4.1. Overall Framework

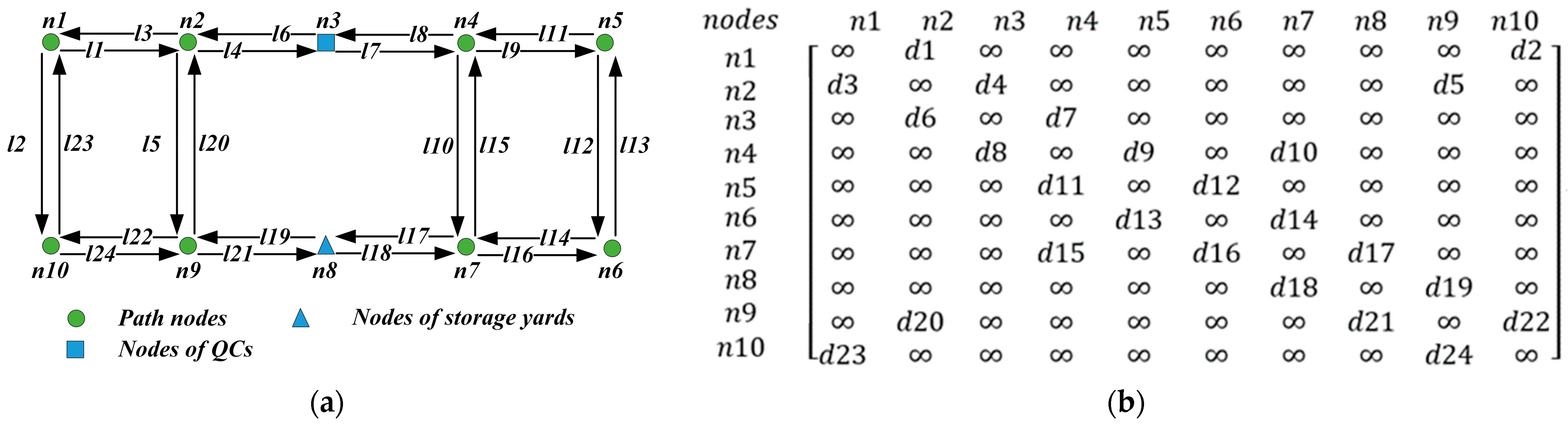

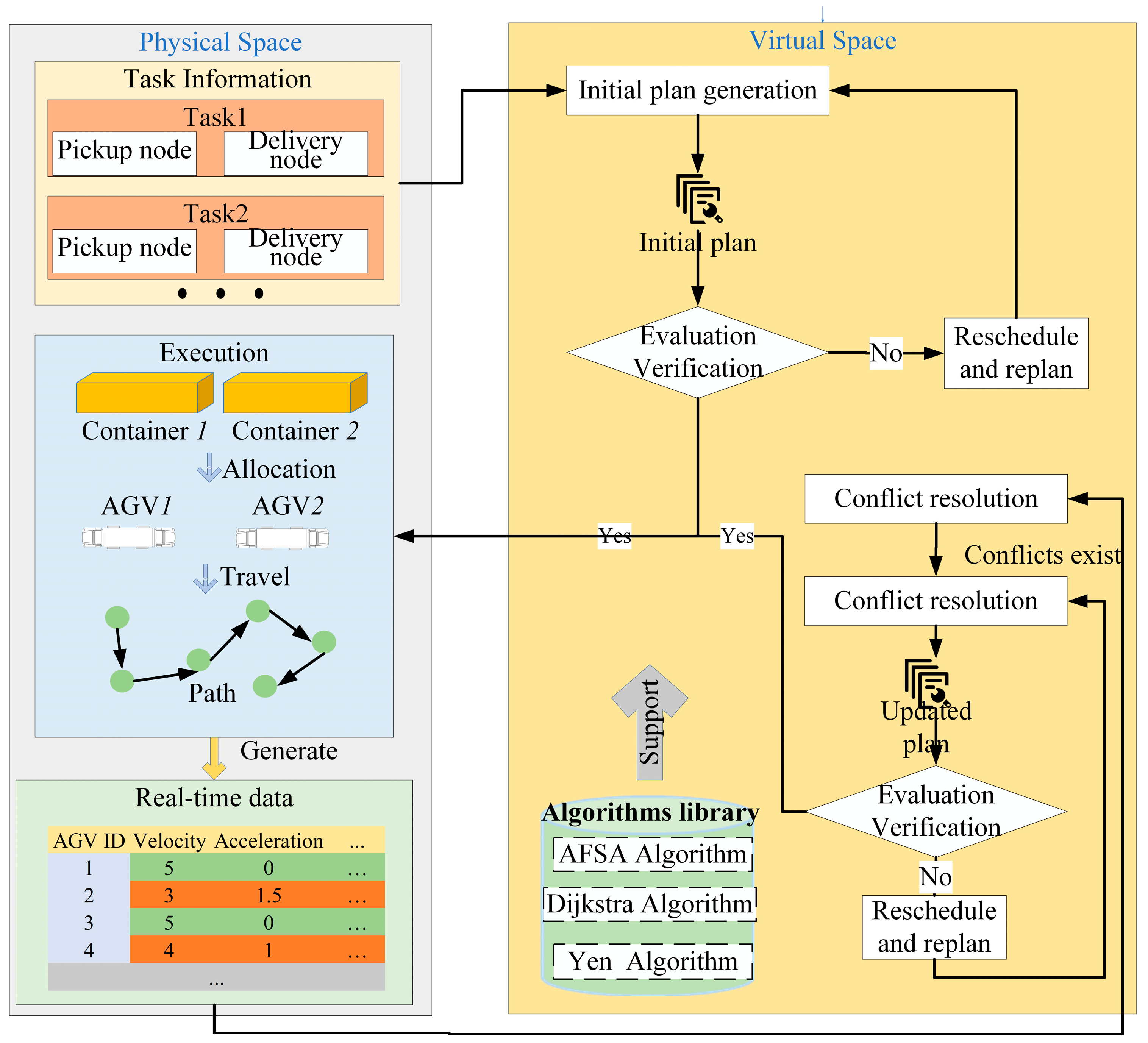

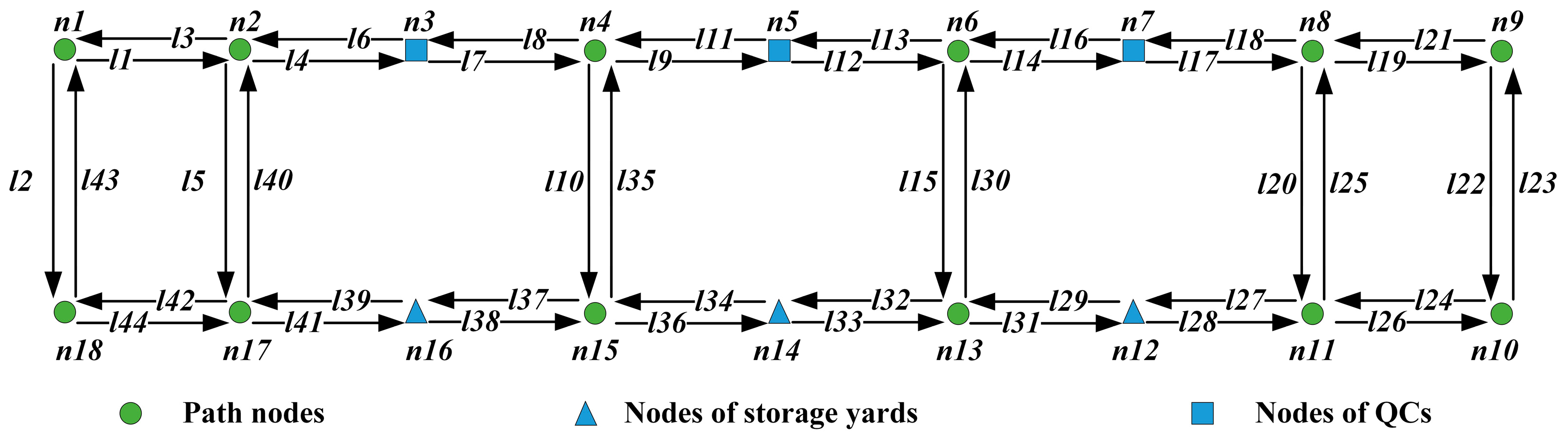

The framework of DT-based AGV scheduling and routing for an ACT consists of two parts, involving the physical space and virtual space (see

Figure 3).

In the physical space, the physical entities mainly involve AGVs, QCs, and YCs. The data sensing the conditions of various devices and its surrounding are collected and also transmitted to the virtual space. In addition, physical devices will execute in real time according to the decision feedback from the virtual space.

The virtual space consists of four parts, involving the service modules, algorithms library, evaluation verification platform, and data center. The functions of the data center are mainly to store data from the physical and virtual space and to process this data to provide data support for service modules. With the assistance of the algorithm library, the function of the service modules primarily consists of (1) generating an initial AGV scheduling and routing plan to guide the AGV transport process; (2) monitoring the ACT operation process and predicting AGV conflicts by comparing simulation data with real-time data; and (3) resolving conflicts caused by uncertain events, revising the initial plan, and feeding it back into the physical space. The purpose of the evaluation verification platform is to verify the feasibility and efficiency of the plan by simulation.

The workflow of the proposed framework is shown in

Figure 4. The specific processes are as follows.

Step 1: By introducing the digital twin, the AGV transport process is continuously monitored, including AGV speed, AGV acceleration, and AGV position. The real-time data are transmitted to the virtual space.

Step 2: IAFSA-Dijkstra is proposed for the optimal AGV scheduling and routing solution, uncertain factors can be detected and handled through the interaction and fusion of physical and virtual spaces, and a conflict resolution method based on the Yen algorithm is explored to resolve predicted conflicts and drive the evolution of the scheme.

Step 3: The evaluation verification platform evaluates the updated plan. The results of scheduling and path planning are fed into physical space to guide AGV for path planning, which timely responds to changes in the environment.

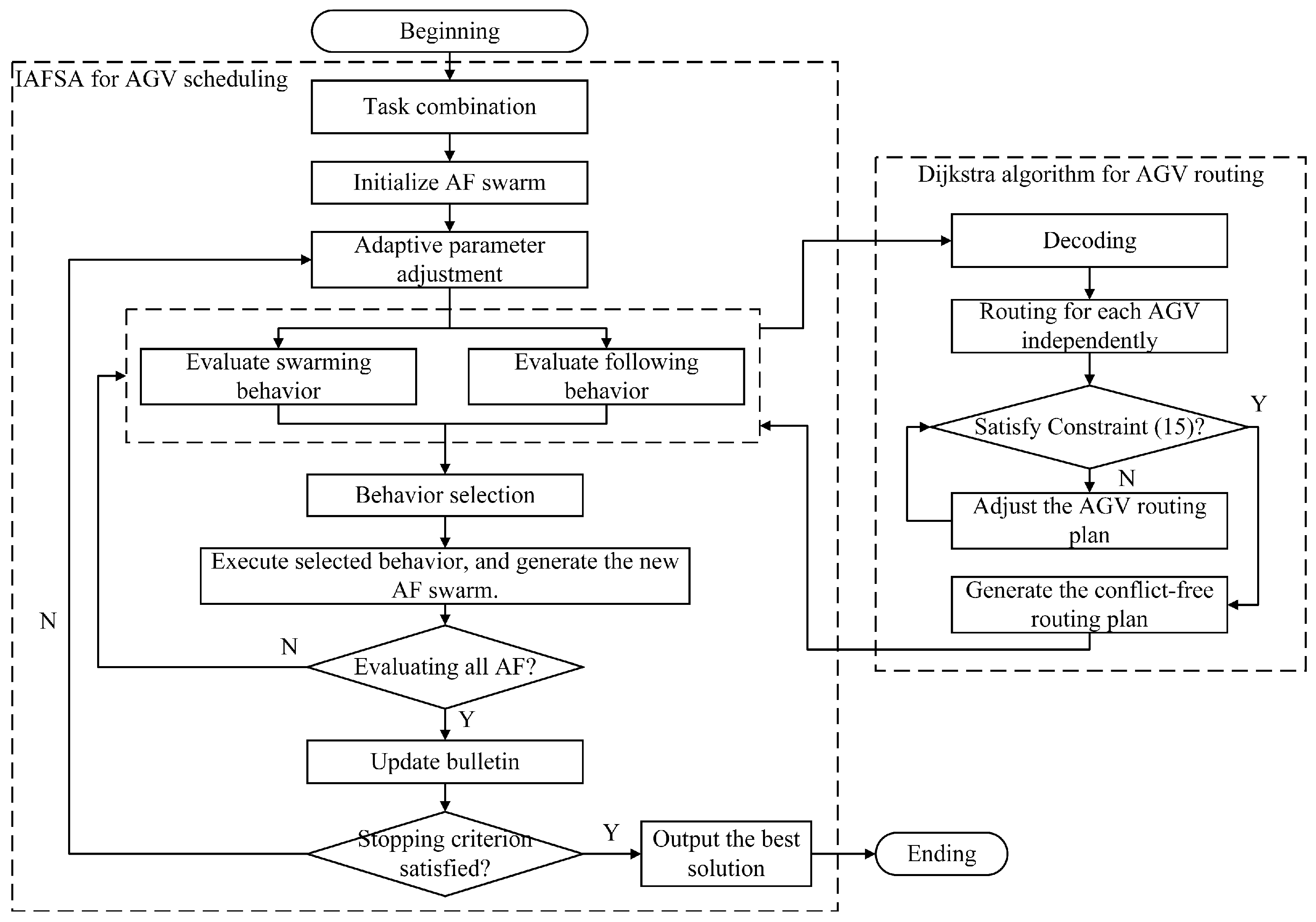

4.2. IAFSA-Dijkstra Algorithm

A bi-level mixed integer programming model is established in

Section 3. The upper level of the model pertains to AGV scheduling, while the lower level of the model concerns collision-free AGV routing. To solve the model, an improved artificial fish swarm algorithm-Dijkstra algorithm (IAFSA-Dijkstra), is presented in this section. The IAFSA is used to optimize AGV scheduling, which determines the start and endpoints of the path. The Dijkstra algorithm is used for collision-free routing, which affects the AGV scheduling process. The flowchart of IAFSA-Dijkstra is shown in

Figure 5.

AFSA has better global optimization capability owing to its parallel search and the nature of controlling the search direction [

50]. There is a more substantial search capability in the early stage of optimization, but the search capability weakens, and it is easily trapped in the local extremum in the later stage. Thus, an adaptive parameter adjustment method is used to improve AFSA. Meanwhile, the encoding method in this work is related to the number of container transport tasks. Therefore, a task combination approach is adopted to combine container tasks according to specific rules to reduce the encoding length.

Encoding and decoding method: A random number encoding method is adopted. The value above each position denotes the container no. The value after rounding in each position denotes the AGV no., and the value range is [0.5, + 0.5), where denotes the number of AGVs. The initial value in each position is randomly generated.

Assume 8 containers and 3 AGVs, and the encoding method is as shown in

Figure 6a. Taking the first position as an example, 1.181 is rounded to 1. Therefore, container 1 is assigned to AGV 1. In the same way as for the other positions, AGV 1 is responsible for transporting containers 1, 7, and 8, AGV 2 is responsible for transporting containers 4 and 6, and AGV 3 is responsible for transporting containers 2, 3, and 5. For containers of each AGV, the order after sorting by their value is the transportation order of AGV. Taking AGV 1 as an example, the values of containers 1, 7, and 8 are 1.181, 1.211, 1.203, respectively. Since 1.181 < 1.203 < 1.211, the transportation order of AGV 1 is container 1–container 8–container 7.

Task combination strategy: Considering the above encoding method, encoding length is related to the number of container transportation tasks. The higher the number of container transportation tasks, the longer the encoding length, which causes a more extended algorithm running time. Therefore, a task combination strategy is introduced to reduce the number of container transportation tasks, shortening the algorithm’s running time. The cost of the method is that the number of solution spaces will be reduced.

Task combination is a strategy of combining multiple tasks into one task. If the pickup point of container

p and the delivery point of container

p’ are the same point, two tasks will be combined into one task. The combined task point is the pickup of container

p’, the delivery point of container

p’ (viz., the pickup point of container

p), and the delivery point of container

p in sequence. The task combination with 8 containers as an example is shown in

Figure 6b.

Adaptive parameter adjustment strategy: In AFSA, Visual and Step are essential parameters that affect the movement of the AF. In the early stage of optimization, a larger Visual and Step can make the AF move quickly and jump out of the local extremum, thus converging faster. Nevertheless, in the later stage of optimization, a larger Visual and Step will lead to the optimal solution being skipped, which is not conducive to optimization.

In traditional AFSA, Visual and Step are fixed, which makes it difficult to reconcile the requirements in the early and later stages of optimization. An adaptive parameter adjustment method is used to address the above problem. The value of Visual and Step will gradually become smaller as the number of iterations increases.

Visual and

Step can be calculated according to Expressions (18) and (19).

where

denotes the number of iterations, and

,

,

, and

denote the maximum and minimum of

Visual and

Step, respectively.

denotes the maximum number of iterations.

and

denote

Visual and

Step with the number of iterations.

The procedure of IAFSA is shown in Algorithm 1. First, combine tasks according to task combination strategy and initialize the artificial fish (AF) population. Then, calculate and based on Equations (18) and (19). Meanwhile, evaluate swarming behavior and following behavior and select the optimal behavior to execute. The fitness values of these two behaviors can be obtained based on Algorithm 2. Repeat the above steps until the stopping criterion condition is satisfied.

The Dijkstra algorithm is a path search algorithm to determine the optimal path in one given path network. The traditional Dijkstra algorithm cannot prevent potential AGV conflict; thus, a criterion called “Node visit time (

)” is presented to record the time at which AGVs visit all nodes, expressed by Equation (20).

makes it possible to take into account the path information of other AGVs when planning paths for one AGV, effectively avoiding potential AGV conflicts.

where

denotes AGV

visits to node

at moment

.

The procedure of the Dijkstra algorithm is shown in Algorithm 2. First, the task assignment result is obtained based on the decoding result. Based on the task assignment results, the start and end nodes of the AGV can be determined so that the optimal route of the AGV can be obtained by Dijkstra algorithm. The plan of AGV

k can be denoted by

, expressed by Expression (21).

where the explanations of

, and

are in

Appendix B.

| Algorithm 1: IAFSA in AGV scheduling. |

| Input: | Problem data, IAFSA parameters. |

| Output: | The optimal solution , the completion time of all tasks . |

| 1: | |

| 2: | Task combination. |

| 3: | Initialize AF population [] |

| 4: | while 1 to do |

| 5: | calculate and by Expressions (18) and (19) |

| 6: | for i 1 to do |

| 7: | // Evaluate swarming behavior, |

| 8: | // Evaluate following behavior |

| 9: | [ |

| 10: | end for |

| 11: | |

| 12: | |

| 13: | end while |

Then,

is updated based on the routing results and sorted in chronological order. If two AGVs visit the same path nodes and their visit moments do not satisfy Equation (15), their infornamtion are recorded into

. The set

records the events that do not satisfy Equation (15), expressed by Equation (22).

where

denotes AGV

visits to node

at moment

, AGV

visits to node

at moment

, and

.

If

is empty, the time relationship of all AGVs visiting the path node satisfies Equation (15), and there is no potential conflict. Otherwise, if

involves two AGVs, the passage priority is decided according to Equation (23), and the low-priority AGV waits for

, where

denotes the time gap between the high-priority AGV and the low-priority AGV to visit the path node. If

involves multiple AGVs, Equation (23) may lead to a circular waiting problem; thus, Equation (24) is used to decide the passage order, and the low-priority AGV waits for

.

where

denotes the moment when AGV

k1 visits the conflicting node and

denotes the passage priority of AGV

k1.

| Algorithm 2: Dijkstra algorithm in AGV routing. |

| Input: | Coding results of IAFSA, problem data |

| Output: | The fitness value of IAFSA . |

| 1: | Decode to obtain task assignment results. |

| 2: | for kV do |

| 3: | planning path for AGV k using Dijkstra algorithm, recorded in |

| 4: | end for |

| 5: | while True do |

| 6: | , |

| 7: | update based on {}, and sort in chronological order |

| 8: | for do |

| 9: | if and and then |

| 10: | record into |

| 11: | end if |

| 12: | end for |

| 13: | if then |

| 14: | break; |

| 15: | end if |

| 16: | sort in chronological order, |

| 17: | for do // update |

| 18: | if and then |

| 19: | , |

| 20: | end if |

| 21: | end for |

| 22: | if involves two AGVs then |

| 23: | decide the pass priority according to Equation (23) and update |

| 24: | else |

| 25: | decide the pass priority according to Equation (24) and update |

| 26: | end if |

| 27: | end while |

| 28: | (kV) |

4.3. Twin-Data-Driven AGV Conflict Prediction Method

During the AGV transport process, the occurrence of disturbance events (e.g., AGV failure, AGV speed fluctuations, and uncertain QC operation times) will influence the execution of the scheduling and routing plan, resulting in the deviation between the actual plan and the expected plan. As the AGV operation is a continuous process, the accumulation of deviations may affect the subsequent AGV operation and cause AGV conflicts. Therefore, it is necessary to predict the subsequent potential AGV conflicts to facilitate early countermeasures to deal with them. A twin-data-driven AGV conflict prediction method is explored to monitor the deviation between the actual and original plans and then predict AGV conflicts. The parameters in this section are shown in

Appendix B. The workflow of the twin-data-driven AGV conflict prediction method is shown in

Figure 7.

During the AGV transport process, each AGV reports its operation state information to the virtual space in real-time, expressed by Expression (25).

If AGV

k is located on the path at moment

t (i.e.,

), the time to reach its next node is predicted according to Expression (26). Expression (27) is used for conflict prediction. When AGV

k and AGV

q satisfy (27), the two AGVs will conflict in their next node. The conflict event

is recorded to the conflict set

. Assume the two conflicts in

, denoted as

; if

, these two events are combined into one event

records the conflict events for all AGVs’ next path nodes,

.

If AGV

k is located on the node at moment

t (i.e.,

), the deviations between the plan and the actual operation will be measured to predict the occurrence of conflicts. Aiming to measure the deviation, a criterion called “Consistency deviation (

)” is presented, defined as the deflection between the planned AGV operation state and the actual AGV operation state, expressed by Expression (28).

Due to the fluctuating AGV speed during the AGV transport process, the actual time of the AGV visiting one node will deviate from the planned time. The consistency deviation of node visit time

is calculated by Expression (29).

Due to the uncertain operation time of QCs and YCs, one container’s actual loading and unloading time will deviate from the planned time. The consistency deviation of loading

and unloading time

is calculated by Expressions (30) and (31).

When , the current AGV’s times of visiting subsequent nodes need to superimpose . Assume that AGV k has a consistency deviation from the expected plan when visiting the ith node. The updated plan of AGV k can be denoted as .

will be updated as the AGV plan is updated and sorted in chronological order. Then, if the time of visiting node by two AGVs in satisfies , the conflict event will be recorded to the conflict set . Assume the two conflicts in , denoted as ; if , these two events are combined into one event . records the conflict events of all AGVs’ non-next path nodes.

4.4. AGV Conflict Resolution Method Based on Yen’s Algorithm

In this section, a conflict resolution method is proposed for resolving AGV conflicts and revising the original plan.

The deviation between the initial plan and the revised plan can affect the stability of the ACT operation. Therefore, the objective of the AGV conflict resolution method is to minimize the time deviation of all AGVs’ task completion time between the initial plan and the revised plan, as in (32), while being subject to Equations (12)–(17).

For those conflicts in , the AGVs are located on the path, and the AGVs will conflict at their next node. Since the AGV transportation area is a directed graph, AGVs can only travel in one direction on a certain path. The conflicts in cannot be resolved by planning a new route—only by the waiting strategy. All conflicting AGVs visit the conflict node sequentially according to the time order, and the time interval between two AGVs visiting the conflicting node is . Taking one conflict as an example, assume that ; then, AGV k1 visits node s at moment , AGV k2 visits node s at moment with waiting time , and AGV k3 visits node s at moment with waiting time .

The conflicts in

can be resolved by re-routing for AGVs. Yen’s algorithm is an algorithm for obtaining multiple shortest paths from a starting point to an endpoint with the idea of a deviated path algorithm in the recursive method. An AGV conflict resolution based on Yen’s algorithm is explored to resolve conflicts in

. The procedure of Yen’s algorithm is shown in Algorithm 3. In Algorithm 3,

m paths are planned from the current node to the phase endpoint for AGV

k if the conflicting phase is the current phase of AGV

k. Otherwise,

m paths are planned from the phase start point to the phase endpoint. The waiting strategy is used to resolve the conflict if the conflict still exists in the conflicting phase after re-routing the path. Otherwise, adopt Yen’s algorithm to resolve the subsequent conflicts.

| Algorithm 3: Yen’s algorithm in AGV conflict resolution. |

| Input: | Problem data, real-time information for all AGVs, |

| Output: | the revised plan |

| 1: | sort in chronological order, and update |

| 2: | for k do |

| 3: | obtain AGV k’s phase at the occurrence of , denoted as |

| 4: | if is the current phase of AGV k then |

| 5: | arrange m paths from the current node to the phase endpoint for AGV k based on Yen’s algorithm, and update |

| 6: | else |

| 7: | arrange m paths from the phase start point to the phase endpoint for AGV k based on Yen’s algorithm, and update |

| 8: | end if |

| 9: | for i 1 to m do |

| 10: | while True do |

| 11: | update , and |

| 12: | if then |

| 13: | |

| 14: | break; |

| 15: | end if |

| 16: | if then |

| 17: | adopt a waiting strategy to resolve the conflict, and update . |

| 18: | else |

| 19: | adopt Yen’s algorithm to resolve the conflict, and update . |

| 20: | end if |

| 21: | end while |

| 22: | end for |

| 23: | end for |

| 24: | select the plan corresponding to min () |