Abstract

A batch of a new product designed by the research and development department was prepared at a private label of a Polish cosmetics company. The product was transferred to the warehouse with no indication of when it would be given to a supplier. A student starting her internship in the factory wondered why the date of delivery for distribution was not indicated. To study this problem, an analysis of the production process was carried out using the tools of the problem-based learning method. SWOT analysis, a flowchart, a questionnaire and an Ishikawa diagram were used as tools for evaluation of the production process of the work of departments involved in the production of one cosmetics line. Analyses and surveys conducted by the observer as well as feedback from employees identified several problems. Among them, poor planning was selected as the so-called specific problem, i.e., the one to which special attention was paid and solutions for which were suggested. Planning with a longer time horizon would allow the preparation of production and the logistics departments to adjust the production line by separating it from other cosmetics, thus avoiding disruptions and interruptions in production in general. Suggestions also included changing or expanding a malfunctioning enterprise resource planning (EPR) system used to manage the organization that does not organize work properly and even delays it.

1. Introduction

Lodz University of Technology has more than a dozen years of experience in the field of implementing various forms of self-directed learning, and one of them is called problem-based learning (PBL). In general terms, PBL can be defined as a method of gaining knowledge and competence in a specific field on the basis of solving a problem. The characteristics of the method were formulated by Howard Barrows, the pioneer of the PBL idea. His definition still describes it very well: it is student-centred; the lecturer plays the role of facilitator—supports the process of communication within the group, motivates them to work; groups work on solving practical tasks; work takes place in small groups; students develop soft skills while working; students acquire tools and information through group work and individual involvement [1]. The knowledge-gathering takes place mostly independently when students search for and obtain information related to the problem, which they then critically analyse together, assessing its usefulness in finding a solution to the problem. Learning here is a self-directed process during the course of teamwork. The effectiveness of such teaching, compared to traditional academic teaching, is also reflected in the development of problem-solving skills and the promotion of creativity. The solutions that the students develop are more independent and innovative. PBL supports the development of concurrent key competencies such as reflective learning, adaptability, creative thinking, and effective work in groups. The development of these attributes is also important for the lifelong learning of skills.

International Faculty of Engineering (IFE) students shape and develop their skills in solving problems during tutorials that are available to them during the 4th semester. One of the former IFE Students, Justyna Kulesza, applied the methods learned in this course to examine a cosmetics manufacturing company’s functioning. The general problem that she noted was that a batch of a new product designed by the research and development (R&D) department was prepared at a private label of one of the Polish cosmetics companies. The product was transferred to the warehouse with no indication of when it would be sent to a supplier. The company did not agree to make its name public, thus the results of the research conducted are presented in a general manner, although they were obtained on the basis of one specific factory.

2. Analysis and Definition of the Problem

2.1. Cosmetics Market in Poland—General Overview

The cosmetics industry tends to be one of the export stars of the national economy. Poland has been maintaining its position in the global cosmetics market for years: sixth in Europe in terms of cosmetics retail turnover and the world’s 14th largest exporter of cosmetics (2020) [2]. According to data from the Central Statistical Office of Poland (GUS) in 2016, cosmetics from Poland were exported to over 160 countries, including such distant countries as Mexico, Indonesia, and Australia. These results make the country a European potentate. The specificity of the Polish cosmetics market is in its structure, which is largely fragmented. There are about 100 large and medium companies and over 300 small and very small producers of cosmetics. According to analysts from Pekao S.A.’s macroeconomic analysis department, there were more than 600 small- and medium-sized cosmetics companies operating in the country in 2020 [3]. According to data on the year 2019 published by the GUS, a total of 16,000 people worked in cosmetics manufacturing entities with more than nine employees [4]. The cosmetics market not only comprises the production itself, but companies closely related to the industry such as laboratories, research companies, chemical and biotechnological companies, as well as packaging manufacturers should also be considered. In the years 2004–2016, Poland’s positive balance of cosmetics trade in the EU increased almost nine times—from PLN 231 million to PLN 2.04 billion. In fact, even the COVID-19 pandemic and lockdown did not cause a break in these upward trends. In the first four months of 2020, exports from Poland increased by 6.2% compared to the same period the year before [5]. The pandemic turned out to be an opportunity, to enter new markets previously unreachable for Polish cosmetics. An increase in exports to very demanding markets such as Sweden, Denmark, and even Switzerland (more than 150%) was reported in April 2020.

However, the pandemic and recession had an impact on consumer behaviour. There was a noticeable increase in at-home consumption as opposed to a more frequent venture outdoors. At the same time, premium products were more frequently chosen. Most luxury brands have experienced growth, especially noticeable compared to the poor performance of 2009 [6]. The prospects for the market are still good, and its value is projected to grow by 19% between 2018 and 2024, according to a new report entitled ‘Cosmetics retail market in Poland 2019. Market analysis and development forecasts for 2019–2024’ [7]. The cosmetics market is still promising. PMR (Polish Market Review)’s forecasts predict that the cosmetics market in Poland will continue to grow in the coming years (2023–2027), growing at an average annual rate of 3–5%, a rate slightly higher than that observed in the last five years [8].

As in no other sector, the market requires innovation from producers to stay in a very competitive market and even overtake the competition; for example, every year about 300 new facial care products are presented to consumers. A new form, ingredients, way of action or application are just examples of the various forms of innovation introduced to cosmetics. A new, surprising ingredient can attract crowds of consumers to even an already known product. Despite the need to source new ingredients not a being a requirement of competition, it is still influenced by constantly changing legislation on cosmetic ingredients. The European Commission issues between a few and more than a dozen impacting legal acts annually, which may restrict or prohibit the use of ingredients that are not assessed as safe in the manufacture of cosmetics. Customers are also a source of pressure on cosmetics composition. They depreciate the opinions issued by the SCCS (Scientific Committee for Consumer Safety, Brussels, Belgium) and create their own ‘blacklists of ingredients’, forcing manufacturers to eliminate safe and authorized ingredients from cosmetic formulas. Reformulation of a cosmetic product, for instance by reducing the concentration of preservatives, is a complex and costly process. Cosmetics companies are very adaptive, easily responding to changes in the market. The desk research showed that the cause of the problem could hardly be the industry’s general economic situation.

2.2. Analysis of the Production Process

Analysis of the production process enables the capturing of possible errors occurring at any stage of production, starting from the sources of raw materials, through the organization of work, ending up with a determination of the quality–price ratio of goods. Owing to such analysis, factories have an opportunity to rapidly improve the demonstrated irregularities in strictly defined zones and to introduce optimizations that serve to increase production efficiency at constant costs. Consequently, the enterprise avoids losses, can produce more and faster, its reputation improves and sales of manufactured goods increase. Production process analysis and quality management system analysis can be carried out in several ways. Interviews with employees, analysis and verification of documents, or evaluation based on a standard checklist are only a few of the approved forms. Depending on the needs and available resources, elements of different forms of audit can be combined.

A product line in the preparation stage was selected for the analysis of the production process of a cosmetic product. The work of each Department involved in the creation of cosmetics was evaluated, however, with a special focus on the stages and tasks assigned to the quality control department. Participatory observation was used as one of the main research methods. It was necessary to familiarize with the work of each department in order to learn and analyse the production process. The documents, protocols and certificates that employees operate and create were also reviewed.

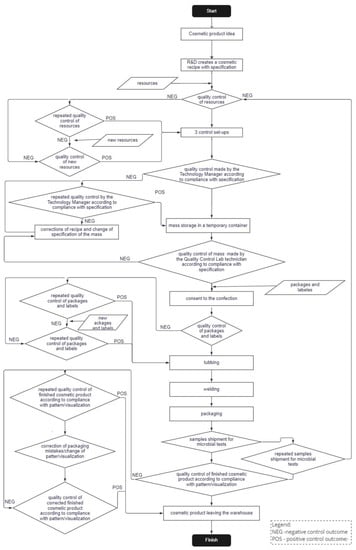

Flowchart

A flowchart is a tool used to illustrate successive stages of manufacturing. Using a few basic figures such as rectangles, ovals, rhombi and arrows, specific types of production stages and the direction of their flow are marked. This type of map allows one to easily indicate the most problematic or complicated stages of production and to plot changes in the production process [9]. The flowchart was prepared in a general manner for the subject before the first implementation (Figure 1).

Figure 1.

Flowchart of the cosmetic product before the first implementation.

Observation of the production process (flowchart) did not reveal any problems in the production line, but delays were detected, which may suggest inadequate planning. During the two-month observation the production of the analysed cosmetics progressed smoothly, with no delays occurring on any of the main lines of the flowchart. However, the prepared cosmetic masses were not delivered to customers but were stuck in the warehouse, where they were stored without a strict distribution date. Such a situation obviously may give rise to potential negative consequences, among which may be: the risk of exposing the company to financial losses related to the loss of this batch of products; unnecessary occupation of warehouse space and associated costs; the risk of reducing the attractiveness of the company’s new product caused by the introduction of a similar product in the portfolio of a competitor.

2.3. SWOT Analysis

A SWOT analysis is one of the tools for strategic assessment of the condition of a given enterprise. Its name stands as an acronym for the English terms of its four components: strengths, weaknesses, opportunities, and threats. In management, this tool is used to delve into the internal and external environment of an organization, where strengths and weaknesses usually define the former, while opportunities and threats describe the external environment of an enterprise [10,11]. It allows for the presentation of an overall picture on the basis of indicating the advantages and strengths, as well as the limitations and disadvantages of the company’s work, and its position in the market [10].

The results of the analysis of the factory were illustrated on a four-part strategic matrix, in which the left half outlined two positive categories and the right half two negative categories (Table 1). The analysis identified the strengths and weaknesses of the factory. One of unquestionable strength is the certification system, the great attention paid to it is reflected in the work in general, which is well-organized. Frequent audits help to avoid the build-up of existing irregularities. On the other hand, the analysis also pointed out serious problems such as proper management of production and personnel. The company’s financial arrears may be of particular importance for its continued functioning.

Table 1.

SWOT analysis of The Company.

The SWOT analysis’ insights into the factory’s functioning were deepened and expanded to include the interrelations between them. A more complete interpretation of the key elements was feasible by subjecting the table’s contents to an interrelations analysis by asking the following questions:

- Will the identified strength enable the company to take a given opportunity?

- Will the identified strength enable the company to eliminate a given threat?

- Will the identified weakness limit a given opportunity?

- Will the identified weakness increase the risk of a threat?

The identified links and their descriptions are summarized in Table 2.

Table 2.

Interrelations between key elements indicated in SWOT analysis and their description.

In the course of the analysis of interrelations between various parts of the matrix, many connections based on strengths were identified, as well as weaknesses and threats. The latter are particularly important for choosing the most relevant marketing strategy and can be the main indicator for selection of the best corrective action strategy. Available among them are:

- Dominant strategy (dominance of strengths and opportunities), which aims to develop the company and take advantage of opportunities that come along;

- Conservative strategy (dominance of strengths and threats), which consists of using strengths to overcome coming threats;

- Competitive strategy (dominance of weaknesses and opportunities) means taking advantage of upcoming opportunities and eliminating your own disadvantages at the same time;

- Defensive strategy (dominance of weaknesses and threats) involving all decisions necessary to prevent the company from likely bankruptcy [10].

The dominance of weaknesses in the SWOT analysis would indicate a defensive strategy is an appropriate corrective action strategy. It focuses on securing as much capital as possible in the event of the company’s probable bankruptcy. However, the analysis of interrelations indicated many connections based on the strengths. Thanks to them, adopting a conservative strategy seemed to be more advisable; it is based on offsetting risks by focusing on the strengths of the business.

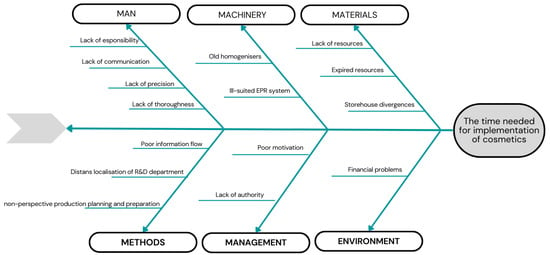

2.4. Ishikawa Diagram

Observations and responses from the conducted research were assembled and compiled into an Ishikawa diagram, which was drawn up according to the 5M + E scheme. Factors affecting the elongation of time required for the preparation of cosmetic products were divided into six categories: man, machinery, materials, methods, management, and environment. The main reasons for the irregularities occurring in a particular area were assigned to each category [12].

The created Ishikawa diagram (Figure 2) allows for the notation of specific aspects that should be taken into account in the context of improving the production process. More than a dozen areas were identified as having a negative impact on the time required to prepare the final cosmetic product. The major among them are: lack of communication between employees and thus the inadequate flow of information; shortages of raw materials and problems with their availability; inadequate planning and preparation of production; the R&D Department’s headquarters 70 km away from the main factory; inadequate motivation of employees; increasing financial irregularities. All of the listed aspects adversely affected the speed of order execution.

Figure 2.

Ishikawa Diagram.

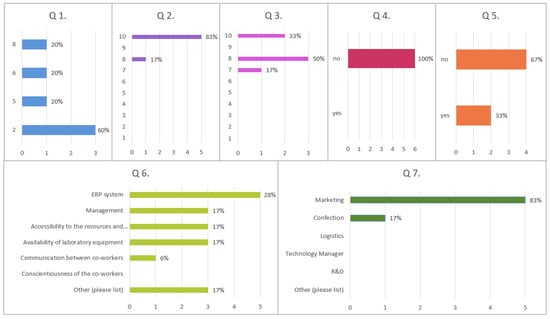

2.5. Questionnaire

In the course of the conducted analysis, improper planning was identified as one of the specific problems. To verify this hypothesis and possibly identify potential sources of delays, a survey was conducted among employees of the quality control department (QCD). The survey was designed to obtain employees’ points of view on the functioning of both their area of work and the company as a whole. An anonymous questionnaire consisting of seven questions in the printed version was given to six of the team’s seven employees. They were given five hours to complete the questionnaire and provide their opinions.

The respondents were people with at least a few years of work experience (4 ± 2.6 years), who highly rated their own and their colleagues’ commitment to their work (9.7 ± 0.82 and 8.5 ± 1.12 on a scale of 0–10, respectively), and thus had a very positive perception of the department’s work (67% of respondents believe that the QCD does not need to do better) (Figure 3). The chi-square test was performed to see the uniformity of the impact of fields on the work of the quality control department. Both Figure 3 (Q6,7) illustrated that the impact of other fields on QCD performance was not equal, the differences were statistically significant at p < 0.05. The respondents noticed problems and mostly considered a malfunctioning ERP system (83% of responses) as the reason for emerging malfunctions at the Factory. This was followed, with equal frequency, by the responses ‘management’ and ‘available laboratory equipment’ (50% of the votes each). In the ‘other’ category, the only indication from the surveyed employees was the answer ‘lack of training’. All respondents specified the marketing department as the one with the least favourable impact on the work of the QCD.

Figure 3.

Survey results. The y-axis shows the response variant to choose from, the x-axis shows the number of responses obtained for the variant. Q1. What is your seniority in the company? Q2. How well do you rate your commitment to your job responsibilities? Q3. How would you rate the commitment of the other employees of the quality control department to their job responsibilities? Q4. On a company-wide basis, would you rate the work of the quality control department positively? Q5. Do you think that from the perspective of the cosmetic production process, the quality control department should better fulfil its job duties? Q6. Would improvement in other fields positively affect the quality control department? (Mark up to 3 from the following: ERP system; management; accessibility to the resources and cosmetic masses under examination; availability of laboratory equipment; communication between co-workers; conscientiousness of the co-workers, or list other that you consider as important in that case.) Q7. Which of the following fields: marketing; confection; logistics; technology manager; R&D, has a negative impact on the work of the quality control department? (Mark up to 2 or list other that you consider as important in that case.)

2.6. Enterprise Resource Planning System

Every enterprise, regardless of its size, possesses a management system. The larger it is, the more branched and complex it becomes. It often covers issues and plans of a company, information on warehousing and production, as well as methods of resource management [13]. Technological development over the past decades has enabled the transfer of complex systems with multiple programs into a single tool that can be accessed even via phone. This does not mean that there are only mobile methods of business management; paper inventories are successfully used in smaller companies. Nevertheless, in the age of the Internet and smartphones, it is becoming more common to manage through an electronic system. Entrepreneurs have a full range of options to choose from—they can create and harmonize tables in spreadsheets (also available without charge), use licensed software by adjusting its scope to the scale of the company’s operations, or even create their own management system [14]. Regardless of the method, the management system is crucial, as it affects the company’s work both directly and indirectly—its financial liquidity, the availability of raw materials, the harmonization of work between departments, the appropriate division of responsibilities and adjustment of the number of orders, or receiving and keeping commitments. The effects of an inadequate management system can be short and long-term, reversible or irreversible, but a failure to make the necessary changes can ultimately lead to the bankruptcy of the company [15]. Audits of the management system, especially quality management, are therefore extremely important [16,17].

During the internship, it was remarked that the ERP system used in the company caused many difficulties, which, in a broader perspective, influences, both directly and indirectly, the speed of preparation of the cosmetic product. The majority of its users (questionnaire) find it difficult to work with it. The problems pointed out cover, for instance: restrained access allowing only ten employees to be logged-in simultaneously; having access only to a few of the available modules, which leads to working both on the computer and preparing paper files, as well as to working on numerous computer programs and a lack of training in the updates of the system.

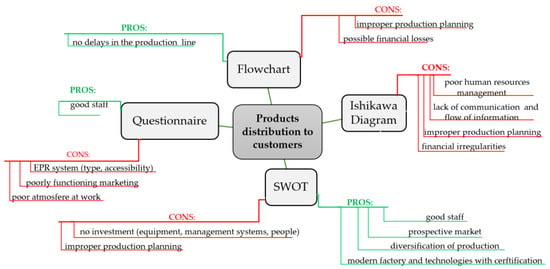

3. Discussion and Suggestions of the Solutions

Using the problem-based Learning method and its tools, planning the time required for the realization of the finished cosmetic product was identified as a specific problem. This problem was identified in each of the four analyses performed: flowchart, SWOT analysis, Ishikawa diagram and Questionnaire (Figure 4).

Figure 4.

Mind map integrating results of the flowchart, SWOT Analysis, Ishikawa diagram, and questionnaire, presenting the main problems and strengths revealed during performed analyses.

The observations and conducted research served to identify diverse approaches to solve the identified specific problem. The first of the proposed potential actions that could make a difference relatively easily and quickly would be for marketing to announce the demand for a cosmetic or series of cosmetics a longer time in advance. Then, the production preparation and logistics departments would have time to prepare and allocate the production of products without causing disruptions on other production lines. Facilitation of the production planning process could be the use of fee-based programs dedicated to this purpose. The research is based on a survey of 205 managers of primarily manufacturing and trading companies that operate in Lithuania that evaluated marketing planning and distribution as the most important marketing functions, while marketing research and price management appeared to be significantly less important [17]. Data also showed a positive relationship between the evaluations of marketing activities and company growth [17]. Marketing planning aligns with different phases of the company’s lifeline and can be used as a diagnostic tool [18].

Employees pointed out the malfunctioning ERP with limited system access as a factor that poses problems during the performance of duties. Thus, changing or upgrading the ERP system is an aspect that would definitely accelerate the work of each department. There are several possibilities for modifying the indicated system that would result in increased work efficiency. These include buying additional licenses, expanding the program with additional modules, changing the system to another one available on the market, or outsourcing the writing of a similar one specifically for the company’s use.

Author Contributions

Conceptualization, M.A.B.; methodology, J.K. and M.A.B.; investigation, J.K.; writing—original draft preparation, J.K.; writing—review and editing, M.A.B.; visualization, J.K. and M.A.B.; supervision, M.A.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Barrows, H.S. A taxonomy of problem-based learning methods. Med. Educ. 1986, 20, 481–486. [Google Scholar] [CrossRef] [PubMed]

- Kosmetyczna, B. Pozycja Międzynarodowa Polskich Producentów w Obliczu Kryzysu Wywołanego Przez Pandemię COVID-19—PDF Darmowe Pobieranie. Available online: https://docplayer.pl/220978735-Branza-kosmetyczna-pozycja-miedzynarodowa-polskich-producentow-w-obliczu-kryzysu-wywolanego-przez-pandemie-covid-19.html (accessed on 2 October 2022).

- Polska Branża Kosmetyczna Dobrze Zarabia i Stawia na Eksport Raport Pekao SA. Available online: https://www.wiadomoscikosmetyczne.pl/artykuly/polska-branza-kosmetyczna-dobrze-zarabia-i-stawia-,68310/2 (accessed on 3 October 2022).

- Polski Rynek Kosmetyczny Rozwija Się Pomimo Pandemii—Poradnik Handlowca. Available online: https://poradnikhandlowca.com.pl/artykuly/polski-rynek-kosmetyczny-rozwija-sie-pomimo-pandemii/ (accessed on 3 October 2022).

- Polski Rynek Kosmetyczny Rozwija Się Pomimo Pandemii—Analiza Santander Bank Polska. Available online: https://ceo.com.pl/polski-rynek-kosmetyczny-rozwija-sie-pomimo-pandemii-analiza-santander-bank-polska-64006 (accessed on 3 October 2022).

- In-Cosmetics Marketing Trends—A Time for Recovery. Available online: https://www.cosmeticsbusiness.com/news/article_page/in-cosmetics_marketing_trends_A_time_for_recovery/55120 (accessed on 3 October 2022).

- PMR Industry Report: Cosmetics Retail Market in Poland 2019. Available online: https://mypmr.pro/products/cosmetics-retail-market-in-poland-2019-1 (accessed on 3 October 2022).

- PMR: Record-Breaking Cosmetics Market Growth in 2022. Available online: https://www.pmrmarketexperts.com/en/pmr-record-breaking-cosmetics-market-growth-in-2022/ (accessed on 3 October 2022).

- What is a Flowchart|Lucidchart. Available online: https://www.lucidchart.com/pages/what-is-a-flowchart-tutorial (accessed on 3 October 2022).

- Hill, T.; Westbrook, R. SWOT analysis: It’s time for a product recall. Long Range Plan. 1997, 30, 46–52. [Google Scholar]

- Bieda, A.; Brzozowska, A. SWOT/TOWS analysis as a method of defining spatial development directions. Acta Sci. Pol. Adm. Locorum 2017, 16, 151–160. [Google Scholar]

- Diagram Ishikawy (Rybia Ość). Available online: https://www.jakosc.biz/diagram-ishikawy/ (accessed on 3 October 2022).

- Jarosz, A.; Unold, J. System Informacyjny w Procesie Kompleksowego Zarządzania Jakością. Przegląd Organ. 1999, 6, 33–38. [Google Scholar] [CrossRef]

- Sołtysik, M. Analiza i Projektowanie Systemów Zarządzania Przedsiębiorstwem (Red.); Stabryła, A., Ed.; Mfiles pl: Krakow, Poland, 2010. [Google Scholar]

- Piasecka-Głuszak, A. Metody planowania potrzeb MRP i Just in Time jako strategie wspomagające system logistyczny w przedsiębiorstwie produkcyjnym. Naukowe Wyższej Szkoły Bankowej we Wrocławiu 2011, 22, 205–206. [Google Scholar]

- Parys, T. System ERP III przykładem zintegrowanego systemu informatycznego ery mobilnej komunikacji. In Innowacje w Zarządzaniu i Inżynierii Produkcji; Wydawnictwo PTZP: Opole, Poland, 2018; Volume 2, pp. 664–672. [Google Scholar]

- Urbonavicius, S.; Dikcius, V. Importance of Marketing Activities in a Company: The Management Perspective. Ekonomika 2008, 83, 41–50. [Google Scholar] [CrossRef]

- Leppard, J.; McDonald, M. A Re-Appraisal of the Role of Marketing Planning. J. Mark. Manag. 1987, 3, 159–171. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).