Numerical Study of MHD Natural Convection inside a Cubical Cavity Loaded with Copper-Water Nanofluid by Using a Non-Homogeneous Dynamic Mathematical Model

Abstract

:1. Introduction

2. Mathematical Model

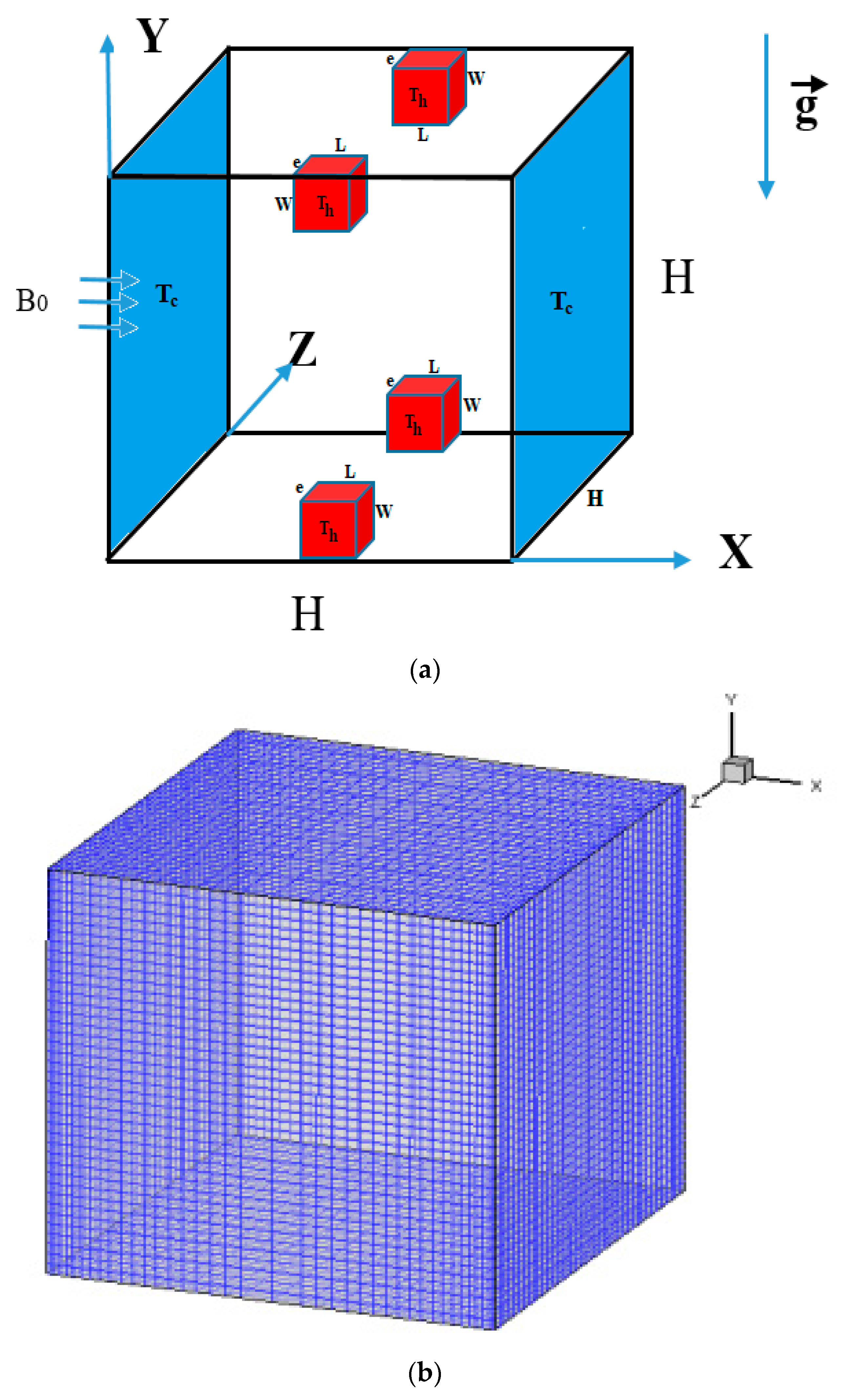

2.1. Problem Geometry, Assumptions, and Governing Equations

- The flow is assumed laminar, steady, Newtonian, 3D, and incompressible.

- The viscous dissipation, chemical reaction, and thermal radiation effects are negligible.

- Boussinesq approximation was adopted.

- Non-homogeneous dynamic mathematical model was taken into account.

- Brownian motion, nanofluid concentration, and thermophoresis are studied and considered.

- The conduction heat transfer in walls was considered negligible.

2.2. Boundary Conditions

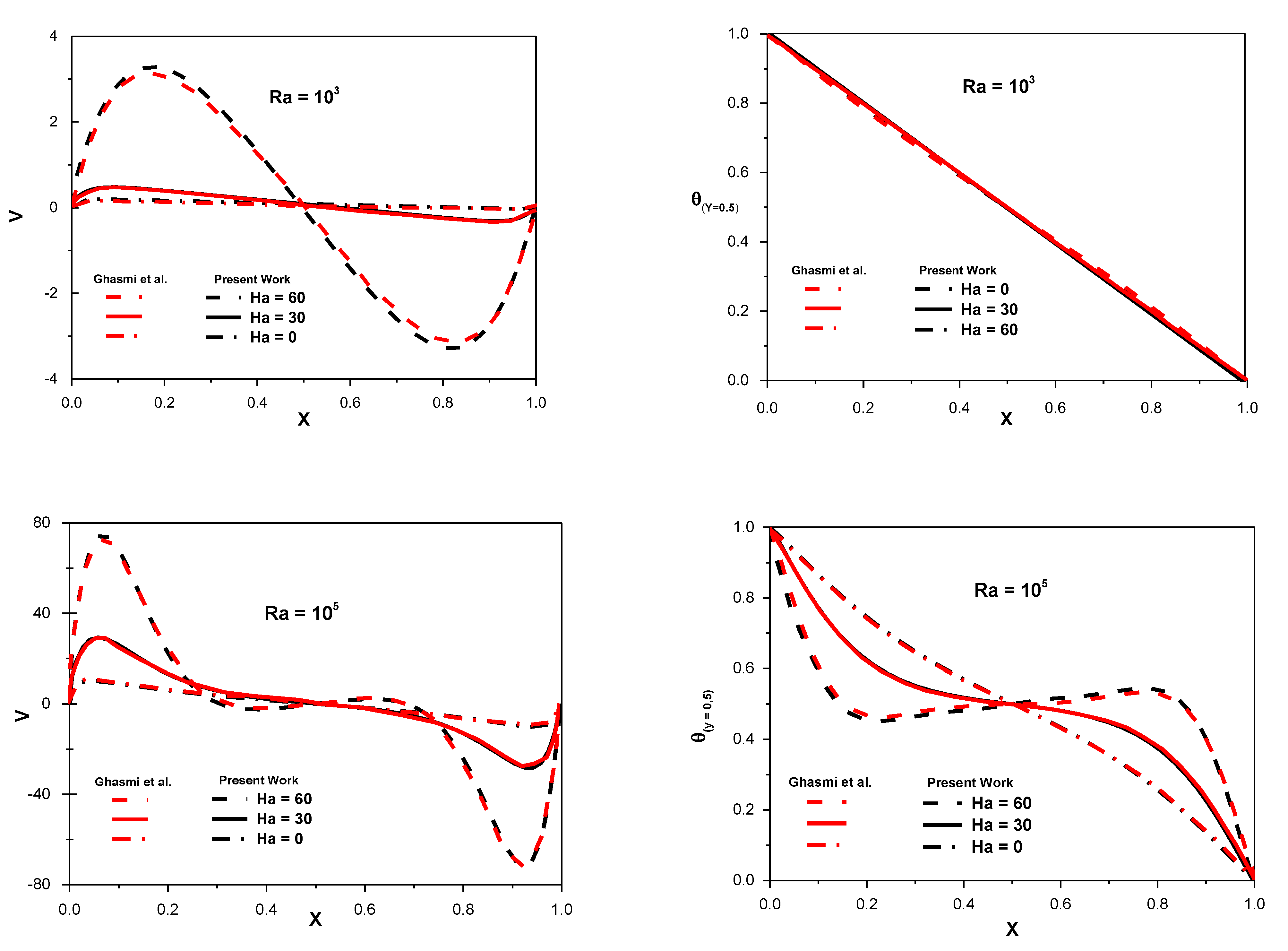

3. Numerical Solution, Validation and Grid-Independent Test

4. Results

5. Discussion

5.1. When the Nanoparticle Diameter Is Considered Fixed at (dp = 10 nm)

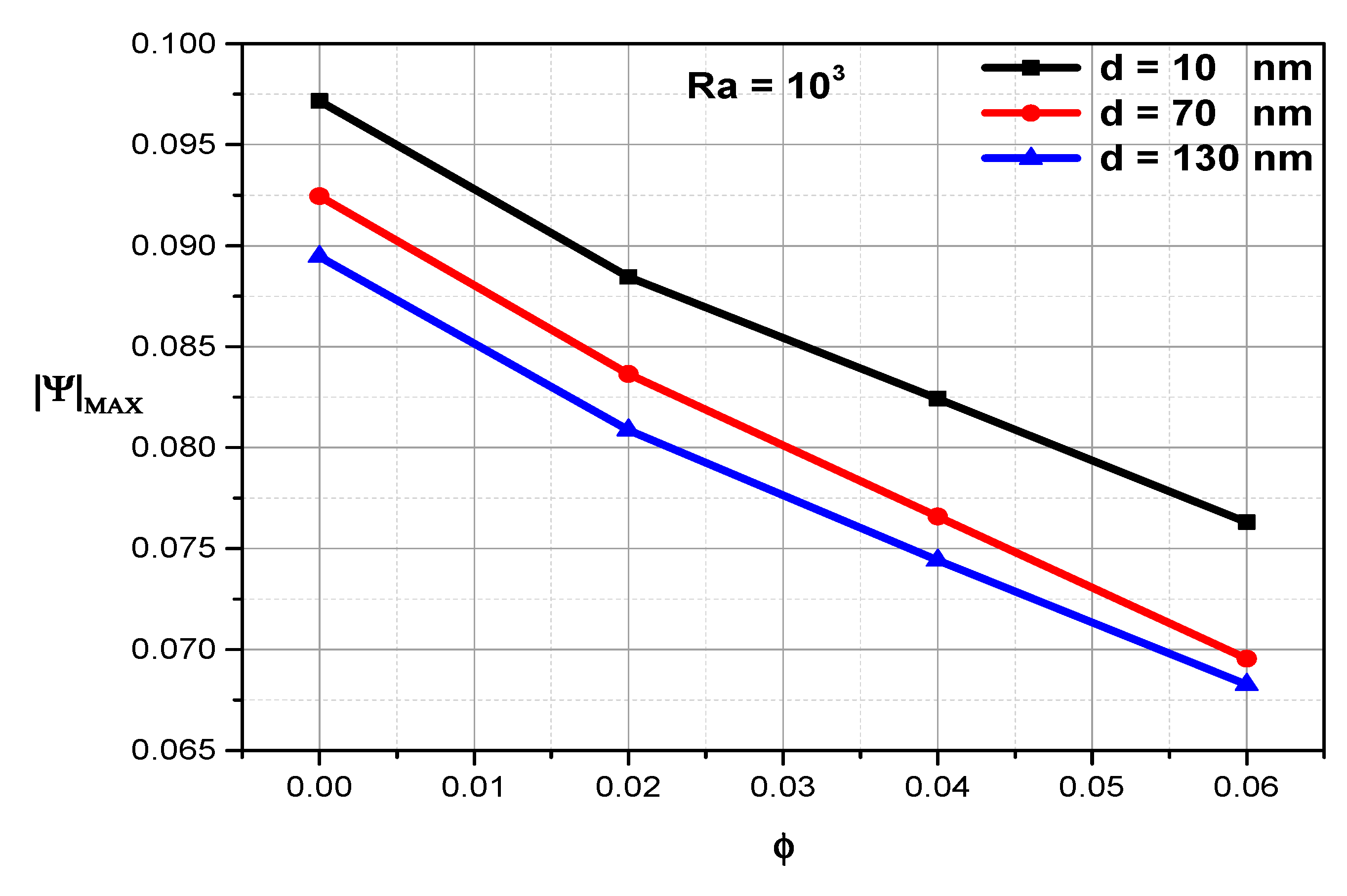

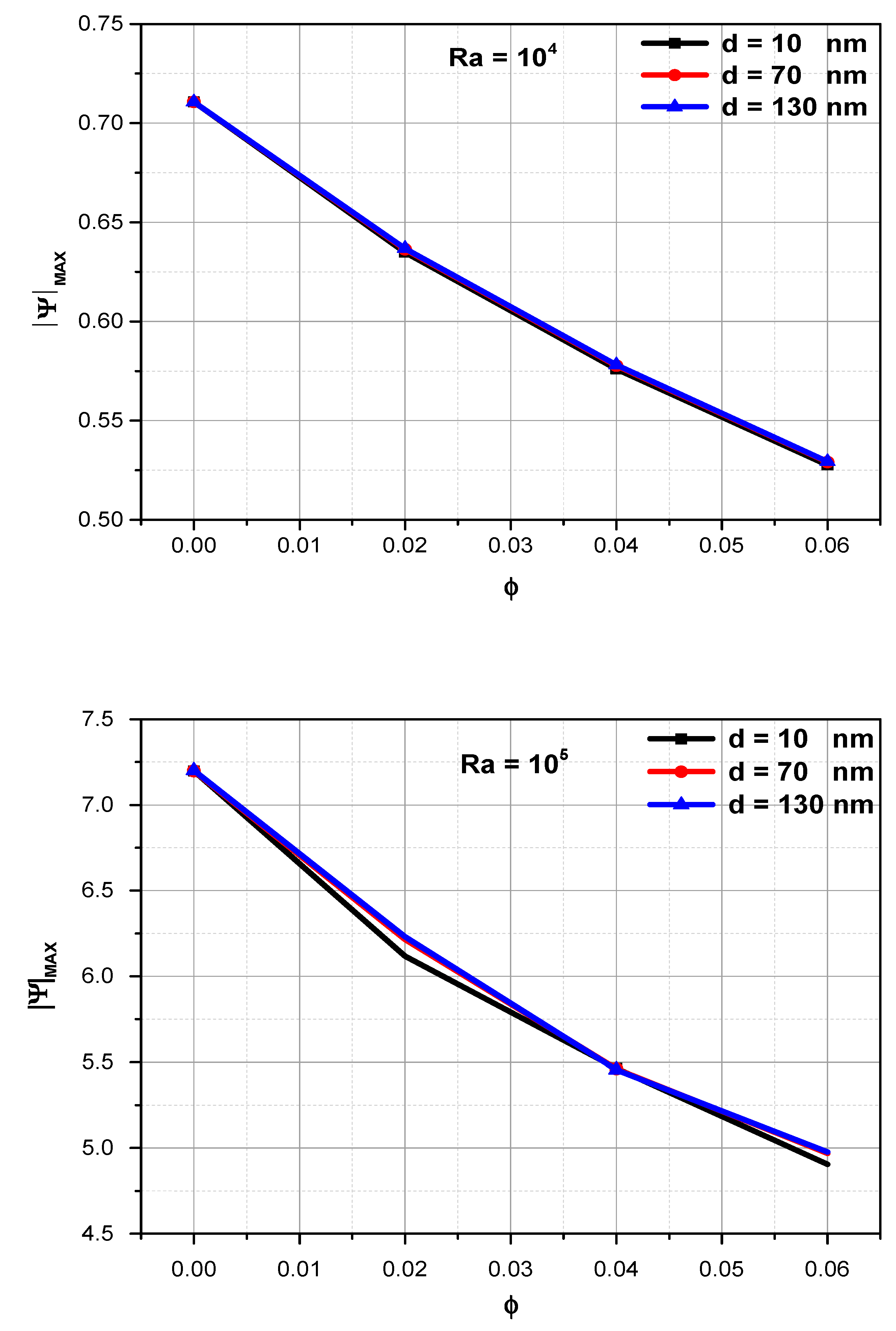

5.2. When the Nanoparticle Diameter Is Considered Variable at (10 nm ≤ dp ≤ 130 nm)

6. Conclusions

6.1. When the Diameter of the Nanoparticle Is Considered Fixed at (dp = 10 nm)

- For (Ra = 103), the temperature distribution is uniform, symmetrical, and seems similar to a semi-ellipse. In this case, the increase in (Ha) and (ϕ) on the temperature profiles are absent, and the conduction effect is predominant.

- For (Ra = 104 and 105), the temperature profiles begin to diverge from each other, and clear confusion can be seen in their shape, especially at (Ra = 105).

- The temperature distribution begins to decrease as the Hartmann number and the solid volumetric fraction increase, especially at (Ra = 105).

- For (Ra = 103 and 104), the maximum temperature distribution can be found in the middle of the x-axis (X = 0.5). For (Ra = 105), this behavior can be found at (30 ≤ Ha ≤ 60). However, at (Ha = 0), they begin to decline suddenly in this region, while they increase on each side of their profiles.

- The temperature distribution increases as Ra increases.

- For (Ra = 103 and 104), the variation of the horizontal velocity profiles decreases strongly as Ha increases. In contrast, an opposite behavior can be found at (Ra = 105).

- For (Ra = 103), the vertical velocity reaches its maximum value when the pure water is used, while it decreases as (ϕ) increases.

- For (Ra = 104 and 105), the use of the nanofluid enhances the horizontal velocity profiles better than water.

- The horizontal velocity profiles increase as the Ra increases up to (Ra = 105).

- For (Ra = 103), the maximum vertical velocity can be found at (Ha = 0) and when the water is used (ϕ = 0).

- For (104 ≤ Ra ≤ 105), the maximum values of vertical velocities increase by increasing (Ra) and decreasing (Ha). While they increase as (ϕ) increases.

- Hartmann number impact on the (NuL) profiles becomes more observable at higher values of Ra (Ra = 105).

- When Ha grows, the average Nusselt number drops; however, when Ra and the solid volumetric fraction increase, the average Nusselt number increases.

- The increasing impact of the magnetic field on the average Nusselt number is absent for (Ra = 103), and this can be seen for all values of (ϕ).

6.2. When the Nanoparticle Diameter Is Considered Variable at (10 nm ≤ dp ≤ 130 nm)

- 15.

- The effect of (dp) and (ϕ) on the flow pattern becomes more clear at (104 ≤ Ra ≤ 105).

- 16.

- The velocity profiles are affected by increasing the nanoparticle diameter when Ra is high (Ra = 105).

- 17.

- The temperature profiles increase as (Ra) increases. They increase continuously along the Y-axis for (Ra = 105), and the effect (dp) on them becomes clearly visible.

- 18.

- The maximum stream function decreases as (ϕ) increases, while it increases as (Ra) increases. On the other side, the effect of (dp) on the relationship between the maximum stream function and the solid volume fraction begins to decrease significantly as Ra increases from 103 to 105.

- 19.

- The average Nusselt is directly proportional to (Ra) and (ϕ) and inversely proportional to (dp).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Bo | Magnetic field (Tesla) |

| C | Concentration |

| CC | Reference or low concentration (mole/m3) |

| Cp | Specific heat at constant pressure (J/kg·K) |

| DB | Brownian diffusion coefficient (m2/s) |

| DT | Thermal diffusion coefficient (m2/s) |

| dp | Diameter of nanoparticle (nm) |

| g | Acceleration due to gravity (m/s2) |

| H | Height or width or depth of the cavity (m) |

| Ha | Hartmann number |

| k | Thermal conductivity (W/m·°C) |

| kB | Boltzmann constant (J/K) |

| Le | Modified Lewis number |

| Dynamic thermo-diffusion parameter | |

| Dynamic diffusion parameter | |

| Nu | Nusselt number |

| N | Empirical nanoparticle shape factor |

| P | Dimensionless Pressure |

| p | Pressure (N/m2) |

| Pr | Prandtl number |

| RaT | Thermal Rayleigh number |

| RaC | Solutal Rayleigh number |

| Sc | Schmidt number |

| T | Temperature (K) |

| TC | Reference temperature (K) |

| U | Dimensionless velocity component in X-direction |

| u | Velocity component in x-direction (m/s) |

| V | Dimensionless velocity component in Y-direction |

| v | Velocity component in y-direction (m/s) |

| W | Dimensionless velocity component in Z-direction |

| w | Velocity component in z-direction (m/s) |

| X | Dimensionless coordinate in the horizontal direction |

| Y | Dimensionless coordinate in the vertical direction |

| Z | Dimensionless coordinate in the axial direction |

| x, y, z | Cartesian coordinates (m) |

| Greek symbols | |

| Thermal diffusivity (m2/s) | |

| ρ | Density (kg/m3) |

| Thermal expansion coefficient (1/K) | |

| Dynamic viscosity (kg/m·s) | |

| Solid volume fraction | |

| Sphericity of the nanoparticle | |

| Kinematic viscosity (m2/s) | |

| θ | Dimensionless temperature |

| Dimensionless concentration | |

| σ | Electrical conductivity (W/m·K) |

| Concentration drop (mole/m3) | |

| Temperature drop (K) | |

| Subscripts | |

| av | Average |

| C | Concentration |

| c | Cold |

| f | Fluid |

| h | Hot |

| nf | Nanofluid |

| np | Nanoparticle |

References

- Mehryan, S.A.M.; Ghalambaz, M.; Gargari, L.S.; Hajjar, A.; Sheremet, M. Natural convection flow of a suspension containing nano-encapsulated phase change particles in an eccentric annulus. J. Energy Storage 2020, 28, 101236. [Google Scholar] [CrossRef]

- Hajjar, A.; Mehryan, S.; Ghalambaz, M. Time periodic natural convection heat transfer in a nano-encapsulated phase-change suspension. Int. J. Mech. Sci. 2020, 166, 105243. [Google Scholar] [CrossRef]

- Ghalambaz, M.; Mehryan, S.M.A.; Hajjar, A.; Veisimoradi, A. Unsteady natural convection flow of a suspension comprising Nano-Encapsulated Phase Change Materials (NEPCMs) in a porous medium. Adv. Powder Technol. 2020, 31, 954–966. [Google Scholar] [CrossRef]

- El-Gendi, M. Numerical simulation of unsteady natural convection flow inside a pattern of connected open square cavities. Int. J. Therm. Sci. 2018, 127, 373–383. [Google Scholar] [CrossRef]

- Kefayati, G. Effect of a magnetic field on natural convection in an open cavity subjugated to water/alumina nanofluid using Lattice Boltzmann method. Int. Commun. Heat Mass Transf. 2013, 40, 67–77. [Google Scholar] [CrossRef]

- Ghachem, K.; Kolsi, L.; Mâatki, C.; Hussein, A.K.; Borjini, M. Numerical simulation of three-dimensional double diffusive free convection flow and irreversibility studies in a solar distiller. Int. Commun. Heat Mass Transf. 2012, 39, 869–876. [Google Scholar] [CrossRef]

- Onyango, O.; Sigey, J.; Okelo, J.; Okwoyo, J. Enhancement of natural convection heat transfer in a square enclosure with localized heating from below. Int. J. Sci. Res. 2013, 2, 82–87. [Google Scholar]

- Hussein, A.K.; Lioua, K.; Chand, R.; Sivasankaran, S.; Nikbakhti, R.; Li, D.; Naceur, B.M.; Habib, B.A. Three-dimensional unsteady natural convection and entropy generation in an inclined cubical trapezoidal cavity with an isothermal bottom wall. Alex. Eng. J. 2016, 55, 741–755. [Google Scholar] [CrossRef] [Green Version]

- Al-Rashed, A.A.; Kolsi, L.; Hussein, A.K.; Hassen, W.; Aichouni, M.; Borjini, M.N. Numerical study of three-dimensional natural convection and entropy generation in a cubical cavity with partially active vertical walls. Case Stud. Therm. Eng. 2017, 10, 100–110. [Google Scholar] [CrossRef]

- Alnaqi, A.; Hussein, A.K.; Kolsi, L.; Al-Rashed, A.; Li, D.; Ali, H. Computational study of natural convection and entropy generation in 3-D cavity with active lateral walls. Therm. Sci. 2020, 24, 2089–2100. [Google Scholar] [CrossRef]

- Ghachem, K.; Hussein, A.K.; Kolsi, L.; Younis, O. CNT-water nanofluid magneto-convective heat transfer in a cubical cavity equipped with perforated partition. Eur. Phys. J. Plus 2021, 136, 377. [Google Scholar] [CrossRef]

- AbdulHussein, W.A.; Abed, A.M.; Mohammed, D.B.; Smaisim, G.F.; Baghaei, S. Investigation of boiling process of different fluids in microchannels and nanochannels in the presence of external electric field and external magnetic field using molecular dynamics simulation. Case Stud. Therm. Eng. 2022, 35, 102105. [Google Scholar] [CrossRef]

- Gangawane, K.M. Effect of angle of applied magnetic field on natural convection in an open ended cavity with partially active walls. Chem. Eng. Res. Des. 2017, 127, 22–34. [Google Scholar] [CrossRef]

- Bakier, M. Flow in open C-shaped cavities : How far does the change in boundaries affect nanofluid ? Eng. Sci. Technol. Int. J. 2014, 17, 116–130. [Google Scholar] [CrossRef] [Green Version]

- Ghoben, Z.; Hussein, A.K. The natural convection inside a 3D triangular cross section cavity filled with nanofluid and included cylinder with different arrangements. Diagnostyka 2022, 23, 2022205. [Google Scholar] [CrossRef]

- Miroshnichenko, I.V.; Sheremet, M.A.; Oztop, H.F.; Al-Salem, K. MHD natural convection in a partially open trapezoidal cavity filled with a nanofluid. Int. J. Mech. Sci. 2016, 119, 294–302. [Google Scholar] [CrossRef]

- Bhuvaneswari, M.; Eswaramoorthi, S.; Sivasankaran, S.; Hussein, A.K. Cross-diffusion effects on MHD mixed convection over a stretching surface in a porous medium with chemical reaction and convective condition. Eng. Trans. 2019, 67, 3–19. [Google Scholar]

- Zarei, M.S.; Abad, A.T.K.; Hekmatifar, M.; Toghraie, D. Heat transfer in a square cavity filled by nanofluid with sinusoidal wavy walls at different wavelengths and amplitudes. Case Stud. Therm. Eng. 2022, 34, 101970. [Google Scholar] [CrossRef]

- Hussein, A.K. Applications of nanotechnology in renewable energies—A comprehensive overview and understanding. Renew Sustain. Energy Rev. 2015, 42, 460–476. [Google Scholar] [CrossRef]

- Hussein, A.K. Applications of nanotechnology to improve the performance of solar collectors—Recent advances and overview. Renew. Sustain. Energy Rev. 2016, 62, 767–792. [Google Scholar] [CrossRef]

- Hussein, A.K.; Li, D.; Kolsi, L.; Kata, S.; Sahoo, B. A review of nanofluid role to improve the performance of the heat pipe solar collectors. Energy Procedia 2017, 109, 417–424. [Google Scholar] [CrossRef]

- Hussein, A.K.; Walunj, A.; Kolsi, L. Applications of nanotechnology to enhance the performance of the direct absorption solar collectors. J. Therm. Eng. 2016, 2, 529–540. [Google Scholar] [CrossRef]

- Haddad, Z.; Abid, C.; Oztop, H.F.; Mataoui, A. A review on how the researchers prepare their nanofluids. Int. J. Therm. Sci. 2014, 76, 168–189. [Google Scholar] [CrossRef]

- Bahiraei, M.; Hangi, M. Flow and heat transfer characteristics of magnetic nanofluids-a review. J. Magn. Magn. Mater. 2015, 374, 125–138. [Google Scholar] [CrossRef]

- Kamel, M.; Lezsovits, F.; Hussein, A.K. Experimental studies of flow boiling heat transfer by using nanofluids: A recent critical review. J. Therm. Anal. Calorim. 2019, 138, 4019–4043. [Google Scholar] [CrossRef] [Green Version]

- Kolsi, L.; Alrashed, A.A.; Al-Salem, K.; Oztop, H.F.; Borjini, M.N. Control of natural convection via an inclined plate of CNT-water nanofluid in an open-sided cubical enclosure under magnetic field. Int. J. Heat Mass Transf. 2017, 111, 1007–1018. [Google Scholar] [CrossRef]

- Kolsi, L.; Oztop, H.; Ghachem, K.; Al-Meshaal, M.; Mohammed, H.; Babazadeh, H.; Abu-Hamden, N. Numerical study of periodic magnetic field effect on 3D natural convection of MWCNT-water/nanofluid with consideration of aggregation. Processes 2019, 7, 957. [Google Scholar] [CrossRef] [Green Version]

- Kolsi, L.; Algarni, S.; Mohammed, H.A.; Hassen, W.; Lajnef, E.; Aich, W.; Almeshaal, M.A. 3D magneto-buoyancy-thermocapillary convection of CNT-water nanofluid in the presence of a magnetic field. Processes 2020, 8, 258. [Google Scholar] [CrossRef] [Green Version]

- Al-Rashed, A.A.; Kolsi, L.; Oztop, H.F.; Aydi, A.; Malekshah, E.H.; Abu-Hamdeh, N.; Borjini, M.N. 3D magneto-convective heat transfer in CNT-nanofluid filled cavity under partially active magnetic field. Phys. E Low-Dimens. Syst. Nanostruct. 2018, 99, 294–303. [Google Scholar] [CrossRef]

- Al-Rashed, A.A.; Kalidasan, K.; Kolsi, L.; Aydi, A.; Malekshah, E.H.; Hussein, A.K.; Kanna, R. Three-dimensional investigation of the effects of external magnetic field inclination on laminar natural convection heat transfer in CNT-water nanofluid filled cavity. J. Mol. Liq. 2018, 252, 454–468. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Ellahi, R. Three-dimensional mesoscopic simulation of magnetic field effect on natural convection of nanofluid. Int. J. Heat Mass Transf. 2015, 89, 799–808. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Bandpy, M.; Ashorynejad, H. Lattice Boltzmann method for simulation of magnetic field effect on hydrothermal behavior of nanofluid in a cubic cavity. Physica A 2015, 432, 58–70. [Google Scholar] [CrossRef]

- Uddin, M.; Alam, M.; Al-Salti, N.; Rahman, M. Investigations of natural convection heat transfer in nanofluids filled horizontal semicircular-annulus using non-homogeneous dynamic model. Am. J. Heat Mass Transf. 2016, 3, 425–452. [Google Scholar]

- Uddin, M.; Rahman, M.; Alam, M. Analysis of natural convective heat transport in homocentric annuli containing nanofluids with an oriented magnetic field using non-homogeneous dynamic model. Neural Comput. Appl. 2018, 30, 3189–3208. [Google Scholar] [CrossRef]

- Uddin, M.; Fazlul Hoque, A.; Rahman, M.; Vajravelu, K. Numerical simulation of convective heat transport within the nanofluid filled vertical tube of plain and uneven sidewalls. Int. J. Thermofluid Sci. Technol. 2019, 6, 19060101. [Google Scholar]

- Al-Balushi, L.; Rahman, M. Natural convective heat transfer in the presence of a sloping magnetic field inside a square enclosure with different wall temperature distributions utilizing magnetic nanoparticles following non-homogeneous dynamic model. J. Therm. Sci. Eng. Appl. 2019, 11, 041013. [Google Scholar] [CrossRef]

- Alhashash, A. Natural convection of nano liquid from a cylinder in square porous enclosure using Buongiorno’s two-phase model. Sci. Rep. 2020, 10, 143. [Google Scholar] [CrossRef]

- Sheikhzadeh, G.; Dastmalchi, M.; Khorasanizadeh, H. Effects of nanoparticles transport mechanisms on Al2O3-water nanofluid natural convection in a square enclosure. Int. J. Therm. Sci. 2019, 66, 51–62. [Google Scholar] [CrossRef]

- Choi, S.; Kim, S.; Lee, T.; Hahn, D. Computation of the natural convection of nanofluid in a square cavity with homogeneous and non-homogeneous models. Numer. Heat Transf. Part A 2014, 65, 287–301. [Google Scholar] [CrossRef]

- Alsabery, A.I.; Tayebi, T.; Chamkha, A.J.; Hashim, I. Effects of non-homogeneous nanofluid model on natural convection in a square cavity in the presence of conducting solid block and corner heater. Energies 2018, 11, 2507. [Google Scholar] [CrossRef] [Green Version]

- Al-Balushi, L.; Uddin, M.; Rahman, M. Natural convective heat transfer in a square enclosure utilizing magnetic nanoparticles. Propuls. Power Res. 2019, 8, 194–209. [Google Scholar] [CrossRef]

- Uddin, M.; Alam, M.; Rahman, M. Natural convective heat transfer flow of nanofluids inside a quarter-circular enclosure using non-homogeneous dynamic model. Arab. J. Sci. Eng. 2017, 42, 1883–1901. [Google Scholar] [CrossRef]

- Uddin, M.; Rahman, M. Numerical computation of natural convective heat transport within nanofluids filled semi-circular shaped enclosure using non-homogeneous dynamic model. Therm. Sci. Eng. Prog. 2017, 1, 25–38. [Google Scholar] [CrossRef]

- Uddin, M.; Rasel, S. Numerical analysis of natural convective heat transport of copper oxide-water nanofluid flow inside a quadrilateral vessel. Heliyon 2019, 5, e01757. [Google Scholar] [CrossRef] [Green Version]

- Alsabery, A.; Ayaal, A.; Hashim, I. Impacts of non-homogeneous nanofluid approach and orientation angle on convection heat transfer within a 3D wavy cavity. IOP Conf. Ser. Mater. Sci. Eng. 2020, 765, 012035. [Google Scholar]

- Suresh Reddy, E.; Panda, S.; Nayak, M.; Makinde, O. Crossflow on transient double-diffusive natural convection in inclined porous trapezoidal enclosures. Heat Transf.-Asian Res. 2021, 50, 849–875. [Google Scholar]

- Ushachew, E.; Sharma, M.; Makinde, O. Heat convection in micropolar nanofluid through porous medium-filled rectangular open enclosure: Effect of an embedded heated object with different geometries. Therm. Anal. Calorim. 2021, 146, 1865–1881. [Google Scholar] [CrossRef]

- Khan, Z.; Makinde, O.; Hamid, M.; Haq, R.; Khan, A. Hydromagnetic flow of ferrofluid in an enclosed partially heated trapezoidal cavity filled with a porous medium. J. Magn. Magn. Mater. 2020, 499, 166241. [Google Scholar] [CrossRef]

- Girish, N.; Sankar, M.; Makinde, O. Developing buoyant convection in vertical porous annuli with unheated entry and exit. Heat Transf.-Asian Res. 2020, 49, 2551–2576. [Google Scholar]

- Hussain, S.; Hussein, A.K. Natural convection heat transfer enhancement in a differentially heated parallelogrammic enclosure filled with copper-water nanofluid. J. Heat Transf.-Trans. ASME 2014, 136, 082502. [Google Scholar] [CrossRef]

- Hussein, A.K.; Hussain, S. Heatline visualization of natural convection heat transfer in an inclined wavy cavities filled with nanofluids and subjected to a discrete isoflux heating from its left sidewall. Alex. Eng. J. 2016, 55, 169–186. [Google Scholar] [CrossRef] [Green Version]

- Hussein, A.K.; Mustafa, A. Natural convection in fully open parallelogrammic cavity filled with Cu-water nanofluid and heated locally from its bottom wall. Therm. Sci. Eng. Prog. 2017, 1, 66–77. [Google Scholar] [CrossRef]

- Hussein, A.K.; Bakier, M.; Ben Hamida, M.; Sivasankaran, S. Magneto-hydrodynamic natural convection in an inclined T-shaped enclosure for different nanofluids and subjected to a uniform heat source. Alex. Eng. J. 2016, 55, 2157–2169. [Google Scholar] [CrossRef] [Green Version]

- Ghasemi, B.; Aminossadati, S.; Raisi, A. Magnetic field effect on natural convection in a nanofluid-filled square enclosure. Int. J. Therm. Sci. 2011, 50, 1748–1756. [Google Scholar] [CrossRef]

- Al-Farhany, K.; Abdulkadhim, A.; Hamzah, H.K.; Ali, F.H.; Chamkha, A. MHD effects on natural convection in a U-shaped enclosure filled with nanofluid-saturated porous media with two baffles. Prog. Nucl. Energy 2022, 145, 104136. [Google Scholar] [CrossRef]

| ρ (kg·m−3) | β (K−1) | k (W·m−1·K−1) | Cp (J·kg−1·K−1) | |

|---|---|---|---|---|

| Pure Water | 997.1 | 21 × 10−5 | 0.613 | 4179 |

| Cu | 8933 | 1.67 × 10−5 | 400 | 385 |

| 41 × 41 × 41 | 51 × 51 × 51 | 61 × 61 × 61 | 71 × 71 × 71 | 81 × 81 × 81 | |

|---|---|---|---|---|---|

| Nuav | 5.748685 | 5.721563 | 5.698485 | 5.695235 | 5.692066 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sannad, M.; Hussein, A.K.; Abidi, A.; Homod, R.Z.; Biswal, U.; Ali, B.; Kolsi, L.; Younis, O. Numerical Study of MHD Natural Convection inside a Cubical Cavity Loaded with Copper-Water Nanofluid by Using a Non-Homogeneous Dynamic Mathematical Model. Mathematics 2022, 10, 2072. https://doi.org/10.3390/math10122072

Sannad M, Hussein AK, Abidi A, Homod RZ, Biswal U, Ali B, Kolsi L, Younis O. Numerical Study of MHD Natural Convection inside a Cubical Cavity Loaded with Copper-Water Nanofluid by Using a Non-Homogeneous Dynamic Mathematical Model. Mathematics. 2022; 10(12):2072. https://doi.org/10.3390/math10122072

Chicago/Turabian StyleSannad, Mohamed, Ahmed Kadhim Hussein, Awatef Abidi, Raad Z. Homod, Uddhaba Biswal, Bagh Ali, Lioua Kolsi, and Obai Younis. 2022. "Numerical Study of MHD Natural Convection inside a Cubical Cavity Loaded with Copper-Water Nanofluid by Using a Non-Homogeneous Dynamic Mathematical Model" Mathematics 10, no. 12: 2072. https://doi.org/10.3390/math10122072

APA StyleSannad, M., Hussein, A. K., Abidi, A., Homod, R. Z., Biswal, U., Ali, B., Kolsi, L., & Younis, O. (2022). Numerical Study of MHD Natural Convection inside a Cubical Cavity Loaded with Copper-Water Nanofluid by Using a Non-Homogeneous Dynamic Mathematical Model. Mathematics, 10(12), 2072. https://doi.org/10.3390/math10122072