Abstract

The parallel processes involved in the production of refinery fuel gas, liquid petroleum gas (LPG), propylene, and polypropylene, occurring in thirteen refinery units, are modeled by the use of a Generalized Net (GN) apparatus. The modeling of the production of these products is important because they affect the energy balance of petroleum refinery and the associated emissions of greenhouse gases. For the first time, such a model is proposed and it is a continuation of the investigations of refinery process modelling by GNs. The model contains 17 transitions, 55 places, and 47 types of tokens, and considers the orders of fuel gas for the refinery power station, refinery process furnaces, LPG, liquid propylene, and 6 grades of polypropylene. This model is intended to be used as a more detailed lower-level GN model in a higher-level GN model that facilitates and optimizes the process of decision making in the petroleum refining industry.

MSC:

68Q85

1. Introduction

Modeling the processes of refined products production in a petroleum refinery is a useful tool in production planning that allows for improvement in performance and refinery profitability.

In the literature, partial models of the diverse processes taking place in the chemical industry and in petroleum refining are made. For example, reference [] deals with risk assessment in the chemical industry; reference [] investigates the integration of engineering models with planning models; reference [] focuses on the refinery-wide planning operations under uncertainties in product demand and price; reference [] studies a nonlinear, multiperiod, industrial refinery problem extended to a two-stage stochastic problem, formulated as a mixed-integer nonlinear program; reference [] employs a product tri-section crude distillation unit model to build an accurate refinery model and determines the optimal crude selection using two-stage stochastic programming; reference [] formulates a large-scale nonconvex mixed-integer nonlinear programming model and applies robust optimization for the multi-period operational planning of a real-world integrated refinery-petrochemical site in China under uncertain product demands and crude oil price; reference [] deals with a refinery planning model that utilizes simplified empirical nonlinear process models with considerations for crude characteristics, product yields, and qualities, etc.; reference [] makes an assessment of refinery efficiency using linear programming; references [,,,,,] present studies related to planning and scheduling; and reference [] investigates the efficiency of the process of crude oil dewatering and desalting. Fuzzy modeling was another modeling technique employed in petroleum refining and renewable energy systems for the selection of the optimum working situations that produce a preferable efficiency with a very good veracity [,,,,,,,,,,,,,].

The approach to the modeling of the processes of manufacturing of petroleum refining products by the use of generalized nets (GN) is original and all publications to date are the work of the authors. To the extent that the GN is a process description tool with at least as much power as the Turing machine, it can describe processes in more detail than Petri nets, which are discussed, for example, in the works of Wu et al. [,,,,,] and Zhang et al. [], as well as many other tools for modeling real-world processes, e.g., linear programming [,], transportation problems [,,], neural networks [,,], etc. For each of these, it is shown that their functions and results of their work are representable by a GN [,,].

In linear programming, the algorithm is carried out step by step because it is sequential [,,,,], whereas in all types of Petri nets, the processes run in parallel as in the real world. Section 2.2 of this article states that the GN includes, as a special case, the other types of Petri nets because of the presence of token characteristics and transition condition predicates. The entire analytics of any means of describing a real-world process (e.g., linear programming) can be described by the token characteristics in the GN model (see []), while the logic of the modeled process is represented by the predicates of the GN.

In our earlier studies [,] we demonstrated that the processes of automotive gasoline [] and diesel fuel production [] in a petroleum refinery can be modeled using generalized nets (GNs). The literature review indicates that there is a lack of models of all the processes taking place in a petroleum refinery that are related to the production of refined products and prepared with some mathematical instrumentation. Our aim is to prepare, in a series of papers, the description of the refining processes leading to the production of specific products using the GNs. The apparatus of GNs provides the capability of easier uniting of diverse GNs models. The GNs models already produced by us [,] can be transformed into the subnets of a general GN model. In the future, this will be realized using a software product developed in the Institute of Biophysics and Biomedical Engineering, Bulgarian Academy of Sciences.

The use of GNs, appearing first as extensions of Petri nets [] and their other extensions and modifications, was found to be a convenient methodology to model the complex parallel-sequential processes taking place in petroleum refinery during the production of finished refined products. They also allow the modeling of the production processes of different refined oil products using distinct GNs which can be further combined using a hierarchical approach. In order to obtain a complete refined oil products production modelling, all the processes involved in the production of all of the products are required. In this article, we focus on the modeling of the production of fuel gas, liquefied petroleum gas (LPG), propylene, and polypropylene, which are part of the production chain of hydrocarbon gas refinery, as a complement to the process modeling of automotive gasoline and diesel fuels production in petroleum refinery using generalized nets. The aim of this research is to investigate the process of production of hydrocarbon gas products: fuel gas, LPG, and propylene, produced from propylene polypropylene in a petroleum refinery, and model it using GNs.

2. Materials and Methods

2.1. Processing Scheme for Production of Fuel Gas, LPG, Propylene, and Polypropylene in a Petroleum Refinery

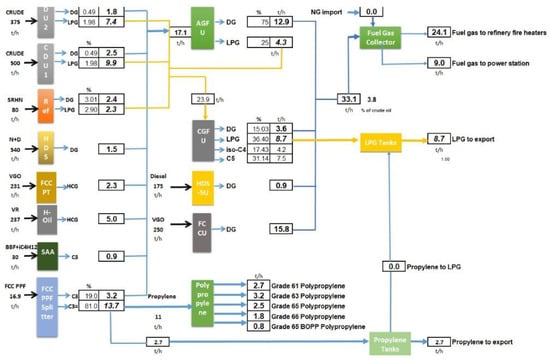

The processing technological chain employed in the LUKOIL Neftohim Burgas (LNB) refinery in order to produce the components and finished products of fuel gas, LPG, propylene, and polypropylene, the subject of this study, is presented in Figure 1.

Figure 1.

Processing scheme of fuel gas, LPG, propylene, and polypropylene production in a petroleum refinery. Note: CDU = Crude distillation unit; Ref = straight run heavy naphtha (SRHN) reformer; HDS = hydrodesulphurization units processing naphtha and diesel streams of primary origin (crude distillation units) and secondary origin (fluid catalytic cracking (FCC), FCC feed hydrotreater (FCCPT), and H-Oil ebullated bed vacuum residue hydrocracking); AGFU = Absorption gas fractionation unit; CGFU = Central gas fractionation unit; HDS-5 = primary and secondary diesel hydrotreating unit 5; SAA = Sulphuric acid alkylation; FCC PPF Splitter = fluid catalytic cracking propane-propylene fraction splitter; Polypropylene = Polypropylene production unit by polymerization of propylene.

Thirteen refinery process units are involved in the production process of fuel gas, LPG, propylene, and polypropylene. The amount of these vapour phase and liquid phase hydrocarbon gaseous products extracted from the crude oil in the process of atmospheric distillation and generated in the process units—the reformer, hydrotreating units, FCC, and H-Oil—as a result of chemical reactions, depends on the crude oil origin and on the operating conditions in the mentioned refinery units. For the case shown in Figure 1, the fuel gas production amounts to 3.8% of the crude oil quantity and more than half of this comes from the fluid catalytic cracking (51.8%). Another important contributor to fuel gas production is H-Oil ebullated bed vacuum residue hydrocracking. Thus, the production of fuel gas is strongly dependent on the severity of the operation conditions applied in both of the heavy oil conversion processes, FCC and H-Oil. The main contributor to LPG production, as evident from the data in Figure 1, is crude oil distillation. It provides 75% of the feed for the central Gas Fractionation Unit (CGFU), where the extraction of the propane and n-butane is carried out; their mixing forms the refined product, LPG. As apparent from the data in Figure 1, LPG production is about four times as low as that of the production of fuel gas. The data in Figure 1 indicates that, in the case that the amount of fuel gas is insufficient to meet the refinery energy needs, an option exists in importing natural gas to replenish the fuel gas availability. Depending on the market requirements, liquid propylene can be exported as a chemical grade for polymerization propylene, or as a component of the LPG product. Typically, six grades of polypropylene products are produced and exported from the polypropylene unit.

2.2. Short Remarks on Generalized Nets

GNs are an extension of the standard Petri nets [] and the rest of their extensions and modifications. GNs are defined in a way that is principally different from the ways of defining other types of Petri nets (see references [,]).

When some of the GN components are omitted, the GN is called a reduced GN. For the needs of the model below, we describe the modeled process as a reduced GN.

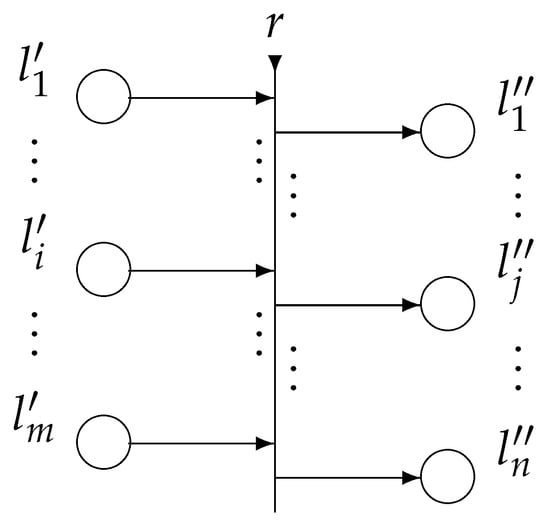

Formally, every transition (see Figure 2) is described using a seven-tuple, but for our purposes, we use its following reduced form:

where:

- and are finite, non-empty sets of places (the transition’s input and output places, respectively); for the transition in Figure 1, these are and

- r is the transition’s condition determining which tokens will pass (or transfer) from the transition’s inputs to its outputs; it has the form of an Index Matrix (IM; see []):is the predicate that corresponds to the i-th input and j-th output place . When its truth value is “true”, a token from the i-th input place transfers to the j-th output place; otherwise, this is not possible.

Figure 2.

The form of a GN transition.

The formal definition of the reduced GN used in the present research has the following form:

where:

- A is a set of transitions;

- K is the set of the GN’s tokens;

- X is the set of all initial characteristics which the tokens can obtain on entering the net;

- is the characteristic function that assigns new characteristics to every token when it makes the transfer from an input to an output place of a given transition.

Operations, relations, and operators are defined over GNs (see references [,]).

The operations defined over the GNs—“union”, “intersection”, “composition” and “iteration” (see references [,])—do not exist anywhere else in Petri net theory. These operations are useful for constructing GN models of real processes.

For example, when we have two GN models of real processes which we know flow in parallel, by operation union, defined over two GNs, we can construct a GN model of both processes.

The idea of defining operators over the set of GNs in the form suggested below dates back to 1982 (see references [,]). It is a proper extension of Valk’s idea from [] for self-modifying Petri nets, in which only the net structure can be changed.

Now, the operator aspect has an important place in the theory of GNs. Six types of operators are defined in its framework. Every operator assigns to a given GN a new GN with some desired properties.

The groups of operators comprise the following:

- Global operators (e.g., one of them changes the functions giving tokens characteristics);

- Local operators (e.g., one of then changes the transition condition predicates);

- Hierarchical operators (e.g., one of them replaces the GN with a whole new (sub)GN, another—a transition of the GN with a whole new (sub)GN, and two others do the opposite activity);

- Dynamic operators (e.g., operators that allow for the union or split of tokens)

and others.

We can mention that, for example, the colored Petri nets (see, e.g., reference []) can be represented by GNs in which the tokens have, as initial and current characteristics, the colors with which they are colored. It is important to mention that, when one token obtains a new colour, it does not “remember” its previous color. Meanwhile, interestingly, if modeled by a GN, the GN tokens can remember their own previous characteristics. For this reason, they can be interpreted as individuals with their own history.

3. Main Results: A GN Model

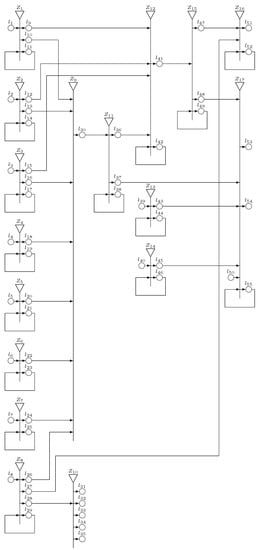

The GN (see Figure 3) contains 17 transitions, 55 places, and 47 types of tokens that correspond to the following feed, products, and processing units:

Figure 3.

A GN model.

- —crude oil processed in CDU-2, t/h

- —crude oil processed in CDU-2, t/h

- —straight run naphtha processed in the catalytic reformer, t/h

- —naphtha and diesel fractions process in hydrotreating units, t/h

- —vacuum gas oil processed in fluid catalytic cracking feed hydrotreater, t/h

- —vacuum residue processed in H-Oil hydrocracker, t/h

- —butane-bytelene fraction and isobutene processed in sulphuric acid alkylation, t/h

- —propane-propylene fraction from fluid catalytic cracking to separate in propane, and propylene, t/h

- —primary and secondary diesel to hydrotreat in HDS-5 unit, t/h

- —hydrotreated and H-Oil vacuum gas oil to process in fluid catalytic cracking, t/h

- —natural gas from importing to replenishing fuel gas in cases of high fuel gas demand, t/h.

- —crude distillation unit 2 (CDU-2)

- —crude distillation unit 1 (CDU-1)

- —catalytic reformer unit

- —naphtha and diesel hydrotreaters

- —fluid catalytic cracking feed hydrotreating unit

- —H-Oil vacuum residue hydrocracking unit

- —sulphuric acid alkylation unit

- —fluid catalytic cracking propane-propylene splitter unit (FCC PPF splitter)

- —absorption gas fractionation unit (AGFU)

- —LPG intermediary reservoir to collect feed for the central gas fractionation unit

- —HDS-5 diesel hydrotreating unit

- —fluid catalytic cracking unit (FCC)

- —central gas fractionation unit (CGFU)

- —liquid petroleum gas (LPG) tank farm

- —fuel gas tank farm

- —LPG product from CDU-2, t/h

- —LPG product from CDU-1, t/h

- —LPG product from naphtha reformer, t/h

- —LPG product from AGFU, t/h

- —CGFU feed, t/h

- —LPG product from CGFU to feed LPG tank farm,

- —fuel gas feed for AGFU, t/h

- —fuel gas product from CDU-2, t/h

- —fuel gas product from CDU-1, t/h

- —fuel gas product from naphtha reformer, t/h

- —fuel gas product from naphtha and diesel hydrotreaters, t/h

- —fuel gas product from FCC feed hydrotreater, t/h

- —fuel gas product from H-Oil vacuum residue hydrocrcker, t/h

- —propane fraction from sulphuric acid alkylation unit, t/h

- —dry fuel gas product from AGFU, t/h

- —dry fuel gas product from CGFU, t/h

- —dry fuel gas product from HDS-5 unit, t/h

- —dry fuel gas product from FCCU, t/h

- —propane product from FCC PPF splitter, t/h

- —propylene product from FCC PPF splitter to feed polypropylene unit, t/h

- —propylene product from FCC PPF splitter, t/h

- —high melting index grade 61 polypropylene product, t/h

- —high melting index grade 63 polypropylene product, t/h

- —high melting index grade 65 polypropylene product, t/h

- —high melting index grade 66 polypropylene product, t/h

- —high melting index grade 65 BOPP polypropylene product, t/h

- —LPG product for export, t/h

- —fuel gas product to feed the refinery power station, t/h

- —fuel gas product to feed the refinery process furnaces, t/h

- “there is a request for LPG product from CDU-2”

- “there is a request for fuel gas product from CDU-2”.

Token enters place and unites with token to obtain a characteristic:

In the next time-step, token splits into three tokens—the same token that continues to stay in place , , and .

The token obtains a characteristic:

in place , token obtains a characteristic:

in place , token obtains a characteristic:

where

- “there is a request for LPG product from CDU-1”;

- “there is a request for fuel gas product from CDU-1”.

Token enters place and unites with token to obtain a characteristic:

In the next time-step, token splits into three tokens—the same token that continues to stay in place , , and .

The token obtains a characteristic:

in place , token obtains a characteristic:

in place , token obtains a characteristic:

where

- “there is a request for LPG product from naphtha catalytic reformer”;

- “there is a request for fuel gas product from naphtha catalytic reformer”.

Token enters place and unites with token to obtain a characteristic:

In the next time-step, token splits into three tokens—the same token that continues to stay in place , , and .

The token obtains a characteristic:

in place , token obtains a characteristic:

in place , token obtains a characteristic:

where

- “there is a request for fuel gas product from naphtha and diesel hydrotreaters”.

Token enters place and unites with token to obtain a characteristic:

In the next time-step, token splits into two tokens—the same token that continues to stay in place and .

The token obtains a characteristic:

in place , token obtains a characteristic:

where

- “there is a request for fuel gas product from FCC feed hydrotreater”.

Token enters place and unites with token to obtain a characteristic:

In the next time-step, token splits into two tokens—the same token that continues to stay in place and .

The token obtains a characteristic:

in place , token obtains a characteristic:

where

- “there is a request for fuel gas product from H-Oil unit”.

Token enters place and unites with token to obtain a characteristic:

In the next time-step, token splits into two tokens—the same token that continues to stay in place and .

The token obtains a characteristic:

in place , token obtains a characteristic:

where

- “there is a request for propane fraction product from sulphuric acid alkylation unit”.

Token enters place and unites with token to obtain a characteristic:

In the next time-step, token splits into two tokens—the same token that continues to stay in place and .

The token obtains a characteristic:

in place , token obtains a characteristic:

where

- “there is a request for propane product from FCC PPF splitter for LPG production”;

- “there is a request for propylene for polymerization from FCC PPF splitter”;

- “there is a request for propylene product from FCC PPF splitter for export”.

Token enters place and unites with token to obtain a characteristic:

In the next time-step, token splits into four tokens—the same token that continues to stay in place and tokens .

The tokens obtain characteristics:

in place ,

in place ,

in place , respectively. Token obtains a characteristic:

All -tokens unite in place , with one token with a characteristic:

where

- “there is a request for high melting index grade 61 polypropylene product from polypropylene unit”;

- “there is a request for high melting index grade 63 polypropylene product from polypropylene unit”;

- “there is a request for high melting index grade 65 polypropylene product from polypropylene unit”;

- “there is a request for high melting index grade 66 polypropylene product from polypropylene unit”;

- “there is a request for high melting index grade 66 BOPP polypropylene product from polypropylene unit”.

Token splits into five tokens that obtain characteristics:

in place ,

in place ,

in place ,

in place ,

in place , respectively.

where

- “there is a request for LPG product from AGFU”;

- “there is a request for fuel gas product from AGFU”.

Token enters place and unites with token to obtain a characteristic:

In the next time-step, token splits into three tokens—the same token that continues to stay in place and tokens and .

The token obtains a characteristic:

in place , token obtains a characteristic:

in place .

All -tokens () unite in place with token and obtain the characteristic:

In the next time-step, the token splits into two tokens—the same token that continues to stay in place and token that enters place with a characteristic:

where

- “there is a request for fuel gas product from HDS-5 unit”.

Token enters place and unites with token to obtains a characteristic:

In the next time-step, the token splits into two tokens—the same token that continues to stay in place with a characteristic:

and token that enters place with a characteristic:

where

- “there is a request for fuel gas product from FCCU”.

Token enters place and unites with token to obtain a characteristic:

In the next time-step, the token splits into two tokens—the same token that continues to stay in place with a characteristic:

and token that enters place with a characteristic

where

- “there is a request for LPG product from CGFU”;

- “there is a request for fuel gas product from CGFU”.

Token enters place and unites with token to obtain a characteristic:

In the next time-step, token splits into three tokens—the same token that continues to stay in place and tokens and .

The token obtains a characteristic:

in place , token obtains a characteristic:

in place .

Tokens and enter place and unite with token to obtain a characteristic:

In the next time-step, the token splits into two tokens—the same token and token that enters place with a characteristic:

where

- “there is a request for fuel gas product for the refinery power station”;

- “there is a request for fuel gas product for the refinery process furnaces”.

Tokens enter place and unite with token to obtain a characteristic:

The token splits into three tokens—the same token that continues to stay in place and tokens and .

The token obtains a characteristic:

in place , token obtains a characteristic:

in place

4. Discussion

The production of fuel gas, LPG, propylene, and polypropylene in a refinery is a complex parallel process involving many process units, which may deliver a variable amount of these oil refining products depending on the crude slate processed, the activity and selectivity of the catalyst employed, and the operating conditions in the process units. This complex process was found to be capable of modeling using generalized nets. The developed GN model can be used for the synchronization and optimization of these processes with the aim of finding and implementing the economically optimal mode of refinery operation. This is achieved by the presence of time parameters in GN and by the presence of token characteristics, which enable the collection of the whole information of the refinery processes; decisions about process optimization and, if necessary, process reorganization, should be made on this basis. For example, if a process unit is unexpectedly shut down due to an emergency, this would include how to organize the process performance in such a case. However, this will be discussed in our next article. Moreover, this model could enable the assessment of the efficiency of adding new process units into the refinery processing scheme before their construction. This paper is a continuation of a series of papers by the authors in which GN models of the production of automotive gasoline [] and diesel [] in a refinery are described. Modeling the processes of heavy oil products in a refinery using GN is the next study already submitted for publication. Then, a higher-level GN model could be created that encompasses the more detailed, already developed lower-level GN models. Based on the higher-level GN model that encompasses the more detailed lower-level GN models, the decision making process in petroleum refinery can be facilitated and optimized. The program realization of the higher-level GN model will be available on the internet and, as such, its vulnerability to stealthy attacks should be considered, as described in references [,].

5. Conclusions

The process of producing gaseous products in a petroleum refinery, such as fuel gas, propane-butane, and propylene, which can be exported as a final finished product or used as a raw material for polypropylene production, is a complex parallel process that is difficult to model using linear and even dynamic programming. The difficulty comes from the inability to reflect the logic of the cause and effect relationships therein which, as stated above, are easily interpreted by transition condition predicates. A visual means of representing the real processes are UML diagrams which, in reference [], are shown to be representable by GN. This paper presents a GN model for the production of fuel gas, LPG, propylene, and polypropylene in a petroleum refinery, and a separate paper will discuss the software implemented with GN and the results of the present model.

Author Contributions

Conceptualization, D.D.S.; methodology, K.A.; software, A.D.; validation, D.D.S.; formal analysis, D.D.S. and A.D.; investigation, D.S., D.D.S. (Danail Stratiev), K.A. and A.D.; resources, D.D.S.; data curation, D.S.; writing—original draft preparation, D.S., K.A.; writing—review and editing, D.D.S. and K.A.; visualization, D.D.S., A.D.; supervision, K.A.; project administration, K.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Asen Zlatarov University—Burgas, Project: Center of Excellence UNITE BG05M2OP001-1.001-0004/28.02.2018 (2018–2023).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhoua, J.; Reniers, G.; Zhang, L. A weighted fuzzy Petri-net based approach for security risk assessment in the chemical industry. Chem. Eng. Sci. 2017, 174, 136–145. [Google Scholar] [CrossRef]

- Predictive Analytics and Dynamic Optimization: The Sweet Spot in Refinery Planning, White Paper. 2018. Infosys Limited. Available online: https://www.infosys.com/industries/oil-and-gas/insights/documents/sweet-spot-refinery-planning.pdf (accessed on 14 December 2022).

- Zhang, L.; Yuan, Z.; Chen, B. Refinery-wide planning operations under uncertainty via robust optimization approach coupled with global optimization. Comput. Chem. Eng. 2021, 146, 107205. [Google Scholar] [CrossRef]

- Boucheikhchoukh, A.A.; Swartz, C.L.E.; Bouveresse, E.; Lutran, P.; Robert, A. Optimization of a multiperiod refinery planning problem under uncertainty. AIChE J. 2022, 68, e17799. [Google Scholar] [CrossRef]

- Qian, F.; Du, W.; Yang, M.; Long, J.; Mahalec, V. Refinery production planning optimization under crude oil quality uncertainty. Comput. Chem. Eng. 2021, 151, 107361. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, Z.; Chen, B. Adjustable Robust Optimization for the Multi-period Planning Operations of an Integrated Refinery-Petrochemical Site under Uncertainty. Comput. Chem. Eng. 2022, 160, 107703. [Google Scholar] [CrossRef]

- Li, W.; Hui, C.W.; Li, A.X. Integrating CDU, FCC and product blending models into refinery planning. Comput. Chem. Eng. 2005, 29, 2010–2028. [Google Scholar] [CrossRef]

- Forman, G.S.; Divita, V.B.; Han, J.; Cai, H.; Elgowainy, A.; Wang, M.U.S. Refinery Efficiency: Impacts Analysis and Implications for Fuel Carbon Policy Implementation. Environ. Sci. Technol. 2014, 48, 7625–7633. [Google Scholar] [CrossRef]

- Yu Yang, Y.; Barton, P.I. Refinery Optimization Integrated with a Nonlinear Crude Distillation Unit Model. IFAC-Pap. Line 2015, 48-8, 205–210. [Google Scholar] [CrossRef]

- Moro, L.F.L.; Zanin, A.C.; Pinto, J.M. A Planning Model for Refinery Diesel Production. Comput. Chem. Eng. 1998, 22, 1039–1042. [Google Scholar] [CrossRef]

- Pinto, J.M.; Joly, M.; Moro, L.F.L. Planning and scheduling models for refinery operations. Comput. Chem. Eng. 2000, 24, 2259–2276. [Google Scholar] [CrossRef]

- Cafaro, V.G.; Pautasso, P.C.; Cerdá, J.; Cafaro, D.C. Efficient planning of crude oil supplies through long-distance pipelines. Comput. Chem. Eng. 2019, 122, 203–217. [Google Scholar] [CrossRef]

- Guerra, O.J.; Le Roux, G.A.C. Improvements in Petroleum Refinery Planning: 1. Formulation of Process Models. Ind. Eng. Chem Res. 2011, 50, 13403–13418. [Google Scholar] [CrossRef]

- Yang, H.; Bernal, D.E.; Franzoi, R.E.; Engineer, F.G.; Kwon, K.; Lee, S.; Grossmann, I.E. Integration of crude-oil scheduling and refinery planning by Lagrangean Decomposition. Comput. Chem. Eng. 2020, 138, 106812. [Google Scholar] [CrossRef]

- Ahmadi, S.; Khormali, A.; Khoutoriansky, F.M. Optimization of the demulsification of water-in-heavy crude oil emulsions using response surface methodology. Fuel 2022, 323, 124270. [Google Scholar] [CrossRef]

- Zhumadillayeva, A.; Orazbayev, B.; Santeyeva, S.; Dyussekeyev, K.; Li, R.Y.M.; Crabbe, M.J.C.; Yue, X.-G. Models for Oil Refinery Waste Management Using Determined and Fuzzy Conditions. Information 2020, 11, 299. [Google Scholar] [CrossRef]

- Abdellatief, T.M.M.; Ershov, M.A.; Kapustin, V.M.; Chernysheva, E.A.; Savelenko, V.D.; Salameh, T.; Abdelkareem, M.A.; Olabi, A.G. Novel promising octane hyperboosting using isoolefinic gasoline additives and its application on fuzzy modeling. Int. J. Hydrogen Energy 2022, 47, 4932–4942. [Google Scholar] [CrossRef]

- Nassef, A.M.; Rezk, H.; Abdelkareem, M.A.; Alaswad, A.; Olabi, A. Application of fuzzy modelling and Particle Swarm Optimization to enhance lipid extraction from microalgae. Sustain. Energy Technol. Assess. 2019, 35, 73e9. [Google Scholar] [CrossRef]

- Nassef, A.M.; Sayed, E.T.; Rezk, H.; Abdelkareem, M.A.; Rodriguez, C.; Olabi, A.G. Fuzzy-modeling with particle swarm optimization for enhancing the production of biodiesel from microalga. Energy Sources Part Recover. Util. Environ. Eff. 2019, 41, 2094–2103. [Google Scholar] [CrossRef]

- Pla, B.; Bares, P.; Jimenez, I.; Guardiola, C.; Zhang, Y.; Shen, T. A fuzzy logic map-based knock control for spark ignition engines. Appl. Energy 2020, 280, 116036. [Google Scholar] [CrossRef]

- Orazbayev, B.; Kozhakhmetova, D.; Wojtowicz, R.; Krawczyk, J. Modeling of a catalytic cracking in the gasoline production installation with a fuzzy environment. Energies 2020, 13, 4736. [Google Scholar] [CrossRef]

- Abdellatief, T.M.M.; Ershov, M.A.; Kapustin, V.M.; Chernysheva, E.A.; Savelenko, V.D.; Salameh, T.; Abdelkareem, M.A.; Olabi, A.G. Uniqueness technique for introducing high octane environmental gasoline using renewable oxygenates and its formulation on Fuzzy modeling. Sci. Total Environ. 2022, 802, 149863. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.-N.; Nhieu, N.-L.; Tran, K.-P.; Wang, Y.-H. Sustainable Integrated Fuzzy Optimization for Multimodal Petroleum Supply Chain Design with Pipeline System: The Case Study of Vietnam. Axioms 2022, 11, 60. [Google Scholar] [CrossRef]

- Alakbari, F.S.; Mohyaldinn, M.E.; Ayoub, M.A.; Muhsan, A.S.; Hussein, I.A. A robust fuzzy logic-based model for predicting the critical total drawdown in sand production in oil and gas wells. PLoS ONE 2021, 26, e0250466. [Google Scholar] [CrossRef] [PubMed]

- Jlibawi, A.H.H.A.; Othman, M.L.; Noor, B.S.; Sajitt, A.H.M.S. Optimization of Distribution Control System in Oil Refinery by Applying Hybrid Machine Learning Techniques. IEEE Access 2022, 10, 3890–3903. [Google Scholar] [CrossRef]

- Okwu, M.O.; Nwachukwu, A.N. A review of fuzzy logic applications in petroleum exploration, production and distribution operations. Pet. Explor. Prod. Technol. 2019, 9, 1555–1568. [Google Scholar] [CrossRef]

- Suganthi, L.; Iniyan, S.; Samuel, A.A. Applications of fuzzy logic in renewable energy systems—A review. Renew. Sustain. Energy Rev. 2015, 48, 585–607. [Google Scholar] [CrossRef]

- Evazabadian, F.; Arvan, M.; Ghodsi, R. Short-term crude oil scheduling with preventive maintenance operations: A fuzzy stochastic programming approach. Int. Trans. Oper. Res. 2017, 26, 2450–2475. [Google Scholar] [CrossRef]

- Tavana, M.; Khalili-Damghani, K.; Arteaga, F.J.S.; Hosseini, A. A fuzzy multi-objective multi-period network DEA model for efficiency measurement in oil refineries. CAIE 2019, 135, 143–155. [Google Scholar] [CrossRef]

- Wu, N.Q.; Zhou, M.; Chu, F. A Petri net-based heuristic algorithm for realizability of target refining schedule for oil refinery. IEEE Trans. Autom. Sci. Eng. 2008, 5, 661–676. [Google Scholar] [CrossRef]

- Wu, N.Q.; Chu, F.; Chu, C.; Zhou, M. Short-term schedulability analysis of crude oil operations in refinery with oil residency time constraint using Petri nets. IEEE Trans. Syst. Man Cybern. Part C 2008, 38, 765–778. [Google Scholar] [CrossRef]

- Wu, N.Q.; Chu, F.; Chu, C.; Zhou, M. Short-term schedulability analysis of multiple distiller crude oil operations in refinery with oil residency time constraint. IEEE Trans. Syst. Man Cybern. Part C 2009, 39, 1–16. [Google Scholar]

- Wu, N.Q.; Chu, F.; Chu, C.; Zhou, M. Hybrid Petri net modeling and schedulability analysis of high fusion point oil transportation under tank grouping strategy for crude oil operations in refinery. IEEE Trans. Syst. Man Cybern. Part C 2010, 40, 159–175. [Google Scholar] [CrossRef]

- Wu, N.Q.; Chu, F.; Chu, C.; Zhou, M. Schedulability analysis of short-term scheduling for crude oil operations in refinery with oil residency time and charging-tank-switch-overlap constraints. IEEE Trans. Autom. Sci. Eng. 2011, 8, 190–204. [Google Scholar] [CrossRef]

- Wu, N.Q.; Zhou, M.; Bai, L.P.; Li, Z.W. Short-term scheduling of crude oil operations in refinery with high fusion point oil and two transportation pipelines. Enterp. Inf. Syst. 2016, 10, 581–610. [Google Scholar] [CrossRef]

- Zhang, S.W.; Li, Z.W.; Qu, T.; Li, C.D. Petri net-based approach to short-term scheduling of crude oil operations with less tank requirement. Inf. Sci. 2017, 417, 247–261. [Google Scholar] [CrossRef]

- Drouven, M.G.; Cafaro, D.C.; Grossmann, I.E. Mathematical Programming Models for Shale Oil & Gas Development: A Review and Perspective. Comput. Chem. Eng. 2023, 177, 108317. [Google Scholar] [CrossRef]

- Wu, Y.; Cui, Z.Y.; Lin, H.; Wang, Y.F.; Feng, X. An optimization method for shale gas gathering system—Consideration of reliability enhancement under earthquake-related uncertainties. Pet. Sci. 2022, 19, 2431–2447. [Google Scholar] [CrossRef]

- Rani, D. Solving non-linear fixed-charge transportation problems using nature inspired non-linear particle swarm optimization algorithm. Appl. Soft Comput. 2023, 2, 110699. [Google Scholar] [CrossRef]

- Flamand, T.; Iori, M.; Haouari, M. The transportation problem with packing constraints. Comput. Oper. Res. 2023, 157, 106278. [Google Scholar] [CrossRef]

- Bera, R.K.; Mondal, S.K. A multi-objective transportation problem under quantity dependent credit period and cost structure policies in triangular intuitionistic fuzzy environment. Eng. Appl. Artif. Intell. 2023, 123, 106396. [Google Scholar] [CrossRef]

- Oulmelk, A.; Srati, M.; Afraites, L.; Hadri, A. An artificial neural network approach to identify the parameter in a nonlinear subdiffusion model. Commun. Nonlinear Sci. Numer. Simul. 2023, 125, 107413. [Google Scholar] [CrossRef]

- Brus, G. Overcoming a recent impasse in the application of artificial neural networks as solid oxide fuel cells simulator with computational topology. Energy AI 2023, 14, 100291. [Google Scholar] [CrossRef]

- Maier, H.R.; Galelli, S.; Razavi, S.; Castelletti, A.; Rizzoli, A.; Athanasiadis, I.N.; Sanchez-Marre, M.; Acutis, M.; Wu, W.; Humphrey, G.B. Exploding the myths: An introduction to artificial neural networks for prediction and forecasting. Environ. Model. Softw. 2023, 167, 105776. [Google Scholar] [CrossRef]

- Atanassov, K. Generalized Nets; World Scientific: Singapore; London, UK, 1991. [Google Scholar]

- Atanassov, K. On Generalized Nets Theory; Prof. M. Drinov Academic Publication House: Sofia, Bulgaria, 2007. [Google Scholar]

- Alexieva, J.; Choy, E.; Koycheva, E. Review and bibloigraphy on generalized nets theory and applications. In A Survey of Generalized Nets; Choy, E., Krawczak, M., Shannon, A., Szmidt, E., Eds.; Raffles KvB Monograph: Sydney, Australia, 2007; pp. 207–301. [Google Scholar]

- He, W.; Zhao, J.; Zhao, L.; Li, Z.; Yang, M.; Liu, T. Data-driven two-stage distributionally robust optimization for refinery planning under uncertainty. Chem. Eng. Sci. 2023, 269, 118466. [Google Scholar] [CrossRef]

- Jiao, Y.; Qiu, R.; Liang, Y.; Liao, Q.; Tua, R.; Wei, X.; Zhang, H. Integration optimization of production and transportation of refined oil: A case study from China. Chem. Eng. Res. Des. 2022, 188, 39–49. [Google Scholar] [CrossRef]

- da Silva, P.R.; Aragão, M.E.; Trierweilera, J.O.; Trierweilera, L.F. Integration of hydrogen network design to the production planning in refineries based on multi- scenarios optimization and flexibility analysis. Chem. Eng. Res. Des. 2022, 187, 434–450. [Google Scholar] [CrossRef]

- Lima, C.; Relvas, S.; Barbosa-Póvoa, A. Designing and planning the downstream oil supply chain under uncertainty using a fuzzy programming approach. Comput. Chem. Eng. 2021, 151, 107373. [Google Scholar] [CrossRef]

- Yu, L.; Wang, S.; Xu, Q. Optimal scheduling for simultaneous refinery manufacturing and multi oil-product pipeline distribution. Comput. Chem. Eng. 2022, 157, 107613. [Google Scholar] [CrossRef]

- Stratiev, D.D.; Zoteva, D.; Stratiev, D.S.; Atanassov, K. Modelling the Process of Production of Automotive Gasoline by the Use of Generalized Nets, In Uncertainty and Imprecision in Decision Making and Decision Support: New Advances, Challenges, and Perspectives; Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2022; Volume 338. [Google Scholar] [CrossRef]

- Stratiev, D.D.; Stratiev, D.; Atanassov, K. Modelling the Process of Production of Diesel Fuels by the Use of Generalized Nets. Mathematics 2021, 9, 2351. [Google Scholar] [CrossRef]

- Petri, C.-A. Kommunication mit Automaten. Ph.D. Thesis, University of Bonn, Bonn, Germany, 1962. [Google Scholar]

- Atanassov, K. Index Matrices: Towards an Augmented Matrix Calculus; Springer: Cham, Switzerland, 2014. [Google Scholar]

- Valk, R. Self-Modifying Nets; Springer: Berlin/Heidelberg, Germany, 1977. [Google Scholar]

- Jensen, K. Coloured Petri Nets. EATCS Monographs on Theoretical Computer Science; Springer: Berlin/Heidelberg, Germany, 1992; Volume 1. [Google Scholar]

- Sui, T.; Mo, Y.; Marelli, D.; Sun, X.; Fu, M. The Vulnerability of Cyber-Physical System under Stealthy Attacks. IEEE Trans. Autom. 2020, 66, 637–650. [Google Scholar] [CrossRef]

- Sui, T.; Sun, X.-M. The vulnerability of distributed state estimator under stealthy attacks. Automatica 2021, 133, 109869. [Google Scholar] [CrossRef]

- Koycheva, E. Entwurfsbegleitende Leistungsanalyse mit UML, MARTE und Generalisierten Netzen; Oldenbourg Verlag: München, Germany, 2013. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).