Towards Lean Teaching: Non-Value-Added Issues in Education

Abstract

1. Introduction

2. Lean Thinking

- Determine which are the non-value-added issues (waste); that is, those activities that do not increase the worth of what is delivered to the customer. For the purpose of identifying these waste sources, a very good tool is value stream mapping (VSM), among others. VSM is a tool that displays the chain of processes (both those that add value and those that do not) for producing a specific product or family of products. VSM helps us to quickly visualize the entire process, understand the value-added and non-value-added activities by identifying bottlenecks or inefficiencies, and where the processes can be streamlined or improved [16].

- After this analysis, elimination or minimization of these non-value-added activities must be led. For this purpose, projects must be led, involving, on the one hand, different Lean tools depending on the type of waste and, on the other hand, the participation of the involved people.

- Once the projects are implemented, a new analysis of where the new non-value-added issues are must be developed. The practice of improving all the elements in the process by eliminating waste is an ongoing effort to pursue perfection. Consequently, processes must be analyzed continuously (to see what adds value or not) and improved by using Lean tools and the commitment of the people to finally convert a Lean project into a Lean culture [21]. Lean culture encourages people to participate in all the initiatives of continuous improvement, and think about which of their routine activities add (or not) value to the system.

- Overproduction: It is defined as producing more than the customer requires or producing something before it is needed.

- Inventory: It is the excessive storage of raw materials, in-process products, or finished products, which the customer does not need. An extra inventory provokes unnecessary costs because it uses valuable space, it consumes financial resources, extra time is needed for controlling it, and it is a source of product losses since it can become obsolete or suffer damage.

- Overprocess: It means to do more processes than the customer requests due to internal needs, such as bureaucratic procedures, or to produce better quality than the customer requires, or to pack better than necessary.

- Defects: They are associated with those products that do not meet quality requirements and, consequently, must be repeated, processed again, or thrown away.

- Transportation: It is the movements of products needed to pass between processes, e.g., to storage or to send them to the customer.

- Motion: It refers to all the movements of people without producing anything, e.g., because they have to inform someone, clean an area, or they need a tool, an order, instructions, or even paper.

- Waiting: It is associated with people not producing and waiting for something to proceed, such as, for instance, to repair equipment, to get permission, or to receive information.

- Unused creativity: This waste refers to the fact of not using the help or the knowledge of people involved in the processes in order to improve the processes, or to have people working in jobs where their capabilities are underutilized.

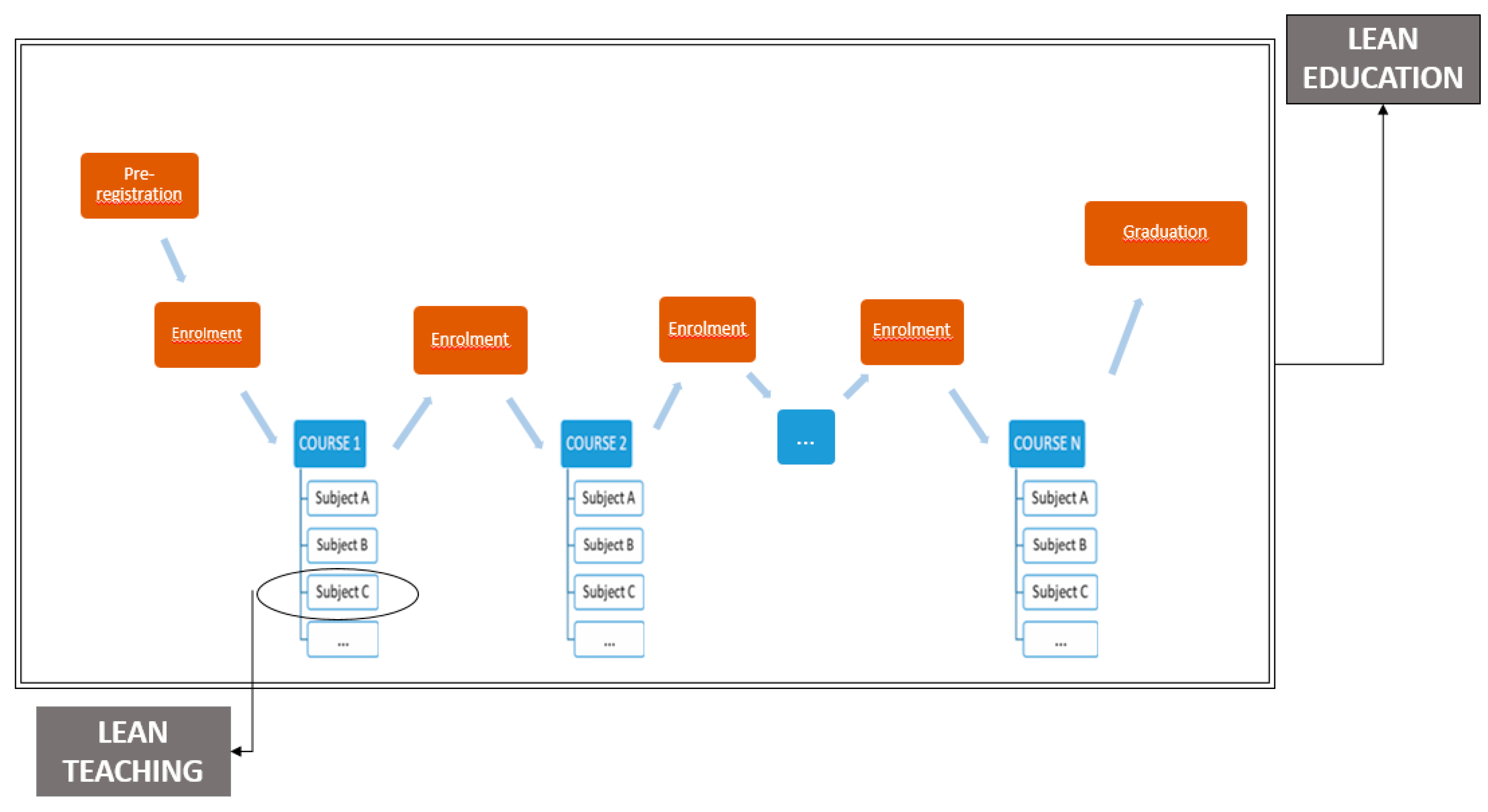

3. Lean Education Approaches

4. Lean Education and Lean Teaching: Non-Added-Value Issues

- Overproduction:

- Inventory:

- Overprocess:

- Defects:

- Transportation:

- Motion:

- Waiting:

- Unused creativity:

5. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Marina, J.A. Despertad al Diplodocus. Una Conspiración Educativa para Transformar la Escuela y todo lo Demás; Ariel: Barcelona, Spain, 2015. [Google Scholar]

- Martinez, S.; Valverde, J.C. University-Industry Collaboration for the Continuous Update on the Manufacturing Process. In INTED2010 Proceedings; IATED: Valencia, Spain, 2010; pp. 2–6. [Google Scholar]

- Alp, N. The lean transformation model for the education system. In Proceedings of the 29th Computers and Industrial Engineering Conference, Montréal, QC, Canada, 1–3 November 2001; pp. 82–87. [Google Scholar]

- Alves, A.C.; Flumerfelt, S.; Kahlen, F.J. (Eds.) Lean Education: An Overview of Current Issues; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Emiliani, B. Improving business school courses by applying lean principles and practices. Qual. Assur. Educ. 2004, 12, 175–187. [Google Scholar] [CrossRef]

- Emiliani, B. Lean Teaching: A Guide to Becoming a Better Teacher; The CLBM: Wethersfield, CT, USA, 2015. [Google Scholar]

- Emiliani, B. Lean University: A Guide to Renewal and Prosperity; The CLBM: Wethersfield, CT, USA, 2015. [Google Scholar]

- Womack, J.P. Lean Thinking for Education. In Proceedings of the LEN/LAI EdNet Meeting, Worchester, MA, USA, 16–18 October 2006. [Google Scholar]

- Valverde, J.C.; Martínez, S. Methodology ideas for improving the learning in Mathematics in multidisciplinary settings. In ICERI2011 Proceedings; IATED: Madrid, Spain, 2011; pp. 5225–5229. [Google Scholar]

- Ohno, T. Toyota Production System: Beyond Large-Scale Production; Productivity Press: Cambridge, MA, USA, 1988. [Google Scholar]

- Seddon, J. Freedom from Command and Control: Rethinking Management for Lean Service; Productivity Press: Portland, OR, USA, 2005. [Google Scholar]

- Balzer, W.K. Lean Higher Education: Increasing the Value and Performance of University Processes; Productivity Press: New York, NY, USA, 2010. [Google Scholar]

- Martinez, S. Lean Teaching: A New Trend in Education. In Didactics of Mathematics: New Trends and Experience, 1st ed.; Magreñan, A., Ed.; Nova Sciences: New York, NY, USA, 2020. [Google Scholar]

- Douglas, A.; Douglas, J.; Antony, J. Gold in the Mine: Recognizing Waste in UK HEIs using Lean Thinking. In Proceedings of the First International Conference on LSS for Higher Education, Glasgow, UK, 24–25 June 2013. [Google Scholar]

- Andrés-López, E.; González-Requena, I.; Sanz-Lobera, A. Lean service: Reassessment of Lean Manufacturing for service activities. Procedia Eng. 2015, 132, 23–30. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine That Changed the World; Rawson Associates: New York, NY, USA, 1990. [Google Scholar]

- George, M. Lean Six Sigma for Service: How to Use Lean Speed and Six Sigma Quality to Improve Services and Transactions; McGraw-Hill: New York, NY, USA, 2003. [Google Scholar]

- Liker, J.K.; Morgan, J.M. The Toyota Way in Services: The Case of Lean Product Development. Acad. Manag. Perspect. 2006, 20, 5–20. [Google Scholar] [CrossRef]

- Radnor, Z.; Boaden, R. Editorial: Lean in Public Services—Panacea or Paradox? Public Money Manag. 2008, 28, 3–7. [Google Scholar]

- Womack, J.P.; Jones, D.T. Lean Thinking—Banish waste and create wealth in your corporation. J. Oper. Res. Soc. 1997, 48, 1148. [Google Scholar] [CrossRef]

- Tilfarlioglu, F. A New Method in Education: Lean. Turk. Stud. 2017, 6, 811–816. [Google Scholar]

- Hines, P.; Taylor, D. Going Lean; Lean Enterprise Research Centre Cardiff Business School: Cardiff, UK, 2000; pp. 3–43. [Google Scholar]

- Smith, S. Muda, Muri and Mura. Lean Six Sigma Rev. 2014, 13, 36. [Google Scholar]

- Chibaira, B.; Haittingh, T. Applying Lean Principles in a School Environment to Reduce Lead Time and Improve Quality. In SAIIE25 Proceedings; Stellenbosch University: Stellenbosch, South Africa, 2013. [Google Scholar]

- Liker, J.K. The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer; McGraw-Hill Education: New York, NY, USA, 2004. [Google Scholar]

- Gupta, S.; Sharma, M.; Sunder, V. Lean services: A systematic review. Int. J. Product. Perform. Manag. 2016, 65, 1025–1056. [Google Scholar] [CrossRef]

- Martínez, S. Teaching innovation projects: Fundamental features to their design, implementation and evaluation. Rev. Cienc. Pedagog. E Innov. 2019, 7, 95–103. [Google Scholar]

- Jordan, C.; Magreñan, A.; Orcos, L. Considerations about Flip Education in the Teaching of Advanced Mathematics. Educ. Sci. 2019, 9, 227. [Google Scholar] [CrossRef]

- Valverde, J.C.; Martínez, S. Blended-learning based on presentations made with the aid of a computer algebra system. In ICERI2009 Proceedings; IATED: Madrid, Spain, 2009; pp. 3764–3772. [Google Scholar]

- Valverde, J.C.; Martínez, S. A mobile assisted blended-learning experience. In EDULEARN12 Proceedings; IATED: Barcelona, Spain, 2012; pp. 288–291. [Google Scholar]

- Orcos, L.; Jordan, C.; Magreñan, A. 3D visualization through the Hologram for the Learning of Area and Volume Concepts. Mathematics 2019, 7, 247. [Google Scholar] [CrossRef]

- Martinez, S.; Valverde, J.C. University-Industry Collaboration for Coaching and Transferring Teamwork Skills. In EDULEARN10 Proceedings; IATED: Barcelona, Spain, 2010; pp. 5076–5080. [Google Scholar]

| Waste Source | Lean Education | Lean Teaching |

|---|---|---|

| Overproduction | To offer and produce more degrees than needed | To teach more subjects and content, and to endow with more skills than required |

| Inventory | To have more graduate students than required | To have content, activities, technological resources, and materials prepared but not used |

| Overprocess | To do or repeat academic or administrative processes that are excessively complex, redundant or unnecessary | To teach content that is already known. To repeat the teaching or assessment of content due to the use of an inappropriate methodology or because of difficulty (poor planning) Excess of practice activities. |

| Defects | Degrees (graduate students) without the proper knowledge, skills, and attitudes | Erroneous or low-quality content, activities, or materials. Inappropriate technological resources. Inadequate methodology and assessment system. |

| Transportation | Excess movement of the students from home to the university | Excess movement of the content, activities, and materials, physically or virtually |

| Motion | Teachers and other staff doing tasks that are irrelevant for the flow of the education system | Teachers doing tasks other than teaching |

| Waiting | Teachers and students waiting for the start of the course or degree (e.g., due to lack of flow of information, administrative processes, social events) | Teachers and students waiting for the start or continuation of the class, to receive feedback or attention (e.g., due to technological breakdown, slow technological systems, delays of people, heterogeneity of students) |

| Unused creativity | Teachers, staff, stakeholders, and students not involved in the improvement of the educational system. Teachers and staff working in underutilized jobs. | Teachers and students not involved in the improvement of the teaching–learning process. Teachers in underutilized jobs; students’ creativity not considered. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez Sanahuja, S. Towards Lean Teaching: Non-Value-Added Issues in Education. Educ. Sci. 2020, 10, 160. https://doi.org/10.3390/educsci10060160

Martínez Sanahuja S. Towards Lean Teaching: Non-Value-Added Issues in Education. Education Sciences. 2020; 10(6):160. https://doi.org/10.3390/educsci10060160

Chicago/Turabian StyleMartínez Sanahuja, Silvia. 2020. "Towards Lean Teaching: Non-Value-Added Issues in Education" Education Sciences 10, no. 6: 160. https://doi.org/10.3390/educsci10060160

APA StyleMartínez Sanahuja, S. (2020). Towards Lean Teaching: Non-Value-Added Issues in Education. Education Sciences, 10(6), 160. https://doi.org/10.3390/educsci10060160