1. Introduction

Sustainability can be considered as the ability of a given community to create and maintain communal existence through the management of local natural resources to ensure the survival and interconnectedness of community members and the environment [

1]. Traditionally, sustainability is divided into three dimensions: economic, social, and environmental [

2]. However, according to Eslami et al. [

3], technology [

4], energy [

5], efficiency [

6], manufacturing [

7], quality [

8], and performance management [

9] are also dimensions of sustainability. This research focuses only on economic, environmental, efficiency, and quality dimensions in manufacturing industries since this sector is considered as one of the sectors that most contributes to economic expansion [

10] and sustainability in its environmental dimension is defined as the ability to maintain the quality and reproducibility of natural resources [

11].

Regarding the economic dimension of sustainability, it is defined as the ability to efficiently use available resources to ensure profitability over time [

11] and, according to Ruiz-Mercado et al. [

12], the costs are the main indicator. Therefore, as the material waste is reduced, the manufacturing cost is also increased [

12] and, consequently, sustainability in the economic dimension is diminished.

So, by reducing solid waste (inorganic pollutants) [

12], manufacturing companies can improve environmental sustainability by minimizing pollution emissions and waste generation in their production process [

13]. On the other hand, in a production process, efficiency is reflected in the resources required to generate the desired product [

12]. Given that analyses of manufacturing process efficiency seek to improve productivity within a specified timeframe [

14], shortening manufacturing cycles helps improve sustainability in its dimension of efficiency. Finally, the quality dimension for a product is defined as the subjective satisfaction that a consumer perceives with it [

15]. This perceived product quality must satisfy consumer needs, including health and safety standards [

16] and the environment [

17], and the indicator for this dimension is the failure rate of a new product [

8]. Therefore, reducing failures (i.e., defects) helps improve sustainability in its quality dimension.

Currently, in the manufacturing sector, companies need to rapidly aim for a higher degree of sustainability [

18] since it can be considered a key factor for competitiveness [

19]. However, even today, manufacturing companies face problems that negatively impact their sustainability, such as defects in their products [

20]; the examples include customer complaints [

21], low sales, or low productivity [

22], to mention a few. As a result, manufacturing companies must implement strategies to efficiently use resources [

23] and thus maintain a good level of sustainability. The literature shows several studies carried out in the manufacturing sector to assess sustainability. However, most of them have focused on assessing the sustainability of products, while efforts to assess the sustainability of production processes are relatively limited, focusing mainly on specific tasks, such as turning, milling, or grinding [

24].

For more than fifty years, Mexico’s economy has relied heavily on manufacturing as a prolific source of job creation and export earnings [

25]. Originally, manufacturing companies were set up as industrial plants where simple tasks were performed, such as assembling manufacturing parts before exporting them to the United States of America or sewing pieces of fabric together [

26]. Today, due to market demands, manufacturing companies specialize in specific areas of industrial production, such as manufacturing parts for the automotive, medical, and aerospace industries, among other niches [

27].

There are currently 5195 manufacturing and export service industries in Mexico nationwide. Of these, 383 are in Baja California state (7.4% of the national total) and 240 are located in Tijuana (62.7% of the state total and 4.6% of the national total). These companies generate 2,895,151 direct jobs nationwide and 389,459 in the state of Baja California (13.5% of the national total) and 269,575 in Tijuana (9.3% of the national total and 69.2% of the state total) [

28], which demonstrates the importance of studying this sector from the economic, social, and environmental dimensions of sustainability.

Based on previous backgrounds, this paper presents a case study of a Mexican manufacturing company that, on previous projects, had low sustainability levels in its products and production processes. This was due to failures in its manufactured products, high material-use costs, solid waste (inorganic contaminants), high material consumption, and delays in project completion. Then, this research aims to show the application of reliability tests as a strategy to increase manufacturing companies’ sustainability. To achieve that goal, different useful tools are applied, such as analysis of variance (ANOVA) [

29], design of experiments (DOE) [

30], and failure mode and effect analysis (FMEA) [

31].

The rest of the document is as follows: the following subsection presents the research problem context for the case study.

Section 2 presents the theoretical foundations of the ANOVA, DOE, and FMEA. Similarly,

Section 3 shows the methodology applied to solve the problem for the case study, whereas

Section 4 comprises the results derived from the methodology. Finally,

Section 5 includes the conclusions for this research.

Research Problem

The current research is carried out in a manufacturing company that produces wired and wireless communication devices, including Bluetooth and digital enhanced cordless telecommunications devices. This company has several plants worldwide; however, the research is performed in a plant located in Tijuana, Mexico. This plant produces a family of products focused on various headsets, telephones, and conference equipment. In the case of headsets, this plant manufactures and distributes 77% of the headsets produced in all the company plants in 150 countries and currently has 2200 employees distributed in a direct workforce, a design center, an international distribution center, and a technical support call center.

The company’s design center’s main function is designing and introducing new products to the market and it has six departments to develop projects. One is the design quality department, which verifies that the product complies with internal company, customer, and governmental requirements. For this purpose, reliability tests are developed to subject the product to mechanical stress that simulates the conditions of use during its useful life to verify its quality. The quality laboratory receives the samples and performs the required tests and, once they are completed, a report is created and the design quality engineer is notified about the result.

Previously, the company has carried out several projects to develop USB A, USB B, USB C, and USB D products.

Table 1 shows that the average delivery time for these four developed projects was 3.5 weeks; however, the required delivery time is 2 weeks from when the laboratory receives the product until the results are delivered.

Currently, within the families of headphones produced, the company is carrying out a project to develop several products within the family that, in this research, are called AA. The products in this series are headsets designed for office use and are called AAXXX model from here.

Included in the delivery time is an environmental test, which was implemented due to a failure found in a previous project carried out in the company. Currently, this test is required for developing all office products in the reliability tests and its duration is 3 days, which increases the test duration time. This test requires three different environmental cycles in a temperature chamber and

Table 2 shows these requirements.

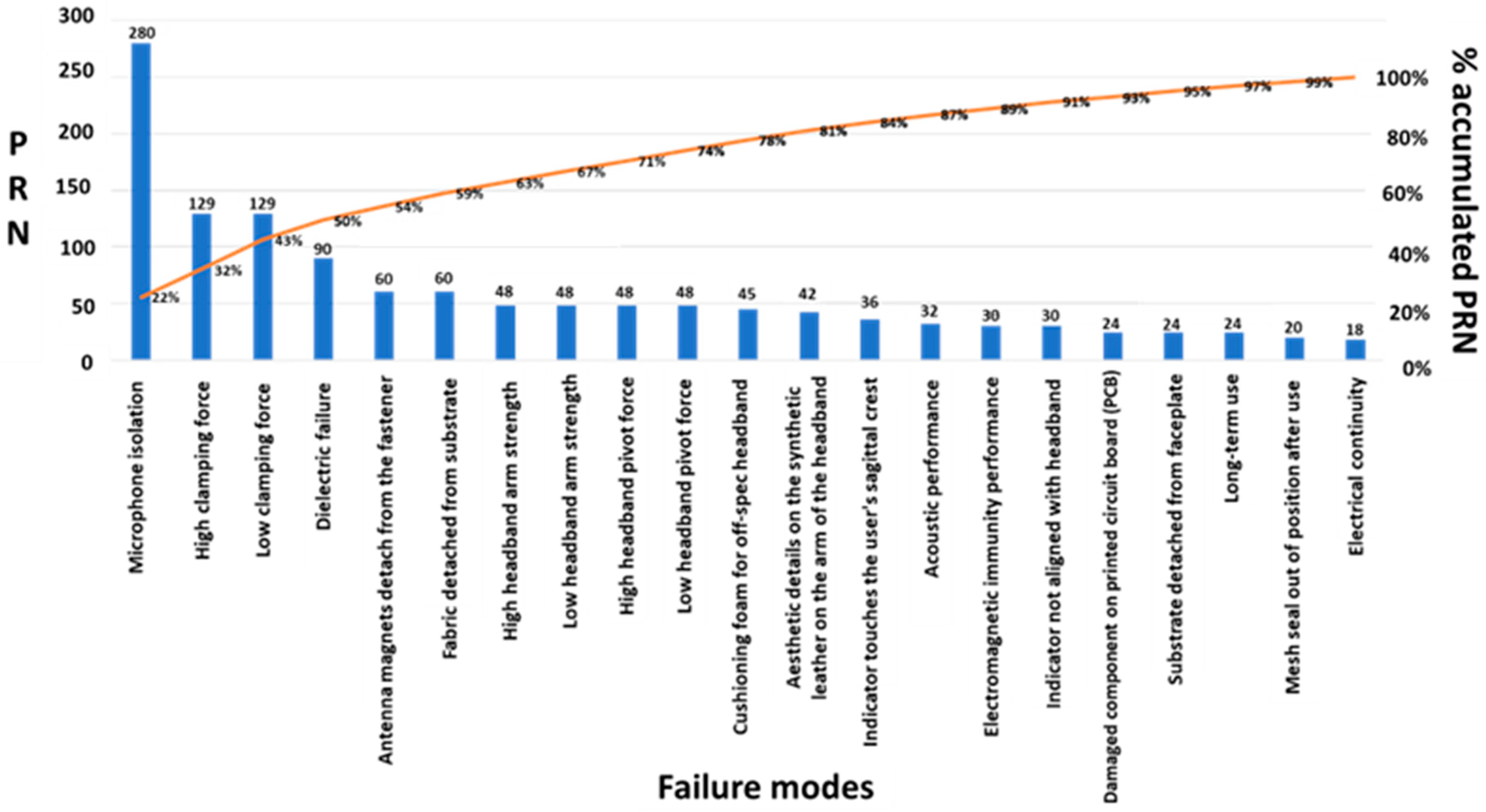

During this test, it was observed that most of the failures were mechanical and

Table 3 shows their frequency. These types of failures are identified during the product verification stage, which causes new iterations to the design that impacts the release of the product, delaying the mass production beginning and shipments to the customer, failing in the delivery date promised, causing some fines or penalties from customers due delays in delivering. Additionally, this delay and production problem has resulted in a low sustainability level regarding the quality, economy, environment, and efficiency of those last four projects.

Based on the problems mentioned above, this research aims to show that reliability tests are an effective strategy to increase manufacturing companies’ sustainability in terms of quality, economy, environment, and efficiency.

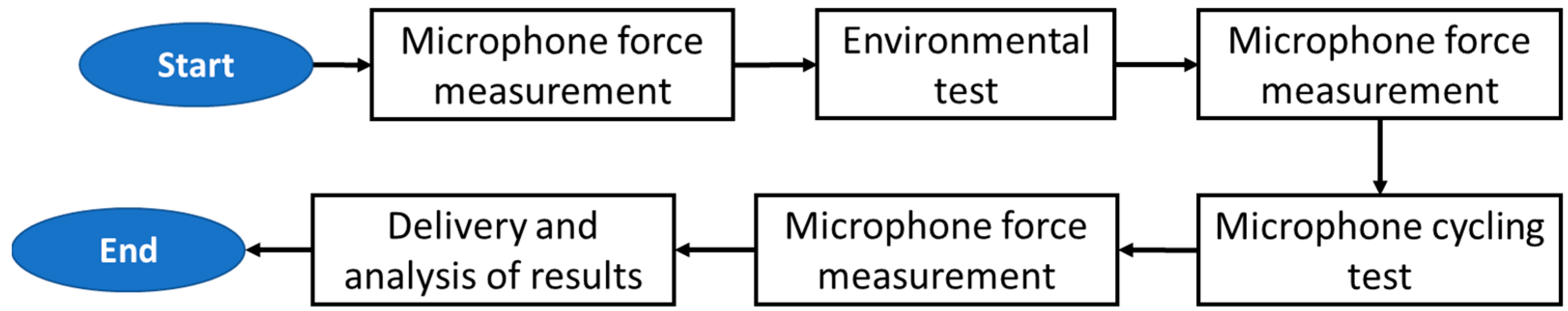

Figure 1 shows the steps to perform the microphone reliability test (microphone cycling) of the AAXXX headset.

3. Materials and Methods

For the design review based on the failure analysis of the AAXXX headset, the following tools are used: Agile PLM

® v9.3.6 software, SolidWorks

® 2020 v28 design software, Microsoft Excel

® 2210 software, and Microsoft Outlook

® 2210 software. In turn, the following tools and materials are used for the verification and validity of the environmental requirements: the AAXXX product, environmental camera Labtech RS-TH, laptop computer, Microsoft Excel

® 2210 software, and Minitab

® 20.4.0 software.

Figure 2 shows the method applied to achieve the objectives mentioned above. As can be seen, the applied method is divided into eleven stages. The following is a detailed description of how each stage of the method is carried out.

3.1. Stage 1: Determine the Product to Be Analyzed

At this stage, the product to be analyzed will be determined, depending on the needs of the project the team is working on or the company’s needs; so, the criteria to determine the product to be analyzed will depend on the project and the company. In this case, the delivery date required to have the product on the market, the product’s position in the market, and the production forecast were considered.

3.2. Stage 2: Describing the Function of Each Product Element

During this stage, and once it is decided which product must be analyzed, three one-hour sessions are scheduled with a multidisciplinary team using the Microsoft Outlook

® software tool. The teamwork introducing the product uses the template shown in

Figure 3. Subsequently, the functions of each element or mechanism of the product to be analyzed are listed. These functions must be described as the end customer will perceive them. For this purpose, the Agile PLM

® software is used to obtain the product’s bill of materials (BOM) and the Solidworks

® software is used to obtain a rendering of the product to be evaluated.

3.3. Stage 3: Determine and List the Possible Failure Modes and Effects of Failure

Here, the possible failure modes and their effects must be determined and listed using the brainstorming technique, where all the situations in which the product may fail due to end-customer use should be considered. Any situation and proposal for improvement must be considered, considering that there are no bad ideas. This information is documented in a worksheet in Microsoft Excel

® software, as shown in

Figure 3.

3.4. Stage 4: Assign Severity, Occurrence and Degree of Detection

Once the failure modes and effects have been determined, the team must determine the severity of each failure. Each failure’s impact on the end customer and the company must be considered. Normally, the impact is usually monetary and a number from 1 to 10 is assigned, depending on the severity determined, as shown in

Table 4 [

60].

On the other hand, the occurrence determines the assessment of failure during the product’s lifetime in the market on a scale from 1 to 10 [

60], as shown in

Table 5. The degree of detection refers to whether the failure can be detected within the company, either at some inspection point within the production line or in some verification test performed in internal laboratories. It is also rated with a number from 1 to 10, as shown in

Table 6, depending on how the failure will be detected by one of the systems mentioned above [

60].

3.5. Stage 5: Calculate the Priority Risk Number

At this stage, the three factors of severity, occurrence, and detectability are multiplied to calculate the so-called priority risk number (PRN), as shown in Equation (1) [

61]:

Once the PRN has been calculated, the faults are prioritized based on this number, prioritizing the faults with the highest PRN.

3.6. Stage 6: Determine Actions to Eliminate or Reduce the Risk of the Failure Mode

Once the failure modes with the highest PRN have been analyzed, the team must determine what actions will help them reduce or eliminate the existing risk of a given failure mode, considering what the action entails. In some cases, the action may change a drawing or requirement; others may require a larger change, such as a redesign or material change. The team must also consider the consequences of cost or an impact on the product’s delivery date.

3.7. Stage 7: Determine the Number of Samples for the Design of Experiments and Analysis of Variance

During this stage, the design of experiments (DOE) method is initiated. Using the Minitab

® statistical tool, the number of product samples needed to perform an ANOVA and verify the requirements of the environmental tests is determined. In the Minitab tool, the calculation is performed using a 95% confidence interval (CI), which indicates the range in which the sample data are found. Additionally, another parameter to be used is a standard deviation equal to 3, based on the Six Sigma methodology [

62]. Finally, the power, which is the probability that the null hypothesis can be correctly rejected, should be considered. In this project, we will seek to use a power of 20%, 50%, and 80% [

63].

3.8. Stage 8: Perform a Pilot Run to Obtain Physical Samples of the Product

In this stage, the requirement is fulfilled to build the samples determined in Stage 7. The team working on the project generates a requisition to build a product (pilot run) for the manufacturing department. This requisition indicates the product to be built, its bill of materials (BOM), and the quantities of the finished product. Within the required quantities, the sample size to be used for the reliability tests and the verification of the environmental tests are estimated using Minitab®. The manufacturing engineer provides the time per part targets and the expected and acceptable scrap. The engineering team and the design quality engineer determine what criteria to evaluate from a design standpoint, both at the component and the finished product levels. This provides teamwork with the target to reach if the run was successful and the product can be used for verification testing. If the objectives are not met, the team must analyze the information obtained and determine what actions are needed to improve the product design to schedule another pilot run and have a high degree of confidence that the objectives will be met.

3.9. Stage 9: Initiate Reliability Tests

Once the samples have been estimated and constructed, they are delivered to the quality laboratory to start reliability tests. A requisition must be generated for these tests, indicating the quantities of samples to which environmental and cycling tests are performed and to which only cycling tests are performed.

The control factors are defined as follows:

A = reference group (sample measured before entering environmental testing and cycling).

B = post-environmental stress test group.

C = post-environmental stress and mechanical stress test group.

D = post-mechanical stress test group.

Group D is not subjected to the environmental test to determine if the environmental tests have a significant effect on the microphone torque of the product. Before starting the environmental tests, the strength of the tested component will be measured, as shown in the diagram in

Figure 1. This variable will help to determine if the environmental tests have any significant effect (out of specification) on the product.

3.10. Stage 10: Analyze the Results and Validate the Significance of the Environmental Test Based on the ANOVA

Once the tests are concluded, the data obtained are extracted, following the ANOVA methodology and the Minitab® tool. Only one factor will be considered, which, in this case, will be the environmental test; a one-factor ANOVA will be used. The data to be used are obtained by measuring the rotational force of the headset microphone, that is, the dynamic torque of the microphone with a motorized torque meter Mark-10. Ten data are measured over a range of 170°; from these, the average torque will be used to verify if the component is within specification. The data obtained from these measurements will be entered into the Minitab tool, where the ANOVA will be performed and the variance will be used to analyze the dispersion with a confidence level of 0.05. The confidence interval indicates the range in which the sample data are.

In ANOVA, the

p-value helps determine the difference between the sample means and thus can determine if the environmental testing has a significant effect on the microphone torque of the product. Since a 95% confidence interval (CI) is used,

p-values less than 0.05 indicate sufficient statistical evidence to conclude that environmental testing significantly affects the product microphone torque [

64].

3.11. Stage 11: Implement New Environmental Requirements

In this stage, the information obtained from Stage 10 is considered and an engineering change (ECO) is generated using Agile PLM® software, where the new environmental requirements and their implementation are indicated.

5. Result Discussions

As the number of defects and the average delivery time were reduced in the project of AAXXX compared with those occurring in the four previous projects, the sustainability was increased in several ways as follows:

Quality—since the number of defects is reduced, the quality is increased.

Economics—since the reduction in defects decreases the cost of production in the long term.

Environment—since defects are reduced, inorganic pollutants and waste discharged into the environment are also reduced.

Efficiency—the sustainability was increased since the delivery time was reduced and agreements with customers for the delivery date were fulfilled.

In the case of the quality dimension, this result is consistent with Braccini and Margherita [

66] because they found that reducing the defects rate increases quality and its economical dimension. Similarly, our findings agree with Goyal et al. [

20] that declares that a defect in a process/product can negatively impact sustainability in its quality, environment, and economic dimensions; so, the quality process can be determined based on the number of defects produced from a quantitative and qualitative point of view and their severity.

Regarding the environmental dimension, our findings converge with Erdil et al. [

67], who mention that environmental sustainability naturally aligns with improvement activities in good-producing industries such as manufacturing. Moreover, these authors point out that an increase in defects leads to an increase in rework, which causes a higher use of materials and energy. Regarding efficiency, the findings from this research agree with Nahmens and Ikuma [

68], who indicate that reducing or eliminating waste (including waiting time) in a manufacturing process helps to increase sustainability. Their report is based on case studies to show the effects of lean strategy (i.e., a strategy based on reducing wastes such as waiting times and defects) on each dimension of sustainability.

5.1. Theoretical Implications

The findings in this research contribute to theoretical knowledge in the following ways:

Statistical reliability testing reduces the number of defects, thus increasing the sustainability of manufacturing processes and products in an easy way because managers can obtain information from their own process.

Temperature and humidity can affect the quality in the product here investigated and, therefore, the sustainability, which is why managers must control these parameters.

Defect reduction significantly impacts the sustainability of manufacturing processes and products in the quality, environmental, and economic dimensions.

The reduction in lead times positively impacts the sustainability of processes, specifically in the efficiency dimension.

Figure 6 shows a model for these theoretical implications.

5.2. Practical Implications

The results of this study lead to the following practical implications, all of them based on the critical realism approach [

69]:

Regardless of their economical size, manufacturing companies should pay special attention to the defects in their products, not only in quantity but also in severity, to be sustainable companies.

Performing a statistical analysis of a product’s defects before its release to the market helps companies to define actions to prevent them once the product is already in the market. ANOVA, DOE, and FMEA are tools that help in this purpose.

Likewise, the results of this study imply that, to maintain or increase their sustainability, companies must adopt a lean manufacturing philosophy aimed at eliminating waste (defects and lead times). This implies adopting and applying tools and methodologies such as the Plan-Do-Check-Act cycle, work standardization, kaizen, and poka-yoke for continuous improvement, to mention a few.

To increase the sustainability of processes and products, companies must consider variables outside the knowledge and skills of workers, such as temperature and humidity, because they know the production process better.

7. Limitations, and Future Research

The limitations of this project were the time available and the necessary human resources since some workers were not specifically assigned to the project and only contributed their knowledge when they had time. Another limitation was access to products and process-related information, as only authorized personnel could access it. Finally, a fourth limitation was the sample size. This was due to financial resource constraints on the part of the company.

For future work, it is recommended that the company review other processes (including projects) and products and perform reliability tests to find improvement opportunities in the first instance and to improve sustainability in the second. Additionally, it is recommended to include the social dimension in future reliability tests.

In future research, it is recommended to perform a more general study about the impact of reliability tests, delivery times, and defects on the different dimensions of sustainability. To perform this, developing different hypothetical causal models and collecting data from different manufacturing companies is suggested. Moreover, it is recommended to increase the sample size.

Finally, designing a framework of reference for sustainability development in manufacturing companies is recommended. To perform this, it is suggested to use indicators that allow continuous evaluations and comparisons of recorded performance.