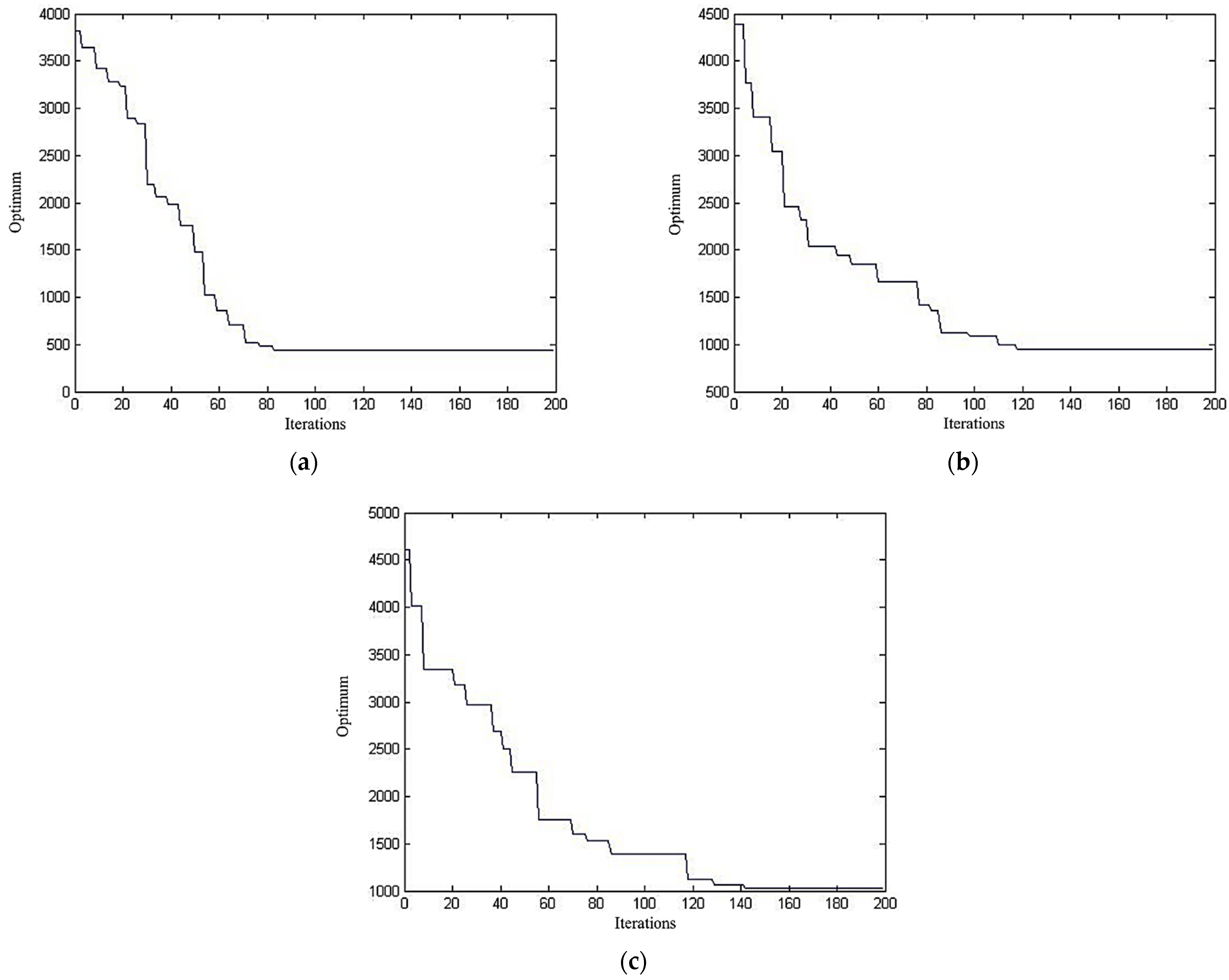

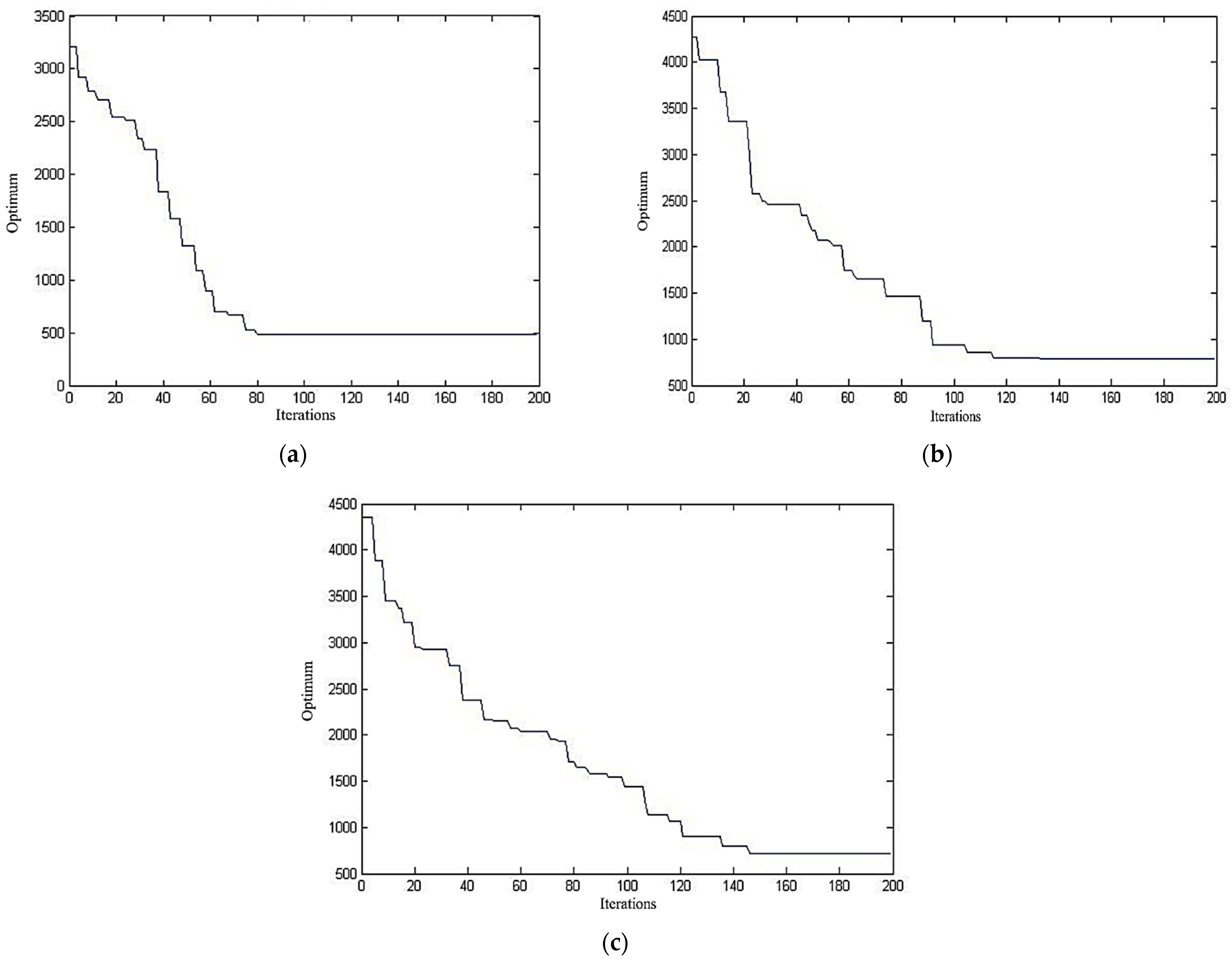

3.1. Constructing Driving Cycles of EVs

The battery level of EVs is directly impacted by their energy consumption behavior, which further influences the necessity to visit a recharging station and the recharging time at the station. Researchers have found out that various factors affect EVs’ energy consumption behavior, mainly including the load, speed, temperature, and road conditions. Thus, the driving states and resistance of EVs directly affects their energy consumption.

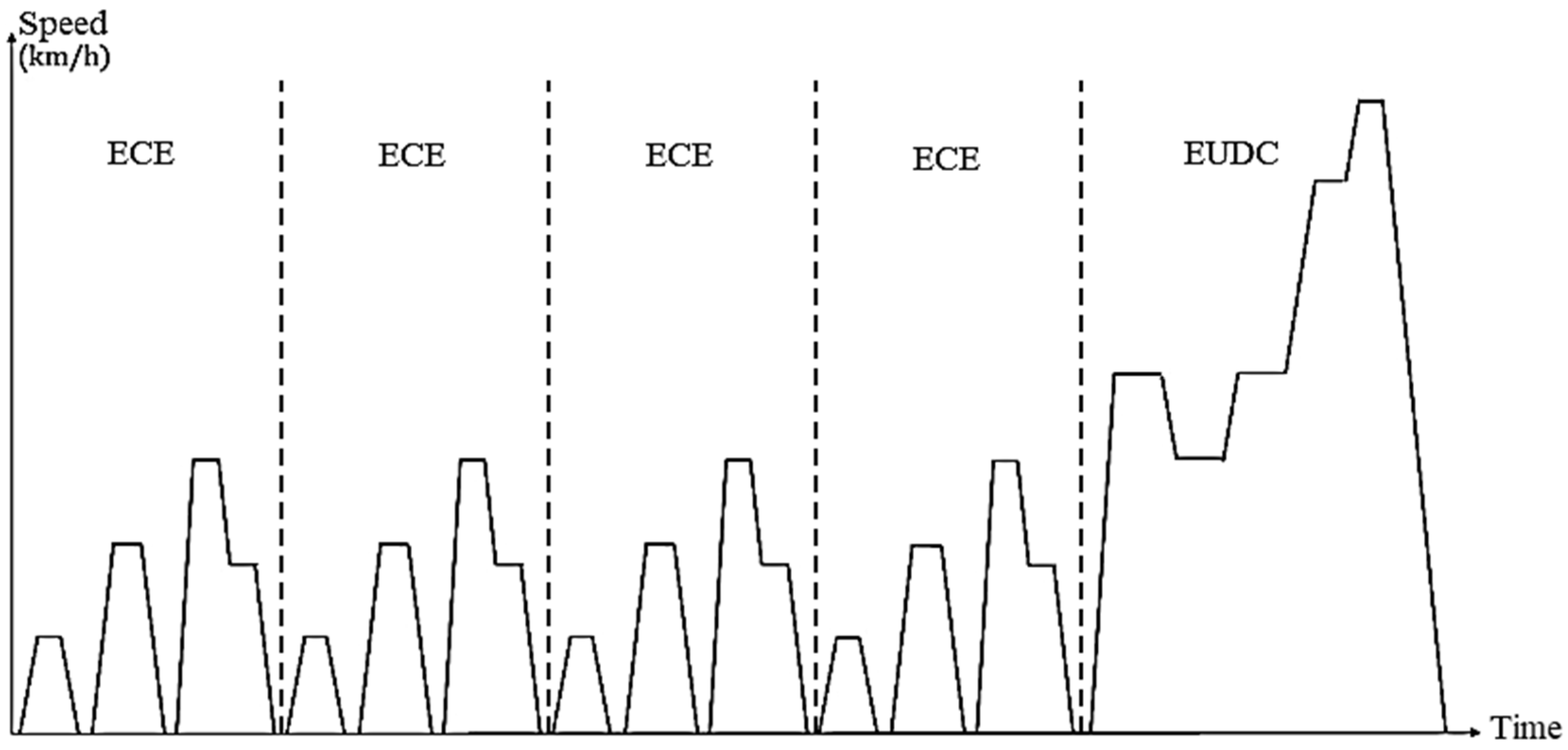

Like that of CVs, the typical driving state of an EV consists of starting, accelerating, constant speed, decelerating, and stopping, and the driving state transforms from one to another during travel. Previous work either assumed a constant speed of EVs, or a linear coefficient between energy consumption and distance, which ignores the changes in driving states. Therefore, in this work, we use a more realistic model based on the driving cycles with consideration of the factors of load, travel distance, and speed. The driving cycle of a vehicle presents the change in speed with the change in driving states. The New European Driving Cycle (NEDC), which is widely used to estimate EVs’ maximum driving range in China, includes two test cycles: that of the Economic Commission for Europe (ECE) and the Extra Urban Driving Cycle (EUDC). The driving cycles of ECE and EUDC are shown in

Figure 1.

ECE tests an EV operating within a city for the first four cycles, whereas EUDC tests it in a suburban area for the last cycle. The EV in EUDC operates at a higher speed than that in ECE. The driving cycle shows the change in speed over time. During ECE, the vehicle first accelerates from rest before it reaches a constant speed and runs for a period, after which it decelerates to stop and then starts to repeat similar movements. By comparison, during EUDC, the vehicle accelerates from a standstill, then undergoes an acceleration and deceleration process with different change rates, before it finally stops.

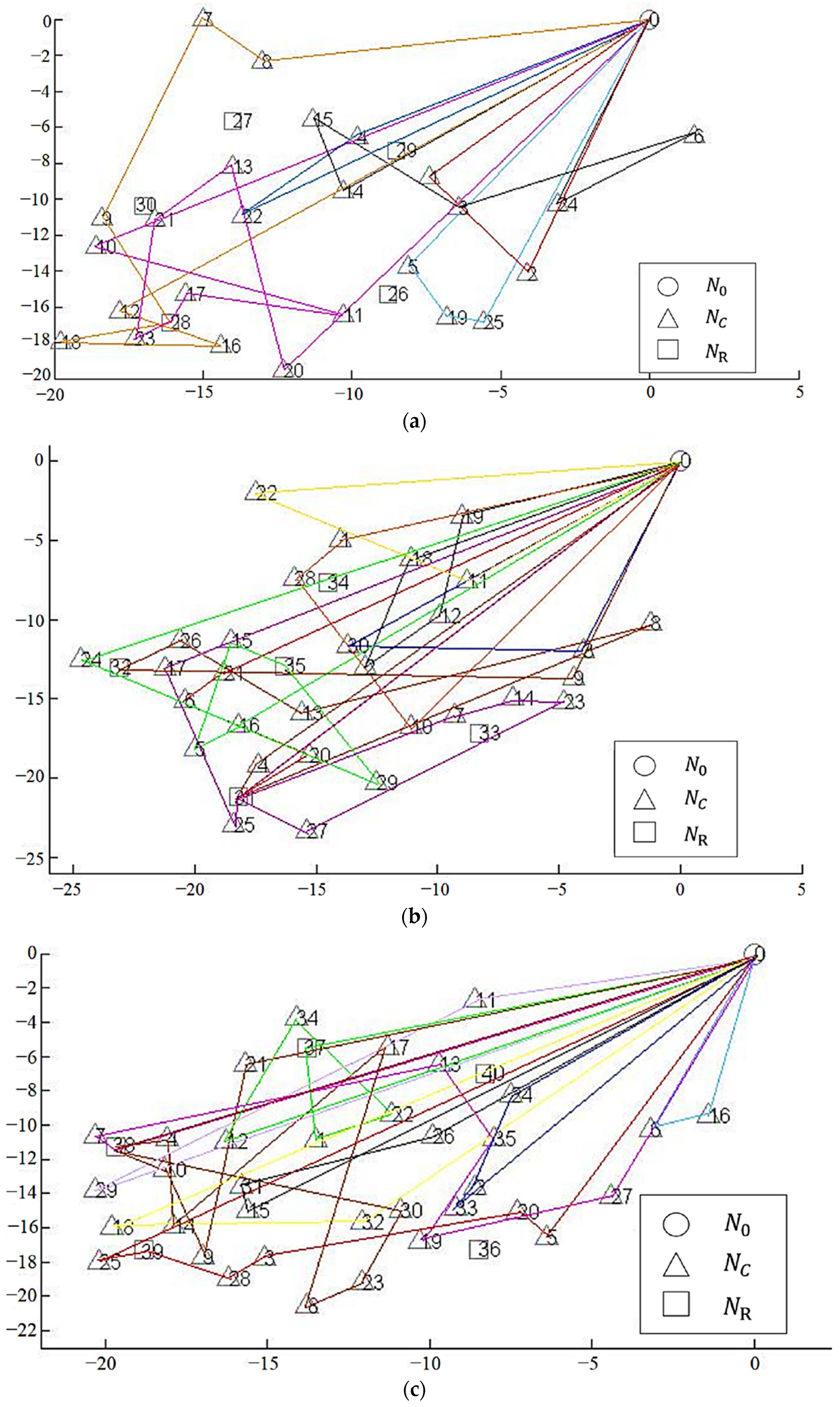

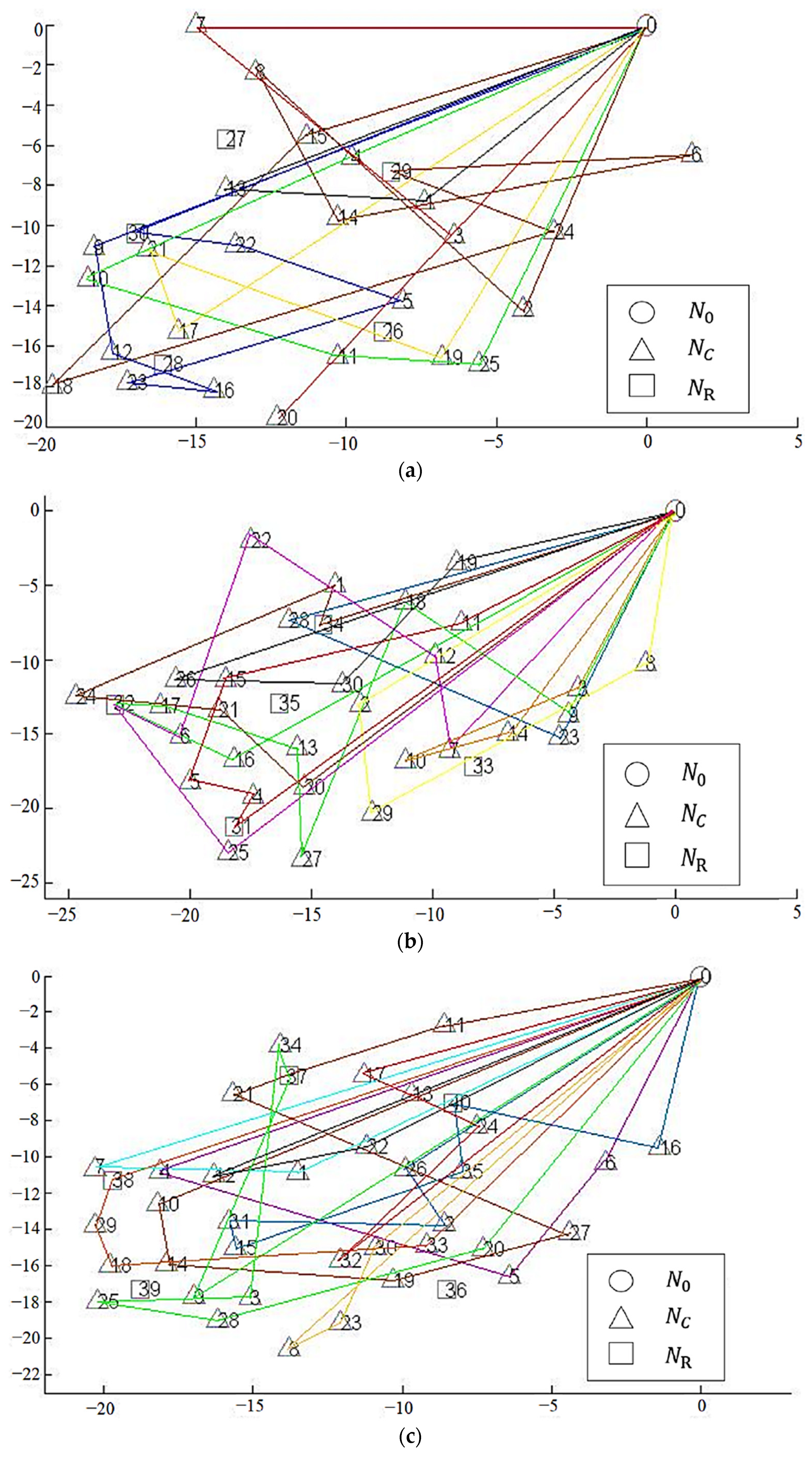

When using EVs in urban distribution, there are three types of nodes in the network: (1) distribution center ; (2) customers ; and (3) recharging stations . EVs depart from in suburban areas and visit in the city for delivery. They visit the recharging stations when necessary, and return to after completing the task. By comparison, the driving cycle of EVs driving from and returning to is similar to that of EUDC, whereas driving between and is similar to that of ECE. Therefore, we present the following driving conditions of EVs to further describe their driving cycles.

Condition A: EVs depart from a distribution center to the first customer, or EVs return to the distribution center from the last customer.

Under this condition, an EV first starts from a stationary position and accelerates at a uniform rate

until its speed reaches

, then it decelerates to

at rate

. Then, it accelerates again at rate

to speed

, then travels at a constant speed

for some time, and finally decelerates to a full stop at rate

. This driving cycle is named cycle A, as shown in

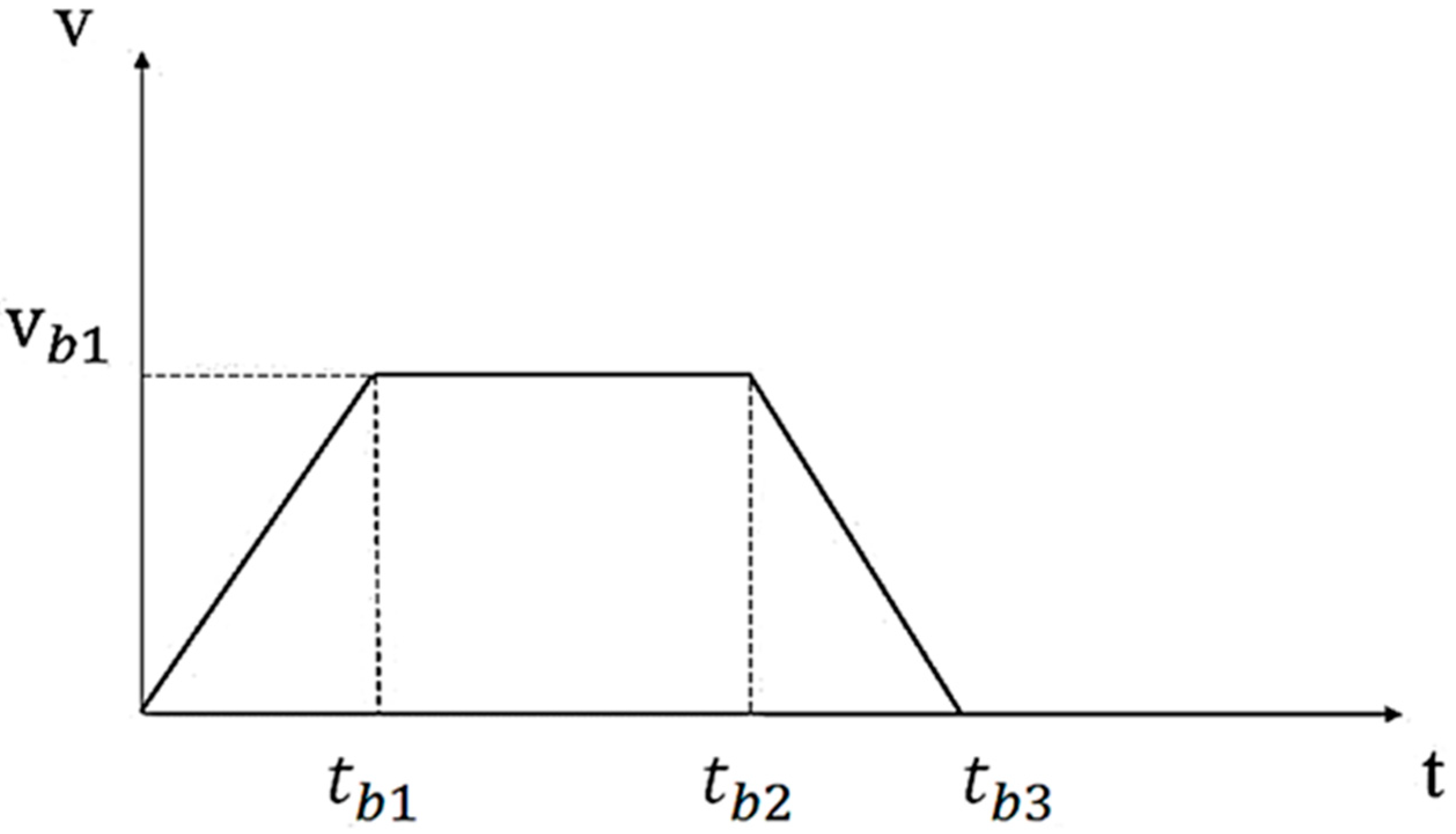

Figure 2.

Condition B: During delivery, EVs travel between customer and customer, or between customer and recharging station.

Under condition B, the driving cycle of an EV is as follows: an EV starts from a stationary position at a customer or recharging station, then accelerates at a uniform rate

to speed

and maintains

for a period, after which it decelerates at rate

to a complete stop when it reaches the next customer or recharging station. This driving cycle B is shown in

Figure 3.

3.2. Energy Consumption Models of EVs Based on Different Driving Cycles

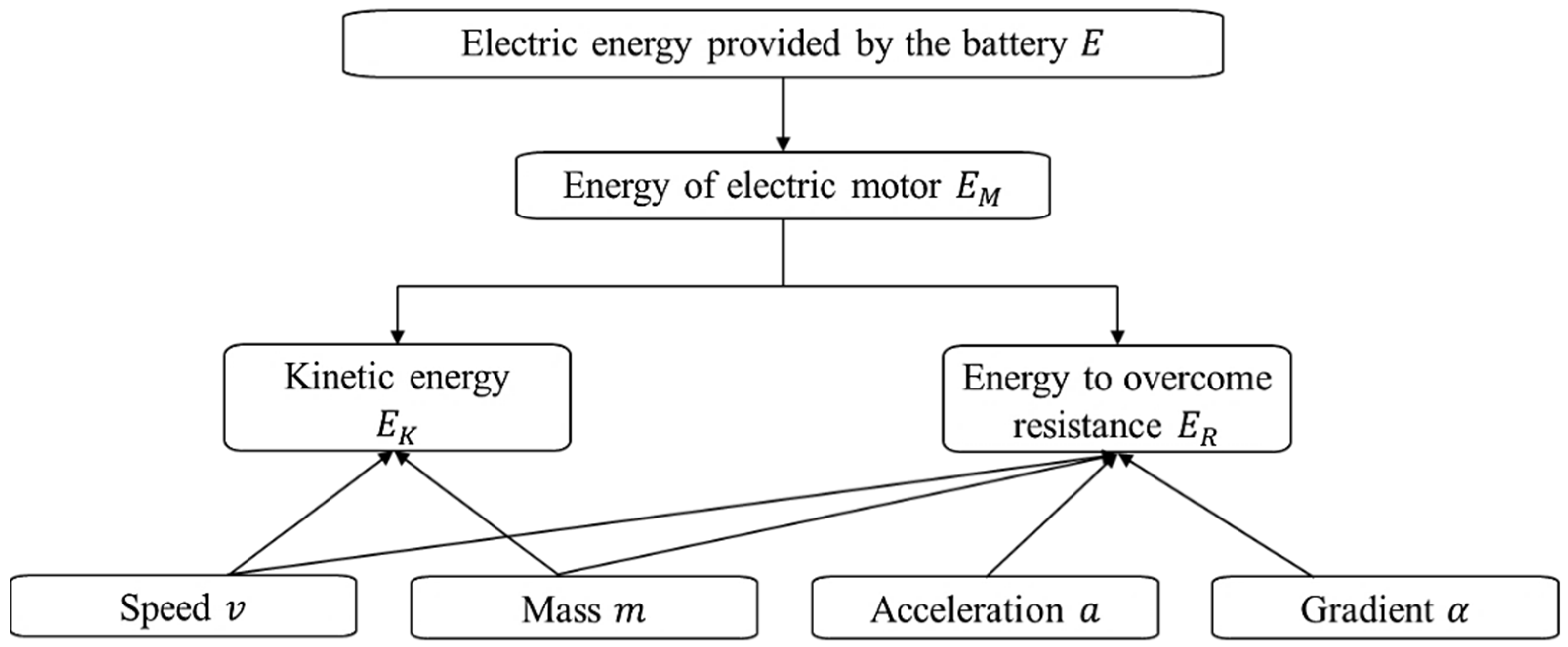

We develop the energy consumption models of an EV in a few steps, as shown in

Figure 4. According to the kinetic energy theorem, the kinetic energy obtained by the vehicle should be equal to the work done by the vehicle’s combined external force, while the total external force is the difference between the vehicle’s traction and resistance. Therefore, during an EV’s driving process, both the kinetic energy

and the energy consumed to overcome resistance

come from the electric energy of the motor

:

is then translated into the electric energy

provided by the battery, that is:

where

is the efficiency of the electric motor.

Similar to combustion vehicles, EVs are influenced by four types of external forces during driving, namely, rolling resistance , acceleration resistance , slope resistance , and air resistance . Resistances are mainly determined by factors of vehicle mass, vehicle load, vehicle dimensions, engine properties, acceleration rate, speed, and gradient.

To present the equations of resistance, we use the notation shown in

Table 1.

Then, the rolling resistance

, the acceleration resistance

, the air resistance

, and the slope resistance

can be respectively determined as:

In the following, the steps to build energy consumption models for driving cycles A and B are described in further detail. Let be the distance between any two nodes, and the distance an EV drives. We start with driving cycle B as it has fewer phases.

Driving cycle B, as shown in previous

Figure 3, consists of three phases: first acceleration phase, second uniform motion phase, and, finally, the deceleration phase.

The first acceleration phase is from speed 0 to

during time 0 to

, that is:

and:

where

is the distance the EV travels during this phase, while

is the distance traveled when facing air resistance.

Based on the law of uniform acceleration:

the intensity of air resistance is changed by speed; then, based on the infinitesimal method:

The battery energy consumed during the acceleration phase of cycle B,

, is then calculated as below:

In the second uniform motion phase, the acceleration resistance

is 0 due to 0 acceleration and constant speed, while air resistance

is constant. The battery energy consumed during this phase of cycle B,

, is determined as:

In the last phase of deceleration, regardless of energy recovery, all the kinetic energy is converted into work to overcome the resistance, so the battery output power is 0, and the battery does not consume energy; that is, .

Based on the law of uniform acceleration and uniform deceleration:

and

are the driving time and distance in the acceleration phase, respectively, and

is the driving distance in the deceleration phase.

With known distance

between any two nodes, the distance traveled in the uniform motion phase is calculated as:

Inserting Equations (15)–(18) into Equations (13) and (14), we have:

Therefore, the total battery energy consumed during the entire driving cycle B is determined as:

Driving cycle A, as in

Figure 2, has five sequential phases: first acceleration, first deceleration, second acceleration, uniform motion, and second deceleration phase. Similar to the case of cycle B, in acceleration phases, the electric energy is converted into kinetic energy and the energy to overcome external resistance; in the uniform motion phase, the energy from the battery is used to overcome resistance; and in deceleration phases, the battery does not consume any energy.

In the first acceleration phase from time 0 to

, the battery energy consumed is:

From time

to

of the second acceleration phase, based on the kinetic energy theorem:

Based on the law of uniform acceleration and uniform deceleration:

Insert

,

, and

into Equation (25); after simplification, we obtain:

In the uniform motion phase, from time

to

, which is similar to that in cycle B, the battery energy in this phase of cycle A is calculated using:

Since the other two phases are the deceleration process,

, and

. Therefore, the total battery energy consumed during driving cycle A is determined as: