A Discrete-Event Simheuristic for Solving a Realistic Storage Location Assignment Problem

Abstract

1. Introduction

2. Literature Review

2.1. The Storage Location Assignment Problem

2.2. Solving Complex Optimization Problems: Simheuristics and Biased Randomization

2.3. FlexSim as Discrete-Event Simulation Research Tool

3. Problem Definition

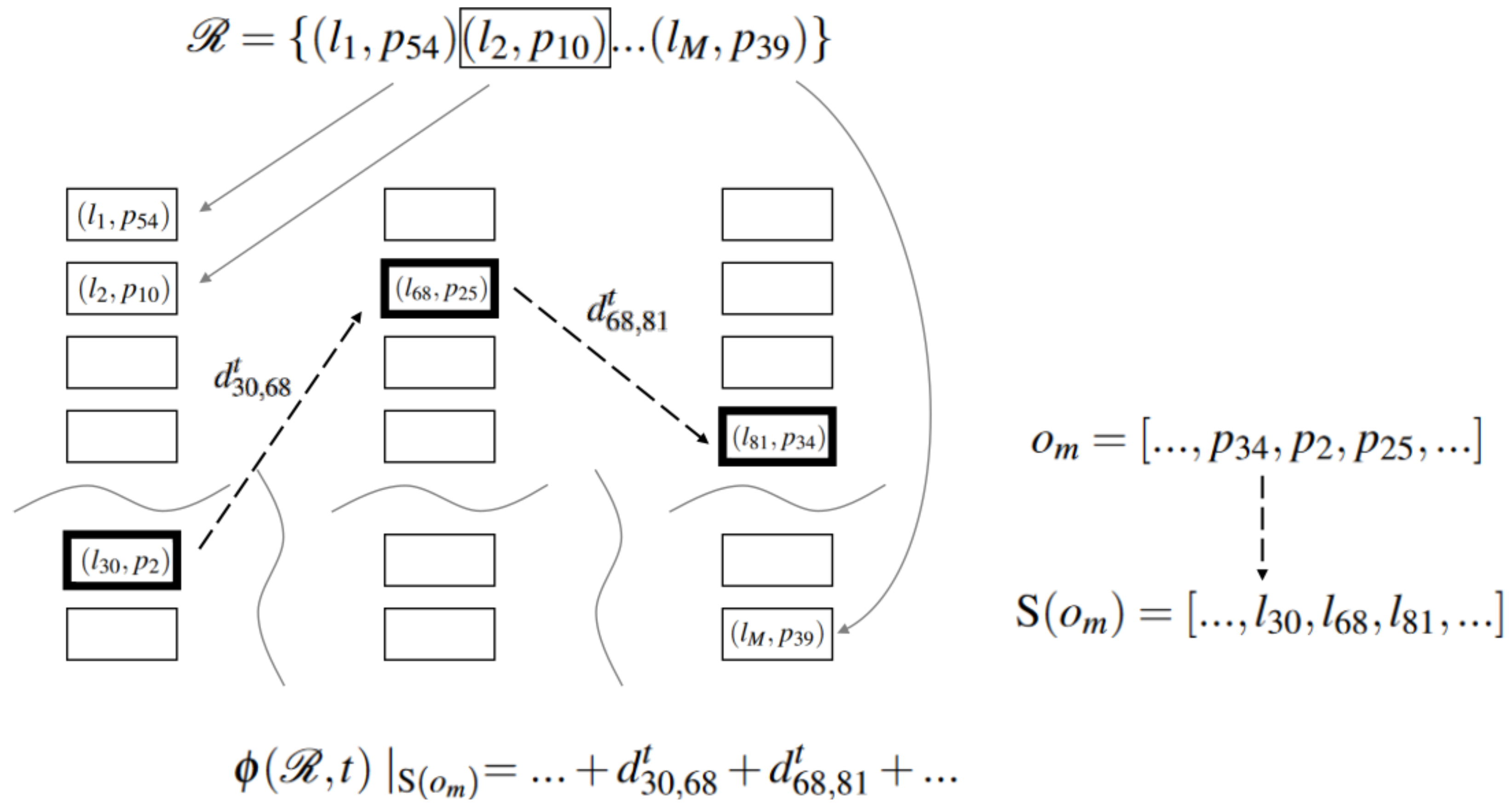

3.1. A Generic Formulation for the Static SLAP with Orders

3.2. Additional Assumptions for the Considered SLAP Study

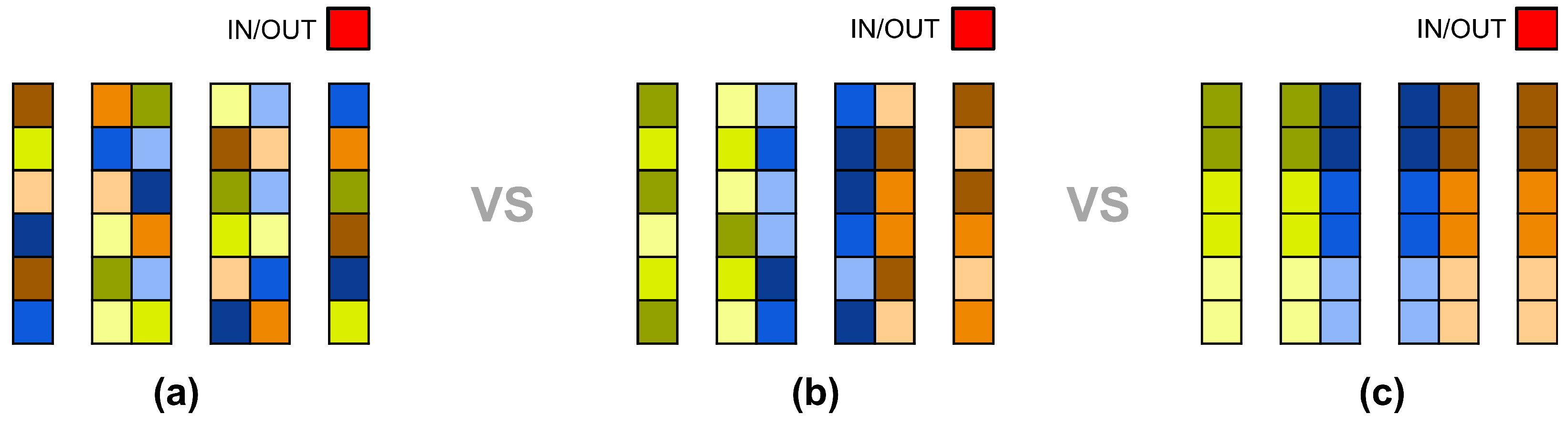

3.2.1. Warehouse

3.2.2. Products

3.2.3. Orders

3.2.4. Solution

4. Modeling Approach

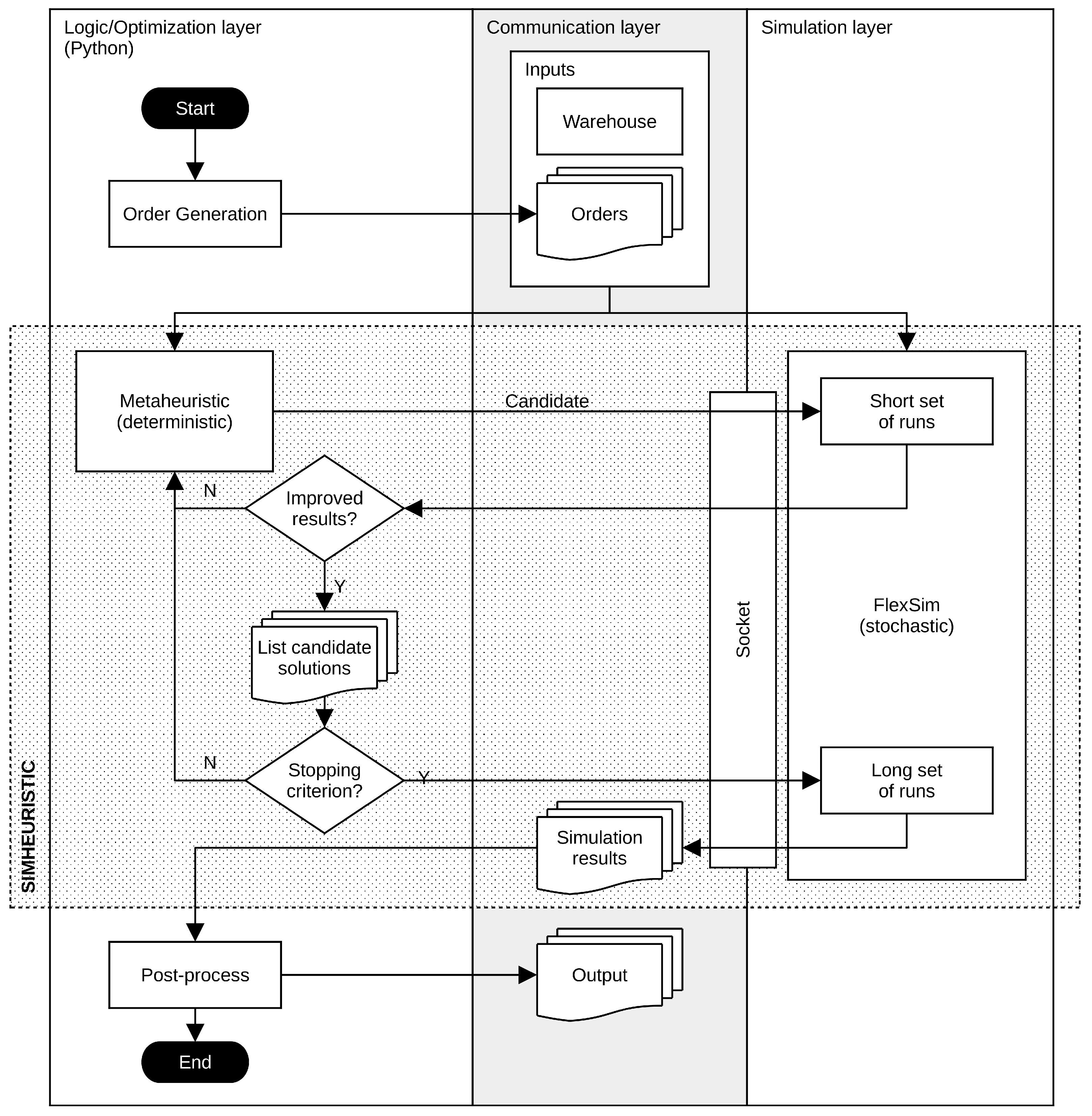

4.1. Simheuristic Framework

4.2. Order Generation

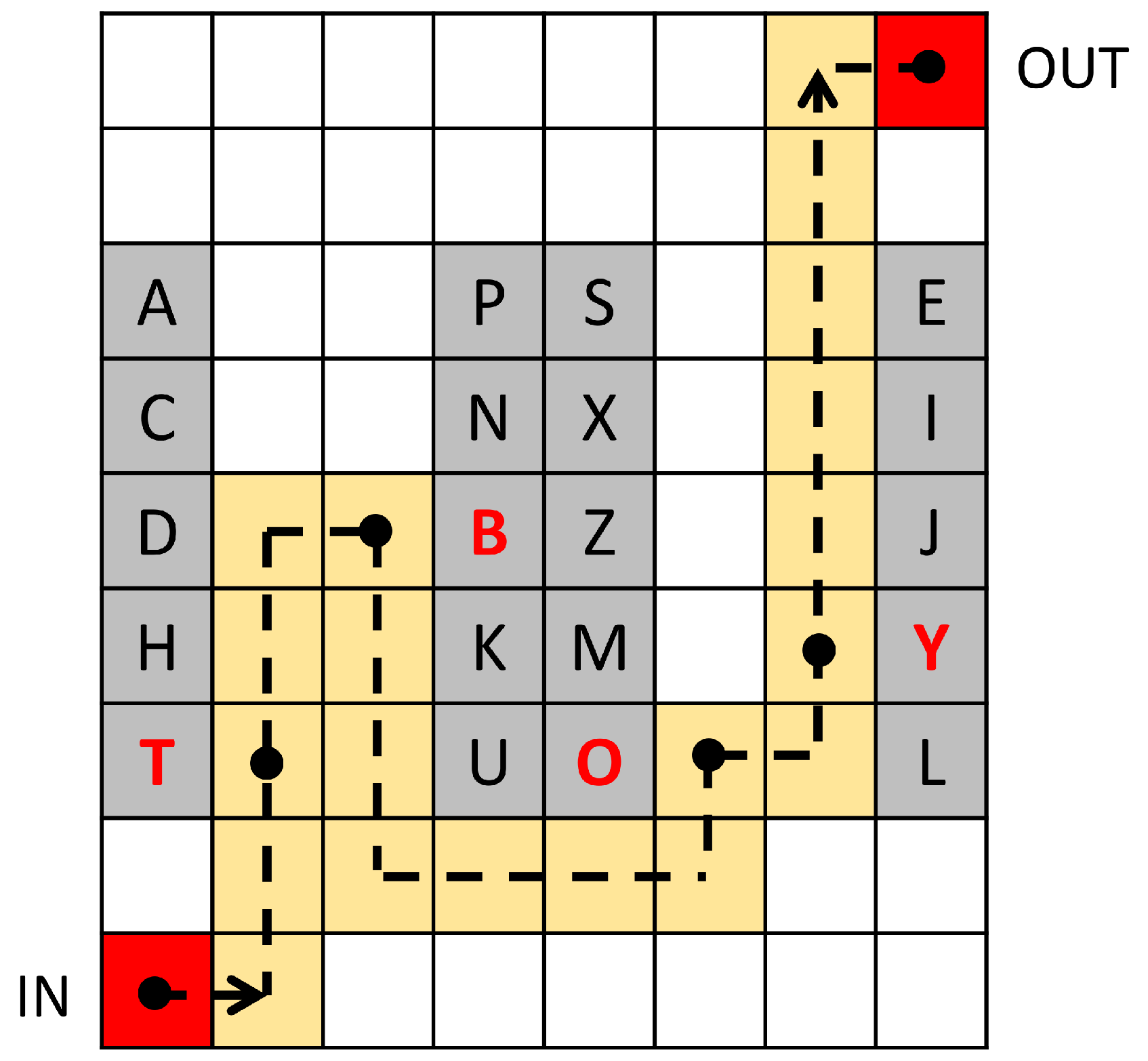

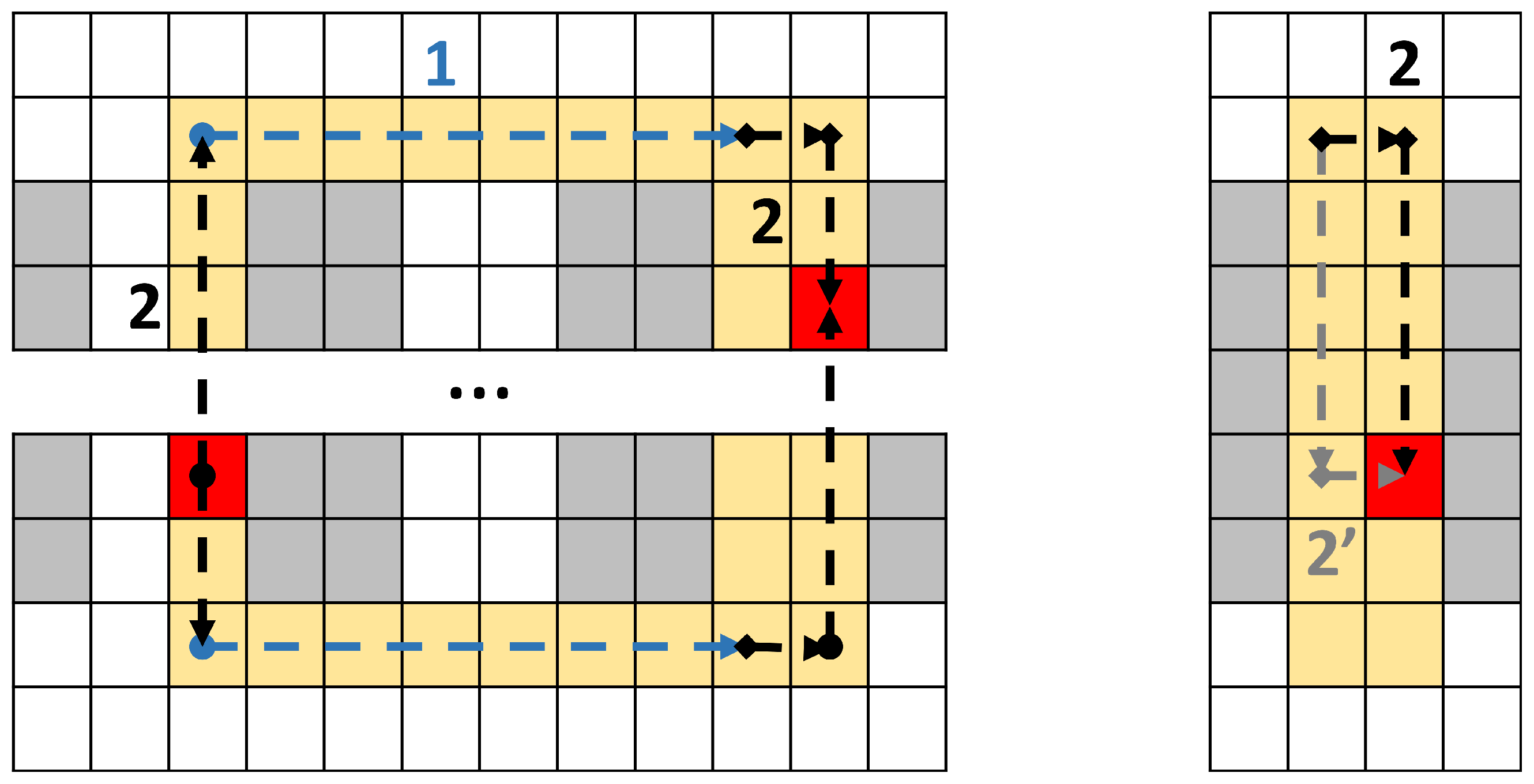

4.3. Warehouse Navigation

| Algorithm 1 W* algorithm. |

Inputs: , , Output:

|

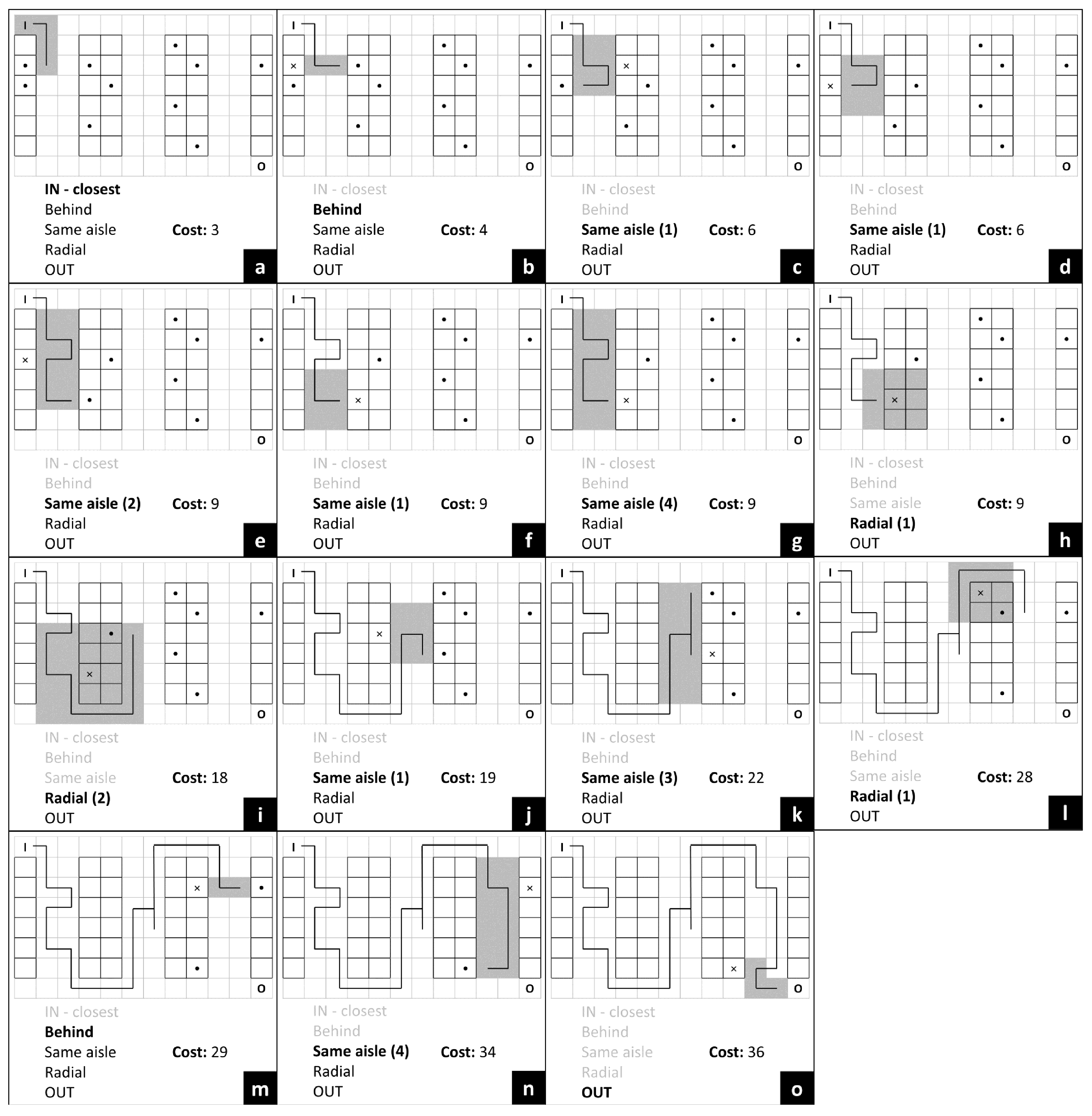

4.4. Picking Operation and Solution Evaluation

| Algorithm 2 Evaluate Deterministic Solution. | |

| Inputs: , | ▹ Storage Location Assignment |

| Outputs: , | ▹ Per order |

| |

| ▹ The route begins from the initial (“IN”) point |

| |

| ▹ Every loop iteration the search step increases |

| ▹ First: search behind |

| |

| ▹ Second: search in the aisle |

| |

| ▹ Third: search in a “round” fashion |

| |

| ▹ The route finishes at the final (“OUT”) point |

4.5. A Simheuristic for Solving the Storage Location Assignment Problem

| Algorithm 3 Biased Randomized Heuristic (BRA). | |

| Inputs: , , | |

| Output: | ▹ Storage Location Assignment |

| ▹ Most frequent first |

| ▹ Closer to input and output first |

| |

| ▹ Biased randomization using geometric distribution with |

| |

| Algorithm 4 Simheuristic. | |

Inputs: , , , Output: | |

| ▹ = 0: greedy |

| ▹ see Algorithm 2 |

| ▹ fast simulation: number of replications |

| ▹ list of elite solutions |

| |

| ▹ update elite list to include new best solution |

| |

| ▹ intensive simulation: number of replications |

| ▹ return solution with minimum stochastic cost |

5. Computational Experiments

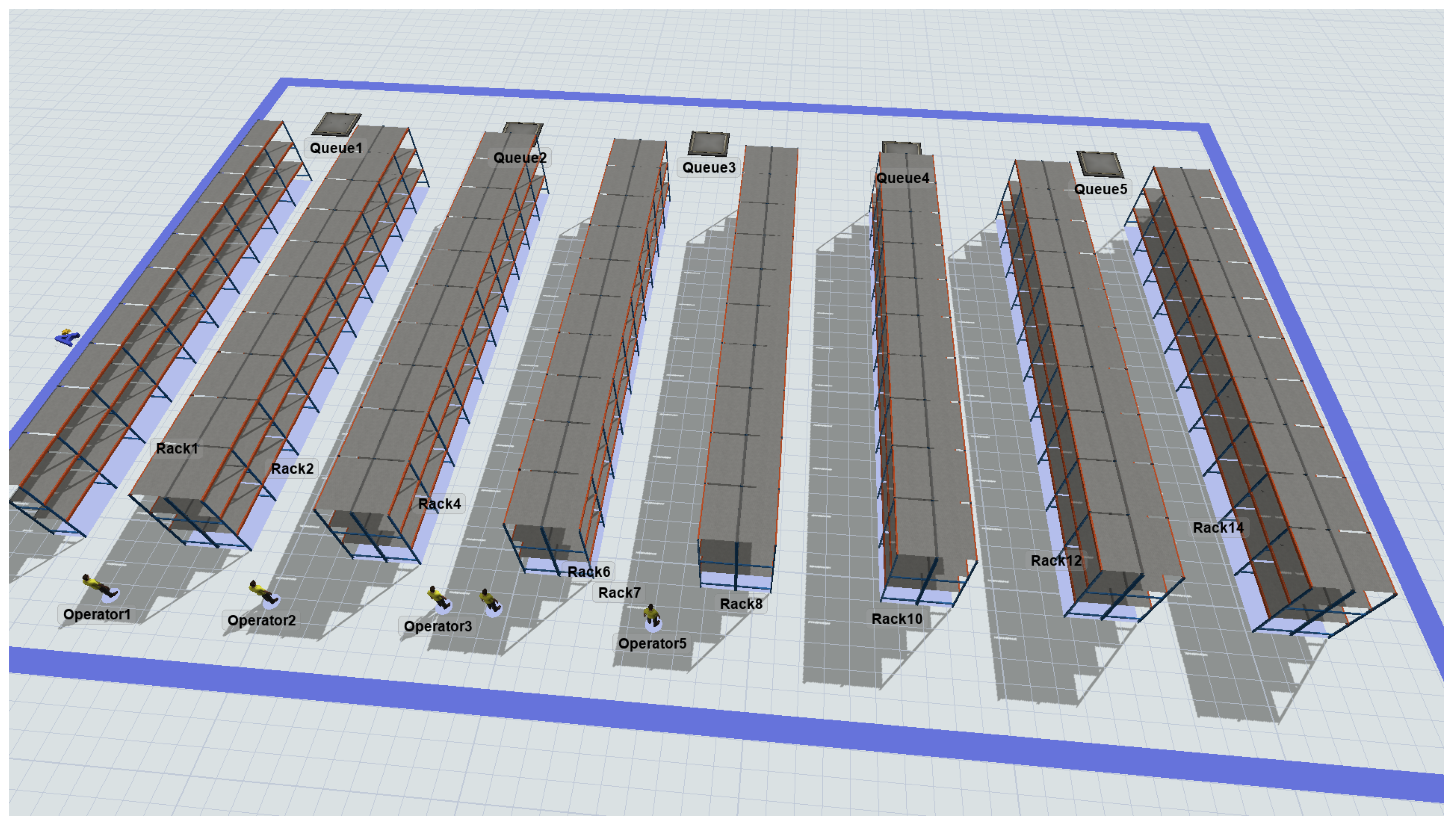

5.1. Experiment Setting

5.2. FlexSim Modeling

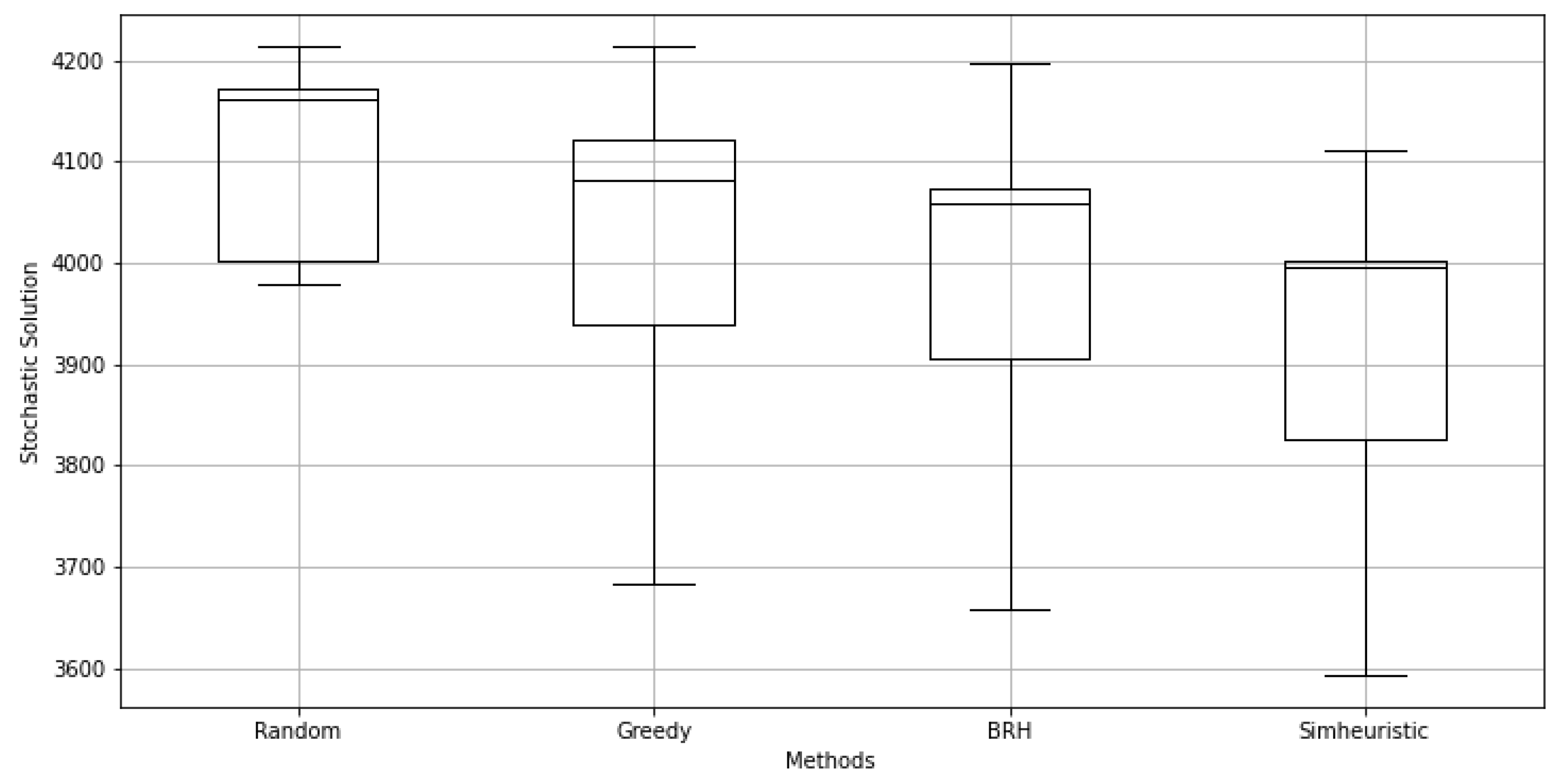

5.3. Results and Discussion

6. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, R.Q.; Wang, M.; Pan, X. New model of the storage location assignment problem considering demand correlation pattern. Comput. Ind. Eng. 2019, 129, 210–219. [Google Scholar] [CrossRef]

- Reyes, J.; Solano-Charris, E.; Montoya-Torres, J. The storage location assignment problem: A literature review. Int. J. Ind. Eng. Comput. 2019, 10, 199–224. [Google Scholar] [CrossRef]

- Chica, M.; Juan, A.A.; Bayliss, C.; Cordón, O.; Kelton, W.D. Why simheuristics? Benefits, limitations, and best practices when combining metaheuristics with simulation. SORT Stat. Oper. Res. Trans. 2020, 44, 311–334. [Google Scholar] [CrossRef]

- van Rossum, G.; Drake, F.L. Python 3 Reference Manual; CreateSpace: Scotts Valley, CA, USA, 2009. [Google Scholar]

- Nordgren, W.B. FlexSim Simulation Environment. In Proceedings of the 2002 Winter Simulation Conference, San Diego, CA, USA, 8–11 December 2002; pp. 250–252. [Google Scholar] [CrossRef]

- Tendeloo, Y.V.; Vangheluwe, H. Discrete event system specification modeling and simulation. In Proceedings of the 2018 Winter Simulation Conference, Gothenburg, Sweden, 9–12 December 2018; pp. 162–176. [Google Scholar] [CrossRef]

- Amorim-Lopes, M.; Guimarães, L.; Alves, J.; Almada-Lobo, B. Improving picking performance at a large retailer warehouse by combining probabilistic simulation, optimization, and discrete-event simulation. Int. Trans. Oper. Res. 2021, 28, 687–715. [Google Scholar] [CrossRef]

- Kofler, M. Optimising the Storage Location Assignment Problem under Dynamic Conditions. Ph.D. Thesis, JKU—Johannes Kepler Universität Linz, Linz, Austria, 2015. [Google Scholar]

- Fumi, A.; Scarabotti, L.; Schiraldi, M.M. Minimizing Warehouse Space with a Dedicated Storage Policy. Int. J. Eng. Bus. Manag. 2013, 5, 21. [Google Scholar] [CrossRef]

- Xie, J.; Mei, Y.; Ernst, A.T.; Li, X.; Song, A. A genetic programming-based hyper-heuristic approach for storage location assignment problem. In Proceedings of the 2014 Congress on Evolutionary Computation (CEC), Beijing, China, 6–11 July 2014; pp. 3000–3007. [Google Scholar] [CrossRef]

- Chen, L.; Langevin, A.; Riopel, D. A Tabu search algorithm for the relocation problem in a warehousing system. Int. J. Prod. Econ. 2011, 129, 147–156. [Google Scholar] [CrossRef]

- Boysen, N.; de Koster, R.; Weidinger, F. Warehousing in the e-commerce era: A survey. Eur. J. Oper. Res. 2019, 277, 396–411. [Google Scholar] [CrossRef]

- Silva, A.; Coelho, L.C.; Darvish, M.; Renaud, J. Integrating storage location and order picking problems in warehouse planning. Transp. Res. Part E Logist. Transp. Rev. 2020, 140, 102003. [Google Scholar] [CrossRef]

- Mantel, R.J.; Schuur, P.C.; Heragu, S.S. Order oriented slotting: A new assignment strategy for warehouses. Eur. J. Ind. Eng. 2007, 1, 301–316. [Google Scholar] [CrossRef]

- Keung, K.L.; Lee, C.K.M.; Ji, P. Data-driven order correlation pattern and storage location assignment in robotic mobile fulfillment and process automation system. Adv. Eng. Inform. 2021, 50, 101369. [Google Scholar] [CrossRef]

- Keung, K.L.; Lee, C.K.M.; Ji, P. Industrial internet of things-driven storage location assignment and order picking in a resource synchronization and sharing-based robotic mobile fulfillment system. Adv. Eng. Inform. 2022, 52, 101540. [Google Scholar] [CrossRef]

- Zhang, G.; Shang, X.; Alawneh, F.; Yang, Y.; Nishi, T. Integrated production planning and warehouse storage assignment problem: An IoT assisted case. Int. J. Prod. Econ. 2021, 234, 108058. [Google Scholar] [CrossRef]

- Lanza, G.; Passacantando, M.; Scutellà, M.G. Assigning and sequencing storage locations under a two level storage policy: Optimization model and matheuristic approaches. Omega 2022, 108, 102565. [Google Scholar] [CrossRef]

- Xu, X.; Ren, C. A novel storage location assignment in multi-pickers picker-to-parts systems integrating scattered storage, demand correlation, and routing adjustment. Comput. Ind. Eng. 2022, 172, 108618. [Google Scholar] [CrossRef]

- Guo, X.; Chen, R.; Du, S.; Yu, Y. Storage assignment for newly arrived items in forward picking areas with limited open locations. Transp. Res. Part E Logist. Transp. Rev. 2021, 151, 102359. [Google Scholar] [CrossRef]

- Montanari, R.; Micale, R.; Bottani, E.; Volpi, A.; La Scalia, G. Evaluation of routing policies using an interval-valued TOPSIS approach for the allocation rules. Comput. Ind. Eng. 2021, 156, 107256. [Google Scholar] [CrossRef]

- Juan, A.A.; Keenan, P.; Martí, R.; McGarraghy, S.; Panadero, J.; Carroll, P.; Oliva, D. A review of the role of heuristics in stochastic optimisation: From metaheuristics to learnheuristics. Ann. Oper. Res. 2021, 320, 831–861. [Google Scholar] [CrossRef]

- Bianchi, L.; Dorigo, M.; Gambardella, L.M.; Gutjahr, W.J. A survey on metaheuristics for stochastic combinatorial optimization. Nat. Comput. 2009, 8, 239–287. [Google Scholar] [CrossRef]

- Rabe, M.; Deininger, M.; Juan, A.A. Speeding up computational times in simheuristics combining genetic algorithms with discrete-event simulation. Simul. Model. Pract. Theory 2020, 103, 102089. [Google Scholar] [CrossRef]

- Figueira, G.; Almada-Lobo, B. Hybrid simulation–optimization methods: A taxonomy and discussion. Simul. Model. Pract. Theory 2014, 46, 118–134. [Google Scholar] [CrossRef]

- Castaneda, J.; Martin, X.A.; Ammouriova, M.; Panadero, J.; Juan, A.A. A Fuzzy Simheuristic for the Permutation Flow Shop Problem under Stochastic and Fuzzy Uncertainty. Mathematics 2022, 10, 1760. [Google Scholar] [CrossRef]

- Antoniadis, N.; Cordy, M.; Sifaleras, A.; Le Traon, Y. A variable neighborhood search simheuristic algorithm for reliability optimization of smart grids under uncertainty. Int. Trans. Oper. Res. 2022, 29, 2172–2200. [Google Scholar] [CrossRef]

- Hatami, S.; Calvet, L.; Fernandez-Viagas, V.; Framinan, J.M.; Juan, A.A. A simheuristic algorithm to set up starting times in the stochastic parallel flowshop problem. Simul. Model. Pract. Theory 2018, 86, 55–71. [Google Scholar] [CrossRef]

- Ferone, D.; Hatami, S.; González-Neira, E.M.; Juan, A.A.; Festa, P. A biased-randomized iterated local search for the distributed assembly permutation flow-shop problem. Int. Trans. Oper. Res. 2020, 27, 1368–1391. [Google Scholar] [CrossRef]

- Bayliss, C.; Guidotti, R.; Estrada-Moreno, A.; Franco, G.; Juan, A.A. A biased-randomized algorithm for optimizing efficiency in parametric earthquake (re) insurance solutions. Comput. Oper. Res. 2020, 123, 105033. [Google Scholar] [CrossRef]

- Nordgren, W.B. FlexSim simulation environment. In Proceedings of the 2003 Winter Simulation Conference, New Orleans, LA, USA, 7–10 December 2003; Volume 1, pp. 197–200. [Google Scholar] [CrossRef]

- Leon, J.F.; Peyman, M.; Li, Y.; Dehghanimohammadabadi, M.; Calvet, L.; Marone, P.; Juan, A.A. A Tutorial On Combining FlexSim With Python For Developing Discrete-Event Simheuristics. In Proceedings of the 2022 Winter Simulation Conference, Singapore, 11–14 December 2022. [Google Scholar]

- Zhu, X.; Zhang, R.; Chu, F.; He, Z.; Li, J. A Flexsim-based Optimization for the Operation Process of Cold-Chain Logistics Distribution Centre. J. Appl. Res. Technol. 2014, 12, 270–278. [Google Scholar] [CrossRef]

- Wu, G.; Yao, L.; Yu, S. Simulation and optimization of production line based on FlexSim. In Proceedings of the 2018 Chinese Control and Decision Conference (CCDC), Shenyang, China, 9–11 June 2018; pp. 3358–3363. [Google Scholar] [CrossRef]

- Pan, J.C.H.; Shih, P.H.; Wu, M.H.; Lin, J.H. A storage assignment heuristic method based on genetic algorithm for a pick-and-pass warehousing system. Comput. Ind. Eng. 2015, 81, 1–13. [Google Scholar] [CrossRef]

- Jiao, Y.L.; Xing, X.C.; Zhang, P.; Xu, L.C.; Liu, X.R. Multi-objective storage location allocation optimization and simulation analysis of automated warehouse based on multi-population genetic algorithm. Concurr. Eng. 2018, 26, 367–377. [Google Scholar] [CrossRef]

- Koster, R.D.; Poort, E.V.D. Routing orderpickers in a warehouse: A comparison between optimal and heuristic solutions. IIE Trans. 1998, 30, 469–480. [Google Scholar] [CrossRef]

- Lee, I.G.; Chung, S.H.; Yoon, S.W. Two-stage storage assignment to minimize travel time and congestion for warehouse order picking operations. Comput. Ind. Eng. 2020, 139, 106129. [Google Scholar] [CrossRef]

| Warehouse Instance A | |||||||

|---|---|---|---|---|---|---|---|

| Input/Output | Random | Greedy | BRA | Simheuristic | Gap | Gap | Gap |

| [1] | [2] | [3] | [4] | [1]–[4] | [2]–[4] | [3]–[4] | |

| C / C | 4163 | 4102 | 4058 | 3998 | −4.0% | −2.5% | −1.5% |

| C / L | 4171 | 3938 | 3905 | 3827 | −8.2% | −2.8% | −2.0% |

| C / R | 4128 | 4129 | 4074 | 3997 | −3.2% | −3.2% | −1.9% |

| L / C | 3985 | 3775 | 3710 | 3675 | −7.8% | −2.6% | −0.9% |

| L / L | 3978 | 3682 | 3658 | 3593 | −9.7% | −2.4% | −1.8% |

| L / R | 4003 | 3946 | 3936 | 3882 | −3.0% | −1.6% | −1.4% |

| R / C | 4167 | 4122 | 4076 | 4050 | −2.8% | −1.7% | −0.6% |

| R / L | 4191 | 4215 | 4197 | 4111 | −1.9% | −2.5% | −2.0% |

| R / R | 4214 | 4081 | 4059 | 4002 | −5.0% | −1.9% | −1.4% |

| Average | 4111 | 3999 | 3964 | 3904 | −5.1% | −2.4% | −1.5% |

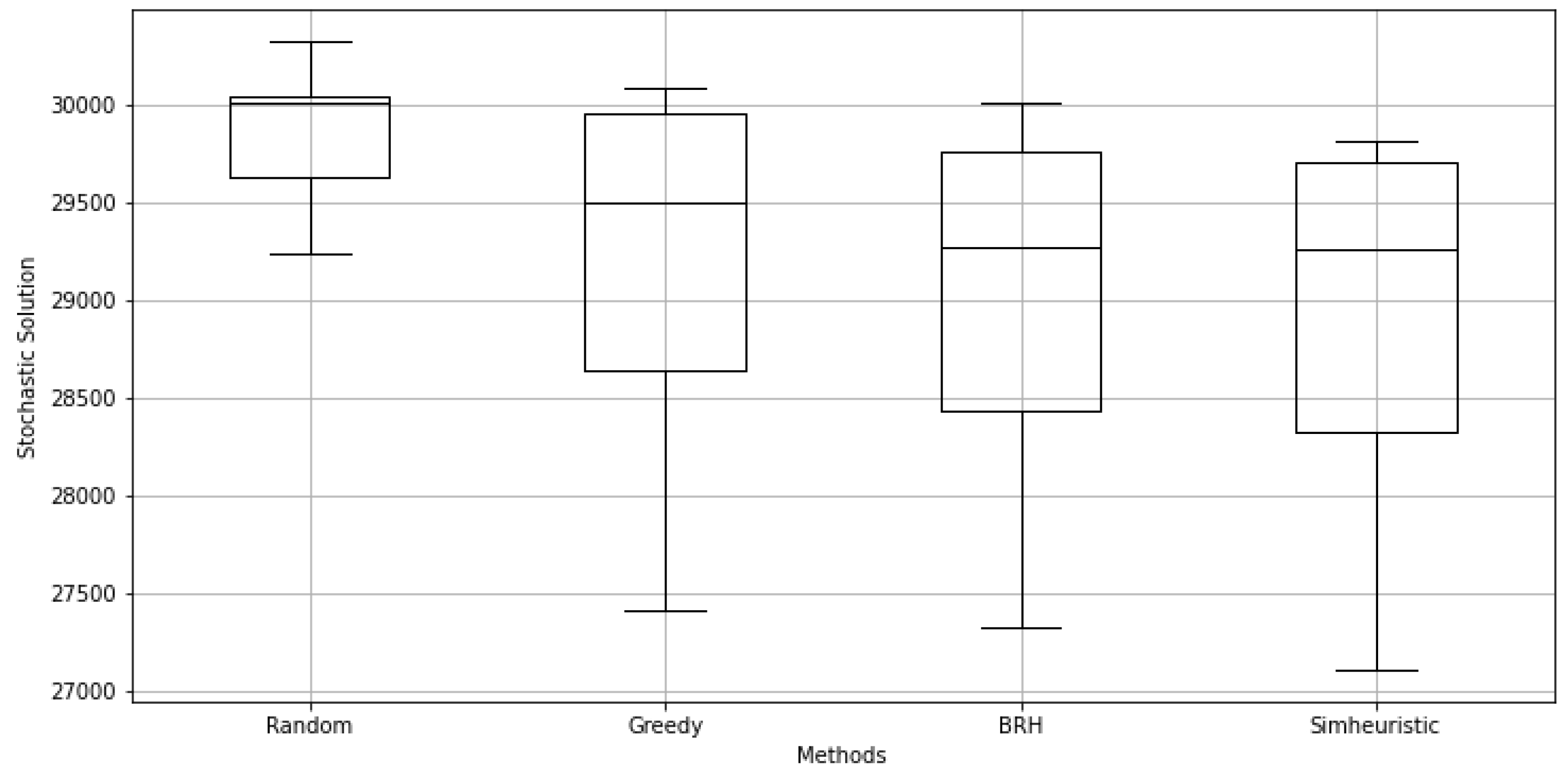

| Warehouse Instance B | |||||||

|---|---|---|---|---|---|---|---|

| Input/Output | Random | Greedy | BRA | Simheuristic | Gap | Gap | Gap |

| [1] | [2] | [3] | [4] | [1]–[4] | [2]–[4] | [3]–[4] | |

| C / C | 30,013 | 29,497 | 29,272 | 29,317 | −2.3% | −0.6% | 0.2% |

| C / L | 29,996 | 28,718 | 28,741 | 28,502 | −5.0% | −0.8% | −0.8% |

| C / R | 30,333 | 30,088 | 29,816 | 29,710 | −2.1% | −1.3% | −0.4% |

| L / C | 29,242 | 27,923 | 27,799 | 27,799 | −4.9% | −0.4% | 0.0% |

| L / L | 29,320 | 27,414 | 27,322 | 27,106 | −7.6% | −1.1% | −0.8% |

| L / R | 29,629 | 28,647 | 28,434 | 28,330 | −4.4% | −1.1% | −0.4% |

| R / C | 30,049 | 29,964 | 29,768 | 29,814 | −0.8% | −0.5% | 0.2% |

| R / L | 30,113 | 29,638 | 29,385 | 29,263 | −2.8% | −1.3% | −0.4% |

| R / R | 30,038 | 29,979 | 30,016 | 29,763 | −0.9% | −0.7% | −0.8% |

| Average | 29,859 | 29,096 | 28,950 | 28,845 | −3.4% | −0.9% | −0.4% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leon, J.F.; Li, Y.; Peyman, M.; Calvet, L.; Juan, A.A. A Discrete-Event Simheuristic for Solving a Realistic Storage Location Assignment Problem. Mathematics 2023, 11, 1577. https://doi.org/10.3390/math11071577

Leon JF, Li Y, Peyman M, Calvet L, Juan AA. A Discrete-Event Simheuristic for Solving a Realistic Storage Location Assignment Problem. Mathematics. 2023; 11(7):1577. https://doi.org/10.3390/math11071577

Chicago/Turabian StyleLeon, Jonas F., Yuda Li, Mohammad Peyman, Laura Calvet, and Angel A. Juan. 2023. "A Discrete-Event Simheuristic for Solving a Realistic Storage Location Assignment Problem" Mathematics 11, no. 7: 1577. https://doi.org/10.3390/math11071577

APA StyleLeon, J. F., Li, Y., Peyman, M., Calvet, L., & Juan, A. A. (2023). A Discrete-Event Simheuristic for Solving a Realistic Storage Location Assignment Problem. Mathematics, 11(7), 1577. https://doi.org/10.3390/math11071577