Optimal Design of Reverse Logistics Recycling Network for Express Packaging Considering Carbon Emissions

Abstract

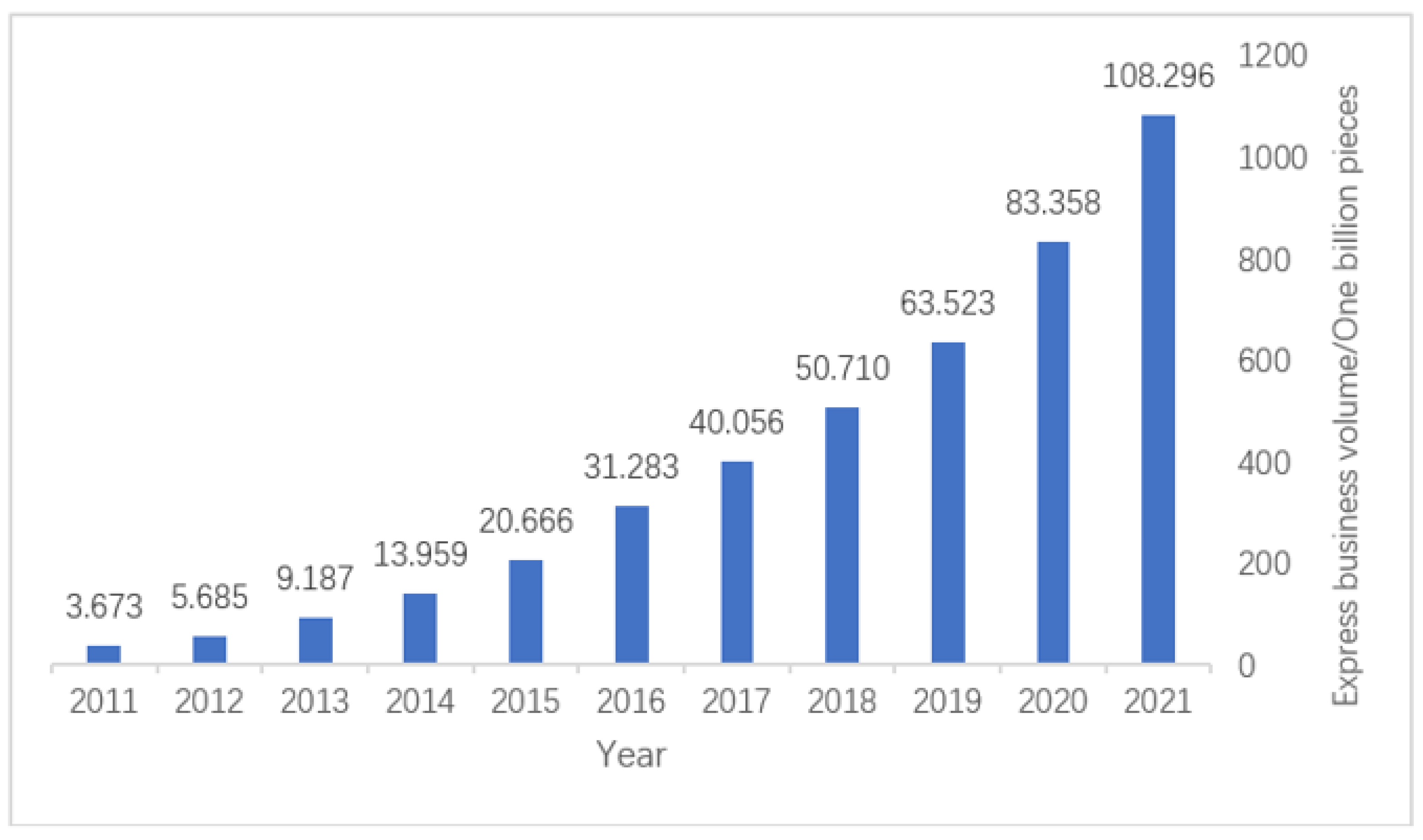

1. Introduction

- (1)

- The phenomenon of excessive packaging of express products. The problem is more common in the current courier industry because the first impression of consumers on the courier packaging directly affects the entire shopping experience, and the contribution of consumer shopping satisfaction is greater, so e-commerce merchants in the delivery of goods based on basic protective protection, usually increase the protective measures to avoid damage and other situations in transit [8,9,10].

- (2)

- Some of the courier packaging used in the production of materials with poor environmental performance, resulting in packaging waste that is difficult to naturally degrade. The common airbag foam padding, tape, and black bags made of PVC and other materials in courier packaging degrade slowly under natural conditions and produce a lot of toxic and harmful substances when incinerated [11].

- (3)

- The existing courier packaging has a low degree of standardization and a low reuse rate. The development of express packaging standards involves many aspects, such as packaging materials, filler materials, size specifications, plastic sealing methods, marking, and inspection methods. Low standardization will, on the one hand, reduce logistics efficiency, reduce the management level and quality of logistics services, and increase unnecessary costs, and on the other hand, reduce packaging mobility, narrow the scope of application, increase the difficulty of coordinating the use of express packaging, and make the overall recycling rate lower [12].

- (4)

- The overall recycling rate of express packaging is low. A related research study shows that the actual recycling rate of cardboard and recyclable plastic in China in a year is less than 10%, and the overall courier packaging recycling rate is less than 20%. In some densely populated cities, the incremental amount of courier packaging waste accounts for more than 90% of the total incremental amount of domestic waste.

- (5)

- The reverse logistics system of express packaging recycling is not sound, and systematic scientific planning guidance is missing, manifested by the lagging work of express packaging classification, the confusion of social recycling channels and the low degree of specialization of treatment methods, the inadequacy of institutional mechanisms of relevant enterprises and government departments, the lack of laws and regulations and policy support, and the low enthusiasm of consumer participation in recycling [13,14,15,16].

- From the concept of reducing carbon emission and environmental pollution, this paper gives the process of designing the reverse logistics network for express packaging recycling, taking the M region as an example, and establishes a four-level network containing primary recycling nodes, recycling centers, processing centers, and terminals.

- Construct a candidate node selection model based on the K-means algorithm, cluster by distance from 535 express outlets, and use the obtained basic data to calculate the distance between each node, the express volume of each node, etc.

- Construct a node selection model based on the NSGA-II algorithm, with the objective function of minimizing the total cost and carbon emission, and consider the effects of different locations of the selected nodes, different types of vehicles between nodes, and different processing technologies adopted by the processing centers.

2. Problem Description

3. Algorithm Introduction

3.1. Introduction to K-Means Algorithm

3.1.1. Principle of K-Means Algorithm

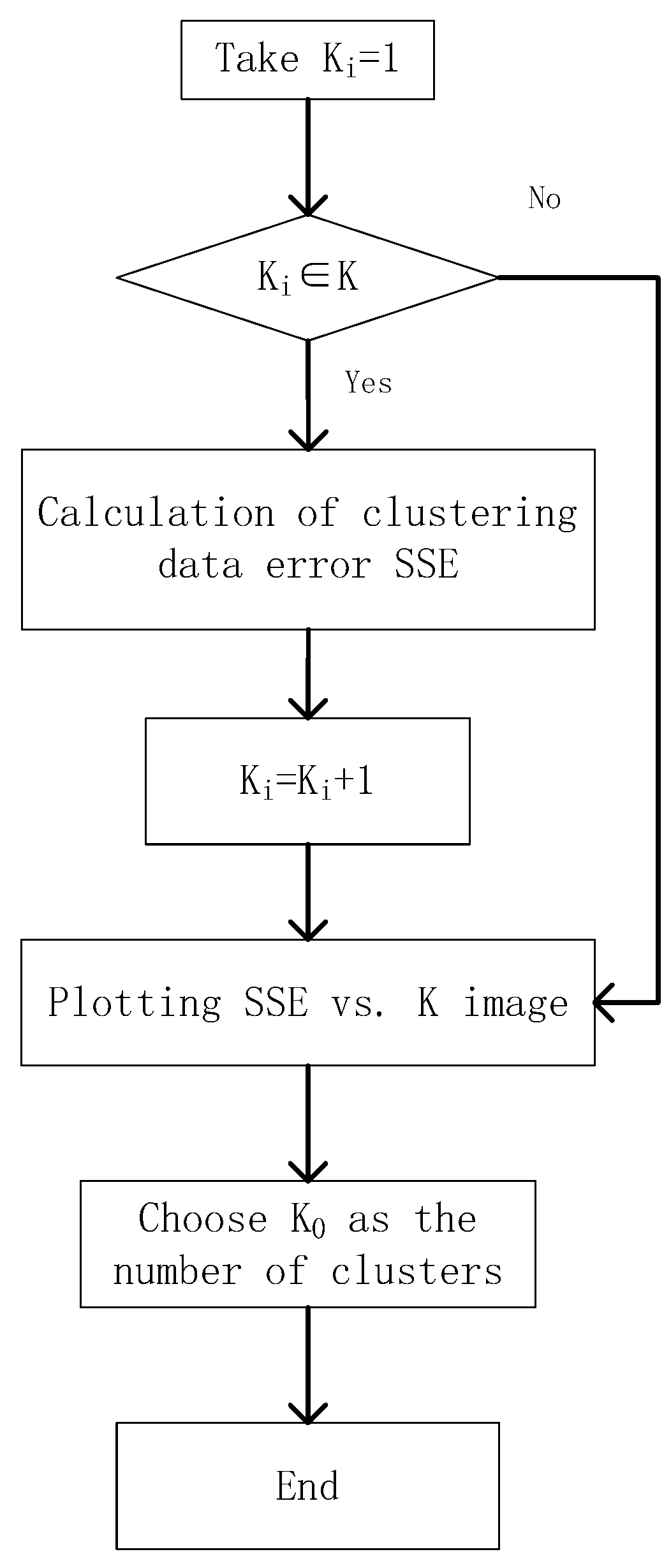

3.1.2. K Value Determination Method

- (1)

- Select-on-demand method: This means that the number of classification groups of data is determined according to the actual demand.

- (2)

- Elbow method: error squared and SSE is a function of the number of clusters K, SSE becomes smaller with the increase of K, and when K increases to a certain value, the rate of change of SSE will rapidly become smaller; that is, as the value of K continues to increase and tends to level off, so that the relationship between K and SSE graph is similar to the elbow, the inflection point of the elbow is the optimal number of clusters K.

- (3)

- Contour coefficient method: the contour coefficient of a certain data point of a cluster is the difference between the average distance (cohesion) of the data and the data of the same cluster and the average distance (separation) of all data of the nearest cluster and the ratio of the larger of the two. After finding the data, the contour coefficient of the rest of the data in the same cluster is obtained, and the average value is the average contour coefficient of the data in the group. The larger the average contour coefficient, the better the clustering effect, the corresponding K value is the optimal number of clusters.

- (4)

- Gap Statistics method: in the sample area in accordance with the uniform distribution of randomly generated and the original sample number of random samples, and these random samples and K-means clustering, calculate the loss of random samples and the actual sample loss of the difference between the maximum value of the corresponding K is the optimal number of clusters.

3.2. Introduction of NSGA-II Algorithm

3.2.1. Introduction to Multi-Objective Optimization Algorithms

3.2.2. Introduction to NSGA-II Algorithm

- (1)

- Introduction to the fast non-dominated sorting method.

- (2)

- Crowding degree profile.

- (3)

- Introduction to the elite strategy.

4. Model Building

4.1. Modeling of Reverse Logistics Network in M Region

4.1.1. Network Level and Node Analysis

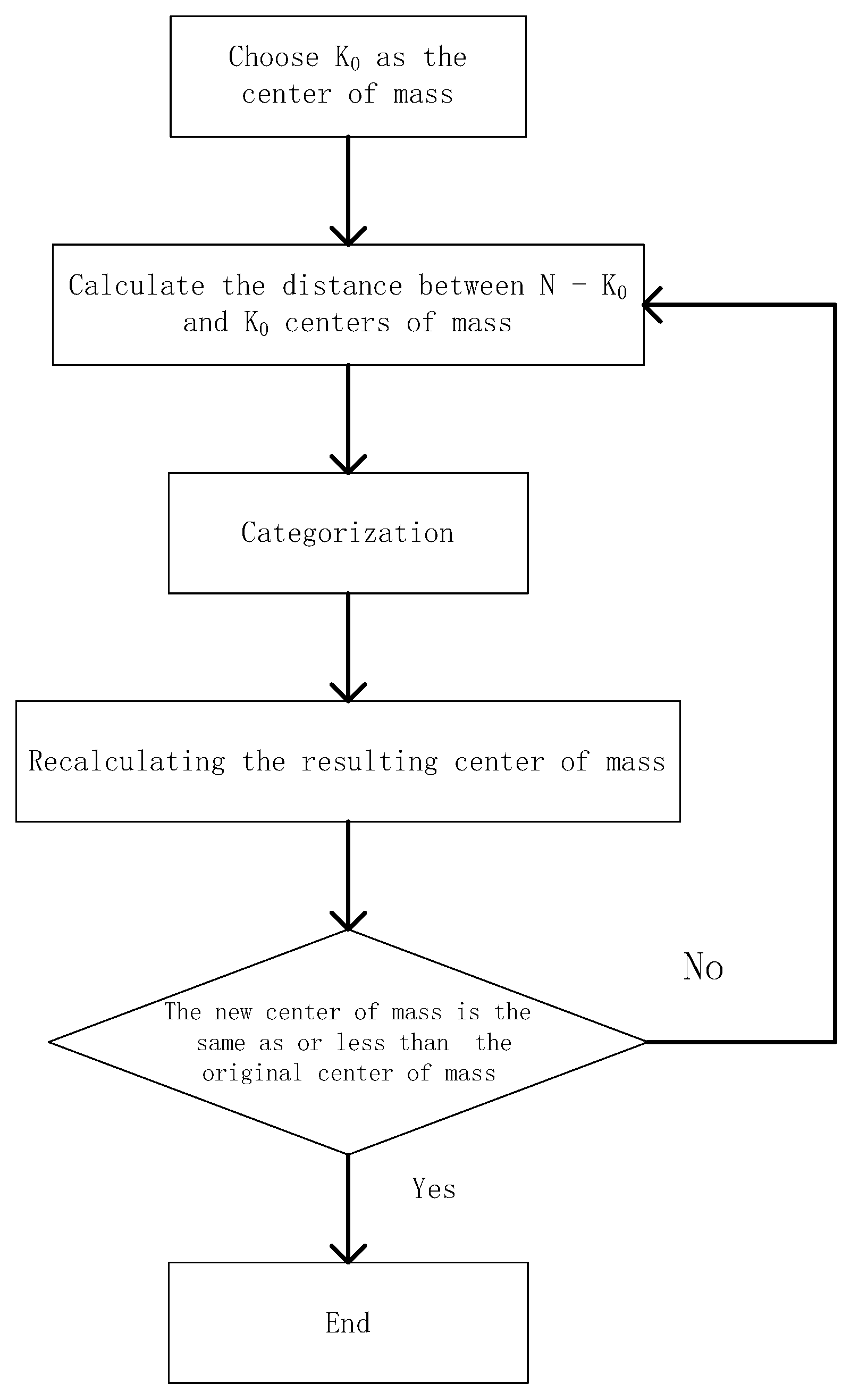

4.1.2. Determination of Candidate nodes Based on the K-Means Algorithm

- Basic assumptions

- Symbol Description

| Symbols | Meaning |

| Clustering error of all sample data. | |

| New cluster center and old cluster center error. | |

| Number of cluster centers set of values, . | |

| Number of clustering centers, . | |

| The clustering center (center of mass), and is an integer. | |

| The center of clustering (center of mass) is the data set of , and is an integer. | |

| The data, |

- Model Building

- K-means clustering algorithm steps

4.2. NSGA-II Algorithm-Based Node Siting Modeling

- Symbol Description

| Symbols | Meaning |

| Total cost | |

| Shipping cost | |

| Processing cost | |

| Construction cost | |

| Number of candidate nodes | |

| The straight-line distance between the jth candidate node and the ith candidate node | |

| Packing volume between the jth candidate node transported to the ith candidate node | |

| Amount of packaging recycling at the ith node | |

| The ith node can carry the maximum recycling volume | |

| Mass equivalent per courier package | |

| Freight rate for the kth vehicle unit, k = 1, 2, 3, 4 | |

| Processing cost using the jth technology unit (j = 1,2,3) | |

| Regional k unit construction costs, k = 1, 2, 3, 4 | |

| Unit storage capacity | |

| emissions during transportation | |

| CO2 emissions from the treatment process | |

| The kth vehicle unit carbon emission factor, k = 1, 2 | |

| Carbon emission factor per unit for the kth vehicle, k = 3, 4 | |

| Fuel consumption per unit distance for the kth vehicle, k = 1, 2 | |

| Electricity consumption per unit distance for the kth vehicle, k = 3, 4 | |

| The fuel consumption per unit distance of the kth vehicle, when fully loaded, k = 1, 2 | |

| The electricity consumption per unit distance of the kth vehicle, when fully loaded, k = 3, 4 | |

| The fuel consumption per unit distance of the kth vehicle, when unloaded, k = 1, 2 | |

| Electricity consumption per unit distance for the kth vehicle, at no load, k = 3, 4 | |

| The kth load capacity | |

| The kth rated capacity | |

| CO2 emissions per unit mass of packaging treated with the jth technology, (j = 1,2,3) | |

| Reuse rate | |

| Percentage of packaging that is disposed of and transported to landfill | |

| Percentage of packaging shipped to paper mills after processing |

- Objective function

- (1)

- Economic perspective: Since the revenue source of reverse logistics is complicated, government subsidies and profit distribution need to be considered, so only cost minimization is considered in this paper.

- (2)

- Constraints

5. Algorithm Design

5.1. NSGA-II Algorithm Description

- First part: site selection code

- Second, third, and fourth parts.

- Fifth part.

5.2. NSGA-II Algorithm Steps

- Step 1:

- encoding by repeatable integer coding.

- Step 2:

- initialize the population and generate a population containing m individuals, each containing one chromosome, at this point, set as the initial population.

- Step 3:

- non-dominated stratification of the individuals of the initial population.

- Step 4:

- calculate the fitness of the individuals of the initial population based on the results of the non-dominated stratification in step 3.

- Step 5:

- select a certain number of individuals in the initial population as the evolutionary generation 0 according to the calculation result in step 4, and all individuals of the initial population are selected as generation 0 in this paper.

- Step 6:

- start evolution, take generation and is an integer}) as the parent, perform crossover and mutation operations on the individuals of the parent to generate the children corresponding to the parent of generation i, and fuse the individuals of the parent and children of generation .

- Step 7:

- decode the fused individuals from step 6 and calculate the objective function values of the fused individuals.

- Step 8:

- non-dominated stratification of the fused individuals from step 6 and calculation of their crowding degree.

- Step 9:

- according to the calculation result of step 8, select m individuals as the generation according to the non-dominated stratification level from the lowest to the highest and when the same level according to the crowding degree from the largest to the smallest, and return to step 6 if the required number of evolutionary iterations is not satisfied.

- Step 10:

6. Analysis of Results

6.1. Candidate Points

6.1.1. Classification of Candidate Nodes in Region M

6.1.2. Determination of The Distance between Candidate Nodes

6.1.3. Determination of the Candidate Node Express Volume

6.2. Number of Iterations, Crossover Variance Probability Selection

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Name of Administrative Region | Year | ||

|---|---|---|---|

| 2020 | 2019 | 2018 | |

| Nanguan District | 764,163 | 744,357 | 717,550 |

| Kuancheng District | 663,020 | 651,892 | 645,688 |

| Chaoyang District | 758,991 | 747,508 | 729,875 |

| Erdao District | 580,277 | 579,356 | 577,012 |

| Lvyuan District | 651,635 | 654,046 | 659,108 |

| Shuangyang District | 364,782 | 366,780 | 371,912 |

| Jiutai District | 667,942 | 671,291 | 679,336 |

| Total population of Changchun | 7,537,969 | 7,512,896 | 7,511,748 |

| Name of Administrative Region | The Percentage of the Population in the Current Year | |||

|---|---|---|---|---|

| 2020 | 2019 | 2018 | 2018–2020 | |

| Nanguan District | 10.14% | 9.91% | 9.55% | 9.95% |

| Kuancheng District | 8.80% | 8.68% | 8.60% | 8.72% |

| Chaoyang District | 10.07% | 9.95% | 9.72% | 9.96% |

| Erdao District | 7.70% | 7.71% | 7.68% | 7.70% |

| Lvyuan District | 8.64% | 8.71% | 8.77% | 8.69% |

| Shuangyang District | 4.84% | 4.88% | 4.95% | 4.87% |

| Jiutai District | 8.86% | 8.94% | 9.04% | 8.92% |

| Serial Number | Serial Number | ||||

|---|---|---|---|---|---|

| 1 | 43.837454 | 125.327664 | 51 | 43.85571 | 125.400205 |

| 2 | 43.789996 | 125.437189 | 52 | 43.843923 | 125.425986 |

| 3 | 43.88474 | 125.350858 | 53 | 43.803751 | 125.315023 |

| 4 | 43.893736 | 125.35813 | 54 | 43.750018 | 125.409793 |

| 5 | 43.834801 | 125.333301 | 55 | 43.899874 | 125.332733 |

| 6 | 43.827144 | 125.329905 | 56 | 43.827882 | 125.414442 |

| 7 | 43.840422 | 125.373367 | 57 | 43.878994 | 125.336723 |

| 8 | 43.826949 | 125.375575 | 58 | 43.896309 | 125.351509 |

| 9 | 43.882053 | 125.349496 | 59 | 43.882392 | 125.347125 |

| 10 | 43.842641 | 125.374858 | 60 | 43.905428 | 125.342984 |

| 11 | 43.906604 | 125.343757 | 61 | 43.861626 | 125.359128 |

| 12 | 43.844766 | 125.380254 | 62 | 43.844444 | 125.38038 |

| 13 | 43.813458 | 125.457464 | 63 | 43.813495 | 125.465922 |

| 14 | 43.897753 | 125.338467 | 64 | 43.802057 | 125.283431 |

| 15 | 43.782392 | 125.406786 | 65 | 43.85151 | 125.450023 |

| 16 | 43.820709 | 125.314338 | 66 | 43.891005 | 125.339234 |

| 17 | 43.842253 | 125.40775 | 67 | 43.903562 | 125.344714 |

| 18 | 43.827599 | 125.32845 | 68 | 43.891354 | 125.337182 |

| 19 | 43.830943 | 125.309065 | 69 | 43.81103 | 125.400753 |

| 20 | 43.879202 | 125.334329 | 70 | 43.835494 | 125.433065 |

| 21 | 43.827144 | 125.329905 | 71 | 43.789372 | 125.375345 |

| 22 | 43.796082 | 125.309145 | 72 | 43.871081 | 125.353375 |

| 23 | 43.869381 | 125.339793 | 73 | 43.893203 | 125.350009 |

| 24 | 43.839403 | 125.356681 | 74 | 43.897777 | 125.345988 |

| 25 | 43.842627 | 125.348033 | 75 | 43.915569 | 125.360708 |

| 26 | 43.805436 | 125.29279 | 76 | 43.77458 | 125.269852 |

| 27 | 43.908228 | 125.353404 | 77 | 43.788377 | 125.267272 |

| 28 | 43.833878 | 125.377279 | 78 | 43.872522 | 125.360277 |

| 29 | 43.793152 | 125.398239 | 79 | 43.80733 | 125.454246 |

| 30 | 43.861092 | 125.388539 | 80 | 43.828481 | 125.318853 |

| 31 | 43.843238 | 125.425431 | 81 | 43.798887 | 125.30516 |

| 32 | 43.840715 | 125.360151 | 82 | 43.793443 | 125.315005 |

| 33 | 43.812281 | 125.402488 | 83 | 43.837223 | 125.406287 |

| 34 | 43.834626 | 125.39462 | 84 | 43.844025 | 125.339175 |

| 35 | 43.85298 | 125.450993 | 85 | 43.792858 | 125.42437 |

| 36 | 43.832712 | 125.391496 | 86 | 43.841206 | 125.410059 |

| 37 | 43.835115 | 125.442014 | 87 | 43.792006 | 125.395835 |

| 38 | 43.893361 | 125.352221 | 88 | 43.852766 | 125.356367 |

| 39 | 43.8931 | 125.34364 | 89 | 43.899677 | 125.344485 |

| 40 | 43.89796 | 125.352507 | 90 | 43.802605 | 125.336546 |

| 41 | 43.860657 | 125.369726 | 91 | 43.880092 | 125.345643 |

| 42 | 43.838179 | 125.460384 | 92 | 43.899882 | 125.332816 |

| 43 | 43.826313 | 125.378839 | 93 | 43.833841 | 125.367847 |

| 44 | 43.83805 | 125.412816 | 94 | 43.840575 | 125.408217 |

| 45 | 43.834954 | 125.392255 | 95 | 43.833253 | 125.388789 |

| 46 | 43.893672 | 125.346473 | 96 | 43.82796 | 125.379248 |

| 47 | 43.903571 | 125.353122 | 97 | 43.835528 | 125.380312 |

| 48 | 43.790302 | 125.440001 | 98 | 43.811003 | 125.397103 |

| 49 | 43.82728 | 125.375988 | 99 | 43.821876 | 125.453335 |

| 50 | 43.837934 | 125.300282 |

References

- Yan, H.; Wu, L.; Yi, X.; Wang, D.D.; Li, X. Discussion on green express packaging. In Proceedings of the International Conference of Green Buildings and Environmental Management (GBEM), Qingdao, China, 23–25 August 2018. [Google Scholar]

- Liang, H.P.; Li, J.G. Research on the creative design of express package recycling system basis on internet. IOP Conf. Ser. Earth Environ. Sci. 2020, 463, 012089. [Google Scholar] [CrossRef]

- Xiao, Y.M.; Zhou, B.Y. Does the development of the delivery industry increase the production of municipal solid waste?-An empirical study of China. Resour. Conserv. Recycl. 2020, 155, 104577. [Google Scholar] [CrossRef]

- High, X.; Liu, C.S. Research on customers’ willingness to participate in express package recycling. In Proceedings of the 5th International Conference on Energy Materials and Environment Engineering, Kuala Lumpur, Malaysia, 12–14 April 2019. [Google Scholar]

- Ding, Z.H.; Sun, J.; Wang, Y.W.; Jiang, X.H.; Liu, R.; Sun, W.B.; Mou, Y.P.; Wang, D.W.; Liu, M.Z. Research on the influence of anthropomorphic design on the consumers’ express packaging recycling willingness: The moderating effect of psychological ownership. Resour. Conserv. Recycl. 2021, 168, 105269. [Google Scholar] [CrossRef]

- Carfí, D.; Donato, A. Plastic-pollution reduction and bio-resources preservation using green-packaging game coopetition. Mathematics 2022, 10, 4553. [Google Scholar] [CrossRef]

- Cheng, L.; Cao, G.R. Present situation and ideas of express packaging organization. Adv. Graph. Commun. Media Technol. 2017, 417, 697–703. [Google Scholar] [CrossRef]

- Yang, H.T.; Li, W.L. Construction of express packaging recovery logistics system from the perspective of ecological innovation—Take Xinyang Normal University as an example. In Proceedings of the 25th Annual International Conference on Management Science and Engineering, Frankfurt, Germany, 17–20 August 2018. [Google Scholar]

- Cai, K.H.; Xie, Y.F.; Song, Q.B.; Sheng, N.; Wen, Z.G. Identifying the status and differences between urban and rural residents’ behaviors and attitudes toward express packaging waste management in Guangdong Province, China. Sci. Total Environ. 2021, 797, 148996. [Google Scholar] [CrossRef]

- Duan, H.B.; Song, G.H.; Qu, S.; Dong, X.B.; Xu, M. Post-consumer packaging waste from express delivery in China. Resour. Conserv. Recycl. 2019, 14, 137–143. [Google Scholar] [CrossRef]

- Ren, X.; Wang, Y.H. Design of express recyclable packaging bag based on green environmental packaging material. In Proceedings of the 5th International Conference on Environmental Science and Material Application (ESMA), Xi’an, China, 15–16 December 2019. [Google Scholar]

- Guo, Y.L.; Luo, G.L.; Hou, G.S. Research on the evolution of the express packaging recycling strategy, considering government subsidies and synergy benefits. Int. J. Environ. Res. Public Health 2021, 18, 1144. [Google Scholar] [CrossRef]

- Hua, Y.F.; Dong, F.; Goodman, J. How to leverage the role of social capital in pro-environmental behavior: A case study of residents’ express waste recycling behavior in China. J. Clean. Prod. 2021, 28, 124376. [Google Scholar] [CrossRef]

- Wu, S.S.; Gong, X.; Wang, Y.F.; Cao, J. Consumer cognition and management perspective on express packaging pollution. Int. J. Environ. Res. Public Health 2022, 19, 4895. [Google Scholar] [CrossRef]

- Chen, F.Y.; Chen, H.; Yang, J.H.; Long, R.Y.; Li, W.B. Impact of regulatory focus on express packaging waste recycling behavior: The moderating role of psychological empowerment perception. Environ. Sci. Pollut. Res. 2019, 26, 8862–8874. [Google Scholar] [CrossRef] [PubMed]

- Zheng, C.L.; Zhou, Y.Y. Multi-criteria group decision-making approach for express packaging recycling under interval-valued fuzzy information: Combining objective and subjective compatibilities. Int. J. Fuzzy Syst. 2022, 24, 1112–1130. [Google Scholar] [CrossRef]

- Lin, G.; Chang, H.M.; Li, X.; Li, R.; Zhao, Y. Integrated environmental impacts and c-footprint reduction potential in treatment and recycling of express delivery packaging waste. Resour. Conserv. Recycl. 2022, 179, 106078. [Google Scholar] [CrossRef]

- Harsaj, F.; Aghaeipour, Y.; Sadeghpoor, M.; Rajaee, Y. A fuzzy multi-objective model for a sustainable end-of-life vehicle reverse logistic network design: Two meta-heuristic algorithms. Int. J. Value Chain Manag. 2022, 13, 47–87. [Google Scholar] [CrossRef]

- Gao, X.H.; Cao, C.J. A novel multi-objective scenario-based optimization model for sustainable reverse logistics supply chain network redesign considering facility reconstruction. J. Clean. Prod. 2020, 270, 122405. [Google Scholar] [CrossRef]

- Nie, D.X.; Li, H.T.; Qu, T.; Liu, Y.; Li, C.D. Optimizing supply chain configuration with low carbon emission. J. Clean. Prod. 2020, 271, 122539. [Google Scholar] [CrossRef]

- Guo, J.Q.; Wang, X.Y.; Fan, S.Y.; Gen, M. Forward and reverse logistics network and route planning under the environment of low-carbon emissions: A case study of Shanghai fresh food e-commerce enterprises. Comput. Ind. Eng. 2017, 106, 351–360. [Google Scholar] [CrossRef]

- Reddy, K.N.; Kumar, A.; Sarkis, J.; Tiwari, M.K. Effect of the carbon tax on reverse logistics network design. Comput. Ind. Eng. 2020, 139, 106184. [Google Scholar] [CrossRef]

- Yang, J.H.; Long, R.Y.; Chen, H.; Sun, Q.Q. A comparative analysis of express packaging waste recycling models based on the differential game theory. Resour. Conserv. Recycl. 2021, 168, 105449. [Google Scholar] [CrossRef]

- Wu, J.; Azarm, S. Metrics for quality assessment of a multiobjective design optimization solution set. J. Mech. Des. 2001, 123, 18–25. [Google Scholar] [CrossRef]

- Liu, Q.G.; Liu, X.X.; Wu, J.; Li, Y.X. Multiattribute group decision-making method using a genetic K-Means clustering algorithm. Math. Probl. Eng. 2020, 2020, 8313892. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Liang, X.; Chen, J.B.; Gu, X.L.; Huang, M. Improved adaptive non-dominated sorting genetic algorithm with elite strategy for solving multi-objective flexible job-shop scheduling problem. IEEE Access 2021, 9, 106352–106362. [Google Scholar] [CrossRef]

- Pulansari, F. The analysis of cost drivers to successful implementation of reverse logistics system. In Proceedings of the 1st International Conference on Industrial and Manufacturing Engineering (ICI and ME), Medan, Indonesia, 16–17 October 2018. [Google Scholar]

- Xu, J.G.; Qiao, Z.; Liu, J.H. Study on cost control of enterprise reverse logistics based on the analysis of cost drivers. In Proceedings of the 3rd International Conference on Wireless Communications, Networking and Mobile Computing (WiCOM 2007), Shanghai, China, 21–25 September 2007. [Google Scholar]

- Fang, X.H.; Li, N.; Mu, H. Research progress on logistics network optimization under low carbon constraints. In Proceedings of the International Conference on Green Development and Environmental Science and Technology (ICGDE), Changsha, China, 18–20 September 2020. [Google Scholar]

- Wang, B.; Li, H.H. Optimization of Electronic Waste Recycling Network Designing. In Proceedings of the 5th International Conference on Electromechanical Control Technology and Transportation (ICECTT), Network, Nanchang, China, 15–17 May 2020. [Google Scholar]

- Chen, M.; Yin, C.J.; Xi, Y.P. A new clustering algorithm Partition K-means. In Proceedings of the International Conference on Advanced Materials and Computer Science, Chengdu, China, 1–2 May 2011. [Google Scholar]

- Ge, F.H.; Luo, Y. An improved K-means algorithm based on weighted euclidean distance. In Proceedings of the 3rd International Confrence on Theoretical and Mathematical Foundations of Computer (ICTMF 2012), Bali, Indonesia, 1–2 December 2012. [Google Scholar]

- Deb, K.; Agrawal, R.B. Simulated binary crossover for continuous search space. Complex Syst. 1995, 9, 115–148. [Google Scholar]

- Deb, K.; Goyal, M.A. Combined genetic adaptive search (GeneAS) for engineering design. Comput. Sci. Inform. 1996, 26, 30–45. [Google Scholar]

- Vachhani, V.L.; Dabhi, V.K.; Prajapati, H.B. Survey of multi objective evolutionary algorithms. In Proceedings of the International Conference on Circuit, Power and Computing Technologies (ICCPCT), Nagercoil, India, 19–20 March 2015. [Google Scholar]

- Osyczka, A.; Krenich, S. Evolutionary algorithms for multicriteria optimization with selecting a representative subset of Pareto optimal solutions. In Proceedings of the 1st International Conference on Evolutionary Multi-Criterion Optimization (EMO 2001), Zurich, Switzerland, 7–9 March 2001. [Google Scholar]

- Takagi, T.; Takadama, K.; Sato, H. Supervised Multi-objective optimization algorithm using estimation. In Proceedings of the IEEE Congress on Evolutionary Computation (CEC), Padua, Italy, 18–23 July 2022. [Google Scholar]

- Abubaker, A.; Baharum, A.; Alrefaei, M. Good solution for multi-objective optimization problem. In Proceedings of the 21st National Symposium on Mathematical Sciences (SKSM), Penang, Malaysia, 6–8 November 2013. [Google Scholar]

- Froese, R.; Klassen, J.W.; Leung, C.K.; Loewen, T.S. The border K-means clustering algorithm for one dimensional data. In Proceedings of the IEEE International Conference on Big Data and Smart Computing (BigComp), Daegu, Republic of Korea, 17–20 January 2022. [Google Scholar]

| Year | Express Business Volume/Million Pieces | Year | Express Business Volume/Million Pieces |

|---|---|---|---|

| 2013 | 27.1409 | 2017 | 98.9954 |

| 2014 | 41.3411 | 2018 | 129.7255 |

| 2015 | 52.3329 | 2019 | 161.9971 |

| 2016 | 78.6633 | 2020 | 237.2633 |

| Serial Number | Actual Value/ Million Pieces | Linear Forecast Value/Million Pieces | Error | Index Forecast Value/Million Pieces | Error |

|---|---|---|---|---|---|

| 1 | 27.1409 | 17.0285 | 37.26% | 29.38209 | 8.26% |

| 2 | 41.3411 | 39.4575 | 4.56% | 39.54682 | 4.34% |

| 3 | 52.3329 | 61.8865 | 18.26% | 53.22803 | 1.71% |

| 4 | 78.6633 | 84.3155 | 7.19% | 71.64226 | 8.93% |

| 5 | 98.9954 | 106.7445 | 7.83% | 96.4269 | 2.59% |

| 6 | 129.7255 | 129.1735 | 0.43% | 129.7858 | 0.05% |

| 7 | 161.9971 | 151.6025 | 6.42% | 174.6851 | 7.83% |

| 8 | 237.2633 | 174.0315 | 26.65% | 23511.74 | 0.90% |

| 9 | / | 196.4605 | / | 316.4563 | / |

| 10 | / | 218.8895 | / | 425.9343 | / |

| 11 | / | 241.3185 | / | 573.2863 | / |

| 12 | / | 263.7475 | / | 771.6146 | / |

| 13 | / | 286.1765 | / | 1038.555 | / |

| Serial Number | Serial Number | ||||

|---|---|---|---|---|---|

| 1 | 44.20957 | 125.9666 | 9 | 43.89134 | 125.3411 |

| 2 | 43.85894 | 125.2093 | 10 | 43.97082 | 125.2716 |

| 3 | 43.54504 | 125.6638 | 11 | 43.9477 | 125.1507 |

| 4 | 43.84200 | 125.2989 | 12 | 43.95960 | 125.4261 |

| 5 | 44.05939 | 125.1975 | 13 | 44.03693 | 125.6269 |

| 6 | 43.82241 | 125.4182 | 14 | 43.89649 | 125.4009 |

| 7 | 43.89262 | 125.2839 | 15 | 43.81163 | 125.2380 |

| 8 | 43.93453 | 125.3227 |

| Candidate Nodes | Classification Area | Administrative District | Candidate Nodes | Classification Area | Administrative District |

|---|---|---|---|---|---|

| 1 | A | Kuancheng District | 9 | C | Lvyuan District |

| 2 | A | Nanguan District | 10 | C | Kuancheng District |

| 3 | A | Lvyuan District | 11 | C | Kuancheng District |

| 4 | B | Lvyuan District | 12 | C | Nanguan District |

| 5 | B | Erdao District | 13 | C | Erdao District |

| 6 | B | Chaoyang District | 14 | D | Jiutai District |

| 7 | C | Chaoyang District | 15 | D | Shuangyang District |

| 8 | C | Lvyuan District |

| Serial Number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 23.86859 | 0 | 40.23685 | 12.67707 | 23.22249 | 44.70217 | 29.2916 | 73.10302 | 13.03013 |

| 16.60001 | 40.23685 | 0 | 29.87562 | 18.59793 | 6.318052 | 10.96083 | 113.3377 | 27.81905 |

| 13.40235 | 12.67707 | 29.87562 | 0 | 11.51298 | 33.4658 | 19.47316 | 84.28883 | 3.378439 |

| 3.75025 | 23.22249 | 18.59793 | 11.51298 | 0 | 21.95307 | 9.150016 | 95.73491 | 10.19329 |

| 20.84032 | 44.70217 | 6.318052 | 33.4658 | 21.95307 | 0 | 16.03422 | 117.6109 | 31.87447 |

| 6.106751 | 29.2916 | 10.96083 | 19.47316 | 9.150016 | 16.03422 | 0 | 102.3944 | 17.09786 |

| 96.87778 | 73.10302 | 113.3377 | 84.28883 | 95.73491 | 117.6109 | 102.3944 | 0 | 85.74007 |

| 11.22128 | 13.03013 | 27.81905 | 3.378439 | 10.19329 | 31.87447 | 17.09786 | 85.74007 | 0 |

| 39.59672 | 63.28908 | 23.0548 | 52.68995 | 41.21885 | 19.52163 | 34.00031 | 136.3915 | 50.81169 |

| 4.792569 | 19.34723 | 20.89395 | 10.23743 | 6.236652 | 25.49322 | 9.973975 | 92.44419 | 7.36417 |

| 8.717617 | 16.11011 | 24.30006 | 9.500052 | 9.929159 | 29.18902 | 13.34816 | 89.14593 | 6.131975 |

| 35.19108 | 48.15778 | 30.43948 | 45.10163 | 38.93564 | 35.71272 | 30.90118 | 114.8546 | 41.757 |

| 16.30645 | 30.78207 | 18.70151 | 25.93917 | 20.0393 | 25.01903 | 13.35269 | 101.709 | 22.63918 |

| 7.435185 | 27.15075 | 14.28599 | 19.15585 | 11.17926 | 20.04865 | 4.903537 | 99.99842 | 16.22207 |

| 0 | 23.86859 | 16.60001 | 13.40235 | 3.75025 | 20.84032 | 6.106751 | 96.87778 | 11.22128 |

| Serial Number | 9 | 10 | 11 | 12 | 13 | 14 | 15 | |

| 1 | 63.28908 | 19.34723 | 16.11011 | 48.15778 | 30.78207 | 27.15075 | 23.86859 | |

| 2 | 23.0548 | 20.89395 | 24.30006 | 30.43948 | 18.70151 | 14.28599 | 16.60001 | |

| 3 | 52.68995 | 10.23743 | 9.500052 | 45.10163 | 25.93917 | 19.15585 | 13.40235 | |

| 4 | 41.21885 | 6.236652 | 9.929159 | 38.93564 | 20.0393 | 11.17926 | 3.75025 | |

| 5 | 19.52163 | 25.49322 | 29.18902 | 35.71272 | 25.01903 | 20.04865 | 20.84032 | |

| 6 | 34.00031 | 9.973975 | 13.34816 | 30.90118 | 13.35269 | 4.903537 | 6.106751 | |

| 7 | 136.3915 | 92.44419 | 89.14593 | 114.8546 | 101.709 | 99.99842 | 96.87778 | |

| 8 | 50.81169 | 7.36417 | 6.131975 | 41.757 | 22.63918 | 16.22207 | 11.22128 | |

| 9 | 0 | 43.94864 | 47.30247 | 39.51704 | 38.13702 | 36.7922 | 39.59672 | |

| 10 | 43.94864 | 0 | 3.958057 | 35.54501 | 16.25327 | 8.920409 | 4.792569 | |

| 11 | 47.30247 | 3.958057 | 0 | 35.63389 | 16.58221 | 11.11113 | 8.717617 | |

| 12 | 39.51704 | 35.54501 | 35.63389 | 0 | 19.29206 | 27.75662 | 35.19108 | |

| 13 | 38.13702 | 16.25327 | 16.58221 | 19.29206 | 0 | 9.082896 | 16.30645 | |

| 14 | 36.7922 | 8.920409 | 11.11113 | 27.75662 | 9.082896 | 0 | 7.435185 | |

| 15 | 39.59672 | 4.792569 | 8.717617 | 35.19108 | 16.30645 | 7.435185 | 0 | |

| Administrative District | Express Business Volume/Million Pieces |

|---|---|

| Nanguan District | 103.3523 |

| Kuancheng District | 90.56302 |

| Chaoyang District | 103.4675 |

| Erdao District | 79.95588 |

| Lvyuan District | 90.23914 |

| Shuangyang District | 50.62379 |

| Jiutai District | 92.637 |

| Candidate Nodes | Express Business Volume/ Million Pieces | Candidate Nodes | Express Business Volume/ Million Pieces |

|---|---|---|---|

| 1 | 54.33781 | 9 | 9.023914 |

| 2 | 72.3466 | 10 | 18.1126 |

| 3 | 45.11957 | 11 | 18.1126 |

| 4 | 27.07174 | 12 | 31.00568 |

| 5 | 47.97353 | 13 | 31.98235 |

| 6 | 62.08048 | 14 | 50.62379 |

| 7 | 41.38699 | 15 | 92.637 |

| 8 | 9.023914 |

| Cross-Variance Probabilities | Indicator Name | Percentage of Non- Dominated Solutions | HV | Spacing |

|---|---|---|---|---|

| 0.9 | Numerical value | 0.24 | 0.016768 | 3312.822067 |

| 0.8 | Numerical value | 0.21 | 0.019379 | 3649.327564 |

| 0.7 | Numerical value | 0.43 | 0.019267 | 2713.471153 |

| 0.6 | Numerical value | 0.88 | 0.017934 | 3232.380758 |

| Processing Center | Recycling Center in Charge | Road Section | Technical Processing | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| 4 | 3 | 1 | 3 | 1 | 1 |

| 5 | 9 | 4 | 4 | 3 | 1 |

| 7 | 4, 6 | 2, 4 | 1, 1 | 2, 1 | 1, 2 |

| 10 | 2 | 1 | 2 | 3 | 3 |

| 11 | 5 | 3 | 2 | 3 | 3 |

| 12 | 14 | 2 | 1 | 4 | 3 |

| 13 | 12, 13 | 4, 4 | 1, 2 | 2, 3 | 3, 3 |

| 14 | 1, 8, 10, 11, 15 | 2, 4, 1, 3, 4 | 2, 2, 2, 2, 2 | 3, 4, 2, 4, 4 | 2, 3, 1, 3, 3 |

| Processing Center | Recycling Center in Charge | Road Section | Technical Processing | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| 3 | 7 | 2 | 2 | 3 | 3 |

| 4 | 3 | 2 | 2 | 3 | 3 |

| 5 | 9 | 4 | 4 | 2 | 2 |

| 6 | 1 | 4 | 2 | 3 | 3 |

| 7 | 4, 6 | 2, 2 | 1, 1 | 2, 1 | 2, 3 |

| 10 | 2 | 2 | 2 | 3 | 3 |

| 11 | 5 | 3 | 2 | 4 | 3 |

| 12 | 14 | 1 | 1 | 3 | 3 |

| 13 | 13 | 4 | 2 | 3 | 3 |

| 14 | 8, 10, 11, 12, 15 | 4, 1, 3, 4, 4 | 2, 1, 2, 2, 2 | 4, 4, 3, 3, 4 | 3, 2, 3, 3, 3 |

| Processing Center | Recycling Center in Charge | Road Section | Technical Processing | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| 1 | 12 | 3 | 2 | 4 | 3 |

| 3 | 7 | 2 | 2 | 3 | 3 |

| 4 | 3 | 3 | 3 | 1 | 2 |

| 5 | 9 | 2 | 4 | 3 | 2 |

| 6 | 1 | 3 | 1 | 3 | 2 |

| 7 | 4, 15 | 3, 4 | 1, 2 | 2, 3 | 2, 2 |

| 9 | 10 | 2 | 1 | 4 | 1 |

| 10 | 2 | 4 | 2 | 3 | 3 |

| 11 | 5 | 3 | 3 | 3 | 3 |

| 12 | 6, 14 | 4, 4 | 4, 1 | 2, 3 | 2, 3 |

| 13 | 13 | 4 | 2 | 3 | 3 |

| 14 | 8, 11 | 4, 3 | 2, 4 | 3, 4 | 3, 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, J.; Cheng, J.; Li, X.; Zhao, H.; Lin, C. Optimal Design of Reverse Logistics Recycling Network for Express Packaging Considering Carbon Emissions. Mathematics 2023, 11, 812. https://doi.org/10.3390/math11040812

Mao J, Cheng J, Li X, Zhao H, Lin C. Optimal Design of Reverse Logistics Recycling Network for Express Packaging Considering Carbon Emissions. Mathematics. 2023; 11(4):812. https://doi.org/10.3390/math11040812

Chicago/Turabian StyleMao, Jia, Jinyuan Cheng, Xiangyu Li, Honggang Zhao, and Ciyun Lin. 2023. "Optimal Design of Reverse Logistics Recycling Network for Express Packaging Considering Carbon Emissions" Mathematics 11, no. 4: 812. https://doi.org/10.3390/math11040812

APA StyleMao, J., Cheng, J., Li, X., Zhao, H., & Lin, C. (2023). Optimal Design of Reverse Logistics Recycling Network for Express Packaging Considering Carbon Emissions. Mathematics, 11(4), 812. https://doi.org/10.3390/math11040812