An Output Cooperative Controller for a Hydraulic Support Multi-Cylinder System Based on Neural Network Compensation

Abstract

1. Introduction

2. System Modeling and Problem Formulation

2.1. System Description

2.2. Dynamic Model

2.3. Dynamic Model

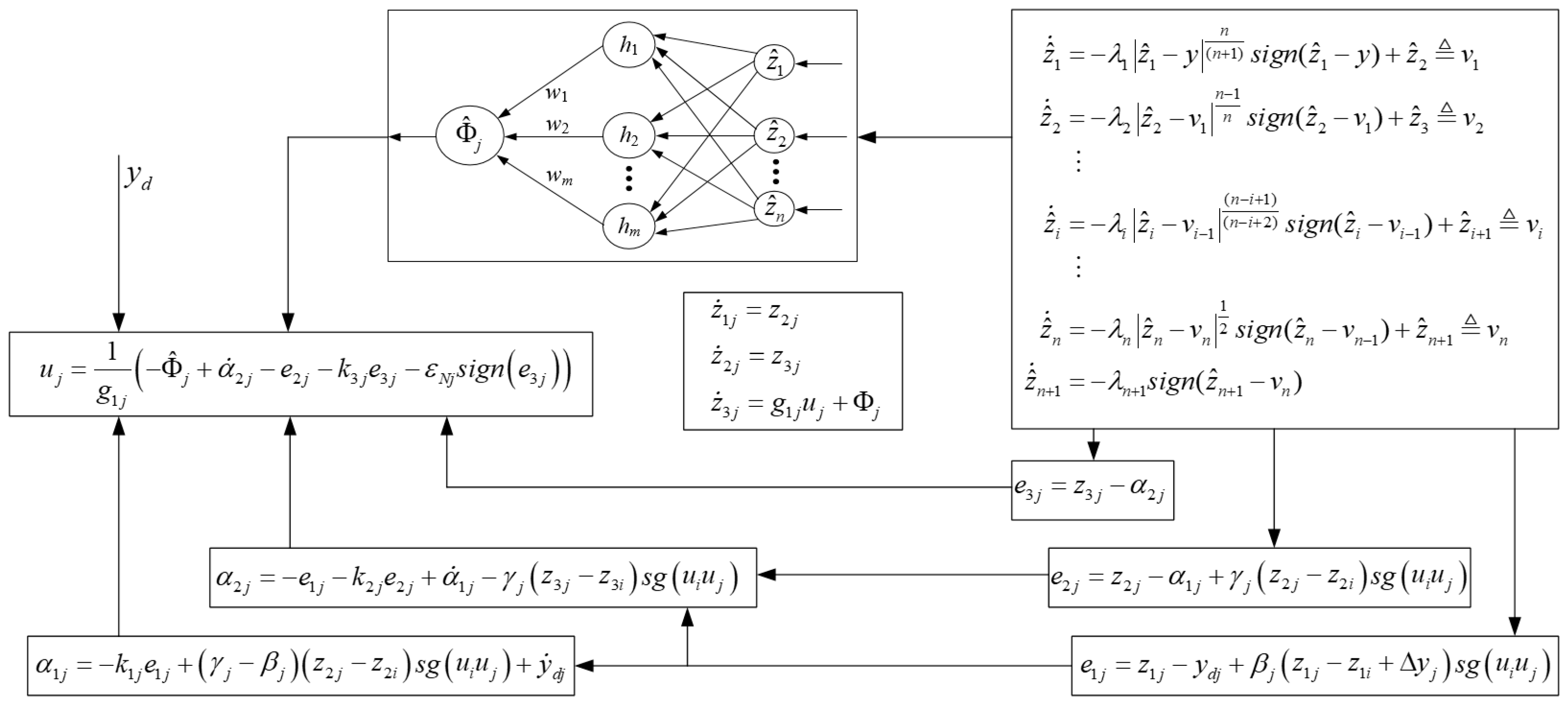

3. Design and Stability Analysis of the Controller

3.1. State Observer Design

3.2. Disturbance Observer Design

3.3. Controller Design

3.4. Stability Analysis

4. Simulation and Experimental Results

4.1. Simulation Results

4.2. Experimental Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, Y.; Zhang, Z.; Liu, Q.; Nie, Z.; Gong, D. Decoupling-based adaptive sliding-mode synchro-position control for a dual-cylinder driven hydraulic support with different pipelines. ISA Trans. 2022, 123, 357–371. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Ding, H.; Zhao, J.; Li, R. Neural network-based output synchronization control for multi-actuator system. Int. J. Adapt. Control Signal Process. 2022, 36, 1155–1171. [Google Scholar] [CrossRef]

- Yang, G.; Yao, J. High-precision motion servo control of double-rod electro-hydraulic actuators with exact tracking performance. ISA Trans. 2020, 103, 266–279. [Google Scholar] [CrossRef] [PubMed]

- Qian, P.; Pu, C.; Liu, L.; Li, X.; Zhang, B.; Gu, Z.; Meng, D. Development of a new high-precision friction test platform and experimental study of friction characteristics for pneumatic cylinders. Meas. Sci. Technol. 2022, 33, 065001. [Google Scholar] [CrossRef]

- Guo, Q.; Chen, Z. Neural adaptive control of single-rod electrohydraulic system with lumped uncertainty. Mech. Syst. Signal Process. 2021, 146, 106869. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, J.; Wang, H.; Ding, H. Output feedback control for the driving cylinder of hydraulic support with error constraint. J. Vib. Control 2023, 29, 3126–3136. [Google Scholar] [CrossRef]

- Yao, J.; Deng, W.; Sun, W. Precision motion control for electro-hydraulic servo systems with noise alleviation: A desired compensation adaptive approach. IEEE/ASME Trans. Mechatron. 2017, 22, 1859–1868. [Google Scholar] [CrossRef]

- Maghareh, A.; Silva, C.; Dyke, S. Parametric model of servo-hydraulic actuator coupled with a nonlinear system: Experimental validation. Mech. Syst. Signal Process. 2018, 104, 663–672. [Google Scholar] [CrossRef]

- Dong, H.; Yang, X. Learning-based super-twisting sliding-mode control for space circumnavigation mission with suboptimal reaching under input constraints. Int. J. Robust Nonlinear Control 2022, 32, 5328–5349. [Google Scholar] [CrossRef]

- Dong, H.; Yang, X.; Basin, M. Practical tracking of permanent magnet linear motor via logarithmic sliding mode control. IEEE-ASME Trans. Mechatron. 2022, 27, 4112–4121. [Google Scholar] [CrossRef]

- Yao, B.; Bu, F.; Chiu, G. Non-linear adaptive robust control of electro-hydraulic systems driven by double-rod actuators. Int. J. Control 2001, 74, 761–775. [Google Scholar] [CrossRef]

- Deng, W.; Yao, J. Extended-state-observer-based adaptive control of electrohydraulic servomechanisms without velocity measurement. IEEE-ASME Trans. Mechatron. 2019, 25, 1151–1161. [Google Scholar] [CrossRef]

- Yao, J.; Jiao, Z.; Ma, D. Extended-state-observer-based output feedback nonlinear robust control of hydraulic systems with backstepping. IEEE Trans. Ind. Electron. 2014, 61, 6285–6293. [Google Scholar] [CrossRef]

- Deng, W.; Yao, J.; Ma, D. Robust adaptive precision motion control of hydraulic actuators with valve dead-zone compensation. ISA Trans. 2017, 70, 269–278. [Google Scholar] [CrossRef] [PubMed]

- Guo, Q.; Yin, J.; Yu, T.; Jiang, D. Coupled-disturbance-observer-based position tracking control for a cascade electro-hydraulic system. ISA Trans. 2017, 68, 367–380. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhao, J.; Ding, H.; Zhang, H. Nonlinear cascade control of an electro-hydraulic actuator with large payload variation. Asian J. Control 2023, 25, 101–113. [Google Scholar] [CrossRef]

- Won, D.; Kim, W.; Shin, D.; Chung, C. High-gain disturbance observer-based backstepping control with output tracking error constraint for electro-hydraulic systems. IEEE Trans. Control Syst. Technol. 2015, 23, 787–795. [Google Scholar] [CrossRef]

- Guo, K.; Wei, J.; Fang, J.; Feng, R.; Wang, X. Position tracking control of electro-hydraulic single-rod actuator based on an extended disturbance observer. Mechatronics 2015, 27, 47–56. [Google Scholar] [CrossRef]

- Na, J.; Jing, B.; Huang, Y.; Gao, G.; Zhang, C. Unknown system dynamics estimator for motion control of nonlinear robotic systems. IEEE Trans. Ind. Electron. 2020, 67, 3850–3859. [Google Scholar] [CrossRef]

- Han, J. From PID to active disturbance rejection control. IEEE Trans. Ind. Electron. 2009, 56, 900–906. [Google Scholar] [CrossRef]

- Deng, W.; Yao, J.; Wang, Y.; Yang, X.; Chen, J. Output feedback backstepping control of hydraulic actuators with valve dynamics compensation. Mech. Syst. Signal Process. 2021, 158, 107769. [Google Scholar] [CrossRef]

- Bakhshande, F.; Soeffker, D. Proportional-integral-observer-based backstepping approach for position control of a hydraulic differential cylinder system with model uncertainties and disturbances. J. Dyn. Syst. Meas. Control-Trans. ASME 2018, 140, 121006. [Google Scholar] [CrossRef]

- Palli, G.; Strano, S.; Terzo, M. Sliding-mode observers for state and disturbance estimation in electro-hydraulic systems. Control Eng. Pract. 2018, 74, 58–70. [Google Scholar] [CrossRef]

- Guo, Q.; Yu, T.; Jiang, D. High-gain observer-based output feedback control of single-rod electro-hydraulic actuator. IET Contr. Theory Appl. 2015, 9, 2395–2404. [Google Scholar] [CrossRef]

- Won, D.; Kim, W.; Tomizuka, M. High-gain-observer-based integral sliding mode control for position tracking of electrohydraulic servo systems. IEEE-ASME Trans. Mechatron. 2017, 22, 2695–2704. [Google Scholar] [CrossRef]

- Yao, J.; Deng, W. Active disturbance rejection adaptive control of hydraulic servo systems. IEEE Trans. Ind. Electron. 2017, 64, 8023–8032. [Google Scholar] [CrossRef]

- Chen, Z.; Guo, Q.; Li, T.; Yan, Y.; Jiang, D. Gait prediction and variable admittance control for lower limb exoskeleton with measurement delay and extended-state-observer. IEEE Trans. Neural Netw. Learn. Syst. 2017, 64, 8693–8706. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.; Yao, J.; Ullah, N. Neuroadaptive control of saturated nonlinear systems with disturbance compensation. ISA Trans. 2022, 122, 49–62. [Google Scholar] [CrossRef]

- Na, J.; Li, Y.; Huang, Y.; Gao, G.; Chen, Q. Output feedback control of uncertain hydraulic servo systems. IEEE Trans. Ind. Electron. 2020, 67, 490–500. [Google Scholar] [CrossRef]

- Na, J.; Wang, S.; Liu, Y.; Huang, Y.; Ren, X. Finite-time convergence adaptive neural network control for nonlinear servo systems. IEEE Trans. Cybern. 2020, 50, 2568–2579. [Google Scholar] [CrossRef]

- Yang, X.; Zheng, X.; Chen, Y. Position tracking control law for an electro-hydraulic servo system based on backstepping and extended differentiator. IEEE-ASME Trans. Mechatron. 2017, 2, 132–140. [Google Scholar] [CrossRef]

- Levant, A. Higher-order sliding modes, differentiation and output-feedback control. Int. J. Control 2003, 76, 924–941. [Google Scholar] [CrossRef]

- Yang, G.; Yao, J. Nonlinear adaptive output feedback robust control of hydraulic actuators with largely unknown modeling uncertainties. Appl. Math. Model. 2020, 79, 824–842. [Google Scholar] [CrossRef]

- Janaideh, M.; Boker, A.; Rakotondrabe, M. Output-feedback control of precision motion systems with uncertain nonlinearities. Mech. Syst. Signal Process. 2021, 153, 107483. [Google Scholar] [CrossRef]

- Zhang, L.; Feng, S.; Luo, M.; Ji, A. A cascaded pushing displacement estimation approach for hydraulic powered roof support based on multi-segmental Kalman filter. Curr. Sci. 2019, 117, 1585–1597. [Google Scholar] [CrossRef]

- Wang, B.; Xie, J.; Wang, X.; Liu, S.; Liu, Y. A new method for measuring the attitude and straightness of hydraulic support groups based on point clouds. Arab. J. Sci. Eng. 2021, 46, 11739–11757. [Google Scholar] [CrossRef]

- Ge, X.; Xie, J.; Wang, X.; Liu, Y.; Shi, H. A virtual adjustment method and experimental study of the support attitude of hydraulic support groups in propulsion state. Measurement 2020, 158, 107743. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, J.; Ding, H.; Zhang, H. Output feedback control of electro-hydraulic asymmetric cylinder system with disturbances rejection. J. Frankl. Inst.-Eng. Appl. Math. 2021, 358, 1839–1859. [Google Scholar] [CrossRef]

- Levant, A. Robust exact differentiation via sliding mode technique. Automatica 1998, 34, 379–384. [Google Scholar] [CrossRef]

- Na, J.; Huang, Y.; Wu, X.; Su, S.; Li, G. Adaptive finite-time fuzzy control of nonlinear active suspension systems with input delay. IEEE Trans. Cybern. 2020, 50, 2639–2650. [Google Scholar] [CrossRef]

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| 1.9625 × 10−3 | 50 | ||

| 1.000875 × 10−3 | 4500 | ||

| 5 × 106 | 7 × 108 | ||

| 0 | 4 × 10−13 | ||

| 3 × 10−3 | 8.43 × 10−8 | ||

| 3 × 10−3 |

| Indexes | Cylinder 1 | Cylinder 2 | Cylinder 3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| PI | 2.87 | 4.31 | 0.59 | 2.87 | 4.1 | 0.6 | 2.64 | 3.99 | 0.57 |

| NNOC | 0.51 | 3.95 | 0.74 | 0.55 | 4.44 | 0.89 | 0.44 | 2.31 | 0.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhao, J.; Zhang, H.; Wang, H.; Wang, J. An Output Cooperative Controller for a Hydraulic Support Multi-Cylinder System Based on Neural Network Compensation. Mathematics 2024, 12, 1866. https://doi.org/10.3390/math12121866

Wang Y, Zhao J, Zhang H, Wang H, Wang J. An Output Cooperative Controller for a Hydraulic Support Multi-Cylinder System Based on Neural Network Compensation. Mathematics. 2024; 12(12):1866. https://doi.org/10.3390/math12121866

Chicago/Turabian StyleWang, Yunfei, Jiyun Zhao, He Zhang, Hao Wang, and Jinxin Wang. 2024. "An Output Cooperative Controller for a Hydraulic Support Multi-Cylinder System Based on Neural Network Compensation" Mathematics 12, no. 12: 1866. https://doi.org/10.3390/math12121866

APA StyleWang, Y., Zhao, J., Zhang, H., Wang, H., & Wang, J. (2024). An Output Cooperative Controller for a Hydraulic Support Multi-Cylinder System Based on Neural Network Compensation. Mathematics, 12(12), 1866. https://doi.org/10.3390/math12121866