Abstract

Order picking is a crucial operation in the storage industry, with a significant impact on storage efficiency and cost. Responding quickly to customer demands and shortening picking time is crucial given the random nature of order arrival times and quantities. This paper presents a study on the order-picking process in a distribution center, employing a “parts-to-picker” system, based on dynamic order batching and task optimization. Firstly, dynamic arriving orders with uncertain information are transformed into static picking orders with known information. A new method of the hybrid time window is proposed by combining fixed and variable time windows, and an order consolidation batch strategy is established with the aim of minimizing the number of target shelves for picking. A heuristic algorithm is designed to select a shelf selection model, taking into account the constraint condition that the goods on the shelf can meet the demand of the selection list. Subsequently, task division of multi-AGV is carried out on the shelf to be picked, and the matching between the target shelf and the AGVs, as well as the order of the AGVs to complete the task of picking, is determined. A scheduling strategy model is constructed to consider the task completion time as the incorporation of moving time, queuing time, and picking time, with the shortest task completion time as the objective function and AGV task selection as the decision variable. The improved ant colony algorithm is employed to solve the problem. The average response time of the order batching algorithm based on a hybrid time window is 4.87 s, showing an improvement of 22.20% and 40.2% compared to fixed and variable time windows, respectively. The convergence efficiency of the improved ant colony algorithm in AGV task allocation is improved four-fold, with a better convergence effect. By pre-selecting the nearest picking station for the AGVs, the multi-AGV picking system can increase the queuing time. Therefore, optimizing the static picking station selection and dynamically selecting the picking station queue based on the queuing situation are proposed. The Flexsim simulation results show that the queue-waiting and picking completion times are reduced to 34% of the original, thus improving the flexibility of the queuing process and enhancing picking efficiency.

Keywords:

multi-AGV dynamic order batch; task assignment; picking table; ant colony optimization; flexsim simulation MSC:

90

1. Introduction

In recent years, the rapid growth of the e-commerce industry has propelled the logistics sector to expand at an unprecedented rate, thereby presenting an elevated demand for logistics service providers. With the rise in order demand, orders are increasingly characterized by small batch sizes, multiple frequencies, small quantities, multiple species, and short cycles, necessitating a faster processing rate for warehousing data and intelligent picking systems [1]. These requirements have motivated the need for innovative solutions to address the challenges associated with e-commerce logistics, thereby promoting the adoption of intelligent and automated warehousing systems. With the development of science and technology, more and more enterprises are paying attention to the “parts to picker” picking system. Compared with the traditional sorting method, the accuracy rate of the “parts to picker” picking system can reach 99.95–99.99%, and the sorting speed is 8–15 times that of the former [2]. In addition, “parts to picker” picking systems have the advantage of efficient storage that takes advantage of dense storage [3,4]. In order to ensure the needs of safe storage and picking needs, the “parts to picker” storage picking system space is more than 2 m below, and the utilization rate is 15–25% [5]. The “parts to picker” picking system adopts intensive storage, and the space utilization rate can reach 45–65%, about four times that of the traditional storage picking system. On this basis, optimization theory and set theory are used to study the dynamic batching problem and task allocation problem in the field of warehousing [6]. Considering the dynamics of the environment and the dynamics of task updating and allocation processes, a more general solution is established which can cover multiple order sets with only one shelf distribution in the assignment task, so as to reduce the amount of shelf handling and achieve the purpose of improving the efficiency of picking [7,8].

1.1. Related Work

In the field of order batching, various batching methods have been developed to improve the efficiency of the picking process. These methods include split-order picking, combined batch picking, and order-based picking, as well as storage layout considerations such as partition picking and category picking. However, there remains a need to optimize these methods for specific warehouse and order characteristics, such as uncertain order arrival time and quantity [9]. Jun et al. [10] addressed the dynamic order batching problem and introduced a hybrid time window algorithm that divides the operation into peak, normal, and off-peak states. In the context of pickers’ skill levels, Marek et al. [11] proposed a human-skill-based picker system that improves the efficiency of traditional batch pickers. Scholz et al. [12] formulated a comprehensive optimization problem that includes storage optimization, order scheduling, task scheduling, and path planning, to derive a globally optimal order scheduling scheme. Xue et al. [13] proposed an improved clustering algorithm to solve the batch model of the order and showed that the batch-before-combination model is more efficient. Menendez [14] developed a two-stage variable domain search method to tackle the order batching problem and demonstrated its effectiveness via a numerical example. Chen et al. [15] presented an approach to the order batching problem based on data mining and integer programming, and used the association rule algorithm to solve the model and obtain a better solution. Araidah et al. [16] designed heuristic rules for order clustering, resulting in a nearly 50% reduction in picking times. Sun et al. [17] developed an accurate analytical model based on the split-order problem in multi-echelon systems and formulated the supplier selection problem as a mixed-integer nonlinear programming (MINLP) model. Wang et al. [18] introduced a hybrid algorithm, which combines large neighborhood search with local search to tackle the multi-warehouse dismantling problem. The authors also proposed data-driven strategies that aim to enhance the efficiency of the most time-consuming module of the algorithm.

In the realm of multi-automated guided vehicle (AGV) task allocation, various heuristic mechanisms and optimization models have been developed to enhance the efficiency of multi-robot systems. Zhou et al. [19] proposed a balancing heuristic mechanism based on task cost and mobile cost to reduce total travel time while maintaining the same travel cost. Yuan et al. [20] developed dedicated and collective robot models based on open queuing networks to optimize the ratio of robots and pickers. Merschformann et al. [21] investigated task allocation decision making using the RAWSim-O simulation platform, while Roy et al. [22] utilized a two-stage stochastic model to balance congestion among different storage areas. Furthermore, Yoshitake et al. [23] analyzed the effect of operation range, goods types, and selected goods volume on the solution method. Boysen et al. [24] optimized order queuing to reduce the time spent moving heavy shelves and studied order queuing and picking after batch processing under the batch-partitioned picking strategy in order to reduce the overall order-picking time [25]. He et al. [26] developed a new policy, called Differential Probabilistic Queuing (DPQ), for serving customer orders via Automated Guided Vehicles (AGVs) in the context of smart warehouse automation services. In addition, Dou et al. [27] proposed a hybrid algorithm that combines task scheduling and path planning of mobile robots to improve the efficiency of a multi-robot intelligent warehouse, while Zou et al. [28] constructed a queuing network model and proposed a neighborhood search method to solve the task assignment problem of multiple robots.

In the study of storage picking path optimization, a number of studies have been conducted to propose effective path strategies for mobile robots in warehouse settings. Specifically, Liu et al. [29] developed Return-type, S-type, and Mixed-type path strategies based on the Chevron layout warehouse, where the cuckoo search algorithm was utilized to solve the generated picking walking distance of the Mixed-type path. Lee et al. [30] presented a decoupling approach to obtain a conflict-free path for the mobile robot by minimizing the total march distance after the destination is assigned. Moons et al. [31] introduced the record-to-record routing algorithm to address the integrated vehicle routing issue, and evaluated its performance with warehouses of varying sizes. Li et al. [32] explored the robot motion uncertainty problem and proposed a risk interval path planning strategy to address the task assignment and path planning problems using deep reinforcement learning. Zhou et al. [33] established a stochastic model of the expected walking distance of the two routing strategies in the fishbone layout warehouse and compared the expected distance under different sorting frequencies and space allocation strategies via simulation. Lastly, Saylam et al. [34] presented a mathematical model and a dynamic programming method to minimize the maximum time required to complete picking activities in any area and balance the workload of order pickers effectively when the area is a set of adjacent aisles. Ammar et al. [35] proposed a top-down hierarchical approach to address the storage allocation problem by merging independent decision processes related to allocation and distribution. Han et al. [36] investigated a multi-drone algorithm that uses an ant colony optimization algorithm for initial order assignment to reduce completion time, flight distance, and crash time. Ehsan et al. [37] introduced a novel heuristic algorithm that combines column generation, genetic algorithm, and artificial neural network techniques to minimize the maximum completion time for manual picking operations. Zhang et al. [38] put forth an agent-based simulation model to demonstrate the efficacy of a hybrid order-picking system in reducing operational costs and manual workload when specific allocation rules for picking tasks are considered. The proposed system is compared against fully manual and fully automated order-picking systems. Chen [39] investigated the optimization of integrating food cold chain order picking with an online order vehicle path using a mixed-integer planning model aimed at minimizing time and cost objectives. Löffler et al. [40] introduced a dynamic planning routine with a polynomial runtime solution for a specific problem variant involving fixed picking sequence.

1.2. Research Status Summary and Analysis

Currently, there is a growing body of literature investigating the implementation and limitations of “parts to picker” systems. The majority of studies focus on optimizing strategies and improving methods related to order batching, task assignment, path optimization, and robotics. Regarding order batching, research efforts primarily revolve around developing effective batching strategies and solution methods. The order batching strategy takes into account factors such as order similarity and arrival time, and utilizes intelligent batching and time window perspectives for effective batching. Concerning task assignment, research is more diverse, with a primary focus on supply chain direction and warehouse picking direction. Studies on task allocation in the picking field mostly consider collaborative scheduling strategies, improved task allocation solution methods, and research based on automated guided vehicle (AGV) resource constraints and multiple mobile cart path problems. Furthermore, task assignment research primarily adopts a holistic perspective, addressing issues such as cargo space assignment, order splitting and reorganization, task assignment, path optimization, and their interconnections. It also provides perspectives for research, such as system evaluation and process optimization for task assignment. Table 1 provides a summary of the relevant theoretical research.

Table 1.

Research status summary.

1.3. Research Content

1.3.1. Research Objectives

To investigate the impact of dynamic order batching and task optimization using the “parts to picker” system on the efficiency of order-picking in storage operations.

1.3.2. Research Questions

- How does the proposed hybrid time window method for order consolidation and the shelf selection model impact the efficiency of the order-picking process?

- What is the effect of the scheduling strategy model and improved ant colony algorithm on task completion time and AGV task allocation?

- How does the dynamic selection of picking station queue impact queuing and picking completion time and overall picking efficiency?

1.3.3. Innovation Points

The paper addresses two critical problems: (1) the order batch problem, which arises due to the uncertainty surrounding order arrival time and quantity, and (2) the multi-AGV task allocation problem in the context of dynamic optimization strategy. By conducting an in-depth analysis of the fundamental issues with the existing “parts-to-picker” picking system, including order batch, task allocation, and path optimization, this paper offers valuable contributions to the field.

- The adoption of a hybrid time window method enables the conversion of dynamic arrival orders into static and efficient picking orders. Building on this foundation, a mathematical model is established to minimize the number of shelves transported, thereby facilitating the rapid and efficient selection of target shelves.

- The warehousing picking problem is addressed through the implementation of an improved ant colony algorithm. An optimization algorithm is proposed that leverages the strengths of both the ant colony algorithm and the genetic algorithm, and its effectiveness is demonstrated through illustrative examples.

- The optimization of the distribution strategy is achieved through the proposal of a dynamic selection platform selection strategy. This approach involves the dynamic selection of the picking table queue based on the current queuing situation, as opposed to the traditional static picking table selection which assigns target shelf handling tasks to picking tables in advance.

1.4. Outlines

The following structure is presented in this paper. In Section 2, the dynamic task update assignment strategy is investigated. Based on the static order generation in Section 2, the multi-AGV task assignment strategy and solving method are explored in Section 3. In Section 4, simulation optimization is employed to analyze the queuing situation of the picking station. Managerial implications are discussed in Section 5, where the experimental results are presented. Finally, in Section 6, this paper concludes with a summary of the findings and future research directions.

2. Research on Dynamic Order Batch Strategy

In this section, a novel strategy for order division based on time window is proposed to address the stochastic nature of order arrival time and quantity. The proposed approach generates static picking orders from dynamic orders while considering an order batch strategy to minimize shelf retrieval times and AGV moving distance, and improve overall order selection efficiency. Moreover, a dynamic batching strategy is integrated to formulate a model, and a corresponding solution algorithm is devised to minimize the number of target shelves required for the order-picking process. By adopting this approach, the overall efficiency of the order-picking process can be improved while reducing operational costs.

2.1. Hybrid Time Window to Divide Order Batch Selection Generation Strategy

The generation of pick orders through the division of order batches often incorporates the use of a time window constraint [61]. Two commonly employed methods for such constraints are the fixed time window and variable time window [62]. However, in practice, due to the presence of various factors, such as order arrival time and the dynamic nature of orders, achieving optimal results through the use of these methods is challenging. To address this issue, a hybrid time window batching strategy is proposed, which combines the two aforementioned methods. The proposed strategy aims to generate static and dynamic pick orders by dividing batches and considering the order arrival time while minimizing retrieval times and AGV travel distance, thus enhancing order selection efficiency. The process for implementing the hybrid strategy is described as follows:

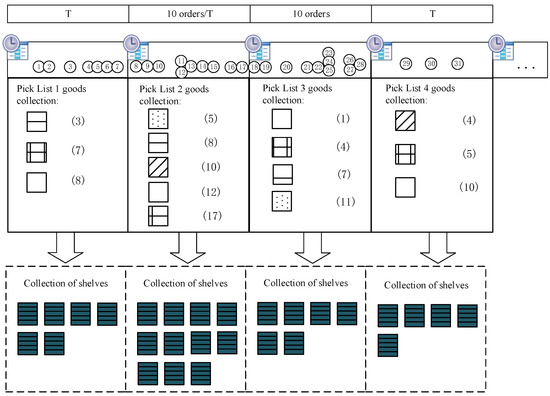

Assuming that orders arrive in accordance with a Poisson distribution of [63], this study proposes a novel approach for generating order batches based on a hybrid time window batching strategy. Specifically, a batch is formed once the cumulative sum of orders reaches , or after a time period of ( being a constant) has elapsed. The generated batches are used to generate pick orders and determine the appropriate target shelf. Figure 1 illustrates the proposed approach, wherein Pick order 1 is generated based on the time interval requirement, Pick order 2 is generated based on both time interval and quantity requirements, Pick order 3 is generated based on the quantity requirement, Pick order 4 is generated based on the time interval requirement, and so on, until all batches are completed. The proposed method addresses the limitations of existing fixed and variable time window batching strategies, thus improving the efficiency of order-picking processes.

Figure 1.

Hybrid time windows divide order batches to generate pick orders.

2.2. Determination of Task Shelf Collection

In this paper, we propose a novel method for determining the optimal shelf from which the selected items should be picked, based on the principle of minimizing the number of shelves used. Specifically, for each batch of orders, if there is only one matching shelf set, the selection of the corresponding shelf set is directly determined. However, if there are multiple matching shelf sets, the selection is based on the principle of minimizing the total cost incurred by AGV delivery of shelves. This approach ensures the efficient selection of items and minimizes the total cost of the order-picking process.

2.3. Basic Assumption

In constructing the mathematical model for the dynamic order of the static picking order generation problem, basic assumptions are made to facilitate research while ignoring the scenarios of shortage and storage allocation.

- Orders that arrive in the dynamic picking system know the order information of each order.

- Each generation of a static pick will trigger a pick task, and each pick is independent of the other.

- Goods are randomly stored in warehouses.

- A sufficient quantity and variety of goods are stored to meet the selection needs for a period of time.

- The storage space in the warehouse is known, and the location information of shelves and the layout of the warehouse are known.

- Batch picking of dynamic orders over a period of time is performed in the same warehouse.

2.4. Symbol Specification

See Appendix A.

2.5. Model Building

When constructing the model for determining the target shelf in static picking order, the objective of minimizing the number of shelves to be picked is considered. The model takes into account the constraints on order quantities and time intervals in both dynamic orders and static picking rooms, as well as the constraints on goods quantities and categories between static picking orders and shelves. The resulting model is formulated as follows:

s.t.

In the above model, the objective function (Equation (1)) represents the minimum number of shelves to be moved for the generated static pick list with known product demand information. Equation (2) means a shelf item constraint, where the number of items contained in the target shelf determined by the warehouse must be sufficient to meet the order-picking requirements for that item. Equation (3) represents a shelf commodity constraint. The quantity of goods contained in the target shelf determined by the warehouse must be able to meet the order selection demand of the commodity. Equation (4) represents the picking shelf constraint. The target shelves to be carried by each picking list shall not be less than one shelf. Equation (5) represents the quantity constraint of order batches. Equations (6) and (7) indicate that the order batch division meets the time interval constraint. Equation (8) indicates that dynamic order division batches meet the quantity constraint. Equation (9) represents the 0–1 variable.

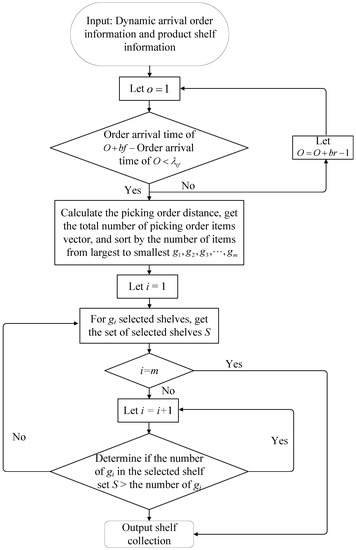

2.6. Design of Picking List Generation Algorithm

This section considers the order generation frequency and the capacity of the system in terms of task fulfillment, and obtains an initial set of picking orders based on the hybrid time window batching method. The minimum number of handling shelves required for the set of picking orders is determined by analyzing the goods storage. A detailed illustration of the process is presented in Figure 2.

Figure 2.

Hybrid time window algorithm flow.

2.7. Case Analysis

In this section, we consider the case of a certain day in the intelligent warehouse system of X retail snacks, where we select the two-hour orders. The dynamic order arrival is modeled using a Poisson distribution with an arrival rate of one order per minute. The dynamic orders are batched every 15 min or based on the number of arrived orders, whichever comes first, resulting in static picking orders. This batch of orders comprises 30 different types of commodities, with each order consisting of 2–5 random types of commodities. The relevant order details are presented in Table 2.

Table 2.

Order requirement.

Please refer to Appendix B for a detailed dataset on the orders. The dynamically arrived orders were batched using the fixed time window, variable time window, and hybrid time window strategies, with the aim of minimizing the number of shelf visits. The generated static selection was solved using the algorithm, and the target shelf was determined, resulting in a set of transport AGV tasks. For the 120 dynamically arrived orders, 9, 8, and 11 picks were generated using the fixed time window, variable time window, and hybrid time window strategies, respectively. The number of orders included in each pick is presented in Table 3.

Table 3.

A pick list contains a collection of order quantities.

The response time of each order from the arrival of the order to the formation of the picking order to the execution of the task is taken as the response time of the order. The total waiting time of each order of each batch of picking orders is counted and analyzed. Under the fixed time window strategy, the total waiting time of each batch of picking orders was min, min, min, min, min, min, min, min, and min. Under the variable time window strategy, the total waiting time of each batch of picking orders was min, min, min, min, min, min, min, and min, respectively. Under the hybrid time window strategy, the total waiting time of each batch of picking orders was min, min, min, min, min, min, min, min, min, min, and min, respectively. The average response time of each order under the three strategies is shown in Table 4. The response time of orders under the hybrid time window is obviously better than that under the fixed time window batching strategy and variable time window batching strategy.

Table 4.

Average response time per order.

By associating the picking list and minimizing the travel distance of the shelf to the picking table, the target shelf set corresponding to the picking list is obtained, that is, the task set facing the handling AGV is obtained. Table 5 shows the solution results of the target shelf under the hybrid time window strategy.

Table 5.

Picking order and target shelf solution under the batching strategy with hybrid time window (part).

3. Research on Task Allocation Strategy of Multi-AGV Picking System

In the context of the “parts to picker” picking system, the core element to optimize storage picking efficiency is the coordinated operation of multiple automated guided vehicles (AGVs) involved in the handling task. Nonetheless, the process of multi-AGV movement and handling presents challenges such as path conflict and collisions. Therefore, a critical endeavor involves addressing the multi-AGV task allocation problem, the multi-AGV cooperative operation problem, and the multi-AGV path planning problem. In this study, we aim to leverage the findings from Section 2 to develop a model that prioritizes the completion time of tasks. Specifically, we propose a random scheduling model that takes into account the time spent on movement, queuing, and picking activities.

3.1. Task Assignment Model Construction and Algorithm Solving

3.1.1. Model Assumption

In the process of constructing the mathematical model related to task allocation of AGVs, the following basic assumptions are followed:

- All selection processes are based in the same warehouse.

- The commodity demand information corresponding to the static picking list is known.

- The handling capacity of AGV in the warehouse is to carry one shelf each time, and the handling speed is always consistent, regardless of the influence of the carrying shelf on the speed of AGV.

- The AGVs have sufficient electric power and can continue to carry out transportation work.

- Each selection list is selected independently, without considering the information correlation between the selection lists.

- The position of shelves and the picking table in the warehouse can be represented by two-dimensional coordinates.

- The goods are stored randomly in the warehouse and the storage status of the goods on the shelves is known.

- The type and quantity of goods stored in the warehouse can meet the picking demand, regardless of replenishment.

3.1.2. Symbol Specification

See Appendix C.

3.1.3. Model Building

Regarding the handling of static pickings that have been batched, the task batches are initiated by launching a batch of pickings each time. In this study, the batching time point presented in Section 3 marks the moment when task allocation is initiated.

- (1)

- Walking time of AGVThe walking time of the AGV is the total time to complete the shelf handling task, which is determined by the picking distance and the walking speed of the AGV:In this regard, the distance covered by a given automated guided vehicle (AGV) r is defined as the sum of the distances from the initial position to the task shelf position and back to the initial position. The distance moved by the AGV r from the initial position o to the task shelf j is denoted by and represented using the Manhattan distance metric.represents the distance moved from the task shelf j to the picking table q:represents the distance moved from the picking table to the task shelf position after picking:Therefore, the walking time of AGV r is expressed asv indicates that the AGV is always moving at a constant speed during the picking process.

- (2)

- Waiting time of AGV rrepresents the queuing time of the AGV r on the picking platform q, which is determined by the difference between the time point at which the sequence completes task j and the time point at which the l sequence of j task arrives on the picking tables q:

Based on the above explanation, the total time taken by each automated guided vehicle (AGV) r to complete a picking task is the sum of the walking time, the picking waiting time, and the picking time.

s.t.

The objective function (Equation (15)) represents the maximum time for minimizing a batch of pick orders corresponding to the completion of the pick task on the target shelf. Equation (17) represents the time for the AGV to complete the picking task, including the moving time of the AGV to carry the shelves, the time of waiting in line at the picking table, and the time spent by a human picking. Equation (18) represents the queuing time of the AGV r when it completes the task l to the task j and arrives at the picking station. The waiting time is determined by the time when the previous task leaves the picking station and the time when it arrives at the picking station. If the arrival time of the latter task is earlier than the end time of the previous task, the time difference is the waiting time. Equation (19) indicates that the time when task picking is completed is the time when task shelves arrive, and the waiting time and picking time at the picking table are determined. Equation (20) indicates that the time point when AGV returns to the position of the original task shelf is the time point when picking is completed plus the movement time of returning to the original task shelf. Equation (21) indicates that a batch of pick order tasks are all assigned to AGVs for handling. Equation (22) indicates that each task can only be carried by one AGV.

3.2. Improved Ant Colony Algorithm

Ant Colony Algorithm for Task Assignment

To optimize the storage picking system, we employed the ant colony algorithm, setting the number of ants as the total number of tasks on the shelves that require picking, while also specifying the maximum number of iterations [64]. Following the ant’s visit to storage site i, it proceeds to the next storage site j based on the pheromone concentration function probability along the chosen path.

In this context, the pheromone intensity of quality inspection between tasks i and j is denoted by , while represents the intensity of heuristic factors between tasks i and j. The pheromone importance factor and the heuristic function importance factor are used to regulate the effect between and , respectively. Here, represents the tasks that the automated guided vehicle (AGV) has not yet completed, i.e., the tasks that are not present in the tabu task list. The pheromone concentration released by ants at time is updated based on Equation (24).

is the pheromone volatile factor, is the pheromone increment, which is the sum of the pheromone increment of each ant from task i to task j, as shown in Equation (25):

is the pheromone increment of the ant from task i to task j, which can be obtained by dividing the pheromone intensity coefficient by the length of the path taken by the ant in the process of seeking the shortest path.

To optimize all the target points in a task, we utilized the ant colony algorithm to obtain the shortest path from the starting point that passes through all the target points and returns to the starting point, thereby forming an ordered task chain.

3.3. Task Assignment Problem Based on Improved Ant Colony Algorithm

The ant colony algorithm has the advantage of being able to select any initial path and having low requirements for initial conditions during the search for the shortest path. However, its convergence speed is slow, and it is prone to getting stuck in local optimal solutions. In this study, we combined the strong global search ability of the genetic algorithm with the ant colony algorithm to overcome its slow convergence drawbacks. We first used the ant colony algorithm to solve the problem and selected one of the best solutions after one iteration. Then, we used the initial population of the genetic algorithm as the basis for the solution and obtained the optimal solution through the rapid convergence advantage of the genetic algorithm.

- (1)

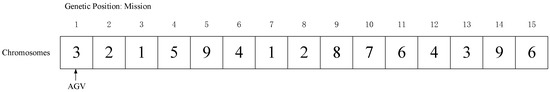

- Population initializationThe initial population size and the number of tasks per call were determined first. The set of solutions generated by the iterative ant colony algorithm was used as the initial population for the genetic algorithm. Chromosomes were encoded, where the length was determined by the number of tasks in a single picking list. Each gene locus in the chromosome represented a task, and the number associated with the gene locus represented the AGV’s serial number assigned to perform the corresponding picking task. This encoding method not only allows for the identification of the AGV assigned to each task, but also enables the analysis of the sequence of tasks performed by the same AGV by analyzing chromosomes with the same serial number (as illustrated in Figure 3).

Figure 3. Chromosome coding mode.

Figure 3. Chromosome coding mode. - (2)

- Calculate the fitness functionThe chromosome’s fitness value is determined as the inverse of the maximum time required by all AGVs to complete the handling, waiting, and picking process. The fitness function is assessed based on the objective function, which seeks to minimize completion time. To this end, the fitness function is designed to both minimize the maximum completion time and maximize the minimum completion time.

- (3)

- Selection operatorThe roulette method is employed to select a specific proportion of parents from the previous generation. Furthermore, excellent individuals with high fitness values are chosen to be the best parents and they are directly passed on to the next generation. This method ensures both diversity among individuals and inheritance of the best individuals in the population to the next generation.

- (4)

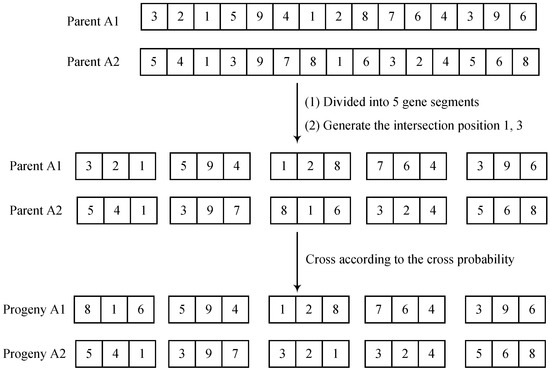

- Crossover operatorThe parent chromosomes are subject to a crossover operation at two randomly chosen crossing points, and the resulting offspring are obtained by exchanging the corresponding segments between the two parents. This process introduces new genetic information and promotes diversity in the population. A schematic of this process is presented in Figure 4.

Figure 4. Crosstabs procedures.

Figure 4. Crosstabs procedures. - (5)

- Mutation operatorDuring the replication process, partial swap mutation is utilized to create a new individual. This involves randomly selecting two gene positions and changing the value of the base chromosome to generate a new progeny.

- (6)

- TerminationThe algorithm is configured with a maximum iteration limit, and this limit is adjusted to examine the optimal solution output. Once the maximum iteration count is reached, the algorithm terminates its iterations, and the resulting output represents the optimal solution.

3.4. Case Analysis

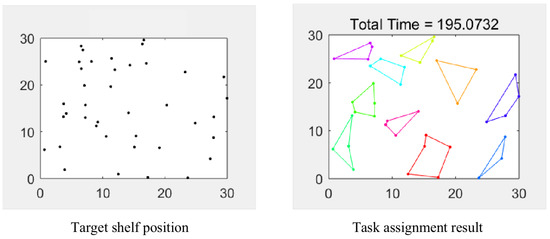

Assuming the picking system involves 10 automated guided vehicles (AGVs), the hybrid time window is used as input for task allocation, and each AGV is assigned to carry out picking tasks for each target shelf. The AGV is scheduled to select the nearest picking platform to complete the assigned picking task. In this study, a simulation experiment was conducted on the task allocation for the fourth batch of selection within the mixed time window using the ant colony genetic algorithm. The figure below (Figure 5) presents the results of target shelf position selection and task assignment for the 10 AGVs.

Figure 5.

Task assignment results of 10 AGVs.

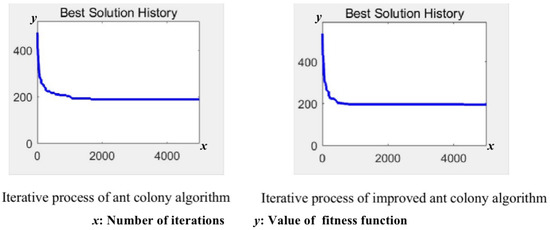

The shelf selection list under the hybrid time window strategy was subjected to simulation experiments to compare the performance of the ant colony algorithm and the improved ant colony algorithm with the genetic algorithm, as demonstrated in Figure 6. The fitness function value of the improved algorithm shows stability after about 500 iterations, while that of the ant colony algorithm tends to stabilize after almost 2000 iterations at about 200. The outcomes indicate that the improved algorithm converges faster than the ant colony algorithm and produces better results.

Figure 6.

Task assignment iterative process.

Assuming that the number of shelves corresponds to the number of tasks, the present study allocated tasks by utilizing all target shelves determined in Section 2 under the mixed time window. The resulting AGV task allocation and selection table are presented in the following table. Subsequently, the number of shelves assigned to each AGV and their corresponding picking numbers were computed.

Based on Table 6, the allocation of tasks for the picking list under the hybrid time window strategy indicates that, on average, each AGV is assigned with 6–15 tasks, and the likelihood of selecting each picking station varies.

Table 6.

Task allocation.

4. Research on Optimization Strategy of Multi-AGV Picking Platform Selection

Based on the findings presented in Section 3, it has been observed that the AGV’s selection of the nearest picking station in a static manner results in an imbalanced utilization of each station. To address this issue, a proposed solution is put forth in this section to adjust the configuration of the picking platform from a static to a dynamic selection platform. This dynamic platform will take the queuing situation of the system’s picking platform into account and subsequently lead to further optimization of the AGV task allocation.

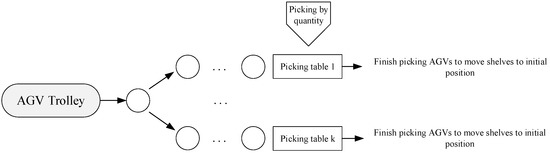

4.1. Selection Platform Queuing System

As per the queuing system constitution, automated guided vehicles (AGVs) that continuously arrive at the picking station are considered constant data sources. A queuing system model diagram, as illustrated in Figure 7, is established based on the order of arrival at the picking station. The process initiates with the AGV trolley carrying the intended shelf, which is inputted into the queuing system. The system then performs pre-allocation to assign the nearest picking station, following which the manual picking starts from the end of the queue at the designated station. The goods are selected based on the available data, and the shelves are returned to their original position after the completion of the picking process.

Figure 7.

The model of AGV queuing.

- (1)

- Data inputting of queued picking systemThe present study examines the queuing system of a picking station wherein an automated guided vehicle (AGV) carrying a target shelf moves to the queuing system, and each task reserves the nearest picking station based on the location of the target shelf. The arrival time of the picking queue is contingent upon the start time of the picking task as well as the movement time of the AGV. Furthermore, the queuing system of the sorting platform accommodates multiple AGVs that arrive continuously as a unified source, with no interference between independent AGVs.

- (2)

- Rules of queuingThe ”parts to picker” picking system relies on an automated guided vehicle (AGV) carrying the target shelf as the data source. In this system, the arrival time of the AGV at the picking station queue is determined by the start time of the picking task and the distance of the shelf’s movement. The task that requires a shorter distance to move arrives at the picking queue ahead of tasks with a longer moving distance, which are ordered according to their arrival. The subsequent tasks experience a queuing time that begins when all prior tasks are queued up and manual picking work has been completed and cleared from the picking platform.

- (3)

- Servicing time of pickingThe duration of automated guided vehicles’ (AGVs) stay in the picking queue is primarily influenced by the queuing time and the manual picking time. The former is largely influenced by the queuing duration of preceding tasks and the time required for sorting. The latter is primarily dependent on the number of goods to be picked. Notably, the impact of manual sorting factors on sorting speed and accuracy is disregarded.

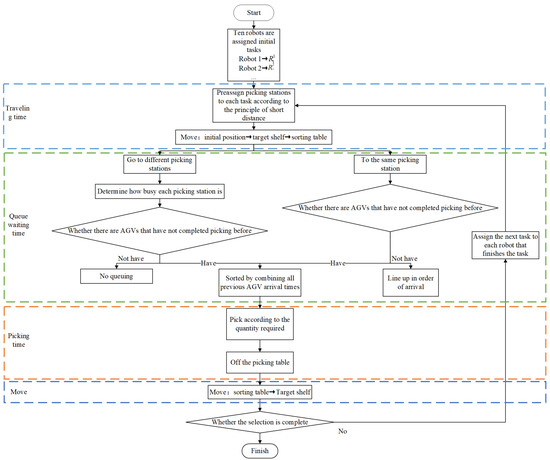

4.2. Selection Desk Queuing Service Process

Prior to conducting a picking operation, the picking station is assigned based on proximity, and the AGV trolley carrying the target shelf proceeds directly to the designated queue at the assigned picking station. Following the establishment of the queue system structure, the entire queuing system must undergo a series of steps, including AGV queue arrival, queue selection, waiting in the queue, picking, and finally leaving the queue. Consequently, following the AGV cart’s transportation of the shelves, the contents of the moved shelves are matched with the preconfigured picking table, and the AGV cart proceeds directly to the corresponding picking table to enter the queue. A detailed illustration of the specific process is provided in Figure 8.

Figure 8.

The process of AGV queue.

The data analysis in Section 3 provides valuable insights into the behavior of AGVs in relation to their selection of picking tables. Specifically, it is important to investigate whether AGVs assigned to the same picking order consistently select the same picking table or if they are allocated to different tables. Additionally, it is necessary to examine the workload distribution of each picking table queue under such conditions. For AGVs assigned to the same picking table queue, a decision tree is employed to determine the appropriate action based on the completion status of previous tasks. If a previous task is incomplete, the AGV is added to the existing queue. Conversely, if there are no incomplete tasks, the AGV is placed in a queue with a wait time of 0 and prioritized based on path walking time. Notably, the queue waiting time and the picking time both influence the queue situation. The queue is only deemed to be finished when the AGV carrying the target shelf arrives and the previous AGV leaves the picking table. Subsequently, the time taken to complete the picking task is calculated based on the number of goods, after which the AGV departs from the picking table and returns to the initial position of the target shelf to await its next handling task.

4.3. Selection Platform Dynamic Selection Optimization Strategy

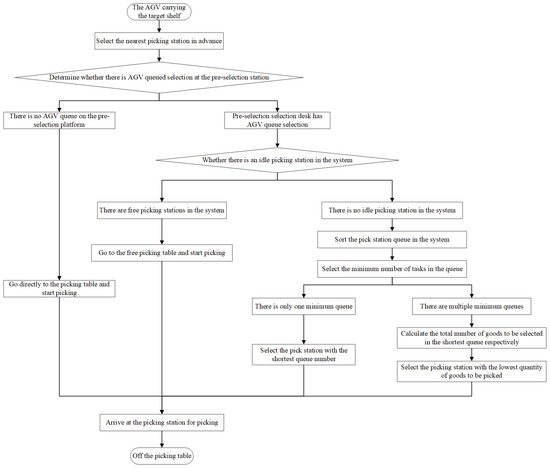

In this section, we present an optimization and enhancement of the static queue selection method. Specifically, we focus on improving the dynamic queue selection process from the perspective of AGVs. Our approach involves adjusting the predetermined static queue of the picking station to a dynamic selection strategy, which takes into account several factors, such as the captain and the availability of idle picking stations in the system. The queuing system of AGV trolleys in front of the picking platform studied in this work considers the utilization of the picking platform and the corresponding queue length of each picking platform when queuing. The optimized picking system not only enhances the picking efficiency, but also promotes a balanced usage of the picking platform and ensures an equitable distribution of workload among the various picking platforms. The dynamic selection of the picking platform is optimized based on the strategies outlined in Figure 9.

Figure 9.

The dynamic optimization strategy of picking platform.

4.4. An Analysis of Flexsim Simulation for Queuing System of Picking Platform

The simulation approach, which leverages a model of actual warehouse operations, provides a visual representation of the selection outcomes and their temporal features. In this study, we employed the Flexsim software to simulate the queuing system of AGVs, where we developed and analyzed a simulation model. The results are evaluated by examining the impact of adjusting the warehousing selection process in accordance with the optimization strategy.

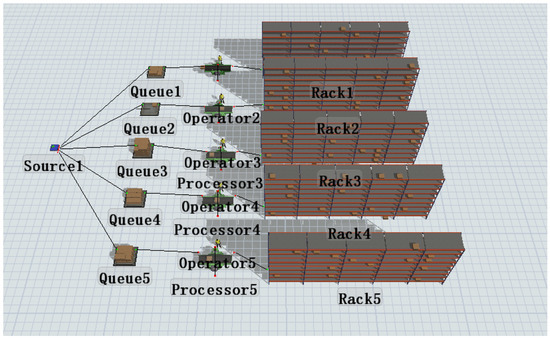

4.4.1. Simulation Model Construction

The model developed using the Flexsim software is depicted in Figure 10. Each element in the model is associated with distinct functions. Utilizing the data collected and analyzed in prior sections, we attribute significance and parameters to each module in order to simulate the queuing system of the sorting platform.

Figure 10.

Simulation model.

- (1)

- Source: It is used to propose the generation of data sources and represents AGVs carrying the shelves that are about to enter the picking table queuing system. Given that the queuing process can be examined independently of the preceding task allocation and walking processes, a data source generator can be employed to produce data sources that represent the tasks awaiting queuing.

- (2)

- Queue: The present study focuses on the warehouse picking system, which comprises five pickers, each capable of being matched with a queue to receive automated guided vehicles (AGVs) transporting desired shelves.

- (3)

- Processor: The storage retrieval system comprises a total of five picking stations, with each station being allocated a dedicated picker who is responsible for carrying out the picking task. The duration of the picking process is primarily dictated by the level of demand for the goods as specified on the picking list. It is worth noting that the duration of the picking process increases proportionally with the number of items to be picked, although other factors such as manual labor requirements are not considered in this assessment.

In this paper, we present a dynamic optimization process that utilizes a queue and table selection strategy to improve the performance of a picking platform. The optimization process begins by controlling the port of each queue and using the content function to obtain the current task quantity of each queue. An if function is subsequently added to identify any pick station with a task quantity of 0. In this case, the processor reads the pick station with a task quantity of 0 as a priority. If no pick station with a task quantity of 0 is available in the system, the current task quantity is obtained from different queues, and the queue with the lowest task quantity is selected for the queuing selection process. Through simulation, the proposed dynamic selection optimization process optimizes the performance of the picking platform.

4.4.2. Simulation Data Analysis

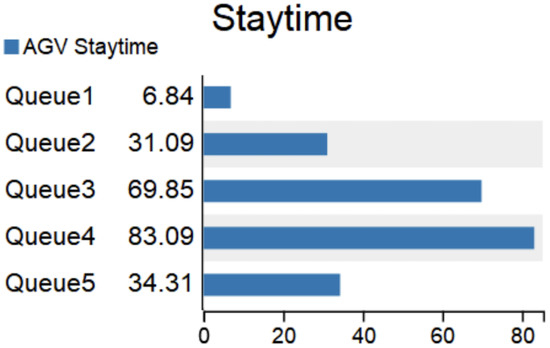

The present study utilizes the mobile end time as the primary data source to power the generator and employs Flexsim to perform simulation experiments that demonstrate the performance of the system and assess the scheme’s merits and demerits. As per the findings of Section 3, the number of shelves selected by each picking table is determined to be 5, 7, 15, 37, and 20. These figures reveal noticeable discrepancies in the task load of each picking table, which has the potential to result in task accumulation in the fourth picking table. The delay in completing the picking tasks at this table is observed to be substantial, leading to a reduction in the efficiency of the entire picking system. Table 7 presents a partial overview of the shelf-carrying automated guided vehicles (AGVs) reaching the picking stations and their corresponding arrival times, as recorded during the simulation experiments. Additionally, Figure 11 depicts the total queuing time of each picking station, as simulated by the Flexsim software during this batch of the picking process.

Table 7.

AGV arrival data of each picking station (Part).

Figure 11.

Queuing time of each station (min).

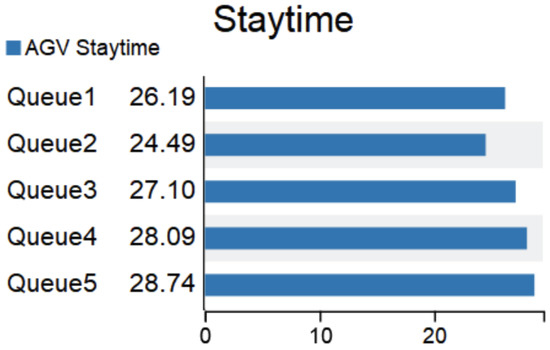

The present study proposes a dynamic queuing approach for automated guided vehicles (AGVs) in a picking station system, aimed at improving the overall efficiency of the system. Simulation experiments were conducted using the Flexsim software, and the number of shelves selected by each picking station was re-calculated based on the proposed approach, resulting in the selection of 17, 13, 20, 19, and 15 shelves, respectively. The queuing time of AGV trolleys was analyzed and the results are presented in Figure 12. Notably, the queuing time of each picking station was observed to be relatively more balanced following the proposed approach, and the longest queuing time of the system was significantly reduced. Specifically, the longest time of queue-picking completion was reduced from to , corresponding to a 34% reduction in the queue-waiting and picking completion time. These findings underscore the potential benefits of the proposed dynamic queuing approach for AGVs in the context of picking station systems, and warrant further validation in practical settings.

Figure 12.

The queuing time of each picking station after dynamic selection (min).

4.5. Characteristics of the Proposed Queuing Model

In this section, we provide a detailed explanation of the characteristics of the queuing model proposed in Section 4.3 and Section 4.4. The queuing system is designed to represent the multi-robot task assignment problem in logistics and supply chain management.

The queuing model consists of a set of servers and customers. The servers represent the picking stations in the warehouse, while the customers represent the tasks that need to be assigned to these picking stations. The service pattern of the queuing system is first-come first-serve (FCFS), which means that the tasks are assigned to the picking stations in the order in which they arrive.

The queuing discipline used in the model is the pre-emptive resume priority discipline. In this discipline, the task with the highest priority is given service preference. If a lower-priority task is currently being served and a higher-priority task arrives, the server interrupts the lower-priority task and begins to serve the higher-priority task. Once the higher-priority task is complete, the server resumes service on the lower-priority task.

To evaluate the performance of the proposed queuing model, we measured the average waiting time, average service time, and average queue length of the tasks. The waiting time is defined as the time elapsed from when the task arrives until it begins to be served. The service time is defined as the time elapsed from when the task begins to be served until it is completed. The queue length is defined as the number of tasks waiting in the queue.

Overall, the proposed queuing model provides a useful tool for analyzing the performance of multi-robot task assignment in logistics and supply chain management. The use of the FCFS service pattern and pre-emptive resume priority discipline allows for a realistic representation of the task assignment process, and the measured performance metrics provide valuable insights for practitioners seeking to optimize their task assignment strategies.

5. Discussion

In this paper, we introduced a novel “parts to picker” picking model that utilizes AGV carts to optimize the picking process at various stages. Specifically, this model addresses three major issues: order batching, multi-AGV task allocation strategies, and dynamic optimization of picking tables for dynamic orders. By leveraging AGV carts, the proposed model aims to enhance the efficiency of the picking process, thereby improving the overall productivity of the warehouse. Through extensive experimentation and simulations, the efficacy of the proposed model is demonstrated, paving the way for further research in this field. The main work of this paper is as follows:

- This paper presents a method for optimizing the dynamic order processing in e-commerce distribution centers using a “parts to picker” approach. To address the uncertainty of dynamic order arrival time and quantity, we propose a hybrid time window algorithm that transforms the dynamic orders into static picking orders. Our approach is designed to minimize the number of shelves required for picking while considering quantity and type constraints. We demonstrate the effectiveness of our approach in reducing order response time and improving picking efficiency through a heuristic algorithm. Moreover, we introduce a novel method for batch processing dynamic orders and determining the minimum number of shelves to be picked.

- In this study, we assign tasks to automated guided vehicles (AGVs) for each batch of picking orders based on the corresponding shelves to be picked. The position coordinates of the shelves are determined according to the layout of warehouse goods, and task assignment is performed for multi-AGV with the aim of achieving the shortest picking completion time. This assignment process involves addressing the matching problem of moving shelves by AGV handling and determining the sequence of handling shelves. To tackle this complex combinatorial optimization problem, the authors utilize an improved ant colony algorithm, which enhances the convergence speed of the solution. The results confirm the effectiveness of the improved algorithm and its potential to better address such complex optimization problems.

- This study utilized Flexsim simulation to optimize the allocation of picking stations from a static assignment to a dynamic selection approach. To accurately simulate the queuing picking process of AGV carts carrying shelves, data sources were simulated based on the arrival of AGV carts at the picking table system, and tasks were triggered to enter the picking system. To address the issue of uneven queues and long waiting times, the proposed strategy adjusts the static picking table selection based on the availability of free picking tables and the queue captain. By dynamically selecting the picking table queue, the effectiveness of this strategy was confirmed through simulation modeling.

5.1. Implications for Theory

This study makes several contributions to the literature on task assignment, order batching, and ant colony intelligent algorithms.

Firstly, in the field of order batching, prior research has primarily utilized fixed and variable time windows, which have been shown to be feasible and stable. However, the operational efficiency of these approaches remains suboptimal. To address this issue, we propose a novel approach for order batching that emphasizes the minimum number of shelves needed to satisfy required types and quantities of goods. This approach selects the most efficient combination of shelves among multiple feasible options. Additionally, we introduce a hybrid time window batching strategy that combines a fixed time window strategy with an order arrival interval constraint and a variable time window strategy that considers the order arrival quantity constraint. The proposed approach and strategy result in a significant improvement in the operational efficiency of order batching.

Secondly, the present study addresses the challenges posed by the “parts to picker” picking system as compared to the traditional “picker to part” system. The former is characterized by greater task complexity, decision variables, and constraints. Therefore, the focus of research on task assignment in the “picker to parts” picking system should be on multiple aspects. First, task assignment involves multiple tasks and robots, and it also requires picking station selection. This makes it a many-to-many process that involves complex task-matching problems. Second, the multi-AGV task assignment problem is a centralized control and decentralized execution process that requires coordination and flexibility in task execution. This requires solving the problem of integrated arrangement and taking into account multiple constraints, such as the number of robot carts and delivery time. Finally, the “parts to picker” picking system must address the dynamic scheduling problem by devising an appropriate response and execution strategy. To optimize the assignment strategy, this study proposes a dynamic picking strategy to address the problem of long queue waiting times due to an unbalanced assignment of tasks to multiple picking stations.

Thirdly, this paper presents an optimization algorithm that combines the advantages of the ant colony algorithm and genetic algorithm. The ant colony algorithm has been extensively used for solving the multi-robot task assignment problem, but it is prone to getting trapped in a local optimal solution due to its slow convergence speed. To overcome this limitation, the ant colony algorithm is improved in this study by integrating the genetic algorithm with the task assignment process. This hybrid algorithm exploits the strong global search ability of the genetic algorithm to enhance the convergence rate of the ant colony algorithm and achieve a better optimization performance. Specifically, the genetic algorithm is used to encode the picking task and to evolve the population of candidate solutions, while the ant colony algorithm is employed to search for the best path for each robot based on the pheromone trail. The proposed algorithm outperforms the traditional ant colony algorithm and genetic algorithm, demonstrating its effectiveness in solving the multi-AGV task assignment problem.

5.2. Implications for Management

The findings of experimental studies on warehousing have practical implications for practitioners as even minor variations in feedback execution can result in significant differences in outcomes. Although the experiments in this paper were conducted through simulation rather than in an actual warehousing environment, they still hold valuable guidance. The proposed enhanced strategy and optimization algorithm in this paper are of great practical importance in addressing the multi-AGV task allocation problem in logistics and supply chain management. This is demonstrated as follows:

- Improved operational efficiency: The proposed improvement strategies and optimization algorithms can help improve the operational efficiency of logistics systems by optimizing the assignment of tasks to multi-AGV. This can lead to faster order fulfillment, reduced waiting times, and improved customer satisfaction.

- Increased flexibility: The proposed improvement strategies and optimization algorithms can also increase the flexibility of logistics systems by enabling adjustments in task assignments based on the urgency of the task. This can help managers respond more effectively to changing demand patterns and prioritize tasks accordingly.

- Better resource utilization: By optimizing the assignment of tasks to multi-AGV, the proposed improvement strategies and optimization algorithms can help managers better utilize available resources, such as robot carts and picking stations. This can help reduce wastage and optimize resource allocation.

- Enhanced competitiveness: The proposed improvement strategies and optimization algorithms can help logistics companies enhance their competitiveness by improving their operational efficiency, flexibility, and resource utilization. This can lead to improved customer loyalty, increased market share, and higher profitability.

Overall, the proposed improvement strategies and optimization algorithms have important practical implications for the management of logistics systems and can help managers improve their decision making and operational efficiency.

6. Conclusions and Prospect

6.1. Innovation

In this paper, we use the “parts to picker” AGV picking mode to study the order batch of a dynamic order, multi-AGV task allocation strategy and the dynamic optimization of a picking table, and optimize the different stages of the picking process. The main work can be summarized as follows:

- This paper proposes a hybrid time window approach for transforming dynamically arriving orders into static picking orders, thereby improving efficiency. To address the uncertainty of dynamic order arrivals in terms of time and quantity, a hybrid approach with a fixed time window by time interval and a variable time window by determined order quantity is adopted to consolidate and batch orders. A mathematical model is then formulated with the objective of minimizing the number of handling shelves, enabling a quick and efficient determination of the target shelves for picking. By utilizing the hybrid time window approach and mathematical model, this study contributes to improving the efficiency of order-picking processes.

- This paper presents an improved ant colony algorithm for solving the warehouse picking problem, which integrates the strengths of both the ant colony algorithm and the genetic algorithm. To enhance the performance of the ant colony algorithm, a genetic algorithm is integrated into the optimization process. Specifically, the picking task is combined with the genetic position to take advantage of the global search ability of the genetic algorithm in the solution process. Through this approach, the convergence speed of the solving process is effectively improved. Overall, this study contributes to the development of more efficient and effective algorithms for warehouse picking optimization.

- This study proposes a dynamic picking table strategy to optimize the allocation strategy for the warehouse picking process. Specifically, the problem of long waiting times in certain picking queues due to uneven assignment of multiple picking tables is addressed by proposing a dynamic selection of picking queues based on the queuing situation. This is achieved by changing the pre-assigned target shelf handling tasks for picking tables from static to dynamic selection. To evaluate the effectiveness of the proposed strategy, Flexsim simulations are conducted. Results indicate that the dynamic selection approach enhances the flexibility of the queuing process and reduces overall picking time. This study provides a valuable contribution to the development of more efficient and effective strategies for warehouse picking optimization.

6.2. Prospect

In this paper, we delve into the dynamic task allocation strategy of “parts to picker” picking systems and proposes a solution to address the issue of dynamic orders. Despite these contributions, practical implications necessitate further inquiry into the research topic, which can be improved in the following ways in future investigations.

- The study’s scope is limited to small-scale task allocation and may not account for the complexities inherent in large-scale order processing, which involve significantly larger commodity demands and operational difficulties. Consequently, subsequent research can enhance the efficiency of large-scale picking by scaling up the study’s task assignments, while considering the impact on path congestion and excessive energy consumption.

- While the paper did not constrain the use of automated guided vehicles (AGVs), real-world applications must consider the charging, congestion, and allocation of robots within the picking system.

- The study assumes independent AGV operations and neglects the potential benefits of collaborative AGV operations in addressing emergency orders.

- The study assumes sufficient materials in the warehouse to meet the demands of orders, which is not always the case in practice. Therefore, future research can expand upon the present study’s limitations and examine the turnover of goods in the warehouse, reducing assumptions and aligning with real-world scenarios.

Author Contributions

Funding acquisition, L.Z.; supervision, J.Y. (Jianglong Yang); validation, H.L.; writing—original draft, K.L.; writing—review and editing, Y.L., F.J., M.S. and J.Y. (Jin Yang). All authors have read and agreed to the published version of the manuscript.

Funding

The study is supported by the national social science project “Research on logistics service quality improvement and low carbon governance mechanism (21FGLB046)”, in part by the Graduate Science and Technology Innovation Project of Capital University of Economics and Business under 2023KJCX062.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Symbols description of model static picking order to determine the target shelf (see Section 2.4).

Table A1.

Symbols description of model static picking order to determine the target shelf (see Section 2.4).

| Symbols | Description |

|---|---|

| G represents the goods in the warehouse. Each number represents an SKU. There are a total of L kinds of goods in the warehouse. | |

| S represents the shelves in the warehouse, and each number represents a shelf. There are n shelves in the warehouse. The shelves are stored in the warehouse according to the raster method, and each shelf can be represented by two-dimensional coordinate points. | |

| O represents the order, each number represents an order; dynamic order information is independent. | |

| B indicates a pick list. Each number represents a pick list. Static pick lists have independent information. | |

| The moment the picking system accesses order O. | |

| Fixed time window; a batch needs to be reassigned every fixed time window. | |

| Variable time window, indicating that the order quantity has reached the need to redivide a batch. | |

| The quantity of g goods in s shelf. | |

| The demand of g goods in s order. |

Table A2.

Variable symbols description of model static picking order to determine the target shelf (see Section 2.4).

Table A2.

Variable symbols description of model static picking order to determine the target shelf (see Section 2.4).

| Variable Symbols | Description |

|---|---|

Appendix B

Table A3.

Symbol description of model static picking order to determine the target shelf.

Table A3.

Symbol description of model static picking order to determine the target shelf.

| The Number of Orders | Commodity Information (Commodity Number, Quantity) | The Number of Orders | Commodity Information (Commodity Number, Quantity) |

|---|---|---|---|

| 1 | 21(5), 27(13), 29(1) | 61 | 13(10), 17(19), 24(17), 28(14) |

| 2 | 11(12), 20(1), 29(4) | 62 | 15(16) |

| 3 | 3(8), 8(5), 21(13) | 63 | 5(14), 11(8), 14(18), 17(7) |

| 4 | 2(18), 11(12), 16(18), 19(8) | 64 | 8(15), 23(13) |

| 5 | 8(7), 17(16), 19(4), 20(12) | 65 | 3(7), 15(4), 16(15), 19(10) |

| 6 | 7(13), 24(19), 26(11) | 66 | 6(5), 10(5) |

| 7 | 4(16), 10(20), 22(20) | 67 | 4(8), 21(8), 22(9) |

| 8 | 28(11), 30(6), 15(8), 16(13) | 68 | 1(10), 4(12), 6(8), 18(14) |

| 9 | 5(4), 8(9), 11(6), 25(8) | 69 | 9(13), 25(10), 28(16) |

| 10 | 10(9), 19(13), 27(19) | 70 | 1(5), 6(20), 15(13) |

| 11 | 2(10), 3(11), 17(6), 20(8), 27(14) | 71 | 5(9), 15(13), 22(15) |

| 12 | 1(20), 9(4), 18(14), 30(4) | 72 | 17(19), 23(11), 26(15) |

| 13 | 13(5), 19(13), 22(8), 25(8) | 73 | 8(4), 11(16) |

| 14 | 8(15), 18(7), 22(5), 28(12) | 74 | 3(10), 13(8) |

| 15 | 1(12), 3(10), 7(5), 15(12) | 75 | 6(10), 16(5), 21(6), 27(8) |

| 16 | 11(5), 17(9) | 76 | 5(5), 30(4) |

| 17 | 3(19), 5(10), 21(10), 25(7) | 77 | 4(16), 9(17), 19(6), 25(12) |

| 18 | 14(10), 15(17) | 78 | 12(10), 13(10) |

| 19 | 3(11), 20(17), 26(9), 30(11) | 79 | 1(18), 5(18), 6(14) |

| 20 | 3(9), 6(9), 11(12) | 80 | 10(16), 14(17), 18(7), 24(17), 30(13) |

| 21 | 4(7), 10(13) | 81 | 7(6), 8(15), 19(19), 21(16) |

| 22 | 3(9), 24(17), 30(15) | 82 | 2(16), 11(20) |

| 23 | 1(16), 4(10), 6(6), 12(13) | 83 | 1(13), 7(12), 13(8), 21(10) |

| 24 | 19(13), 23(16) | 84 | 1(20), 3(8), 16(18) |

| 25 | 10(16), 15(17), 16(18) | 85 | 11(8), 14(16), 24(15) |

| 26 | 8(13), 22(8), 30(13) | 86 | 4(11), 9(8) |

| 27 | 1(17), 12(15) | 87 | 7(4), 18(4), 29(11) |

| 28 | 2(9), 24(11), 29(6) | 88 | 1(12), 9(4) |

| 29 | 4(6), 6(17), 25(9), 27(16), 30(17) | 89 | 10(11), 14(15), 20(12) |

| 30 | 1(9), 15(8), 17(9), 20(18), 28(16) | 90 | 4(10), 5(10), 26(14), 28(16) |

| 31 | 2(12), 21(10), 22(19) | 91 | 2(4), 3(6), 4(10) |

| 32 | 9(4) | 92 | 23(9), 28(15), 30(17) |

| 33 | 6(15), 14(8) | 93 | 10(10), 11(15), 19(9) |

| 34 | 4(9), 8(6) | 94 | 5(4), 9(16), 18(6) |

| 35 | 16(5), 20(13), 26(6) | 95 | 16(4), 22(10), 25(16) |

| 36 | 2(15), 23(19), 24(15) | 96 | 1(16), 5(17), 25(14), 28(9) |

| 37 | 1(6), 20(20), 28(8) | 97 | 20(11), 30(17) |

| 38 | 19(5), 26(19) | 98 | 7(4), 12(9), 14(19) |

| 39 | 11(17), 15(8), 21(5), 28(16) | 99 | 15(20), 18(10), 22(4), 26(8) |

| 40 | 13(13) | 100 | 5(4), 9(4), 20(15) |

| 41 | 4(20), 17(11), 25(7), 30(18) | 101 | 4(8), 21(8), 22(9) |

| 42 | 3(5), 15(19), 17(12) | 102 | 1(10), 4(12), 6(8), 18(14) |

| 43 | 12(11), 19(6), 23(4), 26(10) | 103 | 9(13), 25(10), 28(16) |

| 44 | 6(15), 16(7) | 104 | 1(5), 6(20), 15(13) |

| 45 | 1(11), 20(19), 25(8), 30(5) | 105 | 5(9), 13(10), 17(19) |

| 46 | 4(9), 10(14), 27(13) | 106 | 17(19), 23(11), 26(15) |

| 47 | 8(5), 13(13), 15(19), 18(8) | 107 | 7(14), 8(4), 11(16) |

| 48 | 2(14), 11(9), 21(16), 22(6) | 108 | 24(17), 28(14) |

| 49 | 5(4), 6(19), 25(19), 28(15) | 109 | 15(8), 15(16)17(9) |

| 50 | 7(17), 9(6), 10(8) | 110 | 5(14), 11(8) |

| 51 | 11(5), 12(13), 14(4) | 111 | 8(15), 23(13) |

| 52 | 1(12), 2(11), 30(13) | 112 | 3(7), 15(4), 16(15), 19(10) |

| 53 | 12(10), 13(13), 22(6) | 113 | 6(5), 10(5) |

| 54 | 4(9), 8(5), 21(13), 26(11) | 114 | 4(8), 21(8), 22(9) |

| 55 | 6(4), 10(9), 20(15) | 115 | 1(10), 4(12), 6(8), 18(14) |

| 56 | 1(16), 17(13), 18(13), 28(20), 29(15) | 116 | 1(9), 20(18), 28(16) |

| 57 | 6(4), 11(7), 13(4) | 117 | 4(9), 8(6), 20(13), 26(6) |

| 58 | 2(4), 4(19), 10(6) | 118 | 9(4), 12(15), 14(18) |

| 59 | 7(6), 14(17), 19(13), 23(4), 26(9) | 119 | 6(15), 14(8), 17(7) |

| 60 | 1(13), 5(14), 30(10) | 120 | 3(12), 21(10), 22(19) |

Appendix C

Table A4.

Symbols description of model static picking order to determine the target shelf (see Section 3.1.2).

Table A4.

Symbols description of model static picking order to determine the target shelf (see Section 3.1.2).

| Symbols | Description |

|---|---|

| Collection of AGVs in warehouse. | |

| Collection of AGV picking task set. | |

| Collection of picking stations in warehouse. | |

| m | Amount of AGVs. |

| n | Total number of pick order tasks per batch. |

| k | Total number of picking stations. |

| The number of goods to be selected for the j task. | |

| l | The order in which tasks carrying target shelves are queued in front of the picking table. |

| v | The average speed of AGVs. |

| The time required for manual selection of individual goods. | |

| When the j task starts to execute, the initial position of the unloaded AGV car starts to count. | |

| In the q picking station queue, the moment j task moves to the picking station queue, the order in the queue is l. | |

| In the q picking station queue, j tasks are queued in the order of l, and the time when manual picking is completed at the picking station. | |

| Time for r AGV to queue in q picking station. | |

| The time point at which the shelf is moved to the initial position after the picking task is completed in the j task. | |

| Initial position of the r AGV. | |

| j task position on the shelf. | |

| The location of the q picking station in the warehouse. | |

| The distance r AGV has moved from its initial position to the task shelf. | |

| The distance the r AGV moves from the task shelf to the picking table. | |

| The distance the r AGV has moved from the picking table to the task shelf after picking. |

Table A5.

Variable symbols description of model static picking order to determine the target shelf (see Section 3.1.2).

Table A5.

Variable symbols description of model static picking order to determine the target shelf (see Section 3.1.2).

| Variable Symbols | Description |

|---|---|

References

- Van Gils, T.; Ramaekers, K.; Caris, A.; De Koster, R.B. Designing efficient order picking systems by combining planning problems: State-of-the-art classification and review. Eur. J. Oper. Res. 2018, 267, 1–15. [Google Scholar] [CrossRef]

- Bozer, Y.A.; Aldarondo, F.J. A simulation-based comparison of two goods-to-person order picking systems in an online retail setting. Int. J. Prod. Res. 2018, 56, 3838–3858. [Google Scholar] [CrossRef]

- Winkelhaus, S.; Zhang, M.; Grosse, E.H.; Glock, C.H. Hybrid order picking: A simulation model of a joint manual and autonomous order picking system. Comput. Ind. Eng. 2022, 167, 107981. [Google Scholar] [CrossRef]

- Ellinger, M.; Geißen, T.; Spee, D. How to Choose an Order-Picking System. In Proceedings of the 12th IMHRC, Gardanne, France, 1 June 2012; Volume 32. [Google Scholar]

- Li, Z.P.; Zhang, J.L.; Zhang, H.J.; Hua, G.W. Optimal selection of movable shelves under cargo-to-person picking mode. Int. J. Simul. Model. 2017, 16, 145–156. [Google Scholar] [CrossRef] [PubMed]

- Muter, İ.; Öncan, T. Order batching and picker scheduling in warehouse order picking. Iise Trans. 2022, 54, 435–447. [Google Scholar] [CrossRef]

- Zennaro, I.; Finco, S.; Calzavara, M.; Persona, A. Implementing E-commerce from logistic perspective: Literature review and methodological framework. Sustainability 2022, 14, 911. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, Y.; Zhou, Y. Integrated scheduling of zone picking and vehicle routing problem with time windows in the front warehouse mode. Comput. Ind. Eng. 2022, 163, 107823. [Google Scholar] [CrossRef]

- Sedarage, D.; Fujiwara, O.; Luong, H.T. Determining optimal order splitting and reorder level for N-supplier inventory systems. Eur. J. Oper. Res. 1999, 116, 389–404. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Chan, F.T.S.; Ruan, J. On-line order batching and sequencing problem with multiple pickers: A hybrid rule-based algorithm. Appl. Math. Model. 2017, 45, 271–284. [Google Scholar] [CrossRef]

- Matusiak, M.; de Koster, R.; Saarinen, J. Utilizing individual picker skills to improve order batching in a warehouse. Eur. J. Oper. Res. 2017, 263, 888–899. [Google Scholar] [CrossRef]

- Scholz, A.; Schubert, D.; Wäscher, G. Order picking with multiple pickers and due dates–simultaneous solution of order batching, batch assignment and sequencing, and picker routing problems. Eur. J. Oper. Res. 2017, 263, 461–478. [Google Scholar] [CrossRef]

- Xue, F.; Dong, T.; Qi, Z. An improving clustering algorithm for order batching of e-commerce warehouse system based on logistics robots. Int. J. Wirel. Mob. Comput. 2018, 15, 10–15. [Google Scholar] [CrossRef]

- Menéndez, B.; Pardo, E.G.; Alonso-Ayuso, A.; Molina, E.; Duarte, A. Variable neighborhood search strategies for the order batching problem. Comput. Oper. Res. 2017, 78, 500–512. [Google Scholar] [CrossRef]

- Chen, M.C.; Wu, H.P. An association-based clustering approach to order batching considering customer demand patterns. Omega 2005, 33, 333–343. [Google Scholar] [CrossRef]

- Araidah, O.A.; Dalalah, D.; Azeez, M.A.A.; Khasawneh, M.T. A heuristic for clustering and picking small items considering safe reach of the order picker. Eur. J. Ind. Eng. 2017, 11, 256–269. [Google Scholar] [CrossRef]

- Sun, Y.; Guo, S.C.; Li, X. An order-splitting model for supplier selection and order allocation in a multi-echelon supply chain. Comput. Oper. Res. 2022, 137, 105515. [Google Scholar]

- Wang, Z.; Xu, W.; Hu, X.; Wang, Y. Inventory allocation to robotic mobile-rack and picker-to-part warehouses at minimum order-splitting and replenishment costs. Ann. Oper. Res. 2022, 316, 467–491. [Google Scholar] [CrossRef]

- Zhou, L.; Shi, Y.; Wang, J.; Yang, P. A balanced heuristic mechanism for multirobot task allocation of intelligent warehouses. Math. Probl. Eng. 2014, 2014, 380480. [Google Scholar] [CrossRef]

- Yuan, Z.; Gong, Y.Y. Bot-in-time delivery for robotic mobile fulfillment systems. IEEE Trans. Eng. Manag. 2017, 64, 83–93. [Google Scholar] [CrossRef]

- Merschformann, M.; Lamballais, T.; De Koster, M.B.M.; Suhl, L. Decision rules for robotic mobile fulfillment systems. Oper. Res. Perspect. 2019, 6, 100128. [Google Scholar] [CrossRef]

- Roy, D.; Nigam, S.; De Koster, R.; Adan, I.; Resing, J. Robot-storage zone assignment strategies in mobile fulfillment systems. Transp. Res. Part E Logist. Transp. Rev. 2019, 122, 119142. [Google Scholar] [CrossRef]

- Yoshitake, H.; Kamoshida, R.; Nagashima, Y. New automated guided vehicle system using real-time holonic scheduling for warehouse picking. IEEE Robot. Autom. Lett. 2019, 4, 1045–1052. [Google Scholar] [CrossRef]

- Boysen, N.; Briskorn, D.; Emde, S. Sequencing of picking orders in mobile rack warehouses. Eur. J. Oper. Res. 2017, 259, 293–307. [Google Scholar] [CrossRef]

- Boysen, N.; Fedtke, S.; Weidinger, F. Optimizing automated sorting in warehouses: The minimum order spread sequencing problem. Eur. J. Oper. Res. 2018, 270, 386–400. [Google Scholar] [CrossRef]

- He, Z.; Aggarwal, V.; Nof, S.Y. Differentiated service policy in smart warehouse automation. Int. J. Prod. Res. 2018, 56, 6956–6970. [Google Scholar] [CrossRef]

- Dou, J.; Chen, C.; Yang, P. Genetic scheduling and reinforcement learning in multirobot systems for intelligent warehouses. Math. Probl. Eng. 2015, 2015, 597956. [Google Scholar] [CrossRef]

- Zou, B.P.; Gong, Y.M.; Xu, X.H.; Zhe, Y. Assignment rules in robotic mobile fulfilment systems for online retailers. Int. J. Prod. Res. 2017, 55, 6175–6192. [Google Scholar] [CrossRef]

- Liu, H.; Wang, F.; Zhao, J.; Yang, J.; Tan, C.; Zhou, L. Performance Analysis of Picking Path Strategies in Chevron Layout Warehouse. Mathematics 2022, 10, 395. [Google Scholar] [CrossRef]

- Lee, C.K.M.; Lin, B.B.; Ng, K.K.H.; Lv, T.Q.; Tai, W.C. Smart robotic mobile fulfillment system with dynamic conflict-free strategies considering cyber-physical integration. Adv. Eng. Inform. 2019, 42, 100998. [Google Scholar] [CrossRef]

- Moons, S.; Braekers, K.; Ramaekers, K.; Caris, A.; Arda, Y. The value of integrating order picking and vehicle routing decisions in a B2C e-commerce environment. Int. J. Prod. Res. 2019, 57, 6405–6423. [Google Scholar] [CrossRef]

- Li, M.P. Task Assignment and Path Planning for Autonomous Mobile Robots in Stochastic Warehouse Systems. Ph.D. Thesis, Rochester Institute of Technology, Rochester, NY, USA, 2019. [Google Scholar]

- Zhou, L.; Zhao, J.; Liu, H.; Wang, F.; Yang, J.; Wang, S. Stochastic models of routing strategies under the class-based storage policy in fishbone layout warehouses. Sci. Rep. 2022, 12, 1–17. [Google Scholar] [CrossRef]

- Saylam, S.; Çelik, M.; Süral, H. The min–max order picking problem in synchronised dynamic zone-picking systems. Int. J. Prod. Res. 2023, 61, 1–19. [Google Scholar] [CrossRef]

- Alqahtani, A.Y. Improving order-picking response time at retail warehouse: A case of sugar company. SN Appl. Sci. 2022, 5, 8. [Google Scholar] [CrossRef]