech. 2022, 94, 1995–2001. [Google Scholar] [CrossRef]

- Menara, T.; Baggio, G.; Bassett, D.S.; Pasqualetti, F. Conditions for Feedback Linearization of Network Systems. IEEE Control Syst. Lett. 2020, 4, 578–583. [Google Scholar] [CrossRef]

- Mohamed, M. High order Sliding control with High order observer applied on a bioreactor. Przegląd Elektrotechniczny 2024, 1, 188–193. [Google Scholar] [CrossRef]

- Mohd Ali, J.; Ha Hoang, N.; Hussain, M.A.; Dochain, D. Review and classification of recent observers applied in chemical process systems. Comput. Chem. Eng. 2015, 76, 27–41. [Google Scholar] [CrossRef]

- Moreno, J.A.; Alvarez, J. On the estimation problem of a class of continuous bioreactors with unknown input. J. Process Control 2015, 30, 34–49. [Google Scholar] [CrossRef]

- Moreno, J.A.; Dochain, D. Global observability and detectability analysis of uncertain reaction systems. IFAC Proc. Vol. 2005, 38, 37–42. [Google Scholar] [CrossRef]

- Noll, P.; Henkel, M. History and Evolution of Modeling in Biotechnology: Modeling & Simulation, Application and Hardware Performance. Comput. Struct. Biotechnol. J. 2020, 18, 3309–3323. [Google Scholar] [CrossRef]

- Oliveira, R.; Ferreira, E.C.; Feyo de Azevedo, S. Stability, dynamics of convergence and tuning of observer-based kinetics estimators. J. Process Control 2002, 12, 311–323. [Google Scholar] [CrossRef]

- Pappenreiter, M.; Sissolak, B.; Sommeregger, W.; Striedner, G. Oxygen Uptake Rate Soft-Sensing via Dynamic kLa Computation: Cell Volume and Metabolic Transition Prediction in Mammalian Bioprocesses. Front. Bioeng. Biotechnol. 2019, 7. [Google Scholar] [CrossRef] [PubMed]

- Peng, Q.; Yu, Q.; Song, F. Expression of cry genes in Bacillus thuringiensis biotechnology. Appl. Microbiol. Biotechnol. 2019, 103, 1617–1626. [Google Scholar] [CrossRef]

- Rahmatnejad, V.; Wei, Y.; Rao, G. Recent Developments in Bioprocess Monitoring Systems; Springer: Cham, Switzerland, 2023; pp. 39–66. Available online: https://www.researchgate.net/publication/377318420_Recent_Developments_in_Bioprocess_Monitoring_Systems (accessed on 25 November 2024).

- Richards, J.R.; Congalidis, J.P. Measurement and control of polymerization reactors. Comput. Chem. Eng. 2006, 30, 1447–1463. [Google Scholar] [CrossRef]

- Rómoli, S.; Amicarelli, A.N.; Ortiz, O.A.; Scaglia, G.J.E.; di Sciascio, F. Nonlinear control of the dissolved oxygen concentration integrated with a biomass estimator for production of Bacillus thuringiensis δ-endotoxins. Comput. Chem. Eng. 2016, 93, 13–24. [Google Scholar] [CrossRef]

- Roubíček, T.; Valášek, M. Optimal control of causal differential–algebraic systems. J. Math. Anal. Appl. 2002, 269, 616–641. [Google Scholar] [CrossRef]

- Rowe, G.E. Central Metabolism of Bacillus Thuringiensis During Growth and Sporulation. Digitized Thesis, Western University, London, ON, Canada, 1990. Available online: https://ir.lib.uwo.ca/digitizedtheses/1987 (accessed on 25 November 2024).

- Rowe, G.E.; Margaritis, A.; Wei, N. Specific oxygen uptake rate variations during batch fermentation of Bacillus thuringiensis subspecies kurstaki HD-1. Biotechnol. Prog. 2003, 19, 1439–1443. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Torres, J.D.; Jimenez-Rodriguez, E.; Isaza, J.A.; Botero, H. An equivalent control-based observer for biomass in a batch process. In Proceedings of the 2017 IEEE 3rd Colombian Conference on Automatic Control (CCAC), Cartagena, Colombia, 18–20 October 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Sharabiany, M.G.; Ebrahimkhani, S.; Lataire, J. Nonlinear continuous-time system identification by linearization around a time-varying setpoint. Int. J. Robust Nonlinear Control. 2024. [Google Scholar] [CrossRef]

- Singh, D.; Samiksha; Thayil, S.M.; Sohal, S.K.; Kesavan, A.K. Exploration of insecticidal potential of Cry protein purified from Bacillus thuringiensis VIID1. Int. J. Biol. Macromol. 2021, 174, 362–369. [Google Scholar] [CrossRef]

- Soberón, M.; Monnerat, R.; Bravo, A. Mode of Action of Cry Toxins from Bacillus thuringiensis and Resistance Mechanisms. In Microbial Toxins; Springer: Dordrecht, The Netherlands, 2016; pp. 1–13. [Google Scholar] [CrossRef]

- Sun, Y.; Dong, S.; Zhou, W.; Guo, L.; Guo, G.-L.; Zhang, X. A Comprehensive Review of Secondary Metabolites with Antialgal Activity from Marine Macroalgae against Red Tide Microalgae. J. Coast. Res. 2019, 93, 475. [Google Scholar] [CrossRef]

- Valero, C.E.; Bakosova, M. Classic Methodologies in Control of a Yeast Fermentation Bioreactor. In Proceedings of the 2021 23rd International Conference on Process Control (PC), Strbske Pleso, Slovakia, 1–4 June 2021; pp. 200–205. [Google Scholar] [CrossRef]

- Wei, Y.; Jiao, Y.; An, D.; Li, D.; Li, W.; Wei, Q. Review of Dissolved Oxygen Detection Technology: From Laboratory Analysis to Online Intelligent Detection. Sensors 2019, 19, 3995. [Google Scholar] [CrossRef] [PubMed]

- Winter, M.; Achleitner, L.; Satzer, P. Soft sensor for viable cell counting by measuring dynamic oxygen uptake rate. New Biotechnol. 2024, 83, 16–25. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.; Gu, Z.; Park, J.H.; Xie, X.; Sun, W. Distributed Cooperative Voltage Control of Networked Islanded Microgrid via Proportional-Integral Observer. IEEE Trans. Smart Grid 2024, 15, 5981–5991. [Google Scholar] [CrossRef]

- Zhu, Y.; Dong, Z.; Huang, X. Neural Network Extended State-Observer. In Proceedings of the 2022 China Automation Congress (CAC), Xiamen, China, 25–27 November 2022; pp. 5104–5109. [Google Scholar] [CrossRef]

- Zuluaga-Bedoya, C.C.; Amicarelli, A.; Gómez, L.M.; di Sciascio, F. Bacillus thuringiensis process design using state controllability index. In Proceedings of the 2015 XVI Workshop on Information Processing and Control (RPIC), Cordoba, Argentina, 6–9 October 2015; pp. 1–6. [Google Scholar] [CrossRef]

| Observer Design (Type) | Microorganism | Bioprocesses | Reference |

|---|---|---|---|

| Kalman filter | Kluyveromyces marxianus yeast (β-galactosidase enzyme) | Biochemical reactor | [23] |

| Extended Kalman filter (EKF) | Microalgae | Biotechnological processes (photobioreactors) | [24] |

| Unscented Kalman filter (UKF) (state and parameter estimation) | Microalgae (biomass estimation) | Biotechnological processes (photobioreactors) | [25] |

| Cubature Kalman filter (CKF) | Estimation for penicillin | Biotechnological processes | [26] |

| Linear observer | Biological reactor | [27] | |

| Nonlinear observer | Yeats | Fed-batch reactor for ethanol production | [28,29] |

| Sliding-mode observer | δ-endotoxin production of Bacillus thuringiensis | Batch bioprocess | [30,31] |

| Neural observer | Anaerobic digestion process | Anaerobic process for paper mills’ effluent treatment | [32] |

| Adaptive observer | Estimation of the biomass concentration (Escherichia coli) | Sigma-Point Kalman filter | [33] |

| Modeling Biotechnology: modeling and simulation | In bioprocess | Different bioprocesses | [34,35] |

| Control of a bioreactor | Yeast fermentation | [11] |

| Symbol | Description | Value | Units |

|---|---|---|---|

| Substrate concentration | |||

| Dissolved oxygen | |||

| Time | |||

| Sporulated cells’ concentration | |||

| Vegetative cells’ concentration | |||

| Total cell concentration | |||

| Specific growth rate | |||

| Maximum specific growth rate | |||

| Maintenance constant | |||

| Kinetic constant representing the spore formation | |||

| Cell death specific rate | |||

| Saturation constant | |||

| Growth yield | |||

| Inlet volumetric flow rate of air | 1800 | ||

| Volumetric oxygen transfer coefficient | |||

| Maximum kinetic constant representing the spore formation | 0.5 | ||

| Exponential parameter for spore formation | 1 | ||

| Parameter for spore formation | 1 | ||

| Maximum death cell specific rate | 0.1 | ||

| Exponential parameter for death rate | 5 | ||

| Parameter for death rate | 4.9 | ||

| saturation concentration (OD concentration in equilibrium with the oxygen partial pressure of the gaseous phase) | 0.00759 | ||

| Oxygen consumption constant by growth | |||

| Oxygen consumption constant for maintenance | |||

| Ventilation constant |

| Assumption/Definition | Remark | Reference |

|---|---|---|

| A2. | It is a realistic assumption based on a mass conservation principle. | [58] |

| A3. | Select the parameters g1 and g2 to obey the restriction. | [56,58] |

| D. | Dynamic error. |

| Definition No. | ||

|---|---|---|

| 1 | ||

| 2 |

| [g/L] | [g/L h] Slope of the Line/Coefficient of Determination ) | [g/L h] Slope of the Line/Coefficient of Determination ) | |

|---|---|---|---|

| Process lines (slope of the line in Figure 4) | Exponential growth (first stage, see Figure 4) 2,3 | Sporulation (second stage, see Figure 4) 2,3 | Reference |

Batch | In this work (see Figure 4) | ||

Batch | In this work (see Figure 4) | ||

Batch | In this work (see Figure 4) | ||

Batch | In this work (see Figure 4) | ||

| Run 10 12 | [63] | ||

| Run 11 12 | [63] | ||

| Run 12 12 | [63] |

|

Measurement (Equation (5)) | (Equation (8)) | ||

|---|---|---|---|

| 1 | 4 | ||

| 2 | 4 | ||

| 3 | 4 | ||

| 4 | 4 | ||

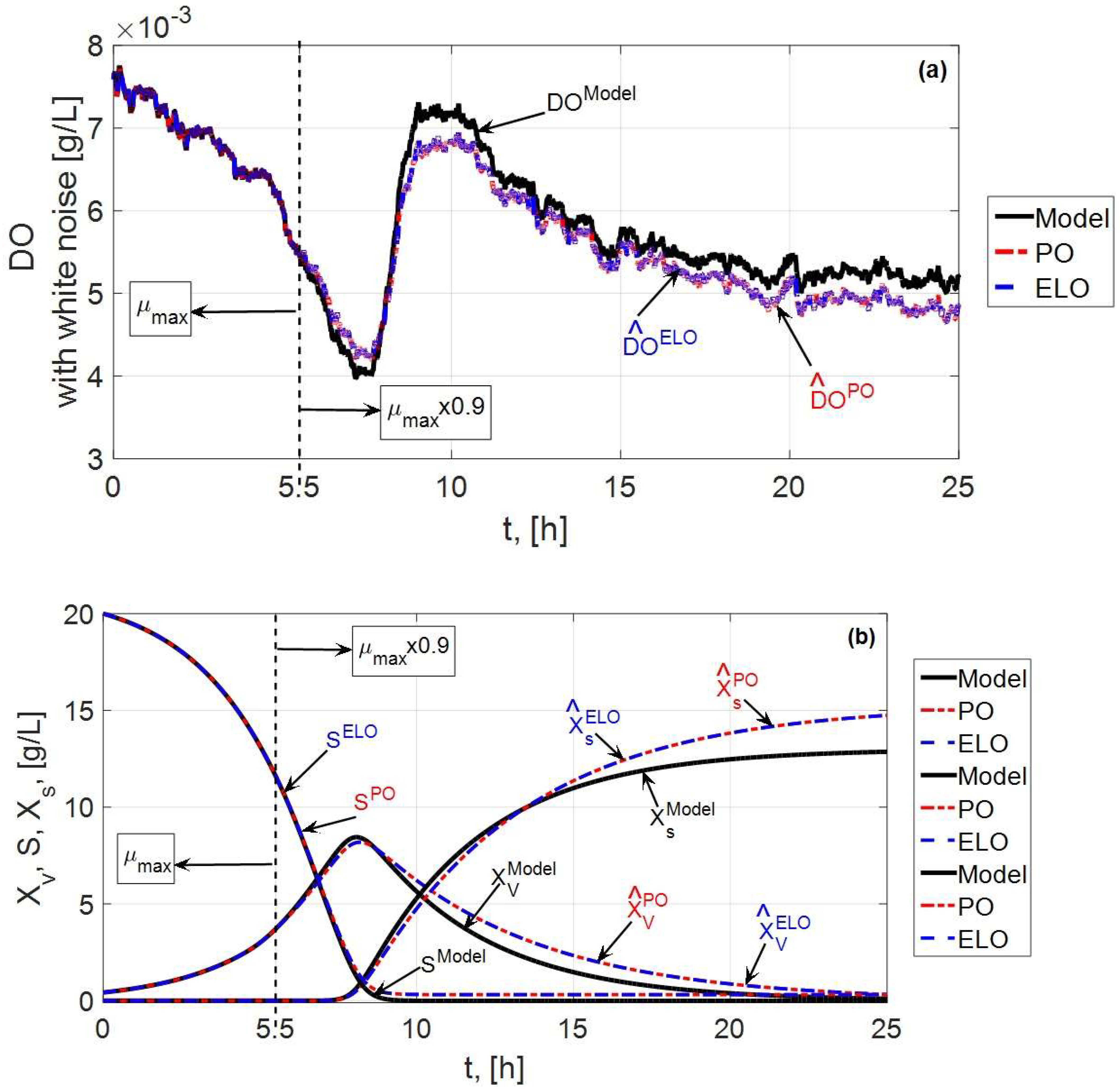

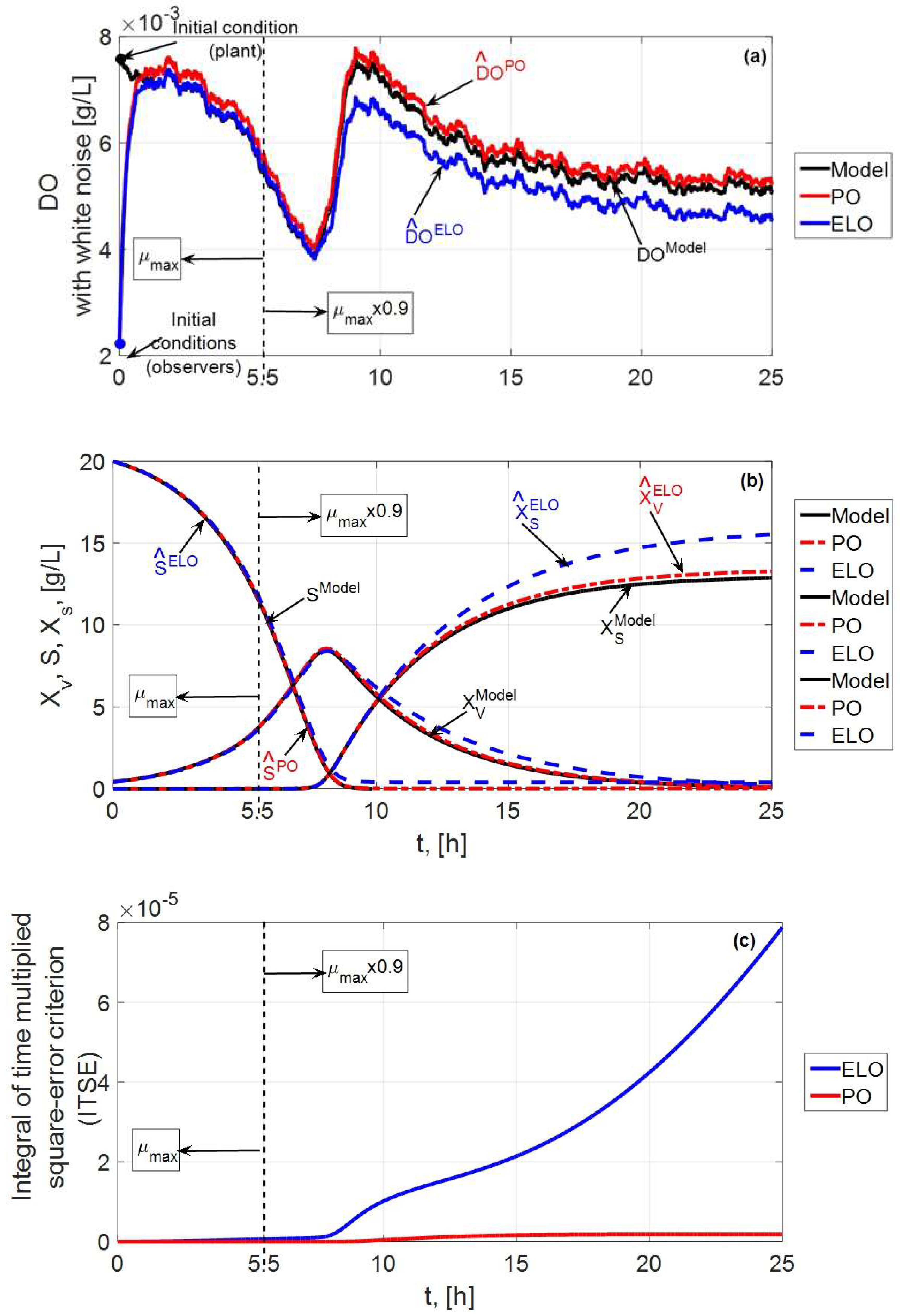

| Test Code | Figure No. | System (Estimator) |

Parameter Disturbance Nominal Value 0.53 1/h |

Initial Conditions: | |||

|---|---|---|---|---|---|---|---|

| T1 | 6a,b | Model | |||||

| ELO | |||||||

| PO | |||||||

| T2 | 7a,b | Model | |||||

| ELO | |||||||

| PO | |||||||

| T3 | 8a,b | Model | |||||

| ELO | |||||||

| PO | |||||||

| T4 | 9a,b | Model | |||||

| ELO | |||||||

| PO | |||||||

| T5 | 10a–c | Model | |||||

| ELO | |||||||

| PO | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zárate-Castrejón, J.L.; López-Pérez, P.A.; López-López, M.; Núñez-Colín, C.A.; Veloz-García, R.A.; Mukhtar, H.; Peña-Caballero, V. Estimation of Sporulated Cell Concentration of Bacillus thuringiensis in a Batch Biochemical Reactor via Simple State Observers. Mathematics 2024, 12, 3996. https://doi.org/10.3390/math12243996

Zárate-Castrejón JL, López-Pérez PA, López-López M, Núñez-Colín CA, Veloz-García RA, Mukhtar H, Peña-Caballero V. Estimation of Sporulated Cell Concentration of Bacillus thuringiensis in a Batch Biochemical Reactor via Simple State Observers. Mathematics. 2024; 12(24):3996. https://doi.org/10.3390/math12243996

Chicago/Turabian StyleZárate-Castrejón, José Luis, Pablo A. López-Pérez, Milagros López-López, Carlos A. Núñez-Colín, Rafael A. Veloz-García, Hamid Mukhtar, and Vicente Peña-Caballero. 2024. "Estimation of Sporulated Cell Concentration of Bacillus thuringiensis in a Batch Biochemical Reactor via Simple State Observers" Mathematics 12, no. 24: 3996. https://doi.org/10.3390/math12243996

APA StyleZárate-Castrejón, J. L., López-Pérez, P. A., López-López, M., Núñez-Colín, C. A., Veloz-García, R. A., Mukhtar, H., & Peña-Caballero, V. (2024). Estimation of Sporulated Cell Concentration of Bacillus thuringiensis in a Batch Biochemical Reactor via Simple State Observers. Mathematics, 12(24), 3996. https://doi.org/10.3390/math12243996