Free and Forced Vibration Analysis of Two-Dimensional Linear Elastic Solids Using the Finite Element Methods Enriched by Interpolation Cover Functions

Abstract

:1. Introduction

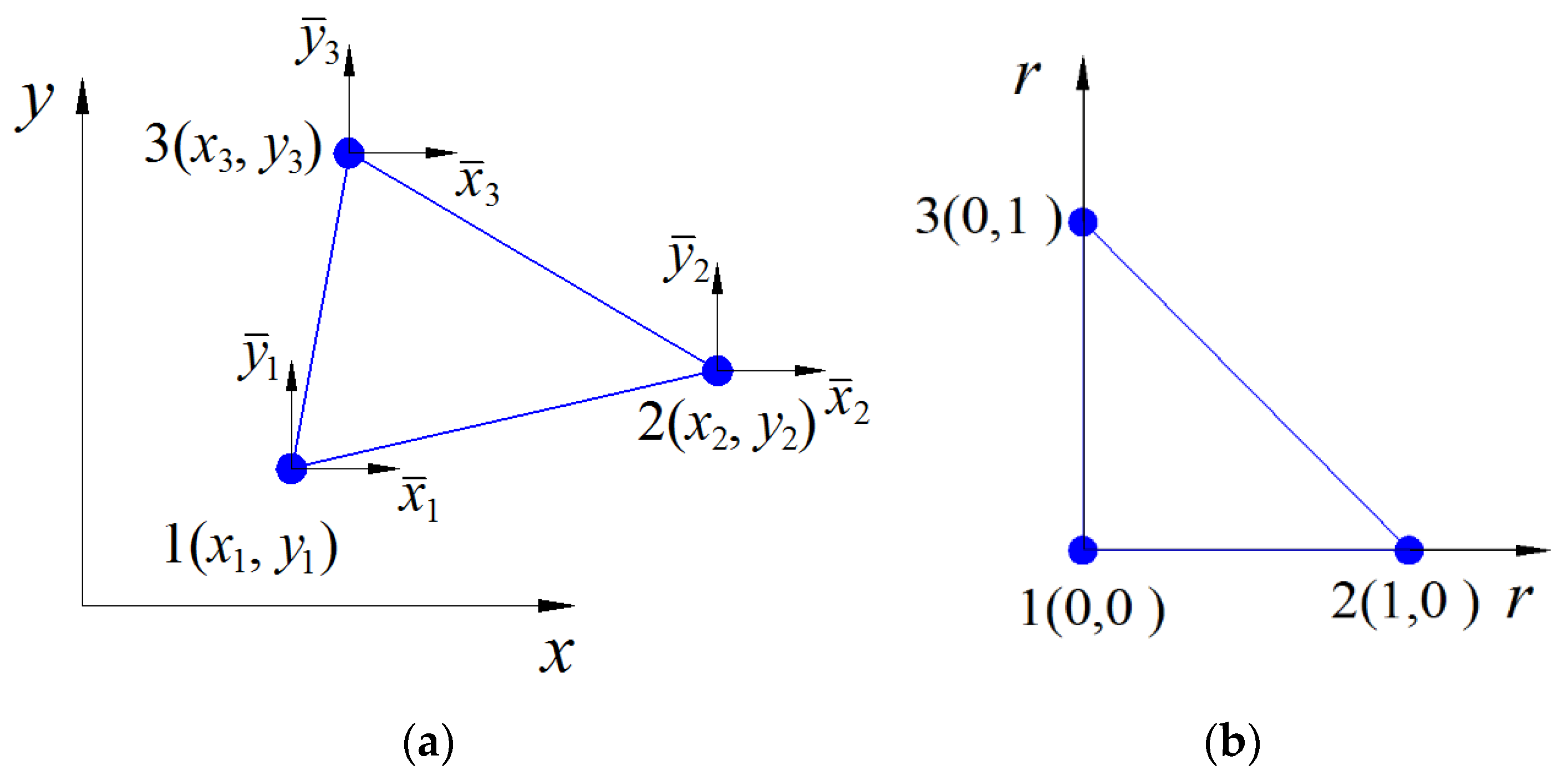

2. Formulation of the FEM Enriched by Interpolation Cover Functions

3. Governing Equations of Dynamics for Linear Elastic Solids

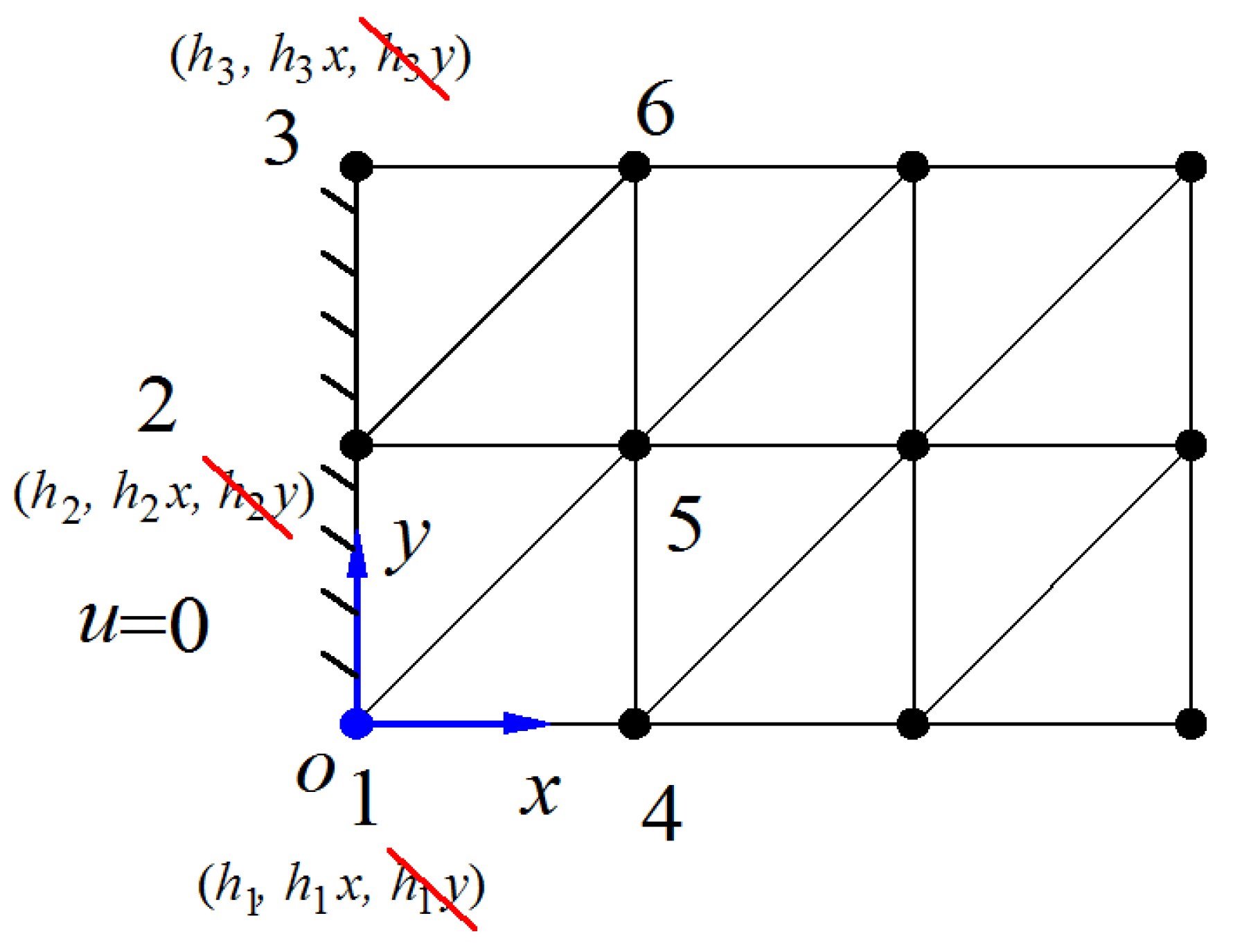

4. The Linear Dependence Issue

5. Imposition of the Dirichlet Boundary Condition

6. Numerical Results

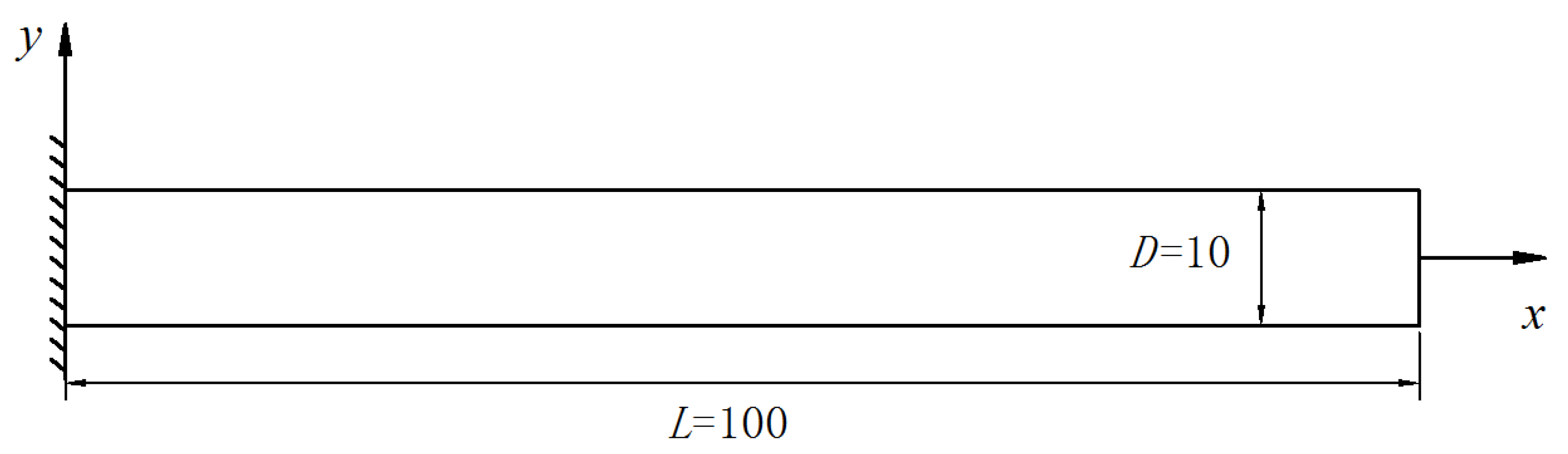

6.1. Free Vibration Analysis of a Cantilever Beam

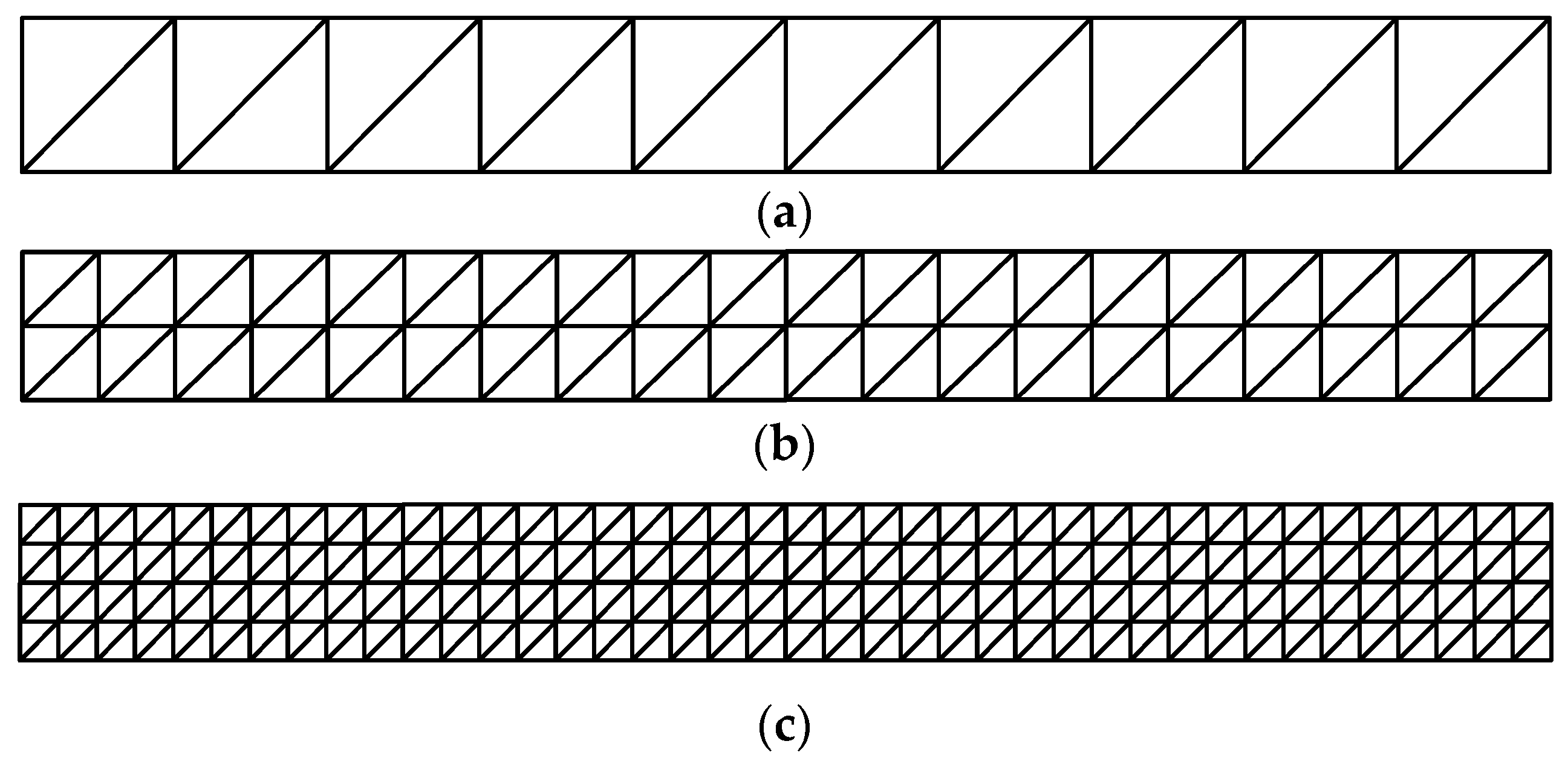

6.1.1. Computation Accuracy Study

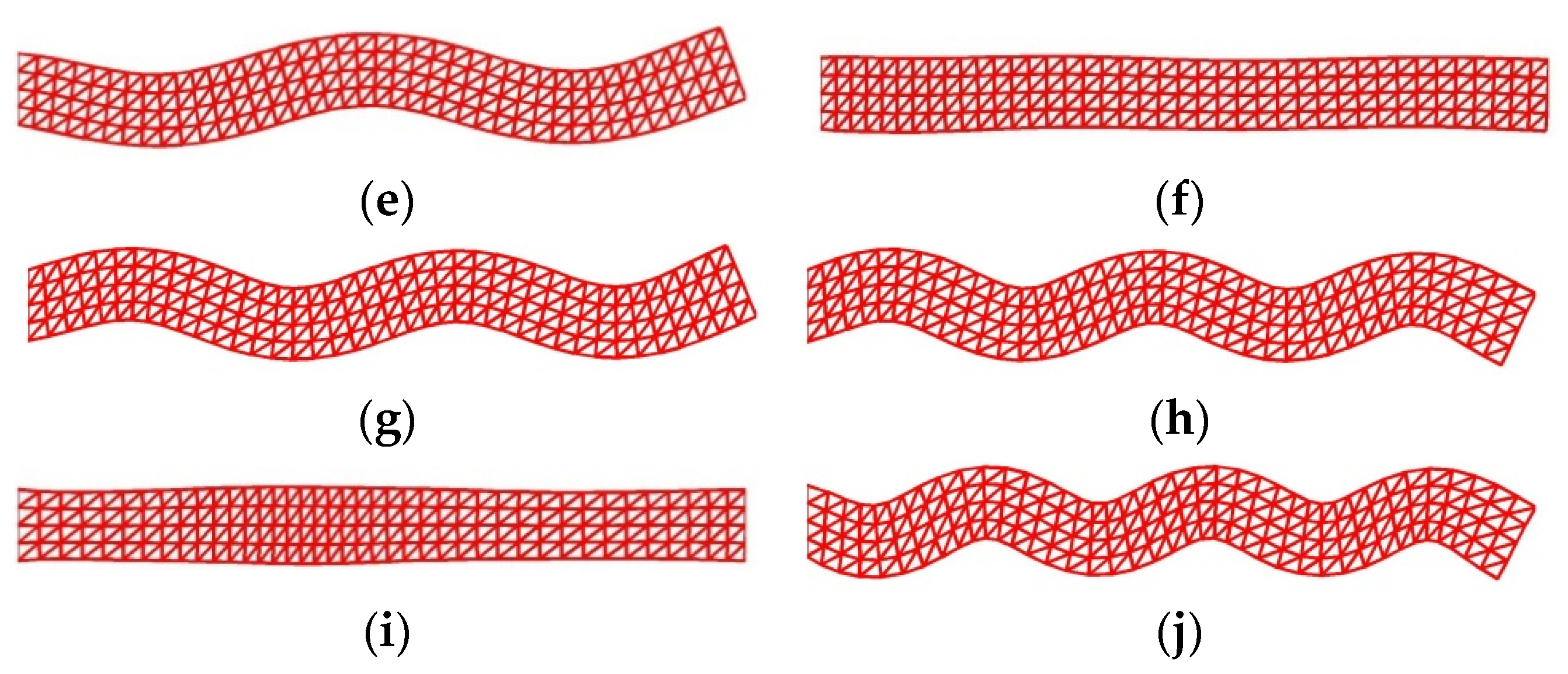

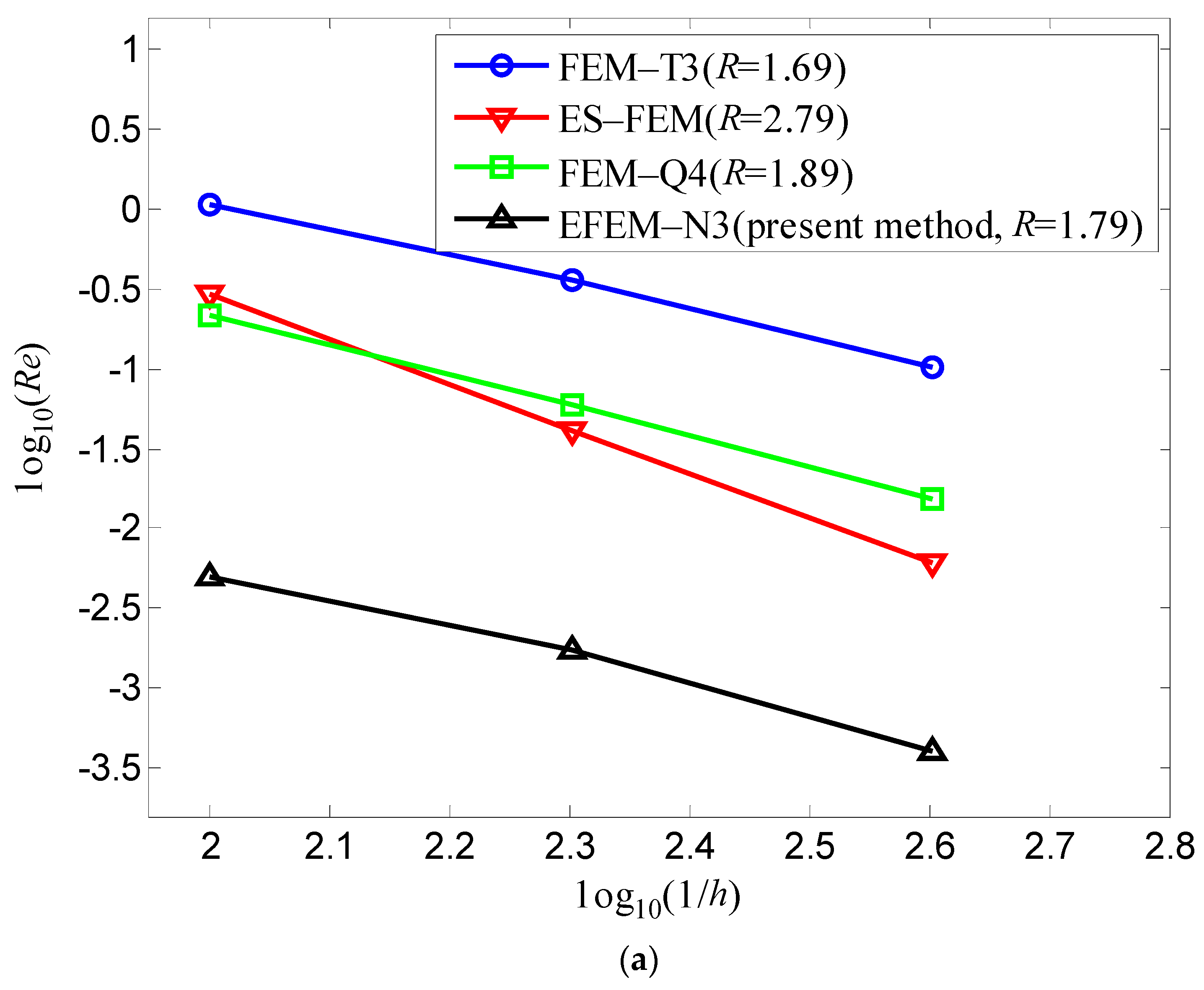

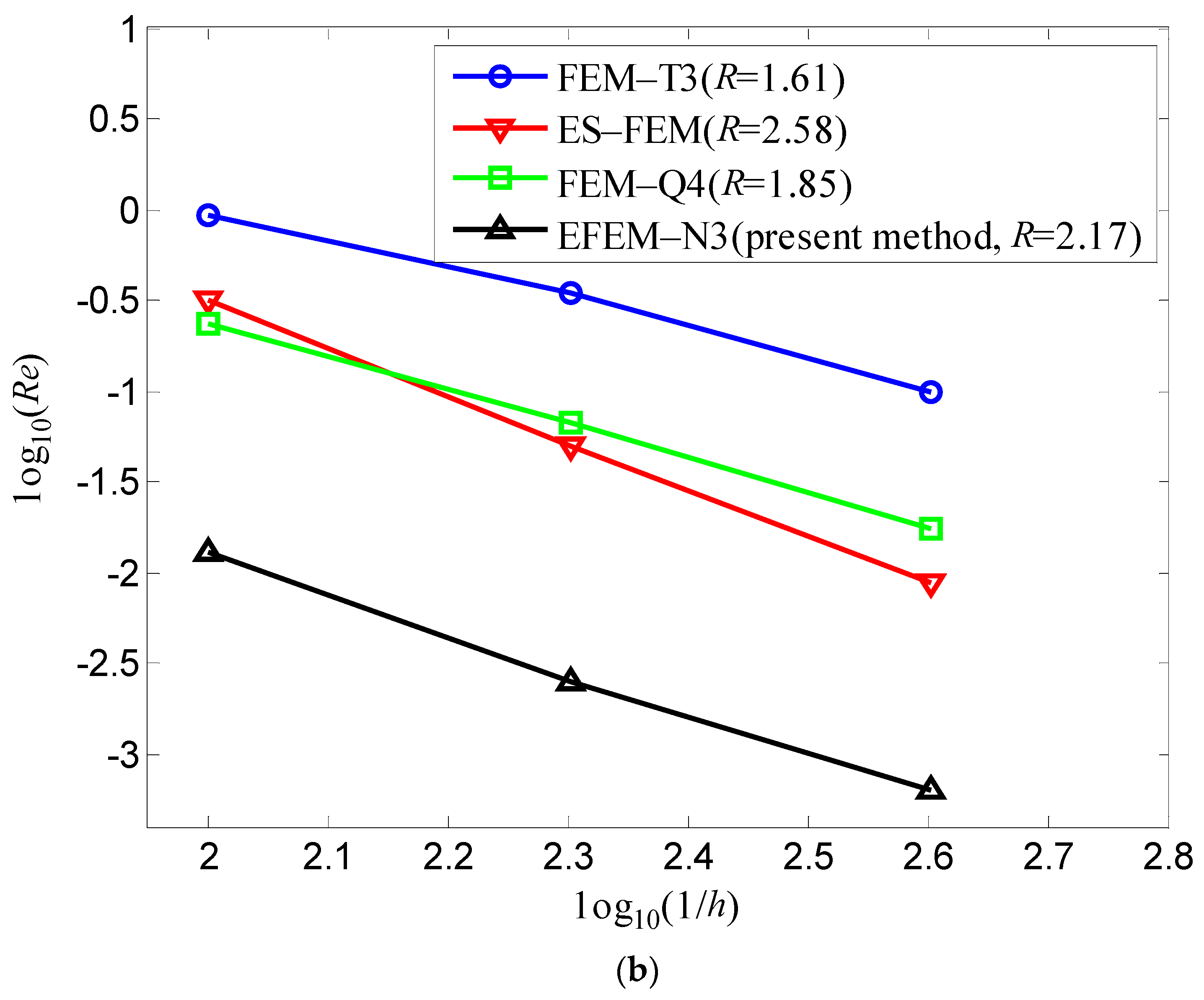

6.1.2. Convergence Study

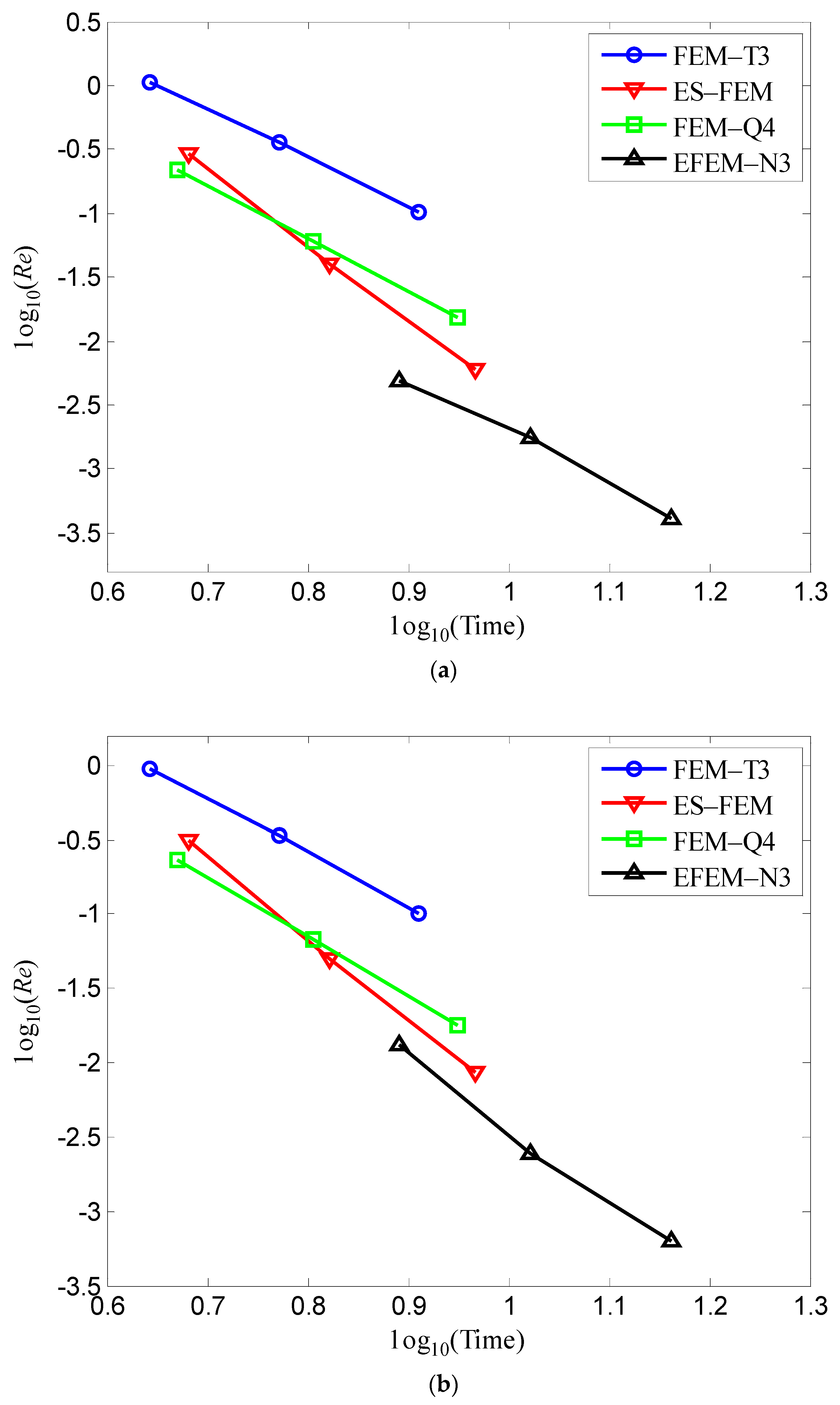

6.1.3. Computation Efficiency Study

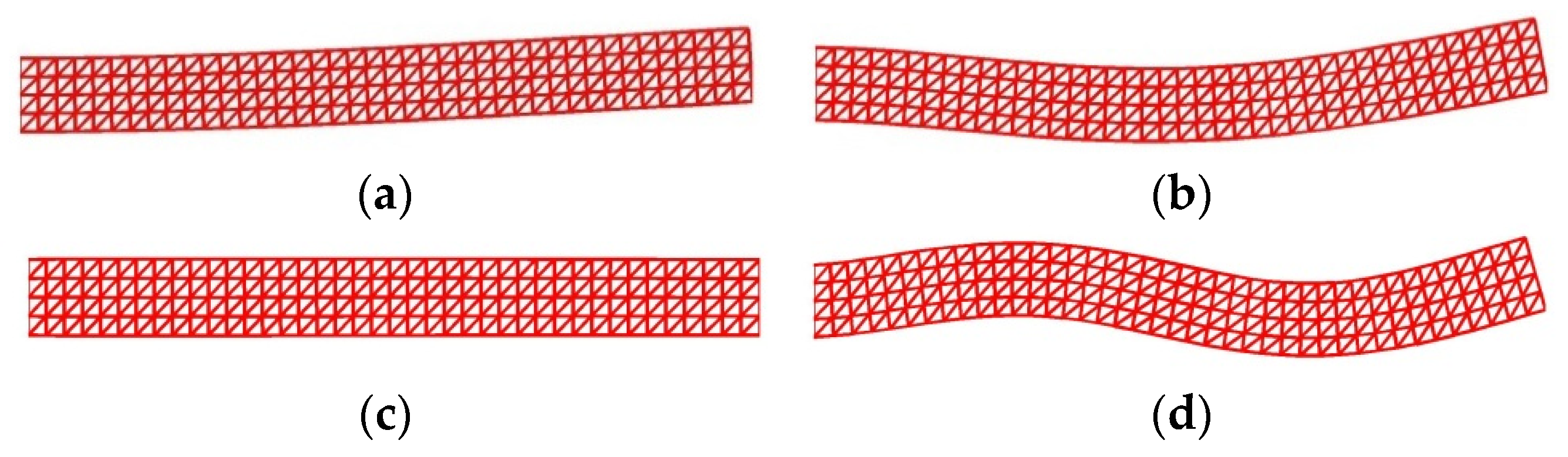

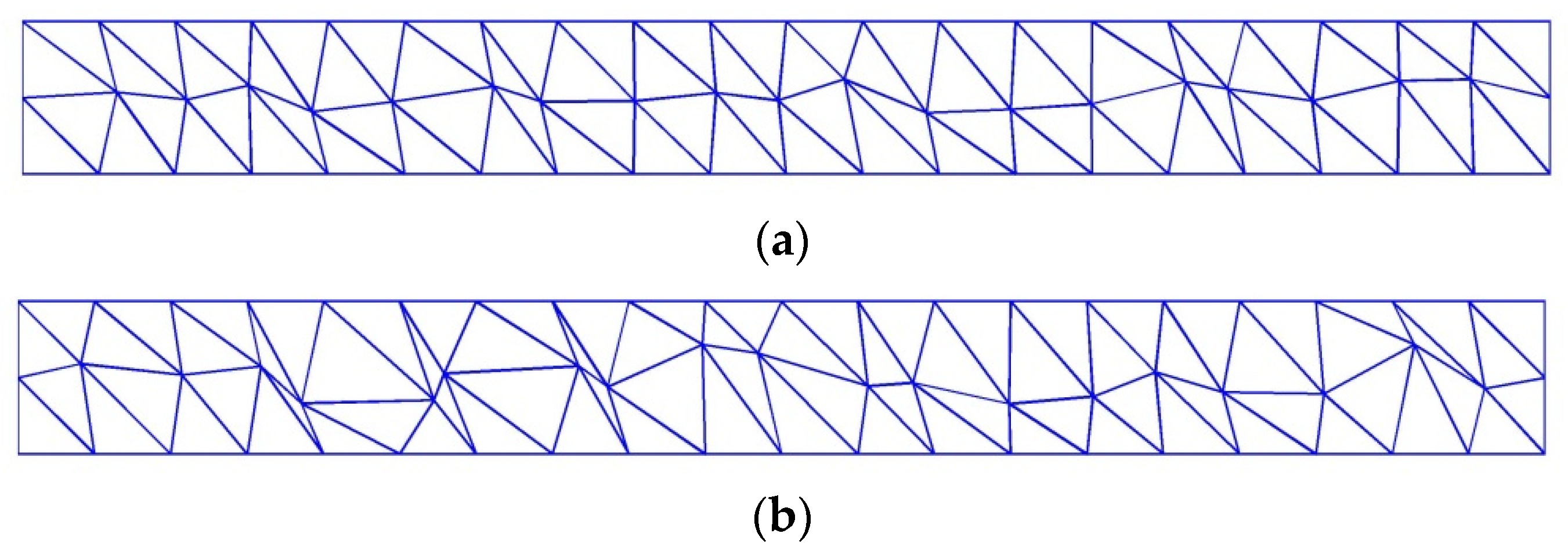

6.1.4. Effects of Mesh Distortion

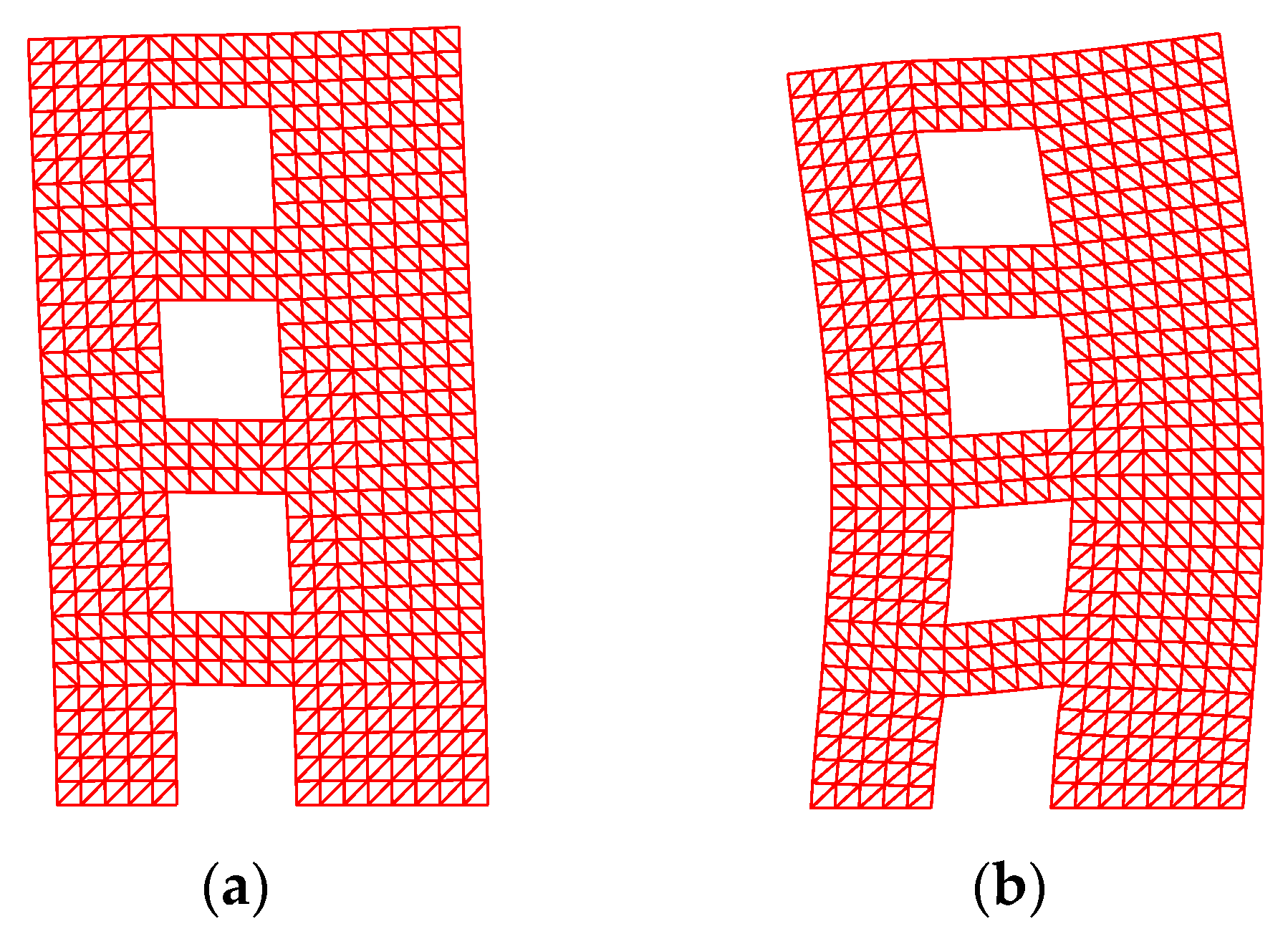

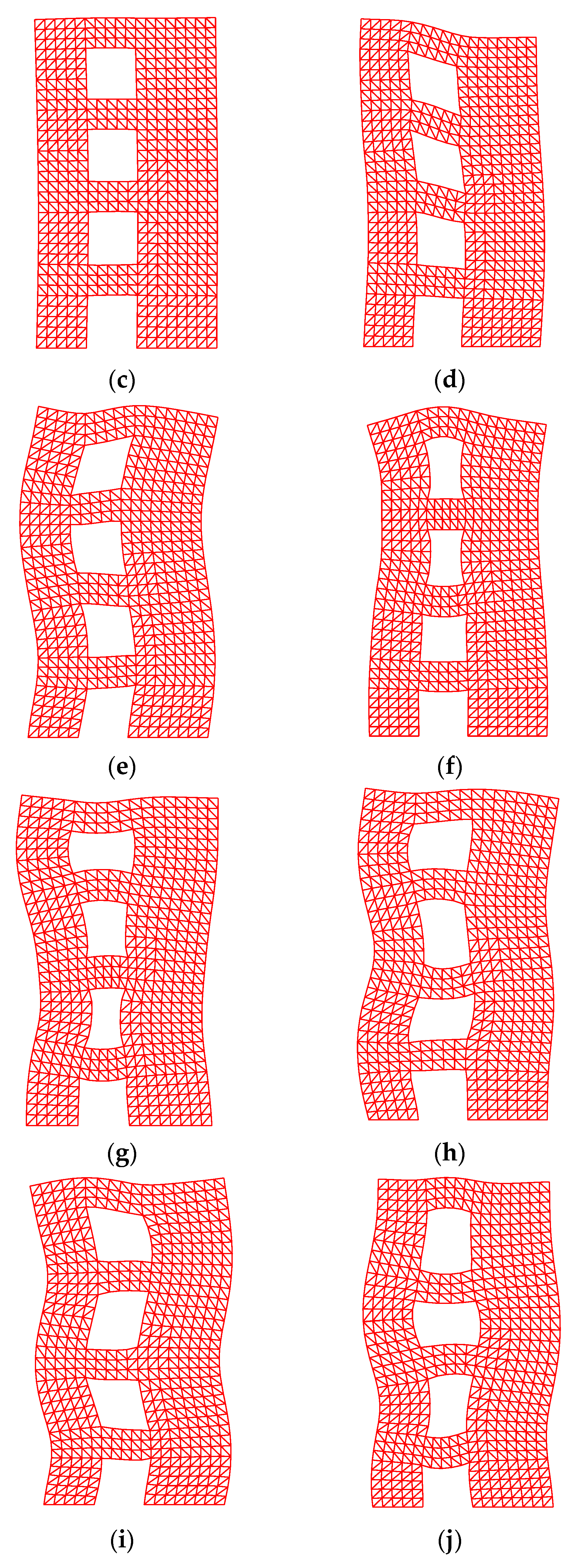

6.2. Free Vibration Analysis of a Shear Wall

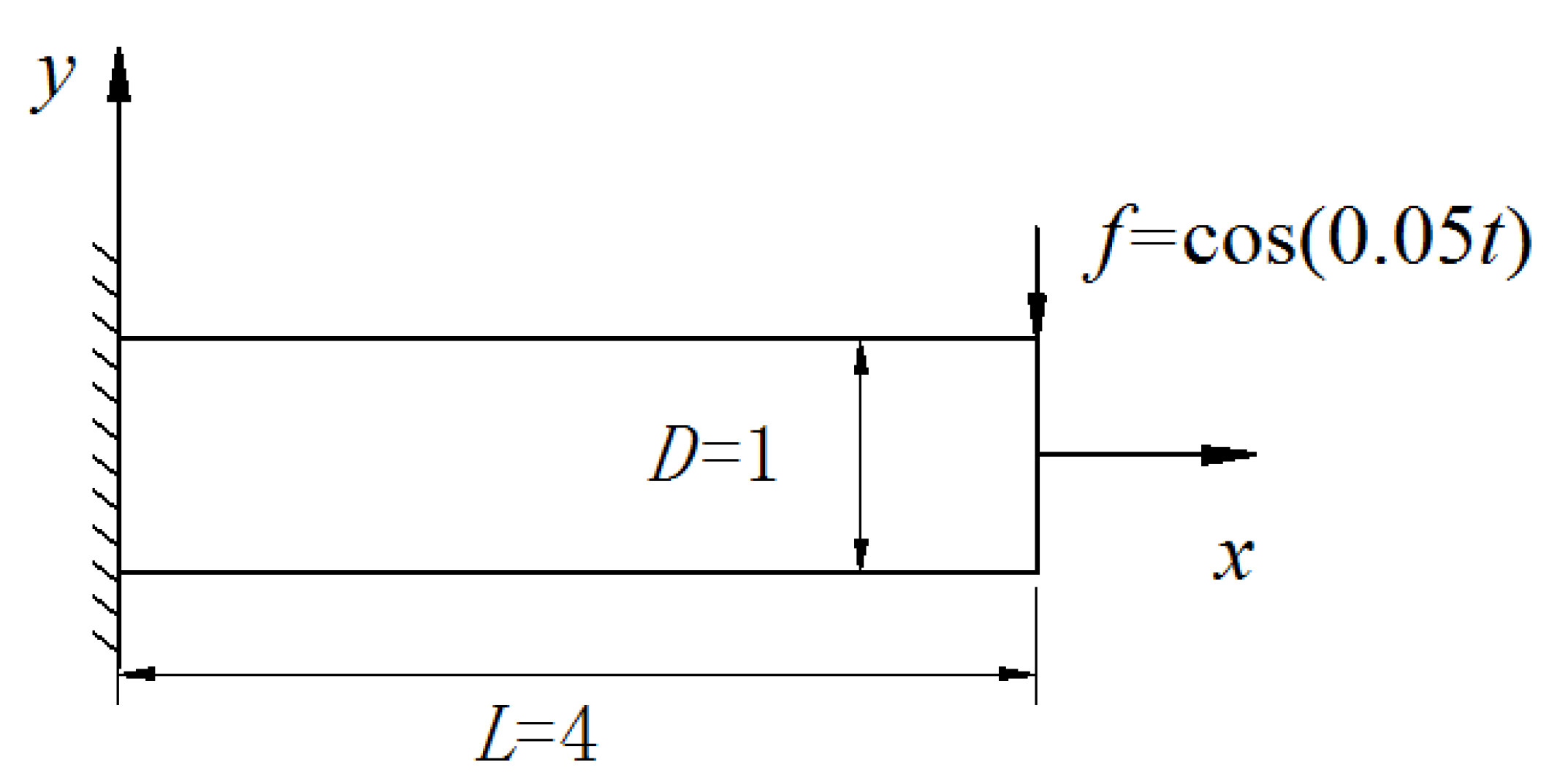

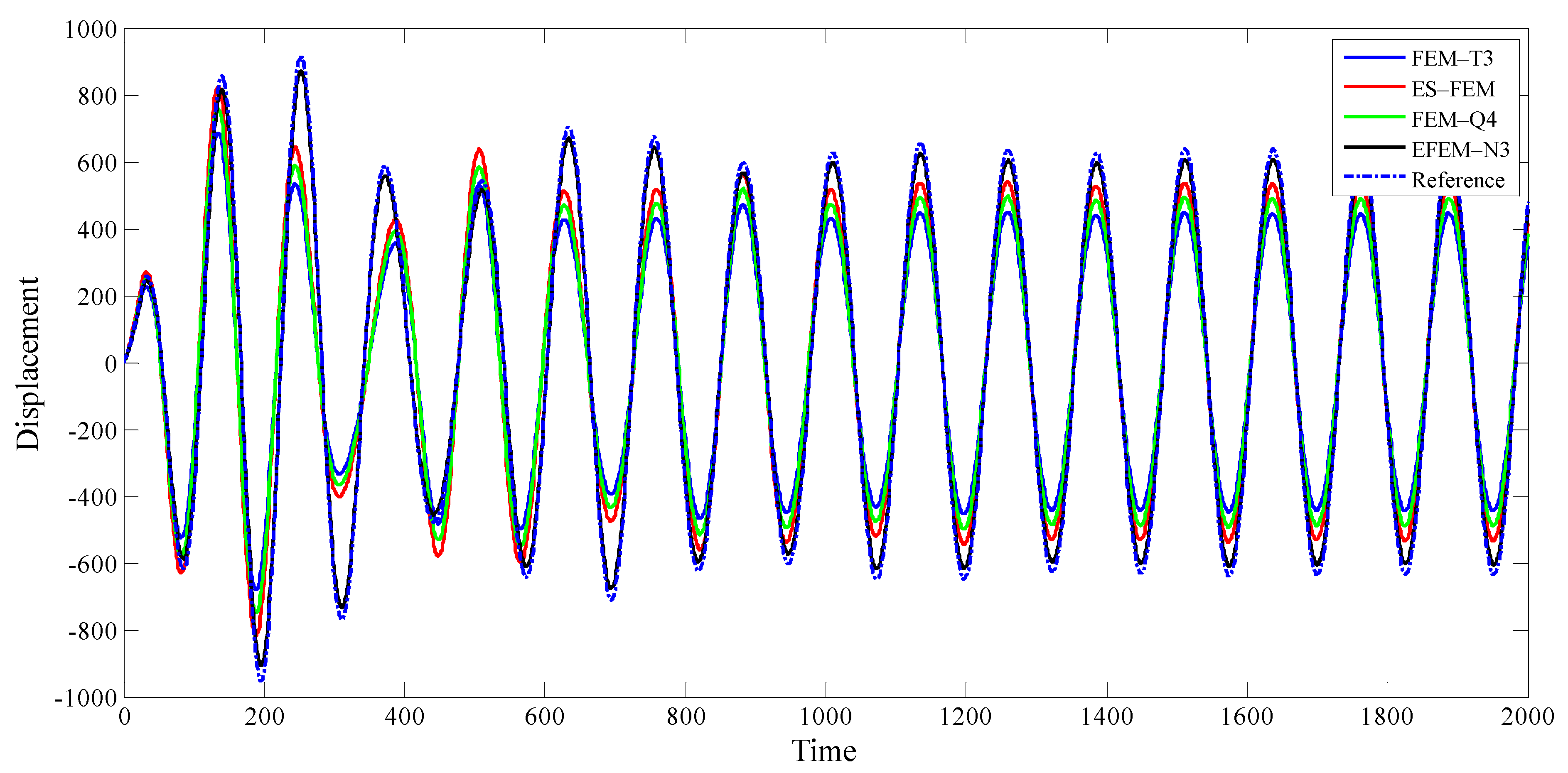

6.3. Forced Vibration Analysis of a Cantilever Beam

7. Conclusions

- (a)

- By employing the proposed scheme in addressing the LD problem in the EFEM-N3, the potential LD issue can be completely removed and then the totally symmetric positive-definite system can be achieved, hence very stable numerical solutions can then be generated.

- (b)

- Compared to the conventional FEM, the proposed EFEM-N3 in this work behaves much better in convergence rate and computation accuracy, and much more natural frequency results and force response results can be obtained, this is because the initial linear approximation space used in the conventional FEM is effectively enhanced by using the constructed interpolation cover functions.

- (c)

- Although no extra nodes are needed in the present EFEM-N3 compared to the high order standard elements, more nodal unknowns are involved and larger size system matrices are always obtained, hence the present EFEM-N3 is clearly more numerically expensive. Nevertheless, the present EFEM-N3 still possesses higher computation efficiency in the solution of free and forced vibration analysis.

- (d)

- The proposed EFEM-N3 is also less sensitive to the mesh distortion than the other conventional elements and quite reliable numerical results can still be produced even if very distorted meshes are employed. Therefore, the present method is very suitable for different areas of engineering applications with complex geometries because the mesh distortion cannot be completely avoided in these cases.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zienkiewicz, O.C.; Taylor, R.L. The Finite Element Method, 5th ed.; Butterworth-Heinemann: Oxford, UK, 2000. [Google Scholar]

- Bathe, K.J. Finite Element Procedures, 2nd ed.; Prentice Hall: Watertown, MA, USA, 2014. [Google Scholar]

- Chai, Y.B.; Li, W.; Liu, G.R.; Gong, Z.X.; Li, T.Y. A superconvergent alpha finite element method (SαFEM) for static and free vibration analysis of shell structures. Comput. Struct. 2017, 179, 27–47. [Google Scholar] [CrossRef]

- Chopra, M.B.; Dargush, G.F. Finite-element analysis of time-dependent large-deformation problems. Int. J. Numer. Methods Eng. 1992, 16, 101–130. [Google Scholar] [CrossRef]

- Moresi, L.; Dufour, F.; Mühlhaus, H.B. A Lagrangian integration point finite element method for large deformation modeling of viscoelastic geomaterials. J. Comput. Phys. 2003, 184, 476–497. [Google Scholar] [CrossRef] [Green Version]

- Liu, G.R. Mesh Free Methods: Moving Beyond the Finite Element Method; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Belytschko, T.; Lu, Y.Y.; Gu, L. Element-free Galerkin methods. Int. J. Numer. Methods Eng. 1994, 37, 229–256. [Google Scholar] [CrossRef]

- Chen, J.S.; Hillman, M.; Chi, S.W. Meshfree methods: Progress made after 20 years. J. Eng. Mech. 2017, 143, 04017001. [Google Scholar] [CrossRef] [Green Version]

- You, X.Y.; Li, W.; Chai, Y.B. A truly meshfree method for solving acoustic problems using local weak form and radial basis functions. Appl. Math. Comput. 2020, 365, 124694. [Google Scholar] [CrossRef]

- Liu, C.S.; Qiu, L.; Lin, J. Simulating thin plate bending problems by a family of two-parameter homogenization functions. Appl. Math. Model. 2020, 79, 284–299. [Google Scholar] [CrossRef]

- Li, W.; Zhang, Q.; Gui, Q.; Chai, Y.B. A coupled FE-Meshfree triangular element for acoustic radiation problems. Int. J. Comput. Methods 2021, 18, 2041002. [Google Scholar] [CrossRef]

- Lin, J.; Zhang, Y.H.; Reutskiy, S.; Feng, W. A novel meshless space-time backward substitution method and its application to nonhomogeneous advection-diffusion problems. Appl. Math. Comput. 2021, 398, 125964. [Google Scholar] [CrossRef]

- Chai, Y.B.; You, X.Y.; Li, W. Dispersion Reduction for the Wave Propagation Problems Using a Coupled “FE-Meshfree” Triangular Element. Int. J. Comput. Methods 2020, 17, 1950071. [Google Scholar] [CrossRef]

- Lin, J.; Feng, W.; Reutskiy, S.; Xu, H.; He, Y. A semi-analytical method for solving a class of time fractional partial differential equations with variable coefficients. Appl. Math. Lett. 2021, 112, 106712. [Google Scholar] [CrossRef]

- Qiu, L.; Lin, J.; Wang, F.J.; Qin, Q.H.; Liu, C.S. A homogenization function method for inverse heat source problems in 3D functionally graded materials. Appl. Math. Model. 2021, 91, 923–933. [Google Scholar] [CrossRef]

- Wu, T.W. Boundary Element Acoustics: Fundamentals and Computer Codes; WIT Press: Southampton, UK, 2000. [Google Scholar]

- Gu, Y.; Lei, J. Fracture mechanics analysis of two-dimensional cracked thin structures (from micro- to nano-scales) by an efficient boundary element analysis. Results Math. 2021, 11, 100172. [Google Scholar] [CrossRef]

- Wang, F.; Fan, C.M.; Zhang, C.; Lin, J. A localized space-time method of fundamental solutions for diffusion and convection-diffusion problems. Adv. Appl. Math. Mech. 2020, 12, 940–958. [Google Scholar] [CrossRef]

- Li, J.P.; Gu, Y.; Qin, Q.H.; Zhang, L. The rapid assessment for three-dimensional potential model of large-scale particle system by a modified multilevel fast multipole algorithm. Comput. Math. Appl. 2021, 89, 127–138. [Google Scholar] [CrossRef]

- Li, J.P.; Fu, Z.J.; Gu, Y.; Qin, Q.H. Recent advances and emerging applications of the singular boundary method for large-scale and high-frequency computational acoustics. Adv. Appl. Math. Mech. 2021, 14, 315–343. [Google Scholar] [CrossRef]

- Fu, Z.J.; Chen, W.; Wen, P.H.; Zhang, C.Z. Singular boundary method for wave propagation analysis in periodic structures. J. Sound Vib. 2018, 425, 170–188. [Google Scholar] [CrossRef]

- Fu, Z.J.; Xi, Q.; Li, Y.; Huang, H.; Rabczuk, T. Hybrid FEM–SBM solver for structural vibration induced underwater acoustic radiation in shallow marine environment. Comput. Methods Appl. Mech. Eng. 2020, 369, 113236. [Google Scholar] [CrossRef]

- Li, J.P.; Zhang, L. High-precision calculation of electromagnetic scattering by the Burton-Miller type regularized method of moments. Eng. Anal. Bound. Elem. 2021, 133, 177–184. [Google Scholar] [CrossRef]

- Li, J.P.; Zhang, L.; Qin, Q.H. A regularized method of moments for three-dimensional time-harmonic electromagnetic scattering. Appl. Math. Lett. 2021, 112, 106746. [Google Scholar] [CrossRef]

- Gu, Y.; Fan, C.M.; Fu, Z.J. Localized method of fundamental solutions for three-dimensional elasticity problems: Theory. Adv. Appl. Math. Mech. 2021, 13, 1520–1534. [Google Scholar]

- Liu, W.K.; Jun, S.; Zhang, Y.F. Reproducing kernel particle methods. Int. J. Numer. Methods Fluids 1995, 20, 1081–1106. [Google Scholar] [CrossRef]

- Nayroles, B.; Touzot, G.; Villon, P. Generalizing the finite element method: Diffuse approximation and diffuse elements. Comput. Mech. 1992, 10, 307–318. [Google Scholar] [CrossRef]

- Li, X.; Li, S. A fast element-free Galerkin method for the fractional diffusion-wave equation. App. Math. Lett. 2021, 122, 107529. [Google Scholar] [CrossRef]

- Li, X.; Li, S. A linearized element-free Galerkin method for the complex Ginzburg-Landau equation. Compu. Math. Appl. 2021, 90, 135–147. [Google Scholar] [CrossRef]

- Harari, I.; Hughes, T.J.R. Galerkin/least-squares finite element methods for the reduced wave equation with non-reflecting boundary conditions in unbounded domains. Comput. Methods Appl. Mech. Eng. 1992, 98, 411–454. [Google Scholar] [CrossRef]

- Xu, Y.Y.; Zhang, G.Y.; Zhou, B.; Wang, H.Y.; Tang, Q. Analysis of acoustic radiation problems using the cell-based smoothed radial point interpolation method with Dirichlet-to-Neumann boundary condition. Eng. Anal. Bound. Elem. 2019, 108, 447–458. [Google Scholar] [CrossRef]

- Qu, W.Z.; He, H. A GFDM with supplementary nodes for thin elastic plate bending analysis under dynamic loading. Appl. Math. Lett. 2022, 124, 107664. [Google Scholar] [CrossRef]

- Qu, W.Z.; Gao, H.W.; Gu, Y. Integrating Krylov deferred correction and generalized finite difference methods for dynamic simulations of wave propagation phenomena in long-time intervals. Adv. Appl. Math. Mech. 2021, 13, 1398–1417. [Google Scholar]

- Fu, Z.J.; Xie, Z.Y.; Ji, S.Y.; Tsai, C.C.; Li, A.L. Meshless generalized finite difference method for water wave interactions with multiple-bottom-seated-cylinder-array structures. Ocean Eng. 2020, 195, 106736. [Google Scholar] [CrossRef]

- Oñate, E.; Perazzo, F.; Miquel, J. A finite point method for elasticity problems. Comput. Struct. 2001, 79, 2151–2163. [Google Scholar] [CrossRef]

- Li, X.; Li, S. A finite point method for the fractional cable equation using meshless smoothed gradients. Eng. Anal. Bound. Elem. 2022, 134, 453–465. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, Q.; Chen, Z.; Fan, C.M. Localized Chebyshev collocation method for solving elliptic partial differential equations in arbitrary 2D domains. Appl. Math. Comput. 2021, 397, 125903. [Google Scholar] [CrossRef]

- Xi, Q.; Fu, Z.J.; Zhang, C.Z.; Yin, D.S. An efficient localized Trefftz-based collocation scheme for heat conduction analysis in two kinds of heterogeneous materials under temperature loading. Comput. Struct. 2021, 255, 106619. [Google Scholar] [CrossRef]

- Xi, Q.; Fu, Z.J.; Wu, W.J.; Wang, H.; Wang, Y. A novel localized collocation solver based on Trefftz basis for Potential-based Inverse Electromyography. Appl. Math. Comput. 2021, 390, 125604. [Google Scholar] [CrossRef]

- Wang, F.; Wang, C.; Chen, Z.T. Local knot method for 2D and 3D convectiondiffusion-reaction equations in arbitrary domains. Appl. Math. Lett. 2020, 105, 106308. [Google Scholar] [CrossRef]

- Zeng, W.; Liu, G.R. Smoothed finite element methods (S-FEM): An overview and recent developments. Arch. Comput. Method Eng. 2018, 25, 397–435. [Google Scholar] [CrossRef]

- Chai, Y.B.; Li, W.; Lei, M.; Liu, G.R. Analysis of coupled structural-acoustic problems based on the smoothed finite element method (S-FEM). Eng. Anal. Bound. Elem. 2014, 42, 84–91. [Google Scholar]

- Li, W.; Gong, Z.X.; Chai, Y.B.; Cheng, C.; Li, T.Y.; Zhang, Q.F.; Wang, M.S. Hybrid gradient smoothing technique with discrete shear gap method for shell structures. Comput. Math. Appl. 2017, 74, 1826–1855. [Google Scholar] [CrossRef]

- Chai, Y.B.; Li, W.; Gong, Z.X.; Li, T.Y. Hybrid smoothed finite element method for two dimensional acoustic radiation problems. Appl. Acoust. 2016, 103, 90–101. [Google Scholar] [CrossRef]

- Chai, Y.B.; Gong, Z.X.; Li, W.; Li, T.Y.; Zhang, Q.F. A smoothed finite element method for exterior Helmholtz equation in two dimensions. Eng. Anal. Bound. Elem. 2017, 84, 237–252. [Google Scholar] [CrossRef]

- Chai, Y.B.; Li, W.; Gong, Z.X.; Li, T.Y. Hybrid smoothed finite element method for two-dimensional underwater acoustic scattering problems. Ocean Eng. 2016, 116, 129–141. [Google Scholar] [CrossRef]

- Chai, Y.B.; Gong, Z.X.; Li, W.; Li, T.Y.; Zhang, Q.F.; Zou, Z.H.; Sun, Y.B. Application of smoothed finite element method to two-dimensional exterior problems of acoustic radiation. Int. J. Comput. Methods 2018, 15, 1850029. [Google Scholar] [CrossRef]

- Jiang, C.; Zhang, Z.Q.; Gao, G.J.; Liu, G.R. A modified immersed smoothed FEM with local field reconstruction for fluid–structure interactions. Eng. Anal. Bound. Elem. 2019, 107, 218–232. [Google Scholar] [CrossRef]

- Liu, M.Y.; Gao, G.J.; Zhu, H.F.; Jiang, C.; Liu, G.R. A cell-based smoothed finite element method (CS-FEM) for three-dimensional incompressible laminar flows using mixed wedge-hexahedral element. Eng. Anal. Bound. Elem. 2021, 133, 269–285. [Google Scholar] [CrossRef]

- Chai, Y.B.; You, X.Y.; Li, W.; Huang, Y.; Yue, Z.J.; Wang, M.S. Application of the edge-based gradient smoothing technique to acoustic radiation and acoustic scattering from rigid and elastic structures in two dimensions. Comput. Struct. 2018, 203, 43–58. [Google Scholar] [CrossRef]

- Li, W.; Chai, Y.B.; Lei, M.; Li, T.Y. Numerical investigation of the edge-based gradient smoothing technique for exterior Helmholtz equation in two dimensions. Comput. Struct. 2017, 182, 149–164. [Google Scholar] [CrossRef]

- Liu, G.R.; Nguyen-Thoi, T.; Nguyen-Xuan, H.; Lam, K.Y. A node-based smoothed finite element method (NS-FEM) for upper bound solutions to solid mechanics problems. Comput. Struct. 2009, 87, 14–26. [Google Scholar] [CrossRef]

- Chai, Y.B.; Li, W.; Li, T.Y.; Gong, Z.X.; You, X.Y. Analysis of underwater acoustic scattering problems using stable node-based smoothed finite element method. Eng. Anal. Bound. Elem. 2016, 72, 27–41. [Google Scholar] [CrossRef]

- Ham, S.; Bathe, K.J. A finite element method enriched for wave propagation problems. Comput. Struct. 2012, 94, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Chai, Y.B.; Bathe, K.J. Transient wave propagation in inhomogeneous media with enriched overlapping triangular elements. Comput. Struct. 2020, 237, 106273. [Google Scholar] [CrossRef]

- Kim, J.; Bathe, K.J. The finite element method enriched by interpolation covers. Comput. Struct. 2013, 116, 35–49. [Google Scholar] [CrossRef]

- Kim, J.; Bathe, K.J. Towards a procedure to automatically improve finite element solutions by interpolation covers. Comput. Struct. 2014, 131, 81–97. [Google Scholar] [CrossRef]

- Chai, Y.B.; Li, W.; Liu, Z.Y. Analysis of transient wave propagation dynamics using the enriched finite element method with interpolation cover functions. Appl. Math. Comput. 2022, 412, 126564. [Google Scholar] [CrossRef]

- Gui, Q.; Zhou, Y.; Li, W.; Chai, Y.B. Analysis of two-dimensional acoustic radiation problems using the finite element with cover functions. Appl. Acoust. 2022, 185, 108408. [Google Scholar] [CrossRef]

- Wu, F.; Zhou, G.; Gu, Q.Y.; Chai, Y.B. An enriched finite element method with interpolation cover functions for acoustic analysis in high frequencies. Eng. Anal. Bound. Elem. 2021, 129, 67–81. [Google Scholar] [CrossRef]

- Jeon, H.M.; Lee, P.S.; Bathe, K.J. The MITC3 shell finite element enriched by interpolation covers. Comput. Struct. 2014, 134, 128–142. [Google Scholar] [CrossRef]

- Jun, H.; Yoon, K.; Lee, P.S.; Bathe, K.J. The MITC3+ shell element enriched in membrane displacements by interpolation covers. Comput. Methods Appl. Mech. Eng. 2018, 337, 58–80. [Google Scholar] [CrossRef]

- Liu, G.R.; Gu, Y.T. A local radial point interpolation method (LRPIM) for free vibration analyses of 2-D solids. J. Sound Vib. 2001, 246, 29–46. [Google Scholar] [CrossRef] [Green Version]

- Dai, K.Y.; Liu, G.R. Free and forced vibration analysis using the smoothed finite element method (SFEM). J. Sound Vib. 2007, 301, 803–820. [Google Scholar] [CrossRef]

| Mode | FEM-T3 | FEM-Q4 | ES-FEM | EFEM-N3 | Reference |

|---|---|---|---|---|---|

| 1 | 1704.07 | 999.94 | 1060.41 | 826.44 | 822.41 |

| 2 | 9550.05 | 6077.08 | 6486.92 | 4997.09 | 4932.71 |

| 3 | 12,898.51 | 12,863.12 | 12,879.18 | 12,833.79 | 12,823.96 |

| 4 | 23,636.40 | 16,422.55 | 17,676.71 | 13,310.92 | 12,993.08 |

| 5 | 38,878.90 | 30,961.53 | 33,611.81 | 24,522.67 | 23,611.65 |

| 6 | 40,960.87 | 38,921.06 | 39,070.31 | 37,946.19 | 36,009.93 |

| 7 | 60,074.90 | 49,338.69 | 54,156.41 | 38,482.34 | 38,443.95 |

| 8 | 66,226.33 | 65,982.06 | 66,621.04 | 53,047.17 | 49,578.22 |

| 9 | 81,228.50 | 71,244.04 | 79,745.90 | 64,058.56 | 63,912.57 |

| 10 | 94,589.79 | 94,728.11 | 96,638.13 | 69,457.19 | 63,974.64 |

| Mode | FEM-T3 | FEM-Q4 | ES-FEM | EFEM-N3 | Reference |

|---|---|---|---|---|---|

| 1 | 1119.29 | 871.76 | 855.74 | 823.84 | 822.41 |

| 2 | 6617.08 | 5263.48 | 5180.43 | 4944.89 | 4932.71 |

| 3 | 12,849.69 | 12,837.12 | 12,840.31 | 12,827.62 | 12,823.96 |

| 4 | 17,162.01 | 14,010.46 | 13,829.41 | 13,038.27 | 12,993.08 |

| 5 | 30,745.07 | 25,816.34 | 25,565.29 | 23,729.46 | 23,611.65 |

| 6 | 38,620.23 | 38,573.48 | 38,608.10 | 36,259.33 | 36,009.93 |

| 7 | 46,401.47 | 40,002.13 | 39,764.95 | 38,455.45 | 38,443.95 |

| 8 | 63,385.94 | 56,042.63 | 55,964.71 | 50,037.34 | 49,578.22 |

| 9 | 64,681.80 | 64,493.66 | 64,650.99 | 63,995.63 | 63,912.57 |

| 10 | 81,520.49 | 73,610.95 | 73,943.12 | 64,678.33 | 63,974.64 |

| Mode | FEM-T3 | FEM-Q4 | ES-FEM | EFEM-N3 | Reference |

|---|---|---|---|---|---|

| 1 | 906.83 | 835.16 | 827.37 | 822.74 | 822.41 |

| 2 | 5425.61 | 5019.96 | 4975.61 | 4935.85 | 4932.71 |

| 3 | 12,833.24 | 12,828.32 | 12,828.93 | 12,825.28 | 12,823.96 |

| 4 | 14,254.61 | 13,263.55 | 13,150.15 | 13,002.27 | 12,993.08 |

| 5 | 25,852.78 | 24,200.63 | 23,997.99 | 23,631.32 | 23,611.65 |

| 6 | 38,493.15 | 37,078.50 | 36,775.32 | 36,045.90 | 36,009.93 |

| 7 | 39,398.63 | 38,479.58 | 38,488.49 | 38,447.96 | 38,443.95 |

| 8 | 54,244.91 | 51,308.85 | 50,906.49 | 49,637.97 | 49,578.22 |

| 9 | 64,160.33 | 64,109.88 | 64,146.76 | 63,980.08 | 63,912.57 |

| 10 | 70,011.80 | 66,507.56 | 66,022.83 | 64,006.94 | 63,974.64 |

| Mode | FEM-T3 | FEM-Q4 | ES-FEM | EFEM-N3 | Reference |

|---|---|---|---|---|---|

| 1 | 1122.20 | 880.70 | 863.63 | 823.81 | 822.41 |

| 2 | 6611.69 | 5314.24 | 5218.07 | 4945.35 | 4932.71 |

| 3 | 12,848.43 | 12,837.54 | 12,840.35 | 12,827.54 | 12,823.96 |

| 4 | 17,091.48 | 14,196.79 | 13,970.51 | 13,040.24 | 12,993.08 |

| 5 | 30,885.01 | 26,093.70 | 25,793.25 | 23,737.90 | 23,611.65 |

| 6 | 38,619.45 | 38,580.22 | 38,615.20 | 36,274.70 | 36,009.93 |

| 7 | 46,957.70 | 40,508.40 | 40,139.30 | 38,455.24 | 38,443.95 |

| 8 | 63,665.54 | 56,599.45 | 56,450.22 | 50,068.29 | 49,578.22 |

| 9 | 64,732.78 | 64,529.76 | 64,683.06 | 63,995.51 | 63,912.57 |

| 10 | 81,946.64 | 74,204.78 | 74,725.45 | 64,739.58 | 63,974.64 |

| Mode | FEM-T3 | FEM-Q4 | ES-FEM | EFEM-N3 | Reference |

|---|---|---|---|---|---|

| 1 | 1145.59 | 898.93 | 884.98 | 823.97 | 822.41 |

| 2 | 6737.77 | 5455.77 | 5369.86 | 4947.20 | 4932.71 |

| 3 | 12,853.75 | 12,837.90 | 12,843.17 | 12,828.10 | 12,823.96 |

| 4 | 17,179.78 | 14,586.04 | 14,420.32 | 13,050.46 | 12,993.08 |

| 5 | 31,362.44 | 26,581.86 | 26,471.00 | 23,766.85 | 23,611.65 |

| 6 | 38,629.17 | 38,580.54 | 38,633.98 | 36,352.11 | 36,009.93 |

| 7 | 47,501.75 | 40,940.73 | 40,865.35 | 38,457.08 | 38,443.95 |

| 8 | 63,711.47 | 57,399.92 | 57,474.63 | 50,197.60 | 49,578.22 |

| 9 | 64,801.35 | 64,531.84 | 64,743.80 | 63,998.94 | 63,912.57 |

| 10 | 82,916.05 | 75,850.72 | 76,237.81 | 64,908.02 | 63,974.64 |

| Mode | FEM-T3 | FEM-Q4 | ES-FEM | EFEM-N3 | Reference |

|---|---|---|---|---|---|

| 1 | 0.1081 | 0.1044 | 0.1032 | 0.1022 | 0.1011 |

| 2 | 0.3681 | 0.3580 | 0.3553 | 0.3522 | 0.3497 |

| 3 | 0.3855 | 0.3839 | 0.3836 | 0.3830 | 0.3825 |

| 4 | 0.6312 | 0.6029 | 0.5916 | 0.5846 | 0.5767 |

| 5 | 0.8094 | 0.7773 | 0.7677 | 0.7594 | 0.7532 |

| 6 | 0.9503 | 0.9275 | 0.9214 | 0.9131 | 0.9094 |

| 7 | 1.0352 | 1.0061 | 0.9983 | 0.9894 | 0.9857 |

| 8 | 1.1459 | 1.1247 | 1.1158 | 1.1060 | 1.1007 |

| 9 | 1.2045 | 1.1673 | 1.1552 | 1.1454 | 1.1389 |

| 10 | 1.2276 | 1.1944 | 1.1844 | 1.1763 | 1.1724 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Dang, S.; Li, W.; Chai, Y. Free and Forced Vibration Analysis of Two-Dimensional Linear Elastic Solids Using the Finite Element Methods Enriched by Interpolation Cover Functions. Mathematics 2022, 10, 456. https://doi.org/10.3390/math10030456

Li Y, Dang S, Li W, Chai Y. Free and Forced Vibration Analysis of Two-Dimensional Linear Elastic Solids Using the Finite Element Methods Enriched by Interpolation Cover Functions. Mathematics. 2022; 10(3):456. https://doi.org/10.3390/math10030456

Chicago/Turabian StyleLi, Yancheng, Sina Dang, Wei Li, and Yingbin Chai. 2022. "Free and Forced Vibration Analysis of Two-Dimensional Linear Elastic Solids Using the Finite Element Methods Enriched by Interpolation Cover Functions" Mathematics 10, no. 3: 456. https://doi.org/10.3390/math10030456

APA StyleLi, Y., Dang, S., Li, W., & Chai, Y. (2022). Free and Forced Vibration Analysis of Two-Dimensional Linear Elastic Solids Using the Finite Element Methods Enriched by Interpolation Cover Functions. Mathematics, 10(3), 456. https://doi.org/10.3390/math10030456