Gearbox Fault Diagnosis Based on Multi-Sensor Deep Spatiotemporal Feature Representation

Abstract

1. Introduction

- (1)

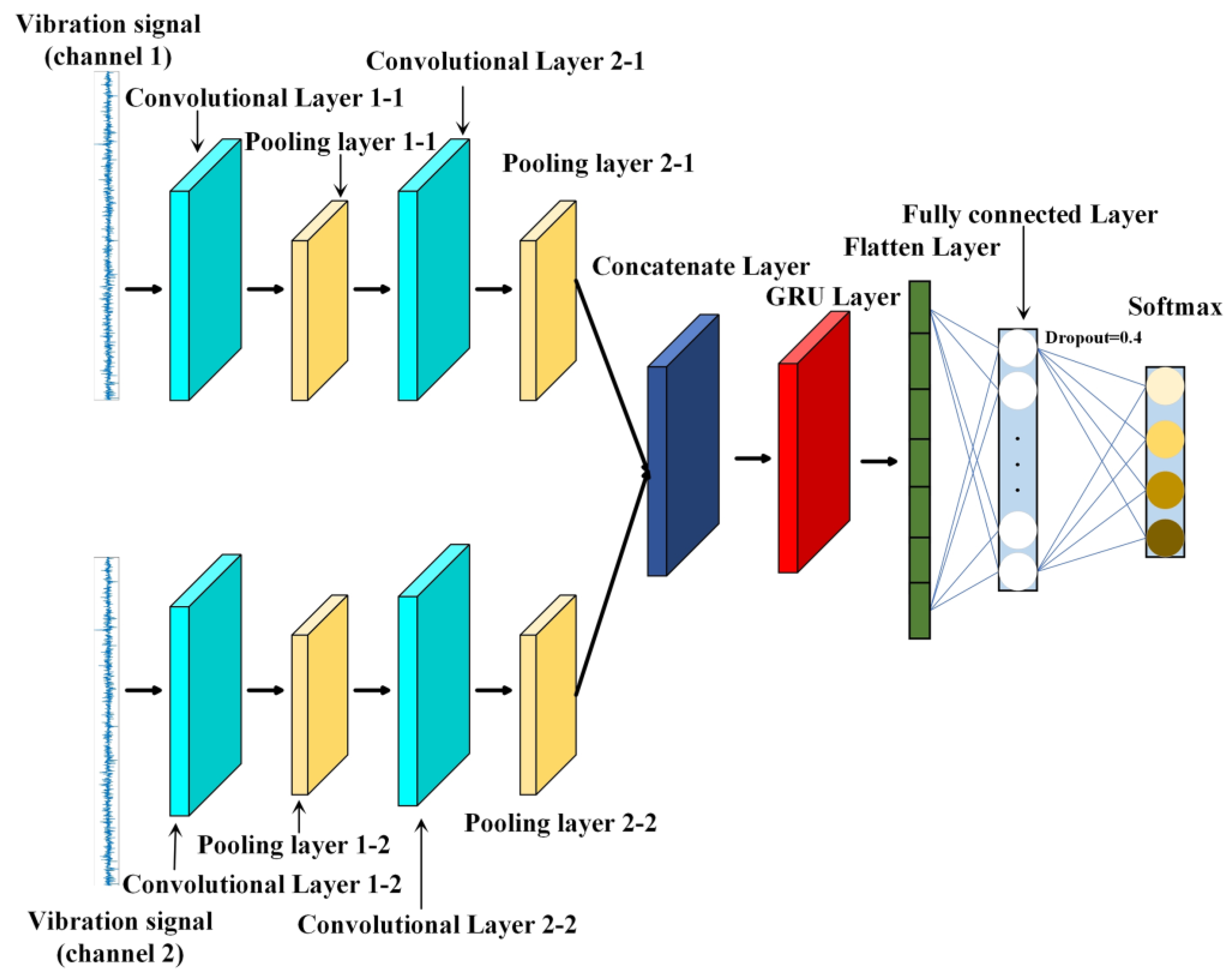

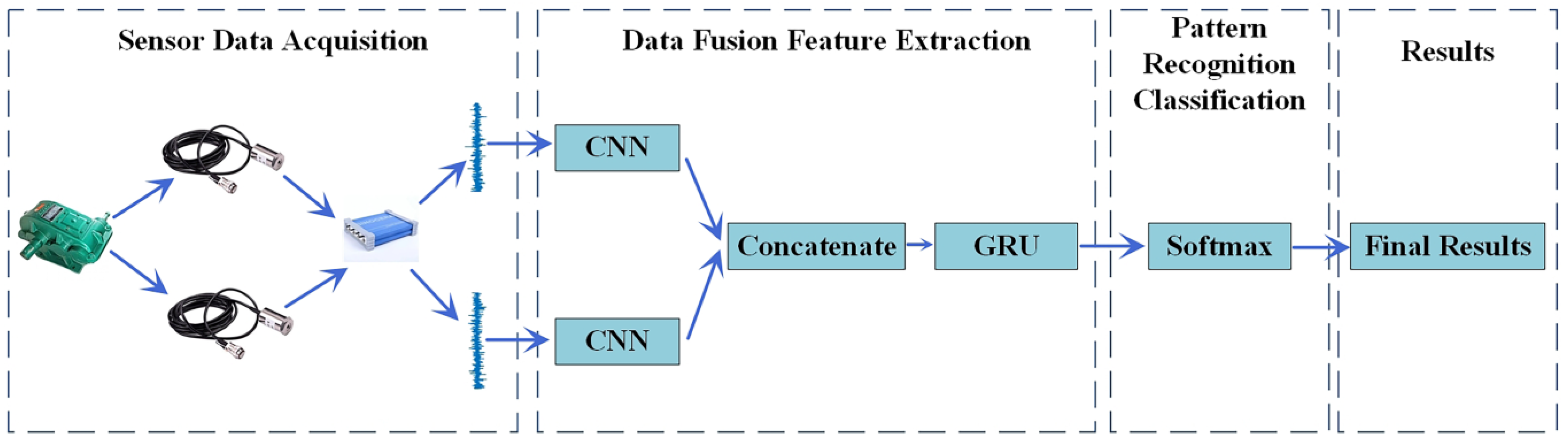

- The vibration signal obtained by a single sensor is susceptible to noise interference and cannot effectively characterize the operating state and fault characteristics of the gearbox. At the same time, it is also necessary to obtain a more effective and stable gearbox fault diagnosis model. A fault diagnosis model based on the PCNN–GRU fusion of multi-sensor information is proposed.

- (2)

- On the basis of CNN–GRU, a parallel CNN combined with the GRU fault diagnosis model is proposed to fuse the vibration signal information acquired by the multiple sensors. Additionally, SoftMax was used to identify and complete the intelligent diagnosis of gearbox “end” to “end”.

- (3)

- A fault diagnosis experiment platform was designed and built, and the validity and stability of the model proposed in this paper were verified by comparing it against other related models.

2. Principle Introduction

2.1. CNN

2.1.1. Convolutional Layer

2.1.2. Pooling Layer

2.1.3. Activation Function

2.1.4. Fully Connected Layer

2.2. GRU

2.3. Multi-Sensor Information Fusion

2.3.1. Fusion at the Data Level

2.3.2. Fusion at the Feature Level

2.3.3. Fusion at the Decision-Making Level

3. Fault Diagnosis Model Construction

4. Gearbox Fault Diagnosis Experiment

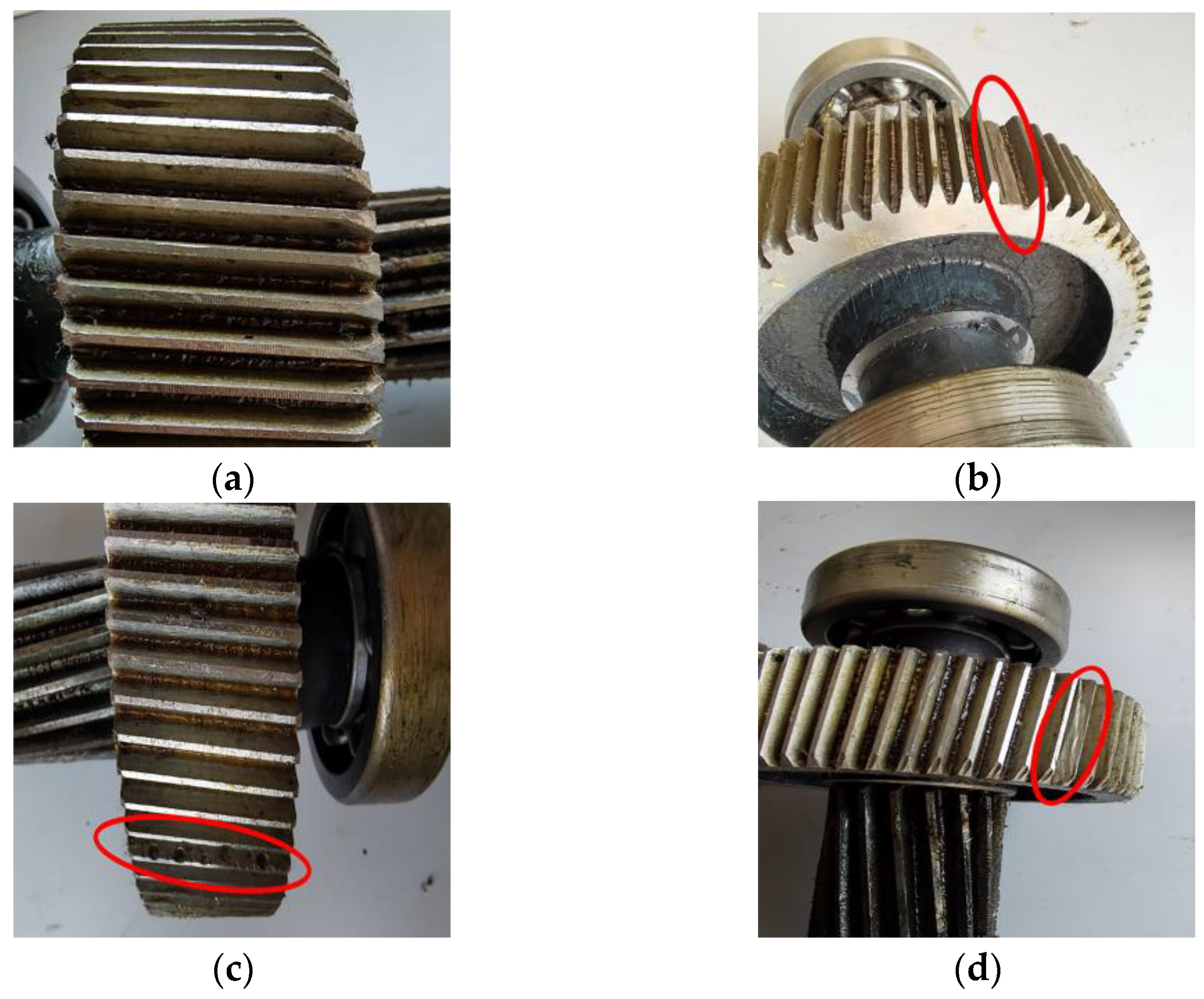

4.1. Analysis of Typical Fault Forms of Gearboxes

4.2. Construction of Gearbox Fault Experiment Platform

4.2.1. Experimental Platform Equipment Selection

4.2.2. Gear Failure Settings

4.2.3. Experimental Platform Construction

4.2.4. Experimental Data Design

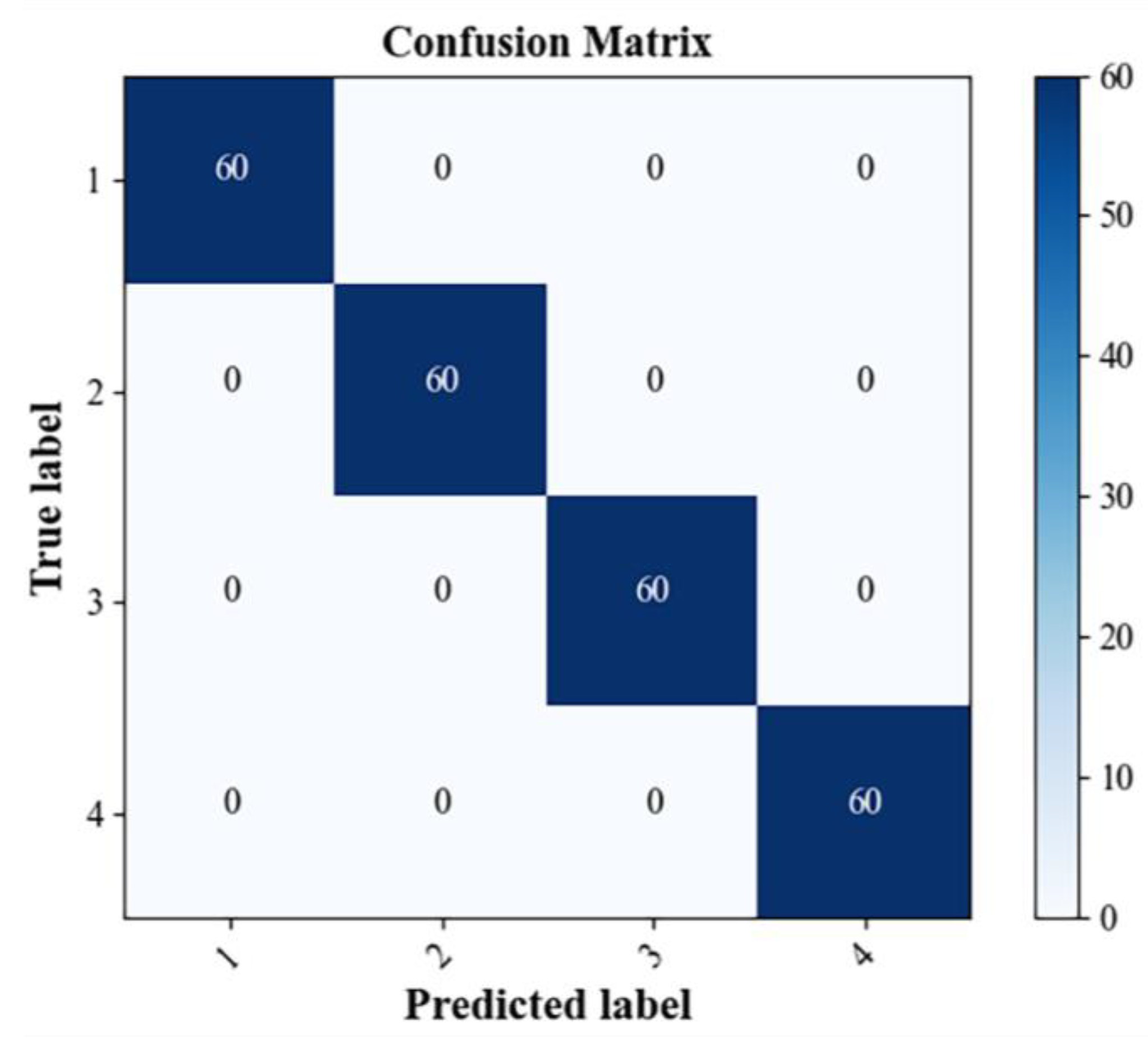

5. Experimental Analysis and Verification

5.1. Experimental Analysis

5.2. t-SNE Visualization

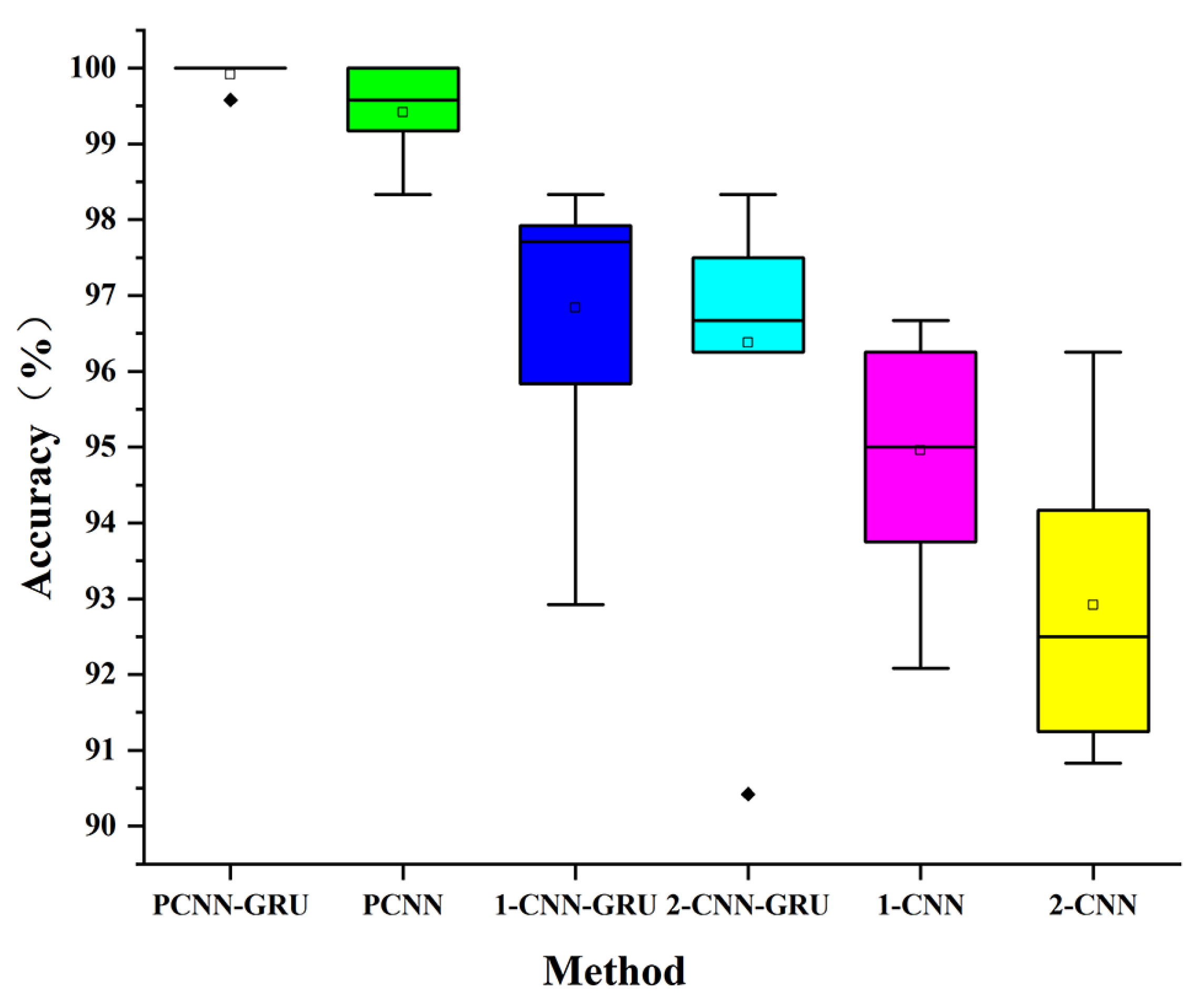

5.3. Comparison of Methods

- (1)

- PCNN: The vibration data of Sensor 1 and Sensor 2 were input into the PCNN;

- (2)

- Upper channel (Sensor 1) + CNN–GRU: Only the upper channel (Sensor 1) vibration signal was used to input into the CNN–GRU;

- (3)

- Lower channel (Sensor 2) + CNN–GRU: Only the lower channel (Sensor 2) vibration signal was used to input into the CNN–GRU;

- (4)

- Upper channel (Sensor 1) + CNN: Only the upper channel (Sensor 1) vibration signal was used to input into the CNN;

- (5)

- Lower channel (Sensor 2) + CNN: Only the vibration signal of the lower channel (Sensor 2) was used to input into the CNN.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khan, A.; Hwang, H.; Kim, H.S. Synthetic Data Augmentation and Deep Learning for the Fault Diagnosis of Rotating Machines. Mathematics 2021, 9, 2336. [Google Scholar] [CrossRef]

- Liang, X.; Zuo, M.J.; Feng, Z. Dynamic modeling of gearbox faults: A review. Mech. Syst. Signal Process. 2018, 98, 852–876. [Google Scholar] [CrossRef]

- Khalid, S.; Hwang, H.; Kim, H.S. Real-World Data-Driven Machine-Learning-Based Optimal Sensor Selection Approach for Equipment Fault Detection in a Thermal Power Plant. Mathematics 2021, 9, 2814. [Google Scholar] [CrossRef]

- Schmidt, S.; Heyns, P.S.; Gryllias, K.C. A methodology using the spectral coherence and healthy historical data to perform gearbox fault diagnosis under varying operating conditions. Appl. Acoust. 2020, 158, 107038. [Google Scholar] [CrossRef]

- Jiang, Z.; Han, Q.; Xu, X. Fault diagnosis of planetary gearbox based on motor current signal analysis. Shock Vib. 2020, 2020, 8854776. [Google Scholar] [CrossRef]

- Praveenkumar, T.; Saimurugan, M.; Krishnakumar, P.; Ramachandran, K.I. Fault diagnosis of automobile gearbox based on machine learning techniques. Procedia Eng. 2014, 97, 2092–2098. [Google Scholar] [CrossRef]

- Saufi, S.R.; Ahmad, Z.A.B.; Leong, M.S.; Lim, M.H. Gearbox fault diagnosis using a deep learning model with limited data sample. IEEE Trans. Ind. Inform. 2020, 16, 6263–6271. [Google Scholar] [CrossRef]

- Fan, X.; Zuo, M.J. Gearbox fault detection using Hilbert and wavelet packet transform. Mech. Syst. Signal Process. 2006, 20, 966–982. [Google Scholar] [CrossRef]

- Feng, Z.; Zhu, W.; Zhang, D. Time-Frequency demodulation analysis via Vold-Kalman filter for wind turbine planetary gearbox fault diagnosis under nonstationary speeds. Mech. Syst. Signal Process. 2019, 128, 93–109. [Google Scholar] [CrossRef]

- Yoon, J.; He, D.; Van Hecke, B. On the use of a single piezoelectric strain sensor for wind turbine planetary gearbox fault diagnosis. IEEE Trans. Ind. Electron. 2015, 62, 6585–6593. [Google Scholar] [CrossRef]

- Singh, J.; Azamfar, M.; Ainapure, A.; Lee, J. Deep learning-based cross-domain adaptation for gearbox fault diagnosis under variable speed conditions. Meas. Sci. Technol. 2020, 31, 055601. [Google Scholar] [CrossRef]

- Manikandan, S.; Duraivelu, K. Fault diagnosis of various rotating equipment using machine learning approaches–A review. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2021, 235, 629–642. [Google Scholar] [CrossRef]

- Xia, T.; Jiang, Y.; Zhuo, P.; Xi, L.; Wang, D. Dual-ensemble multi-feedback neural network for gearbox fault diagnosis. IEEE Trans. Instrum. Meas. 2021, 70, 3519610. [Google Scholar] [CrossRef]

- Liao, Y.; Zhang, L.; Li, W. Regrouping particle swarm optimization based variable neural network for gearbox fault diagnosis. J. Intell. Fuzzy Syst. 2018, 34, 3671–3680. [Google Scholar] [CrossRef]

- Zhang, X.; Han, P.; Xu, L.; Zhang, F.; Wang, Y.; Gao, L. Research on bearing fault diagnosis of wind turbine gearbox based on 1DCNN-PSO-SVM. IEEE Access 2020, 8, 192248–192258. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, J.; Wang, Y. An intelligent diagnosis scheme based on generative adversarial learning deep neural networks and its application to planetary gearbox fault pattern recognition. Neurocomputing 2018, 310, 213–222. [Google Scholar] [CrossRef]

- Tong, S.; Li, J.; Cong, F.; Fu, Z.; Tong, Z. Vibration Separation Methodology Compensated by Time-Varying Transfer Function for Fault Diagnosis of Non-Hunting Tooth Planetary Gearbox. Sensors 2022, 22, 557. [Google Scholar] [CrossRef]

- Jia, F.; Lei, Y.; Guo, L.; Lin, J.; Xing, S. A neural network constructed by deep learning technique and its application to intelligent fault diagnosis of machines. Neurocomputing 2018, 272, 619–628. [Google Scholar] [CrossRef]

- Hinton, G.E.; Salakhutdinov, R.R. Reducing the dimensionality of data with neural networks. Science 2006, 313, 504–507. [Google Scholar] [CrossRef]

- He, M.; He, D. Deep learning based approach for bearing fault diagnosis. IEEE Trans. Ind. Appl. 2017, 53, 3057–3065. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Wang, S.; Li, W.; Sarkodie-Gyan, T.; Feng, S. A hybrid deep-learning model for fault diagnosis of rolling bearings. Measurement 2021, 169, 108502. [Google Scholar] [CrossRef]

- Huang, D.; Zhang, W.A.; Guo, F.; Liu, W.; Shi, X. Wavelet Packet Decomposition-Based Multiscale CNN for Fault Diagnosis of Wind Turbine Gearbox. IEEE Trans. Cybern. 2023, 53, 443–453. [Google Scholar] [CrossRef]

- Jin, T.; Yan, C.; Chen, C.; Yang, Z.; Tian, H.; Wang, S. Light neural network with fewer parameters based on CNN for fault diagnosis of rotating machinery. Measurement 2021, 181, 109639. [Google Scholar] [CrossRef]

- Yin, A.; Yan, Y.; Zhang, Z.; Li, C.; Sánchez, R.-V. Fault Diagnosis of Wind Turbine Gearbox Based on the Optimized LSTM Neural Network with Cosine Loss. Sensors 2020, 20, 2339. [Google Scholar] [CrossRef] [PubMed]

- Miao, X.; Li, S.; Zhu, Y.; An, Z. A novel real-time fault diagnosis method for planetary gearbox using transferable hidden layer. IEEE Sens. J. 2020, 20, 8403–8412. [Google Scholar] [CrossRef]

- Du, Z.; Fan, B.; Chi, J.; Jin, X. Sensor fault detection and its efficiency analysis in air handling unit using the combined neural networks. Energy Build. 2014, 72, 157–166. [Google Scholar] [CrossRef]

- Hussain, S.; Mokhtar, M.; Howe, J.M. Sensor failure detection, identification, and accommodation using fully connected cascade neural network. IEEE Trans. Ind. Electron. 2014, 62, 1683–1692. [Google Scholar] [CrossRef]

- Wang, H.; Xu, J.; Yan, R.; Sun, C.; Chen, X. Intelligent bearing fault diagnosis using multi-head attention-based CNN. Procedia Manuf. 2020, 49, 112–118. [Google Scholar] [CrossRef]

- Chen, J.; Jiang, J.; Guo, X.; Tan, L. A self-Adaptive CNN with PSO for bearing fault diagnosis. Syst. Sci. Control Eng. 2021, 9, 11–22. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Q.; Qin, X.; Sun, Y. K-SVD-based WVD enhancement algorithm for planetary gearbox fault diagnosis under a CNN framework. Meas. Sci. Technol. 2019, 31, 025003. [Google Scholar] [CrossRef]

- Jiang, J.; Bie, Y.; Li, J.; Yang, X.; Ma, G.; Lu, Y.; Zhang, C. Fault diagnosis of the bushing infrared images based on mask R-CNN and improved PCNN joint algorithm. High Volt. 2021, 6, 116–124. [Google Scholar] [CrossRef]

- Ruan, D.; Song, X.; Gühmann, C.; Yan, J. Collaborative optimization of CNN and GAN for bearing fault diagnosis under unbalanced datasets. Lubricants 2021, 9, 105. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, C.; Wang, T.; Cheng, L. An attention enhanced dilated CNN approach for cross-axis industrial robotics fault diagnosis. Auton. Intell. Syst. 2022, 2, 11. [Google Scholar] [CrossRef]

- Wang, J.; Yang, J.; Wang, Y.; Bai, Y.; Zhang, T.; Yao, D. Ensemble decision approach with dislocated time–frequency representation and pre-trained CNN for fault diagnosis of railway vehicle gearboxes under variable conditions. Int. J. Rail Transp. 2022, 10, 655–673. [Google Scholar] [CrossRef]

- Ma, Y.; Jia, X.; Bai, H.; Liu, G.; Wang, G.; Guo, C.; Wang, S. A new fault diagnosis method based on convolutional neural network and compressive sensing. J. Mech. Sci. Technol. 2019, 33, 5177–5188. [Google Scholar] [CrossRef]

- Liu, H.; Ma, R.; Li, D.; Yan, L.; Ma, Z. Machinery fault diagnosis based on deep learning for time series analysis and knowledge graphs. J. Signal Process. Syst. 2021, 93, 1433–1455. [Google Scholar] [CrossRef]

- Tao, Y.; Wang, X.; Sánchez, R.V.; Yang, S.; Bai, Y. Spur gear fault diagnosis using a multilayer gated recurrent unit approach with vibration signal. IEEE Access 2019, 7, 56880–56889. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, B.; Yang, T.; Lyu, D.; Gao, W. Multitask convolutional neural network with information fusion for bearing fault diagnosis and localization. IEEE Trans. Ind. Electron. 2019, 67, 8005–8015. [Google Scholar] [CrossRef]

- Xu, Z.; Bashir, M.; Zhang, W.; Yang, Y.; Wang, X.; Li, C. An intelligent fault diagnosis for machine maintenance using weighted soft-voting rule based multi-attention module with multi-scale information fusion. Inf. Fusion 2022, 86, 17–29. [Google Scholar] [CrossRef]

- Aherwar, A. An investigation on gearbox fault detection using vibration analysis techniques: A review. Aust. J. Mech. Eng. 2012, 10, 169–183. [Google Scholar] [CrossRef]

- Chen, J.P.; Wang, Y.L.; Zhao, C.X.; Li, X. Failure Analysis and Preventive Measures of Cooling Tower Fan Gearbox. Adv. Mater. Res. 2014, 989, 3302–3305. [Google Scholar] [CrossRef]

- Fischer, K.; Besnard, F.; Bertling, L. Reliability-centered maintenance for wind turbines based on statistical analysis and practical experience. IEEE Trans. Energy Convers. 2011, 27, 184–195. [Google Scholar] [CrossRef]

| Information Fusion Method | Advantages | Disadvantages |

|---|---|---|

| Data level | Less information loss, higher fusion accuracy | The amount of calculation is too large, and the information needs to come from the same type of sensor |

| Feature level | Can effectively compress and extract information | Recognition accuracy depends on whether the proposed features are valid |

| Decision-making level | Has strong anti-interference ability, no requirement for sensor type | Large amount of information loss and poor accuracy |

| Network Layer | Number of Convolution Kernels | Convolution Kernel Size | Step Length | Activation Function | Output Size |

|---|---|---|---|---|---|

| Convolutional layer 1–1 | 32 | 64 | 8 | ReLU | 256 × 32 |

| Pooling layer 1–1 | 32 | 4 | 1 | — | 64 × 32 |

| Convolutional layer 2–1 | 64 | 5 | 1 | ReLU | 64 × 64 |

| Pooling layer 2–1 | 64 | 2 | 1 | — | 32 × 64 |

| Convolutional layer 1–2 | 32 | 64 | 8 | ReLU | 256 × 32 |

| Pooling layer 1–2 | 32 | 4 | 1 | — | 64 × 32 |

| Convolutional layer 2–2 | 64 | 5 | 1 | ReLU | 64 × 64 |

| Pooling layer 2–2 | 64 | 2 | 1 | — | 32 × 64 |

| Fusion layer | — | — | — | — | 32 × 128 |

| GRU layer | 16 | — | — | Tanh | 32 × 16 |

| Fully connected layer | 32 | — | — | Tanh | 32 |

| SoftMax | 4 | — | — | SoftMax | 4 |

| Type | Gearbox Status | Motor Speed/Hz | Brake Load/A | Data Length | Number of Datasets |

|---|---|---|---|---|---|

| 1 | Broken | 30 | 0.5 | 2048 | 300 × 2 |

| 2 | Pitting | 30 | 0.5 | 2048 | 300 × 2 |

| 3 | Normal | 30 | 0.5 | 2048 | 300 × 2 |

| 4 | Wear | 30 | 0.5 | 2048 | 300 × 2 |

| Type | Gearbox Status | Number of Training Sets | Number of Validation Sets | Number of Test Sets | Label |

|---|---|---|---|---|---|

| 1 | Broken | 180 × 2048 × 2 | 60 × 2048 × 2 | 60 × 2048 × 2 | 1 0 0 0 |

| 2 | Pitting | 180 × 2048 × 2 | 60 × 2048 × 2 | 60 × 2048 × 2 | 0 1 0 0 |

| 3 | Normal | 180 × 2048 × 2 | 60 × 2048 × 2 | 60 × 2048 × 2 | 0 0 1 0 |

| 4 | Wear | 180 × 2048 × 2 | 60 × 2048 × 2 | 60 × 2048 × 2 | 0 0 0 1 |

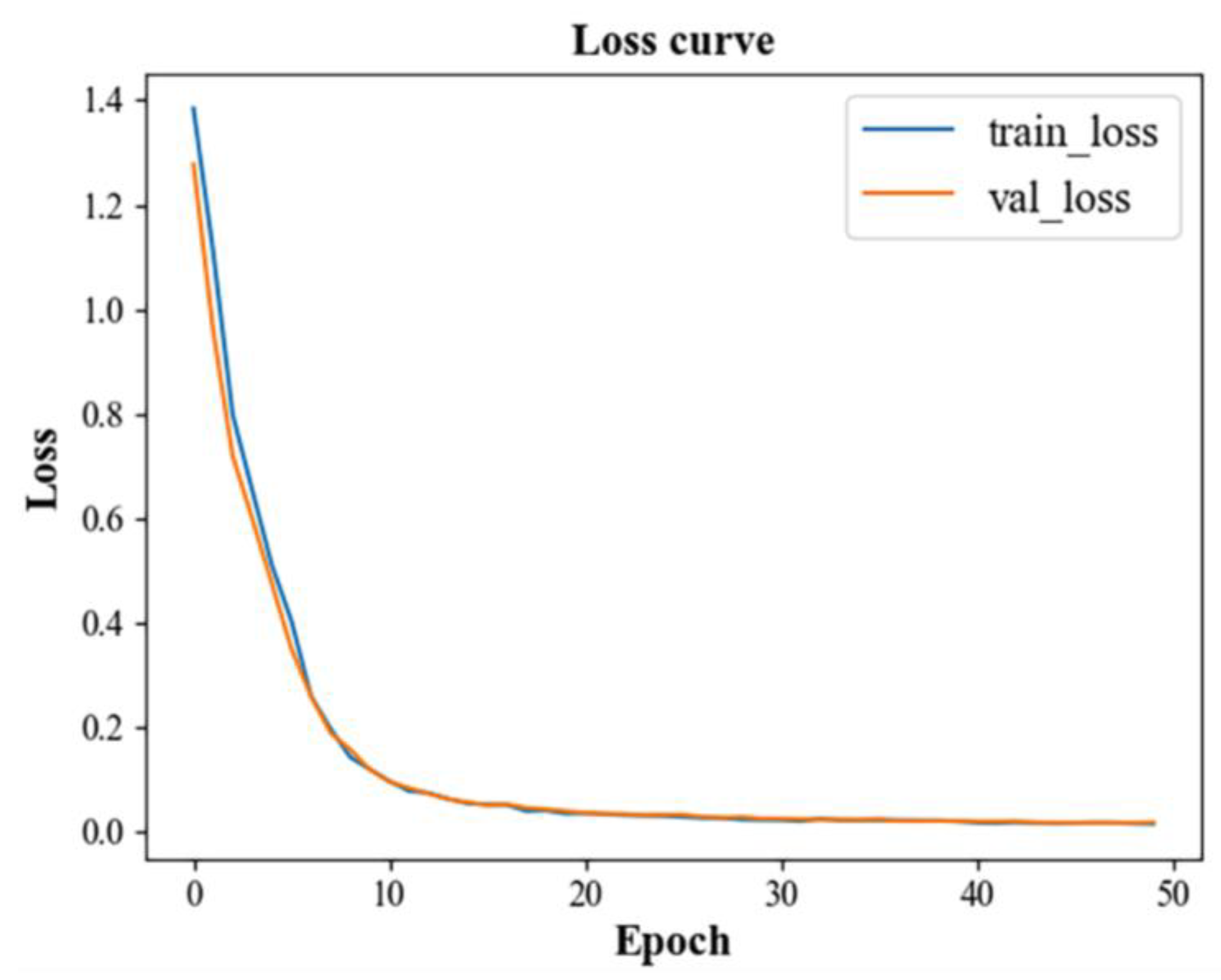

| Number of Times | Loss Rate/% | Accuracy/% | Average Accuracy Rate/% | Average Loss Rate/% |

|---|---|---|---|---|

| 1 | 0.06 | 100 | 99.92 | 0.09 |

| 2 | 0.11 | 99.58 | ||

| 3 | 0.11 | 100 | ||

| 4 | 0.18 | 100 | ||

| 5 | 0.04 | 99.58 | ||

| 6 | 0.13 | 100 | ||

| 7 | 0.18 | 100 | ||

| 8 | 0.03 | 100 | ||

| 9 | 0.09 | 100 | ||

| 10 | 0.01 | 100 |

| Method | Average Loss Rate of 10 Tests/% | Average Recognition Rate of 10 Tests/% |

|---|---|---|

| PCNN–GRU | 0.09 | 99.92 |

| PCNN | 5.67 | 99.42 |

| Sensor 1-CNN–GRU | 9.32 | 96.84 |

| Sensor 2-CNN–GRU | 11.12 | 96.38 |

| Sensor 1-CNN | 17.84 | 94.96 |

| Sensor 2-CNN | 24.79 | 92.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, F.; Wang, G.; Shang, J.; Sun, E.; Xie, S. Gearbox Fault Diagnosis Based on Multi-Sensor Deep Spatiotemporal Feature Representation. Mathematics 2023, 11, 2679. https://doi.org/10.3390/math11122679

Xie F, Wang G, Shang J, Sun E, Xie S. Gearbox Fault Diagnosis Based on Multi-Sensor Deep Spatiotemporal Feature Representation. Mathematics. 2023; 11(12):2679. https://doi.org/10.3390/math11122679

Chicago/Turabian StyleXie, Fengyun, Gan Wang, Jiandong Shang, Enguang Sun, and Sanmao Xie. 2023. "Gearbox Fault Diagnosis Based on Multi-Sensor Deep Spatiotemporal Feature Representation" Mathematics 11, no. 12: 2679. https://doi.org/10.3390/math11122679

APA StyleXie, F., Wang, G., Shang, J., Sun, E., & Xie, S. (2023). Gearbox Fault Diagnosis Based on Multi-Sensor Deep Spatiotemporal Feature Representation. Mathematics, 11(12), 2679. https://doi.org/10.3390/math11122679