Simulation and State Feedback Control of a Pressure Swing Adsorption Process to Produce Hydrogen

Abstract

:1. Introduction

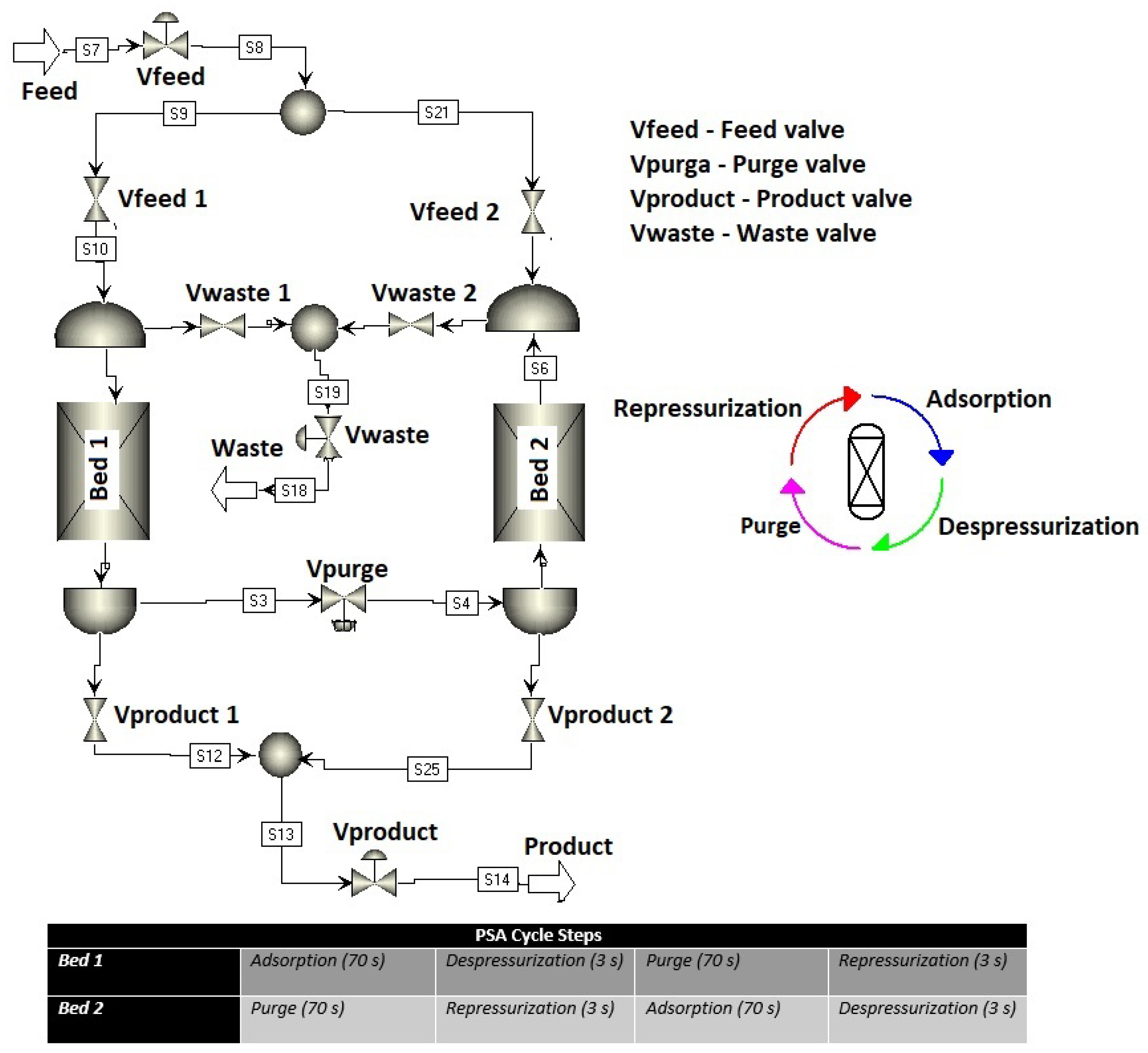

2. Description of the PSA Model

- (1)

- There are no reactions between the elements of the mixture ().

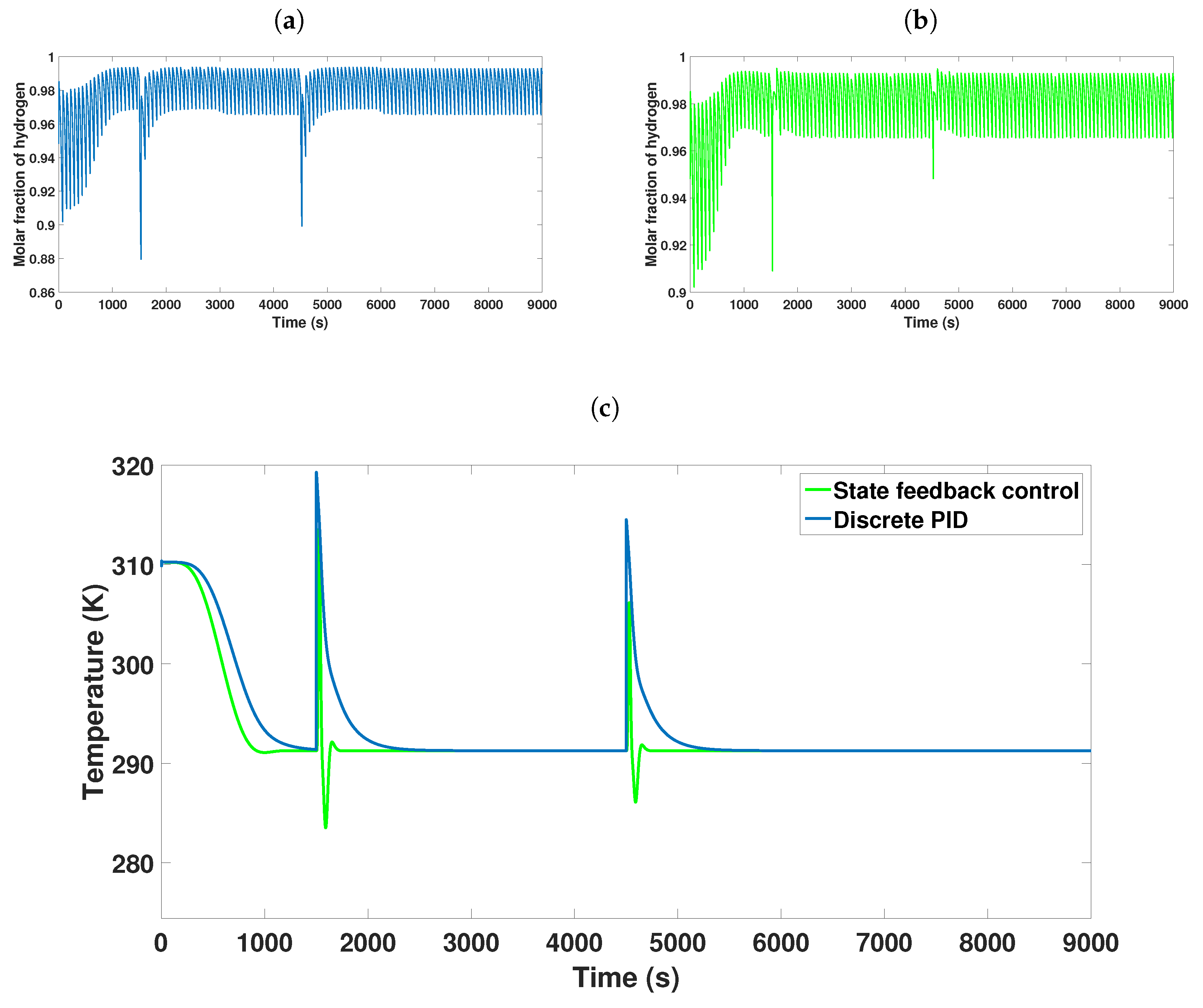

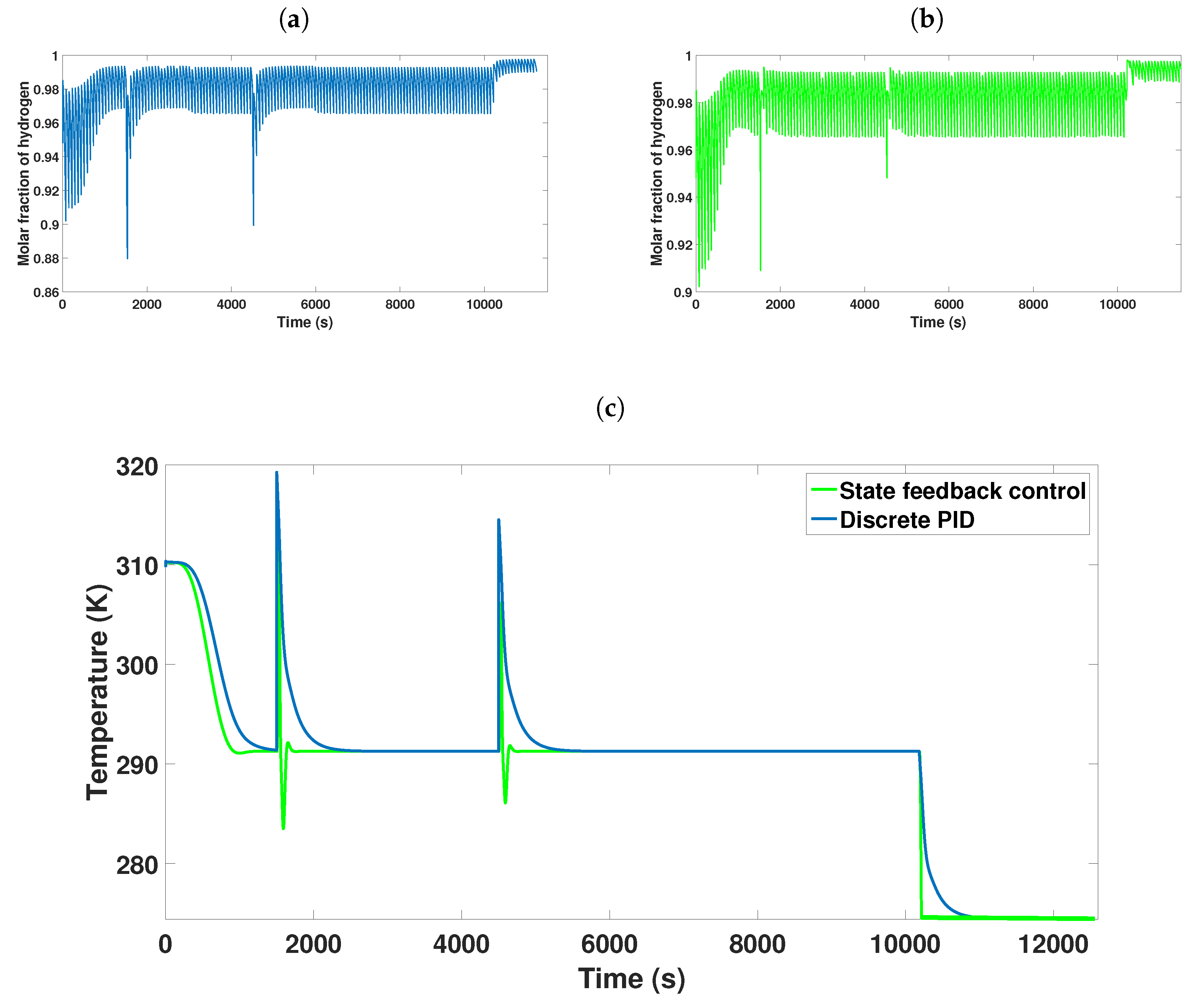

- (2)

- The mass transfer coefficient was considered constant.

- (3)

- The gaseous phase is only convective, and axial dispersion was considered negligible.

- (4)

- The energy balance was considered to be isothermal.

- (5)

- The adsorption equilibrium was modeled by the Langmuir model, expressed in terms of partial-pressure-dependent parameters.

- Mass balance for gas phase:

- Gas phase energy balance:

- Momentum balance:

- Langmuir equation:

- Kinetic model:

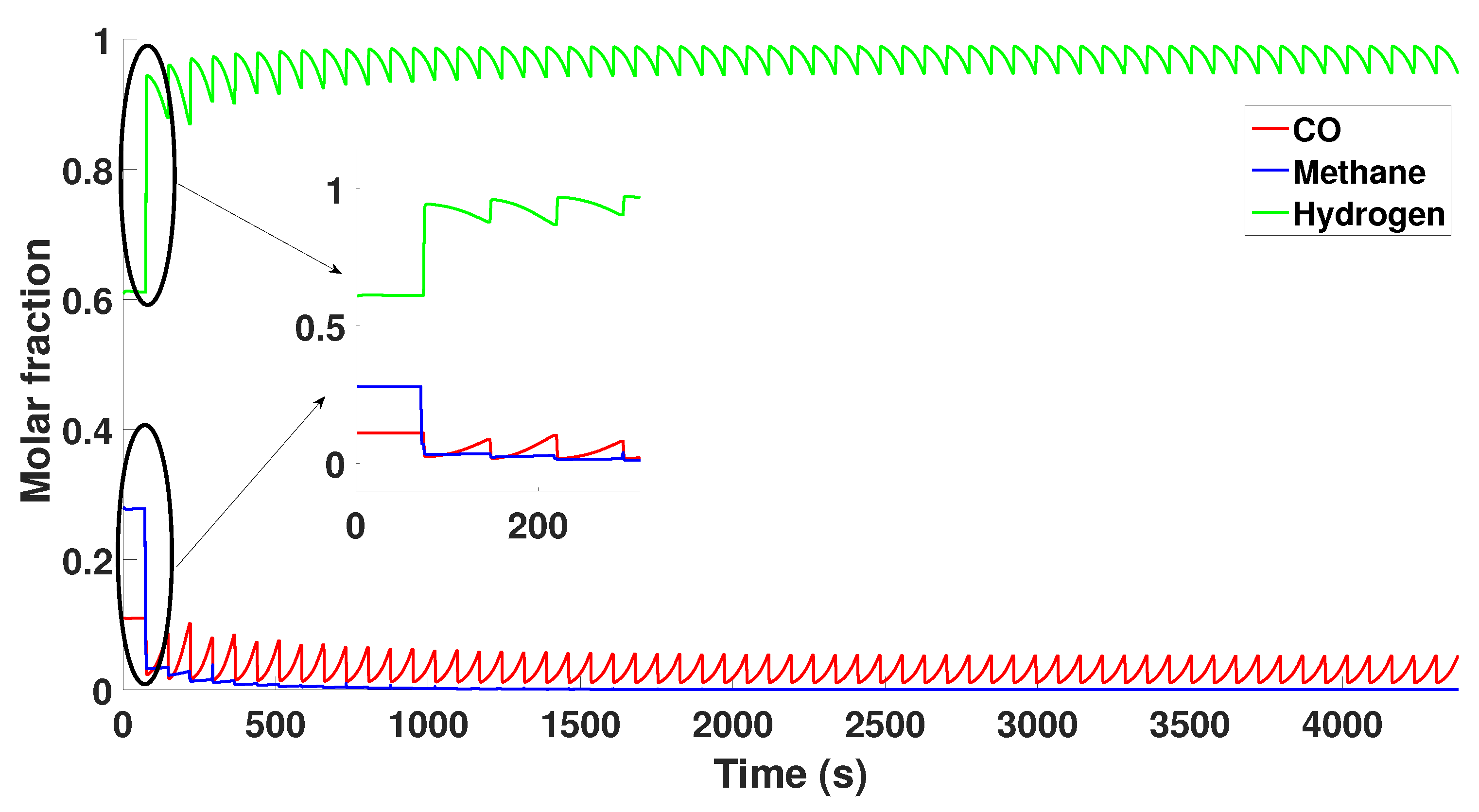

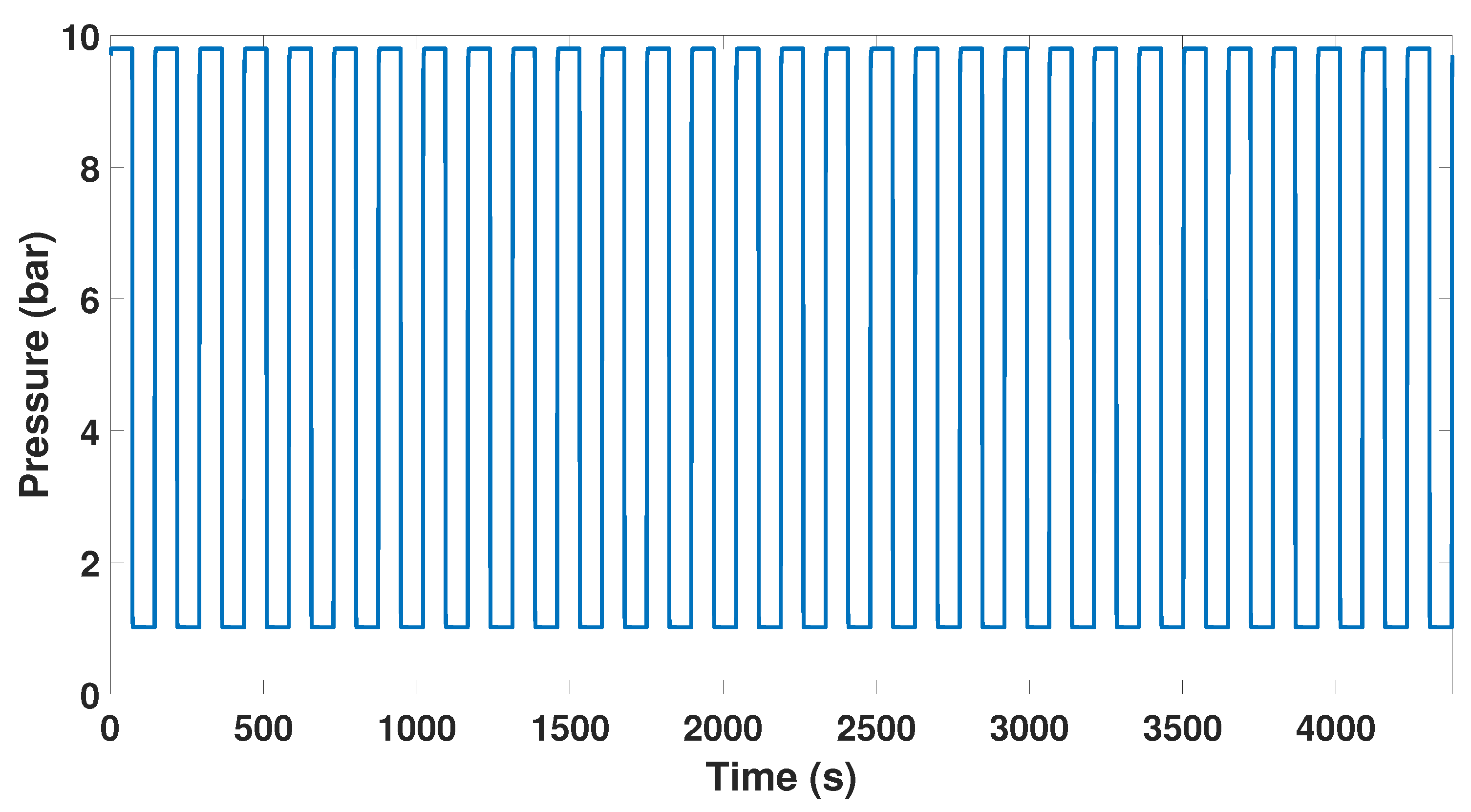

3. Simulation of the PSA Process

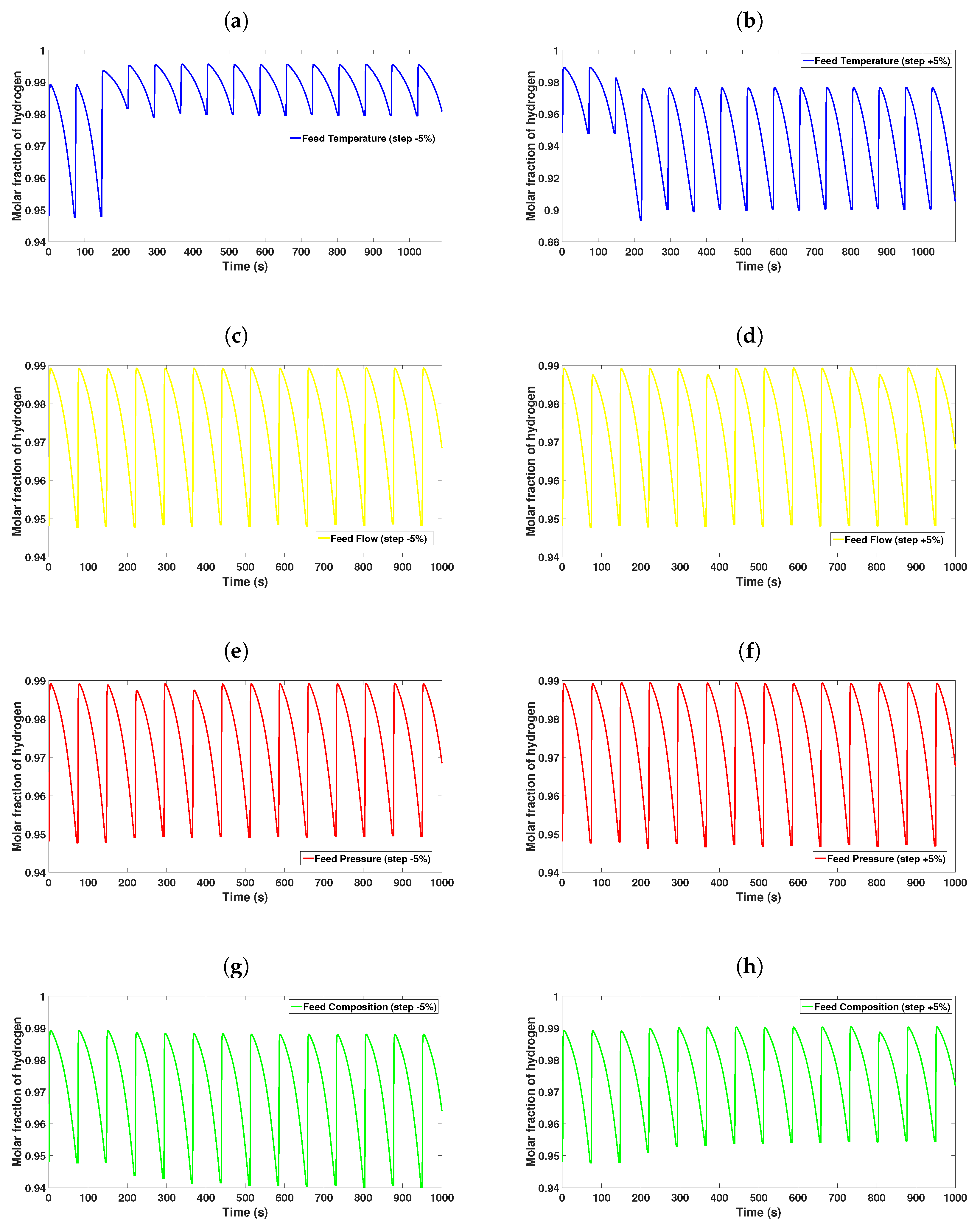

Sensitivity Analysis of the PSA Process

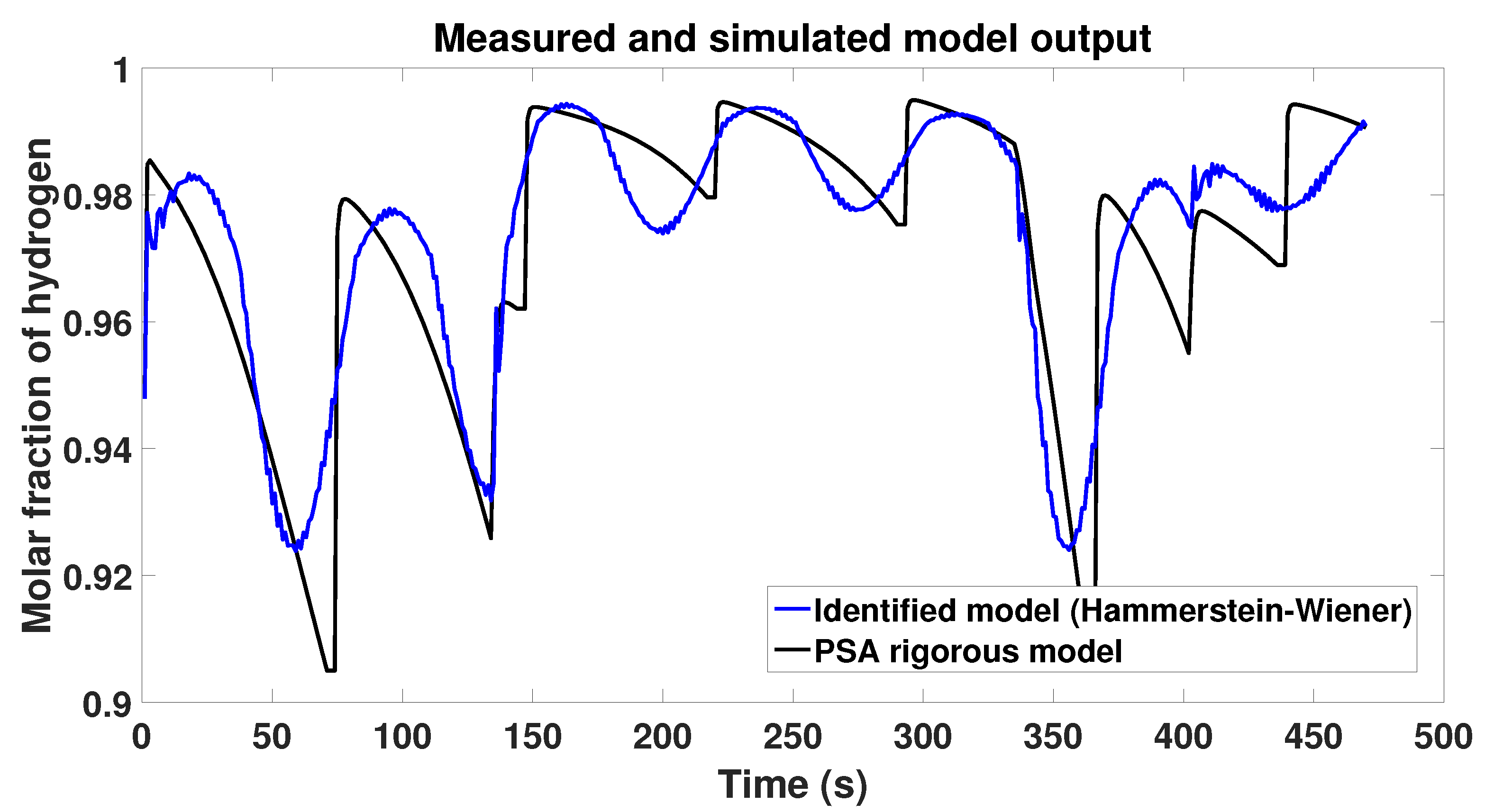

4. System Identification

- At least 1 step must take into account the time for the hydrogen purity to converge to a new CSS.

- A percentage that generates effects on the output variable must be established.

- A number of bits must be proposed, in such a way that they do not excite the PSA process too much, since this can generate a bad identification. However, this cannot be an input with a minimum value of bits either.

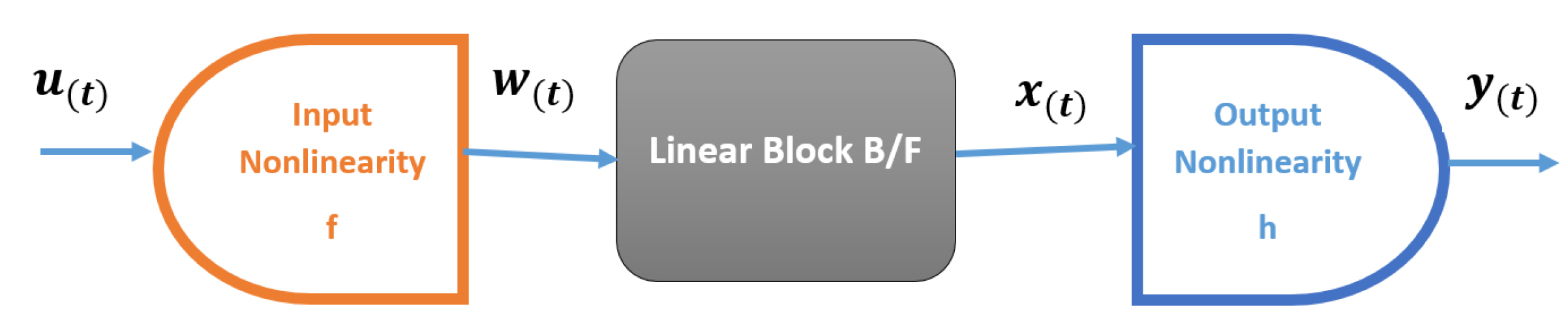

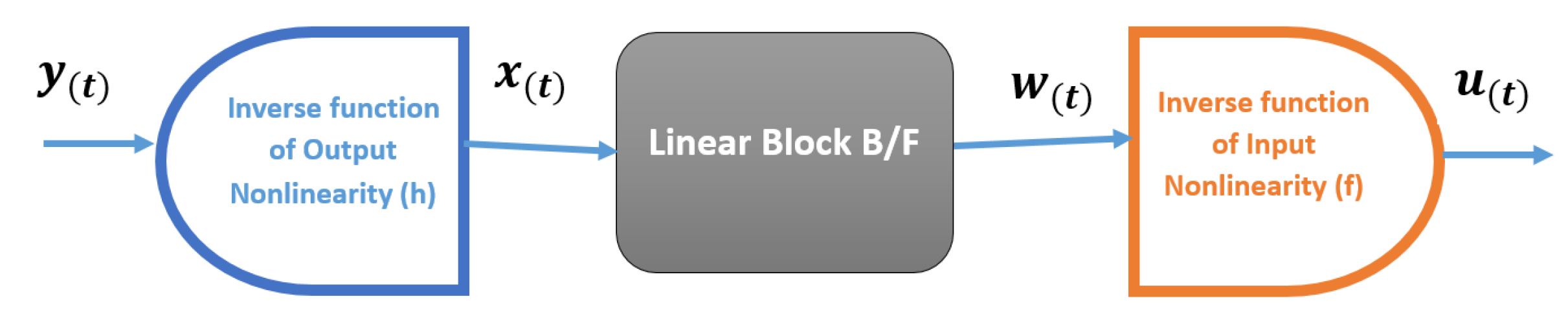

Structure of the Hammerstein–Wiener Model

5. Discrete State Feedback Controller Design

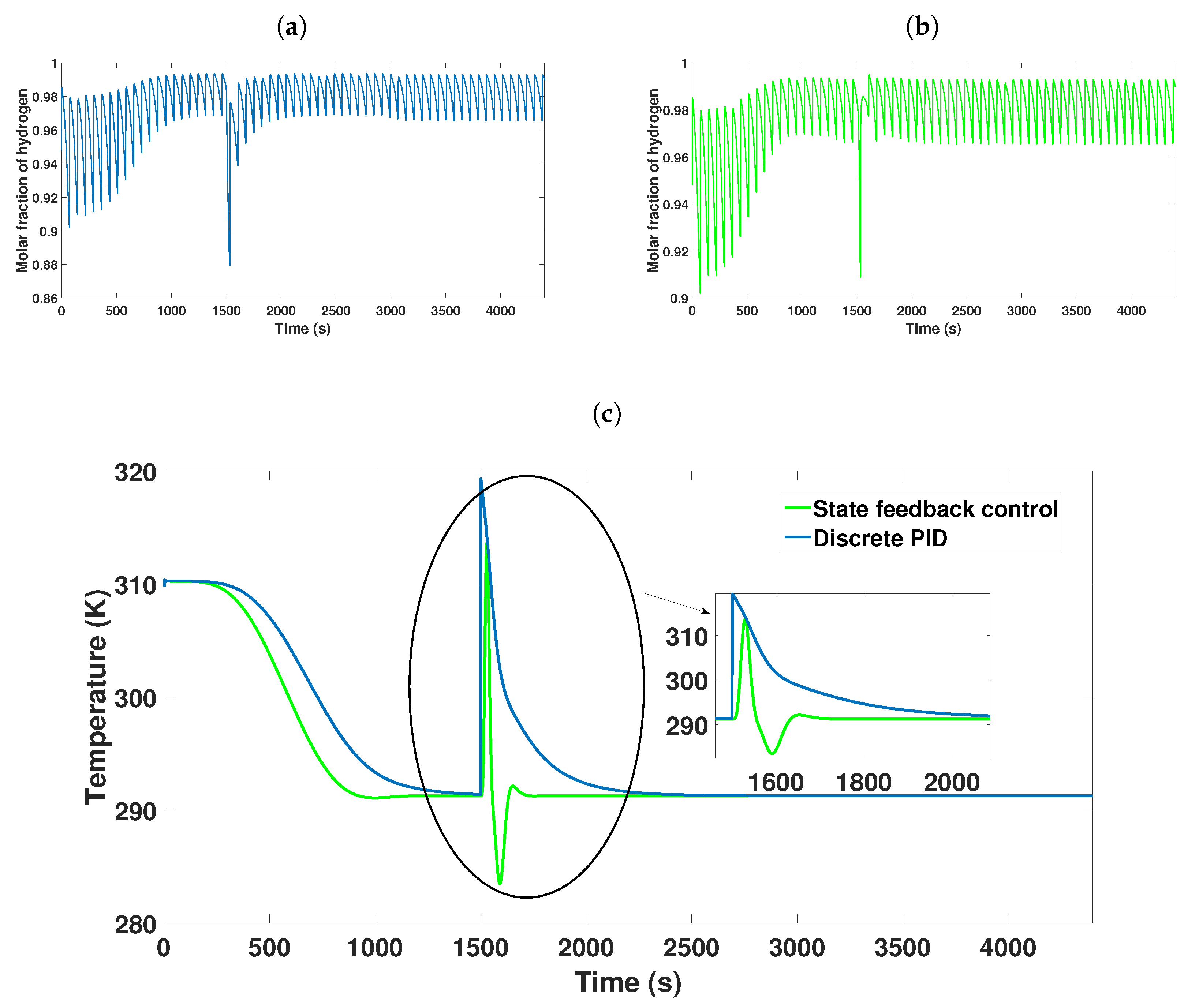

6. Results

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Specific particle surface (m m) | |

| Concentration (kmol m) | |

| Heat capacity of adsorbent (MJ kmol K) | |

| Heat capacity of gas phase (MJ kmol K) | |

| Specific heat capacity of the adsorbed phase (MJ kg K) | |

| Bed diameter (m) | |

| Particle diameter (m) | |

| Axial dispersion (m s) | |

| Heat transfer coefficient (Js m K) | |

| Heat adsorption gradient (J mol) | |

| Isothermal parameters of component i | |

| Ḵ | Langmuir isotherm equilibrium constant (Pa) |

| M | Molar weight (kg mol) |

| Mass transfer coefficient solid (s) | |

| P | Pressure (Pa) |

| Q | Isosteric heat of adsorption (J mol) |

| R | Universal gas constant (J mol K) |

| t | Time (s) |

| Gas temperature (K) | |

| Solid temperature (K) | |

| T | Temperature (K) |

| Surface gas velocity (m s) | |

| Adsorbed amount of the component i (kmol kg) | |

| Adsorbed equilibrium amount of component i (kmol kg) | |

| Molar fraction of the gas component i | |

| z | Coordinate of axial distance (m) |

| Greek symbols | |

| Bed porosity | |

| Particle porosity | |

| Dynamic viscosity (m s) | |

| Bed density (kg m) | |

| Particle density (kg m) |

References

- Shah, G.; Ahmad, E.; Pant, K.K.; Vijay, V.K. Comprehending the contemporary state of art in biogas enrichment and CO2 capture technologies via swing adsorption. Int. J. Hydrogen Energy 2021, 46, 6588–6612. [Google Scholar] [CrossRef]

- Majlan, E.H.; Wan Daud, W.R.; Iyuke, S.E.; Mohamad, A.B.; Kadhum, A.A.H.; Mohammad, A.W.; Takriff, M.S.; Bahaman, N. Hydrogen purification using compact pressure swing adsorption system for fuel cell. Int. J. Hydrogen Energy 2009, 34, 2771–2777. [Google Scholar] [CrossRef]

- Papadias, D.D.; Lee, S.H.; Ahmed, S. Facilitating analysis of trace impurities in hydrogen: Enrichment based on the principles of pressure swing adsorption. Int. J. Hydrogen Energy 2012, 37, 14413–14426. [Google Scholar] [CrossRef]

- Delgado Dobladez, J.A.; Águeda Maté, V.I.; Torrellas, S.Á.; Larriba, M.; Brea, P. Efficient recovery of syngas from dry methane reforming product by a dual pressure swing adsorption process. Int. J. Hydrogen Energy 2021, 46, 17522–17533. [Google Scholar] [CrossRef]

- Guan, Z.; Wang, Y.; Yu, X.; Shen, Y.; He, D.; Tang, Z.; Li, W.; Zhang, D. Simulation and analysis of dual-reflux pressure swing adsorption using silica gel for blue coal gas initial separation. Int. J. Hydrogen Energy 2021, 46, 683–696. [Google Scholar] [CrossRef]

- Lively, R.P.; Bessho, N.; Bhandari, D.A.; Kawajiri, Y.; Koros, W.J. Thermally moderated hollow fiber sorbent modules in rapidly cycled pressure swing adsorption mode for hydrogen purification. Int. J. Hydrogen Energy 2012, 37, 15227–15240. [Google Scholar] [CrossRef]

- Chicano, J.; Dion, C.T.; Pasaogullari, U.; Valla, J.A. Simulation of 12-bed vacuum pressure-swing adsorption for hydrogen separation from methanol-steam reforming off-gas. Int. J. Hydrogen Energy 2021, 46, 28626–28640. [Google Scholar] [CrossRef]

- Park, Y.; Kang, J.H.; Moon, D.K.; Jo, Y.S.; Lee, C.H. Parallel and series multi-bed pressure swing adsorption processes for H2 recovery from a lean hydrogen mixture. Chem. Eng. J. 2021, 408, 127299. [Google Scholar] [CrossRef]

- Fakhroleslam, M.; Bozorgmehry Boozarjomehry, R.; Fatemi, S. Design of a dynamical hybrid observer for pressure swing adsorption processes. Int. J. Hydrogen Energy 2017, 42, 21027–21039. [Google Scholar] [CrossRef]

- Shukla, A.; Sahoo, S.; Moharir, A.S. Non-isothermal Multi-cell Model for pressure swing adsorption process. Int. J. Hydrogen Energy 2017, 42, 5150–5167. [Google Scholar] [CrossRef]

- Kuroda, S.; Nagaishi, T.; Kameyama, M.; Koido, K.; Seo, Y.; Dowaki, K. Hydroxyl aluminium silicate clay for biohydrogen purification by pressure swing adsorption: Physical properties, adsorption isotherm, multicomponent breakthrough curve modelling, and cycle simulation. Int. J. Hydrogen Energy 2018, 43, 16573–16588. [Google Scholar] [CrossRef]

- Rumbo-Morales, J.Y.; Lopez-Lopez, G.; Alvarado, V.M.; Valdez-Martinez, J.S.; Sorcia-Vázquez, F.D.; Brizuela-Mendoza, J.A. Simulation and control of a pressure swing adsorption process to dehydrate ethanol. Rev. Mex. Ing. Quim. 2018, 17, 1051–1081. [Google Scholar] [CrossRef]

- Mondal, M.; Datta, A. Energy transfer in hydrogen separation from syngas using pressure swing adsorption (PSA) process: A thermodynamic model. Int. J. Energy Res. 2017, 41, 448–458. [Google Scholar] [CrossRef]

- Silva, B.; Solomon, I.; Ribeiro, A.M.; Lee, U.H.; Hwang, Y.K.; Chang, J.S.; Loureiro, J.M.; Rodrigues, A.E. H2 purification by pressure swing adsorption using CuBTC. Sep. Purif. Technol. 2013, 118, 744–756. [Google Scholar] [CrossRef]

- Renteria-Vargas, E.M.; Zuniga Aguilar, C.J.; Rumbo Morales, J.Y.; Vazquez, F.D.J.S.; De-La-Torre, M.; Cervantes, J.A.; Bustos, E.S.; Calixto Rodriguez, M. Neural Network-Based Identification of a PSA Process for Production and Purification of Bioethanol. IEEE Access 2022, 10, 27771–27782. [Google Scholar] [CrossRef]

- Ye, F.; Ma, S.; Tong, L.; Xiao, J.; Bénard, P.; Chahine, R. Artificial neural network based optimization for hydrogen purification performance of pressure swing adsorption. Int. J. Hydrogen Energy 2019, 44, 5334–5344. [Google Scholar] [CrossRef]

- Yu, X.; Shen, Y.; Guan, Z.; Zhang, D.; Tang, Z.; Li, W. Multi-objective optimization of ANN-based PSA model for hydrogen purification from steam-methane reforming gas. Int. J. Hydrogen Energy 2021, 46, 11740–11755. [Google Scholar] [CrossRef]

- Xiao, J.; Li, C.; Fang, L.; Böwer, P.; Wark, M.; Bénard, P.; Chahine, R. Machine learning–based optimization for hydrogen purification performance of layered bed pressure swing adsorption. Int. J. Energy Res. 2020, 44, 4475–4492. [Google Scholar] [CrossRef]

- Vo, N.D.; Oh, D.H.; Kang, J.H.; Oh, M.; Lee, C.H. Dynamic-model-based artificial neural network for H2 recovery and CO2 capture from hydrogen tail gas. Appl. Energy 2020, 273, 115263. [Google Scholar] [CrossRef]

- Khajuria, H.; Pistikopoulos, E.N. Optimization and Control of Pressure Swing Adsorption Processes Under Uncertainty. AIChE J. 2013, 59, 120–131. [Google Scholar] [CrossRef]

- Akulinin, E.; Ishin, A.; Skvortsov, S.; Dvoretsky, D.; Dvoretsky, S. Mathematical Modeling of Hydrogen Production Process by Pressure Swing Adsorption Method. Adv. Mater. Technol. 2017, 2, 38–49. [Google Scholar] [CrossRef]

- Fakhroleslam, M.; Boozarjomehry, R.B.; Fatemi, S.; De Santis, E.; Di Benedetto, M.D.; Pola, G. Design of a Hybrid Controller for Pressure Swing Adsorption Processes. IEEE Trans. Control Syst. Technol. 2018, 27, 1878–1892. [Google Scholar] [CrossRef]

- Rumbo Morales, J.Y.; López López, G.; Alvarado Martínez, V.M.; Sorcia Vázquez, F.d.J.; Brizuela Mendoza, J.A.; Martínez García, M. Parametric study and control of a pressure swing adsorption process to separate the water-ethanol mixture under disturbances. Sep. Purif. Technol. 2020, 236, 116214. [Google Scholar] [CrossRef]

- Rumbo Morales, J.Y.; Brizuela Mendoza, J.A.; Ortiz Torres, G.; Sorcia Vázquez, F.d.J.; Rojas, A.C.; Pérez Vidal, A.F. Fault-Tolerant Control implemented to Hammerstein–Wiener model: Application to Bio-ethanol dehydration. Fuel 2022, 308, 121836. [Google Scholar] [CrossRef]

- Fu, Q.; Yan, H.; Shen, Y.; Qin, Y.; Zhang, D.; Zhou, Y. Optimal design and control of pressure swing adsorption process for N2/CH4 separation. J. Clean. Prod. 2018, 170, 704–714. [Google Scholar] [CrossRef]

- Peng, H.; Couenne, F.; Le Gorrec, Y. Robust control of a pressure swing adsorption process. IFAC Proc. Vol. 2011, 44, 7310–7315. [Google Scholar] [CrossRef] [Green Version]

- Zhang, N.; Xiao, J.; Bénard, P.; Chahine, R. Single- and double-bed pressure swing adsorption processes for H2/CO syngas separation. Int. J. Hydrogen Energy 2019, 44, 26405–26418. [Google Scholar] [CrossRef]

- Xiao, J.; Peng, Y.; Bénard, P.; Chahine, R. Thermal effects on breakthrough curves of pressure swing adsorption for hydrogen purification. Int. J. Hydrogen Energy 2016, 41, 8236–8245. [Google Scholar] [CrossRef]

- Xiao, J.; Fang, L.; Bénard, P.; Chahine, R. Parametric study of pressure swing adsorption cycle for hydrogen purification using Cu-BTC. Int. J. Hydrogen Energy 2018, 43, 13962–13974. [Google Scholar] [CrossRef]

- Zhang, N.; Bénard, P.; Chahine, R.; Yang, T.; Xiao, J. Optimization of pressure swing adsorption for hydrogen purification based on Box-Behnken design method. Int. J. Hydrogen Energy 2021, 46, 5403–5417. [Google Scholar] [CrossRef]

- Lee, J.J.; Kim, M.K.; Lee, D.G.; Ahn, H.; Kim, M.J.; Lee, C.H. Heat-exchange pressure swing adsorption process for hydrogen separation. AIChE J. 2008, 54, 2054–2064. [Google Scholar] [CrossRef]

- Duan, G.; Yu, H.H. LMIs in Control Systems: Analysis, Design and Applications; CRC Press: Boca Raton, FL, USA, 2013; p. 449. [Google Scholar]

- Caverly, R.J.; Forbes, J.R. LMI Properties and Applications in Systems, Stability, and Control Theory. arXiv 2019, arXiv:1903.08599. [Google Scholar] [CrossRef]

- Lofberg, J. YALMIP: A toolbox for modeling and optimization in MATLAB. In Proceedings of the 2004 IEEE International Conference on Robotics and Automation (IEEE Cat. No. 04CH37508), Taipei, Taiwan, 2–4 September 2004; pp. 284–289. [Google Scholar]

| I. Adsorption | |

| t = 0 | |

| z = 0 | |

| z = L | |

| II. Depressurization | |

| t = 0 | |

| z = 0 | |

| z = L | |

| III. Purge | |

| t = 0 | |

| z = 0 | |

| z = L | |

| IV. Repressurization | |

| t = 0 | |

| z = 0 | |

| z = L |

| Run | Temperature (K) | Flow | Pressure kPa | Composition Hydrogen-Methane-CO | Purity % Molar Fraction of Hydrogen | Number of Cycles |

|---|---|---|---|---|---|---|

| 1 | 298.15 | 0.162 | 980 | 0.61-0.28-0.11 | 94.85 | 30 |

| 2 | 283.24 | 0.162 | 980 | 0.61-0.28-0.11 | 98.01 | 2 |

| 3 | 313.05 | 0.162 | 980 | 0.61-0.28-0.11 | 90.02 | 2 |

| 4 | 298.15 | 0.153 | 980 | 0.61-0.28-0.11 | 94.95 | 1 |

| 5 | 298.15 | 0.170 | 980 | 0.61-0.28-0.11 | 94.75 | 1 |

| 6 | 298.15 | 0.162 | 931 | 0.61-0.28-0.11 | 95.00 | 1 |

| 7 | 298.15 | 0.162 | 1029 | 0.61-0.28-0.11 | 94.65 | 1 |

| 8 | 298.15 | 0.162 | 980 | 0.6405-0.2495-0.11 | 94.00 | 2 |

| 9 | 298.15 | 0.162 | 980 | 0.5795-0.3105-0.11 | 95.50 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez García, M.; Rumbo Morales, J.Y.; Torres, G.O.; Rodríguez Paredes, S.A.; Vázquez Reyes, S.; Sorcia Vázquez, F.d.J.; Pérez Vidal, A.F.; Valdez Martínez, J.S.; Pérez Zúñiga, R.; Renteria Vargas, E.M. Simulation and State Feedback Control of a Pressure Swing Adsorption Process to Produce Hydrogen. Mathematics 2022, 10, 1762. https://doi.org/10.3390/math10101762

Martínez García M, Rumbo Morales JY, Torres GO, Rodríguez Paredes SA, Vázquez Reyes S, Sorcia Vázquez FdJ, Pérez Vidal AF, Valdez Martínez JS, Pérez Zúñiga R, Renteria Vargas EM. Simulation and State Feedback Control of a Pressure Swing Adsorption Process to Produce Hydrogen. Mathematics. 2022; 10(10):1762. https://doi.org/10.3390/math10101762

Chicago/Turabian StyleMartínez García, Mario, Jesse Y. Rumbo Morales, Gerardo Ortiz Torres, Salvador A. Rodríguez Paredes, Sebastián Vázquez Reyes, Felipe de J. Sorcia Vázquez, Alan F. Pérez Vidal, Jorge S. Valdez Martínez, Ricardo Pérez Zúñiga, and Erasmo M. Renteria Vargas. 2022. "Simulation and State Feedback Control of a Pressure Swing Adsorption Process to Produce Hydrogen" Mathematics 10, no. 10: 1762. https://doi.org/10.3390/math10101762

APA StyleMartínez García, M., Rumbo Morales, J. Y., Torres, G. O., Rodríguez Paredes, S. A., Vázquez Reyes, S., Sorcia Vázquez, F. d. J., Pérez Vidal, A. F., Valdez Martínez, J. S., Pérez Zúñiga, R., & Renteria Vargas, E. M. (2022). Simulation and State Feedback Control of a Pressure Swing Adsorption Process to Produce Hydrogen. Mathematics, 10(10), 1762. https://doi.org/10.3390/math10101762