Development of Final Projects in Engineering Degrees around an Industry 4.0-Oriented Flexible Manufacturing System: Preliminary Outcomes and Some Initial Considerations

Abstract

:1. Introduction

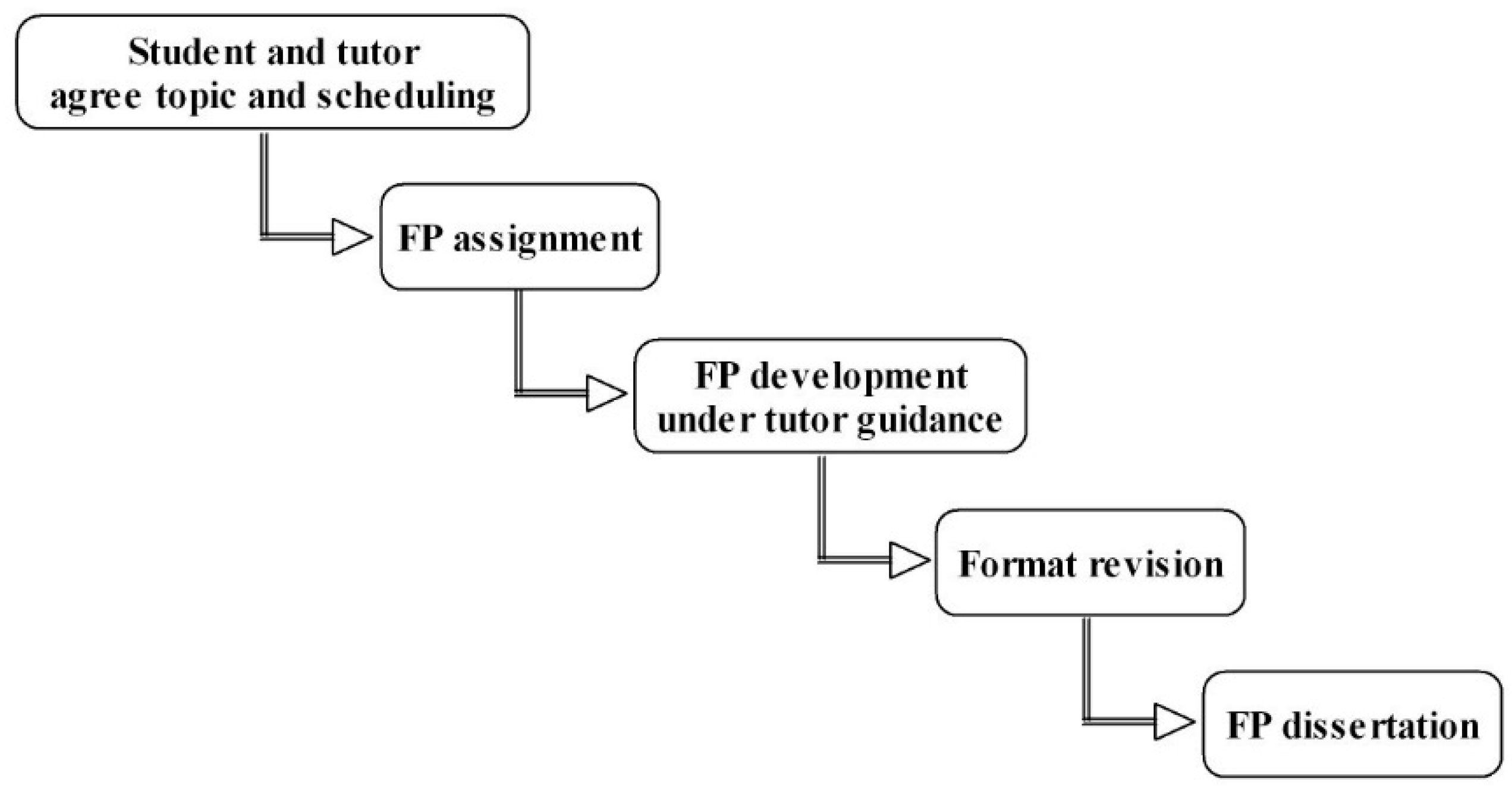

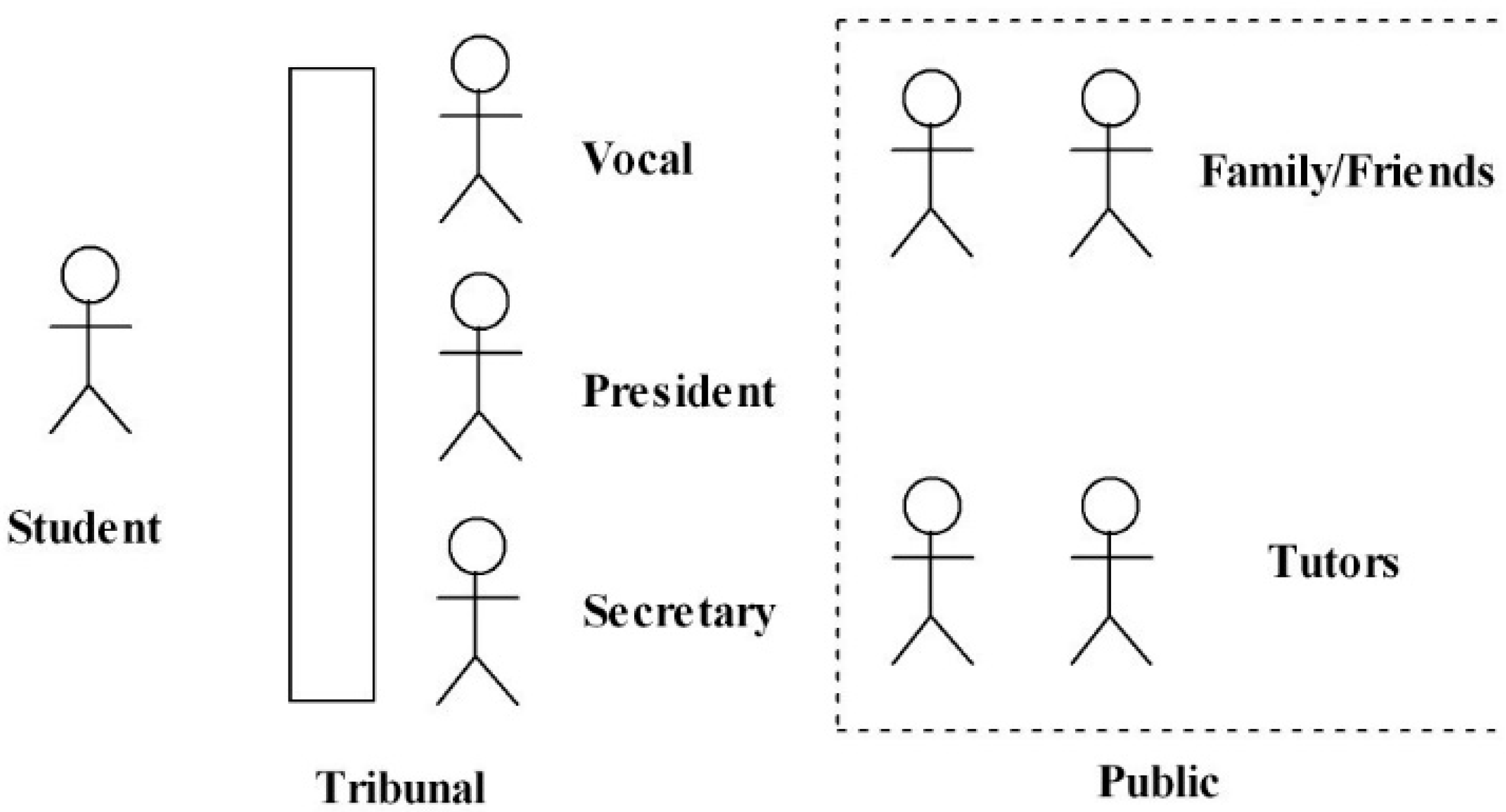

2. FP Procedure

3. FMS and FPs Description

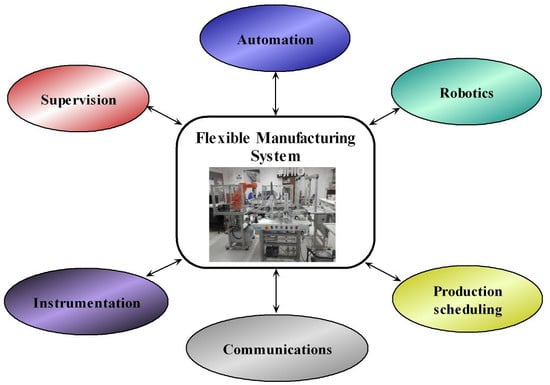

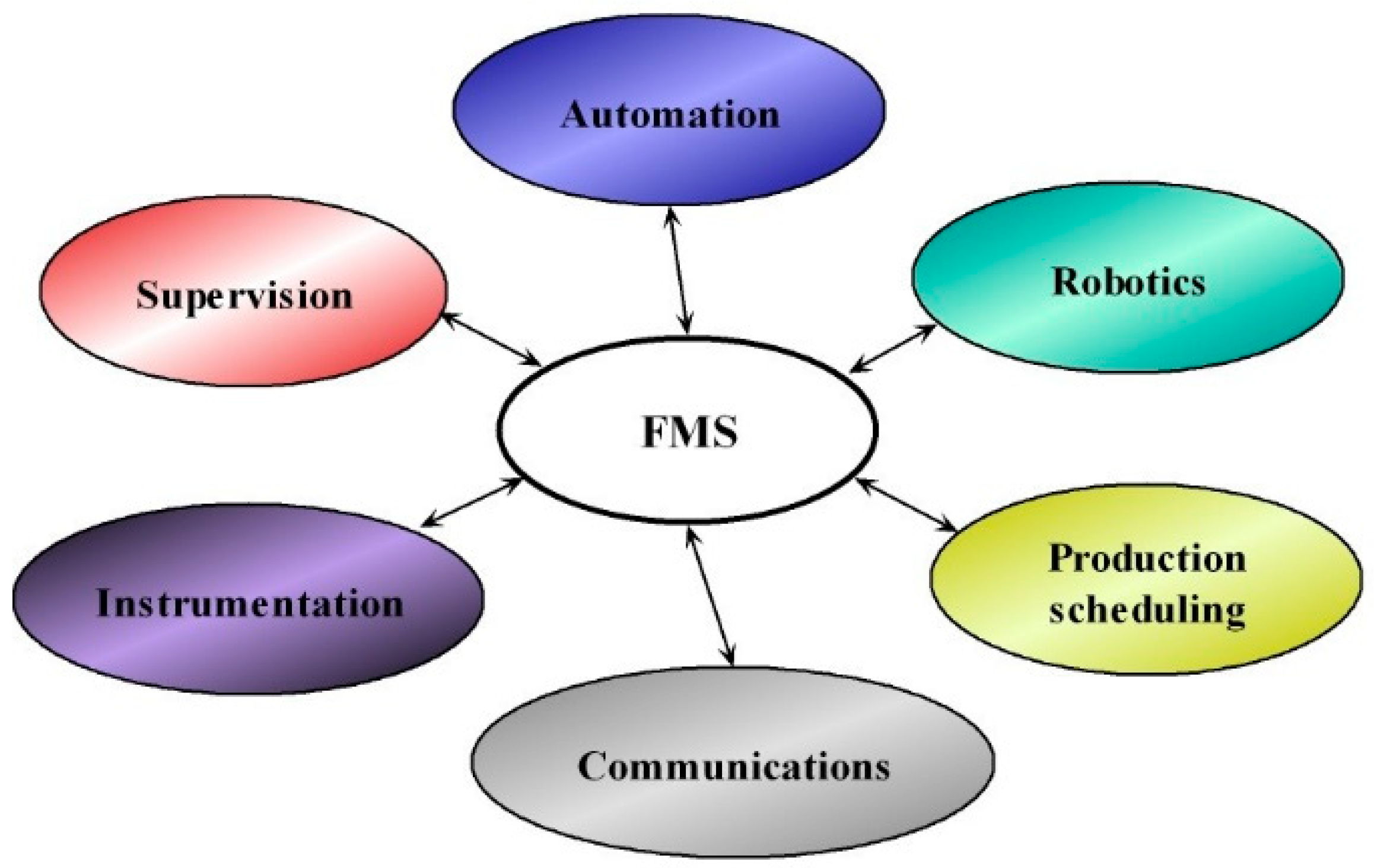

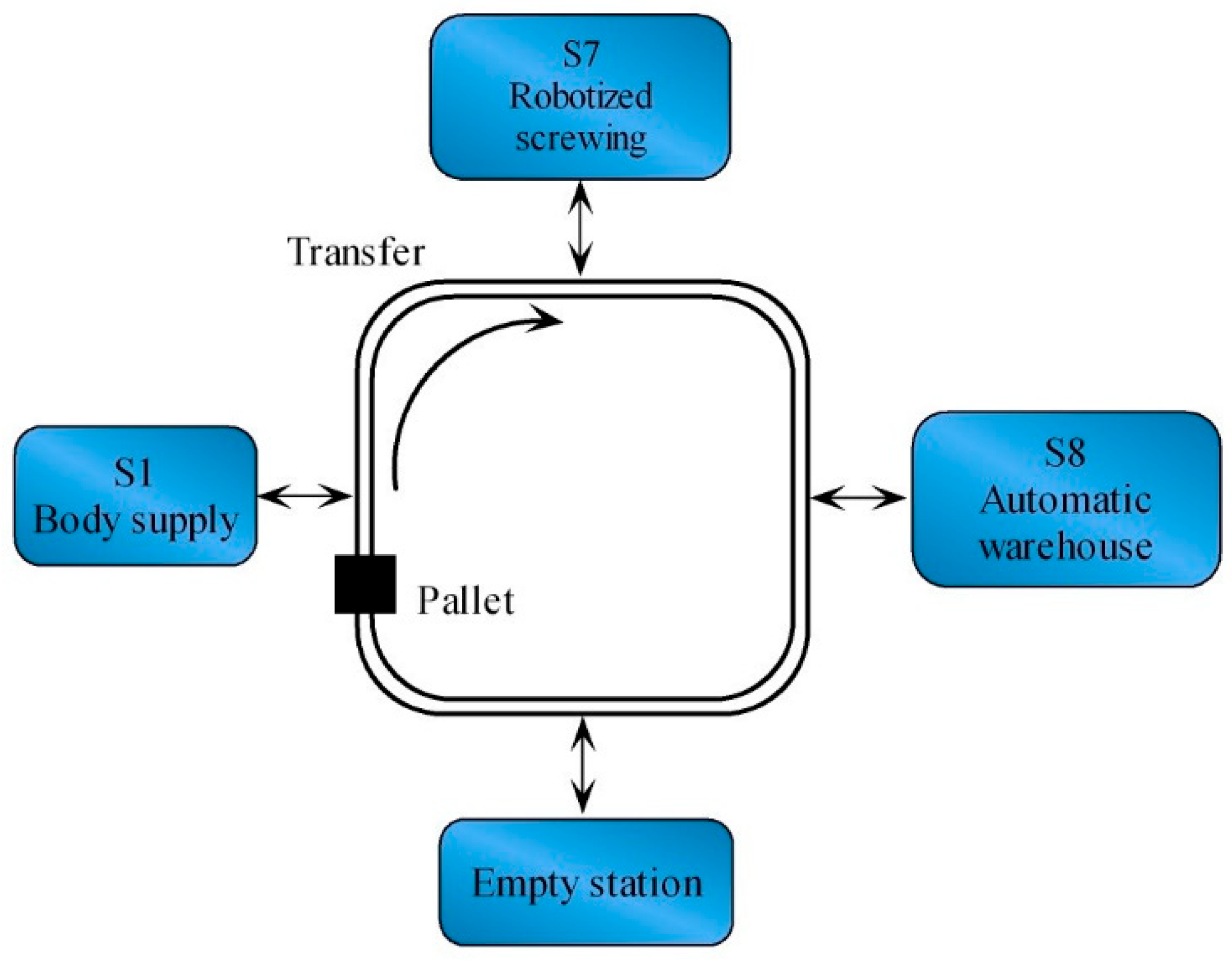

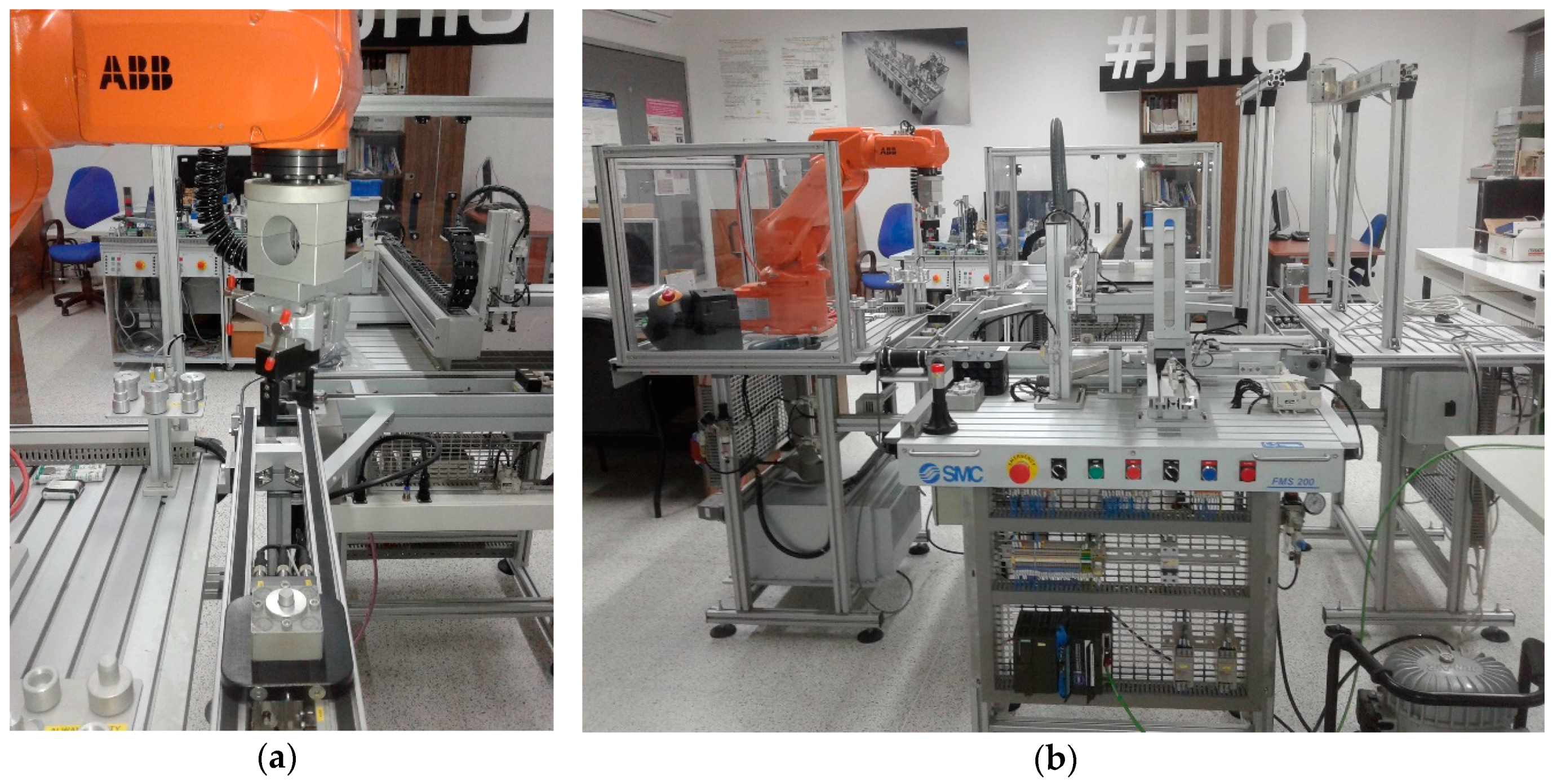

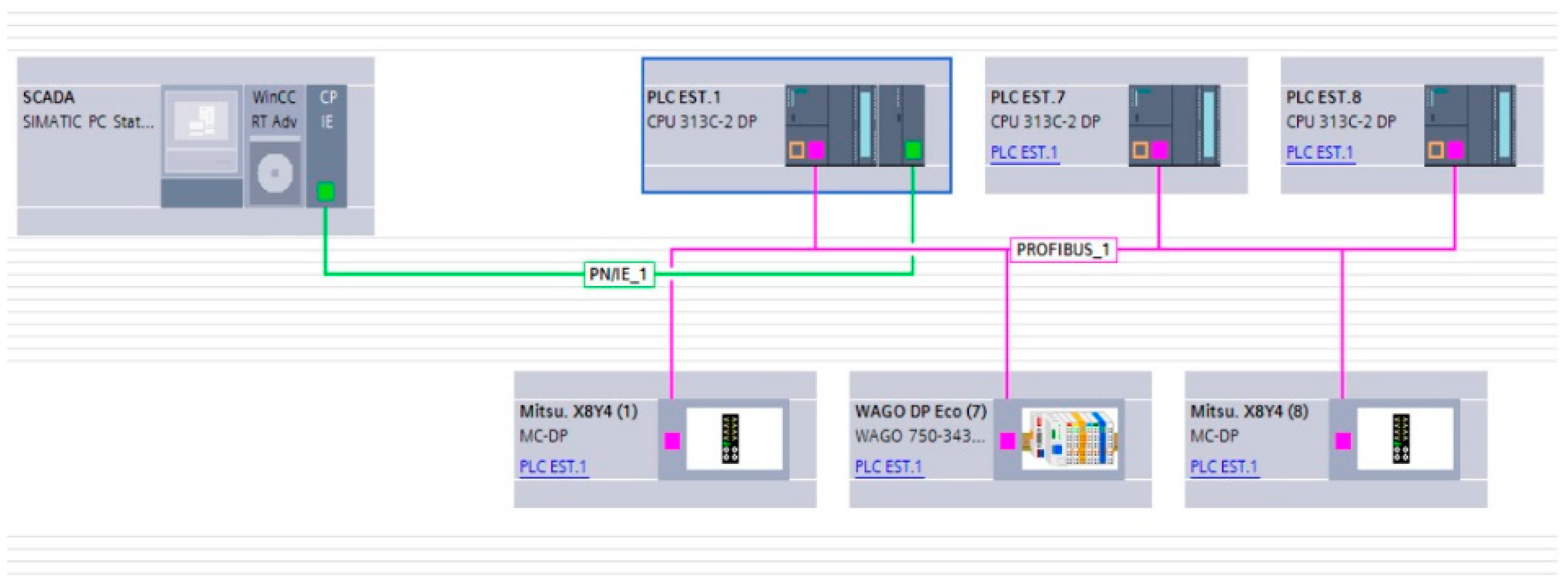

3.1. FMS Description

3.2. Illustrative FPs

3.2.1. First-Step Project: Automation of the First Version of the FMS

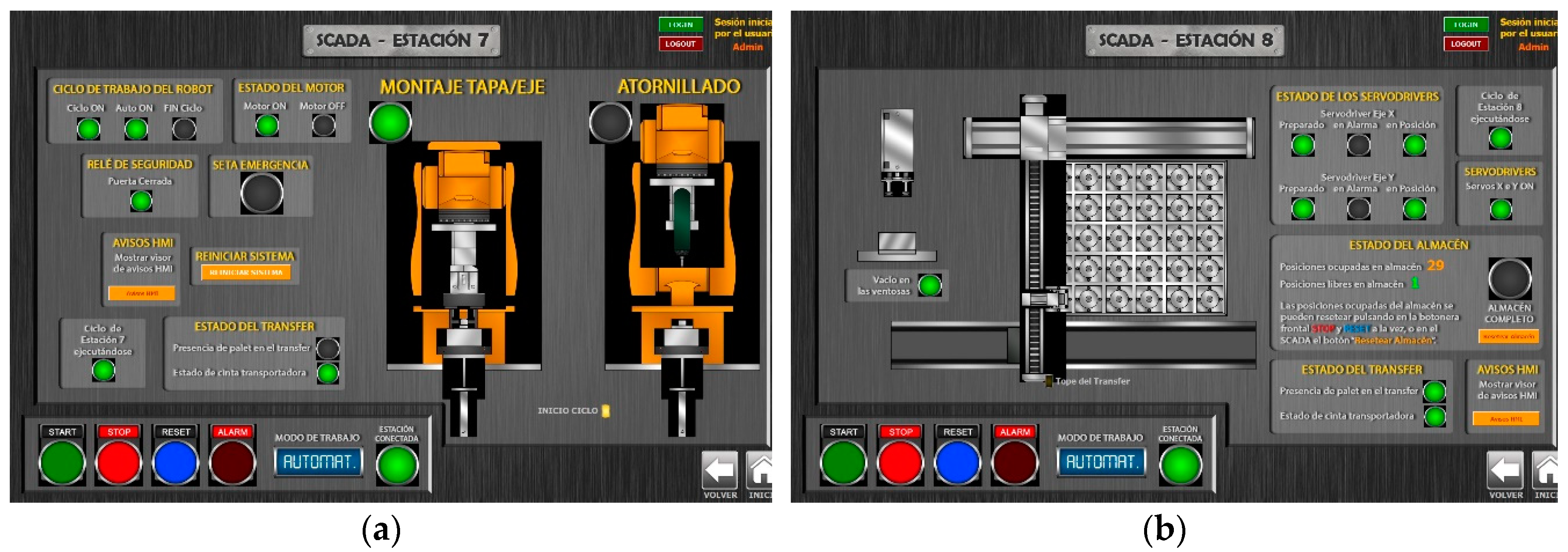

3.2.2. Supervisory Control and Data Acquisition (SCADA) System Development

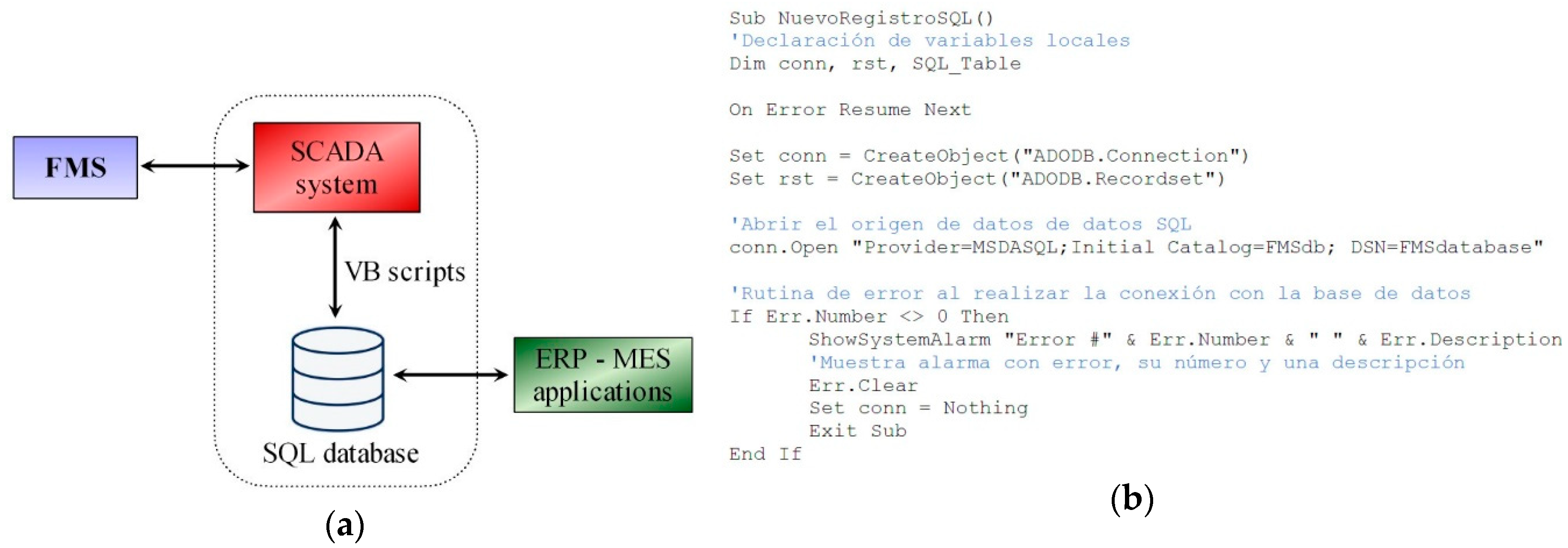

3.2.3. Data Storage in a Database

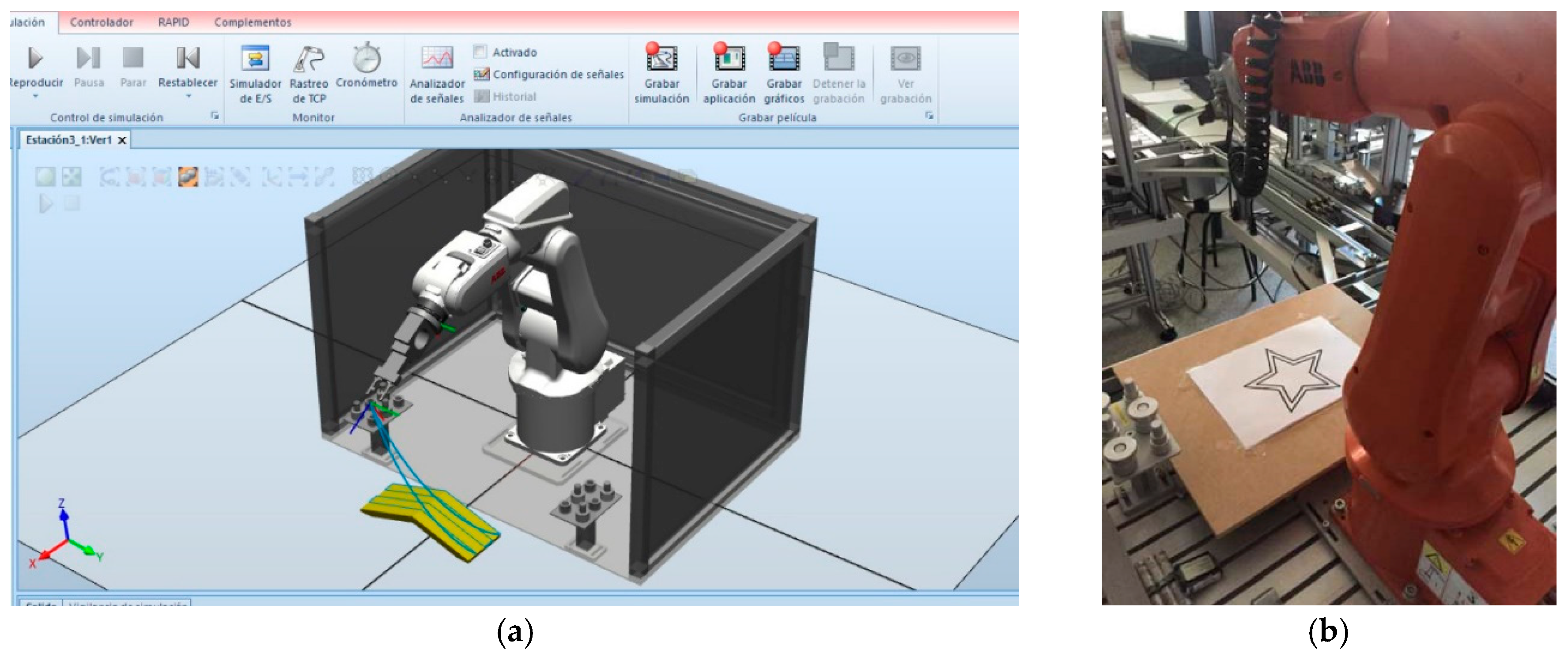

3.2.4. Anthropomorphic Robot Arm Programming

4. Discussion

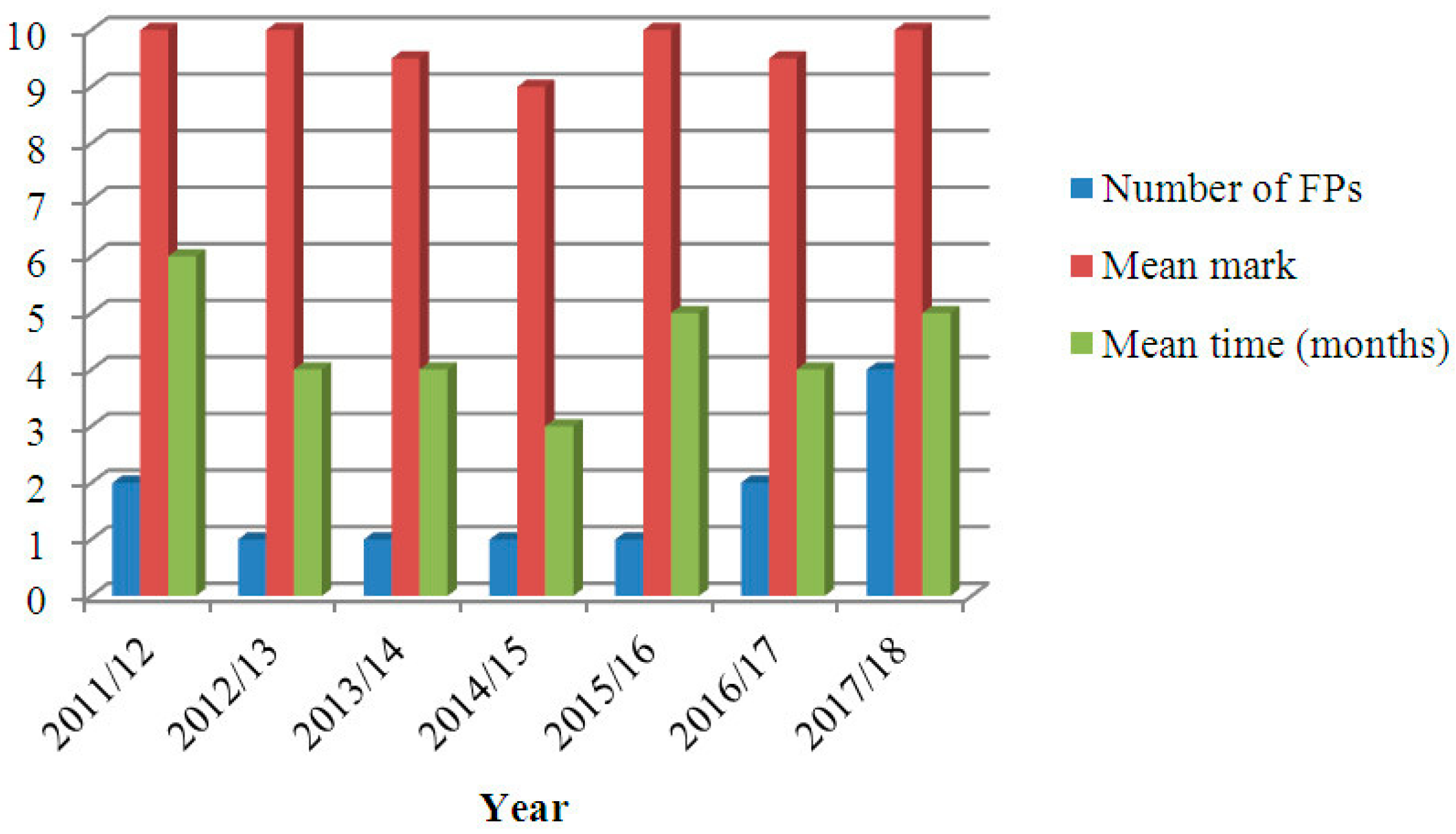

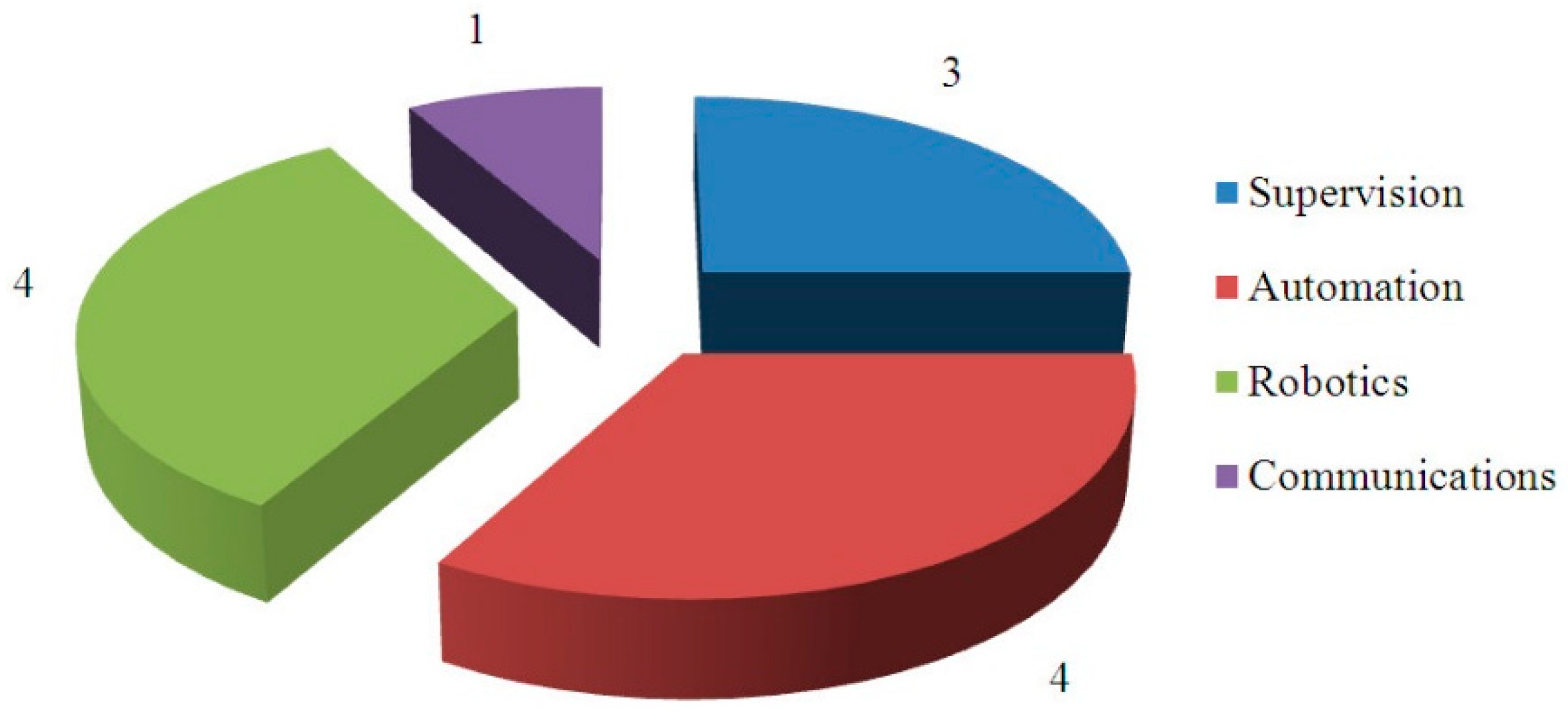

4.1. Academic Outcomes

4.2. Considerations from Tutors

- The handling of real industrial equipment constitutes one of the most significant advantages of the system. The FMS is composed of industrial components and is not specifically designed for educational purposes. Students learn and train using the same equipment and technologies that they will face in future professional environments. From the technical perspective, this feature facilitates the modification, addition, or reparation of components, since they use standardized signal ranges, communication protocols, and so forth.

- Accommodation of a number of emerging trends: The FMS can integrate different innovative approaches such as open source tools, virtual environments, and condition monitoring. This will be thoroughly commented on in the next subsection.

- The FMS does not suppose a disruptive scenario, since it is composed of well-known equipment such as PLCs and SCADA systems, as well as sensors and actuators. This feature contributes to facilitate the learning process of the educators, who in fact are also required to acquire deep expertise on innovative paradigms.

- Another benefit is the transversality of the FMS derived from the coexistence of different technologies common to engineering training such as ICT, informatics, and hardware skills, thus enabling the development of multidisciplinary projects.

- Applicability of the FMS for different degrees: As it has been commented on, the degree in Electronic Engineering and Automation is the most appropriate to deal with the FMS. However, other specializations that can also take advantage of the FMS capabilities are Electrical Engineering, Mechanical Engineering, and Chemical Engineering. In addition, out of the typically industrial engineering scope, other disciplines can be supported such as those devoted to telecommunications and informatics. They can be trained around the FMS with an orientation toward advanced networked communications and cyber-security issues, directly related to the Industry 4.0.

- Students become familiar with advanced concepts related to Industry 4.0, acquiring the basis to successfully develop their professional tasks within this challenging framework.

- Students are free to design the solutions that the FP implements, so their creative thinking and curiosity are expected to be stimulated. That is, the tutors guide the development but do not impose boundaries upon the incorporation of the ideas of the students. For instance, when designing the SCADA system, the student decided the layout, visual aspects, and other items according to his own criteria.

- All the FPs were agreed on by students and tutors instead of chosen from a list of available topics. This is considered to be a signal of the attraction that the FMS generates among the students.

- Different levels of autonomy were detected by the tutors. One of the main goals of the FPs is to promote the autonomy of students to learn by themselves and to solve troubles found in their path.

- Operational staff training could also be performed, for instance within a collaboration framework with industrial enterprises or vocational educational institutions. The integration of workers into an Industry 4.0 system is signaled as a significant challenge [35]: Even the term “operator 4.0” is gaining attention in the literature [35,36].

- Utilization of proprietary technology both for software and hardware tools: For instance, this fact implies high costs in the acquisition of software licenses. It must be noted that, in order to solve this issue, some effort is being currently devoted to using open source hardware and software in the FMS. In addition, as is evident, the students acquire necessary knowledge and skills regardless of the particular software or hardware resources.

- Previous expertise is required from students before the assignment of the FP. Aiming at maximizing the learning outcomes of the students, a minimum level of previous knowledge and skills are desirable before working with the FMS. The FMS is a complex and valuable equipment, so nowadays the criteria of the teachers is that students must have passed previous courses, mainly dealing with automation. Nonetheless, as it was stated in the second section, the FP offers an opportunity to reinforce or to acquire new knowledge and skills.

- Impossibility of performing a number of tasks outside of the physical laboratory: Students have to physically use the FMS for most of the FPs, so they need access to the laboratory and to stay inside during the required time. In other words, scarce tasks can be performed out of the laboratory, and therefore the FMS-based FPs are not suitable for those students that have some reason not to attend the laboratory (e.g., job, illness, childcare, or elder care).

- The tutoring task is scarcely considered within the teaching occupation. Despite the fact that tutors are commonly proud of encouraging the academic growth of FP students, the time and effort dedicated are not correctly valorized. The guidance of a FP is a time-consuming task, especially if it involves an experimental complex facility like the FMS. As was indicated in the second section, tutoring a FP is worth 0.25 European credits for the teacher. This is especially important when educators must face challenging topics such as the Industry 4.0 and related paradigms.

- Utilization of the FMS under project-based learning (PBL) methodology: Out of the FPs, within automation-related courses the FMS could be used to develop projects following the PBL technique so students have an active role and face a number of tasks that reinforce the contents provided during classes. Despite being an interesting application, deep expertise is required in order to avoid damage to the components of the FMS and of the students, though for advanced courses, a PBL approach could be conducted under the proper supervision of an educator.

- A small number of developed FPs around the FMS: Despite the fact that FPs have been successfully completed, the number of projects, and hence the number of involved students, is still small. In an exercise of self-criticism, this is considered to be a limitation of the presented work. Further analyses about pedagogical methodologies and the acquisition of Industry 4.0-related skills will be conducted when a larger amount is reached.

- Higher introduction of the Industry 4.0 paradigm in the engineering degrees: The challenges that this complex concept involves for educational institutions are still being discovered. It does not only require managing advanced equipment (hardware and software), but it implies a framework where a number of disciplines are orchestrated in an integrated manner. In this sense, the FMS has demonstrated itself to be a powerful platform in covering a number of scopes and is expected to incorporate new Industry 4.0-compliant features. Apart from this, institutions, particularly at the university level, need to update and adapt theoretical and practical content toward this new reality. This is in reference to both curricula and available equipment. Educators are also engaged in this process, since they have to modernize their own knowledge and skills. Even more, social aspects of the real deployment of Industry 4.0 must be tackled also in engineering degrees in order to generate successful engineers.

4.3. Modern Manufacturing Trends Related to FMS

- Sustainability and environmental concerns achieve increasing attention for manufacturing systems [37]: Hence, various approaches can be carried out in the FMS in that sense. The monitoring of energy consumption in order to be considered in production planning or scheduling is an example.

- Condition monitoring and data acquisition are directly linked to advanced maintenance techniques such as prognostics and health management (PHM) schemes. The widespread deployment of various types of sensors makes it possible to achieve so-called smart monitoring [38]. In this sense, sensors to measure temperature and vibrations of the motors of the conveyor and the robotic arm will be added to provide information that will be used for PHM analysis. In a similar way, data-driven models and algorithms to improve decision-making processes require massive data acquisition and are aligned with big data analytics. These issues can also be handled using the FMS as a benchmark to deploy a number of sensors and process the gathered data.

- Cyber-security is a paramount issue in modern automation networks, so its efficient management must be performed by engineering students [39]. Protections in the SCADA system will be the main issue to handle in the FMS.

- Open source hardware and software resources are receiving efforts in the automation and monitoring scopes [40,41,42]. Indeed, these resources are being signaled as key accelerators for the industry adoption of the IoT [43]. Supervisory systems and microcontrollers of this nature can be accommodated in the FMS through FPs to evaluate their functionalities. Even more, students can use their own devices, which constitutes a modern trend termed bring your own device (BYOD), aiming to encourage their motivation. Particularly, inexpensive open source hardware platforms such as the Arduino microcontroller or the Raspberry Pi microprocessor can be applied under such a movement.

- Online remote laboratories constitute a useful resource for educational purposes [44] and are also under the umbrella of the Industry 4.0 [45]. Indeed, the above-mentioned open source technology facilitates the deployment of remote laboratories [46], so their application to the FMS could promote its utilization as an online laboratory.

- Radio frequency identification (RFID) technology is a key technology for Industry 4.0 and IIoT scenarios [49]. Its integration, through proprietary or open source means, in the FMS will enable traceability and continuous tracking purposes.

- Additive manufacturing or 3D printing is considered to be one of the enabling technologies of Industry 4.0 [19]. The 3D Cartesian robot that is under development will allow for introducing this technology in the FMS.

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| BYOD | Bring your own device |

| CM | Cloud manufacturing |

| DM | Dissertation mark |

| EHEA | European Higher Education Area |

| ERP | Enterprise resource planning |

| ICPS | Industrial cyber-physical systems |

| ICT | Information and communication technology |

| IE | Industrial Ethernet |

| IES | Industrial Engineering School |

| IIoT | Industrial Internet of Things |

| FM | Final mark |

| FMS | Flexible manufacturing system |

| FP | Final project |

| LAN | Local area network |

| LF | Learning factory |

| LMS | Learning management system |

| MES | Manufacturing execution systems |

| PBL | Project-based learning |

| PHM | Prognostics and health management |

| PLC | Programmable logic controller |

| PROFIBUS | Process Fieldbus |

| RAPID | Robotics application programming interactive dialogue |

| RFID | Radio frequency identification |

| RM | Report mark |

| SCADA | Supervisory control and data acquisition |

| SQL | Structured Query Language |

| UEX | University of Extremadura |

| VB | Visual Basic |

References

- Ismail, A.; Kastner, W. A middleware architecture for vertical integration. In Proceedings of the 1st International Workshop on Cyber Physical Production Systems (CPPS), Vienna, Austria, 12 April 2016. [Google Scholar] [CrossRef]

- Iglesias-Urkia, M.; Orive, A.; Barcelo, M.; Moran, A.; Bilbao, J.; Urbieta, A. Towards a lightweight protocol for Industry 4.0: An implementation based benchmark. In Proceedings of the IEEE International Workshop of Electronics, Control, Measurement, Signals and Their Application to Mechatronics, San Sebastian, Spain, 24–26 May 2017. [Google Scholar] [CrossRef]

- Cohen, Y.; Faccio, M.; Gabriele, F.; Mora, C.; Pilati, F. Assembly system configuration through Industry 4.0 principles: The expected change in the actual paradigms. IFAC-PapersOnLine 2017, 50, 14958–14963. [Google Scholar] [CrossRef]

- Müller, J.M.; Voigt, K.-I. Sustainable Industrial Value Creation in SMEs: A Comparison between Industry 4.0 and Made in China 2025. Int. J. Precis. Eng. Manuf.-Green Technol. 2018, 5, 659–670. [Google Scholar] [CrossRef]

- Ji, X.; He, G.; Xu, J.; Guo, Y. Study on the mode of intelligent chemical industry based on cyber-physical system and its implementation. Adv. Eng. Softw. 2016, 99, 18–26. [Google Scholar] [CrossRef]

- Redutskiy, Y. Conceptualization of smart solutions in oil and gas industry. Procedia Comput. Sci. 2017, 109, 745–753. [Google Scholar] [CrossRef]

- González, I.; Calderón, A.J.; Figueiredo, J.; Sousa, J.M.C. Design of an educational platform for automation and supervision under the Industry 4.0 framework. In Proceedings of the 12th International Technology, Education and Development Conference (INTED), Valencia, Spain, 5–7 March 2018. [Google Scholar]

- Müller, J.M.; Kiel, D.; Voigt, K.-I. What Drives the Implementation of Industry 4.0? The Role of Opportunities and Challenges in the Context of Sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Benešová, A.; Tupa, J. Requirements for Education and Qualification of People in Industry 4.0. Procedia Manuf. 2017, 11, 2195–2202. [Google Scholar] [CrossRef]

- Simons, S.; Abé, P.; Neser, S. Learning in the AutFab—The fully automated Industrie 4.0 learning factory of the University of Applied Sciences Darmstadt. Procedia Manuf. 2017, 9, 81–88. [Google Scholar] [CrossRef]

- Prinz, C.; Morlock, F.; Freith, S.; Kreggenfeld, N.; Kreimeier, D.; Kuhlenkötter, B. Learning Factory modules for smart factories in Industrie 4.0. Procedia CIRP 2016, 54, 113–118. [Google Scholar] [CrossRef]

- Madsen, O.; Moller, C. The AAU Smart Production Laboratory for teaching and research in emerging digital manufacturing technologies. Procedia Manuf. 2017, 9, 106–112. [Google Scholar] [CrossRef]

- Mourtzis, D.; Vlachou, E.; Dimitrakopoulos, G.; Zogopoulos, V. Cyber- Physical Systems and Education 4.0—The Teaching Factory 4.0 Concept. Procedia Manuf. 2018, 23, 129–134. [Google Scholar] [CrossRef]

- Ramirez-Mendoza, R.A.; Morales-Menendez, R.; Iqbal, H.; Parra-Saldivar, R. Engineering Education 4.0—Proposal for a new Curricula. In Proceedings of the IEEE Global Engineering Education Conference (EDUCON), Canary Islands, Spain, 17–20 April 2018. [Google Scholar] [CrossRef]

- Rojko, A.; Hercog, D.; Jezernik, K. E-training in mechatronics using innovative remote laboratory. Math. Comput. Simul. 2011, 82, 508–516. [Google Scholar] [CrossRef]

- Villa-López, F.H.; García-Guzmán, J.; Vélez Enríquez, J.; Leal-Ortíz, S.; Ramírez-Ramírez, A. Electropneumatic system for industrial automation: A remote experiment within a web-based learning environment. Procedia Technol. 2013, 7, 198–207. [Google Scholar] [CrossRef]

- Balid, W.; Abdulwahed, M. The Impact of Different Pre-Lab Preparation Modes on Embedded Systems Hands-on Lab. In Proceedings of the 9th Annual American Society for Engineering Education (ASEE) Global Colloquium on Engineering Education, Budapest, Hungary, 12–15 October 2009. [Google Scholar]

- Calderón Godoy, A.J.; González Pérez, I. Integration of Sensor and Actuator Networks and the SCADA System to Promote the Migration of the Legacy Flexible Manufacturing System towards the Industry 4.0 Concept. J. Sens. Actuator Netw. 2018, 7, 23. [Google Scholar] [CrossRef]

- Bortolini, M.; Galizia, F.G.; Mora, C. Reconfigurable manufacturing systems: Literature review and research trend. J. Manuf. Syst. 2018, 49, 93–106. [Google Scholar] [CrossRef]

- Girbea, A.; Suciu, C.; Nechifor, S.; Sisak, F. Design and implementation of a service-oriented architecture for the optimization of industrial applications. IEEE Trans. Ind. Inform. 2014, 10, 185–196. [Google Scholar] [CrossRef]

- Kammoun, M.A.; Ezzeddine, W.; Rezg, N.; Achour, Z. FMS Scheduling under Availability Constraint with Supervisor Based on Timed Petri Nets. Appl. Sci. 2017, 7, 399. [Google Scholar] [CrossRef]

- Scholze, S.; Barata, J.; Stokic, D. Holistic Context-Sensitivity for Run-Time Optimization of Flexible Manufacturing Systems. Sensors 2017, 17, 455. [Google Scholar] [CrossRef]

- Priore, P.; Ponte, B.; Puente, J.; Gómez, A. Learning-based scheduling of flexible manufacturing systems using ensemble methods. Comput. Ind. Eng. 2018, 126, 282–291. [Google Scholar] [CrossRef]

- García, M.V.; Irisarri, E.; Pérez, F.; Estévez, E.; Marcos, M. OPC-UA Communications Integration using a CPPS architecture. In Proceedings of the IEEE Ecuador Technical Chapters Meeting (ETCM), Guayaquil, Ecuador, 12–14 October 2016. [Google Scholar] [CrossRef]

- Pisching, M.A.; Pessoa, M.A.O.; Junqueira, F.; Filho, D.J.; Miyagi, P.E. An architecture based on RAMI 4.0 to discover equipment to process operations required by products. Comput. Ind. Eng. 2018, 125, 574–591. [Google Scholar] [CrossRef]

- Prada, M.A.; Fuertes, J.J.; Alonso, S.; García, S.; Domínguez, M. Challenges and solutions in remote laboratories. Application to a remote laboratory of an electro-pneumatic classification cell. Comput. Educ. 2015, 85, 180–190. [Google Scholar] [CrossRef]

- Reynard, S.; Gomis-Bellmunt, O.; Sudriá-Andreu, A.; Boix-Aragonés, O.; Benítez-Pina, I. Flexible manufacturing cell SCADA system for educational purposes. Comput. Appl. Eng. Educ. 2008, 16, 21–30. [Google Scholar] [CrossRef]

- Yabanova, I.; Taskin, S.; Ekiz, H. Development of remote monitoring and control system for mechatronics engineering practice: The case of flexible manufacturing system. Int. J. Elec. Eng. Educ. 2015, 52, 264–275. [Google Scholar] [CrossRef]

- Hincapié, M.; Ramírez, M.J.; Valenzuela, A.; Valdez, J.A. Mixing real and virtual components in automated manufacturing systems using PLM tools. Int. J. Interact. Des. Manuf. 2014, 8, 209–230. [Google Scholar] [CrossRef]

- Toivonen, V.; Lanz, M.; Nylund, H.; Nieminen, H. The FMS Training Center—A versatile learning environment for engineering education. Procedia Manuf. 2018, 23, 135–140. [Google Scholar] [CrossRef]

- Pacaux-Lemoine, M.-P.; Trentesaux, D.; Zambrano, G.; Millot, P. Designing intelligent manufacturing systems through Human-Machine Cooperation principles: A human-centered approach. Comput. Ind. Eng. 2017, 111, 581–595. [Google Scholar] [CrossRef]

- Tisch, M.; Hertle, C.; Abele, E.; Metternich, J.; Tenberg, R. Learning factory design: A competency-oriented approach integrating three design levels. Int. J. Comput. Integr. Manuf. 2016, 29, 1355–1375. [Google Scholar] [CrossRef]

- Webpage of the Industrial Engineering School of the University of Extremadura. Available online: eii.unex.es (accessed on 15 September 2018).

- SMC Webpage. Available online: https://www.smc.eu/portal_ssl/WebContent/main/index_restyling.jsp?lang=en&ctry=EU&is_main=yes&dfl_locale=yes (accessed on 10 September 2018).

- Ruppert, T.; Jaskó, S.; Holczinger, T.; Abonyi, J. Enabling Technologies for Operator 4.0: A Survey. Appl. Sci. 2018, 8, 1650. [Google Scholar] [CrossRef]

- Zolotová, I.; Papcun, P.; Kajáti, E.; Miskuf, M.; Mocnej, J. Smart and Cognitive Solutions for Operator 4.0: Laboratory H-CPPS Case Studies. Comput. Ind. Eng. 2018, in press. [Google Scholar] [CrossRef]

- Esmaeilian, B.; Behdad, S.; Wang, B. The evolution and future of manufacturing: A review. J. Manuf. Syst. 2016, 39, 79–100. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Domínguez, M.; Prada, M.A.; Reguera, P.; Fuertes, J.J.; Alonso, S.; Morán, A. Cybersecurity training in control systems using real equipment. IFAC-PapersOnLine 2017, 50, 12179–12184. [Google Scholar] [CrossRef]

- Calderón, A.J.; González, I.; Calderón, M.; Segura, F.; Andújar, J.M. A New, Scalable and Low Cost Multi-Channel Monitoring System for Polymer Electrolyte Fuel Cells. Sensors 2016, 16, 349. [Google Scholar] [CrossRef] [PubMed]

- González, I.; Calderón, A.J.; Mejías, A.; Andújar, J.M. Novel networked remote laboratory architecture for open connectivity based on PLC-OPC-LabVIEW-EJS integration. Application to remote fuzzy control and sensors data acquisition. Sensors 2016, 16, 1822. [Google Scholar] [CrossRef]

- González, I.; Calderón, A.J.; Andújar, J.M. Novel Remote Monitoring Platform for RES-Hydrogen based Smart Microgrid. Energy Conv. Manag 2017, 148, 489–505. [Google Scholar] [CrossRef]

- Martinez, B.; Vilajosana, X.; Kim, I.H.; Zhou, J.; Tuset-Peiró, P.; Xhafa, A.; Poissonnier, D.; Lu, X. I3Mote: An Open Development Platform for the Intelligent Industrial Internet. Sensors 2017, 17, 986. [Google Scholar] [CrossRef] [PubMed]

- Viegas, C.; Pavani, A.; Lima, N.; Marques, A.; Pozzo, I.; Dobboletta, E.; Atencia, V.; Barreto, D.; Calliari, F.; Fidalgo, A.; et al. Impact of a remote lab on teaching practices and student learning. Comput. Educ. 2018, 126, 201–216. [Google Scholar] [CrossRef]

- Grodotzki, J.; Ortelt, T.R.; Tekkaya, A.E. Remote and Virtual Labs for Engineering Education 4.0. Procedia Manuf. 2018, 26, 1349–1360. [Google Scholar] [CrossRef]

- Mejías, A.; Reyes, M.; Márquez, M.A.; Calderón, A.J.; González, I.; Andújar, J.M. Easy handling of sensors and actuators over TCP/IP Networks by Open Source Hardware/Software. Sensors 2017, 17, 94. [Google Scholar] [CrossRef] [PubMed]

- Bruzzone, A.G.; Longo, F. 3D simulation as training tool in container terminals: The TRAINPORTS simulator. J. Manuf. Syst. 2013, 32, 85–98. [Google Scholar] [CrossRef]

- Scurati, G.W.; Gattullo, M.; Fiorentino, M.; Ferrise, F.; Bordegoni, M.; Uva, A.E. Converting maintenance actions into standard symbols for Augmented Reality applications in Industry 4.0. Comput. Ind. 2018, 98, 68–79. [Google Scholar] [CrossRef]

- González, I.; Calderón, A.J.; Barragán, A.J.; Andújar, J.M. Integration of Sensors, Controllers and Instruments Using a Novel OPC Architecture. Sensors 2017, 17, 1512. [Google Scholar] [CrossRef]

- Fisher, O.; Watson, N.; Porcu, L.; Bacon, D.; Rigley, M.; Gomes, R.L. Cloud manufacturing as a sustainable process manufacturing route. J. Manuf. Syst. 2018, 47, 53–68. [Google Scholar] [CrossRef]

| Title | Course | Character |

|---|---|---|

| Bachelor’s Degree in Electronic Engineering and Automation | Introduction to Automation Automation I Automation II Industrial Process Control Robotics and Perception Systems Supervisory Control Systems | Obligatory Obligatory Obligatory Obligatory Obligatory Optional |

| Bachelor’s Degree in Electrical Engineering | Introduction to Automation Industrial Automation Supervisory Systems | Obligatory Obligatory Optional |

| Bachelor’s Degree in Mechanical Engineering | Introduction to Automation Industrial Automation | Obligatory Optional |

| Bachelor’s Degree in Industrial Chemical Engineering | Electronic Engineering and Automation Process Engineering II | Obligatory Obligatory |

| Master’s Degree in Industrial Engineering | Electronic Technology and Automation Automation of Production Systems | Obligatory Optional |

| Master’s Degree in Research in Engineering and Architecture | Introduction to Research in Advanced Automation Techniques | Optional |

| Risk | Security Means |

|---|---|

| Electrical | Electrical protections against discharges |

| Physical | Physical barriers surrounding the FMS; emergency buttons; limited access to the laboratory |

| Software | Boundaries in programmable logic controller (PLC) code; user authentication for supervisory management |

| Cyber threats | Isolation of the local area network (LAN) devoted to FMS-related communications |

| Software | Sensors | Actuators | Control Units | Supervisory Devices | Network Fieldbus |

|---|---|---|---|---|---|

| TIA Portal | Presence | Electrical | PLC S7-300 and S7-1200 | Windows PC Runtime | PROFINET/Ethernet |

| SQL Manager | Position | Pneumatic | Servomotor driver | KTP 600 | PROFIBUS |

| Robot Studio | Encoder | Servomotor | Robot controller |

| Advantages | Drawbacks |

|---|---|

| To my knowledge, this is the first time that the students have managed equipment with a focus on the Industry 4.0. They have heard about the concept, the new industrial revolution, but they have not really handled any laboratory system compliant with it. This is imperative for them to start to apprehend Industry 4.0 implications. | Using proprietary software packages imposes an important limit for the student because he/she cannot follow programming or configuring tasks at home: Their presence in the laboratory is imposed. For the next projects, the utilization of open source software and hardware should be approached. |

| Each new project relies to a high degree on the previous ones. For instance, the inclusion of the new station was based on the automation and communication of the rest of the stations. This is seen as a positive feature since students do not learn isolated technologies but an integrated and multidisciplinary environment. | Tutoring a project in the Industry 4.0 is an exciting task: However, the devoted time and effort have been higher than in the case of covering automation systems with more traditional focuses. I have dedicated a lot of time to studying the state of the art as well as the Industry 4.0 requirements. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

González, I.; Calderón, A.J. Development of Final Projects in Engineering Degrees around an Industry 4.0-Oriented Flexible Manufacturing System: Preliminary Outcomes and Some Initial Considerations. Educ. Sci. 2018, 8, 214. https://doi.org/10.3390/educsci8040214

González I, Calderón AJ. Development of Final Projects in Engineering Degrees around an Industry 4.0-Oriented Flexible Manufacturing System: Preliminary Outcomes and Some Initial Considerations. Education Sciences. 2018; 8(4):214. https://doi.org/10.3390/educsci8040214

Chicago/Turabian StyleGonzález, Isaías, and Antonio José Calderón. 2018. "Development of Final Projects in Engineering Degrees around an Industry 4.0-Oriented Flexible Manufacturing System: Preliminary Outcomes and Some Initial Considerations" Education Sciences 8, no. 4: 214. https://doi.org/10.3390/educsci8040214

APA StyleGonzález, I., & Calderón, A. J. (2018). Development of Final Projects in Engineering Degrees around an Industry 4.0-Oriented Flexible Manufacturing System: Preliminary Outcomes and Some Initial Considerations. Education Sciences, 8(4), 214. https://doi.org/10.3390/educsci8040214