1. Introduction

Economic, reliable, and robust issues are the main operation necessities of modern power system in all countries. The optimization of active and reactive power flow can achieve minimum cost of fuel, improve voltage profile at all system buses and minimize real power losses and emission in power system. Optimal power flow (OPF) is non-convex, non-continuous, non-linear, large scale and constrained optimization problem [

1,

2,

3].

Solving OPF still considered a challenge in electric power system [

4,

5]. Through OPF both discrete and continuous control variables including generator bus active power and voltages, on-load tap changer of transformers, and reactive compensators sizing while satisfying both equality and inequality constraints, are optimized [

6,

7,

8].

Due to the non-linearity of the OPF problem, meta-heuristic techniques were used to investigate the OPF. The main objectives of these studies include minimizing total cost of fuel, emission, transmission line power losses (P

Loss), transmission cost, voltage deviation (VD) and ameliorating voltage stability index (VSI) [

7,

9,

10]. Different innovative meta-heuristic algorithms were applied to solve OPF.

Meta-heuristic techniques were employed to avoid the disadvantages of conventional mathematical methods [

11]. Some of these methods were presented for reactive power solution include modified genetic algorithms (MGA) [

12], particle swarm optimization (PSO) [

13,

14,

15], gravitational search algorithm [

16], Artificial bee colony algorithm [

17,

18], Gray wolf optimizer [

19,

20], moth-flame optimization (MFO) [

21], and Ant lion optimizer [

22], JAYA optimizer [

23], artificial bee colony [

23], marine predators algorithm (MPA) [

24]. Recent Algorithms were used such as: Salp Swarm Optimization (SSO) algorithm [

25], multiphase search optimization algorithm [

26], crow search optimizer [

27], sine cosine algorithm [

28], hybrid PSO and SSO [

29], equilibrium optimizer [

30] and modified coyote optimization algorithm (MCOA) [

31].

The popular studies that investigated the optimal power flow problem are reported. In [

32], an adaptive genetic algorithm called self-adaptive real coded genetic algorithm (SARGA) is presented to solve economic dispatch considering the nonlinear characteristics of generation units. The proposed SARGA could optimize discrete, continuous and binary control variable to reach through applying binary crossover operator and polynomial mutation. Results indicated that SARGA efficiently achieved superiority over the evolutionary programming approach in solving the economic dispatch problem.

The Elephant Herding Optimizer (EHO), as a meta-heuristic algorithm, has been discussed in [

33]. EHO was used to solve non-convex OPF problem considering valve-loading effect and prohibited operating zones of generation units. Standard IEEE 30-bus was used for evaluating EHO against well-known optimization methods in literature, results indicated that EHO achieved near optimal results through solving non-convex OPF. Swarm Intelligence-based algorithm such as ABC [

34], GWO [

35,

36], MFO [

37], HHO [

38], MPA [

39] and COA [

40] were successfully optimized the non-linear OPF problem.

M. Z. Islam et al. in [

38] discussed making benefit of the intelligent cooperative behaviors of (HHO) to realize global solution with effective convergence through solving OPF. IEEE 30-bus power system was used for evaluating Harris hawk optimizer (HHO) clarifying its superiority over the state of art in solving single and multi-objective with the computational time. In [

23], JAYA algorithm was proposed for reaching global optima through solving single objective function as well as multi-objective OPF while reducing the computational cost. For evaluation, simulation was conducted using IEEE, 30-bus and 57-bus for testing JAYA efficiency. Results indicated that JAYA has a promising impact on various scale power systems.

The ability and effectiveness of optimization methods can be enhanced by integrating them with other algorithms having advanced merits. The main advantage and the reason gradient-free methods are employed is for convenience and the potential of converging to global solutions. In [

41], the cuckoo search (CS) was integrated with krill herd algorithm (KHA). The resulted hybrid CS-KHA benefits merits of CS and enhances the efficiency of KHA. The ability of CS-KHA is expanded to solve single- and multi-objective OPF for standard IEEE 30-bus, 57-bus and 118-bus test systems. Hybridization of the optimization methods is beneficial in improving the convergence and computational time of the new hybrid method to deal with the more complex system with single and multi-objectives OPF, MOHFPSO [

42], PSO-GWO [

43], QOMJaya [

44], DA-PSO [

45], DA-APSO [

46], HIC-GWA [

47], PSO [

48], and WOA-PS [

49].

The complexity of the modern system increased with the integrated renewable energy sources, while the power flow was improved. Solutions of such system require more accurate and effective optimization methods. In [

50], GWO was proposed to handle the uncertainty of renewable energy sources in power system. GWO optimized a new cost function including the under and over-estimated of wind and solar energy sources. The method was applied to solve OPF of IEEE 30-bus and IEEE-57 bus with stochastic wind and solar energy. In [

51], the random-fuzzy chance-constrained programing was employed to consider the nature of wind speed in OPF. Moreover, many researches solved OPF considering the advanced reactive power sources such as TCSC [

52], and STATCOM [

53]. All of these algorithms have their advantages and disadvantages.

From all of the above discussion, it can be seen that the OPF represents an attractive area to researchers in AI field as general and in meta-heuristic swarm optimization algorithms in particular. These algorithms avoid several drawbacks of conventional analytical algorithms in solution trapping in local minimum.

In this paper we explored the effect of using one of the new released meta-heuristic optimization algorithms proposed by Ghasemi et al. [

54] called Turbulent Flow of Water-based Optimization (TFWO). TFWO is a new meta-heuristic algorithm inspired by the whirlpool phenomena. Any whirlpool contains a downdraft that is capable of sucking objects beneath the water’s surface. In TFWO, the downdraft represents the best member in the group, which is capable of pulling the other members of the group to the center applying the centripetal force on them. The group members move in circular direction towards the center or the best member because of the centripetal force, which is positively proportional with the speed of the circular move.

In this paper, the TFWO optimization algorithm is applied for optimizing the control variables of the OPF to minimize the fuel cost, emission, active power loss, voltage deviation at the load buses, and ameliorating voltage stability index (VSI). This method is simulated for two IEEE 30-, 57-bus test system and four large scale power systems called IEEE, 300-bus, 1354pegase, 3012wp, and IEEE 9241pegase power systems. The superiority of the proposed algorithm is tested by comparing the results obtained with the other work in literature.

The salient contribution issues of this paper can be summarized as follows:

A novel meta-heuristic TFWO is used to solve the OPF with single and multi-objective functions.

Simulating and testing TFWO performance in solving the OPF problem is conducted with 17 different cases.

Single, bi, triple, quad, and quinta objective functions using two IEEE standard power systems. The proposed algorithm is validated on four large scale test systems IEEE 300-bus and 1354pegase, 3012wp, and IEEE 9241pegase power systems.

Evaluating the performance of TFWO proves its competitive performance compared with others.

Significant improvements are achieved in the technical, economical point of views.

The rest of this paper is organized as follows: In

Section 2, the formulation of the OPF problem is presented. The proposed TFWO algorithm is illustrated in

Section 3. In

Section 4, simulation results are investigated for the IEEE test systems.

Section 5 discuss the results, and

Section 6 concludes the main research outputs gives the future trend.

5. Discussion on Simulation Results

5.1. IEEE 30-Bus System

The IEEE 30-bus test system is studied under 14 cases considering single, bi-, tri-, quad-, and quinta-objective functions as shown in

Table 1. The simulation results can be explained according to studied cases, as follows:

- -

Results of single objectives cases

The simulation results of OPF of single objectives are reported in

Table 2 and

Table A1 for the complete control variables for Cases 1–5. In Case 1, the objective function aims to minimize the fuel cost. The reported fuel cost equals 799.071

$/h. In Case 2, the main objective is minimizing the voltage deviation at all load buss. The VD equals 0.084 p.u using the TFWO algorithm. In Case 3, the reported voltage stability index is 0.1 p.u. The minimum power losses obtained in Case 4 is 2.851 MW. The lowest emission rate is obtained in Case 5 (0.205 ton/kg).

Table 3 shows a comparison between the TFWO and some recent optimization algorithms from the literature for Cases 1–5. It is clear that the proposed TFWO leads to the most competitive solutions for different objectives.

The lowest value of voltage deviation (0.084 p.u) for Case 2 is via the proposed TFWO. In addition, the best voltage stability index, the lower value of power losses, and a notable improvement in emission level are noticed using TFWO compared to the literature works.

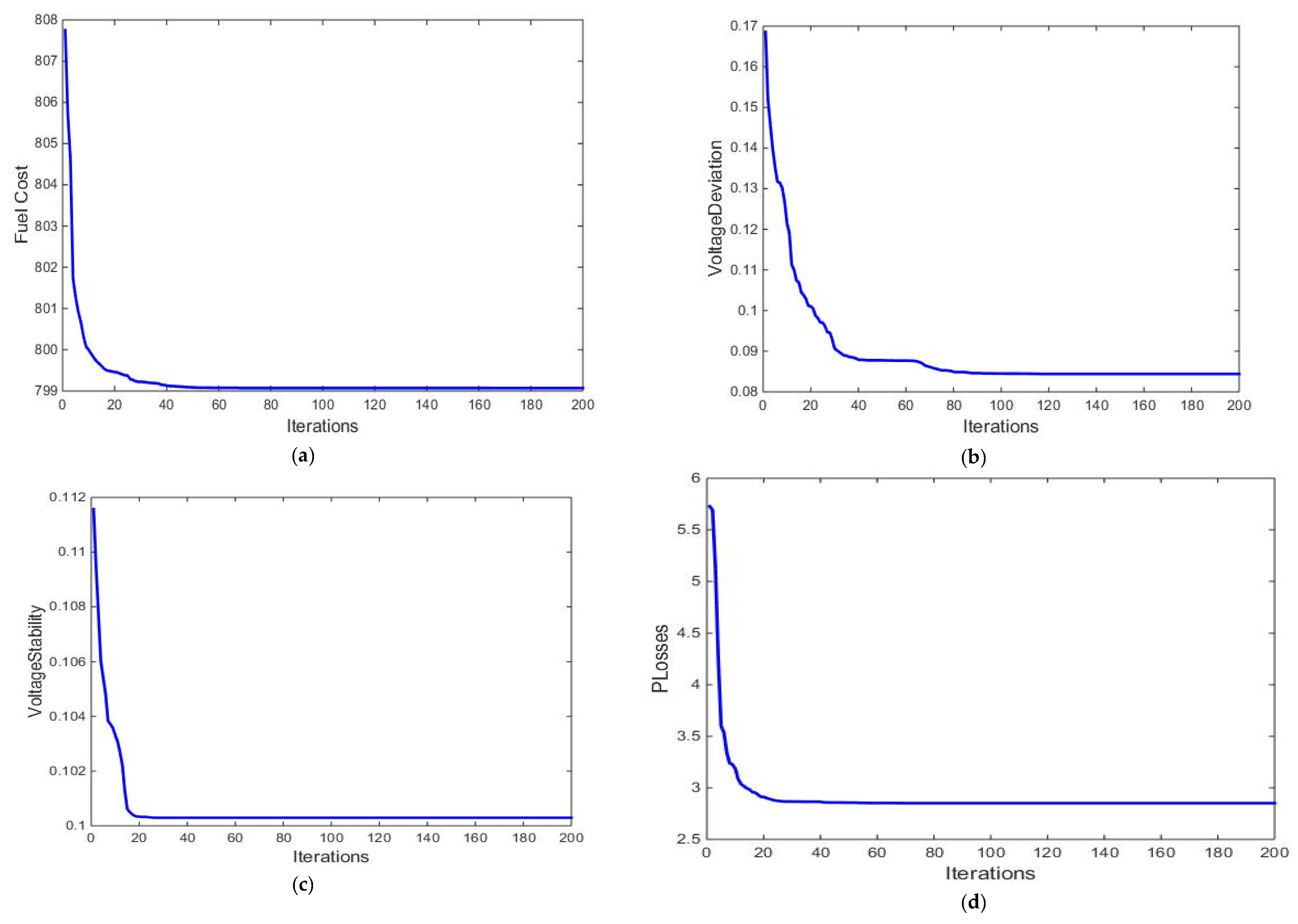

Figure 1 shows good convergence rates using the proposed TFWO for all studied cases in finding the optimal solution of single objective functions, Cases 1–5. The convergence curves show that the TFWO reaches the optimal solution fast and stay stable, and we noted that reaching the optimal solution occurred within 10–20% of the total number of iterations.

- -

Results of bi-objective cases

Table 4 shows the simulation results of bi-, tri-, and quad-objective functions for Cases 6–14, while

Table A2 shows the settings of various control variables for the tested cases. The Cases 6–9 represent the bi-objective cases. The fuel costs and emissions level are optimized simultaneously in Case 6. Case 7 optimizes the fuel costs and power losses. The fuel costs and the voltage stability index are considered in Case 8, while Case 9 optimizes the fuel costs and the voltage deviation as the primary bi- objectives. The simulation results using the proposed TFWO algorithm are compared to other related works in the literature [

46,

53,

58,

61,

62,

64].

Table 5 shows that the proposed TFWO leads to the most efficient solutions for Cases 6–9.

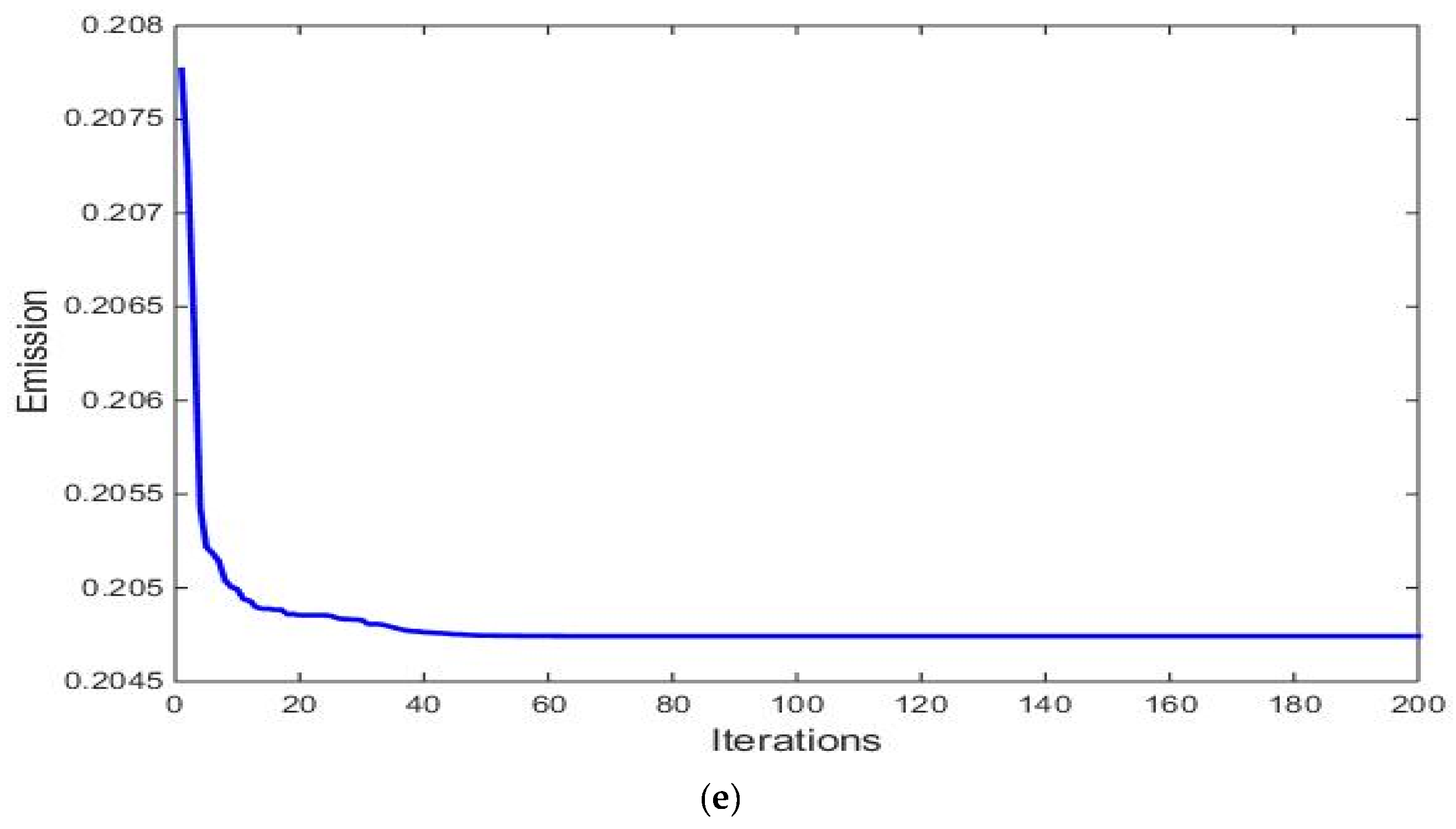

Figure 2 shows Pareto sets for Cases 6–9.

- -

Results of the triple-objective cases

The triple-objective cases are considered in Cases 10–12.

Table 4 shows the simulation results reported for these cases using the proposed TFWO algorithm. In Case 10, three objectives, fuel costs, voltage deviation, and power losses are optimized simultaneously. In Case 11, the triple function aims at minimizing the fuel costs, the power losses and the emission level, while Case 12 optimizes the fuel costs, the voltage deviation, and the emission level simultaneously.

The efficiency of the proposed TFWO algorithm is confirmed by comparing the simulated results obtained with other studies in literature [

53,

58,

59,

62,

64]. It is clear from

Table 6 that the proposed TFWO leads to enhanced fuel costs and power losses, while an increase in voltage deviation is reported compared to PSO-SSO [

53] for Case 10. In addition, the economic/technical and environmental benefits are enhanced in Cases 11–12 compared to PSO, SSO, PSO-SSO [

53], and MOAD [

58]. Pareto solutions of Cases 10–12 are shown in

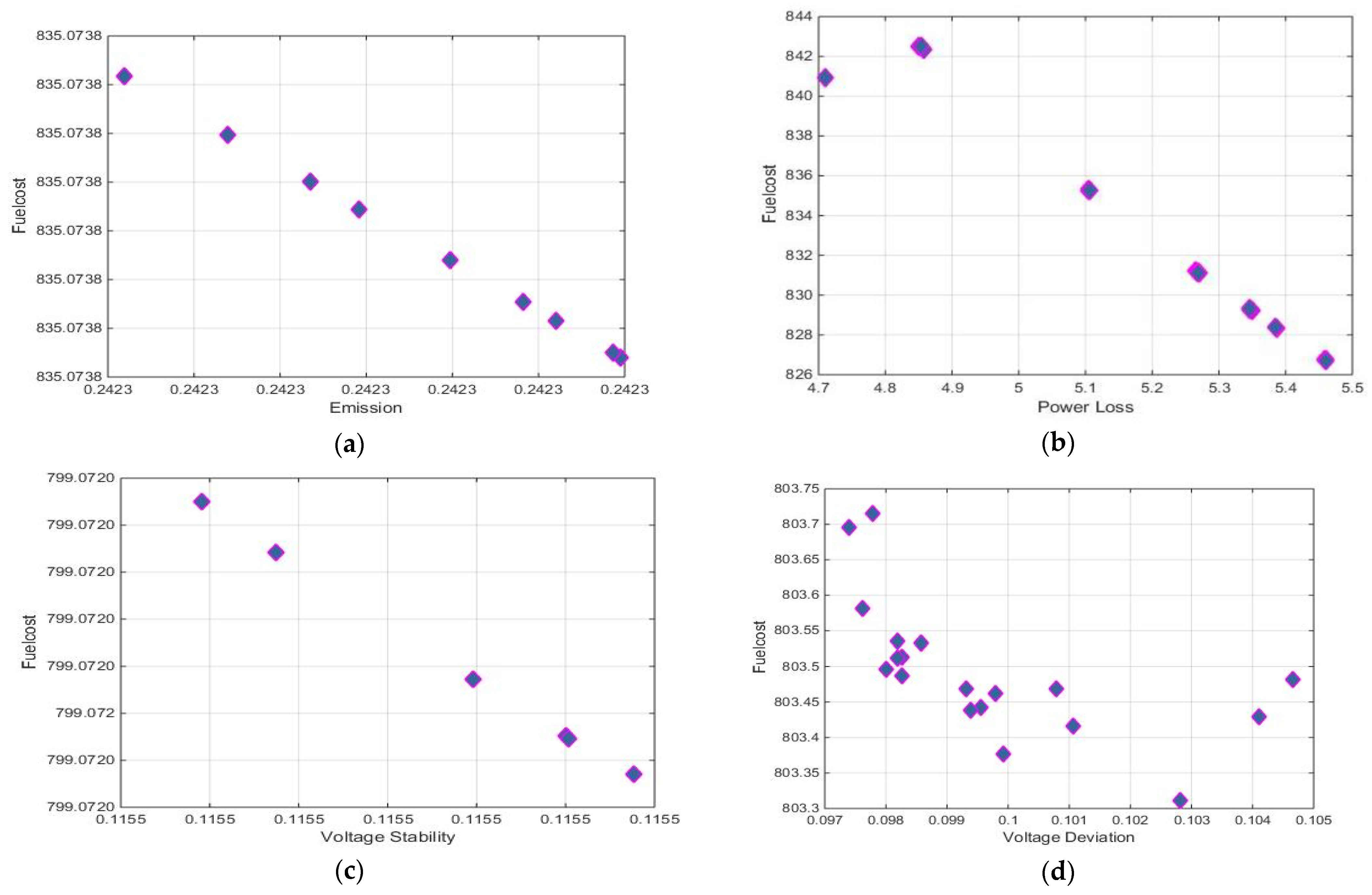

Figure 3.

- -

Results of the multi-objectives cases

Table 7 shows a comparison between simulation results using TFWO and others. Case 13 optimizes the fuel costs, voltage deviation, power losses, and emission level simultaneously. The five objective functions are considered in Case 14. Acceptable economic, technical and environmental benefits are obtained compared to the competitive PSO-SSO and MODA in Cases 13 and 14. The effectiveness and ability of the proposed TFWO are confirmed through these comparison studies with well-known competitive algorithms.

5.2. Simulation Results of IEEE 57-Bus System

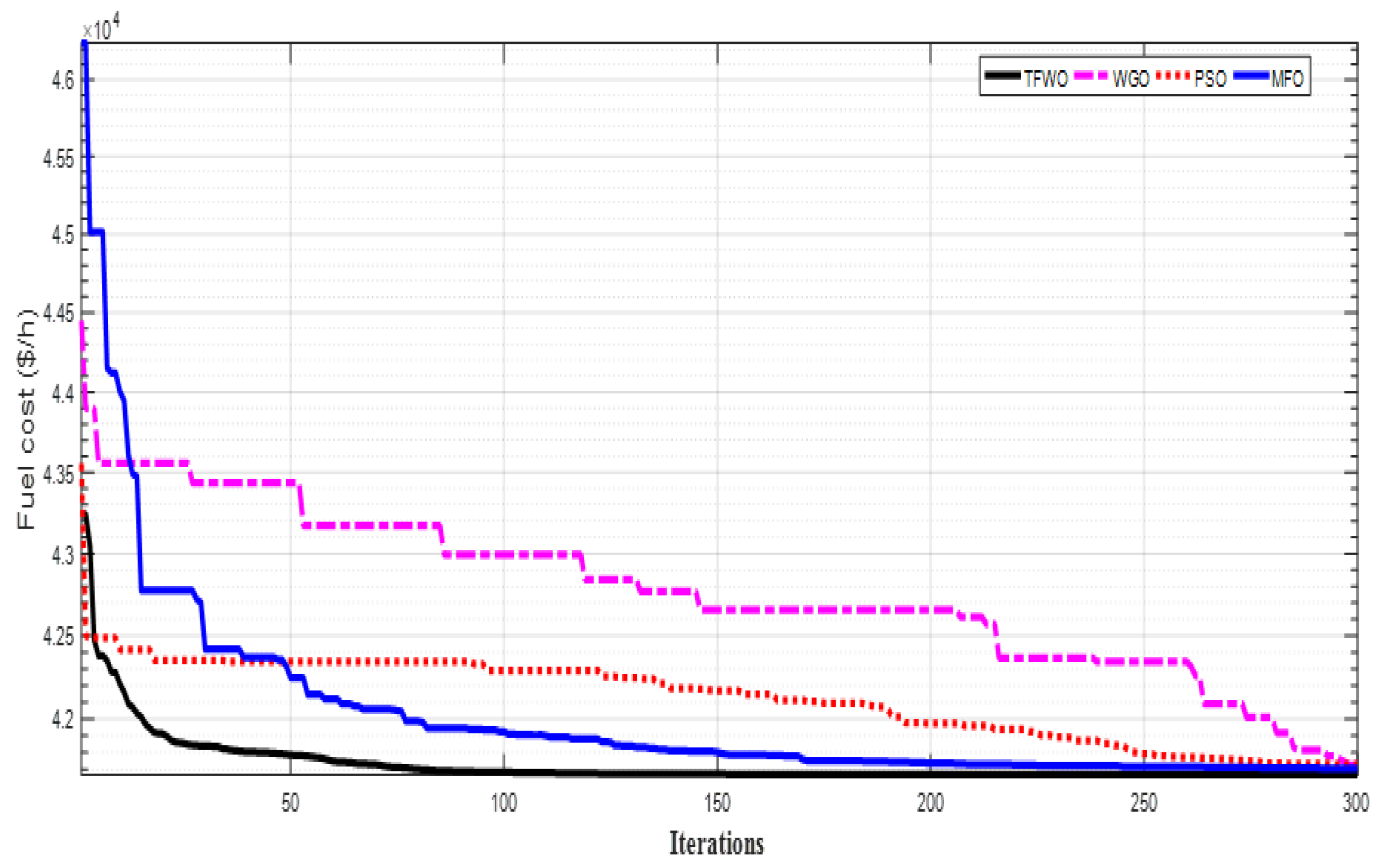

The IEEE 57-bus system consists of 7-generation buses, 80 branches. It has 17 tap changers (at branches 19, 20, 31, 35, 36, 37, 41, 46, 54, 58, 59, 65, 66, 71, 73, 76, and 80) with upper and lower bounds at 1.1–0.9 p.u. There are three shunt reactive sources located at buses 18, 25, and 53 with bounds of 0.2–0.0 in p.u. The boundaries for voltages of all generator buses are considered as 1.05–0.95 p.u. The scalability of the TFWO algorithm was tested on IEEE 57-bus system to investigate the ability to solve single and multi-objectives in large system. The population is 100, and the maximum number of iterations is 300. The OPF problem was solved for three cases: two single objective and a multi-objective. A single objective function is considered in Cases 15 and 16 for minimizing the fuel costs and power losses, respectively. In Case 17, bi-objectives were considered to optimize fuel costs and power losses simultaneously.

Cases 15–17 were optimized using three competitive algorithms GWO, PSO, and MFO in addition to the proposed TFWO. The simulation results of the proposed TFWO algorithm were compared to the competitive algorithms to prove the ability, efficiency and the effectiveness of the proposed method.

Table 8 shows the OPF simulation results obtained for Cases 15–17 using the proposed TFWO algorithm and the other three competitive algorithms. In Case 15, the minimum fuel costs were 41,667.07

$/h with TFWO and 41,804.91, 41,727.01, and 41,708.38

$/h with GOW, PSO, and MFO, respectively. It is clear that the minimum fuel costs obtained is via TFWO. The active power loss in Case 16 was reported as 11.18 MW using the proposed TFWO. In Case 17, the best results obtained using TFWO (41,702.0

$/h and 13.89 MW).

Table 9 presents a comparison of TFWO to recent well-known algorithms in literature. Moreover, the convergence rate of TFWO compared to the three competitive algorithms are shown in

Figure 4. It is clear from the convergence curves that TFWO has the faster convergence rate compared with the others. Statistical indices applied on Case 15 for 50 runs of each algorithm are extracted in

Table 10. It is noticed again that TFWO has the best fuel costs, the lower variance and standard deviation (STD) considered as a good indicator for the efficiency and effectiveness of the proposed TFWO algorithm.

5.3. Simulation Results for Large Scale Test Systems

Four additional large scale test systems are employed to validate the proposed TFWO (Cases 18–21). These systems have varied number of buses power systems. The main data for each tested system is customized from the MATPOWER 6.2 package [

67].

The first large scale system is called the IEEE 300-bus test system. The IEEE 300-bus system consists of 69-generating units and 411 branches. The system supplies a demand apparent power of (23,525.85 + j 7780) MVA. This test system consists of 259 control variables. These variables are 69 active powers of generating units, 69 voltage magnitudes of generating buses, 107 tap changers, and 14 shunt reactive sources for reactive power compensation. The upper and lower bounds of voltage magnitudes are at 1.1–0.95 p.u. The tap changers of transformers are regulated with the limits of [1.1–0.9].

The second large power system network is called 1354pegase test case. This system consists of 1354 buses, 260 generators, and 1991 branches. The system supplies a demand apparent power of (73,059.7 + j 13,401.4) MVA. This test system consists of 1836 control variables. These variables are 260 active power of generating units, 260 voltage magnitudes of generating buses, 234 tap changers, and 1082 shunt reactive sources for reactive power compensation. The upper and lower bounds of voltage magnitudes are at 1.1–0.9 p.u. The tap changers of transformers are regulated with the limits of [1.1–0.9].

The third large scale test system is called IEEE 3012 bus test system. This system consists of 3012 buses, 502 generators, and 3572 branches. The system supplies a demand apparent power of (27,169.7 + j 10,200.6) MVA. This test system consists of 1214 control variables. These variables are 502 active powers of generating units, 502 voltage magnitudes of generating buses, 201 tap changers, and nine shunt reactive sources for reactive power compensation. The upper and lower bounds of voltage magnitudes are at 1.1–0.95 p.u. The tap changers of transformers are regulated with the limits of [1.1–0.9]. The fourth large scale test system is called IEEE 9241pegase test system.

This system consists of 9241 buses, 1445 generator, 16,049 branches. The system supplies a demand apparent power of (312,354.1 + j 73,581.6) MVA. This test system consists of 11,536 control variables. These variables are 1445 active power of generating units, 1445 voltage magnitudes of generating buses, 1319 tap changers, and 7327 shunt reactive sources for reactive power compensation. The upper and lower bounds of voltage magnitudes are at 1.1–0.90 p.u. The tap changers of transformers are regulated with the limits of [1.1–0.9]. The data of these systems are customized from Matpower6.0b2 software [

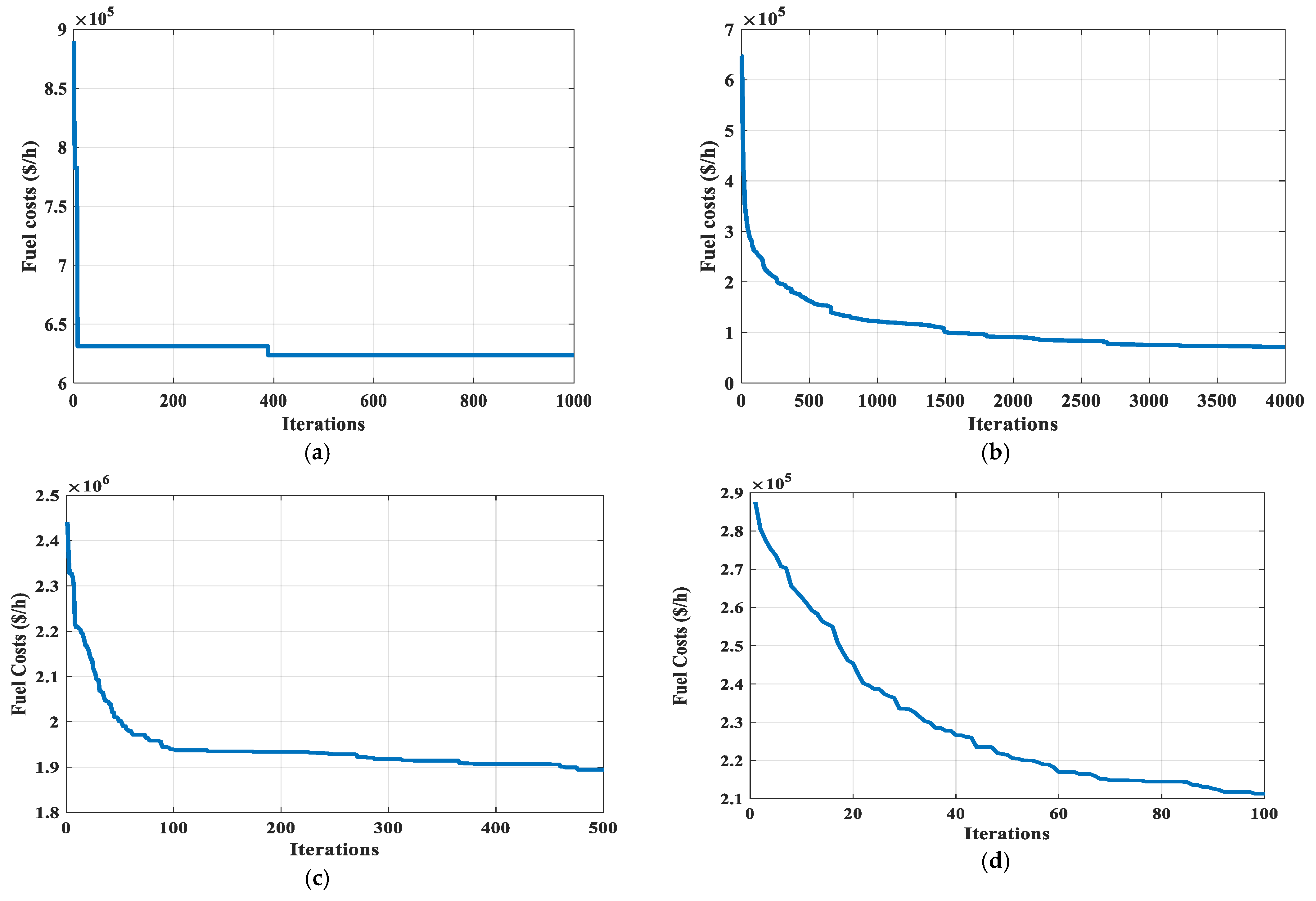

67]. The four large scale systems are optimized to minimize the fuel costs of generating units for Cases 18–21 as reported in

Table 1.

Table 11 shows the simulation results of the proposed TFWO compared to the results of the Matpower6.0b2 simulator for the four large scale test systems to validate the scalability and efficiency of the TFWO algorithm. For the IEEE 300-bus test system, the fuel costs obtained using the TFWO (623,581.39

$/h) are compared with those obtained by the MATPOWER (719,692.27

$/h).

A reduction of 13.4% is achieved by the proposed TFWO. For the IEEE 1354-bus test system, the objective function of fuel costs obtained using the proposed TFWO is 70,810.49 $/h compared to 74,069.35 $/h using the Matpower6.0b2 simulator. A reduction of 4.6% is achieved by the proposed TFWO. For the third large scale system, the fuel costs obtained using the proposed TFWO is 1894369.136 $/h compared to 2,591,706.57 $/h $/h using the Matpower6.0b2 simulator with a reduction of 27%. For the fourth large scale test system, the fuel costs using the proposed TFWO equals 211,308.43 $/h compared to 315,912.43 $/h $/h using the Matpower6.0b2.

A reduction of 33.12% is achieved by the proposed TFWO.

Figure 5 shows the convergence rates for the tested large-scale systems. From the previous simulation results, the proposed TFWO is validated on small- and large-scale test systems. All results obtained emphasize that the TFWO algorithm outperforms the others and has a fast, smooth and stable convergence rate with the increased variables number. These are acceptable techno-economic benefits compared with previous methods as the economical reduction lies in the range of 4.6–33.12%.

6. Conclusions

In this paper, a novel meta-heuristic intelligent algorithm called TFWO algorithm has been implemented to solve OPF problem for small and large systems. Single and multi-objective functions were employed to minimize the cost of fuel, emission level, power losses, enhance voltage deviation and voltage stability index. The proposed algorithm was tested and investigated on the IEEE 30-bus and 57-bus systems and seventeen different cases.

Evaluation of the effectiveness and robustness of the proposed TFWO algorithm was conducted through a comparison of the simulation results, convergence rate, and statistical indices to other well-known recent algorithms in the literature. Statistical indices showed that TFWO had the best fuel costs, the lower average, variance, and standard deviation that also considered indicators for the effectiveness and accuracy of the proposed algorithm. The scalability of the proposed algorithm was validated through optimizing the IEEE 300-bus, IEEE 1354-bus, IEEE 3012-bus, and IEEE 9241pegase test systems.

A reduction in the fuel costs reached 4.6% in the IEEE 1354-bus, and its level increased for the IEEE-bus 300-bus and for IEEE 9241pegase test system to 13.4% and 33.12%, respectively. The simulation results at the small, medium, and large test system emphasize that TFWO algorithm is efficient, effective, robust and superior in solving OPF optimization problems. It had a better convergence rate than other well-known algorithms that make it an outperforming algorithm in complex engineering problems.

The main weakness is the solution concentration particularly with the increase of the system size. The problem was solved under normal operation only. In this direction, two future trends can be considered to extend this study. The first one aims at solving the OPF in the emergency events such as the outage of one or more generation units and the outage of transmission networks. The second trend is the development of recent optimization algorithms to solve the target problem.