Abstract

In recent years, reducing the energy consumption in a hydraulic excavator has received deep attention in many studies. The implementation of the novel independent metering valve system (NIMV) has emerged as a promising solution in this regard. However, external factors such as noise, throttling loss, and leakage have negative influences on the tracking precision and energy saving in the NIMV system. In this paper, a novel control method, simple but effective, called a neural network-fractional order-proportional-integral-derivative controller is developed for the NIMV system. In detail, the fractional order-proportional-integral-derivative (FOPID) controller is used to improve the precision, stability, and fast response of the control system due to the inclusion of non-integer orders in the proportional, integral, and derivative terms. Along with that, the auto-tuning algorithm of the neural network controller is applied for adjusting five parameters in the FOPID controller under noise, throttling loss, and leakage. In addition, the proposed controller alleviates the amount of calculation for the system by using model-free control. To verify the effectiveness of the proposed controller, the simulation and experiment are conducted on the AMESim/MATLAB and a real test bench. As a result, the proposed controller not only operates the NIMV system accurately in the target trajectory but also reduces energy consumption, saving up 23.33% and 29.25% compared to FOPID and PID in the experimental platform, respectively.

Keywords:

energy saving; energy consumption; fractional order-proportional-integral-derivative; independent metering valve; neural network; tracking precision MSC:

93C10; 93D21

1. Introduction

Nowadays, due to a high power-to-weight ratio, high load capabilities, and robustness, construction machinery plays an important role in infrastructure development, especially hydraulic excavators [1,2,3]. Hydraulic excavators (HEs) are versatile heavy equipment commonly used in many fields of industry, such as building, digging, moving, drilling, mining, and other industries for various earth-moving tasks. They possess several distinctive characteristics that make them suitable for a wide range of applications: providing high force and torque, multi-functional use, high flexibility, and work in harsh environments [4,5]. However, consuming a lot of fossil fuels and emitting a lot of pollutant emissions into the environment are challenges that still exist in HEs [6,7,8]. Hence, reducing energy consumption in hydraulic excavators is one of the important tasks.

One of the widely used solutions today is the energy regeneration system (ERS) that is used to store and reuse the potential energy in the HEs. In particular, the boom system contains the biggest potential energy up to 51% of total recoverable energy due to the gravitational force during the lowering process [9,10,11,12]. The ERS can be classified into three main types, namely electric ERS, mechanical ERS, and hydraulic ERS. In the mechanical ERS structure, a flywheel, the hydraulic pump/motor, and the clutch were the main components. The hydraulic energy was converted to rotation energy with the hydraulic motor when the boom cylinder moved down and stored in the flywheel. Then, through clutch adjustment, the hydraulic pump was driven by the stored energy and supplied the oil to operate the system in the next cycle [13,14]. The structure of the electric ERSs was composed of a hydraulic motor, which was connected to an oil return line to the tank, used to drive a generator to convert the gravitational potential energy into electricity and store it in a battery or capacitor. After that, this electricity power was used to operate the electric motor or supply to other electric devices in the HE, leading to a significant energy consumption reduction [15,16,17]. In the approach of hydraulic ERS, the gravitational potential energy was stored in the hydraulic accumulator through the valve, a booster cylinder, or a transformer system and reused for the system via auxiliary devices [18,19,20]. Overall, the ERSs are a highly effective solution for minimizing energy consumption on the HEs. However, adding recovery, storage, and reuse components increases investment costs. At the same time, it also leads to increasing hardware size and complexity in controlling elements.

An independent metering valve system (IMV) is known as another effective solution for reducing the energy consumption in the HEs [21,22,23]. By connecting four proportional valves logically, the IMV system takes advantage of the gravitational potential energy to lower the boom cylinder without energy from the pump, resulting in saving up to 30% of energy consumption in the system [24,25,26]. Moreover, the original IMV systems do not use energy storage and reuse components, leading to lower investment costs and being more compact than the ERSs. Nonetheless, the IMV system still has certain limitations that warrant improvement. These include the continued use of many proportional valves; the issues of tracking precision stemming from factors like leakage, throttling loss, and noise; and further strides in energy-saving efficiency.

To solve the above problem, a coordination control method between the pump and valve has been developed [27]. In detail, the valve control plays the role of controlling the tracking performance while the pump control helps improve the energy saving in the system. Along with that is the development of advanced controllers to enhance the effectiveness of the IMV system. Lyu et al. [28,29,30] proposed the high-performance adaptive robust control approach for the IMV system with the configuration that combines the hydraulic accumulator to guarantee tracking precision and energy saving. Through experimental verification, this control method not only demonstrated remarkable tracking performance but also led to a reduction in energy consumption by approximately 35–47%. Ding et al. [31] presented a management algorithm that combined meter-out valve control and pump control based on the pressure and flow rate in the system. In detail, the inverse flow mapping approach was used for flow control, and the proportional integral derivative (PID) was applied for pressure control, or a combination of both methods based on the working condition. The experiment result showed that this proposed algorithm had a high stability and fast response while saving up to 28% energy compared to the load-sensing system. Shi et al. [32] proposed the velocity feed forward and position feedback control (VFPB) method for the boom and arm of HEs. In this, the velocity feed forward control was built based on the target trajectory and the model base of the valve or pump (open-loop control) while displacement error between the target position and the real position of the cylinder was used for position feedback control (closed-loop control). The results indicated the system could meet the smooth and high precision during the use of low energy consumption. The common feature of these studies is to build a controller based on the model-based control of the system, which provides robustness control and high accuracy for the system [33,34]. However, the hydraulic system is a complex and non-linear system, so determining the exact model of the system takes a lot of time and makes calculations difficult. In addition, model-based controllers also need a lot of sensors to control the system, causing high costs. Meanwhile, model-free control is still frequently applied in industry, especially on hydraulic systems, such as PID controllers [35,36], or FOPID controllers [37,38,39]. In this case, the FOPID had superior advantages over PID controllers when easily applied in complex systems, because it was capable of processing the delay and the noise in the system due to the fractional-order dynamics [40,41,42]. Nevertheless, when the IMV system frequently faces negative factors, such as leaks and throttling losses on the hydraulic system, the control performance of the FOPID controller is reduced. Consequently, the auto-tuning methods for the FOPID controller were developed for hydraulic systems to deal with negative factors in the system. Although several studies focused on adjusting the parameters of FOPID by using a fuzzy logic control, only three parameters could be tuned [43,44]. In addition, compared to fuzzy logic, neural networks could learn and adapt better to the negative factors mentioned above; in addition, it could also adjust five parameters of the FOPID controller. Despite these advantages, the application of this tuning method remains constrained, particularly in the field of hydraulic systems.

Based on the above analysis, in this paper, a novel control method has been proposed, a neural network-fractional order PID controller (NNFOPID). Specifically, the neural network was used to tune five parameters in the FOPID controller under the effect of external factors such as noise, leakage, and throttling loss. In addition, the proposed controller was applied to the NIMV, which utilized three proportional valves and a directional valve to control the boom cylinder (the NIMV system has been demonstrated to not only better track precision and energy saving but also work similarly to the IMV system in our previous studies [45,46]). The primary contributions of this study are outlined as follows:

- For the first time, the NNFOPID controller was applied to a real test rig that mimics the motion of the boom cylinder of a hydraulic excavator. The advantage of this controller was used for the system without identifying the model of the system (model-free), resulting in minimizing the amount of computing and hardware of the controller on the NIMV system.

- The tuning method of five parameters based on the neural network algorithm was applied to the FOPID controller to enhance the tracking precision and energy saving.

- Both co-simulation and experimental platforms were employed to validate the effectiveness of the proposed controller.

- Compared with the PID and FOPID controllers, the proposed controller not only achieved high tracking precision but also used less energy consumption, saving up to 23.33% and 29.25% under experimental conditions, respectively.

The rest of the paper is arranged as follows: The description of the system is presented in Section 2 and the control algorithm is designed in Section 3. Subsequently, the verification with the co-simulation and experiment is shown in Section 4. Finally, conclusions and future work are discussed in Section 5.

2. System Description

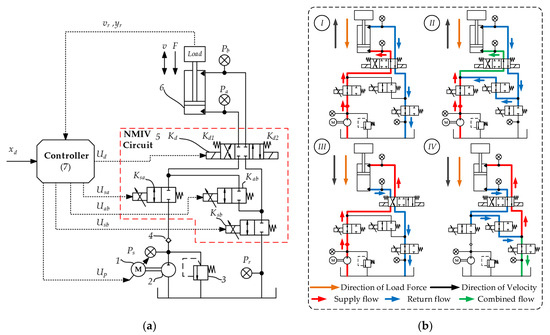

2.1. The Novel Independent Metering Valve System

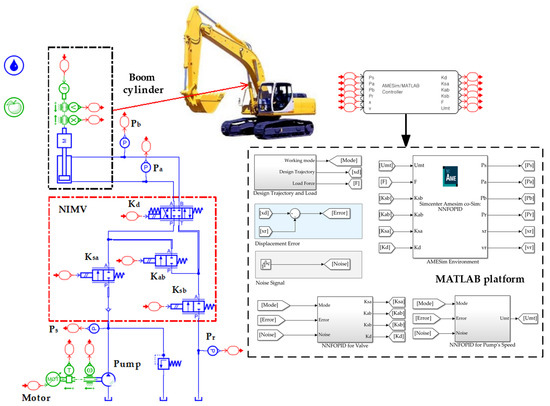

Due to the high energy-saving efficiency demonstrated in previous studies [45,46], the NIMV system continues to be used to investigate the effectiveness of the proposed controller. Figure 1 displays the NIMV system consisting of the following components: an electric motor (1) that drives the main pump (2) to supply the oil for the system, the NIMV circuit (5) with three proportional valves (Ksa, Ksb, Kab) and a directional control valve (Kd), a relief valve (3) for protecting the system from excessive pressure, a check valve (4) to protect the pump from system return pressure, a boom cylinder (6), and the controller (7). In addition, four metering modes are utilized for controlling the boom cylinder’s operation, including the power extension (PE) and high-side regeneration extension (HSRE) modes that are applied for the boom-up mode and power retraction (PR) and low-side regeneration retraction (LSRR) modes that are used for the boom-down mode.

Figure 1.

The configuration of the system: (a) the hydraulic circuit of the NIMV system, and (b) four working modes of the NIMV system—(I) PE mode, (II) HSRE mode, (III) PR mode, and (IV) LSRR mode.

2.2. Analysis of Energy Consumption of the System

According to Newton’s Law, the force acting on the boom cylinder can be expressed as follows [47]:

where , , , and are the pressure and area of the bore and rod chamber, respectively, m is the weight of the load, x is the cylinder displacement, and is the viscous friction coefficient. To reduce throttling loss in the valve, a control strategy that involves adjusting the meter-out valve and fully opening the meter-in valve is employed [48]. Therefore, the pressure at the pump outlet can be given as follows:

Based on the cylinder’s velocity v, the required flow rate from the pump to the cylinder chamber is calculated as follows:

From Equations (2) and (3), the torque and rotation speed at the pump shaft are represented as follows:

where is the pump’s displacement; and are the torque and rotation speed of the hydraulic pump, respectively. From that, the hydraulic energy required to control the hydraulic boom cylinder can be written as

where is the energy required for the pump. In addition, the energy consumption of the system can be determined with the energy consumption of the electric motor, which replaces the internal combustion engine to drive the hydraulic pump. The energy consumption of the system , which is calculated based on the torque and the rotation speed of the electric motor, is given with the following [49]:

From Equations (6) and (7), the energy consumption efficiency of the NIMV system can be obtained as follows:

where is the energy consumption efficiency. In addition, the energy saving of the proposed method compared with another control approach, such as PID and FOPID, is calculated as follows [45]:

where is the energy-saving efficiency, is the energy consumption in the NIMV system of the compared controller (PID and FOPID controller), and is the energy consumption of the NIMV system that is controlled with the NNFOPID controller.

3. Control Algorithm

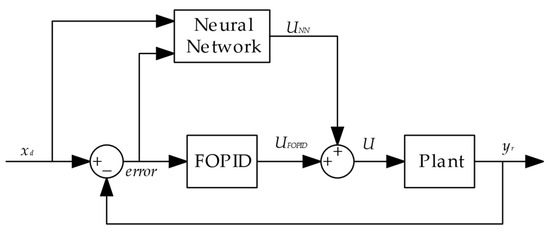

To enhance the tracking precision and energy saving in the NIMV system, the coordination control between the pump and valve is conducted with the NNFOPID controller. In detail, valve control plays the role of taking over the tracking performance of the cylinder through adjusting the area of the orifice of the proportional valve. Meanwhile, the pump control performs the function of managing the energy consumption in the system. The structure of the NNFOPID controller is depicted in Figure 2, and its detailed functionality is described in the subsequent section.

Figure 2.

Block diagram of the neural network-FOPID controller.

3.1. Fractional Order PID

The general representation for the fractional calculus of the fractional order integration and differentiation operator is as follows [43]:

where represents the fractional calculus, a and b are the lower and upper limits of the operation, and α is the fractional order . Additionally, the definitions for fractional calculus that are frequently employed are Grunwald–Letnikov and Caputo, and particularly the Riemann–Liouville fractional integral formulation. It is described as follows:

where is the Gamma function, J represents the integral operator, and n denotes the integer value (). The Gamma function can be calculated as follows:

In this paper, for fractional integral and derivative calculation, the Riemann–Liouville definition is applied. In addition, the fractional-order modeling and control (FOMCON) toolbox is used to simulate the FOPID controller in MATLAB/Simulink software [50]. The formulation of the FOPID controller that is applied to the pump and valve is presented as follows:

where is the output of the FOPID controller at the sampling period t; , , , λ, and μ are the coefficients of the FOPID controller, namely the proportional, integral, derivative coefficients, the order of fractional integration, and the fractional derivative, respectively. is the displacement error, which is calculated based on the design trajectory () and the real trajectory () from the cylinder, and is given as follows:

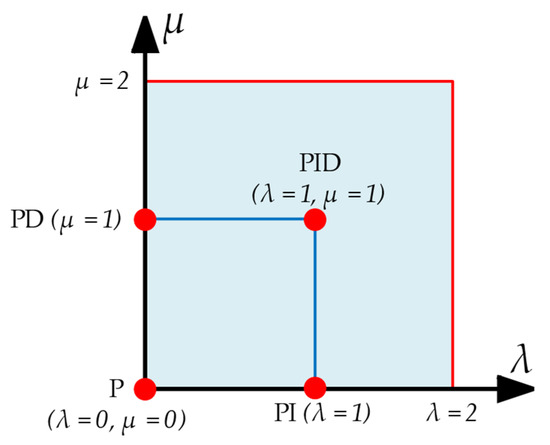

In the FOPID controller, besides setting , , and for the controller, it is necessary to specify two parameters, λ and μ, because they determine the orders of fractional integration and fractional differentiation, respectively. Notably, the range for adjusting λ and μ can extend from 0 to 2, as illustrated in Figure 3. By tuning these two additional fractional orders (λ and μ), the controller becomes more flexible and stable, meaning the performance of the system can be enhanced. However, it is important to acknowledge that these parameter settings are fixed. External factors such as noise, throttling loss, or system leakage alter the working environment conditions, leading to the controller’s performance being degraded. To address this challenge, a neural network (NN) controller can be employed to tune the five parameters of the FOPID controller. This approach ensures that the system performs effectively even under the influence of external factors, promoting its robustness and reliability.

Figure 3.

The representation of the FOPID controller based on the λ and μ.

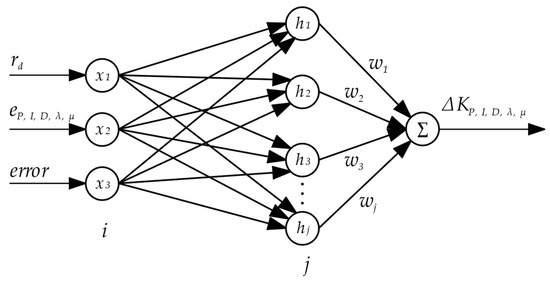

3.2. Neural Network FOPID Controller Design

The schematic of the NNFOPID controller is represented in Figure 2 and the structure of NNs is shown in Figure 4. To tune the FOPID parameter, the gradient descent (GD) method is used for the weight-updating procedure of NNs [51]. This method is a fundamental and powerful optimization method for neural networks. It provides the necessary tools to efficiently train neural networks, optimize their parameters, and improve their performance on the system. Below is the presentation of the tuning parameter and the learning algorithm of the proportional coefficient; the remaining parameters are calculated similarly.

Figure 4.

Neural network structure used to tune control parameters for FOPID controller.

The performance index function is shown with the following equation:

where is the tuning parameters of the proportional and is the proportional coefficient after the update of the NNFOPID controller. According to the GD method, the learning algorithm is established as follows:

where is the learning rate, with is the Gaussian function value for neural net in the hidden layer, and can be calculated as

where is the input vector, reflects the coordinate value of the center point of the Gaussian function of neural net j for the i-th input, and is the width value of the Gaussian function. Finally, the weight update value of is defined as follows:

where α is the momentum factor. From Equations (8) and (9), the tuning parameter of the proportional coefficient can be expressed in Laplace form with the following equation:

The remaining coefficients, i.e., , and , are similarly calculated as the calculation of . Now, the output of the NN will be described as follows:

where , and are the tuning parameters of the proportional, integral, derivative coefficients, the order of fractional integration, and the fractional derivative for the FOPID controller, respectively. Hence, the output of the NNFOPID can be written as

where , , , , and are the initial setting values of the FOPID controller, namely the proportional, integral, derivative coefficients, the order of fractional integration, and the fractional derivative, respectively.

4. Simulation and Experiment Results

In this section, the effectiveness of the proposed controller is evaluated based on two criteria: tracking precision and energy consumption of the system. To assess the tracking precision, the displacement error of the cylinder is evaluated using the root mean square error (RMSE) and the mean absolute error (MAE). The RMSE and MAE methods allow for a quantitative comparison of the proposed controller and other controllers, enabling informed conclusions about their effectiveness in achieving accurate and precise control over the cylinder’s displacement. The RMSE and MAE methods are defined as follows:

where n is the sample’s number of displacement errors .

4.1. Simulation Study

4.1.1. Simulation Model

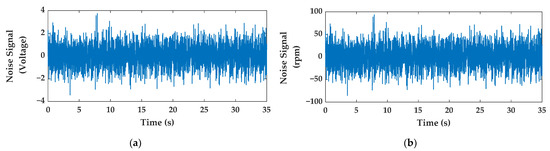

To validate the effectiveness and reliability of the proposed controller, the co-simulations on four working modes of the NIMV system were performed in the commercial software AMESim 2022 and MATLAB 2017a with the simulation model as presented in Figure 5. The main parameter of the simulation model was installed based on the real test bench, and their specifications can be found in Table 1. This ensures that the simulation model closely aligns with the characteristics of the actual NIMV system. Furthermore, Table 2 provides the valve’s conductivity and operating time for each of the four working modes of the NIMV system. These values play a crucial role in defining and distinguishing the various operating modes within the system. Finally, the simulation results of the proposed controller will be compared with the PID and FOPID controllers under the same condition simulation. Notably, the noise signal, which is shown in Figure 6, is used to simulate external factors affecting pumps and valves such as throttling loss, or system leakage. This comparative analysis aims to evaluate and highlight the advantages of the suggested controller in terms of performance and efficiency. The PID controller is used in the comparison as shown as follows:

Figure 5.

The simulation model of the NIMV system for the boom cylinder.

Table 1.

The main parameter of the NIMV system was used for the simulation and experiment.

Table 2.

The valve’s conductivity and operating time on four working modes.

Figure 6.

Noise signal used for simulation model, (a) noise signal affects the valve and (b) noise signal affects the speed of the electric motor.

Remark 1.

To facilitate a fair comparison, it is worth noting that the control coefficients for the PID, FOPID, and proposed controllers have been carefully configured to have the same parameter values. These coefficients have been appropriately selected based on the specific working characteristics of each mode, and their corresponding values can be found in Table 3.

Table 3.

The control coefficients were installed for the simulation.

4.1.2. Simulation Result

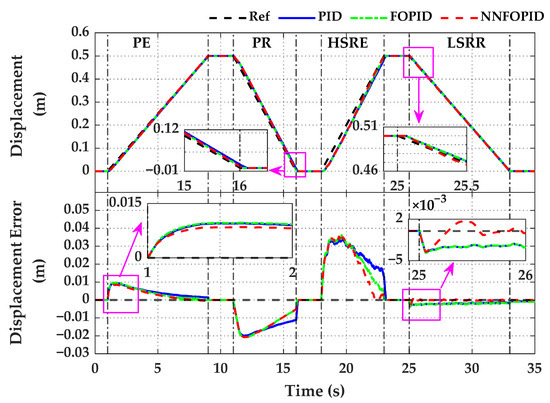

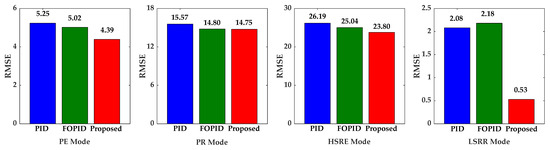

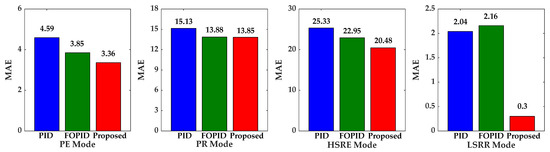

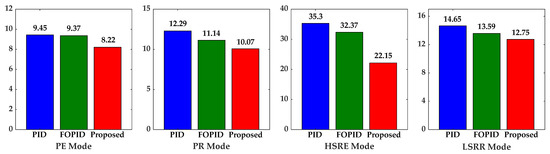

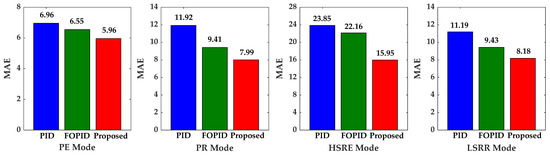

Figure 7 illustrates the comparison of the displacement and error of the boom cylinder on three controllers under the same effect of disturbance (as shown in Figure 6) on the time of 35 s. During the lifting and lowering of the cylinder, the FOPID and NNFOPID controllers have better tracking than the PID controller. It is obvious that the fractional order components allow for better handling of noise in the system, enabling more robust control. Meanwhile, through the tuning of five control coefficients in the FOPID controller, the proposed controller with the NN technique not only achieves the highest tracking precision but also exhibits a faster convergence rate. Notably, it shows a detail from time 20–23 s on the HSRE mode and the zoom in 25–27 s on the LSRR mode. In addition, to ensure fairness in comparison, the RMSE and MAE calculation results of the three controllers are presented in Figure 8 and Figure 9. It is evident from these results that the RMSE of the proposed controller consistently yields as lower compared to the other two controllers, especially in the LSRR mode, about 75.7% and 74.5% of those from FOPID and PID controllers, respectively. Moreover, MAE results are similar to RMSE results when the MAE value of the proposed controller is the smallest. This proves that the accuracy tracking of the system has been improved through the process of tuning the control coefficients.

Figure 7.

Comparison of the tracking precision of the NIMV system in the simulation model.

Figure 8.

The RMSE chart of four working modes in the simulation.

Figure 9.

The MAE chart of four working modes in the simulation.

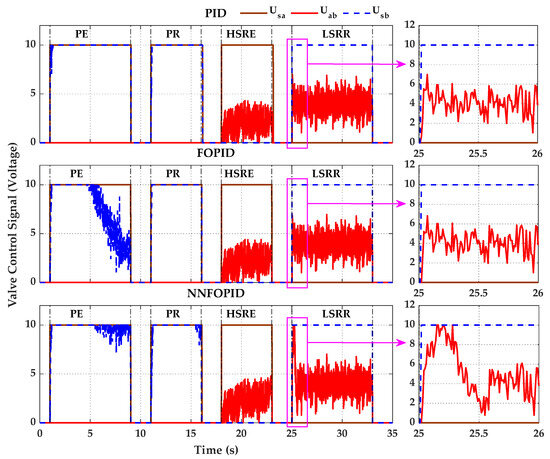

Most of the time, the proposed controller always has better tracking precision. This advantage is achieved through the seamless coordination between the valve and the pump control. Figure 10 shows the comparison of the valve control signal in three controllers and Figure 11 represents the rotation speed, torque, and energy consumption of the electric motor. The most notable disparities appear prominently in PE, HSRE, and LSRR modes when the valve control signal and motor speed have been significantly changed during operation. This is because the fractional order integral component and tuning of their parameters allow the controller to respond more quickly to changes in the system’s behavior, resulting in faster adjustments to the control signal. Particularly detailed is the LSRR mode, where the valve control signal of the NNFOPID controller rapidly increases to 10 V upon entering the mode, only gradually declining to 4 V once the system stabilizes. In contrast, in PID and FOPID controllers, the signal control only fluctuates at about 4 V when opening this mode.

Figure 10.

The comparison of the valve control signal in the simulation model.

Figure 11.

Comparison of the energy consumption in the simulation model.

In addition to the criterion of tracking precision, energy consumption serves as another pivotal measure in evaluating the effectiveness of the proposed controller. In Figure 11, the energy consumption of the three controllers is almost the same in the PE and PR mode, especially in the zoom of 6–7 s when the curves are very close together. However, when delving into a more specific energy consumption analysis for each mode (depicted in Figure 12), the NNFOPID controller consumes 0.005 kJ more energy than the PID controller but 0.021 kJ less than the FOPID controller in the PE mode. In the PR mode, it consumes 0.013 kJ more energy compared to the PID controller, and equivalently to the FOPID controller. While it does require slightly more power in these modes, the difference is relatively minor. The most notable differentiation emerges in the HSRE mode, where the NNFOPID controller showcases remarkable efficiency. Consuming a mere 4.289 kJ to lift the cylinder, it significantly outperforms the FOPID controller’s consumption of 4.787 kJ and the PID controller’s 6.053 kJ. In conclusion, the proposed controller demonstrates high energy-saving performance for the NIMV system, particularly in the HSRE mode.

Figure 12.

Details of the energy consumption of each mode.

In summary, the simulation results offer a comprehensive evaluation of the NNFOPID controller performance in the NIMV system. Under complex noise, the proposed controller not only ensures high tracking accuracy but also saves energy admirably across four working modes, saving 10.4% energy when compared with the FOPID controller and 29.14% compared with the PID controller.

4.2. Experiment Verification

4.2.1. Experiment Setup

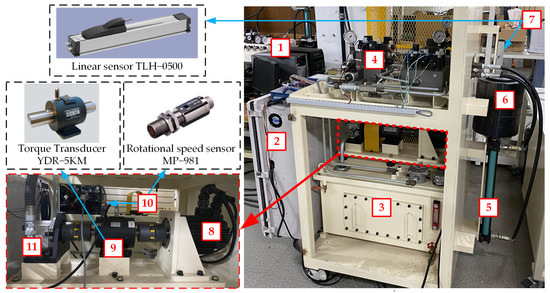

The real test bench of the NIMV system was used to demonstrate the effectiveness and practical applicability of the NNFOPID controller. Figure 13 portrays the experimental setup meticulously designed to emulate the hydraulic boom excavator within the laboratory conditions. The proposed controller was configured in the program computer (1), operating through Simulink Desktop Real-Time on the MATLAB/Simulink software. The control signals were subsequently transmitted to the control box (2) via the PCI card, thereby orchestrating the actions of the servo motor (8) and valve’s conductance. In conjunction, the torque sensor (9) and rotational speed sensor (10) were affixed to the motor shaft to facilitate data acquisition for energy consumption calculations. Simultaneously, the linear sensor (7) was integrated with the cylinder to measure its tracking position. An enumeration of devices employed within the experimental setup is itemized in Table 1 and Table 4.

Figure 13.

The experimental platform of the NIMV system for the hydraulic boom excavator system. (1) Program computer; (2) control box; (3) hydraulic tank; (4) NIMV circuit; (5) hydraulic cylinder; (6) load; (7) linear sensor; (8) servo motor; (9) torque sensor; (10) rotational speed sensor; (11) hydraulic gear pump.

Table 4.

Device setting of the test bench system.

As the same in the simulation section, three controllers were compared to demonstrate the advantage of the proposed controller for application in the real practice of the NIMV system. In addition, the trial-and-error strategy was used to find the suitable parameter for the experiment, as chosen in Table 5.

Table 5.

Control coefficients are applied to the experimental system.

4.2.2. Experimental Results

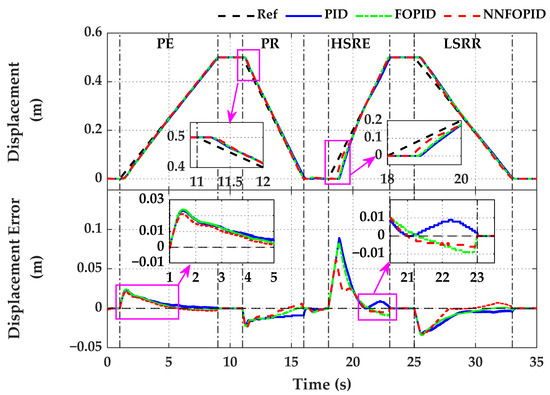

The tracking position results in the NIMV system of the three controllers, which are shown in Figure 14, Figure 15 and Figure 16. Following this result, the proposed controller provides better tracking performance when compared with the PID and FOPID controllers on four working modes with a maximum error held less than 0.062 m, as shown in Figure 14. In addition, the proposed controller has a faster response time in the PE and HSRE modes and a rapid convergence rate in all modes thanks to the advantages of tuning the control parameters in the NNFOPID controller. This result is further reinforced in Figure 15 and Figure 16 when the proposed controller always gives the lowest RMSE and MAE values during operation.

Figure 14.

Comparison of tracking performance of the NIMV system in the experimental platform.

Figure 15.

The RMSE chart of four working modes in experiment.

Figure 16.

The MAE chart of four working modes in experiment.

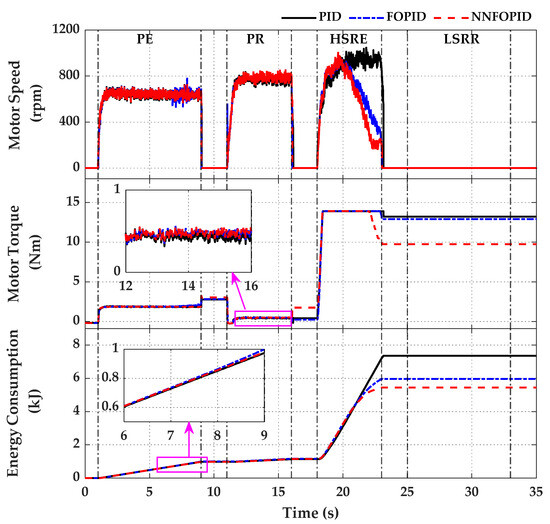

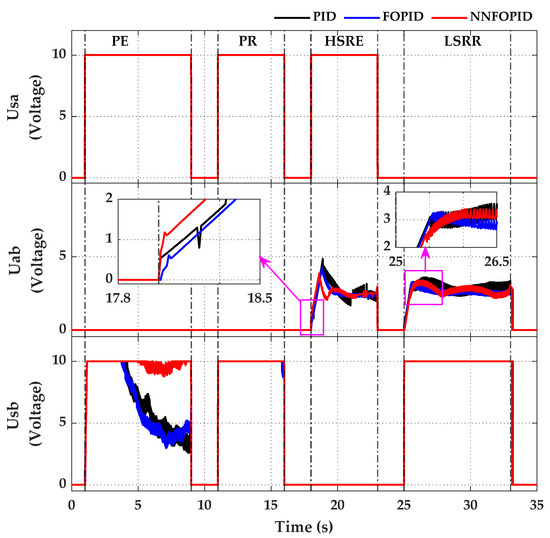

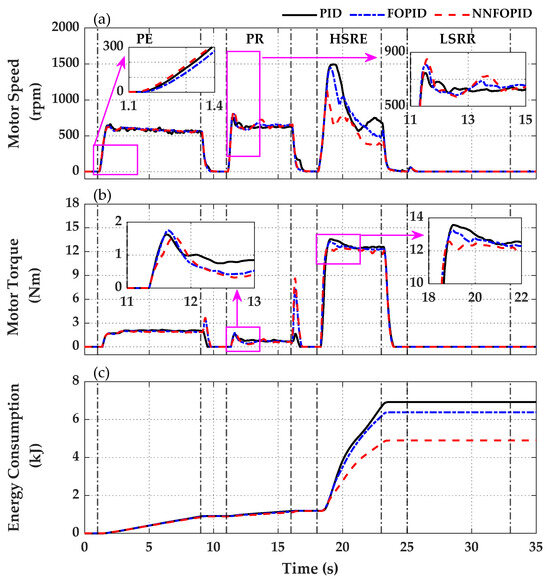

In addition, the input control signal of the valve and pump are shown in Figure 17 and Figure 18a. As shown in Figure 17, in the HSRE mode, the signal control of the Kab valve (Uab) of the proposed controller increases quickly to 1.2 V when the system starts in this mode, higher than the other two controllers (detail on the zoom-in of 17.8–18 s), resulting in the cylinder being operated earlier than the rest of the controllers. Meanwhile, the signal of the Uab increment up to 3.4 V in the LSRR mode from 25 to 26 s helps the proposed controller to close more closely to the reference signal. In contrast to HSRE and LSRR modes, the tracking performance in the PE and PR modes is decided by the pump control signal. In the PE mode, the valve control signal of the Ksb valve is at the maximum (Usb = 10 V) for 1 to 4 s, and gradually decreases to control the accuracy after that. With the advantage of the proposed controller, the speed of the motor is increased rapidly from 1 to 1.4 s (detail on zoom-in of 1.1–1.4 s, Figure 18a), leading to the faster response time of the cylinder in this mode. While in the PR mode, the Ksb valve is fully open during the operation time. The motor speed rises quickly to 850 rpm from 11 to 11.6 s in the proposed controller, resulting in displacement error reducing faster.

Figure 17.

Comparing the valve control signal of the proportional valve.

Figure 18.

Comparison of rotation speed (a), torque (b), and energy consumption (c) in the NIMV experimental system.

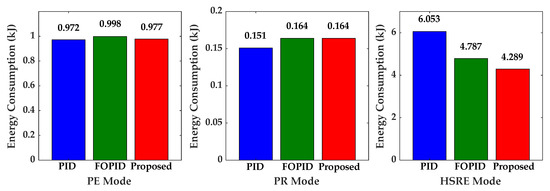

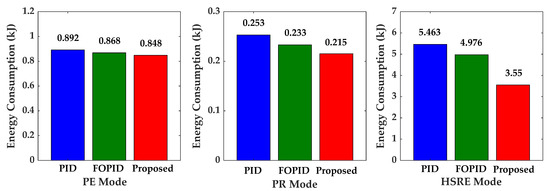

Finally, the comparison of the energy consumption is presented in Figure 18c and Figure 19. By using the NNFOPID controller, the NIMV system consumes less energy in four working modes, saving up 23.33% and 29.25% compared with the FOPID and PID controllers, respectively. Figure 19 shows in detail the energy consumption of the NIMV system of each mode. In general, the energy used in PE and PR modes is relatively similar, the difference only occurs in the HSRE mode due to the fast response ability of the NNFOPID controller.

Figure 19.

Details of the energy consumption in the experimental platform of each mode.

From the above results, the proposed controller not only effectively extinguishes disturbance factors (noise, throttling loss, or system leakage) but also has high tracking precision and energy saving in the NIMV system. Through experimental verification, the NNFOPID controller shows high efficiency in practical application to the NIMV system on the boom excavator.

5. Conclusions

In this paper, the control method of NNFOPID was proposed for the NIMV system to enhance the tracking performance and energy saving in the boom excavator. Specifically, the fractional order derivative and integral component of the FOPID contribute to precision, stability, and fast response for the system. In addition, five parameters of the FOPID controller were automatically tuned using the NN controller to ensure the performance of the system under the influence of external factors. From the simulation and experimental results, the proposed system proved excellent control ability under complex influence conditions from noise, leakage, to throttling loss. As a result, the NIMV system provided better tracking performance and energy saving, saving up 23.33% and 29.25% compared to FOPID and PID in the experimental platform, respectively. Future endeavors will focus on optimizing the cylinder response time in the NIMV system to enhance the tracking precision for hydraulic excavators. Additionally, we will explore the potential for storing and reusing gravitational potential energy from the NIMV system, aiming to enhance energy-saving capabilities even further.

Author Contributions

Conceptualization, T.H.N. and V.D.P.; methodology, T.H.N. and V.D.P.; software, T.H.N. and T.C.D.; validation, T.H.N., T.C.D. and V.D.P.; investigation, T.H.N. and T.C.D.; writing—original draft preparation, T.H.N.; writing—review and editing, T.C.D. and V.D.P.; supervision, K.K.A.; project administration, K.K.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Regional Innovation Strategy (RIS) through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (MOE) (2021RIS-003) and by University of Economics Ho Chi Minh City, Vietnam.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Li, Z.; Wang, C.; Quan, L.; Hao, Y.; Ge, L.; Xia, L. Study on energy efficiency characteristics of the heavy-duty manipulator driven by electro-hydraulic hybrid active-passive system. Autom. Constr. 2021, 125, 103646. [Google Scholar] [CrossRef]

- Yang, J.; Liu, B.; Zhang, T.; Hong, J.; Zhang, H. Application of energy conversion and integration technologies based on electro-hydraulic hybrid power systems: A review. Energy Convers. Manag. 2022, 272, 116372. [Google Scholar] [CrossRef]

- Xu, B.; Cheng, M. Motion control of multi-actuator hydraulic systems for mobile machineries: Recent advancements and future trends. Front. Mech. Eng. 2018, 13, 151–166. [Google Scholar] [CrossRef]

- Yang, C.; Zhou, L.; Wang, J.; Xu, T.; Yang, C.; Ye, G. Research on energy saving system of hydraulic excavator based on three-chamber accumulator. J. Energy Storage 2023, 72, 108571. [Google Scholar] [CrossRef]

- Qin, T.; Li, Y.; Quan, L.; Yang, L. An Adaptive Robust Impedance Control Considering Energy-Saving of Hydraulic Excavator Boom and Stick Systems. IEEE/ASME Trans. Mechatron. 2022, 27, 1928–1936. [Google Scholar] [CrossRef]

- Wu, B.; Wang, W.; Yao, Z.; Xuan, K.; Wu, Z.; Shen, X.; Li, X.; Zhang, H.; Xue, Y.; Cao, X.; et al. Multi-pollutant emission characteristics of non-road construction equipment based on real-world measurement. Sci. Total Environ. 2022, 853, 158601. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, Q. Review on Energy Conservation of Construction Machinery for Pumping Concrete. Processes 2023, 11, 842. [Google Scholar] [CrossRef]

- Yi, H.-S.; Cha, S. Optimal Energy Management of the Electric Excavator Using Super Capacitor. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 151–164. [Google Scholar] [CrossRef]

- Lin, T.; Chen, Q.; Ren, H.; Huang, W.; Chen, Q.; Fu, S. Review of boom potential energy regeneration technology for hydraulic construction machinery. Renew. Sustain. Energy Rev. 2017, 79, 358–371. [Google Scholar] [CrossRef]

- Chen, M.; Zhao, D. The gravitational potential energy regeneration system with closed-circuit of boom of hydraulic excavator. Mech. Syst. Signal Process. 2017, 82, 178–192. [Google Scholar] [CrossRef]

- Mahato, A.C.; Ghoshal, S.K. Energy-saving strategies on power hydraulic system: An overview. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2020, 235, 147–169. [Google Scholar] [CrossRef]

- He, X.; Xiao, G.; Hu, B.; Tan, L.; Tang, H.; He, S.; He, Z. The applications of energy regeneration and conversion technologies based on hydraulic transmission systems: A review. Energy Convers. Manag. 2020, 205, 112413. [Google Scholar] [CrossRef]

- Li, J.; Zhao, J. Energy recovery for hybrid hydraulic excavators: Flywheel-based solutions. Autom. Constr. 2021, 125, 103648. [Google Scholar] [CrossRef]

- Li, J.; Zhao, J.; Zhang, X. A Novel Energy Recovery System Integrating Flywheel and Flow Regeneration for a Hydraulic Excavator Boom System. Energies 2020, 13, 315. [Google Scholar] [CrossRef]

- Do, T.C.; Dinh, T.Q.; Yu, Y.; Ahn, K.K. Innovative powertrain and advanced energy management strategy for hybrid hydraulic excavators. Energy 2023, 282, 128951. [Google Scholar] [CrossRef]

- Chen, Q.; Lin, T.; Ren, H.; Fu, S. Novel potential energy regeneration systems for hybrid hydraulic excavators. Math. Comput. Simul. 2019, 163, 130–145. [Google Scholar] [CrossRef]

- Gong, J.; Zhang, D.; Liu, C.; Zhao, Y.; Hu, P.; Quan, W. Optimization of electro-hydraulic energy-savings in mobile machinery. Autom. Constr. 2019, 98, 132–145. [Google Scholar] [CrossRef]

- Tan, L.; He, X.; Xiao, G.; Jiang, M.; Yuan, Y. Design and energy analysis of novel hydraulic regenerative potential energy systems. Energy 2022, 249, 123780. [Google Scholar] [CrossRef]

- Jung, T.; Raduenz, H.; Krus, P.J.; De Negri, V.; Lee, J. Boom energy recuperation system and control strategy for hydraulic hybrid excavators. Autom. Constr. 2022, 135, 104046. [Google Scholar] [CrossRef]

- Liu, J.; Jiao, Z.; Xian, F.; Liu, W. Energy recovery and utilization system of excavator boom based on flow regeneration and balance theory. J. Braz. Soc. Mech. Sci. Eng. 2019, 42, 35. [Google Scholar] [CrossRef]

- Tong, Z.-M.; Wu, S.-S.; Tong, S.-G.; Yue, Y.-Q.; Li, Y.-S.; Xu, Z.-Y.; Zhong, Y.-W. Energy-saving technologies for construction machinery: A review of electro-hydraulic pump-valve coordinated system. J. Zhejiang Univ.-Sci. A 2020, 21, 331–349. [Google Scholar] [CrossRef]

- Zhong, Q.; Bao, H.; Li, Y.; Hong, H.; Zhang, B.; Yang, H. Investigation into the Independent Metering Control Performance of a Twin Spools Valve with Switching Technology-controlled Pilot Stage. Chin. J. Mech. Eng. 2021, 34, 91. [Google Scholar] [CrossRef]

- Hu, S.; Wang, L.; Li, Y.; Zhang, L. Variable Universe Fuzzy Controller for an Independent Metering System of Construction Machinery. Processes 2023, 11, 901. [Google Scholar] [CrossRef]

- Weber, J. Independent metering systems. Int. J. Hydromechatron. 2018, 1, 91–106. [Google Scholar] [CrossRef]

- Choi, K.; Seo, J.; Nam, Y.; Kim, K.U. Energy-saving in excavators with application of independent metering valve. J. Mech. Sci. Technol. 2015, 29, 387–395. [Google Scholar] [CrossRef]

- Abuowda, K.; Okhotnikov, I.; Noroozi, S.; Godfrey, P.; Dupac, M. A review of electrohydraulic independent metering technology. ISA Trans. 2019, 98, 364–381. [Google Scholar] [CrossRef]

- Lyu, L.; Chen, Z.; Yao, B. Development of parallel-connected pump–valve-coordinated control unit with improved performance and efficiency. Mechatronics 2020, 70, 102419. [Google Scholar] [CrossRef]

- Lyu, L.; Chen, Z.; Yao, B. Energy Saving Motion Control of Independent Metering Valves and Pump Combined Hydraulic System. IEEE/ASME Trans. Mechatron. 2019, 24, 1909–1920. [Google Scholar] [CrossRef]

- Lyu, L.; Chen, Z.; Yao, B. Development of Pump and Valves Combined Hydraulic System for Both High Tracking Precision and High Energy Efficiency. IEEE Trans. Ind. Electron. 2019, 66, 7189–7198. [Google Scholar] [CrossRef]

- Li, C.; Lyu, L.; Helian, B.; Chen, Z.; Yao, B. Precision Motion Control of an Independent Metering Hydraulic System with Nonlinear Flow Modeling and Compensation. IEEE Trans. Ind. Electron. 2022, 69, 7088–7098. [Google Scholar] [CrossRef]

- Ding, R.; Zhang, J.; Xu, B. Advanced Energy Management of a Novel Independent Metering Meter-Out Control System: A Case Study of an Excavator. IEEE Access 2018, 6, 45782–45795. [Google Scholar] [CrossRef]

- Shi, J.; Quan, L.; Zhang, X.; Xiong, X. Electro-hydraulic velocity and position control based on independent metering valve control in mobile construction equipment. Autom. Constr. 2018, 94, 73–84. [Google Scholar] [CrossRef]

- Phan, V.D.; Ahn, K.K. Fault-tolerant control for an electro-hydraulic servo system with sensor fault compensation and disturbance rejection. Nonlinear Dyn. 2023, 111, 10131–10146. [Google Scholar] [CrossRef]

- Nguyen, M.H.; Ahn, K.K. Output Feedback Robust Tracking Control for a Variable-Speed Pump-Controlled Hydraulic System Subject to Mismatched Uncertainties. Mathematics 2023, 11, 1783. [Google Scholar] [CrossRef]

- Borase, R.P.; Maghade, D.K.; Sondkar, S.Y.; Pawar, S.N. A review of PID control, tuning methods and applications. Int. J. Dyn. Control 2021, 9, 818–827. [Google Scholar] [CrossRef]

- Wrat, G.; Bhola, M.; Ranjan, P.; Mishra, S.K.; Das, J. Energy saving and Fuzzy-PID position control of electro-hydraulic system by leakage compensation through proportional flow control valve. ISA Trans. 2020, 101, 269–280. [Google Scholar] [CrossRef]

- Tepljakov, A.; Alagoz, B.B.; Yeroglu, C.; Gonzalez, E.A.; Hosseinnia, S.H.; Petlenkov, E.; Ates, A.; Cech, M. Towards Industrialization of FOPID Controllers: A Survey on Milestones of Fractional-Order Control and Pathways for Future Developments. IEEE Access 2021, 9, 21016–21042. [Google Scholar] [CrossRef]

- Maddahi, A.; Sepehri, N.; Kinsner, W. Fractional-Order Control of Hydraulically Powered Actuators: Controller Design and Experimental Validation. IEEE/ASME Trans. Mechatron. 2019, 24, 796–807. [Google Scholar] [CrossRef]

- Edet, E.; Katebi, R. On Fractional-order PID Controllers. IFAC-Pap. 2018, 51, 739–744. [Google Scholar] [CrossRef]

- Tepljakov, A.; Alagoz, B.B.; Yeroglu, C.; Gonzalez, E.; HosseinNia, S.H.; Petlenkov, E. FOPID Controllers and Their Industrial Applications: A Survey of Recent Results. IFAC-Pap. 2018, 51, 25–30. [Google Scholar] [CrossRef]

- Essa, M.E.-S.M.; Aboelela, M.A.S.; Hassan, M.A.M. Application of Fractional Order Controllers on Experimental and Simulation Model of Hydraulic Servo System. In Fractional Order Control and Synchronization of Chaotic Systems; Azar, A.T., Vaidyanathan, S., Ouannas, A., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 277–324. [Google Scholar]

- Bingi, K.; Ibrahim, R.; Karsiti, M.N.; Hassan, S.M.; Harindran, V.R. Fractional-Order Systems and PID Controllers; Springer: Berlin/Heidelberg, Germany, 2020; Volume 264. [Google Scholar]

- Do, T.C.; Tran, D.T.; Dinh, T.Q.; Ahn, K.K. Tracking Control for an Electro-Hydraulic Rotary Actuator Using Fractional Order Fuzzy PID Controller. Electronics 2020, 9, 926. [Google Scholar] [CrossRef]

- Jiangbo, Z.; Junzheng, W. The fractional order PI control for an energy saving electro-hydraulic system. Trans. Inst. Meas. Control 2015, 39, 505–519. [Google Scholar] [CrossRef]

- Nguyen, T.-H.; Do, T.-C.; Ahn, K.-K. A Study on a New Independent Metering Valve for Hydraulic Boom Excavator. Appl. Sci. 2022, 12, 605. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Do, T.C.; Nguyen, V.H.; Ahn, K.K. High Tracking Control for a New Independent Metering Valve System Using Velocity-Load Feedforward and Position Feedback Methods. Appl. Sci. 2022, 12, 9827. [Google Scholar] [CrossRef]

- Bao, H.; He, D.; Zhang, B.; Zhong, Q.; Hong, H.; Yang, H. Research on Dynamic Performance of Independent Metering Valves Controlling Concrete-Placing Booms Based on Fuzzy-LADRC Controller. Actuators 2023, 12, 139. [Google Scholar] [CrossRef]

- Zhang, X.; Qiao, S.; Quan, L.; Ge, L. Velocity and Position Hybrid Control for Excavator Boom Based on Independent Metering System. IEEE Access 2019, 7, 71999–72011. [Google Scholar] [CrossRef]

- Jun, G.; Daqing, Z.; Yong, G.; Zhongyong, T.; Changsheng, L.; Peng, H.; Yuming, Z.; Weicai, Q.; Yongping, J. Potential energy recovery method based on alternate recovery and utilization of multiple hydraulic cylinders. Autom. Constr. 2020, 112, 103105. [Google Scholar] [CrossRef]

- Tepljakov, A.; Petlenkov, E.; Belikov, J. FOMCOM: A MATLAB toolbox for fractional-order system identification and control. Int. J. Microelectron. Comput. Sci. 2011, 2, 51–62. [Google Scholar]

- Liu, J. Radial Basis Function (RBF) Neural Network Control for Mechanical Systems: Design, Analysis and Matlab Simulation; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).