Advanced Algorithms in Automatic Generation Control of Hydroelectric Power Plants

Abstract

1. Introduction

2. Materials and Methods

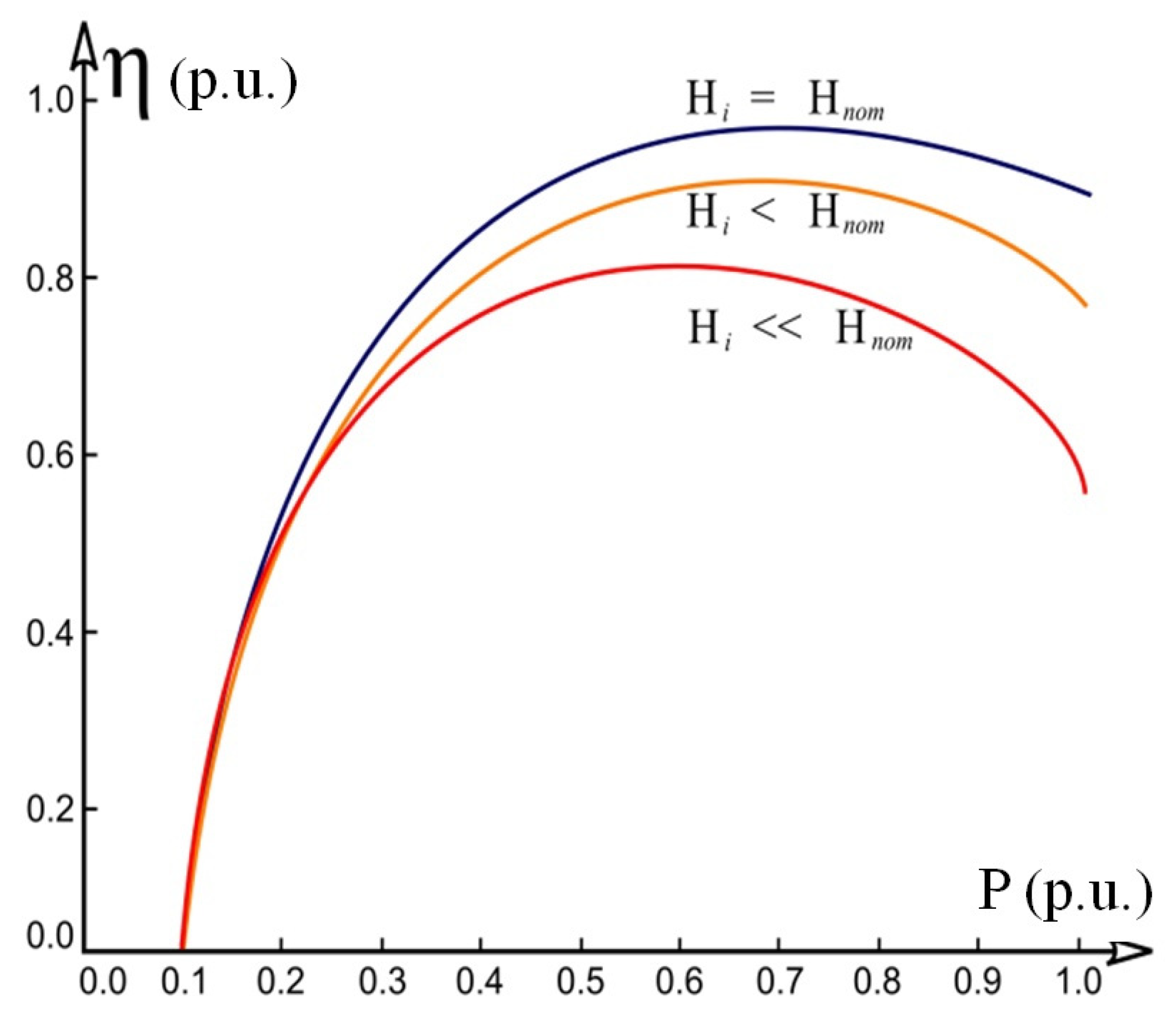

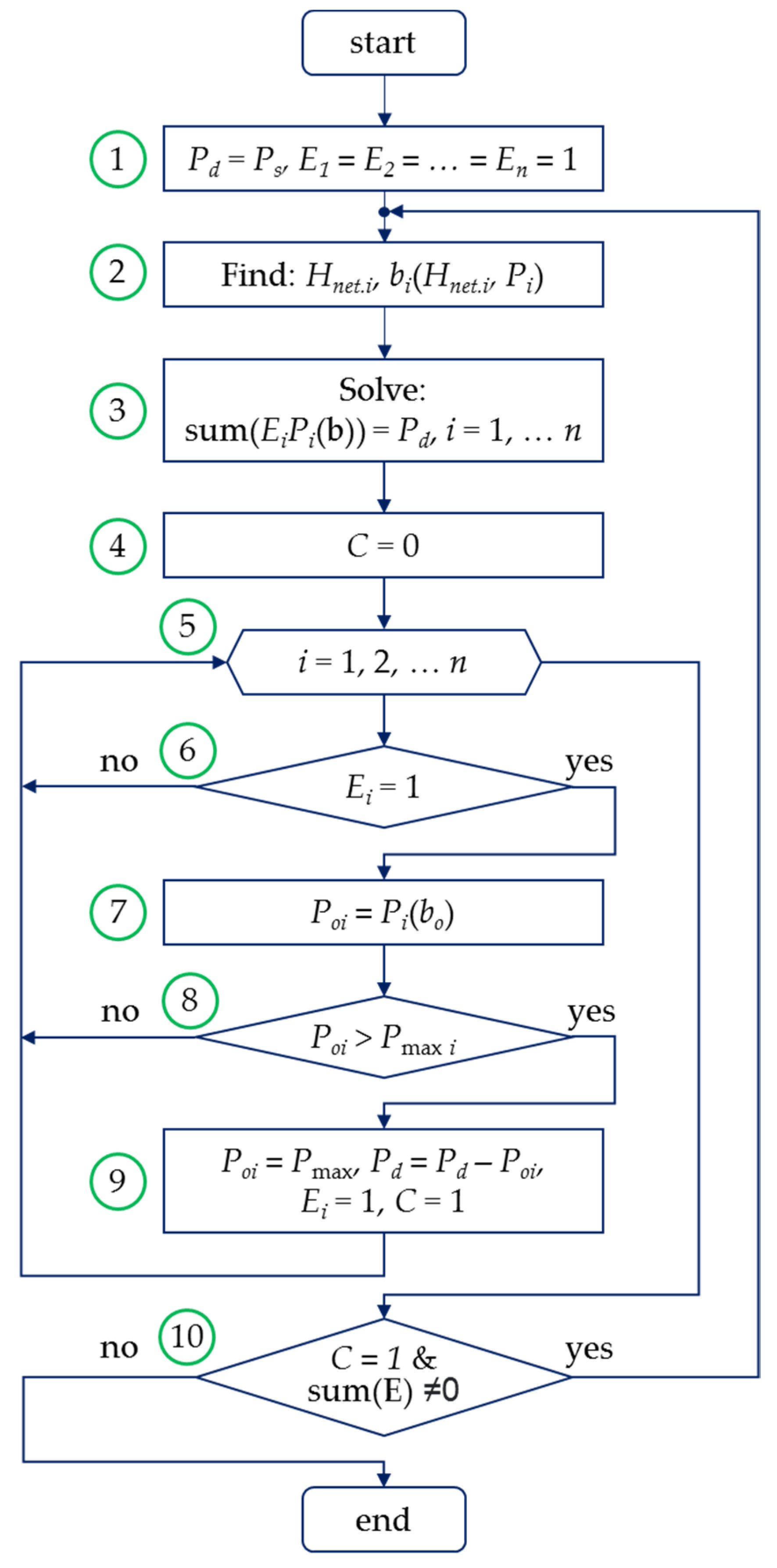

2.1. Optimal Active Power Distribution between the HPP Units

- the sum of the active power output of all the power generation units should be equal to the HPPs active power setpoint, i.e., the value of the active power to be generated by the HPP according to the load schedule (PS), MW:

- the active power output of each unit must stay within the individual constraints:

- determine the objective (fitness) function (2) taking into account (6);

- set the constraints (7) and (8);

- assign the number of population to 0 (t = 0).

- randomly create chromosomes, representing the total power output (PS) distribution between the HPP power generation units, taking into account (7) and (8);

- calculate the value of the fitness function for each of the chromosomes F(chi) taking into account the system of Equation (6).

- select the parents using the “roulette-wheel” method:

- Randomly form the parent pairs from the population P(t) and apply crossover and mutation operators;

- Replace the old population with the newly generated population;

- Assign the number of population to t = t + 1;

2.2. Optimal Reactive Power Distribution between HPP Units

- Maximum rotor current limitation (to avoid rotor winding overheating);

- Minimum rotor current limitation (to avoid the reversal of the polarity of the field);

- Constraint on the stator end windings heating;

- Constraint on the stator current (output apparent power);

- Constraint on the steady-state stability.

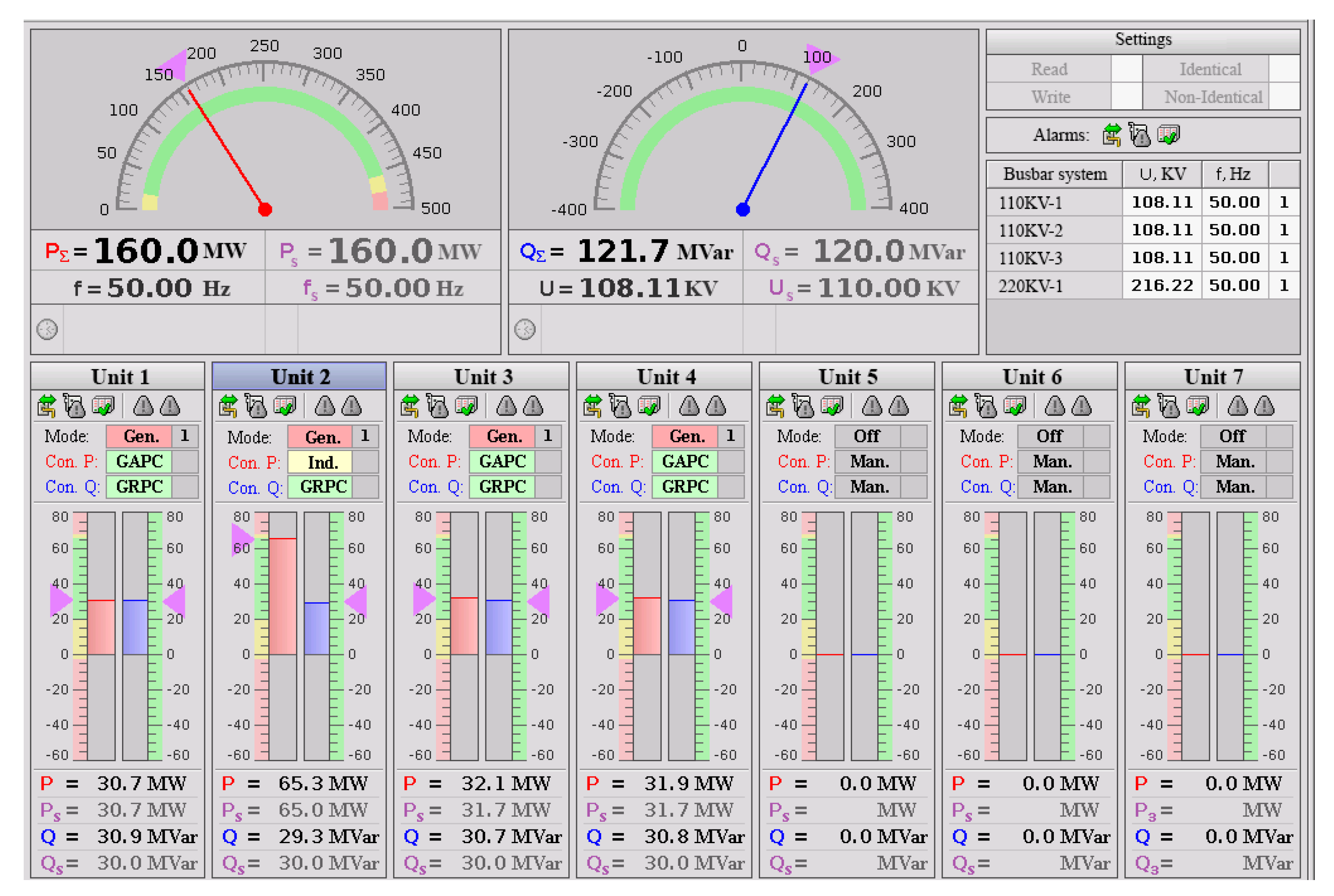

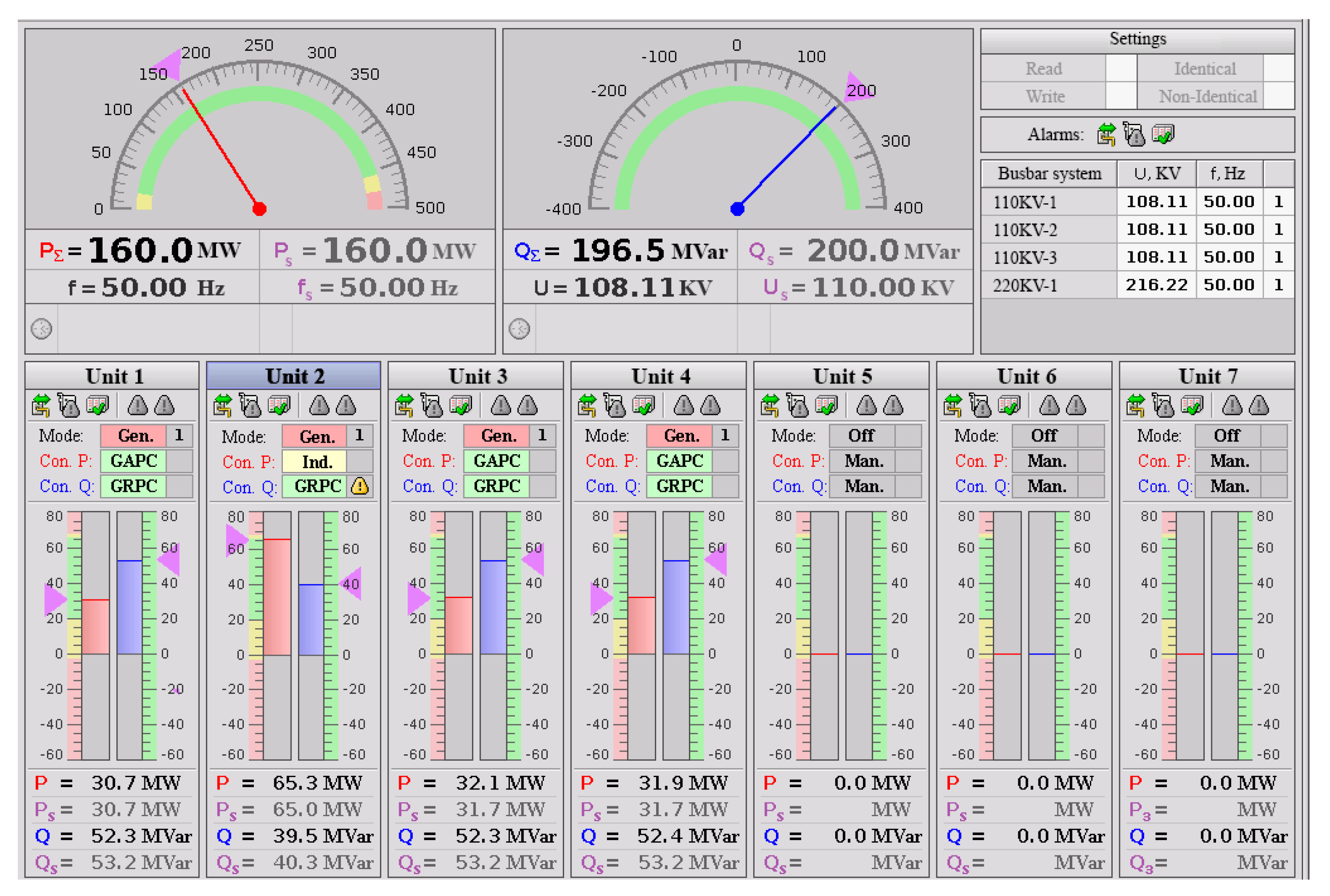

3. Results and Discussion

3.1. Active Power Distribution Algorithms Comparison

3.2. Reactive Power Distribution Algorithms Comparison

- Active power Pi;

- Reactive load limit Qmin i;

- Given reactive power Qi;

- Apparent power Si.

- Less active power losses;

- The simplicity of the power distribution logic and calculations of constraints on apparent power and steady-state stability.

4. Conclusions

- The algorithm of active power distribution considers the individual control range of each of the hydraulic units and the head losses in the track rack. The algorithm also minimizes the total water discharge.

- The algorithm of reactive power distribution optimally minimizes the active power losses in the stator windings and the circuits of the unit transformers. The algorithm considers constraints on the apparent power, field current, and steady-state stability.

- An analytical expression is obtained for determining the minimum reactive power of a salient-pole generator that ensures its steady-state stability for the given value of the safety margin and the current values of the active power and voltage.

- The above algorithms and techniques are implemented in the digital AGC of the two hydropower plants.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cutululis, N.A.; Farahmand, H.; Jaehnert, S.; Detlefsen, N.; Byriel, I.P.; Sørensen, P.E. Hydropower flexibility and transmission expansion to support integration of offshore wind. In Offshore Wind Farms: Technologies, Design and Operation, 1st ed.; Ng, C., Ran, L., Eds.; Woodhead Publishing: Sawston, UK, 2016; pp. 495–523. [Google Scholar]

- Farahmand, H.; Jaehnert, S.; Aigner, T.; Huertes-Hernando, D. Nordic hydropower flexibility and transmission expansion to support integration of North European wind power. Wind Energy 2015, 18, 1075–1103. [Google Scholar] [CrossRef]

- Matrenin, P.; Safaraliev, M.; Dmitriev, S.; Kokin, S.; Eshchanov, B.; Rusina, A. Adaptive ensemble models for medium-term forecasting of water inflow when planning electricity generation under climate change. Energy Rep. 2022, 8, 439–447. [Google Scholar] [CrossRef]

- Khalyasmaa, A.; Eroshenko, S.; Bramm, A.; Tran, D.C.; Chakravarthi, T.P.; Hariprakash, R. Strategic planning of renewable energy sources implementation following the country-wide goals of energy sector development. In Proceedings of the International Conference on Smart Technologies in Computing, Electrical and Electronics, Bengaluru, India, 9–10 October 2020; pp. 433–438. [Google Scholar]

- Mo, W.K.; Chen, Y.P.; Chen, H.Y.; Liu, Y.; Zhang, Y.; Hou, J.; Gao, Q.; Li, C. Analysis and Measures of Ultralow-Frequency Oscillations in a Large-Scale Hydropower Transmission System. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 1077–1085. [Google Scholar] [CrossRef]

- Pico, H.V.; McCalley, J.D.; Angel, A.; Leon, R.; Castrillon, N.J. Analysis of very low frequency oscillations in hydro-dominant power systems using multi-unit modeling. IEEE Trans. Power Syst. 2012, 27, 1906–1915. [Google Scholar] [CrossRef]

- Khalyasmaa, A.; Eroshenko, S.; Arestova, A.; Mitrofanov, S.; Rusina, A.; Kolesnikov, A. Integrating GIS technologies in hydro power plant cascade simulation model. E3S Web Conf. 2020, 191, 02006. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, G.; Liu, B.; Zhang, Y.; Liu, C.; Zeng, Z.; Fan, C.; Han, X. Emergency Control Strategy of Ultra-low Frequency Oscillations Based on WAMS. In Proceedings of the IEEE Innovative Smart Grid Technologies—Asia (ISGT Asia), Chengdu, China, 21–24 May 2019; pp. 296–301. [Google Scholar]

- Nanda, J.; Kaul, B.L. Automatic generation control of an interconnected power system in Electrical Engineers. Proc. Inst. Electr. Eng. 1978, 125, 385–390. [Google Scholar] [CrossRef]

- Kusic, G.L.; Sutterfield, J.A.; Caprez, A.R.; Haneline, J.; Bergman, B. Automatic generation control for hydro systems. IEEE Trans. Energy Convers. 1988, 3, 33–39. [Google Scholar] [CrossRef] [PubMed]

- Kazantsev, Y.V.; Glazyrin, G.V.; Shayuk, S.M.; Tanfilyeva, D.; Tanfilyev, O.; Fyodorova, V. Hydro unit active power controller minimizing water hammer effect. In Proceedings of the IEEE Ural Smart Energy Conference (USEC), Ekaterinburg, Russia, 13–15 November 2020. [Google Scholar]

- IEC 61362:2012; Guide to Specification of Hydraulic Turbine Governing Systems. 2012; p. 62. Available online: https://standards.iteh.ai/catalog/standards/iec/aa52f8df-d6ea-41dc-ac8c-1c03078ef02e/iec-61362-2012 (accessed on 12 September 2022).

- Glazyrin, G.V.; Kazantsev, Y.V. Optimal control law for minimization of active power overshoot due to water hammer effect in a hydro unit. In Proceedings of the IEEE 11 International Forum on Strategic Technology (IFOST), Novosibirsk, Russia, 1–3 June 2016; pp. 329–333. [Google Scholar]

- Campaner, R.; Chiandone, M.; Arcidiacono, V.; Milano, F.; Sulligoi, G. Automatic Voltage Control of a Cluster of Hydro Power Plants to Operate as a Virtual Power Plant. In Proceedings of the International Conference on Environment and Electrical Engineering (EEEIC), Rome, Italy, 10–13 June 2015. [Google Scholar]

- Urin, V.D. Hydroelectric Plants Autoopearators Design Experience; Energoizdat: Moscow, Russia, 1969. [Google Scholar]

- Manov, N.A.; Chukreev, Y.Y. Prototype of an expert system for dispatch adviser software in the regional power system. In New Information Technologies for Power System Dispatching; Ural Branch of the Russian Academy of Sciences: Ekaterinburg, Russia, 2002; pp. 43–59. [Google Scholar]

- Mitrofanov, S.; Svetlichnaya, A.; Arestova, A.; Rusina, A. Development of a Software Module of Intra-Plant Optimization for Short-Term Forecasting of Hydropower Plant Operating Conditions. In Proceedings of the IEEE Ural-Siberian Smart Energy Conference (USSEC), Novosibirsk, Russia, 13–15 November 2021. [Google Scholar]

- Gaidukov, J.; Glazyrin, G.; Glazyrin, V.; Eroshenko, S. Control algorithms and optimization method of the hydroelectric power plant’s microprocessing joint power control. In Proceedings of the 2020 Ural Smart Energy Conference, Ekaterinburg, Russia, 13–15 November 2020; p. 9281275. [Google Scholar]

- Alterman, D.Z. Hydroelectric Plants Autocontrol Systems with Active Power Correction; Energoizdat: Moscow, Russia, 1959. [Google Scholar]

- Kiselev, G.S. The experience of serial microcontroller application to hydro unit automation. Energetik 1998, 4, 37–45. [Google Scholar]

- Muraviev, O.A.; Berlin, V.V. The experience of setup up of group control of active power of Kureiskaya hydroelectric plant. Proc. MSSU 2001, 1, 107–114. [Google Scholar]

- Garcia, D.J.; Loreto, J.L. Automatic generation control of the caruachi hydro-electric power plant. In Proceedings of the IEEE Transmission and Distribution Conference and Exposition, Caracas, Venezuela, 15–18 August 2006. [Google Scholar]

- Lansberry, J.E.; Wozniak, L. Adaptive hydrogenerator governor tuning with a genetic algorithm. IEEE Trans. Energy Convers. 1994, 9, 179–183. [Google Scholar] [CrossRef]

- Rusina, A.G.; Sovban, E.A.; Khujasaidov, J.K.; Filippova, T.A. Tasks of optimal performance of hydroelectric in power system. In Proceedings of the 11th International Forum on Strategic Technology (IFOST), Novosibirsk, Russia, 1–3 June 2016. [Google Scholar]

- Liu, S.L.; Song, Y.X.; Hao, P.L. The Fuzzy Comprehensive Evaluation of Hydropower Plant Production and Operating Conditions Based on the BP Neural Network Improved. Appl. Mech. Mater. 2011, 71–78, 4170–4173. [Google Scholar]

- Liu, B.; Liao, S.; Cheng, C.; Wu, X. Multi-Core Parallel Genetic Algorithm for the Long-Term Optimal Operation of Large-Scale Hydropower Systems. In Proceedings of the World Environmental and Water Resources Congress, West Palm Beach, FL, USA, 22–26 May 2016; pp. 220–230. [Google Scholar]

- Robert, Q.; Planque, J.L. Robust Digital Automatic Reactive Power Regulator for Hydro Power Plants. In Proceedings of the 2007 International Conference on Clean Electrical Power, Capri, Italy, 21–23 May 2007; pp. 175–179. [Google Scholar]

- Arce, A.; Ohishi, T.; Soares, S. Optimal Dispatch of Generating Units of the Itaipú Hydroelectric Plant. IEEE Trans. Power Syst. 2002, 17, 154–158. [Google Scholar] [CrossRef]

- Sheble, G.B.; Fahd, G.N. Unit Commitment Literature Synopsis. IEEE Trans. Power Syst. 1994, 9, 128–135. [Google Scholar] [CrossRef]

- Byrd, R.H.; Gilbert, J.C.; Nocedal, J. A Trust Region Method Based on Interior Point Techniques for Nonlinear Programming. Math. Program. 2000, 89, 149–185. [Google Scholar] [CrossRef]

- Byrd, R.H.; Hribar, M.E.; Nocedal, J. An Interior Point Algorithm for Large-Scale Nonlinear Programming. SIAM J. Optim. 1999, 9, 877–900. [Google Scholar] [CrossRef]

- Waltz, R.A.; Morales, J.L.; Nocedal, J.; Orban, D. An interior algorithm for nonlinear optimization that combines line search and trust region steps. Math. Program. 2006, 107, 391–408. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, Y.; Wei, H. An interior point method based on continuous Newton’s method for optimal power flow. In Proceedings of the IEEE PES Innovative Smart Grid Technologies, Tianjin, China, 21–24 May 2012. [Google Scholar]

- Jie, Z.; Shengchun, L.; Yao, R.; Liang, D.; Zhanshan, Y.; Yongfei, M. Reactive power optimization for AVC system based on decoupled interior point method. In Proceedings of the 2022 14th International Conference on Measuring Technology and Mechatronics Automation (ICMTMA), Changsha, China, 15–16 January 2022; pp. 131–133. [Google Scholar]

- Wang, Y.; Jiang, Q. Reactive power optimizatin of distribution network based on primal-dual interior point method and simplified branch and bound method. In Proceedings of the 2014 IEEE PES T&D Conference and Exposition, Chicago, IL, USA, 14–17 April 2014. [Google Scholar]

- Rojas, D.G.; Lezama, J.L.; Villa, W. Metaheuristic Techniques Applied to the Optimal Reactive Power Dispatch: A Review. IEEE Lat. Am. Trans. 2016, 14, 2253–2263. [Google Scholar] [CrossRef]

- Saka, B.; Aibinu, A.M.; Mohammed, Y.S.; Olatunji, D.E. Voltage Stability of the Power System using Genetic Algorithm: A Review. In Proceedings of the 2021 1st International Conference on Multidisciplinary Engineering and Applied Science (ICMEAS), Abuja, Nigeria, 15–16 July 2021. [Google Scholar]

- Steihaug, T. The Conjugate Gradient Method and Trust Regions in Large Scale Optimization. SIAM J. Numer. Anal. 1983, 20, 626–637. [Google Scholar] [CrossRef]

- Brent, R. Algorithms for Minimization Without Derivatives; Prentice-Hall: Hoboken, NJ, USA, 1973. [Google Scholar]

- Kundur, P. Power System Stability and Control; McGraw-Hill: New York, NY, USA, 1994. [Google Scholar]

- Jackson, J.Y. Interpretation and Use of Generator Reactive Capability Diagrams. IEEE Trans. Ind. Gen. Appl. 1971, IGA-7, 729–732. [Google Scholar] [CrossRef]

- El-Kady, M.A.; Bell, B.D.; Carvalho, V.F.; Burchett, R.C.; Happ, H.H.; Vierath, D.R. Assessment of Real-Time Optimal Voltage Control. IEEE Trans. Power Syst. 1986, PWRS-1, 98–107. [Google Scholar] [CrossRef]

| Distribution Method | The Criterion of Power Distribution | Account for Steady-State Stability | Active Losses Minimization Criterion |

|---|---|---|---|

| Proportional distribution | Qi = kPTi, where PTi is the active output power of the ith turbine, and k is the adopted distribution factor. | +/− | − |

| Equality of stator currents (equality of apparent powers) | I1 = I2 = … = In, where Ij is the stator currents of the jth generator | − | |

| Uniform distribution | − | Equation (27) | |

| Uniform distribution with constraints on steady-state stability | Equations (22)–(24) | Equation (27) |

| Algorithm | P1, MW | P2, MW | P3, MW | tcalc, s | QHPP, m3/s | dQHPP, % |

|---|---|---|---|---|---|---|

| Uniform distribution | 54 | 54 | 54 | 0.000002 | 1434.7 | 0 |

| Equality of incremental water discharge | 45.5 | 45.5 | 71 | 0.07 | 1400 | −2.42 |

| Genetic algorithm | 44.22 | 42.78 | 75 | 2.218 | 1380.81 | −3.74 |

| Internal point algorithm | 43.5 | 43.5 | 75 | 0.711 | 1380.54 | −3.77 |

| The proposed one | 45.21 | 45.21 | 71.58 | 0.078 | 1385.20 | −3.47 |

| dPsum | Proportional | Equality of Stator Current | Uniform |

|---|---|---|---|

| dPsum1, kW | 2255.3 | 2255.6 | 2199.9 |

| dPsum2, kW | 3596.2 | 3511. 4 | 3511.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kazantsev, Y.V.; Glazyrin, G.V.; Khalyasmaa, A.I.; Shayk, S.M.; Kuparev, M.A. Advanced Algorithms in Automatic Generation Control of Hydroelectric Power Plants. Mathematics 2022, 10, 4809. https://doi.org/10.3390/math10244809

Kazantsev YV, Glazyrin GV, Khalyasmaa AI, Shayk SM, Kuparev MA. Advanced Algorithms in Automatic Generation Control of Hydroelectric Power Plants. Mathematics. 2022; 10(24):4809. https://doi.org/10.3390/math10244809

Chicago/Turabian StyleKazantsev, Yury V., Gleb V. Glazyrin, Alexandra I. Khalyasmaa, Sergey M. Shayk, and Mihail A. Kuparev. 2022. "Advanced Algorithms in Automatic Generation Control of Hydroelectric Power Plants" Mathematics 10, no. 24: 4809. https://doi.org/10.3390/math10244809

APA StyleKazantsev, Y. V., Glazyrin, G. V., Khalyasmaa, A. I., Shayk, S. M., & Kuparev, M. A. (2022). Advanced Algorithms in Automatic Generation Control of Hydroelectric Power Plants. Mathematics, 10(24), 4809. https://doi.org/10.3390/math10244809