Supervisory Event-Triggered Control of Uncertain Process Networks: Balancing Stability and Performance †

Abstract

:1. Introduction

2. Mathematical Preliminaries

2.1. Class of Process Networks

2.2. Overview of Problem Formulation

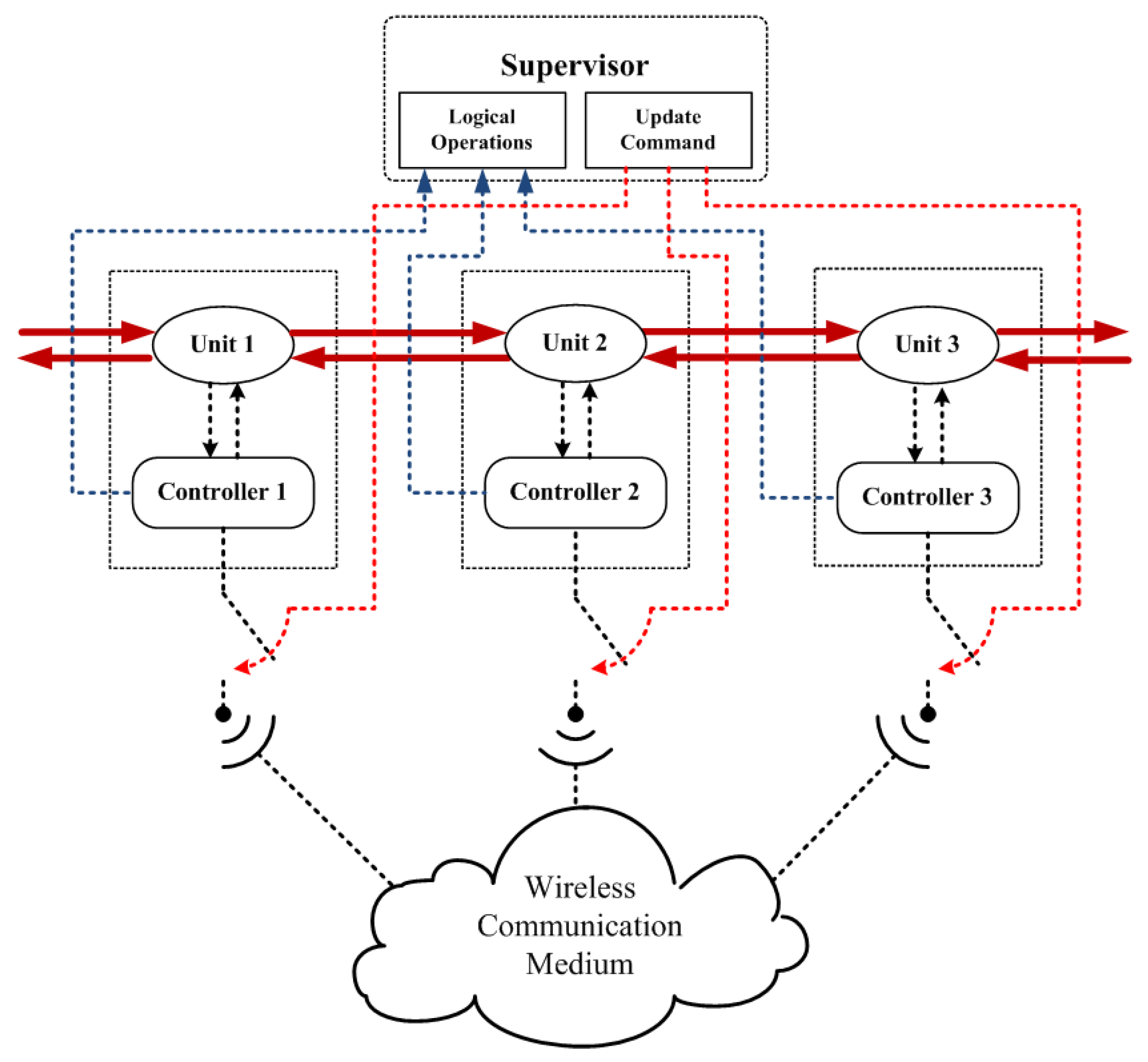

3. Networked Model-Based Control Using a Proactive Communication Strategy

3.1. Design of Local Model-Based Controllers

3.2. Closed-Loop Stability Analysis under Plant–Model Mismatch

3.3. Proactive Broadcast-Based Communication Strategy

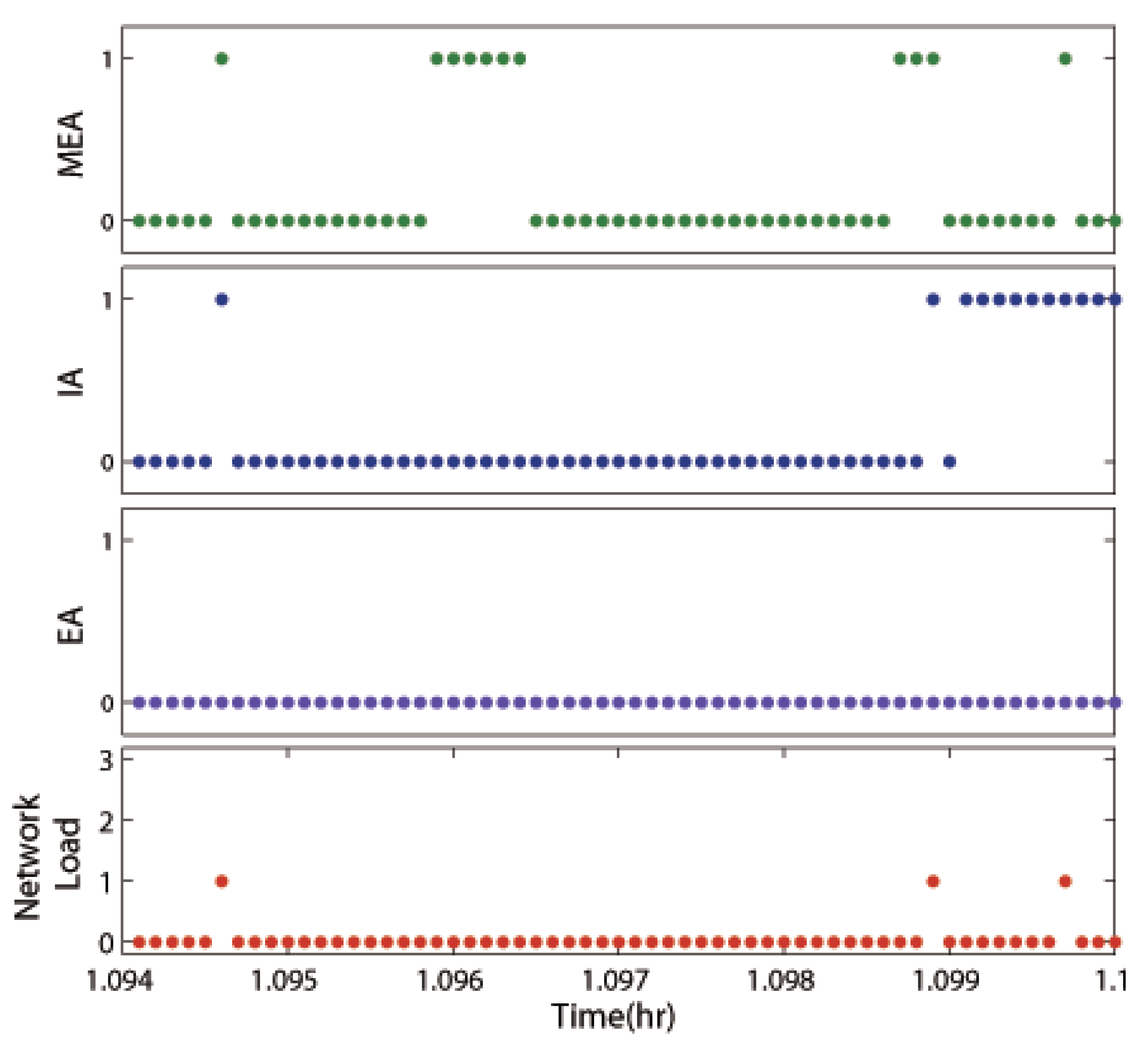

4. Development and Implementation of Supervisory Control Logic

4.1. Case I: No Alarm Signals Reported to the Supervisor (IA = 0, MEA = 0, EA = 0)

4.2. Case II: Only Local Instability Alarms Reported to the Supervisor (IA = 1, MEA = 0, EA = 0)

4.3. Case III: Supervisor Receives Model State Estimation Error Alarms Only (IA = 0, MEA = 1, EA = 0)

4.4. Case IV: Supervisor Receives Both Local Instability and Model State Estimation Error Alarms (IA = 1, MEA = 1, EA = 0)

4.5. Case V: Supervisor Receives Emergency Alarms (EA = 1)

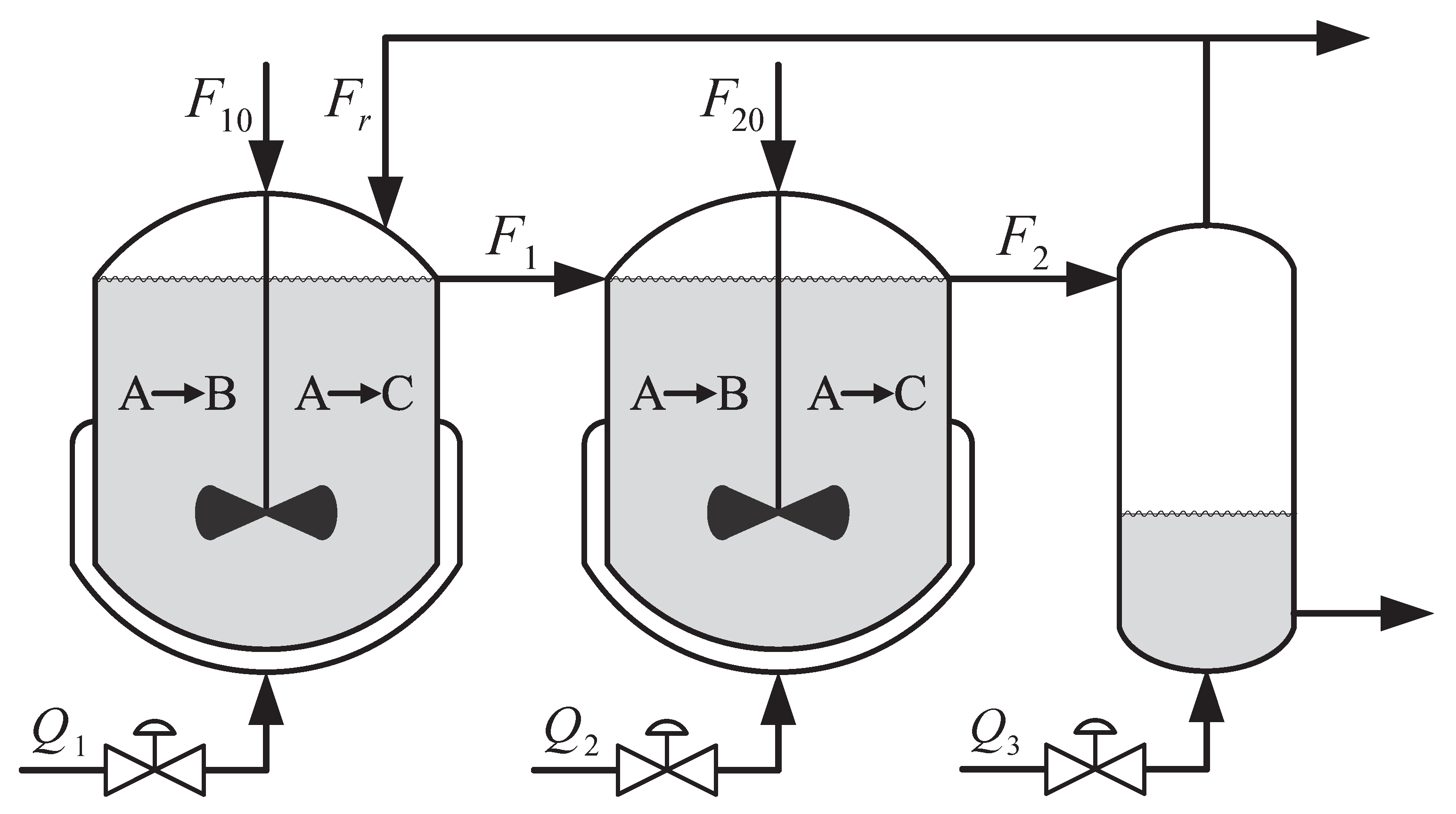

5. Case Study: Application to a Reactor-Separator Network

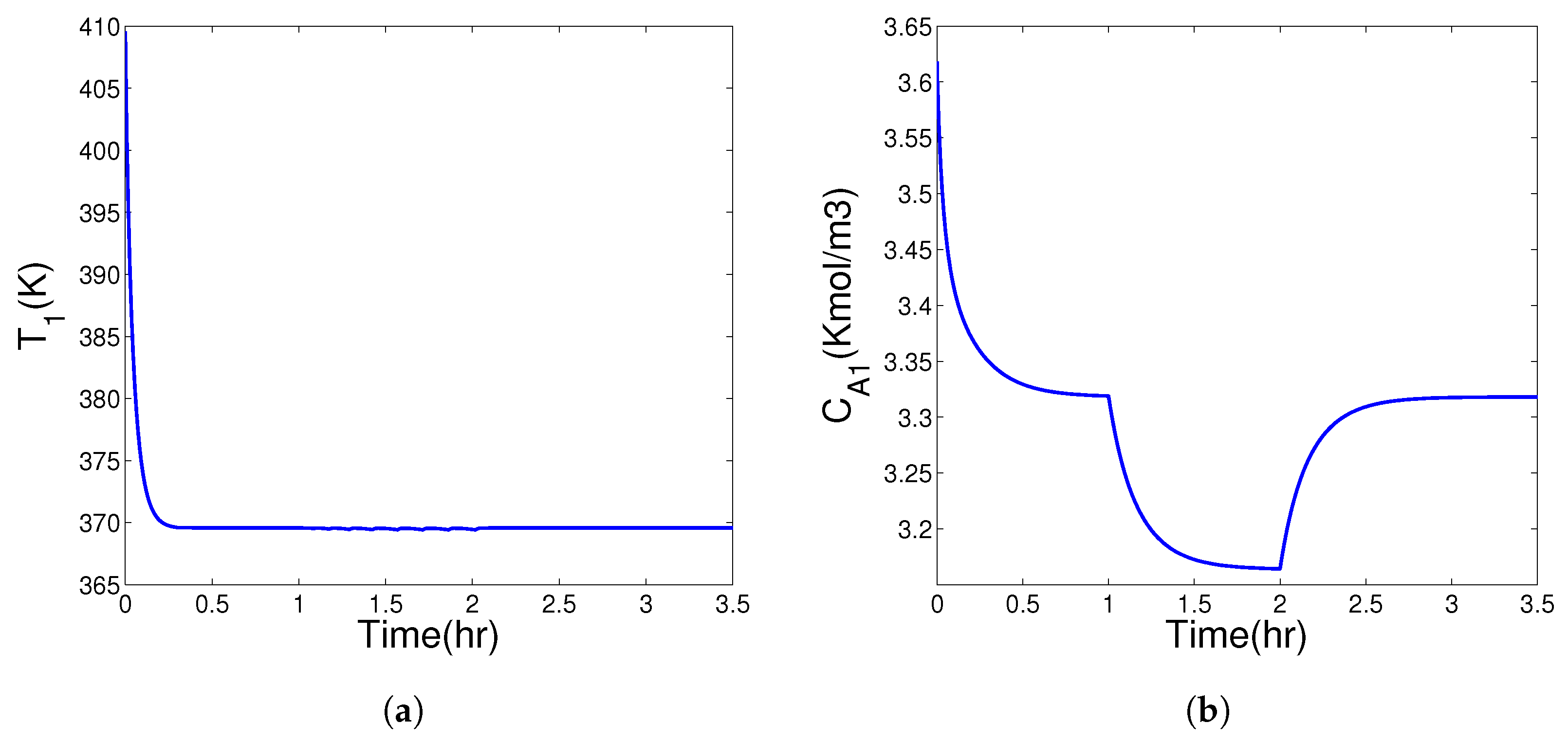

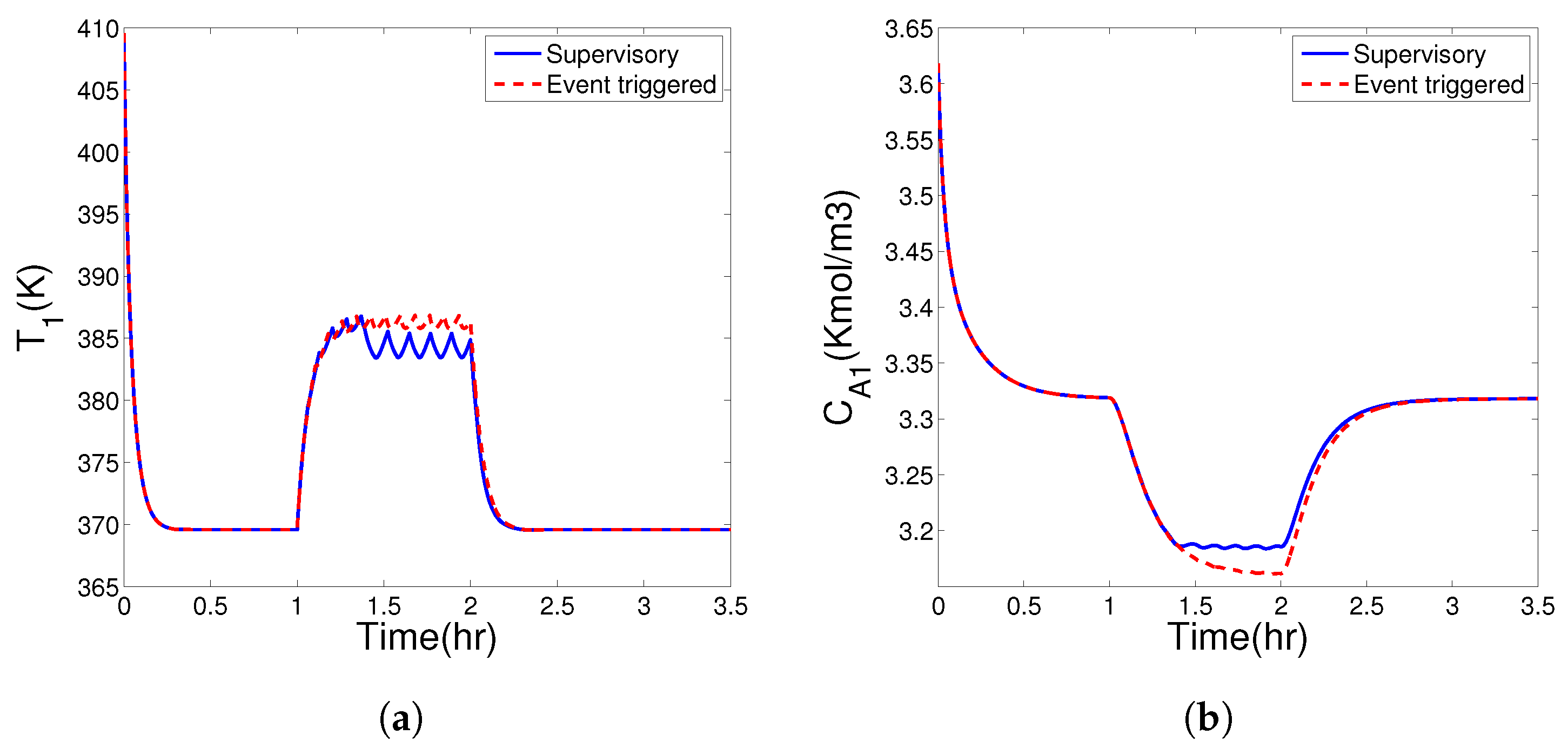

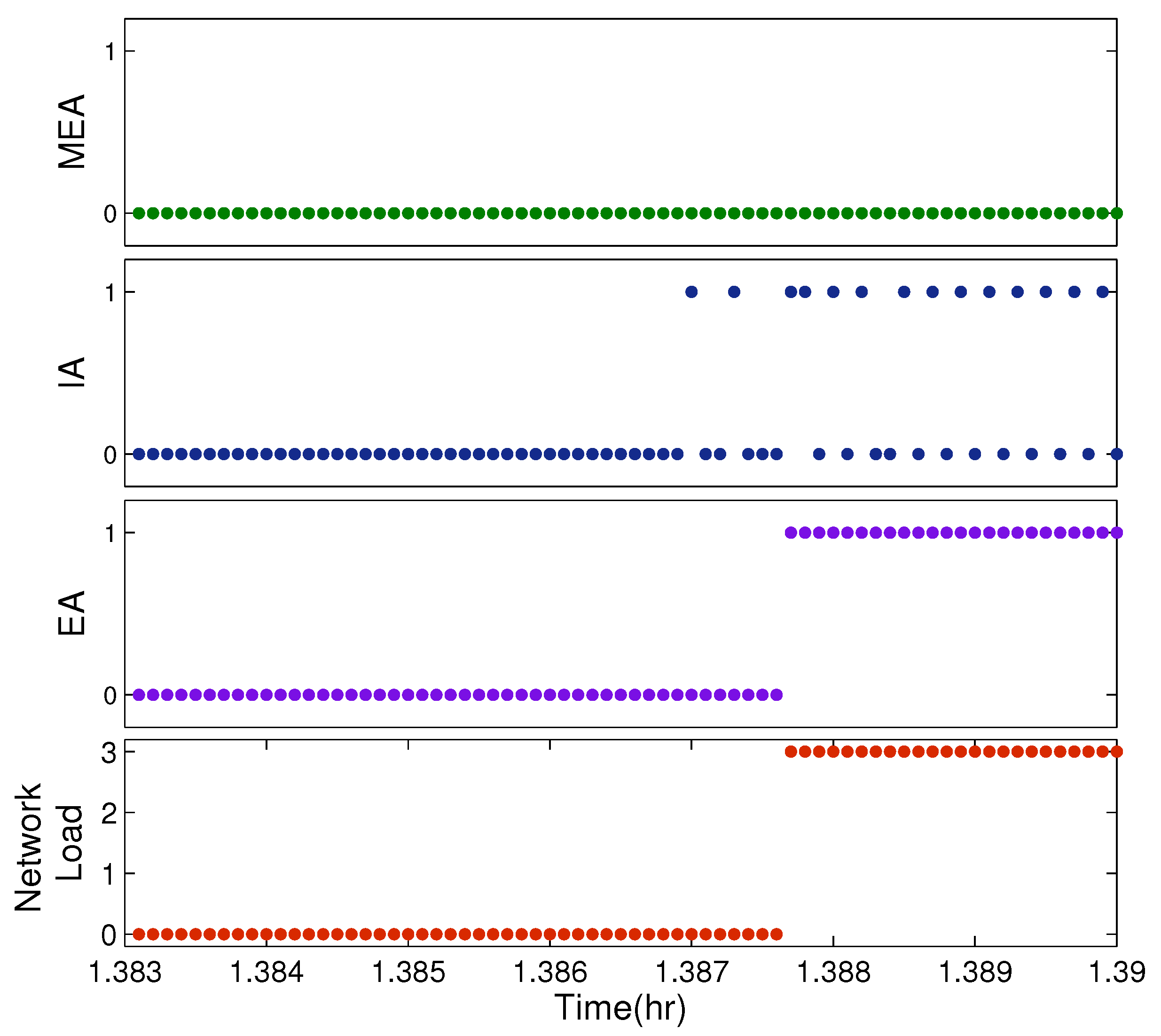

5.1. Implementation of Supervisory Control Approach under Disturbances

5.2. Comparison between Supervised and Unsupervised Broadcast-Based Communication Strategies

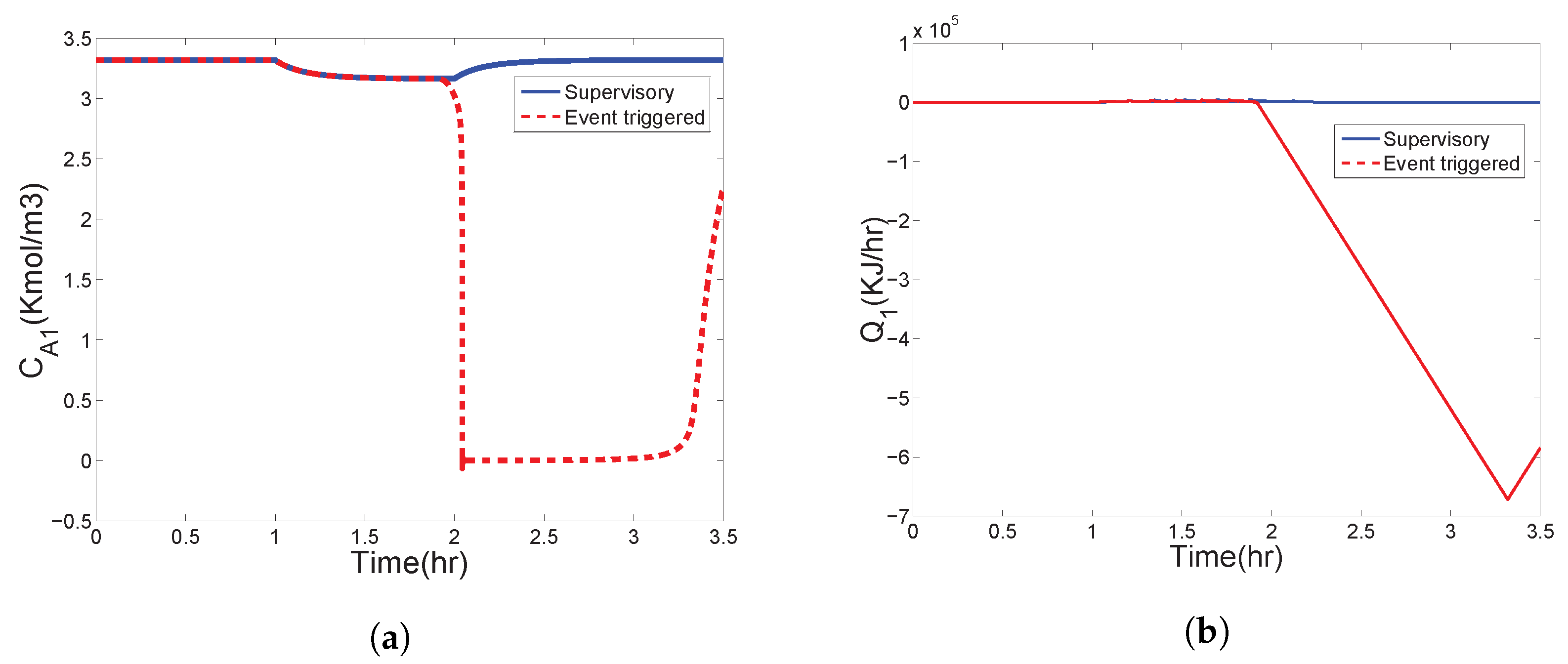

5.3. Supervisory Event-Based Controller Implementation under Input Rate Constraints

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cui, H.; Jacobsen, E.W. Performance limitations in decentralized control. J. Proc. Contr. 2002, 12, 485–494. [Google Scholar] [CrossRef]

- Kordestani, M.; Safavi, A.A.; Saif, M. Recent Survey of Large-Scale Systems: Architectures, Controller Strategies, and Industrial Applications. IEEE Syst. J. 2021, 15, 5440–5453. [Google Scholar] [CrossRef]

- Svoboda, F.; Hengster-Movric, K.; Hromčík, M. Decentralized control for large scale systems with inherently coupled subsystems. J. Vib. Control. 2021. [Google Scholar] [CrossRef]

- Tharanidharan, V.; Sakthivel, R.; Shanmugam, H.; Almakhles, D.J. Decentralized observer-based controller design for large-scale systems with quantized measurements and actuator faults. Asian J. Control. 2022, 1–11. [Google Scholar] [CrossRef]

- Jogwar, S.; Baldea, M.; Daoutidis, P. Dynamics and control of process networks with large energy recycle. Ind. Eng. Chem. Res. 2009, 48, 6087–6097. [Google Scholar] [CrossRef]

- Debnath, S.; Sahoo, S.R.; Decardi-Nelson, B.; Liu, J. Subsystem decomposition and distributed state estimation of nonlinear processes with implicit time-scale multiplicity. Aiche J. 2022, 68, e17661. [Google Scholar] [CrossRef]

- Jillson, K.R.; Ydsite, B.E. Process networks with decentralized inventory and flow control. J. Proc. Contr. 2007, 17, 399–413. [Google Scholar] [CrossRef]

- Zheng, C.; Tippett, M.; Bao, J.; Liu, J. Dissipativity-based distributed model predictive control with low rate communication. AIChE J. 2015, 61, 3288–3303. [Google Scholar] [CrossRef]

- Aboudonia, A.; Martinelli, A.; Lygeros, J. Passivity-based Decentralized Control for Discrete-time Large-scale Systems. In Proceedings of the American Control Conference, Philadelphia, PA, USA, 25–28 May 2021; pp. 2037–2042. [Google Scholar]

- Tetiker, M.D.; Artel, F.; Cinar, A. Control of grade transitions in distributed chemical reactor networks: An agent-based approach. Comp. Chem. Eng. 2008, 32, 1984–1994. [Google Scholar] [CrossRef]

- Chen, F.; Ren, W. On the Control of Multi-Agent Systems: A Survey. Found. Trends Syst. Control. 2019, 6, 339–499. [Google Scholar] [CrossRef]

- Christofides, P.D.; Liu, J.; de la Pena, D.M. Networked and Distributed Predictive Control: Methods and Nonlinear Process Network Applications; Springer: London, UK, 2011. [Google Scholar]

- Cai, X.; Tippett, M.; Xie, L.; Bao, J. Fast distributed MPC based on active set method. Comp. Chem. Eng. 2014, 71, 158–170. [Google Scholar] [CrossRef]

- Coordinating distributed MPC efficiently on a plant-wide scale: The Lyapunov envelope algorithm. Comput. Chem. Eng. 2021, 155, 107532. [CrossRef]

- Christofides, P.D.; Davis, J.; El-Farra, N.H.; Clark, D.; Harris, K.; Gipson, J. Smart plant operations: Vision, progress and challenges. AIChE J. 2007, 53, 2734–2741. [Google Scholar] [CrossRef]

- El-Farra, N.H.; Christofides, P.D. Speical issue on control and optimization of smart plant operations. Chem. Eng. Sci. 2015, 136, 1. [Google Scholar] [CrossRef]

- Zhang, D.; Shi, P.; Wang, Q.G.; Yu, L. Analysis and synthesis of networked control systems: A survey of recent advances and challenges. ISA Trans. 2017, 66, 376–392. [Google Scholar] [CrossRef]

- Ge, X.; Yang, F.; Han, Q.L. Distributed networked control systems: A brief overview. Inf. Sci. 2017, 380, 117–131. [Google Scholar] [CrossRef]

- Zhou, W.; Wang, Y.; Liang, Y. Sliding mode control for networked control systems: A brief survey. ISA Trans. 2021, 124, 249–259. [Google Scholar] [CrossRef] [PubMed]

- Sandberg, H.; Gupta, V.; Johansson, K.H. Secure Networked Control Systems. Annu. Rev. Control. Robot. Auton. Syst. 2022, 5, 445–464. [Google Scholar] [CrossRef]

- Chanfreut, P.; Maestre, J.M.; Camacho, E.F. A survey on clustering methods for distributed and networked control systems. Annu. Rev. Control. 2021, 52, 75–90. [Google Scholar] [CrossRef]

- Gautam, M.K.; Pati, A.; Mishra, S.K.; Appasani, B.; Kabalci, E.; Bizon, N.; Thounthong, P. A comprehensive review of the evolution of networked control system technology and its future potentials. Sustainability 2021, 13, 2962. [Google Scholar] [CrossRef]

- Wu, J.; Peng, C.; Yang, H.; Wang, Y.L. Recent advances in event-triggered security control of networked systems: A survey. Int. J. Syst. Sci. 2022, 23, 1–20. [Google Scholar] [CrossRef]

- Sun, Y.; El-Farra, N.H. Quasi-decentralized model-based networked control of process systems. Comput. & Chem. Eng. 2008, 32, 2016–2029. [Google Scholar]

- Sun, Y.; El-Farra, N.H. Quasi-decentralized networked process control using an adaptive communication policy. In Proceedings of the American Control Conference, Baltimore, MA, USA, 30 June–2 July 2010; pp. 2841–2846. [Google Scholar]

- Wang, X.; Lemmon, M. Event-triggering in distributed networked control systems. IEEE Trans. Autom. Control. 2011, 56, 586–601. [Google Scholar] [CrossRef] [Green Version]

- Garcia, E.; Cao, Y.; Yu, H.; Antsaklis, P.; Casbeer, D. Decentralised event-triggered cooperative control with limited communication. Int. J. Control. 2013, 86, 1479–1488. [Google Scholar] [CrossRef]

- Garcia, E.; Antsaklis, P.J. Model-based event-triggered control for systems with quantization and time-varying network delays. IEEE Trans. Autom. Control. 2013, 58, 422–434. [Google Scholar] [CrossRef]

- Xue, D.; El-Farra, N.H. Supervisory logic for control of networked process systems with event-based communication. In Proceedings of the American Control Conference, Boston, MA, USA, 6–8 July 2016; pp. 7135–7140. [Google Scholar]

- Khalil, H.K. Nonlinear Systems, 2nd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 1996. [Google Scholar]

- Christofides, P.D.; El-Farra, N.H. Control of Nonlinear and Hybrid Process Systems: Designs for Uncertainty, Constraints and Time-Delays; Springer: Berlin, Germany, 2005. [Google Scholar]

- Zhang, J.; Liu, S.; Li, L.; Feng, Q. The KKT optimality conditions in a class of generalized convex optimization problems with an interval-valued objective function. Optim. Lett. 2014, 8, 607–631. [Google Scholar] [CrossRef]

- Treanţă, S. Robust saddle-point criterion in second-order partial differential equation and partial differential inequation constrained control problems. Int. J. Robust Nonlinear Control. 2021, 31, 9282–9293. [Google Scholar] [CrossRef]

- Treanţă, S. Efficiency in uncertain variational control problems. Neural Comput. Appl. 2021, 33, 5719–5732. [Google Scholar] [CrossRef]

| Constraint | Update Frequency (%) | Hit Bound Frequency (%) | ||||

|---|---|---|---|---|---|---|

| CSTR 1 | CSTR 2 | Flash Unit | Overall | |||

| Supervisory control | ✕ | - | ||||

| approach | ✔ | 2.97 | ||||

| Broadcast- | ✕ | 0.23 | 0.38 | - | ||

| based approach | ✔ | 0.24 | 0.13 | 0.45 | 3.38 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, D.; El-Farra, N.H. Supervisory Event-Triggered Control of Uncertain Process Networks: Balancing Stability and Performance. Mathematics 2022, 10, 1964. https://doi.org/10.3390/math10121964

Xue D, El-Farra NH. Supervisory Event-Triggered Control of Uncertain Process Networks: Balancing Stability and Performance. Mathematics. 2022; 10(12):1964. https://doi.org/10.3390/math10121964

Chicago/Turabian StyleXue, Da, and Nael H. El-Farra. 2022. "Supervisory Event-Triggered Control of Uncertain Process Networks: Balancing Stability and Performance" Mathematics 10, no. 12: 1964. https://doi.org/10.3390/math10121964

APA StyleXue, D., & El-Farra, N. H. (2022). Supervisory Event-Triggered Control of Uncertain Process Networks: Balancing Stability and Performance. Mathematics, 10(12), 1964. https://doi.org/10.3390/math10121964