Needleless Electrospinning of a Chitosan Lactate Aqueous Solution: Influence of Solution Composition and Spinning Parameters

Abstract

1. Introduction

2. Materials and Methods

2.1. Chitosan Characterization

2.2. Electrospinning Solutions

2.3. Determination of Solution Parameters

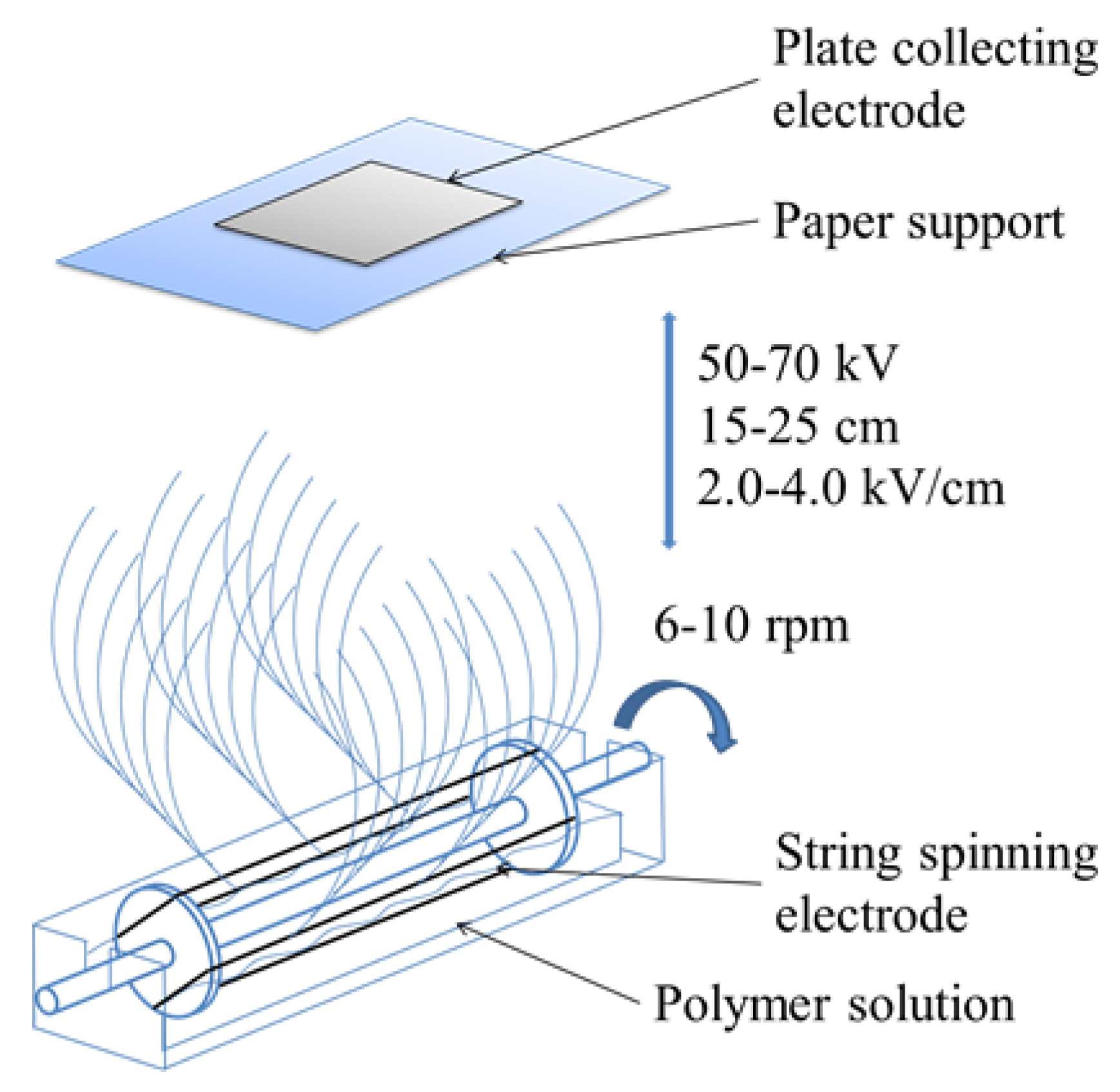

2.4. Electrospinning

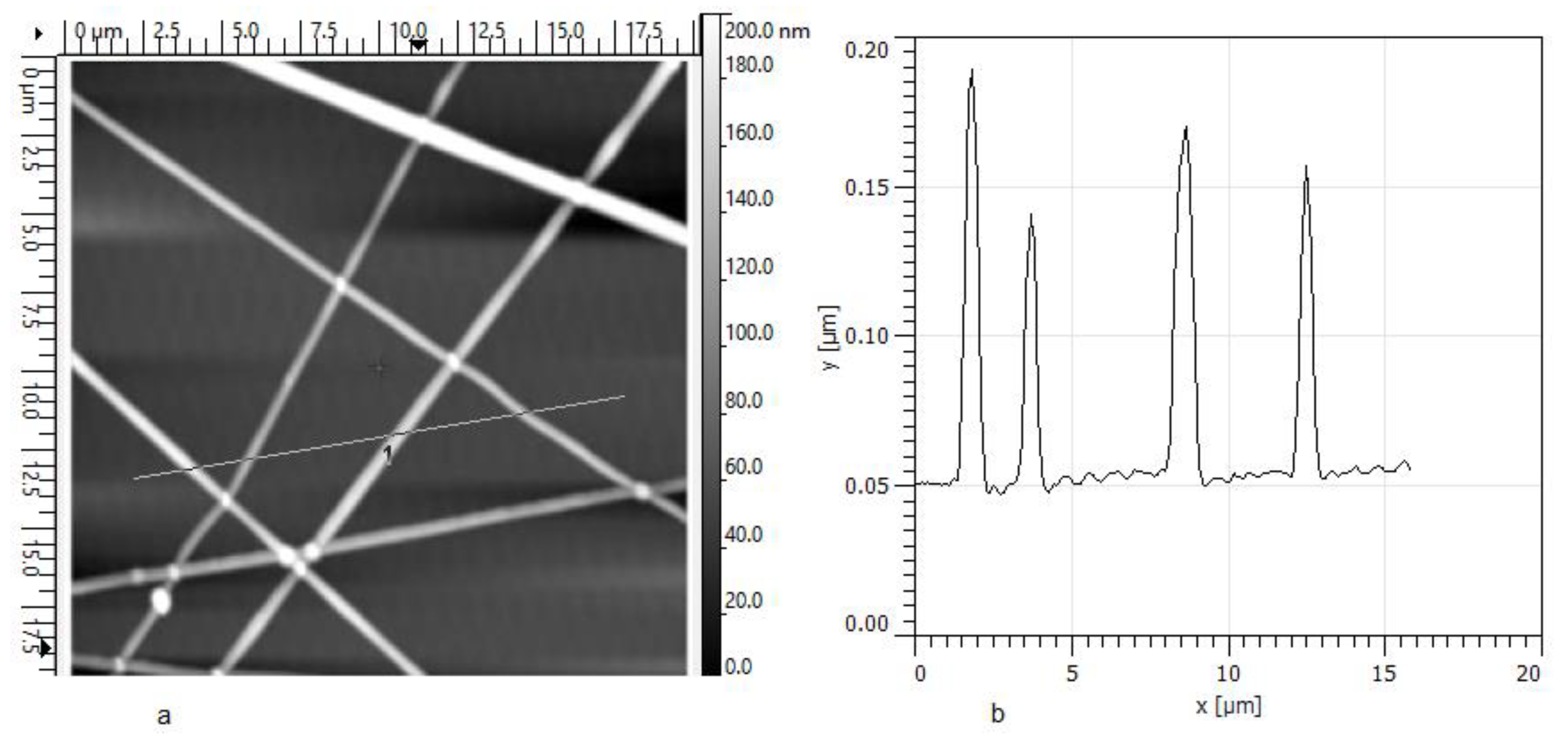

2.5. Fiber Morphology and Diameter

2.6. Statistical Analysis

3. Results and Discussion

3.1. The Influence of Solution Composition and Properties

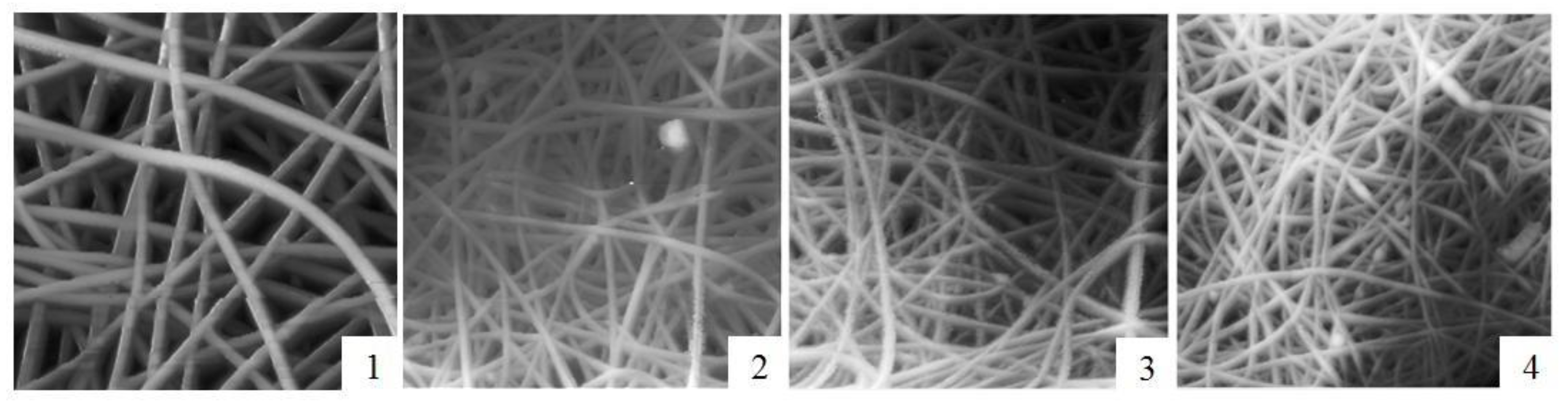

3.2. Fiber Morphology

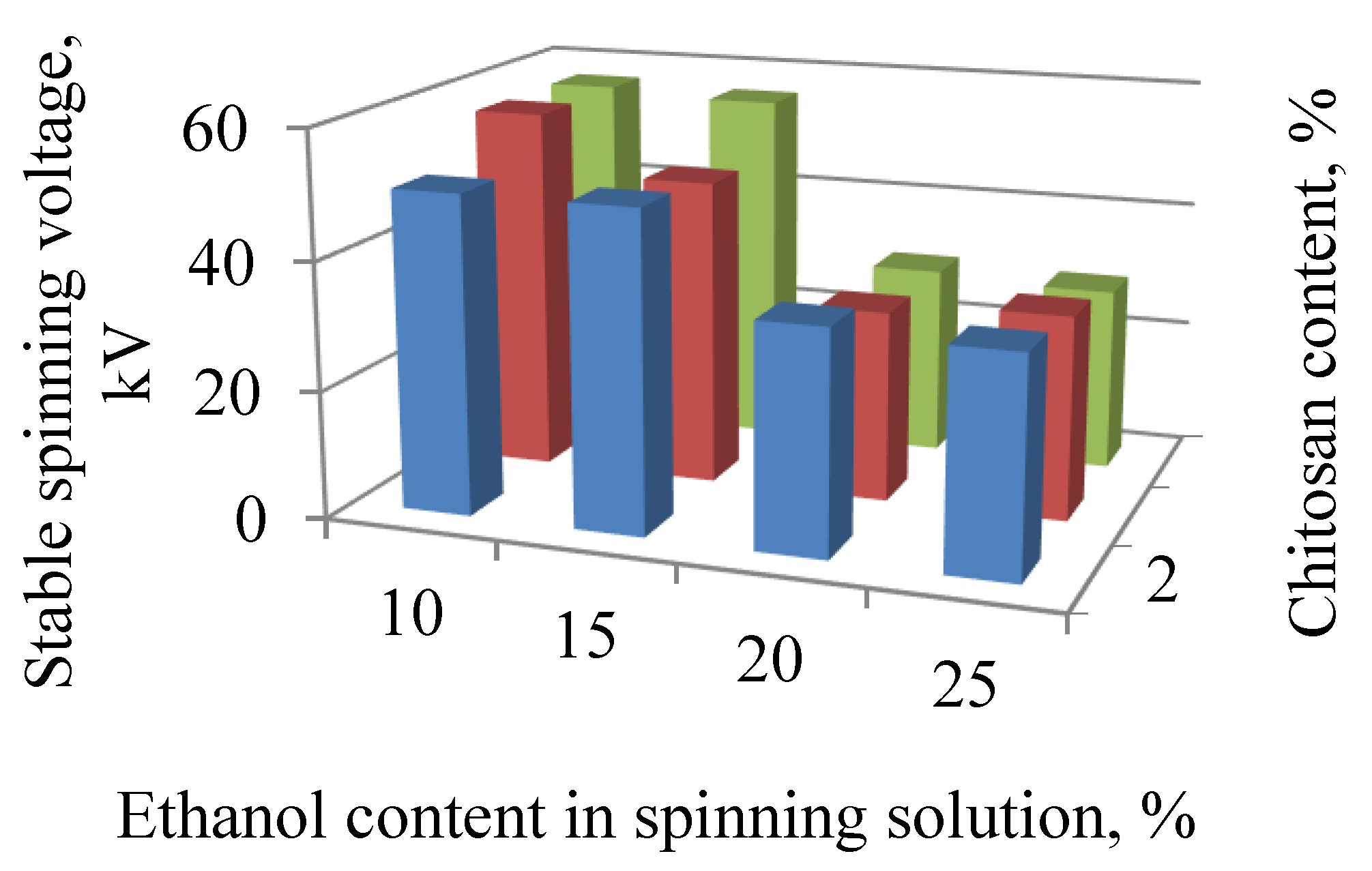

3.3. The Influence of Ethanol Addition

3.4. The Influence of the Process Parameters

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Qasim, S.B.; Zafar, M.S.; Najeeb, S.; Khurshid, Z.; Shah, A.H.; Husain, S.; Rehman, I.U. Electrospinning of chitosan-based solutions for tissue engineering and regenerative medicine. Int. J. Mol. Sci. 2018, 19, 407. [Google Scholar] [CrossRef] [PubMed]

- Bossard, F.; Rinaudo, M. Biomaterials from chitosan processed by electrospinning. Nano World J. 2019, 5, 33–36. [Google Scholar] [CrossRef]

- Kalantari, K.; Afifi, A.M.; Jahangirian, H.; Webster, T.J. Biomedical applications of chitosan electrospun nanofibers as a green polymer—Review. Carbohydr. Polym. 2019, 207, 588–600. [Google Scholar] [CrossRef] [PubMed]

- Petrova, V.A.; Chernyakov, D.D.; Poshina, D.N.; Gofman, I.V.; Romanov, D.P.; Mishanin, A.I.; Golovkin, A.S.; Skorik, Y.A. Electrospun bilayer chitosan/hyaluronan material and its compatibility with mesenchymal stem cells. Materials 2019, 12, 2016. [Google Scholar] [CrossRef]

- Younes, I.; Rinaudo, M. Chitin and chitosan preparation from marine sources. Structure, properties and applications. Mar. Drugs 2015, 13, 1133–1174. [Google Scholar] [CrossRef]

- Cheung, R.C.F.; Ng, T.B.; Wong, J.H.; Chan, W.Y. Chitosan: An update on potential biomedical and pharmaceutical applications. Mar. Drugs 2015, 13, 5156–5186. [Google Scholar] [CrossRef]

- Poshina, D.N.; Raik, S.V.; Poshin, A.N.; Skorik, Y.A. Accessibility of chitin and chitosan in enzymatic hydrolysis: A review. Polym. Degrad. Stab. 2018, 156, 269–278. [Google Scholar] [CrossRef]

- Mengistu Lemma, S.; Bossard, F.; Rinaudo, M. Preparation of pure and stable chitosan nanofibers by electrospinning in the presence of poly(ethylene oxide). Int. J. Mol. Sci. 2016, 17, 1790. [Google Scholar] [CrossRef]

- Haider, A.; Haider, S.; Kang, I.-K. A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology. Arab. J. Chem. 2015, 11, 1165–1188. [Google Scholar] [CrossRef]

- Prokopchuk, N.R.; Shashok, Z.S.; Prishchepenko, D.V.; Melamed, V.D. Nanofibres electrospinning from chitosan solutions (a review). Polimernye Materialy I Tekhnologii 2015, 1, 36–56. [Google Scholar]

- Jun, I.; Han, H.-S.; Edwards, J.R.; Jeon, H. Electrospun fibrous scaffolds for tissue engineering: Viewpoints on architecture and fabrication. Int. J. Mol. Sci. 2018, 19, 745. [Google Scholar] [CrossRef] [PubMed]

- Baji, A.; Mai, Y.-W.; Wong, S.-C.; Abtahi, M.; Chen, P. Electrospinning of polymer nanofibers: Effects on oriented morphology, structures and tensile properties. Compos. Sci. Technol. 2010, 70, 703–718. [Google Scholar] [CrossRef]

- Berry, C.C. Progress in functionalization of magnetic nanoparticles for applications in biomedicine. J. Phys. D Appl. Phys. 2009, 42, 224003. [Google Scholar] [CrossRef]

- Bosiger, P.; Richard, I.M.T.; Le Gat, L.; Michen, B.; Schubert, M.; Rossi, R.M.; Fortunato, G. Application of response surface methodology to tailor the surface chemistry of electrospun chitosan-poly(ethylene oxide) fibers. Carbohydr. Polym. 2018, 186, 122–131. [Google Scholar] [CrossRef] [PubMed]

- Ahmadipourroudposht, M.; Fallahiarezoudar, E.; Yusof, N.M.; Idris, A. Application of response surface methodology in optimization of electrospinning process to fabricate (ferrofluid/polyvinyl alcohol) magnetic nanofibers. Mater. Sci. Eng. C 2015, 50, 234–241. [Google Scholar] [CrossRef] [PubMed]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017; p. 752. [Google Scholar]

- Noordin, M.Y.; Venkatesh, V.C.; Chan, C.L.; Abdullah, A. Performance evaluation of cemented carbide tools in turning aisi 1010 steel. J. Mater. Process. Technol. 2001, 116, 16–21. [Google Scholar] [CrossRef]

- Thiele, J.D.; Melkote, S.N. Effect of cutting edge geometry and workpiece hardness on surface generation in the finish hard turning of aisi 52100 steel. J. Mater. Process. Technol. 1999, 94, 216–226. [Google Scholar] [CrossRef]

- Sung, Y.K.; Ahn, B.W.; Kang, T.J. Magnetic nanofibers with core (fe3o4 nanoparticle suspension)/sheath (poly ethylene terephthalate) structure fabricated by coaxial electrospinning. J. Magn. Magn. Mater. 2012, 324, 916–922. [Google Scholar] [CrossRef]

- Sukigara, S.; Gandhi, M.; Ayutsede, J.; Micklus, M.; Ko, F. Regeneration of bombyx mori silk by electrospinning. Part 2. Process optimization and empirical modeling using response surface methodology. Polymer 2004, 45, 3701–3708. [Google Scholar] [CrossRef]

- Reneker, D.H.; Kataphinan, W.; Theron, A.; Zussman, E.; Yarin, A.L. Nanofiber garlands of polycaprolactone by electrospinning. Polymer 2002, 43, 6785–6794. [Google Scholar] [CrossRef]

- Baumgarten, P.K. Electrostatic spinning of acrylic microfibers. J. Colloid Interface Sci. 1971, 36, 71–79. [Google Scholar] [CrossRef]

- Katti, D.S.; Robinson, K.W.; Ko, F.K.; Laurencin, C.T. Bioresorbable nanofiber-based systems for wound healing and drug delivery: Optimization of fabrication parameters. J. Biomed. Mater. Res. Part B Appl. Biomater. 2004, 70, 286–296. [Google Scholar] [CrossRef]

- Begum, H.A.; Khan, M.K.R. Study on the various types of needle based and needleless electrospinning system for nanofiber production. Int. J. Text. Sci. 2017, 6, 110–117. [Google Scholar]

- Cheng, T.; Hund, R.D.; Aibibu, D.; Horakova, J.; Cherif, C. Pure chitosan and chitsoan/chitosan lactate blended nanofibres made by single step electrospinning. Autex Res. J. 2013, 13, 128–133. [Google Scholar] [CrossRef]

- Nguyen, T.T.T.; Chung, O.H.; Park, J.S. Coaxial electrospun poly(lactic acid)/chitosan (core/shell) composite nanofibers and their antibacterial activity. Carbohydr. Polym. 2011, 86, 1799–1806. [Google Scholar] [CrossRef]

- Shan, X.; Li, F.; Liu, C.; Gao, Q. Electrospinning of chitosan/poly(lactic acid) nanofibers: The favorable effect of nonionic surfactant. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Cooper, A.; Bhattarai, N.; Kievit, F.M.; Rossol, M.; Zhang, M. Electrospinning of chitosan derivative nanofibers with structural stability in an aqueous environment. Phys. Chem. Chem. Phys. 2011, 13, 9969–9972. [Google Scholar] [CrossRef]

- Pogodina, N.V.; Pavlov, G.M.; Bushin, S.V.; Mel’nikov, A.B.; Lysenko, Y.B.; Nud’ga, L.A.; Marsheva, V.N.; Marchenko, G.N.; Tsvetkov, V.N. Conformational characteristics of chitosan molecules as demonstrated by diffusion-sedimentation analysis and viscometry. Polym. Sci. USSR 1986, 28, 251–259. [Google Scholar] [CrossRef]

- Sonina, A.N.; Uspenskii, S.A.; Vikhoreva, G.A.; Filatov, Y.N.; Gal’braikh, L.S. Production of nanofibre materials from chitosan by electrospinning (review). Fibre Chem. 2011, 42, 350–358. [Google Scholar] [CrossRef]

- Pakravan, M.; Heuzey, M.-C.; Ajji, A. A fundamental study of chitosan/peo electrospinning. Polymer 2011, 52, 4813–4824. [Google Scholar] [CrossRef]

- Ma, P.X.; Zhang, R. Synthetic nano-scale fibrous extracellular matrix. J. Biomed. Mater. Res. 1999, 46, 60–72. [Google Scholar] [CrossRef]

- Fong, H.; Chun, I.; Reneker, D.H. Beaded nanofibers formed during electrospinning. Polymer 1999, 40, 4585–4592. [Google Scholar] [CrossRef]

- Yalcinkaya, B.; Yener, F.; Jirsak, O.; Cengiz-Callioglu, F. On the nature of electric current in the electrospinning process. J. Nanomater. 2013, 2013, 538179. [Google Scholar] [CrossRef]

| Entry | Concentration, % | Solution Properties | E 1, kV/cm | Fiber Diameter, nm | ||||

|---|---|---|---|---|---|---|---|---|

| Chitosan Lactate (A) | PEO (B) | Ethanol (C) | η, mPa∙s | σ, mN/m | Conductivity, mSm/cm | |||

| 1 | 4 | 20 | 10 | 6317 | 52.4 | 2.2 | 1.8 | 850 ± 110 |

| 2 | 4 | 5 | 0 | 781 | 65.4 | 3.2 | 2.4 | 500 ± 90 |

| 3 | 2 | 20 | 0 | 218 | 60.1 | 2.3 | 2.6 | 380 ± 70 |

| 4 | 2 | 5 | 10 | 210 | 48.0 | 1.7 | 2.3 | 470 ± 80 |

| Component | Viscosity | Surface Tension | Conductivity | Intensity of the Stable Electrospinning | Fiber Diameter |

|---|---|---|---|---|---|

| Chitosan lactate (A) | ++ | + | ++ | −− | ++ |

| PEO (B) | ++ | 0 | − | − | + |

| Ethanol (C) | ++ 2 | −− | −− | −− 2 | ++ 2 |

| Factor | Low (−1) | Center (0) | High (+1) |

|---|---|---|---|

| Voltage (A, kV) | 50 | 60 | 70 |

| Distance (B, cm) | 20 | 22 | 24 |

| Rotating speed (C, rpm) | 3 | 7 | 11 |

| Entry | Run Order | U, kV | d, cm | ω, rpm | Fiber Diameter, nm | Current, μA | |||

|---|---|---|---|---|---|---|---|---|---|

| AFM | SEM | ||||||||

| Mica | Paper Support | Average | Mode | ||||||

| 1 | 3 | 70 | 24 | 11 | 350 ± 80 | 510 ± 70 | 286 | 244 | 32.5 |

| 2 | 7 | 70 | 24 | 3 | 460 ± 75 | 500 ± 65 | 271 | 253 | 34.5 |

| 3 | 8 | 70 | 20 | 11 | 455 ± 60 | 475 ± 70 | 242 | 228 | 40.0 |

| 4 | 6 | 70 | 20 | 3 | 380 ± 70 | 510 ± 50 | 279 | 251 | 47.0 |

| 5 | 4 | 50 | 24 | 11 | 530 ± 105 | 530 ± 70 | 279 | 227 | 12.0 |

| 6 | 2 | 50 | 24 | 3 | 310 ± 90 | 555 ± 90 | 307 | 282 | 14.5 |

| 7 | 1 | 50 | 20 | 11 | 200 ± 50 | 500 ± 85 | 260 | 235 | 22.0 |

| 8 | 5 | 50 | 20 | 3 | 400 ± 75 | 560 ± 60 | 290 | 199 | 14.0 |

| Source | df | Sum of Squares | Mean Square | F-Value | p-Value | Status |

|---|---|---|---|---|---|---|

| linear | 3 | 1869 | 623 | 2.97 | 0.160 | insignificant |

| a (U, kV) | 1 | 421 | 421 | 2.00 | 0.230 | insignificant |

| b (d, cm) | 1 | 648 | 648 | 3.09 | 0.154 | insignificant |

| c (ω, rpm) | 1 | 800 | 800 | 3.81 | 0.123 | insignificant |

| error | 4 | 839 | 210 | |||

| total | 7 | 2708 |

| Source | df | Sum of Squares | Mean Square | F-Value | p-Value | Status |

|---|---|---|---|---|---|---|

| linear | 3 | 1520 | 507 | 0.81 | 0.552 | insignificant |

| a (U, kV) | 1 | 132 | 132 | 0.21 | 0.670 | insignificant |

| b (d, cm) | 1 | 1070 | 1070 | 1.70 | 0.262 | insignificant |

| c (ω, rpm) | 1 | 319 | 319 | 0.51 | 0.515 | insignificant |

| error | 4 | 2512 | 628 | |||

| total | 7 | 4032 |

| Source | df | Sum of Squares | Mean Square | F-Value | p-Value | Status |

|---|---|---|---|---|---|---|

| linear | 3 | 1157 | 386 | 20.88 | 0.007 | significant |

| a (U, kV) | 1 | 1047 | 1047 | 56.66 | 0.002 | significant |

| b (d, cm) | 1 | 109 | 109 | 5.89 | 0.072 | insignificant |

| c (ω, rpm) | 1 | 1.53 | 1.53 | 0.08 | 0.788 | insignificant |

| error | 4 | 73.9 | 18.5 | |||

| total | 7 | 1231 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poshina, D.N.; Khadyko, I.A.; Sukhova, A.A.; Serov, I.V.; Zabivalova, N.M.; Skorik, Y.A. Needleless Electrospinning of a Chitosan Lactate Aqueous Solution: Influence of Solution Composition and Spinning Parameters. Technologies 2020, 8, 2. https://doi.org/10.3390/technologies8010002

Poshina DN, Khadyko IA, Sukhova AA, Serov IV, Zabivalova NM, Skorik YA. Needleless Electrospinning of a Chitosan Lactate Aqueous Solution: Influence of Solution Composition and Spinning Parameters. Technologies. 2020; 8(1):2. https://doi.org/10.3390/technologies8010002

Chicago/Turabian StylePoshina, Daria N., Igor A. Khadyko, Arina A. Sukhova, Ilya V. Serov, Natalia M. Zabivalova, and Yury A. Skorik. 2020. "Needleless Electrospinning of a Chitosan Lactate Aqueous Solution: Influence of Solution Composition and Spinning Parameters" Technologies 8, no. 1: 2. https://doi.org/10.3390/technologies8010002

APA StylePoshina, D. N., Khadyko, I. A., Sukhova, A. A., Serov, I. V., Zabivalova, N. M., & Skorik, Y. A. (2020). Needleless Electrospinning of a Chitosan Lactate Aqueous Solution: Influence of Solution Composition and Spinning Parameters. Technologies, 8(1), 2. https://doi.org/10.3390/technologies8010002