Basic Study of Ventilation Using Semi-Transparent Organic Photovoltaic Sheets for Solar Chimney Systems

Abstract

1. Introduction

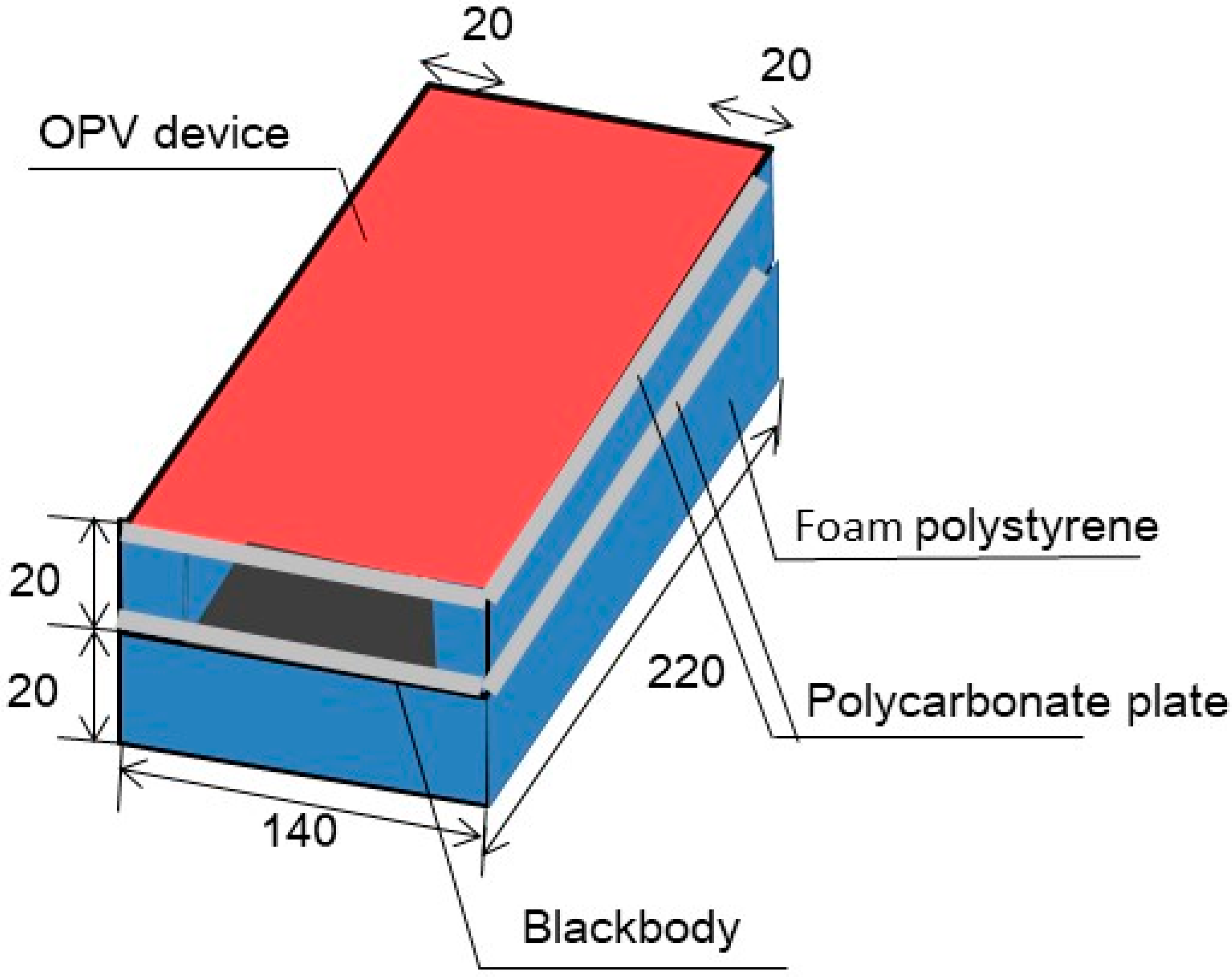

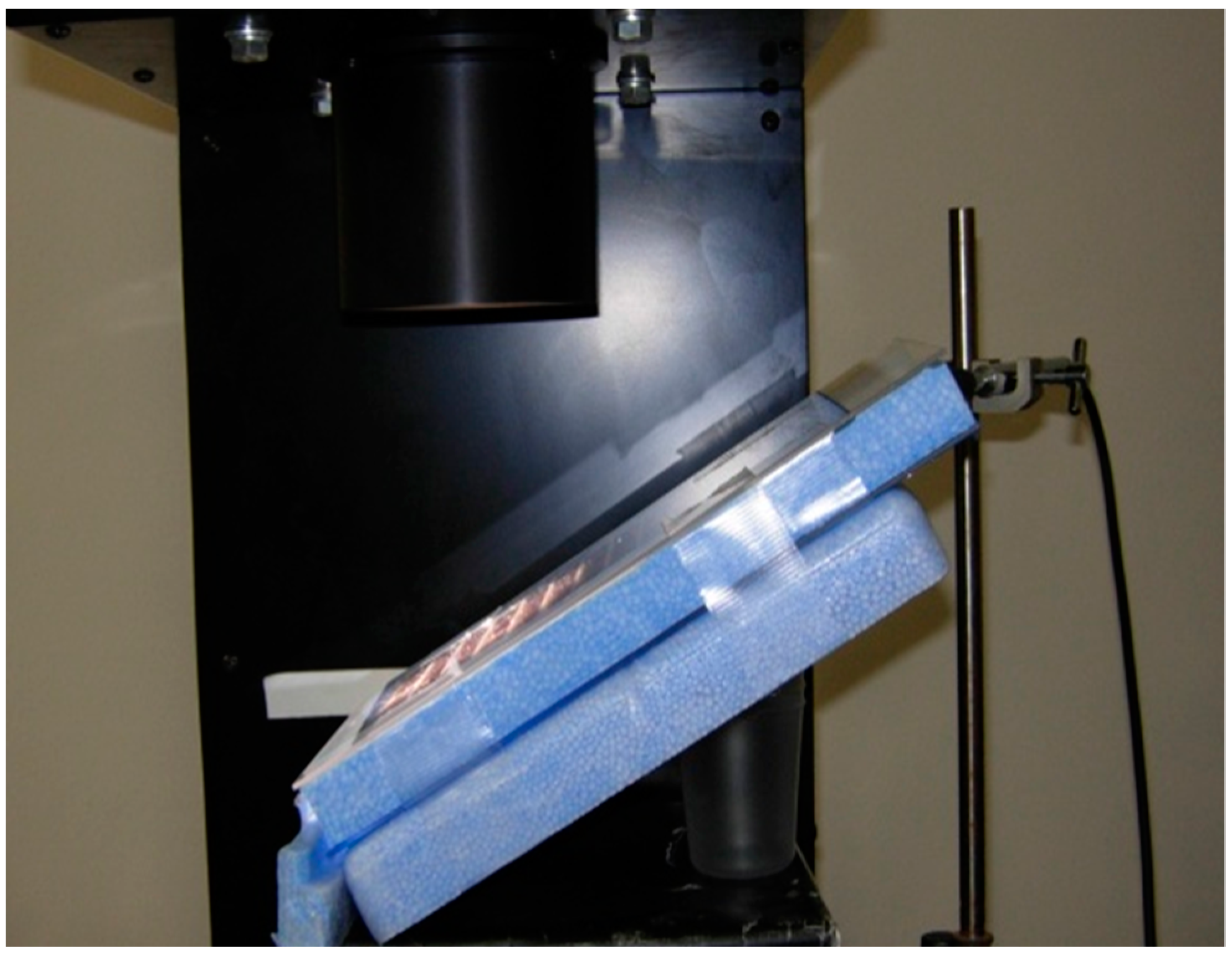

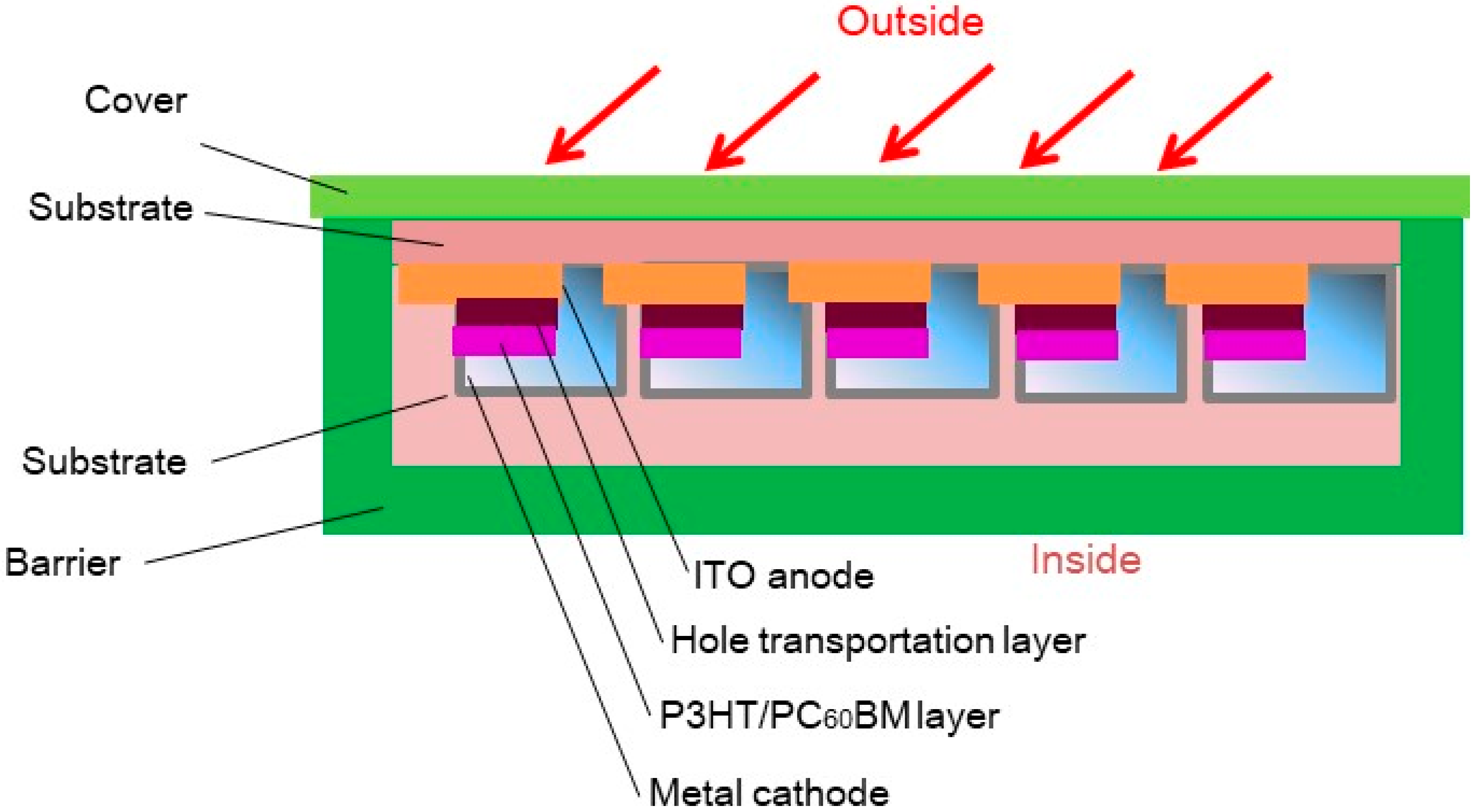

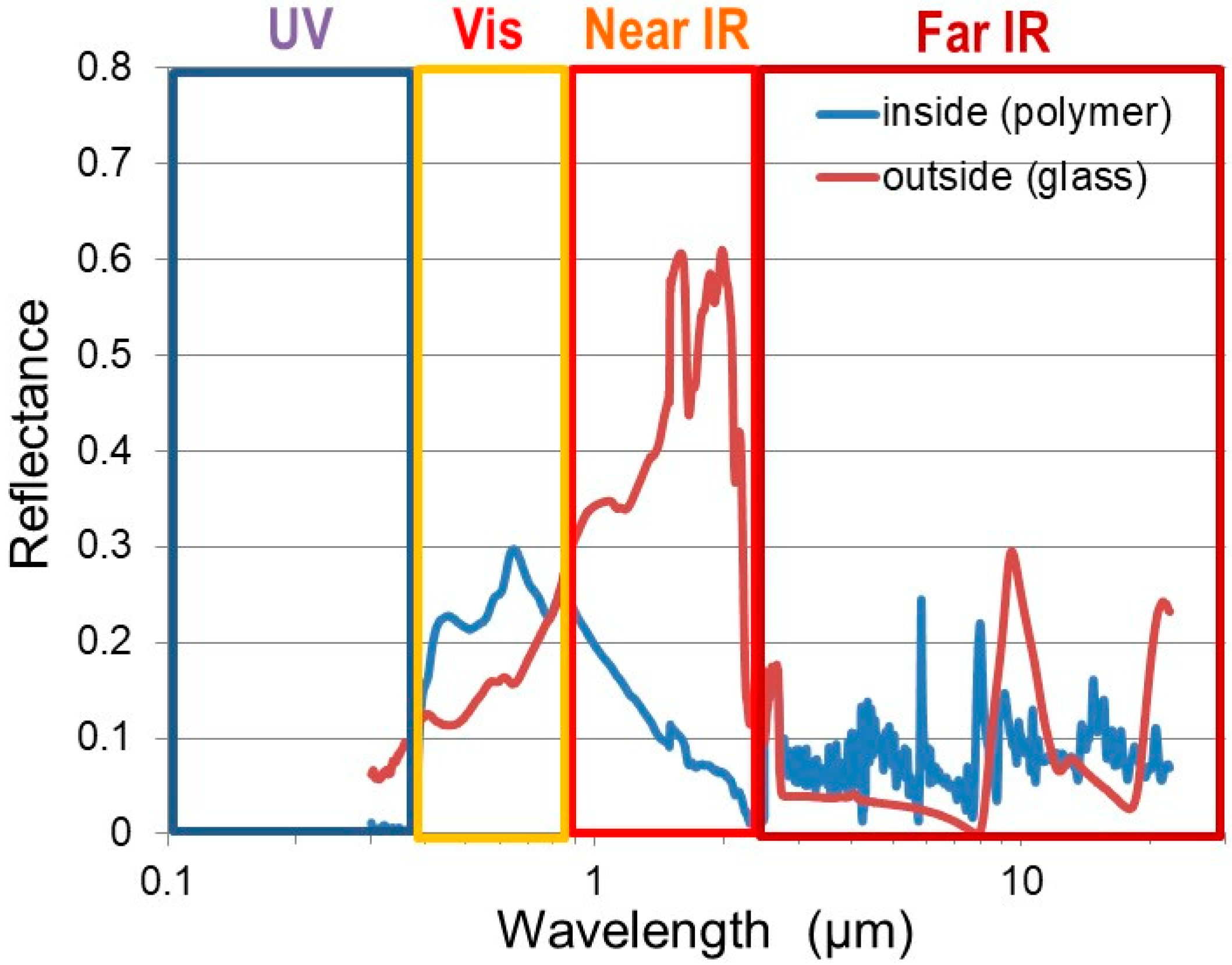

2. Materials and Methods

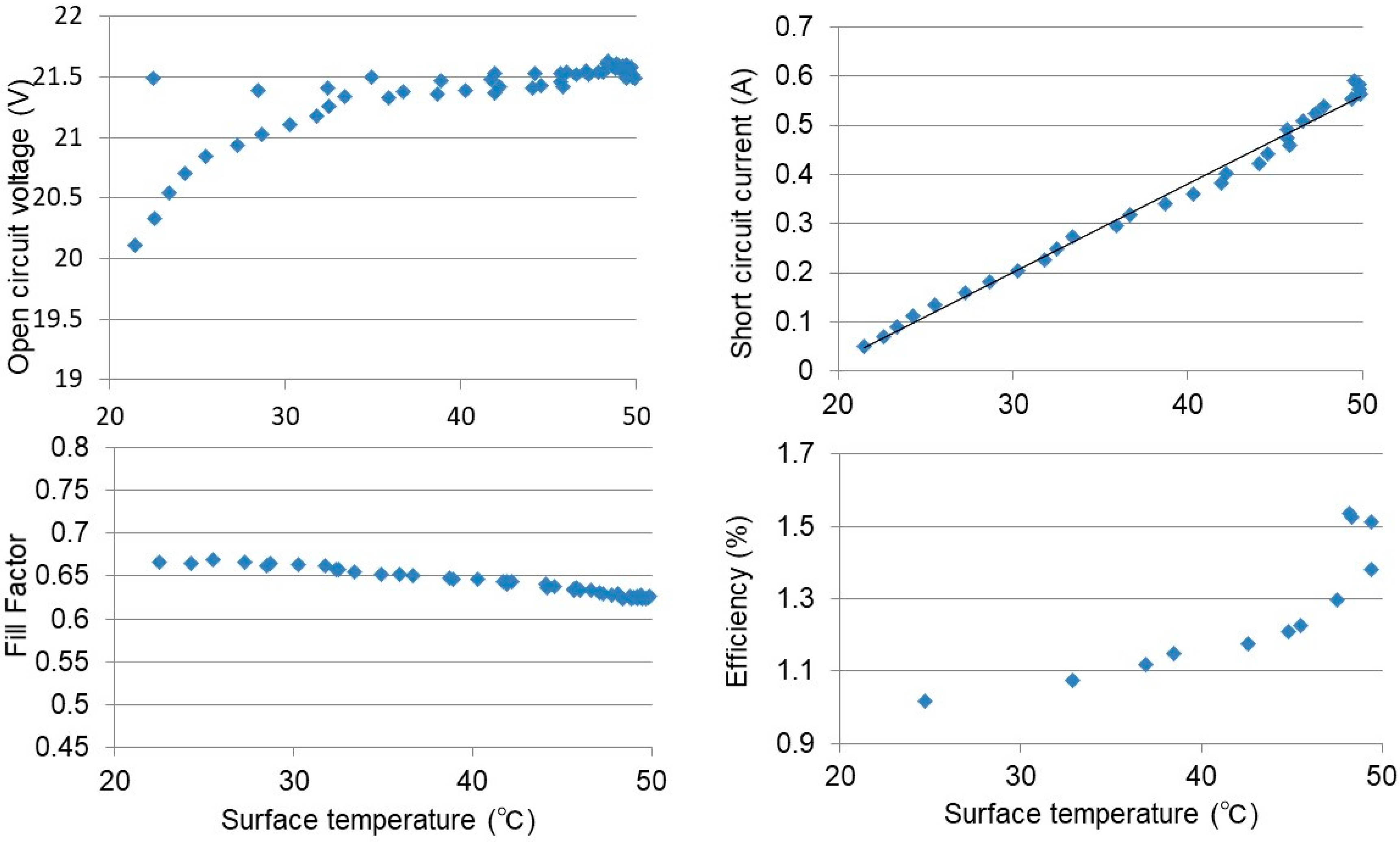

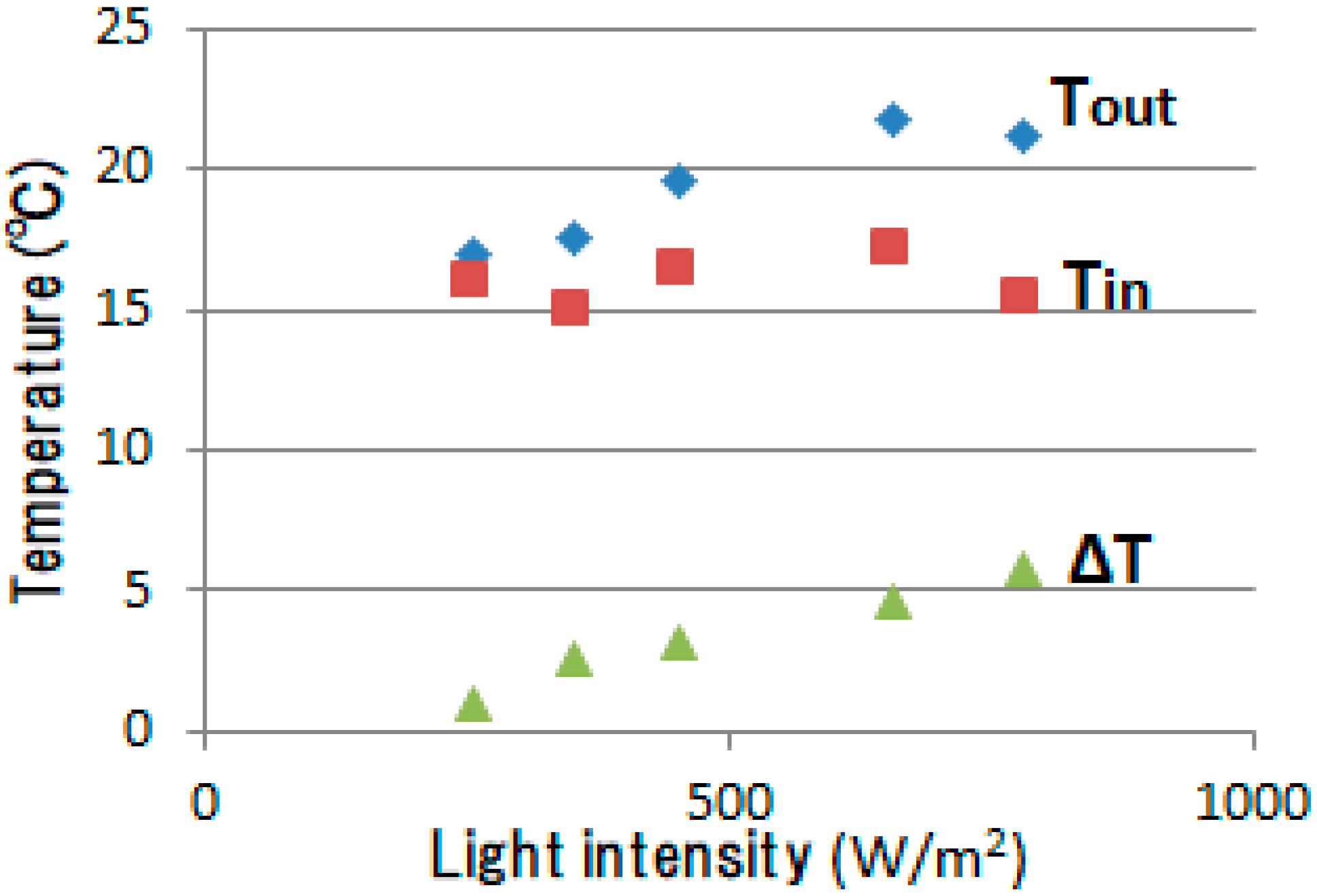

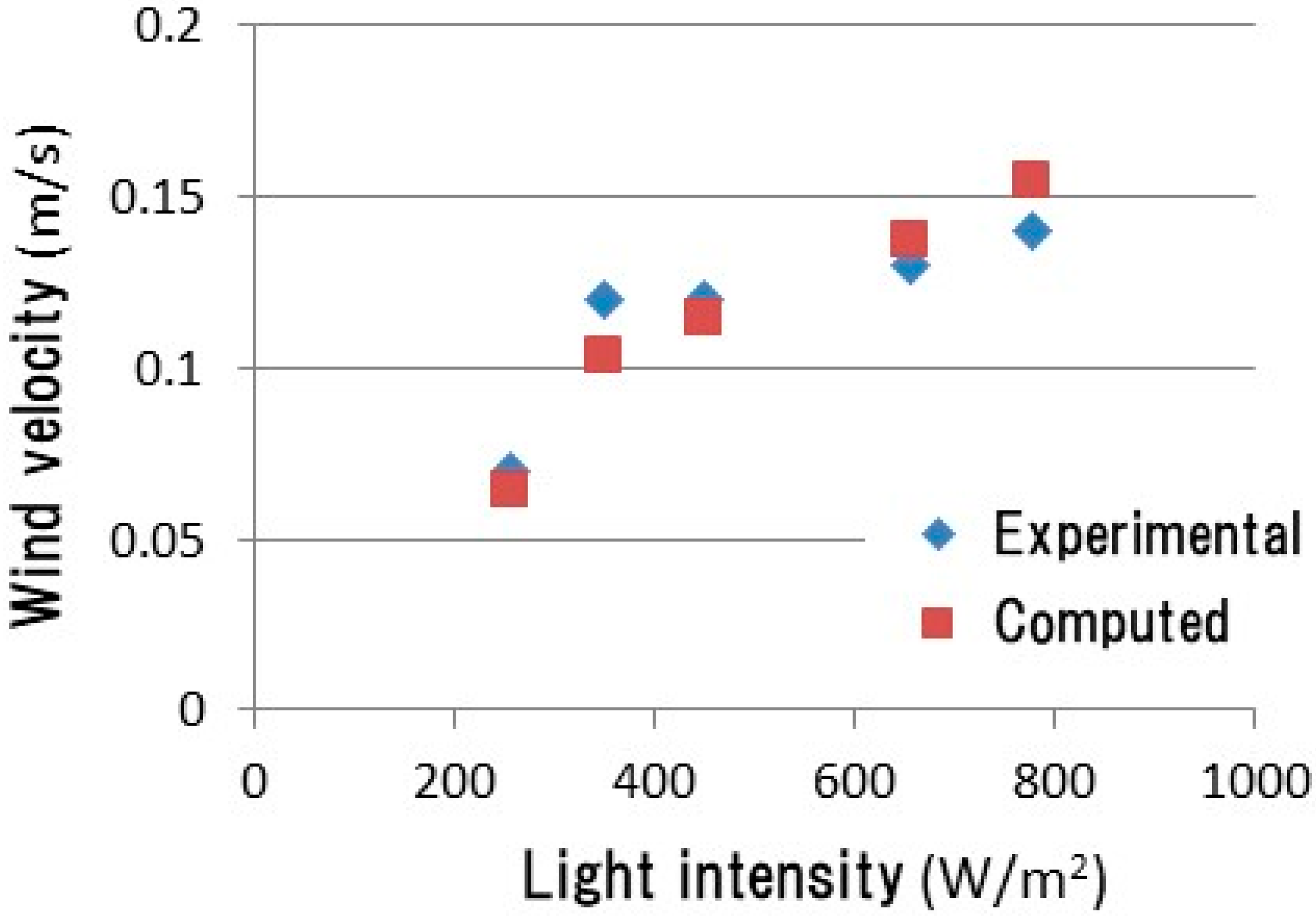

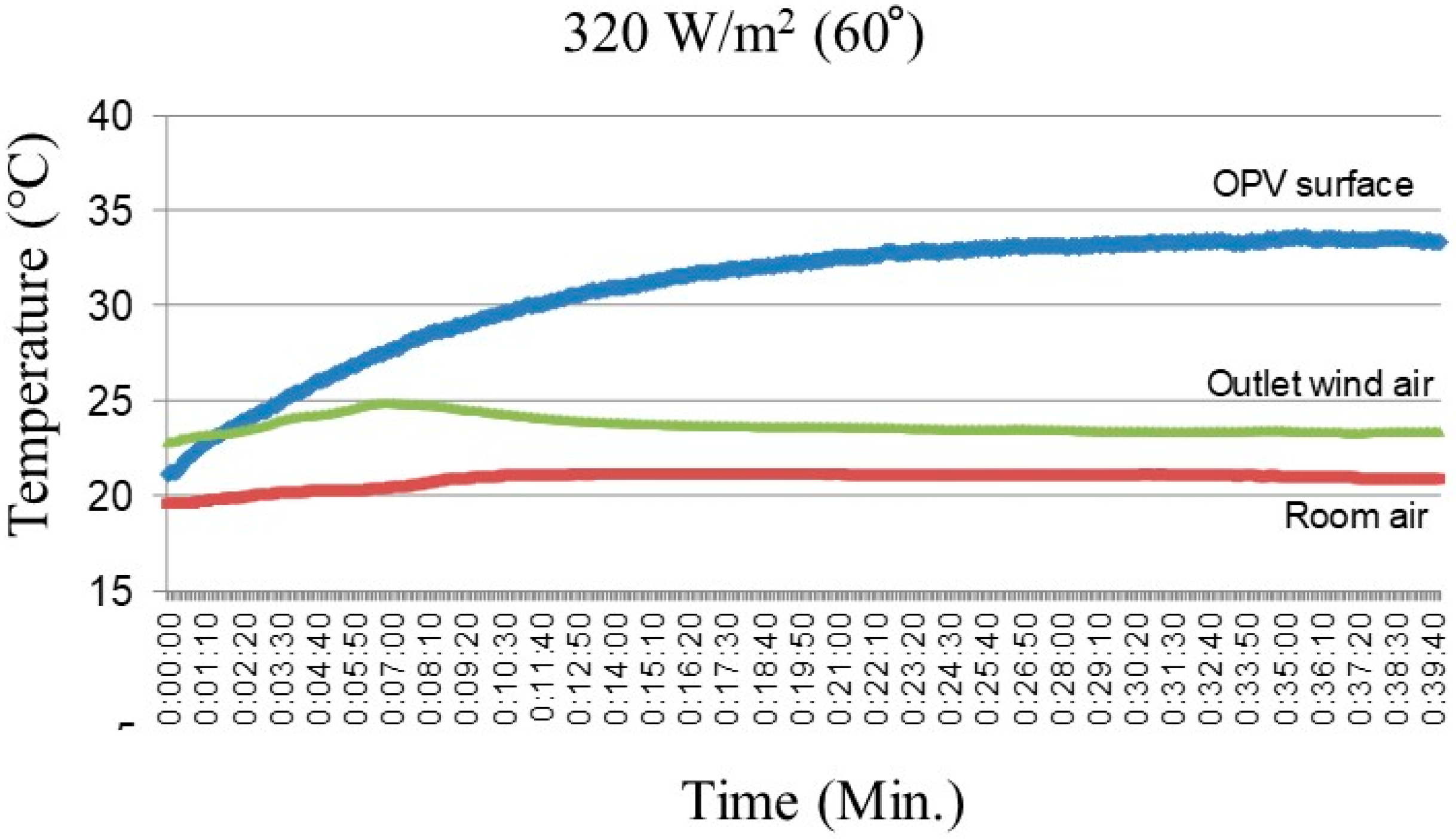

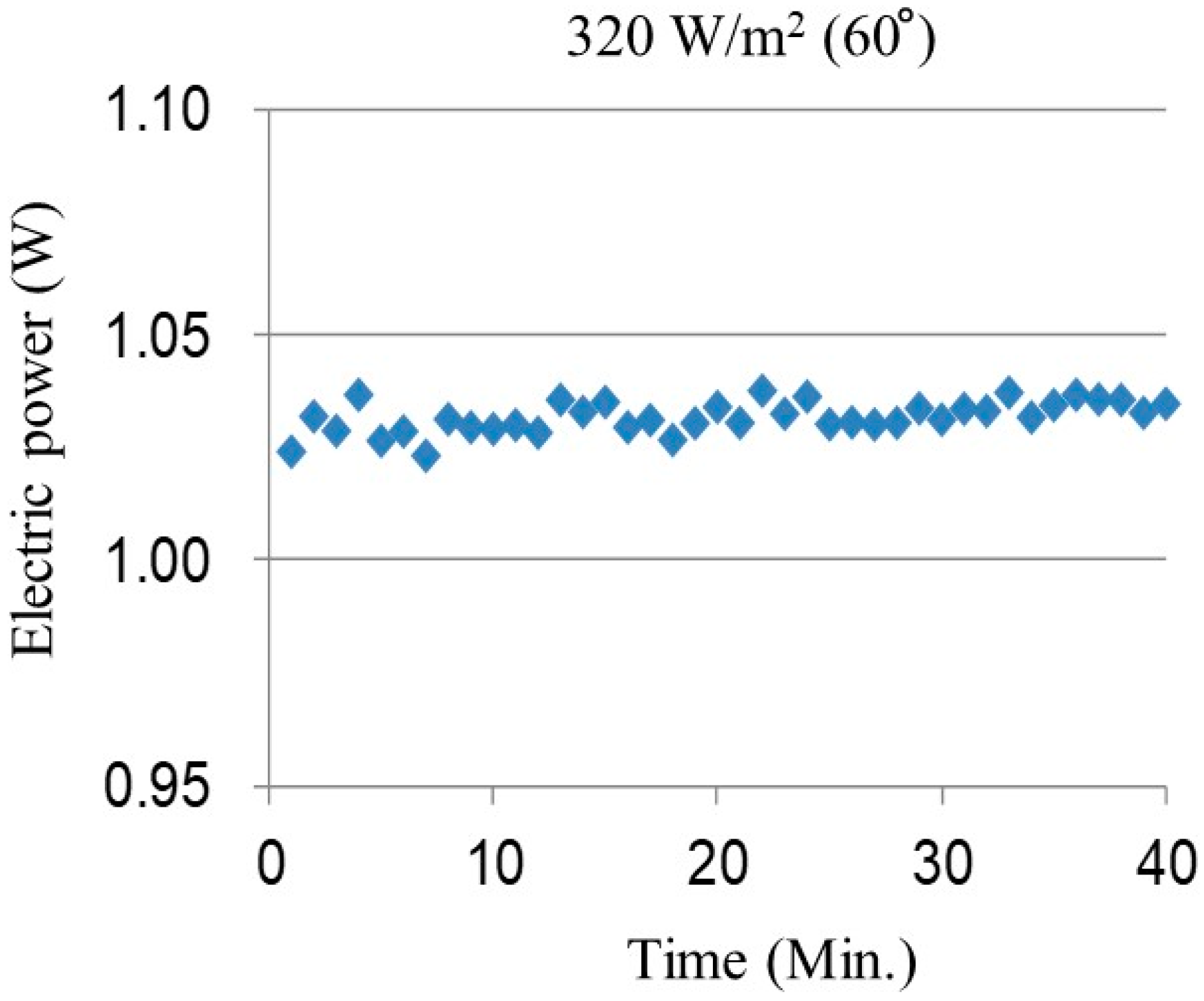

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- International Energy Agency. World Energy Outlook 2017; International Energy Agency: Paris, France, 2017. [Google Scholar]

- Zeng, B.; Zhang, J.; Yang, X.; Wang, J.; Dong, J.; Zhang, Y. Integrated Planning for Transition to Low-Carbon Distribution System with Renewable Energy Generation and Demand Response. IEEE Trans. Power Syst. 2014, 29, 1153–1165. [Google Scholar] [CrossRef]

- Erdin, O.; Paterakis, N.G.; Pappi, I.N.; Bakirtzis, A.G.; Catalao, J.P.S. A new perspective for sizing of distributed generation and energy storage for smart households under demand response. Appl. Energy 2015, 143, 26–37. [Google Scholar] [CrossRef]

- Prasad, D.; Snow, M. Designing with Solar Power; Earthscan: London, UK, 2005. [Google Scholar]

- Akata, A.M.E.A.; Njomo, D.; Agrawal, B. Assessment of Building Integrated Photovoltaic (BIPV) for sustainable energy performance in tropical regions of Cameroon. Renew. Sustain. Energy Rev. 2017, 80, 1138–1152. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P. Recent Advancement in BIPV product technologies: A review. Energy Build. 2017, 140, 188–195. [Google Scholar] [CrossRef]

- Pomponi, F.; Piroozfar, P.A.E.; Southall, R.; Ashton, P.; Farr, E.R.P. Energy performance of double-skin façades in temperate climates: a systematic review and meta-analysis. Renew. Sustain. Energy Rev. 2016, 54, 1525–1536. [Google Scholar] [CrossRef]

- Gracia, A.; Navarro, L.; Castell, A.; Cabeza, L.F. Energy performance of a ventilated double skin facade with PCM under different climates. Energy Build. 2015, 91, 37–42. [Google Scholar] [CrossRef]

- Mateus, N.M.; Pinto, A.; da Graça, G.C. Validation of EnergyPlus thermal simulation of a double skin naturally and mechanically ventilated test cell. Energy Build. 2014, 75, 511–522. [Google Scholar] [CrossRef]

- Imran, A.A.; Jalil, J.M.; Ahmed, S.T. Induced flow for ventilation and cooling by a solar chimney. Renew. Energy 2015, 78, 236–244. [Google Scholar] [CrossRef]

- Khanal, R.; Lei, C. A numerical investigation of buoyancy induced turbulent air flow in an inclined passive wall solar chimney for natural ventilation. Energy Build. 2015, 93, 217–226. [Google Scholar] [CrossRef]

- Peng, J.; Curcija, D.C.; Lu, L.; Selkowitz, S.E.; Yang, H.; Mitchell, R. Developing a method and simulation model for evaluating the overall energy performance of a ventilated semi-transparent photovoltaic double-skin facade. Prog. Photovolt. 2015, 24, 781–799. [Google Scholar] [CrossRef]

- Agathokleous, R.A.; Kalogirou, S.A. Double skin facades (DSF) and building integrated photovoltaics (BIPV): A review of configurations and heat transfer characteristics. Renew. Energy 2016, 89, 743–756. [Google Scholar] [CrossRef]

- Wang, M.; Peng, J.; Li, N.; Yang, H.; Wang, C.; Li, X.; Lu, T. Comparison of energy performance between PV double skin facades and PV insulating glass units. Appl. Energy 2017, 194, 148–160. [Google Scholar] [CrossRef]

- Lai, C.-M.; Hokoi, S. Solar façades: A review. Build. Environ. 2015, 91, 152–165. [Google Scholar] [CrossRef]

- Klimeš, L.; Charvát, P.; Hejčík, J. Comparison of the Energy Conversion Efficiency of a Solar Chimney and a Solar PV-Powered Fan for Ventilation Applications. Energies 2018, 11, 912. [Google Scholar] [CrossRef]

- Peng, J.; Curcija, D.C.; Lu, L.; Selkowitz, S.E.; Yang, H.; Zhang, W. Numerical investigation of the energy saving potential of a semi-transparent photovoltaic double-skin facade in a cool-summer Mediterranean climate. Appl. Energy 2016, 165, 345–356. [Google Scholar] [CrossRef]

- Bloem, J.J.; Lodi, C.; Cipriano, J.; Chemisana, D. An outdoor Test Reference Environment for double skin applications of Building Integrated Photovoltaic Systems. Energy Build. 2012, 50, 63–73. [Google Scholar] [CrossRef]

- Charron, R.; Athienitis, A.K. Optimization of the performance of double-façades with integrated photovoltaic panels and motorized blinds. Sol. Energy 2006, 80, 482–491. [Google Scholar] [CrossRef]

- Yoon, S.; Tak, S.; Kim, J.; Jun, Y.; Kang, K.; Park, J. Application of transparent dye-sensitized solar cells to building integrated photovoltaic systems. Build. Environ. 2011, 46, 1899–1904. [Google Scholar] [CrossRef]

- Olivieri, L.; Caamano, E.; Olivieri, F.; Neila, J. Integral energy performance characterization of semi-transparent photovoltaic elements for building integration under real operation conditions. Energy Build. 2014, 68, 280–291. [Google Scholar] [CrossRef]

- Peng, J.; Lin, L.; Yang, H. Influences of ambient air speed and internal heat load on the performance of solar chimney in the tropics. Sol. Energy 2014, 102, 116–125. [Google Scholar]

- Tan, A.Y.K.; Wong, N.H. An experimental study of the thermal performance of a novel photovoltaic double-skin facade in Hong Kong. Sol. Energy 2013, 97, 293–304. [Google Scholar]

- Lee, J.W.; Park, J.; Jung, H.-J. A feasibility study on a building’s window system based on dye-sensitized solar cells. Energy Build. 2014, 81, 38–47. [Google Scholar] [CrossRef]

- Chen, C.-C.; Dou, L.; Zhu, R.; Chung, C.-H.; Song, T.-B.; Zheng, Y.B.; Hawks, S.; Li, G.; Weiss, P.S.; Yang, Y. Visibly Transparent Polymer Solar Cells Produced by Solution Processing. ACS Nano 2012, 6, 7185–7190. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Lin, J.; Wu, N.; Nie, S.; Luo, Q.; Ma, C.-Q.; Cui, Z. Inkjet printed silver nanowire network as top electrode for semi-transparent organic photovoltaic devices. Appl. Phys. Lett. 2015, 106, 093302. [Google Scholar] [CrossRef]

- Kapsis, K.; Athienitis, A.K. A study of the potential benefits of semi-transparent photovoltaics in commercial buildings. Sol. Energy 2015, 115, 120–132. [Google Scholar] [CrossRef]

- Yoshimoto, N.; Suenaga, Y.; Hidaka, K.; Mitsuji, K.; Nagai, Y. Perimeter Energy System applied for Transparent Organic Photovoltaics. In Proceedings of the 11th International Symposium on Architectural Interchanges in Asia (ISAIA2016), Sendai, Japan, 20–23 September 2016. [Google Scholar]

- Suenaga, Y.; Yoshimoto, N.; Hidaka, K.; Mitsuji, K.; Nagai, Y. Solar Chimney System embedded Transparent Organic Photovoltaics Part 1: Basic Study of Natural Ventilation Behavior under Irradiation Condition with Solar Simulator. In Proceedings of AIJ Tohoku Chapter Architectural Design Meeting; Architectural Institute of Japan: Tohoku, Japan, 2010; p. A-12. [Google Scholar]

- Cho, S.W.; Kimura, K.-I. Experimental Study on The Performance Prediction of Natural Ventilation System with Solar Chimney. J. Soc. Heat. Air-Cond. Sanit. Eng. Jpn. 2001, 81, 11–19. [Google Scholar]

| Intensity of Light (W/m²) | Simulated Weather |

|---|---|

| 255 | Rain |

| 350 | Cloudy |

| 450 | Partly sunny in winter |

| 655 | Sunny in winter, partly sunny in summer |

| 780 | Sunny in summer |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hidaka, K.; Miyazawa, A.; Hu, H.; Mitsuji, K.; Nagai, Y.; Yoshimoto, N.; Suenaga, Y. Basic Study of Ventilation Using Semi-Transparent Organic Photovoltaic Sheets for Solar Chimney Systems. Technologies 2018, 6, 93. https://doi.org/10.3390/technologies6040093

Hidaka K, Miyazawa A, Hu H, Mitsuji K, Nagai Y, Yoshimoto N, Suenaga Y. Basic Study of Ventilation Using Semi-Transparent Organic Photovoltaic Sheets for Solar Chimney Systems. Technologies. 2018; 6(4):93. https://doi.org/10.3390/technologies6040093

Chicago/Turabian StyleHidaka, Kishio, Akari Miyazawa, Hong Hu, Kazuya Mitsuji, Yasuo Nagai, Naoki Yoshimoto, and Yuko Suenaga. 2018. "Basic Study of Ventilation Using Semi-Transparent Organic Photovoltaic Sheets for Solar Chimney Systems" Technologies 6, no. 4: 93. https://doi.org/10.3390/technologies6040093

APA StyleHidaka, K., Miyazawa, A., Hu, H., Mitsuji, K., Nagai, Y., Yoshimoto, N., & Suenaga, Y. (2018). Basic Study of Ventilation Using Semi-Transparent Organic Photovoltaic Sheets for Solar Chimney Systems. Technologies, 6(4), 93. https://doi.org/10.3390/technologies6040093