Generalized Net Model of Heavy Oil Products’ Manufacturing in Petroleum Refinery

Abstract

:1. Introduction

2. Materials and Methods

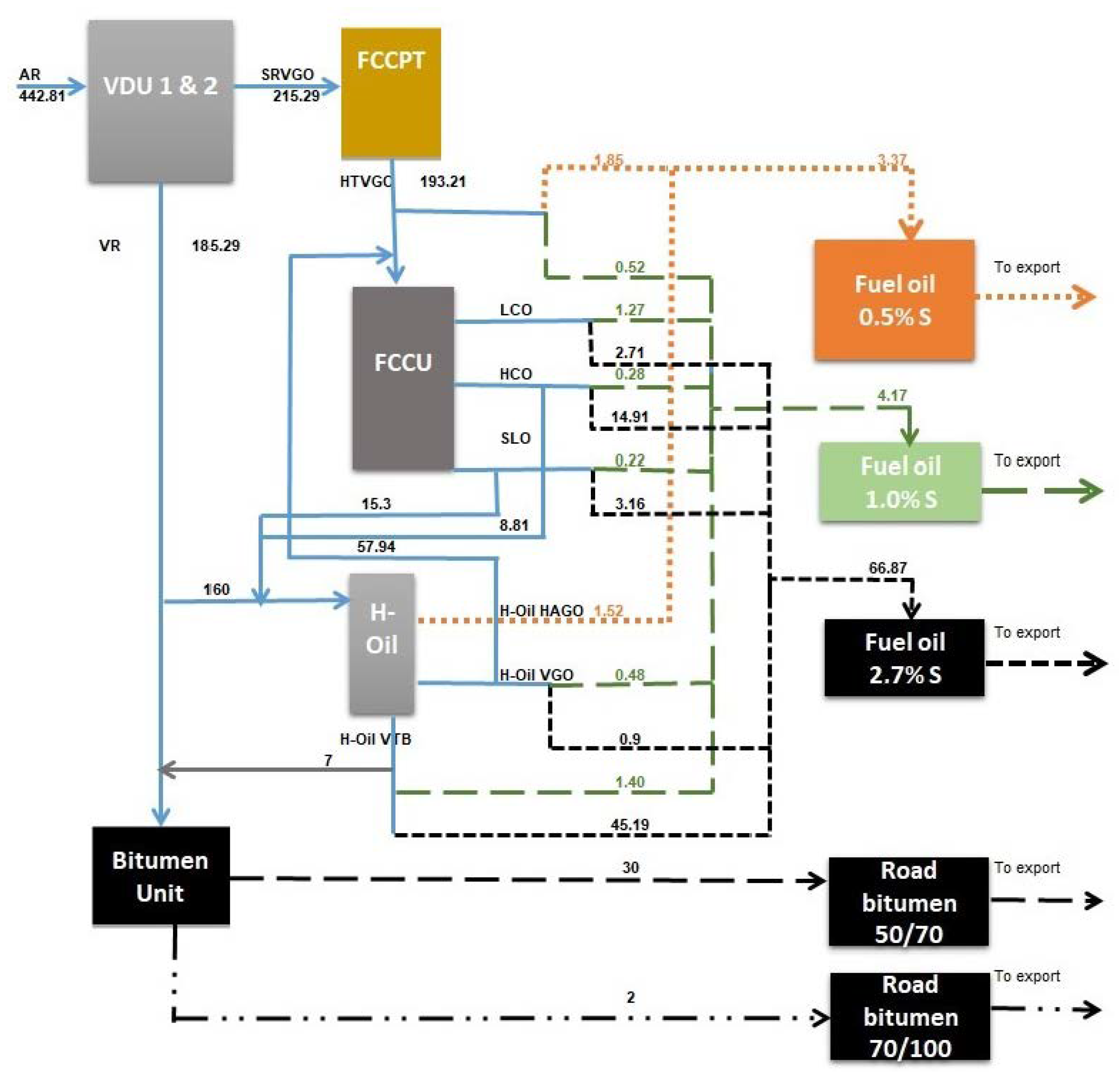

2.1. Processing Scheme for Production of Different Grades of Heavy Fuel Oil and Road Pavement Bitumen in a Petroleum Refinery to Be Modeled Using GNs

2.2. Short Notes on the Theory of GNs

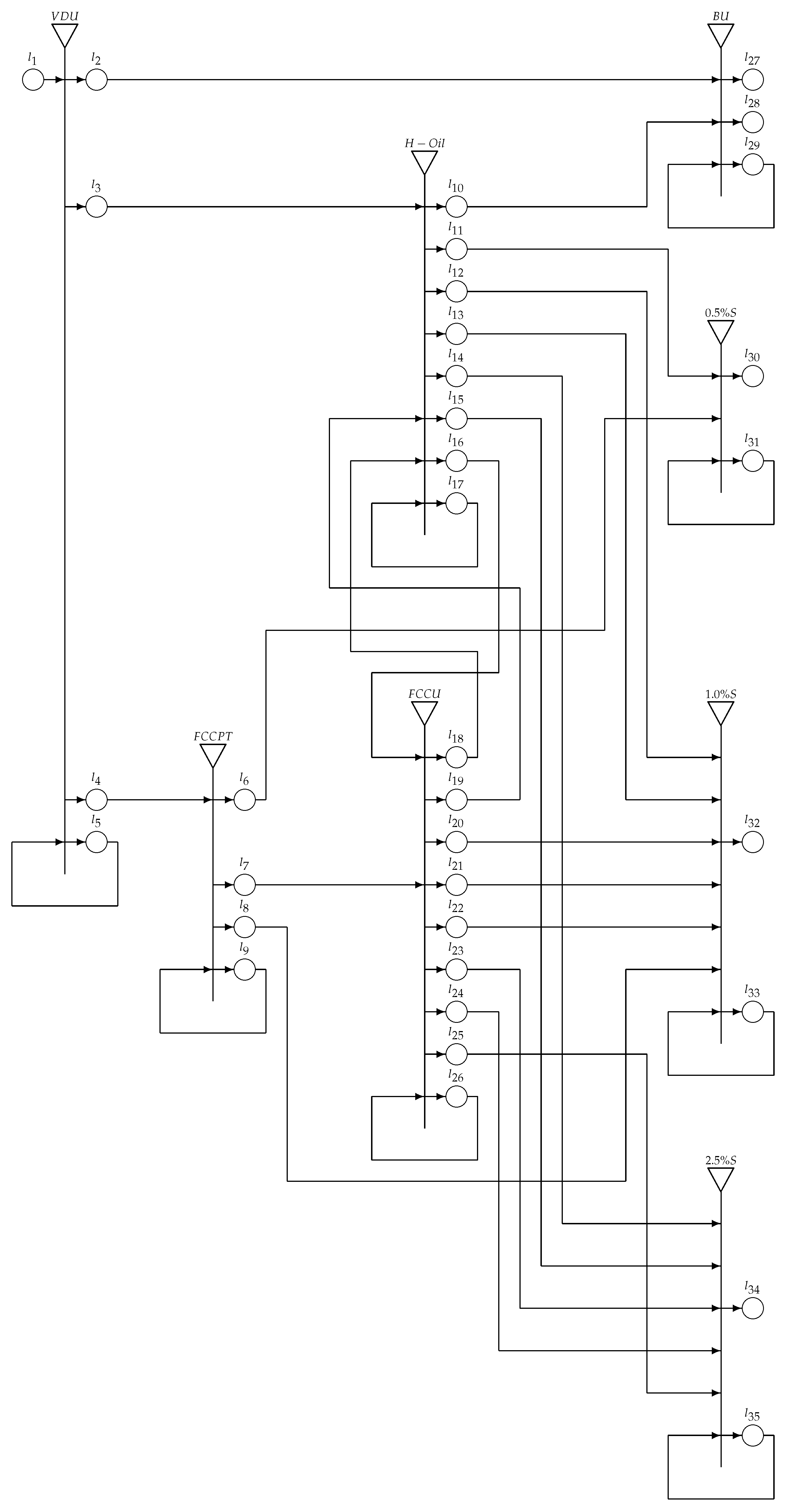

3. Results of Modeling Heavy Oil Product Manufacturing in a Petroleum Refinery Using Generalized Nets

- •

- VDU—Vacuum distillation unit

- •

- FCCPT—Fluid catalytic cracking feed pretreater

- •

- H-Oil—H-Oil vacuum residue hydrocracker

- •

- FCCU—Fluid catalytic cracking unit

- •

- BU—Road pavement (asphalt) bitumen production unit

- •

- 0.5 S—Fuel oil containing maximum of 0.5 wt.% sulfur

- •

- 1.0 S—Fuel oil containing maximum of 1.0 wt.% sulfur

- •

- 2.5 S—Fuel oil containing maximum of 2.5 wt.% sulfur

- “there is a request for AR from BU”,

- “there is a request for AR from H-Oil”,

- “there is a request for AR from FCCPT”.

- = “there is a request for HTVGO for production of fuel oil with maximum sulfur content of 0.5% S”,

- = “there is a request for HTVGO as a feed for fluid catalytic cracking unit”,

- = “there is a request for HTVGO for production of fuel oil with maximum sulfur content of 1.0% S”.

- = “there is a request for SLO as a feed for H-Oil unit”,

- = “there is a request for HCO as a feed for H-Oil unit”,

- = “there is a request for LCO for Fuel oil 1.0% S”,

- = “there is a request for HCO for Fuel oil 1.0% S”,

- = “there is a request for SLO for Fuel oil 1.0% S”,

- = “there is a request for LCO for Fuel oil 2.5% S”,

- = “there is a request for HCO for Fuel oil 2.5% S”,

- = “there is a request for SLO for Fuel oil 2.5 % S”.

- = “there is a request for Road bitumen grade 50/70”,

- = “there is a request for Road bitumen grade 70/100”.

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Atanassov, K. Generalized Nets; World Scientific: Singapore, 1991. [Google Scholar]

- Stratiev, D.D.; Zoteva, D.; Stratiev, D.S.; Atanassov, K. Modelling the Process of Production of Automotive Gasoline by the Use of Generalized Nets. In Uncertainty and Imprecision in Decision Making and Decision Support: New Advances, Challenges, and Perspectives; IWIFSGN BOS/SOR 2020; Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2022; Volume 338. [Google Scholar]

- Stratiev, D.D.; Stratiev, D.; Atanassov, K. Modelling the Process of Production of Diesel Fuels by the Use of Generalized Nets. Mathematics 2021, 9, 2351. [Google Scholar] [CrossRef]

- Stratiev, D.D.; Dimitriev, A.; Stratiev, D.; Atanassov, K. Modeling the Production Process of Fuel Gas, LPG, Propylene, and Polypropylene in a Petroleum Refinery Using Generalized Nets. Mathematics 2023, 11, 3800. [Google Scholar] [CrossRef]

- Kaiser, M.J.; De Klerk, A.; Gary, J.H.; Handwerk, G.E. Petroleum Refining: Technology, Economics, and Markets, 6th ed.; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Merdrignac, I.; Espinat, D. Physicochemical characterization of petroleum fractions: The state of the art. Oil Gas Sci. Technol. Rev. IFP 2007, 62, 8–29. [Google Scholar] [CrossRef]

- Efimov, I.; Smyshlyaeva, K.I.; Povarov, V.G.; Buzyreva, E.D. UNIFAC residual marine fuels stability prediction from NMR and elemental analysis of SARA components. Fuel 2023, 352, 129014. [Google Scholar] [CrossRef]

- Gautam, R.; AlAbbad, M.; Guevara, E.R.; Sarathy, S.M. On the products from the pyrolysis of heavy fuel and vacuum residue oil. J. Anal. Appl. Pyrolysis 2023, 173, 106060. [Google Scholar] [CrossRef]

- Konovnin, A.A.; Presnyakov, V.V.; Shigabutdinov, R.A.; Ahunov, R.N.; Idrisov, M.R.; Novikov, M.A.; Hramov, A.A.; Urazaikin, A.S.; Shigabutdinov, A.K. Deep Processing of Vacuum Residue on the Basis of Heavy Residue Conversion Complex of TAIF-NK JSC. Chem. Technol. Fuels Oils 2023, 635, 3–7. [Google Scholar] [CrossRef]

- Jafarian, M.; Haseli, P.; Saxena, S.; Dali, B. Emerging technologies for catalytic gasification of petroleum residue derived fuels for sustainable and cleaner fuel production—An overview. Energy Rep. 2023, 9, 3248–3272. [Google Scholar] [CrossRef]

- Schlehöfer, D.; Vráblík, A.; Chrudimská, K.; Jenčík, J.; Hradecká, I. Evaluation of High-Viscosity Residual Fractions by Hot Filtration. Energy Fuels 2023, 37, 13686–13697. [Google Scholar] [CrossRef]

- Gaikwad, R.W.; Warade, A.R.; Bhagat, S.L.; Bhasarkar, J.B. Optimization and simulation of refinery vacuum column with an overhead condenser. Mater. Today Proc. 2022, 57, 1593–1597. [Google Scholar] [CrossRef]

- Mishra, P.; Yadav, A. Modelling of a vacuum residue hydrocracking in an industrial slurry phase reactor. Can. J. Chem. Eng. 2023, 101, 7275–7292. [Google Scholar] [CrossRef]

- Ye, L.; Qin, X.; Murad, A.; Liu, J.; Ying, Q.; Xie, J.; Hou, L.; Yu, W.; Zhao, J.; Sun, H.; et al. Calculation of reaction network and product properties of delayed coking process based on structural increments. Chem. Eng. J. 2022, 431, 133764. [Google Scholar] [CrossRef]

- Selalame, T.W.; Patel, R.; Mujtaba, I.M.; John, Y.M. A Review of Modelling of the FCC Unit–Part I: The Riser. Energies 2022, 15, 308. [Google Scholar] [CrossRef]

- Selalame, T.W.; Patel, R.; Mujtaba, I.M.; John, Y.M. A Review of Modelling of the FCC Unit—Part II: The Regenerator. Energies 2022, 15, 388. [Google Scholar] [CrossRef]

- Selalame, T.W.; Patel, R.; Mujtaba, I.M.; John, Y.M. The Effects of Vaporisation Models on the FCC Riser Reactor. Energies 2023, 16, 4831. [Google Scholar] [CrossRef]

- Wang, Y.; Shang, D.; Yuan, X.; Xue, Y.; Sun, J. Modeling and Simulation of Reaction and Fractionation Systems for the Industrial Residue Hydrotreating Process. Processes 2020, 8, 32. [Google Scholar] [CrossRef]

- Sun, J.; Yu, H.; Yin, Z.; Jiang, L.; Wang, L.; Hu, S.; Zhou, R. Process Simulation and Optimization of Fluid Catalytic Cracking Unit’s Rich Gas Compression System and Absorption Stabilization System. Processes 2023, 11, 2140. [Google Scholar] [CrossRef]

- Piskunov, I.V.; Bashkirceva, N.Y.; Emelyanycheva, E.A. The mathematical modeling of bitumen properties interrelations (review). J. Chem. Technol. Metal. 2022, 57, 464–479. [Google Scholar]

- Munoz, J.; Ancheyta, J.; Castaneda, L. Selection of heavy oil upgrading technologies by proper estimation of petroleum prices. Petrol Sci. Technol. 2022, 40, 217–236. [Google Scholar] [CrossRef]

- Aquilar, R.; Ancheyta, J.; Trejo, F. Simulation and planning of a petroleum refinery based on carbon rejection processes. Fuel 2012, 100, 80–90. [Google Scholar] [CrossRef]

- He, W.; Zhao, J.; Zhao, L.; Li, Z.; Yang, M.; Liu, T. Data-driven two-stage distributionally robust optimization for refinery planning under uncertainty. Chem. Eng. Sci. 2023, 269, 118466. [Google Scholar] [CrossRef]

- Jiao, Y.; Qiu, R.; Liang, Y.; Liao, Q.; Tua, R.; Wei, X.; Zhang, H. Integration optimization of production and transportation of refined oil: A case study from China. Chem. Eng. Res. Des. 2022, 188, 39–49. [Google Scholar] [CrossRef]

- da Silva, P.R.; Aragão, M.E.; Trierweilera, J.O.; Trierweilera, L.F. Integration of hydrogen network design to the production planning in refineries based on multi- scenarios optimization and flexibility analysis. Chem. Eng. Res. Des. 2022, 187, 434–450. [Google Scholar] [CrossRef]

- Lima, C.; Relvas, S.; Barbosa-Póvoa, A. Designing and planning the downstream oil supply chain under uncertainty using a fuzzy programming approach. Comp. Chem. Eng. 2021, 151, 107373. [Google Scholar] [CrossRef]

- Yu, L.; Wang, S.; Xu, Q. Optimal scheduling for simultaneous refinery manufacturing and multi oil-product pipeline distribution. Comp. Chem. Eng. 2022, 157, 107613. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, X.; Lu, W. A Cyber–Physical Systems-Based Double-Layer Mapping Petri Net Model for Factory Process Flow Control. Appl. Sci. 2023, 13, 8975. [Google Scholar] [CrossRef]

- Zhang, S.W.; Li, Z.W.; Qu, T.; Li, C.D. Petri net-based approach to short-term scheduling of crude oil operations with less tank requirement. Inf. Sci. 2017, 417, 247–261. [Google Scholar] [CrossRef]

- Alexieva, J.; Choy, E.; Koycheva, E. Review and bibloigraphy on generalized nets theory and applications. In A Survey of Generalized Nets; Choy, E., Krawczak, M., Shannon, A., Szmidt, E., Eds.; Raffles KvB Monograph No. 10; Raffles Publ. House: Sydney, Australia, 2007; pp. 207–301. [Google Scholar]

- Zoteva, D.; Krawczak, M. Generalized Nets as a Tool for the Modelling of Data Mining Processes. In Issues in Intuitionistic Fuzzy Sets and Generalized Nets; EXIT Publ. House: Warsaw, Poland, 2017; Volume 13, pp. 1–60. [Google Scholar]

- Zoteva, D.; Angelova, N. Generalized Nets. An Overview of the Main Results and Applications. In Research in Computer Science in Bulgarian Academy of Sciences; Atanassov, K., Ed.; Springer: Cham, Switzerland, 2021; pp. 177–226. [Google Scholar]

- Vedachalam, S.; Baquerizo, N.; Dalai, A.K. Review on impacts of low sulfur regulations on marine fuels and compliance options. Fuel 2022, 310, 122243. [Google Scholar] [CrossRef]

- BDS EN ISO 3675:2004; Crude Petroleum and Liquid Petroleum Products—Laboratory Determination of Density—-Hydrometer Method. Bulgarian Institute for Standardization: Sofia, Bulgaria, 2004.

- BDS EN ISO 12185:2002; Crude Petroleum and Petroleum Products—Determination of Density—-Method by Oscillation with U Tube. Bulgarian Institute for Standardization: Sofia, Bulgaria, 1996.

- BDS EN ISO 3104:2020; Petroleum Products—Transparent and Opaque Liquids—Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity. Bulgarian Institute for Standardization: Sofia, Bulgaria, 2020.

- ASTM D445-23; Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity). ASTM International: West Conshohocken, PA, USA, 2023.

- BDS EN ISO 8754:2006; Petroleum Products—Determination of Sulfur Content Energy-Dispersive X-ray Fluorescence Spectrometry. Bulgarian Institute for Standardization: Sofia, Bulgaria, 2003.

- ASTM D4294-21; Standard Test Method for Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-ray Fluorescence Spectrometry. ASTM International: West Conshohocken, PA, USA, 2021.

- BDS EN ISO 2719:2016; Determination of Flash Point Pensky-Martens Closed Cup Method. Bulgarian Institute for Standardization: Sofia, Bulgaria, 2016.

- ASTM D93-20; Standard Test Methods for Flash Point by Pensky-Martens Closed Cup Tester. Anton Paar: Graz, Austria, 2020.

- IP 570: 2021; Determination of Hydrogen Sulfide in Fuel Oils—Rapid Liquid Phase Extraction Method. Energy Institute: London, UK, 2018.

- ASTM D664-18e2; Standard Test Method for Acid Number of Petroleum Products by Potentiometric Titration. ASTM International: West Conshohocken, PA, USA, 2019.

- BDS ISO 10307-2:2016; Petroleum Products—Total Sediment in Residual Fuel Oils—Part 2: Determination Using Standard Procedures for Ageing. Bulgarian Institute for Standardization: Sofia, Bulgaria, 1993.

- IP 390: 2017; Petroleum Products—Total Sediment in Residual Fuel Oils—Part 2: Determination Using Standard Procedures for Ageing. Energy Institute: London, UK, 1993.

- BDS EN ISO 10370:2001; Petroleum Products—Determination of Carbon Residue—Micro Method. Bulgarian Institute for Standardization: Sofia, Bulgaria, 2015.

- BDS EN ISO 3016:2019; Petroleum and Related Products from Natural or Synthetic Sources. Determination of Pour Point. Bulgarian Institute for Standardization: Sofia, Bulgaria, 2019.

- BDS ISO 3733:2003; Petroleum Products and Bituminous Materials—Determination of Water—Distillation Method. Bulgarian Institute for Standardization: Sofia, Bulgaria, 2003.

- BDS EN ISO 6245:2004; Petroleum Products—Determination of Ash. Bulgarian Institute for Standardization: Sofia, Bulgaria, 2004.

- IP 501: 2019; Determination of Aluminium, Silicon, Vanadium, Nickel, Iron, Sodium, Calcium, Zinc and Phosphorous in Residual Fuel Oil by Ashing, Fusion and Inductively Coupled Plasma Emission Spectrometry. Energy Institute: London, UK, 2005.

- IP 470:2005; Determination of Aluminium, Silicon, Vanadium, Nickel, Iron, Calcium, Zinc and Sodium in Residual Fuel Oil by Ashing, Fusion and Atomic Absorption Spectrometry. Energy Institute: London, UK, 2005.

- ISO 10478:1994; Petroleum Products—Determination of Aluminium and Silicon in Fuel Oils—Inductively Coupled Plasma Emission and Atomic Absorption Spectroscopy Methods. International Organization for Standardization: Geneva, Switzerland, 1994.

- ASTM D4809-18; Standard Test Method for Heat of Combustion of Liquid Hydrocarbon Fuels by Bomb Calorimeter (Precision Method). ASTM International: West Conshohocken, PA, USA, 2018.

- BDS EN ISO 3735:2003; Crude Petroleum and Fuel Oils—Determination of Sediment—Extraction Method. Bulgarian Institute for Standardization: Sofia, Bulgaria, 2006.

- ASTM D97-17b(2022); Standard Test Method for Pour Point of Petroleum Products. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D240-19; Standard Test Method for Heat of Combustion of Liquid Hydrocarbon Fuels by Bomb Calorimeter. ASTM International: West Conshohocken, PA, USA, 2019.

- BDS ISO 8217:2017; Petroleum Products—Fuels (Class F)—Specifications of Marine Fuels. Bulgarian Institute for Standardization: Sofia, Bulgaria, 2017.

- IP 375:2022; Petroleum Products—Total Sediment in Residual Fuel Oils—Part 1: Determination by Hot Filtration. Energy Institute: London, UK, 2011.

- BDS ISO 10307-1:2016; Petroleum Products—Total Sediment in Residual fuel Oils—Part 1: Determination by Hot Filtration. Bulgarian Institute for Standardization: Sofia, Bulgaria, 2016.

- ASTM D6560-17; Standard Test Method for Determination of Asphaltenes (Heptane Insolubles) in Crude Petroleum and Petroleum Products. ASTM International: West Conshohocken, PA, USA, 2022.

- IP 143:2021; Determination of Asphaltenes (Heptane Insolubles) in Crude Petroleum and Petroleum Products. Energy Institute: London, UK, 2021.

- ASTM D1298-12b(2017)e1; Standard Test Method for Density, Relative Density, or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer Method. ASTM International: West Conshohocken, PA, USA, 2023.

- BDS 1766:1974; Petroleum products—Determination of Specific Viscosity with the Engler Viscometer. Bulgarian Institute for Standardization: Sofia, Bulgaria, 1974.

- ASTM D95-13(2018); Standard Test Method for Water in Petroleum Products and Bituminous Materials by Distillation. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D473-07(2017)e1; Standard Test Method for Sediment in Crude Oils and Fuel Oils by the Extraction Method. ASTM International: West Conshohocken, PA, USA, 2017.

- BDS EN ISO 2592:2017; Petroleum and Related Products—Determination of Flash and Fire Points—Cleveland Open Cup Method. European Standards: Plzen, Czech Republic, 2017.

- ASTM D92-18; Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D482-19; Standard Test Method for Ash from Petroleum Products. ASTM International: West Conshohocken, PA, USA, 2019.

- BDS 5252:1984; Petroleum Products—Determination of the Presence of Water-Soluble Acids and Bases. Bulgarian Institute for Standardization: Sofia, Bulgaria, 1988.

- ASTM D5863-00a(2016); Standard Test Methods for Determination of Nickel, Vanadium, Iron, and Sodium in Crude Oils and Residual Fuels by Flame Atomic Absorption Spectrometry. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D189-06(2019); Standard Test Method for Conradson Carbon Residue of Petroleum Products. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D4530-15(2020); Standard Test Method for Determination of Carbon Residue (Micro Method). ASTM International: West Conshohocken, PA, USA, 2020.

- Stratiev, D.; Shishkova, I.; Dinkov, R.; Dobrev, D.; Argirov, G.; Yordanov, D. The Synergy between Ebullated Bed Vacuum Residue Hydrocracking and Fluid Catalytic Cracking Processes in Modern Refining—Commercial Experience; Professor Marin Drinov Publishing House of Bulgarian Academy of Sciences: Sofia, Bulgaria, 2022; ISBN 978-619-245-234-6. [Google Scholar]

- BDS EN 1426:2015; Bitumen and Bituminous Binders—Determination of Needle Penetration. European Standards: Plzen, Czech Republic, 2019.

- BDS EN 1427:2015; Bitumen and Bituminous Binders—Determination of the Softening Point—Ring and Ball Method. European Standards: Plzen, Czech Republic, 2015.

- BDS EN 12593:2015; Bitumen and Bituminous Binders—Determination of the Fraass Breaking Point. European Standards: Plzen, Czech Republic, 2015.

- BDS EN 12607-1:2014; Bitumen and Bituminous Binders—Determination of the Resistance to Hardening under Influence of Heat and Air—Part 1: RTFOT Method. European Standards: Plzen, Czech Republic, 2014.

- BDS EN 12592:2014; Bitumen and Bituminous Binders—Determination of Solubility. European Standards: Plzen, Czech Republic, 2014.

- BDS EN 12606-1; Bitumen and Bituminous Binders—Determination of the Paraffin Wax Content—Method by Distillation. European Standards: Plzen, Czech Republic, 2015.

- Jensen, K. Coloured Petri nets and the invariant–method. Theor. Comput. Sci. 1981, 14, 317–336. [Google Scholar] [CrossRef]

- Genrich, H.K. Lautenbach. In The Analysis of Distributed Systems by Means of Predicate/Transition Nets; Lecture Notes in Computer Science; Springer: Berlin, Germany, 1979; Volume 70, pp. 123–146. [Google Scholar]

- Atanassov, K. Generalized Nets and Intuitionistic Fuzziness in Data Mining; Professor Marin Drinov Academic Publishing House: Sofia, Bulgaria, 2020. [Google Scholar]

| No | Properties | Unit | Min | Max | Test Method |

|---|---|---|---|---|---|

| Value | Value | ||||

| 1 | Density at 15 C | kg/m | - | 991.0 | BDS EN ISO 3675 [34] |

| BDS EN ISO 12185 [35] | |||||

| 2 | Kinematic viscosity at 50 C | mm/s | - | 380.0 | BDS EN ISO 3104 [36] |

| ASTM D 445 [37] | |||||

| 3 | Calculated Carbon Aromaticity | - | 870 | ||

| Index | |||||

| 4 | Sulfur | % (m/m) | - | 0.5 | BDS EN ISO 8754 [38] |

| ASTM D 4294 [39] | |||||

| 5 | Flash point | C | 60 | - | BDS EN ISO 2719 [40] |

| ASTM D 93 (B) [41] | |||||

| 6 | Hydrogen sulfide | mg/kg | - | 2.00 | IP 570 [42] |

| 7 | Acid number | mg KOH/g | - | 2.5 | ASTM D 664 [43] |

| 8 | Total sediment | % (m/m) | - | 0.10 | BDS ISO 10307-2 [44] |

| Determination using standard | IP 390 [45] | ||||

| procedures for aging | |||||

| thermal aging (procedure A) | |||||

| 9 | Carbon residue: micro method | % (m/m) | - | 18.00 | BDS EN ISO 10370 [46] |

| 10 | Pour point (upper) | C | - | 30 | BDS EN ISO 3016 [47] |

| 11 | Water | % (V/V) | - | 0.50 | BDS EN ISO 3733 [48] |

| 12 | Ash | % (m/m) | - | 0.100 | BDS EN ISO 6245 [49] |

| 13 | Vanadium | mg/kg | - | 350 | IP 501, IP 470 [50,51] |

| 14 | Sodium | mg/kg | - | 100 | IP 501, IP 470 [52] |

| 15 | Aluminum + Silicon | mg/kg | - | 60 | IP 501, IP 470 [50,51] |

| ISO 10478 [52] | |||||

| 16 | Used lubricating oils (ULO): | mg/kg | IP 501, IP 470 [50,51] | ||

| Calcium | >30 | ||||

| and Zinc | >15 | ||||

| or Calcium | >30 | ||||

| and Phosphorus | >15 |

| No | Properties | Unit | Min | Max | Test Method |

|---|---|---|---|---|---|

| Value | Value | ||||

| 1 | Density at 15 C | kg/m | - | 995 | BDS EN ISO 3675 [53] |

| BDS EN ISO 12185 [34] | |||||

| 2 | Kinematic viscosity at C | mm/s | 75 | 380 | BDS EN ISO |

| 3104+AC ASTM [36] | |||||

| D 445 [37] | |||||

| 3 | Sulfur content | % (m/m) | - | 0.9 | BDS EN ISO 8754 [38] |

| ASTM D 4294 [39] | |||||

| 4 | Water content | % (v/v) | - | 1.0 | BDS EN ISO 3733 [48] |

| 5 | Sediments, content | % (m/m) | - | 0.5 | BDS EN ISO 3735 [54] |

| 6 | Flash point in closed cup | C | 65 | - | BDS EN ISO 2719 [40] |

| ASTM D 93 (B) [41] | |||||

| 7 | Pour point | C | - | 30 | BDS EN ISO 3016 [47] |

| ASTM D 97 [55] | |||||

| 8 | Specific combustion heat (lower) | MJ/kg | 40.2 | - | ASTM D 240 [56] |

| BDS ISO 8217 [57] | |||||

| 9 | Carbon residue: micro method | % (m/m) | - | 15 | BDS EN ISO 10370 [46] |

| 10 | Ash content | % (m/m) | - | 0.15 | BDS EN ISO 6245 [49] |

| 11 | Total sediment | ||||

| Determination via hot filtration | % (m/m) | - | 0.15 | IP 375 [58] | |

| BDS ISO 10307-1 [59] | |||||

| 12 | Nickel | mg/kg | - | 60 | IP 470, IP 501 [50,51] |

| 13 | Vanadium | mg/kg | - | 120 | IP 470, IP 501 [50,51] |

| 14 | Aluminum + Silicon | mg/kg | - | 150 | IP 470, IP 501 [50,51] |

| 15 | Sodium | mg/kg | - | 40 | IP 470, IP 501 [50,51] |

| 16 | Asphaltenes | % (m/m) | - | 7 | ASTM D 6560 [60] |

| IP 143 [61] |

| No | Properties | Unit | Min | Max | Test Method |

|---|---|---|---|---|---|

| Value | Value | ||||

| 1 | Density at 15 C | g/cm | - | 1.025 | BDS EN ISO 3675 [34] |

| ASTM D 1298 [62] | |||||

| BDS EN ISO 12185 [35] | |||||

| 2 | Kinematic viscosity at 80 C | mm/s | - | 113.6 | BDS EN ISO 3104 [36] |

| ASTM D 445 [37] | |||||

| or Engler specific viscosity at | E | - | 15.0 | BDS 1766-74 [63] | |

| 80 C | |||||

| 3 | Sulfur content | % (m/m) | - | 2.5 | BDS EN ISO 8754 [38] |

| ASTM D 4294 [39] | |||||

| 4 | Water content | % (m/m) | - | 0.5 * | ASTM D 95 [64] |

| 5 | Mechanical impurities, content | % (m/m) | - | 0.5 * | ASTM D 473 [65] |

| 6 | Flash point in open cup | C | 110 | - | BDS EN ISO 2592 [66] |

| ASTM D 92 [67] | |||||

| 7 | Flash point in closed cup | C | 60 | - | BDS EN ISO 2719 [40] |

| ASTM D 93 (B) [41] | |||||

| 8 | Pour point | C | - | 30 | BDS EN ISO 3016 [47] |

| ASTM D 97 [55] | |||||

| 9 | Specific combustion heat | MJ/kg | 39.8 | - | ASTM D 4809 [53] |

| (lower) | BDS ISO 8217 [57] | ||||

| 10 | Ash content | % (m/m) | - | 0.10 | BDS EN ISO 6245 [49] |

| ASTM D 482 [68] | |||||

| 11 | Water soluble acids and alkaly | none | none | BDS 5252-84 [69] | |

| 12 | Vanadium | ppm | - | 300 | ASTM D 5863 (A) [70] |

| IP 470, IP 501 [50,51] | |||||

| 13 | Polypropylene | free | free | BP/V.4/09-99 | |

| 14 | Conradson Carbon residue | % (m/m) | - | 18 | ASTM D 189 [71] |

| ASTM D 4530 [72] | |||||

| 15 | Asphaltenes | % (m/m) | to be | repor | ASTM D 6560 [60] |

| ted | IP 143 [61] |

| Properties | AR | SRVGO | SRVR | HTVGO | FCC LCO | FCC HCO | FCC SLO | H-Oil HAGO | H-Oil VGO | H-Oil VTB |

|---|---|---|---|---|---|---|---|---|---|---|

| Density at 15 C, g/cm | 0.9408 | 0.9200 | 1.0024 | 0.9030 | 0.9412 | 1.0336 | 1.1146 | 0.9504 | 0.9707 | 1.025 |

| HTSD (ASTM D-7169) | ||||||||||

| IBP | 310 | 321 | 433 | 348 | 138 | 196 | 196 | 313 | 320 | 432 |

| 5 | 371 | 361 | 496 | 365 | 177 | 251 | 321 | 342 | 347 | 494 |

| 10 | 398 | 378 | 520 | 377 | 195 | 267 | 341 | 355 | 361 | 522 |

| 20 | 434 | 402 | 551 | 387 | 207 | 281 | 366 | 364 | 371 | 573 |

| 30 | 466 | 420 | 575 | 396 | 220 | 296 | 383 | 372 | 380 | 591 |

| 40 | 498 | 435 | 596 | 403 | 230 | 306 | 399 | 379 | 389 | 591 |

| 50 | 531 | 451 | 617 | 411 | 232 | 321 | 413 | 386 | 397 | 609 |

| 60 | 567 | 466 | 638 | 418 | 247 | 332 | 428 | 393 | 404 | 629 |

| 70 | 604 | 483 | 657 | 426 | 253 | 344 | 444 | 398 | 411 | 651 |

| 80 | 642 | 501 | 681 | 433 | 258 | 358 | 463 | 404 | 419 | 679 |

| 90 | 684 | 525 | 708 | 439 | 272 | 379 | 487 | 410 | 428 | 712 |

| 95 | 705 | 544 | 722 | 445 | 282 | 397 | 506 | 417 | 435 | |

| FBP | 453 | 319 | 446 | 539 | 424 | 442 | ||||

| Sulfur, wt.% | 2.34 | 1.78 | 2.84 | 0.20 | 0.20 | 0.80 | 0.95 | 0.753 | 0.85 | 1.12 |

| Viscosity at 80 C, | 72.0 | 14.8 | 3000 | 12.6 | 1.35 | 2.91 | 56.7 | 12.9 | 16.7 | 2172 |

| mm/s | ||||||||||

| Softening point, C | 40.0 | 36.0 | ||||||||

| Saturates, wt.% | 50.0 | 55.3 | 25.6 | 60.3 | 19.9 | 18.2 | 15.1 | 48.8 | 40.6 | 26.0 |

| Aromatics, wt.% | 36.8 | 42.8 | 52.5 | 39.3 | 80.1 | 76.4 | 53.8 | 49.0 | 56.9 | 50.9 |

| Resins, wt.% | 6.5 | 1.9 | 7.8 | 0.4 | 0 | 5.4 | 27.6 | 2.2 | 2.5 | 7.0 |

| Asphaltenes, wt.% | 6.7 | 0 | 14.1 | 0 | 0 | 0 | 3.5 | 0 | 0 | 16.1 |

| No | Properties | Unit | Min | Max | Test Method |

|---|---|---|---|---|---|

| Value | Value | ||||

| 1 | Penetration at 25 C | 0.1mm | 50 | 70 | BDS EN 1426 [37] |

| 2 | Softening point | C | 46.0 | 54.0 | BDS EN 1427 [74] |

| 3 | Fraass breaking point | C | - | minus 8 | BDS EN 12593 [75] |

| 4 | Flash point | C | 230 | - | BDS EN ISO 2592 [76] |

| 5 | Resistance to hardening, C | EN 12607-1 [66] | |||

| at 163 | |||||

| • change in mass (absolute value) | % (m/m) | - | 0.5 | ||

| • retained penetration | % (m/m) | 50 | - | BDS EN 1426 [77] | |

| • increase in softening point | C | - | 9 | BDS EN 1427 [78] | |

| 6 | Solubility | % (m/m) | 99.0 | - | BDS EN 12592 [79] |

| 7 | Paraffin wax content | % (m/m) | - | 2.2 | BDS EN 12606-1 [54] |

| No | Properties | Unit | Min | Max | Test Method |

|---|---|---|---|---|---|

| Value | Value | ||||

| 1 | Penetration at 25 C | 0.1mm | 70 | 100 | BDS EN 1426 [37] |

| 2 | Softening point | C | 43.0 | 51.0 | BDS EN 1427 [74] |

| 3 | Fraass breaking point | C | - | minus 10 | BDS EN 12593 [75] |

| 4 | Flash point | C | 230 | - | BDS EN ISO 2592 [76] |

| 5 | Resistance to hardening, C | EN 12607-1 [66] | |||

| at 163 | |||||

| • change in mass (absolute value) | % (m/m) | - | 0.8 | ||

| • retained penetration | % (m/m) | 46 | - | BDS EN 1426 [77] | |

| • increase in softening point | C | - | 9 | BDS EN 1427 [78] | |

| 6 | Solubility | % (m/m) | 99.0 | - | BDS EN 12592 [79] |

| 7 | Paraffin wax content | % (m/m) | - | 2,2 | BDS EN 12606-17 [54] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stratiev, D.; Dimitriev, A.; Stratiev, D.; Atanassov, K. Generalized Net Model of Heavy Oil Products’ Manufacturing in Petroleum Refinery. Mathematics 2023, 11, 4753. https://doi.org/10.3390/math11234753

Stratiev D, Dimitriev A, Stratiev D, Atanassov K. Generalized Net Model of Heavy Oil Products’ Manufacturing in Petroleum Refinery. Mathematics. 2023; 11(23):4753. https://doi.org/10.3390/math11234753

Chicago/Turabian StyleStratiev, Danail, Angel Dimitriev, Dicho Stratiev, and Krassimir Atanassov. 2023. "Generalized Net Model of Heavy Oil Products’ Manufacturing in Petroleum Refinery" Mathematics 11, no. 23: 4753. https://doi.org/10.3390/math11234753

APA StyleStratiev, D., Dimitriev, A., Stratiev, D., & Atanassov, K. (2023). Generalized Net Model of Heavy Oil Products’ Manufacturing in Petroleum Refinery. Mathematics, 11(23), 4753. https://doi.org/10.3390/math11234753