Development of a Change Management Instrument for the Implementation of Technologies †

Abstract

1. Introduction

1.1. Background

1.2. Need for a Sociotechnical Approach

1.3. Benefits in the Change Management Process

1.4. Aim and Contribution of Our Study

2. Materials and Methods

2.1. Instrument for the Assessment of Scenarios of Digitized Work Based on Sociotechnical Criteria

2.1.1. Classification and Rating of the Human Dimension

2.1.2. Classification and Rating of the Technological Dimension

2.1.3. Classification and Rating of the Organizational Dimension

2.2. Scenarios Under Investigation

2.2.1. Mixed Mock-up

Short Description

Process

2.2.2. Conformity Management Supported by a Graph Database

Short Description

Process

2.2.3. Digital Documentation of the Production Progress

Short Description

Process

2.3. Study Design

3. Results

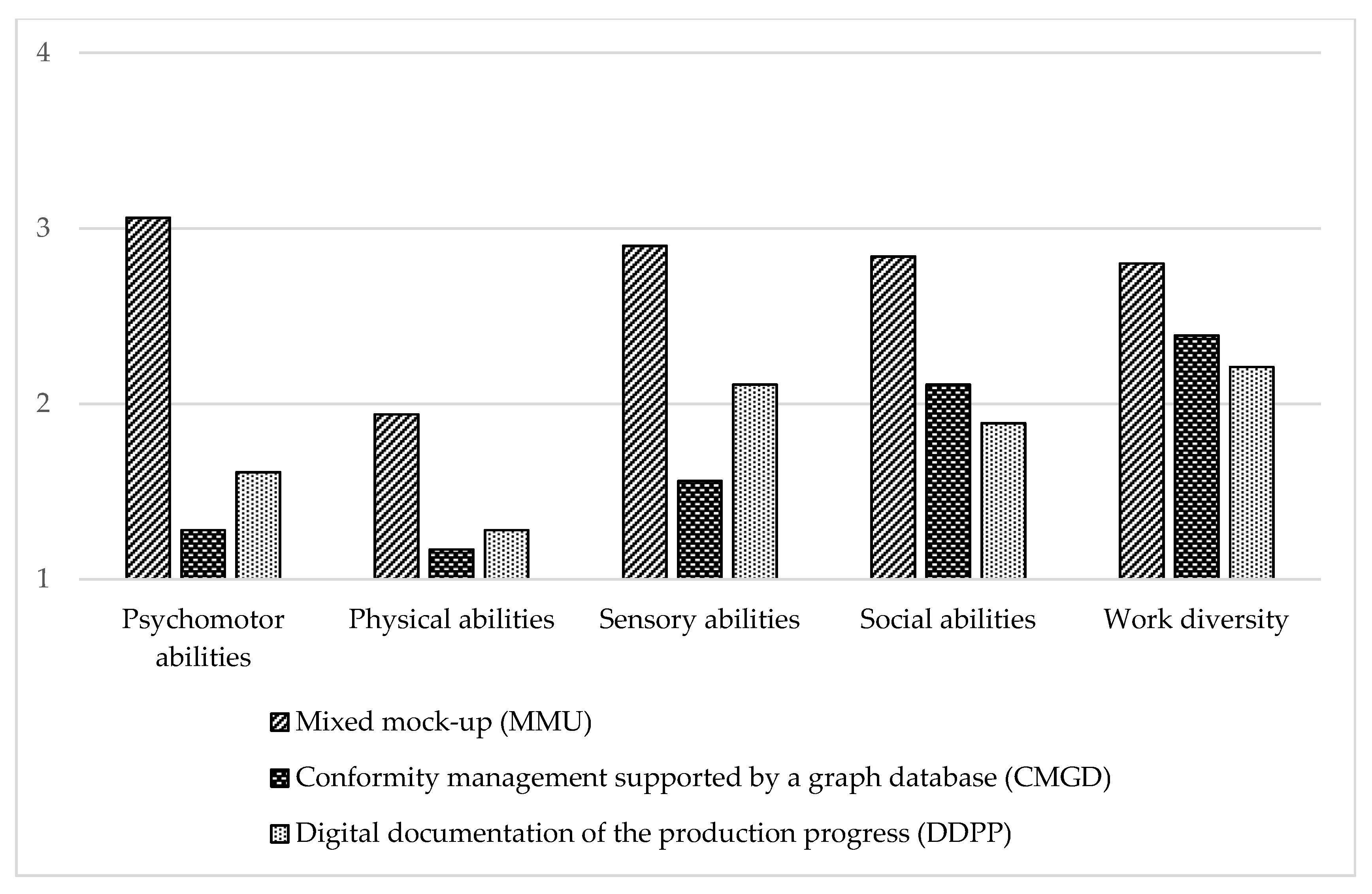

3.1. Results Human Dimension

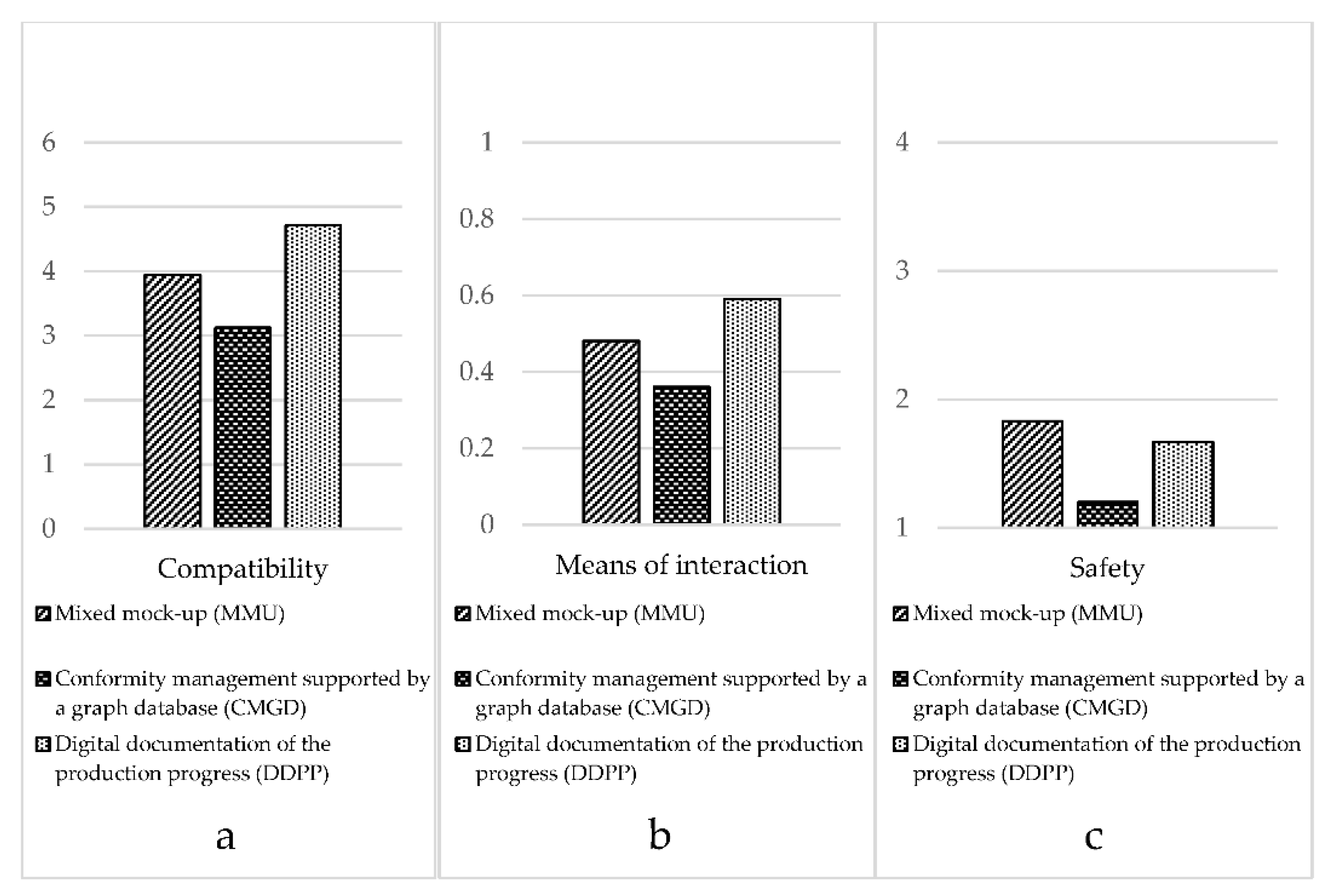

3.2. Results Technological Dimension

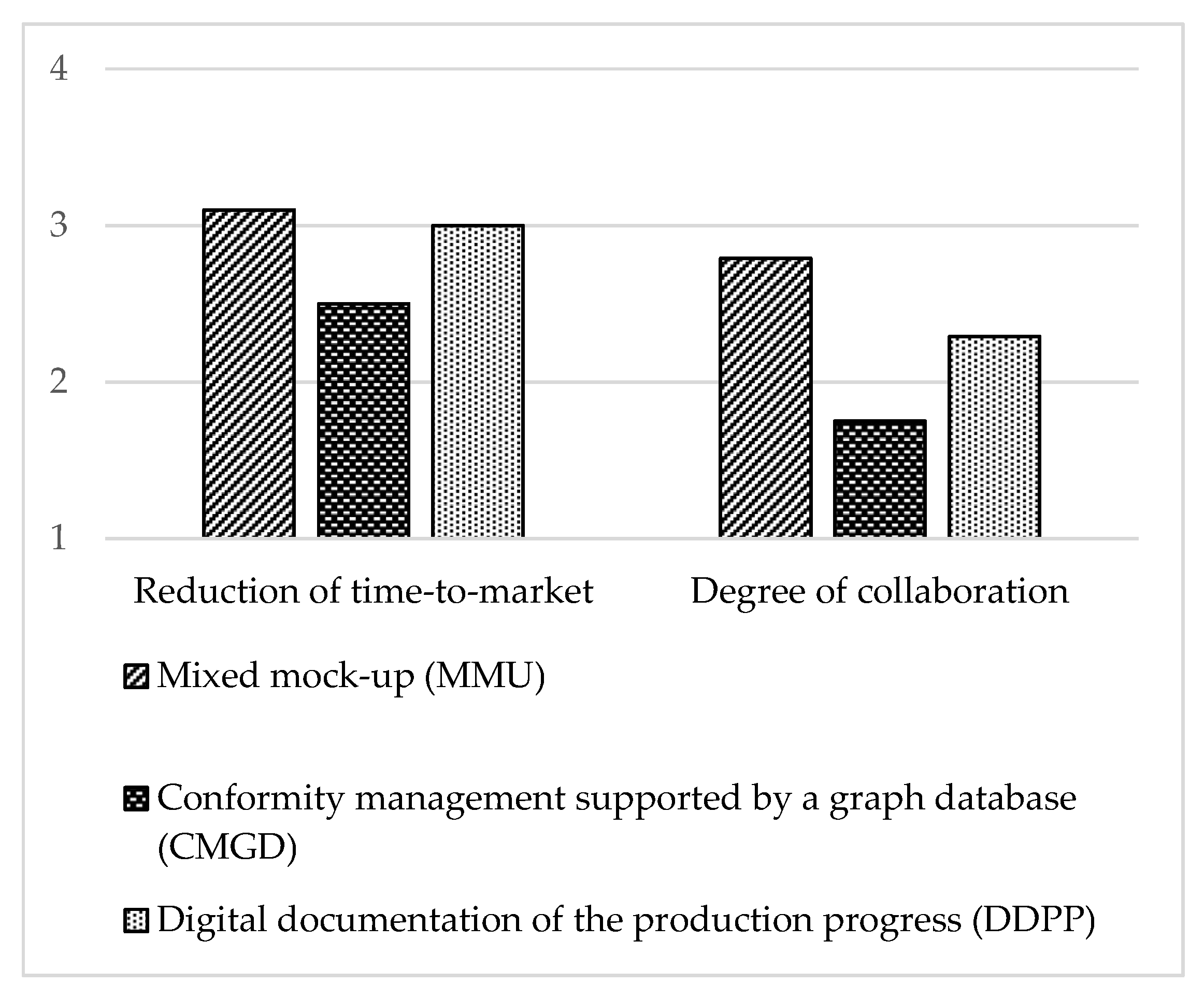

3.3. Results Organizational Dimension

4. Discussion

4.1. Limitations and Future Research

4.2. Practical Implications

4.3. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Wamba, S.F.; Papadopoulos, T. The impact of big data on world-class sustainable manufacturing. Int. J. Adv. Manuf. Technol. 2016, 84, 631–645. [Google Scholar] [CrossRef]

- Rosen, R.; Wichert, G.; von Lo, G.; Bettenhausen, K.D. About the importance of autonomy and digital twins for the future of manufacturing. IFAC-PapersOnLine 2015, 48, 567–572. [Google Scholar] [CrossRef]

- Peng, D.X.; Heim, G.R.; Mallick, D.N. Collaborative product development: The effect of project complexity on the use of information technology tools and new product development practices. Prod. Oper. Manag. 2014, 23, 1421–1438. [Google Scholar] [CrossRef]

- Wang, L.; Törngren, M.; Onori, M. Current status and advancement of cyber-physical systems in manufacturing. J. Manuf. Syst. 2015, 37, 517–527. [Google Scholar] [CrossRef]

- Schuh, G.; Rozenfeld, H.; Assmus, D.; Zancul, E. Process oriented framework to support PLM implementation. Comput. Ind. 2008, 59, 210–218. [Google Scholar] [CrossRef]

- SmartGrid.gov. Available online: https://www.smartgrid.gov/ (accessed on 26 October 2018).

- Hermann, M.; Pentek, T.; Otto, B. Design principles for industrie 4.0 scenarios: A literature review. In Proceedings of the 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; Bui, T.X., Sprague, R.H., Jr., Eds.; Conference Publishing Services: Los Alamitos, CA, USA, 2016; pp. 3928–3937. [Google Scholar]

- Fink, A.; Siebe, A. Szenario-Management. Von Strategischem Vorausdenken zu Zukunftsrobusten Entscheidungen; Campus Verlag: Frankfurt, NY, USA, 2016; ISBN 9783593506036. [Google Scholar]

- Mellor, S.; Hao, L.; Zhang, D. Additive manufacturing: A framework for implementation. Int. J. Prod. Econ. 2014, 149, 194–201. [Google Scholar] [CrossRef]

- Djuric, A.M.; Urbanic, R.J.; Rickli, J.L. A framework for collaborative robot (CoBot) integration in advanced manufacturing systems. SAE Int. J. Mater. Manuf. 2016, 9. [Google Scholar] [CrossRef]

- Hold, P.; Erol, S.; Reisinger, G.; Sihn, W. Planning and evaluation of digital assistance systems. Procedia Manuf. 2017, 9, 143–150. [Google Scholar] [CrossRef]

- Stowers, K.; Oglesby, J.; Sonesh, S.; Leyva, K.; Iwig, C.; Salas, E. A framework to guide the assessment of human-machine systems. Hum. Factors 2017, 59, 172–188. [Google Scholar] [CrossRef]

- Boy, G.A. The Handbook of Human-Machine Interaction. A Human-Centered Design Approach; CRC Press: Boca Raton, FL, USA, 2017; ISBN 9780754675808. [Google Scholar]

- Winter, S.; Berente, N.; Howison, J.; Butler, B. Beyond the organizational ‘container’: Conceptualizing 21st century sociotechnical work. Inf. Organ. 2014, 24, 250–269. [Google Scholar] [CrossRef]

- Jede, A.; Teuteberg, F. Understanding socio-technical impacts arising from Software-as-a-Service usage in companies. Bus. Inf. Syst. Eng. 2016, 58, 161–176. [Google Scholar] [CrossRef]

- Macy, B.A.; Izumi, H. Organizational change, design, and work innovation: A meta-analysis of 131 North American field studies—1961–1991. In Research in Organizational Change and Development: An Annual Series Featuring Advances in Theory, Methodology and Research; Woodman, R.W., Pasmore, W.A., Eds.; JAI Press: Greenwich, CT, USA, 1993; pp. 235–313. ISBN 1559385391. [Google Scholar]

- Cawsey, T.F.; Deszca, G.; Ingols, C. Organizational Change. An Action-Oriented Toolkit, 3rd ed.; Sage Publications: Los Angeles, CA, USA, 2016; ISBN 9781483359304. [Google Scholar]

- Leão, H.; Canedo, E. Best practices and methodologies to promote the digitization of public services citizen-driven: A systematic literature review. Information 2018, 9, 197. [Google Scholar] [CrossRef]

- Finney, S.; Corbett, M. ERP implementation: A compilation and analysis of critical success factors. Bus. Process. Manag. J. 2007, 13, 329–347. [Google Scholar] [CrossRef]

- Todnem By, R. Organisational change management: A critical review. J. Chang. Manag. 2005, 5, 369–380. [Google Scholar] [CrossRef]

- Oreg, S.; Vakola, M.; Armenakis, A. Change recipients’ reactions to organizational change: A 60-year review of quantitative studies. J. Appl. Behav. Sci. 2011, 47, 461–524. [Google Scholar] [CrossRef]

- Cohen-Charash, Y.; Spector, P.E. The role of justice in organizations: A meta-analysis. Organ. Behav. Hum. Decis. Process. 2001, 86, 278–321. [Google Scholar] [CrossRef]

- Michel, A.; Stegmaier, R.; Sonntag, K. I scratch your back—You scratch mine. Do procedural justice and organizational identification matter for employees’ cooperation during change? J. Chang. Manag. 2010, 10, 41–59. [Google Scholar] [CrossRef]

- Deci, E.L.; Olafsen, A.H.; Ryan, R.M. Self-determination theory in work organizations: The state of a science. Annu. Rev. Organ. Psychol. Organ. Behav. 2017, 4, 19–43. [Google Scholar] [CrossRef]

- Schlicher, K.D.; Helling, R.; Maier, G.W. Need Satisfaction Is the Key: How Organizational Support Influences Positive Change Attitude during Information Technology Implementation. Unpublished Work.

- Demerouti, E. Design your own job through job crafting. Eur. Psychol. 2014, 19, 237–247. [Google Scholar] [CrossRef]

- Leana, C.; Appelbaum, E.; Shevchuk, I. Work process and quality of care in early childhood education: The role of job crafting. Acad. Manag. J. 2009, 52, 1169–1192. [Google Scholar] [CrossRef]

- Wrzesniewski, A.; Dutton, J.E. Crafting a job: Revisioning employees as active crafters of their work. Acad. Manag. Rev. 2001, 26, 179–201. [Google Scholar] [CrossRef]

- Jenderny, S.; Foullois, M.; Kato-Beiderwieden, A.-L.; Bansmann, M.; Wöste, L.; Lamß, J.; Maier, G.W.; Röcker, C. Development of an instrument for the assessment of scenarios of work 4.0 based on socio-technical criteria. In Proceedings of the 11th PErvasive Technologies Related to Assistive Environments Conference on–PETRA’18, Corfu, Greece, 26–29 June 2018; ACM Press: New York, NY, USA, 2018; pp. 319–326. [Google Scholar]

- Bundesministerium für Arbeit und Soziales. Weißbuch Arbeiten 4.0; Bundesministerium für Arbeit und Soziales, Abteilung Grundsatzfragen des Sozialstaats, der Arbeitswelt und der sozialen Marktwirtschaft: Berlin, Germany, 2016.

- Cascio, W.F.; Montealegre, R. How technology is changing work and organizations. Annu. Rev. Organ. Psychol. Organ. Behav. 2016, 3, 349–375. [Google Scholar] [CrossRef]

- Fleishman, E.A.; Quaintance, M.K. Taxonomies of Human Performance: The Description of Human Tasks; Academic Press: Orlando, FL, USA, 1984; ISBN 978-0122604508. [Google Scholar]

- Rauner, F.; Rasmussen, L.; Corbett, J.M. The social shaping of technology and work: Human centred computer integrated manufacturing systems. AI Soc. 1988, 2, 47–61. [Google Scholar] [CrossRef]

- Morgeson, F.P.; Delaney-Klinger, K.; Hemingway, M.A. The importance of job autonomy, cognitive ability, and job-related skill for predicting role breadth and job performance. J. Appl. Psychol. 2005, 90, 399–406. [Google Scholar] [CrossRef] [PubMed]

- Jong, J. The role of performance feedback and job autonomy in mitigating the negative effect of role ambiguity on employee satisfaction. Public Perform. Manag. Rev. 2016, 39, 814–834. [Google Scholar] [CrossRef]

- Morgeson, F.P.; Humphrey, S.E. The Work Design Questionnaire (WDQ): Developing and validating a comprehensive measure for assessing job design and the nature of work. J. Appl. Psychol. 2006, 91, 1321–1339. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Zhang, P. The role of moderating factors in user technology acceptance. Int. J. Hum.-Comput. Stud. 2006, 64, 53–78. [Google Scholar] [CrossRef]

- Wrzesniewski, A.; Dutton, J.E.; Debebe, G. Interpersonal sensemaking and the meaning of work. Res. Organ. Behav. 2003, 25, 93–135. [Google Scholar] [CrossRef]

- Ulich, E. Arbeitspsychologie; Schäffer-Poeschel: Stuttgart, Germany, 2011; ISBN 9783791030494. [Google Scholar]

- Sims, H.P., Jr.; Szilagyi, A.D.; Keller, R.T. The measurement of job characteristics. Acad. Manag. J. 1976, 19, 195–212. [Google Scholar] [CrossRef]

- Hackman, R.; Oldham, G.R. Motivation through the design of work: Test of a theory. Organ. Behav. Hum. Perform. 1976, 16, 250–279. [Google Scholar] [CrossRef]

- Roussel, P.A. Technological maturity proves a valid and important concept. Res. Manag. 1984, 27, 29–34. [Google Scholar] [CrossRef]

- Duncan, N.B. Capturing flexibility of information technology infrastructure: A study of resource. J. Manag. Inf. Syst. 1995, 12, 37–57. [Google Scholar] [CrossRef]

- Byrd, T.A.; Turner, D.E. An exploratory analysis of the value of the skills of IT personnel: Their relationship to IS infrastructure and competitive advantage. Decis. Sci. 2001, 32, 21–47. [Google Scholar] [CrossRef]

- Schmitt, P.; Fleisch, E.; Boutellier, R. Adoption und Diffusion Neuer Technologien am Beispiel der Radiofrequenz-Identifikation (RFID). Ph.D. Thesis, ETH Zürich, Zürich, Switzerland, 2008. [Google Scholar]

- Broekel, T. Measuring Technological Complexity-Current Approaches and a New Measure of Structural Complexity. Available online: https://arxiv.org/pdf/1708.07357.pdf (accessed on 29 October 2018).

- Dolata, U. Soziotechnischer Wandel, Nachhaltigkeit und politische Gestaltungsfähigkeit. In Nachhaltigkeit als radikaler Wandel; Lange, H., Ed.; Vs. Verlag für Sozialwissenschaften: Wiesbaden, Germany, 2008; pp. 261–286. ISBN 9783531150932. [Google Scholar]

- Rammert, W.; Schulz-Schaeffer, I. Technik und Handeln-Wenn Soziales Handeln Sich auf Menschliche Artefakte Verteilt. 2002. Available online: https://www.uni-due.de/imperia/md/content/soziologie/technikundhandeln.pdf (accessed on 29 October 2018).

- Gruber, A.; von Roon, S.; Pellinger, C. Lastflexibilisierung in der Industrie in Konkurrenz zu Weiteren Funktionalen Speichern. Available online: https://www.ffegmbh.de/download/veroeffentlichungen/339_Vortrag_VDI_Lastflex_und_Speicher/20130319_VDI Expertenforum.pdf (accessed on 29 October 2018).

- Hansson, S.O. Risk and Safety in Technology. In Philosophy of Technology and Engineering Sciences; Gabbay, D., Thagard, P., Woods, J., Eds.; Elsevier: Amsterdam, The Netherlands, 2009; pp. 1069–1102. ISBN 9780444516671. [Google Scholar]

- Saleh, M.S.; Alfantookh, A. A new comprehensive framework for enterprise information security risk management. Appl. Comput. Inf. 2011, 9, 107–118. [Google Scholar] [CrossRef]

- Dacier, M.; Deswarte, Y.; Kaâniche, M. Models and tools for quantitative assessment of operational security. In Proceedings of the 12th International Information Security Conference (IFIP/SEC’96), Island of Samos, Greece, 21–24 May 1996; pp. 177–186. [Google Scholar]

- Gausemeier, J.; Anacker, H.; Czaja, A.; Waßmann, H.; Dumitrescu, R. Auf dem Weg zu intelligenten technischen Systemen. In 9. Paderborner Workshop Entwurf mechatronischer Systeme; Gausemeier, J., Dumitrescu, R., Rammig, F.-J., Schäfer, W., Trächtler, A., Eds.; Heinz Nixdorf Institut: Paderborn, Germany, 2013; pp. 11–47. [Google Scholar]

- Rammer, C.; Weißenfeld, B. Innovationsverhalten der Unternehmen in Deutschland 2006. Aktuelle Entwicklungen und ein Internationaler Vergleich; Studien zum Deutschen Innovationssystem 04-2008. 2008. Available online: https://www.e-fi.de/fileadmin/Studien/StuDIS_4_2008_Innovation.pdf (accessed on 30 October 2018).

- Hoff, A. “Back to the Roots”: Vor der 4. Welle der Arbeitszeitflexibilisierung. Personalwirtschaft, 2006; 17–19. [Google Scholar]

- Aufwandsschätzung und Schätzverfahren. Available online: https://www.projektmanagementhandbuch.de/handbuch/projektplanung/aufwandsschaetzung-und-schaetzverfahren/ (accessed on 30 October 2018).

- Acatech-Deutsche Akademie der Technikwissenschaften. Kompetenzentwicklungsstudie Industrie 4.0—Erste Ergebnisse und Schlussfolgerungen. 2016. Available online: https://www.acatech.de/wp-content/uploads/2018/03/acatech_DOSSIER_neu_Kompetenzentwicklung_Web.pdf (accessed on 30 October 2018).

- Weaver, B. Coordination, Cooperation, and Collaboration: Defining the C3 Framework. Ph.D. Thesis, Bryant University, Smithfield, RI, USA, 2012. [Google Scholar]

- Ittermann, P.; Niehaus, J.; Hirsch-Kreinsen, H. Arbeiten in der Industrie 4.0–Trendbestimmungen und Arbeitspolitische Handlungsfelder; No. 308. Düsseldorf, Germany, 2015. Available online: https://www.boeckler.de/pdf/p_study_hbs_308.pdf (accessed on 29 October 2018).

- Nedbal, D.; Auinger, A.; Hochmeier, A. Addressing transparency, communication and participation in enterprise 2.0 projects. Proc. Technol. 2013, 9, 676–686. [Google Scholar] [CrossRef]

- Cicchetti, D.V. Guidelines, criteria, and rules of thumb for evaluating normed and standardized assessment instruments in psychology. Psychol. Assess. 1994, 6, 284–290. [Google Scholar] [CrossRef]

- Kwahk, K.-Y.; Lee, J.-N. The role of readiness for change in ERP implementation: Theoretical bases and empirical validation. Inf. Manag. 2008, 45, 474–481. [Google Scholar] [CrossRef]

- Hwang, Y. Investigating enterprise systems adoption: Uncertainty avoidance, intrinsic motivation, and the technology acceptance model. Eur. J. Inf. Syst. 2005, 14, 150–161. [Google Scholar] [CrossRef]

| Criterion | Factors |

|---|---|

| Human Dimension | |

| Prioritization of abilities | Cognitive Psychomotor Physical Sensory Social/interpersonal |

| Qualification of employees | Amount of effort Form of qualification |

| Autonomy/scope of action | Work scheduling Decision making Work methods |

| (Possibility) of social interaction | Social interaction at the workplace Interaction with external parties Interdependent work tasks Task independence |

| Holistic nature of the task | Influence of the work on others Holistic nature of the work Automatic performance feedback |

| Work diversity | Task variety Task complexity Amount of information processing Creativity Variety of skills Variety of tools |

| Technological Dimension | |

| Technological maturity | Category of technological maturity (introduction, growth, maturity, decline) |

| Compatibility | Mobile interoperability Stationary interoperability Personalized services Time-based services Location-based services Platform independence |

| Means of (human) interaction | Information tags Visual codes Direct tactile interaction Direct textual interaction Acoustic interaction Gesture recognition |

| Flexibility | Compatibility Connectivity Modularity |

| Complexity | (Inter)connectivity of the components Degree of understanding and active participation Specialization of the technology |

| Invest | Price (€) |

| Effort of implementation | Implementation effort |

| Cost of maintenance | Overhead System maintenance Upgrades System management Employee training |

| Safety | Training of employees Supervision of the work environment Implementation of security technologies |

| Security | Training of employees Supervision of the work environment Implementation of security technologies |

| Organizational Dimension | |

| Product development process | Stage of the product development process (strategic product planning, product development, service development, production system development) |

| Promotion of innovation | Product orientation Customer orientation |

| Reduction of time-to-market | Process control Process optimization Infrastructural changes Interdisciplinary collaboration |

| Labour expenditures | Number of different activities Complexity of activities Number of participants Training period Necessity of distributed persons |

| Need for competencies/expert knowledge | Technology-/data-oriented Process-/customer-oriented Infrastructure-/organization-oriented |

| Influence on process organization | Adjacent/related processes Organizational units Customers/suppliers |

| Degree of collaboration | Organizational structure Mutual management |

| Degree of blurring of boundaries of work | Decentralisation Working time flexibility Project flexibility |

| Agility | Customer orientation and participation Transparency Decentralisation Breaking up disciplinary boundaries |

| Human Dimension | |||

| Criterion | Sample Item | No. of Items | Scale |

| Prioritization of abilities | To what extent are the following capabilities used in the scenario? | 5 | 4-point Likert scale |

| Qualification of employees | There is a need for qualification. | 2 | 4/5-point Likert scale |

| Autonomy/scope of action | The work can be planned independently. | 3 | 4-point Likert scale |

| (Possibility) of social interaction | The exchange with other people in the workplace is given. | 4 | 4-point Likert scale |

| Holistic nature of the task | The result of the work has a great impact on other people. | 3 | 4-point Likert scale |

| Work diversity | A lot of information is processed at work. | 6 | 4-point Likert scale |

| Technological Dimension | |||

| Technological maturity | The technology used in the scenario is a ... (a) pacemaker, (b) key, (c) basic, (d) repressed technology. | 1 | 4-point Likert scale |

| Compatibility | The system offers situational services. | 7 | Dichotomous scale |

| Means of (human) interaction | The system uses acoustic interaction (e.g., voice control). | 6 | Dichotomous scale |

| Flexibility | The technology used in the scenario is highly compatible. | 3 | 4-point Likert scale |

| Complexity | The technology used in the scenario is very specific for each application. | 3 | 4-point Likert scale |

| Invest | Please rate the (estimated) cost of the technology. | 1 | 4-point Likert scale |

| Effort of implementation | The installation of the technology used in the scenario requires complex re-planning and conversion of a system. | 1 | 4-point Likert scale |

| Cost of maintenance | Please evaluate the operating effort of the technology used in the scenario with regard to system maintenance. | 5 | 4-point Likert scale |

| Safety | With regard to security, the technology used in the scenario requires constant monitoring and documentation of the working environment. | 3 | 4-point Likert scale |

| Security | With regard to safety, the technology used in the scenario requires a high level of training and safety instruction of employees. | 3 | 4-point Likert scale |

| Organizational Dimension | |||

| Product development process | Which product development process applies? | 4 | Dichotomous scale |

| Promotion of innovation | In the scenario described, product orientation is made possible in the company. | 4 | 4-point Likert scale |

| Reduction of time-to-market | The described scenario reduces the time-to-market by improving process control. | 4 | 4-point Likert scale |

| Labour expenditures | The scenario described must be carried out by many people. | 5 | 4-point Likert scale |

| Need for competencies/expert knowledge | Which experts are required for data evaluation and analysis? | 16 | Dichotomous scale |

| Influence on process organization | The scenario described has effects on other processes. | 3 | 4-point Likert scale |

| Degree of collaboration | The scenario described favours an open and flexible organizational structure. | 2 | 4-point Likert scale |

| Degree of blurring of boundaries of work | The scenario described favours a decentralisation of the company organization. | 4 | 4-point Likert scale |

| Agility | The scenario described favours customer orientation and participation in dynamic projects. | 4 | 4-point Likert scale |

| Mixed Mock-Up | Conformity Management Supported by a Graph Database | Digital Documentation of the Production Progress | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Human Dimension | M | SD | M | SD | M | SD | F(2) | p | ηp2 |

| Cognitive abilities | 2.94 | 0.87 | 2.89 | 0.90 | 2.50 | 0.79 | 1.87 | 0.17 | 0.10 |

| Psychomotor abilities | 3.06 | 1.00 | 1.28 | 0.57 | 1.61 | 0.78 | 30.61 | 0.00 | 0.64 |

| Physical abilities | 1.94 | 0.73 | 1.17 | 0.38 | 1.28 | 0.46 | 17.20 | 0.00 | 0.50 |

| Sensory abilities | 2.90 | 0.83 | 1.56 | 0.92 | 2.11 | 0.83 | 21.93 | 0.00 | 0.56 |

| Social abilities | 2.84 | 1.19 | 2.11 | 0.74 | 1.89 | 0.94 | 4.69 | 0.02 | 0.21 |

| Qualification of employees | 2.63 | 0.90 | 2.79 | 1.08 | 2.47 | 0.96 | 0.84 | 0.44 | 0.04 |

| Autonomy/scope of action | 3.55 | 0.42 | 3.44 | 0.42 | 3.52 | 0.43 | 0.20 | 0.82 | 0.02 |

| (Possibility) of social interaction | 2.55 | 0.77 | 2.76 | 0.65 | 2.60 | 0.67 | 0.56 | 0.47 | 0.03 |

| Holistic nature of the task | 2.80 | 0.56 | 3.02 | 0.65 | 2.72 | 0.73 | 1.80 | 0.18 | 0.09 |

| Work diversity | 2.80 | 0.56 | 2.39 | 0.50 | 2.21 | 0.37 | 9.99 | 0.00 | 0.36 |

| Technological dimension | |||||||||

| Compatibility | 3.94 | 1.48 | 3.12 | 1.50 | 4.71 | 1.36 | 5.82 | 0.01 | 0.27 |

| Means of interaction | 0.48 | 0.29 | 0.36 | 0.28 | 0.59 | 0.21 | 5.83 | 0.01 | 0.27 |

| Flexibility | 2.72 | 0.63 | 2.40 | 0.64 | 2.79 | 0.57 | 2.02 | 0.15 | 0.13 |

| Complexity | 2.68 | 0.63 | 2.67 | 0.70 | 2.65 | 0.65 | 0.02 | 0.99 | 0.00 |

| Invest | 2.74 | 0.73 | 2.32 | 1.06 | 2.68 | 0.95 | 2.00 | 0.15 | 0.10 |

| Effort of implementation | 2.84 | 0.90 | 2.53 | 1.26 | 3.11 | 0.88 | 2.04 | 0.14 | 0.10 |

| Cost of maintenance | 2.48 | 0.60 | 2.32 | 0.62 | 2.39 | 0.64 | 0.54 | 0.59 | 0.03 |

| Safety | 1.83 | 0.68 | 1.20 | 0.43 | 1.67 | 0.80 | 4.70 | 0.02 | 0.22 |

| Security | 2.11 | 0.78 | 2.46 | 0.98 | 2.47 | 0.78 | 1.22 | 0.31 | 0.06 |

| Organizational dimension | |||||||||

| Promotion of innovation | 2.89 | 0.58 | 2.95 | 0.70 | 2.77 | 0.72 | 0.36 | 0.70 | 0.02 |

| Reduction of time-to-market | 3.10 | 0.57 | 2.50 | 0.57 | 3.00 | 0.57 | 9.27 | 0.00 | 0.35 |

| Labour expenditures | 2.20 | 0.61 | 1.74 | 0.55 | 1.92 | 0.63 | 3.17 | 0.05 | 0.15 |

| Influence on process organization | 2.82 | 0.83 | 2.98 | 0.79 | 3.25 | 0.66 | 2.10 | 0.14 | 0.11 |

| Degree of collaboration | 2.79 | 0.84 | 1.75 | 0.62 | 2.29 | 0.92 | 7.30 | 0.00 | 0.40 |

| Degree of blurring of boundaries of work | 2.48 | 0.70 | 2.19 | 0.78 | 2.43 | 0.74 | 1.50 | 0.24 | 0.10 |

| Agility | 3.17 | 0.65 | 2.82 | 0.74 | 3.10 | 0.67 | 1.49 | 0.24 | 0.09 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mlekus, L.; Paruzel, A.; Bentler, D.; Jenderny, S.; Foullois, M.; Bansmann, M.; Woeste, L.; Röcker, C.; Maier, G.W. Development of a Change Management Instrument for the Implementation of Technologies. Technologies 2018, 6, 120. https://doi.org/10.3390/technologies6040120

Mlekus L, Paruzel A, Bentler D, Jenderny S, Foullois M, Bansmann M, Woeste L, Röcker C, Maier GW. Development of a Change Management Instrument for the Implementation of Technologies. Technologies. 2018; 6(4):120. https://doi.org/10.3390/technologies6040120

Chicago/Turabian StyleMlekus, Lisa, Agnieszka Paruzel, Dominik Bentler, Sascha Jenderny, Marc Foullois, Michael Bansmann, Lars Woeste, Carsten Röcker, and Günter W. Maier. 2018. "Development of a Change Management Instrument for the Implementation of Technologies" Technologies 6, no. 4: 120. https://doi.org/10.3390/technologies6040120

APA StyleMlekus, L., Paruzel, A., Bentler, D., Jenderny, S., Foullois, M., Bansmann, M., Woeste, L., Röcker, C., & Maier, G. W. (2018). Development of a Change Management Instrument for the Implementation of Technologies. Technologies, 6(4), 120. https://doi.org/10.3390/technologies6040120