Virtual Reality and Digital Twins for Mechanical Engineering Lab Education: Applications in Composite Manufacturing

Abstract

1. Introduction

- RQ1.

- How does VR-based training compare with traditional physical laboratory training in terms of procedural accuracy and task performance?

- RQ2.

- How does VR-based training influence different dimensions of cognitive load—mental demand, physical demand, effort, and frustration—relative to a physical laboratory setting?

- RQ3.

- How do learners perceive the usability, realism, and pedagogical value of the VR environment compared with the physical laboratory?

2. Literature Review

2.1. Background and Evolution of VR in Engineering Education

2.2. Theoretical Frameworks for VR-Based Learning

2.2.1. Constructivism and Situated Learning

2.2.2. Experiential Learning Theory

2.2.3. Technology Acceptance Model and Motivation

2.2.4. Cognitive Load Theory

2.3. Empirical Findings on VR Learning in Engineering and Manufacturing

2.4. Research Gaps and Contribution of the Present Study

3. Methodology

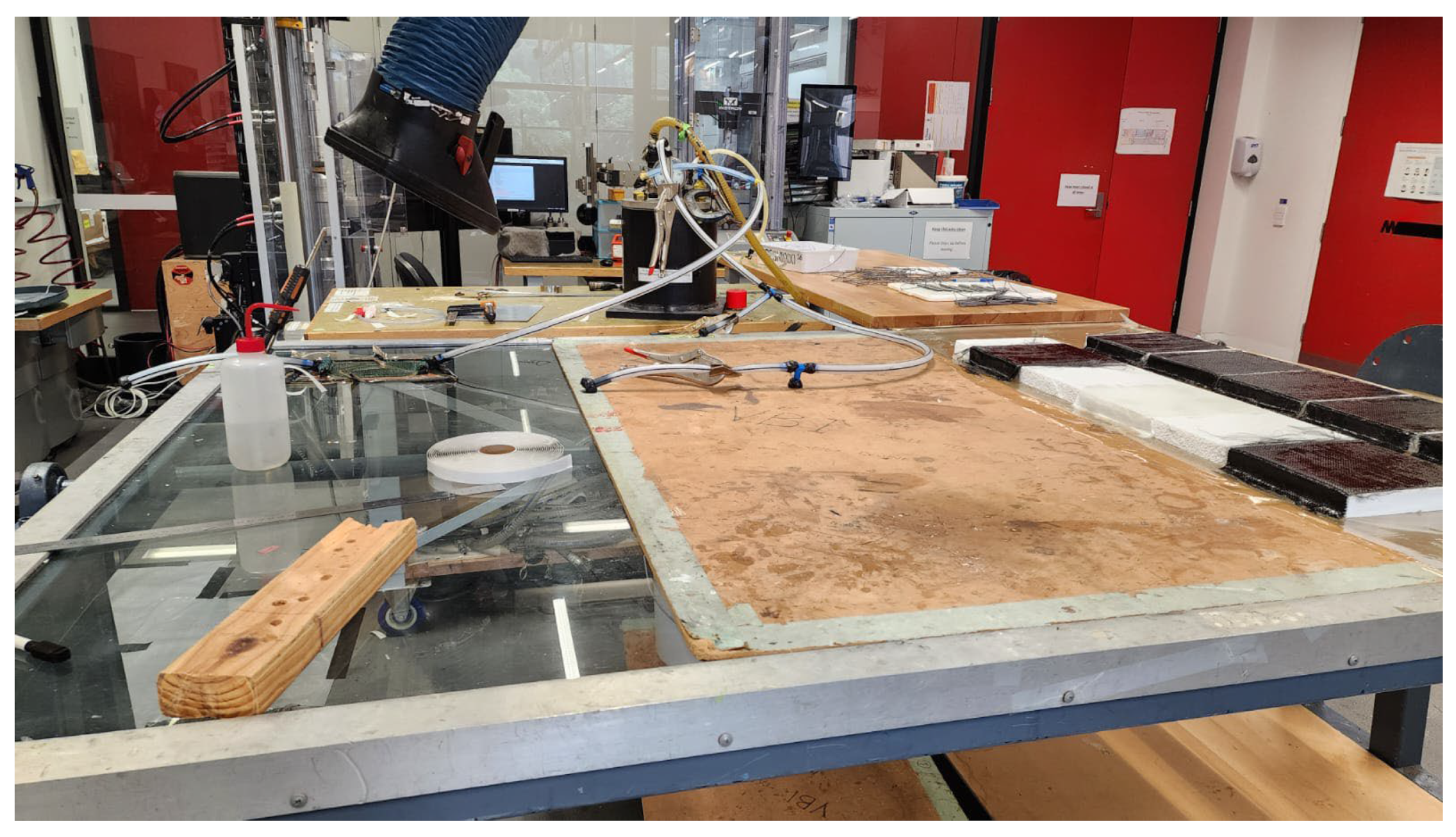

3.1. Research Design

3.2. Participants

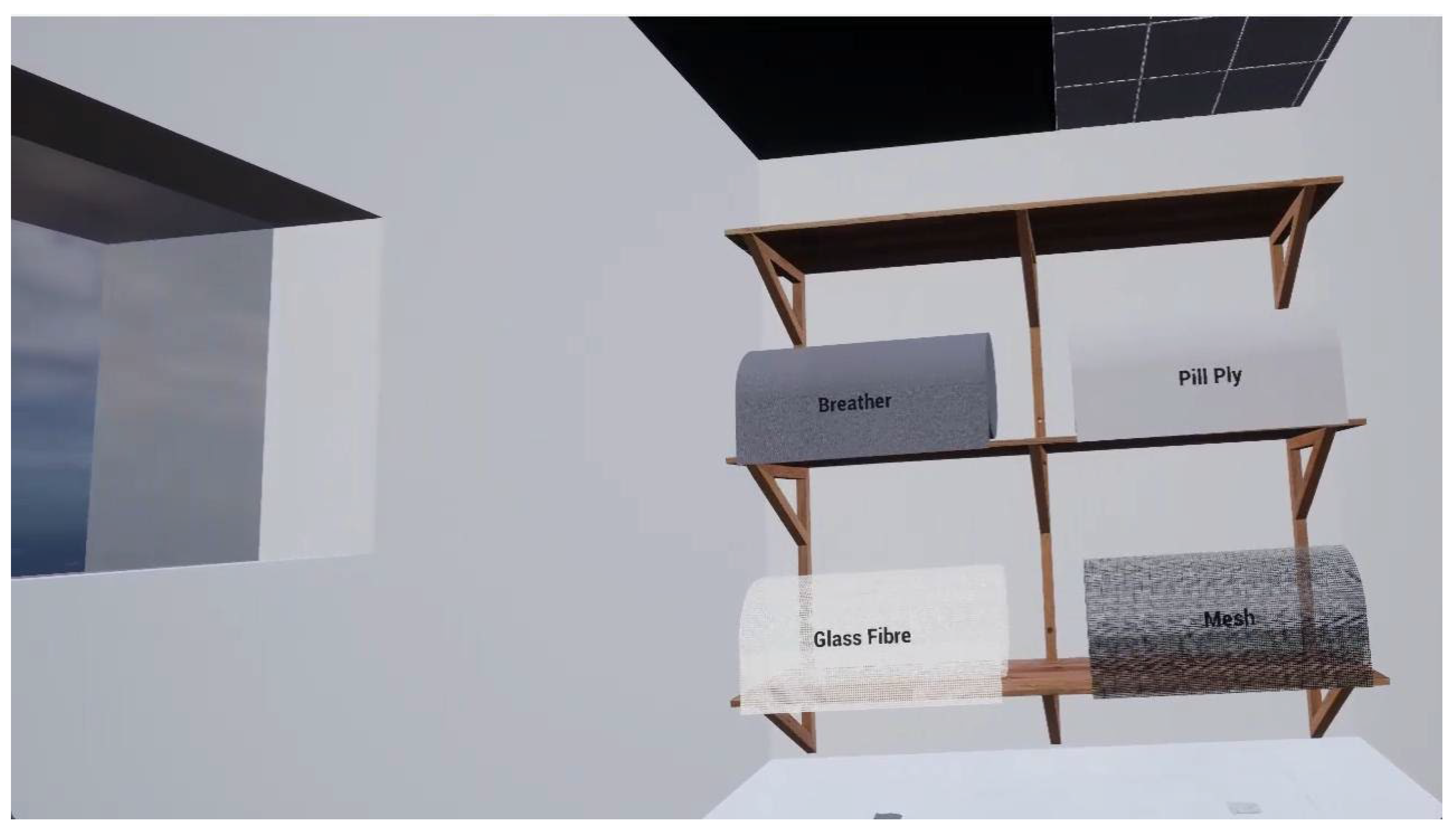

3.3. VR Application Development

3.4. Experimental Procedure

- (a)

- Pre-Experiment Phase

- (b)

- Training Phase

- (c)

- Post-Task Data Collection

- Did you find any of the activities especially difficult? Why?

- Did you feel overwhelmed at any point during the activities? When and why?

- Which parts of the system did you like the most? Why?

- Which parts of the system were the easiest to use? Why?

- Do you believe this system could replace in-person laboratories after being further refined? Why?

- Do you believe completing these tasks in person would have been easier or harder? Why?

3.5. Data Analysis

4. Results

4.1. Task Performance (Quantitative Results)

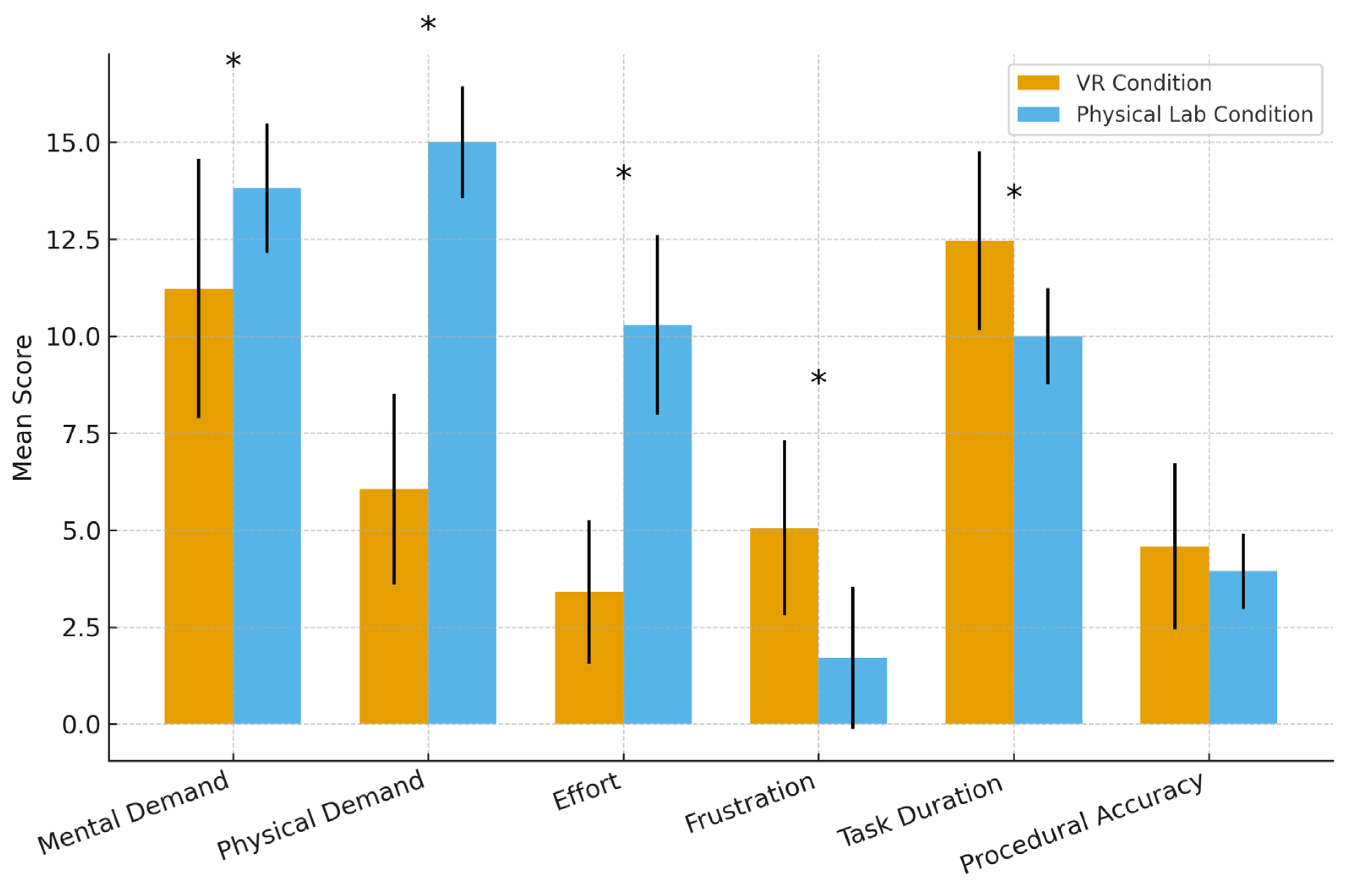

4.2. Cognitive Load

- Mental Demand: Significantly lower in VR (M = 11.23, SD = 3.35) compared to the physical lab (M = 13.82, SD = 1.67), t(16) = −4.28, p = 0.001.

- Physical Demand: Markedly reduced in VR (M = 6.06, SD = 2.46) compared to the physical lab (M = 15.00, SD = 1.44), t(16) = −9.75, p < 0.001.

- Effort: Lower in VR (M = 3.41, SD = 1.85) than in the physical lab (M = 10.29, SD = 2.31), t(16) = −8.42, p < 0.001.

- Frustration: Higher in VR (M = 5.06, SD = 2.25) compared to the physical lab (M = 1.71, SD = 1.83), t(16) = 4.86, p = 0.0002.

4.3. Learner Perceptions (Qualitative Results)

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abulrub, A. H. G., Attridge, A. N., & Williams, M. A. (2011). Virtual reality in engineering education: The future of creative learning. International Journal of Emerging Technologies in Learning, 6(4), 20–30. [Google Scholar] [CrossRef]

- Akpan, I. J., & Offodile, O. F. (2024). The role of virtual reality simulation in manufacturing in industry 4.0. Systems, 12(1), 26. [Google Scholar] [CrossRef]

- Alpala, L. O., Quiroga-Parra, D. J., Torres, J. C., & Peluffo-Ordóñez, D. H. (2022). Smart factory using virtual reality and online multi-user: Towards a metaverse for experimental frameworks. Applied Sciences, 12(12), 6258. [Google Scholar] [CrossRef]

- Bano, F., Alomar, M. A., Alotaibi, F. M., Serbaya, S. H., Rizwan, A., & Hasan, F. (2024). Leveraging virtual reality in engineering education to optimize manufacturing sustainability in industry 4.0. Sustainability, 16(18), 7927. [Google Scholar] [CrossRef]

- Braun, V., & Clarke, V. (2006). Using thematic analysis in psychology. Qualitative Research in Psychology, 3(2), 77–101. [Google Scholar] [CrossRef]

- Chuang, T.-J., Tsai, Y.-Y., & Smith, S. (2023). A visuo-haptic mixed-reality manual milling training simulator. Virtual Reality, 27(6), 2417–2430. [Google Scholar] [CrossRef]

- Darejeh, A. (2023, October 16–20). Empowering education through EERP: A customizable educational VR escape room platform. 2023 IEEE International Symposium on Mixed and Augmented Reality Adjunct (ISMAR-Adjunct) (pp. 764–766), Sydney, Australia. [Google Scholar]

- Darejeh, A., Huynh, L., Ji, X., Marcus, N., & Polly, P. (2024a, October 21–25). Assessing the efficacy of virtual reality-based laboratories versus real-life settings for PCR procedures, within medical science laboratories. 2024 IEEE International Symposium on Mixed and Augmented Reality Adjunct (ISMAR-Adjunct) (pp. 489–492), Bellevue, WA, USA. [Google Scholar]

- Darejeh, A., Marcus, N., & Sweller, J. (2022). Increasing learner interactions with E-learning systems can either decrease or increase cognitive load depending on the nature of the interaction. L’Année Psychologique, 122(3), 405–437. [Google Scholar] [CrossRef]

- Darejeh, A., & Mashayekh, S. (2025). 5 How the metaverse and brain computer interfaces can revolutionise. In Futureshock: Happenings in computer science (p. 76). CRC Press. [Google Scholar]

- Darejeh, A., Moghadam, T. S., Delaramifar, M., & Mashayekh, S. (2024b, February 27–29). A framework for AI-powered decision making in developing adaptive e-learning systems to impact learners’ emotional responses. 2024 11th International and the 17th National Conference on E-Learning and E-Teaching (ICeLeT) (pp. 1–6), Isfahan, Iran. [Google Scholar]

- Darejeh, A., Mondal, M., Marcus, N., & Vassar, A. (2024c, October 21–25). Exploring the cognitive load effects of diverse virtual reality interaction methods in interactive educational platforms. 2024 IEEE International Symposium on Mixed and Augmented Reality Adjunct (ISMAR-Adjunct) (pp. 435–438), Bellevue, WA, USA. [Google Scholar]

- Davis, F. D., Bagozzi, R. P., & Warshaw, P. R. (1989). Technology acceptance model. Journal of Management Science, 35(8), 982–1003. [Google Scholar]

- Di Natale, A. F., Repetto, C., Riva, G., & Villani, D. (2020). Immersive virtual reality in K-12 and higher education: A 10-year systematic review of empirical research. British Journal of Educational Technology, 51(6), 2006–2033. [Google Scholar] [CrossRef]

- Ellis, S. R. (1991). Nature and origin of virtual environments: A bibliographical essay. Computing Systems in Engineering, 2(4), 321–347. [Google Scholar] [CrossRef]

- Falcão, C. S., & Soares, M. M. (2013). Application of virtual reality technologies in consumer product usability. In Design, user experience, and usability. Web, mobile, and product design: Second international conference, DUXU 2013, held as part of HCI international 2013, Las Vegas, NV, USA, 21–26 July 2013, Proceedings, Part IV 2 (pp. 342–351). Springer. [Google Scholar]

- Fisher, M. (1999). The use of Virtual Reality in automotive design: Lessons from Ford’s VR center. Automotive Engineer, 24(3), 17–20. [Google Scholar]

- Fussell, S. G., & Truong, K. N. (2022). Using virtual reality for dynamic learning: An extended technology acceptance model. Virtual Reality, 26(1), 249–267. [Google Scholar] [CrossRef]

- Georgiou, J., Dimitropoulos, K., & Manitsaris, A. (2007). A virtual reality laboratory for distance education in chemistry. International Journal of Social Sciences, 2, 306–313. [Google Scholar] [CrossRef]

- Ghazali, A. K., Ab. Aziz, N. A., Ab. Aziz, K., & Tse Kian, N. (2024). The usage of virtual reality in engineering education. Cogent Education, 11(1), 2319441. [Google Scholar] [CrossRef]

- Halabi, O. (2020). Immersive virtual reality to enforce teaching in engineering education. Multimedia Tools and Applications, 79(4), 2987–3004. [Google Scholar] [CrossRef]

- Hernández-Chávez, M., Cortés-Caballero, J. M., Pérez-Martínez, Á. A., Hernández-Quintanar, L. F., Roa-Tort, K., Rivera-Fernández, J. D., & Fabila-Bustos, D. A. (2021). Development of virtual reality automotive lab for training in engineering students. Sustainability, 13(17), 9776. [Google Scholar] [CrossRef]

- Hosseinia, S., Abbasi, A., Magalhaes, L. G., Fonseca, J. C., da Costa, N. M. C., Moreira, A. H. J., & Borges, J. (2024). Immersive interaction in digital factory: Metaverse in manufacturing. Procedia Computer Science, 232, 2310–2320. [Google Scholar] [CrossRef]

- Huang, C. L., Luo, Y. F., Yang, S. C., Lu, C. M., & Chen, A. S. (2020). Influence of students’ learning style, sense of presence, and cognitive load on learning outcomes in an immersive virtual reality learning environment. Journal of Educational Computing Research, 58(3), 596–615. [Google Scholar] [CrossRef]

- Kamińska, D., Zwoliński, G., Wiak, S., Petkovska, L., Cvetkovski, G., Barba, P. D., Mognaschi, M. E., Haamer, R. E., & Anbarjafari, G. (2021). Virtual reality-based training: Case study in mechatronics. Technology, Knowledge and Learning, 26, 1043–1059. [Google Scholar] [CrossRef]

- Kapilan, N., Vidhya, P., & Gao, X.-Z. (2021). Virtual laboratory: A boon to the mechanical engineering education during COVID-19 pandemic. Higher Education for the Future, 8(1), 31–46. [Google Scholar] [CrossRef]

- Kaplan-Rakowski, R., Lin, L., & Wojdynski, T. (2022). Learning vocabulary using 2D pictures is more effective than using immersive 3D stereoscopic pictures. International Journal of Human–Computer Interaction, 38(4), 299–308. [Google Scholar] [CrossRef]

- Kolb, D. A. (1984). Experiential learning: Experience as the source of learning and development. Prentice Hall. [Google Scholar]

- Le Chénéchal, M., & Chatel-Goldman, J. (2018, November). HTC Vive Pro time performance benchmark for scientific research. In Icat-Egve 2018. HAL Open Science. [Google Scholar]

- Leppink, J., Paas, F., Van der Vleuten, C. P. M., Van Gog, T., & Van Merriënboer, J. J. G. (2013). Development of an instrument for measuring different types of cognitive load. Behavior Research Methods, 45(4), 1058–1072. [Google Scholar] [CrossRef]

- Li, V., Siniosoglou, I., Sarigiannidis, P., & Argyriou, V. (2025, June 16–19). Enhancing manufacturing training through VR simulations. 2025 IEEE International Conference on Engineering, Technology, and Innovation (ICE/ITMC) (pp. 1–9), Valencia, Spain. [Google Scholar]

- Li, W., Liu, X., Zhang, Q., Zhou, B., & Wang, B. (2023). VR-enhanced cognitive learning: Method, framework, and application. Applied Sciences, 13(8), 4756. [Google Scholar] [CrossRef]

- Ma, J., Jaradat, R., Ashour, O., Hamilton, M., Jones, P., & Dayarathna, V. L. (2019). Efficacy investigation of virtual reality teaching module in manufacturing system design course. Journal of Mechanical Design, 141(1), 012002. [Google Scholar] [CrossRef]

- Makransky, G., Lilleholt, L., & Aaby, A. (2017). Development and validation of the Multimodal Presence Scale for virtual reality environments: A confirmatory factor analysis and item response theory approach. Computers in Human Behavior, 72, 276–285. [Google Scholar] [CrossRef]

- Makransky, G., & Mayer, R. E. (2022). Benefits of taking a virtual field trip in immersive virtual reality: Evidence for the immersion principle in multimedia learning. Educational Psychology Review, 34(3), 1771–1798. [Google Scholar] [CrossRef]

- Makransky, G., & Petersen, G. B. (2021). The cognitive affective model of immersive learning (CAMIL). Educational Psychology Review, 33(3), 937–958. [Google Scholar] [CrossRef]

- Makransky, G., Terkildsen, T. S., & Mayer, R. E. (2019). Adding immersive virtual reality to a science lab simulation causes more presence but less learning. Learning and Instruction, 60, 225–236. [Google Scholar] [CrossRef]

- Nasri, M., Narayan, U., Sonbudak, M. F., Simonson, A., Chiu, M., Donati, J., Sivak, M., Kosa, M., & Harteveld, C. (2024, October 21–25). Designing a virtual reality training apprenticeship for cold spray advanced manufacturing. 2024 IEEE International Symposium on Mixed and Augmented Reality Adjunct (ISMAR-Adjunct) (pp. 541–544), Bellevue, WA, USA. [Google Scholar]

- Parong, J., & Mayer, R. E. (2021). Cognitive, affective, and transfer outcomes in immersive virtual reality versus desktop learning. Journal of Computer Assisted Learning, 37(1), 226–241. [Google Scholar] [CrossRef]

- Petersen, G. B., Petkakis, G., & Makransky, G. (2022). A study of how immersion and interactivity drive learning in virtual reality. Computers & Education, 179, 104429. [Google Scholar] [CrossRef]

- Pfotenhauer, J. M., & Gagnon, D. J. (2021, July 19–26). ThermoVR: A virtual laboratory to enhance learning in undergraduate thermodynamics. 2021 ASEE Virtual Annual Conference Content Access, Virtual Conference. [Google Scholar]

- Piaget, J. (1972). Intellectual evolution from adolescence to adulthood. Human Development, 15(1), 1–12. [Google Scholar] [CrossRef]

- Radianti, J., Majchrzak, T. A., Fromm, J., & Wohlgenannt, I. (2020). A systematic review of immersive virtual reality applications for higher education: Design elements, lessons learned, and research agenda. Computers & Education, 147, 103778. [Google Scholar] [CrossRef]

- Saravanan, S., Vijay, U., Tran, S., Mathew, M. M., Apostolova, D. Y., Gandarias, I., Leclere, A., Lelong, R., & Franco, A. A. (2025). Metaverse for battery manufacturing: Connecting students from different geographical locations to solve battery manufacturing problems in the virtual reality space. Batteries & Supercaps. Advance online publication. [Google Scholar] [CrossRef]

- Sargazi Moghadam, T., Darejeh, A., Delaramifar, M., & Mashayekh, S. (2024). Toward an artificial intelligence-based decision framework for developing adaptive e-learning systems to impact learners’ emotions. Interactive Learning Environments, 32(7), 3665–3685. [Google Scholar] [CrossRef]

- Seth, A., Vance, J. M., & Oliver, J. H. (2001). Virtual reality for assembly methods prototyping: A review. Virtual Reality, 5(3), 161–174. [Google Scholar] [CrossRef]

- Srinivasa, A. R., Jha, R., Ozkan, T., & Wang, Z. (2020). Virtual reality and its role in improving student knowledge, self-efficacy, and attitude in the materials testing laboratory. International Journal of Mechanical Engineering Education, 49(4), 382–409. [Google Scholar] [CrossRef]

- Sweller, J. (1988). Cognitive load during problem solving: Effects on learning. Cognitive Science, 12(2), 257–285. [Google Scholar] [CrossRef]

- Venter, H., & Ogterop, W. (2022). Unreal engine 5 character creation, animation, and cinematics: Create custom 3D assets and bring them to life in unreal engine 5 using MetaHuman, Lumen, and Nanite. Packt Publishing Ltd. [Google Scholar]

- Vergara, D., Bosque, A. D., & Fernández-Arias, P. (2025). A decade of digital twins in materials science and engineering. Computers, Materials & Continua, 85(1), 41–64. [Google Scholar] [CrossRef]

- Vygotsky, L. S. (1978). Mind in society: The development of higher psychological processes. Harvard University Press. [Google Scholar]

- Wang, J., Suo, J., Song, Z., Li, W. J., & Wang, Z. (2023). Nanomaterial-based flexible sensors for metaverse and virtual reality applications. International Journal of Extreme Manufacturing, 5, 032013. [Google Scholar] [CrossRef]

- Zhao, R., Aqlan, F., Elliott, L. J., & Lum, H. C. (2019, August 26–30). Developing a virtual-reality-based game for manufacturing education. 14th International Conference on the Foundations of Digital Games (FDG’19), San Luis Obispo, CA, USA. [Google Scholar] [CrossRef]

| Workload Dimension | VR (M ± SD) | Physical Lab (M ± SD) | t(16) | p |

|---|---|---|---|---|

| Mental Demand | 11.23 ± 3.35 | 13.82 ± 1.67 | −4.28 | 0.001 |

| Physical Demand | 6.06 ± 2.46 | 15.00 ± 1.44 | −9.75 | <0.001 |

| Effort | 3.41 ± 1.85 | 10.29 ± 2.31 | −8.42 | <0.001 |

| Frustration | 5.06 ± 2.25 | 1.71 ± 1.83 | 4.86 | 0.0002 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Darejeh, A.; Chilcott, G.; Oromiehie, E.; Mashayekh, S. Virtual Reality and Digital Twins for Mechanical Engineering Lab Education: Applications in Composite Manufacturing. Educ. Sci. 2025, 15, 1519. https://doi.org/10.3390/educsci15111519

Darejeh A, Chilcott G, Oromiehie E, Mashayekh S. Virtual Reality and Digital Twins for Mechanical Engineering Lab Education: Applications in Composite Manufacturing. Education Sciences. 2025; 15(11):1519. https://doi.org/10.3390/educsci15111519

Chicago/Turabian StyleDarejeh, Ali, Guy Chilcott, Ebrahim Oromiehie, and Sara Mashayekh. 2025. "Virtual Reality and Digital Twins for Mechanical Engineering Lab Education: Applications in Composite Manufacturing" Education Sciences 15, no. 11: 1519. https://doi.org/10.3390/educsci15111519

APA StyleDarejeh, A., Chilcott, G., Oromiehie, E., & Mashayekh, S. (2025). Virtual Reality and Digital Twins for Mechanical Engineering Lab Education: Applications in Composite Manufacturing. Education Sciences, 15(11), 1519. https://doi.org/10.3390/educsci15111519