Solving the Job-Shop Scheduling Problem in the Industry 4.0 Era

Abstract

1. Introduction

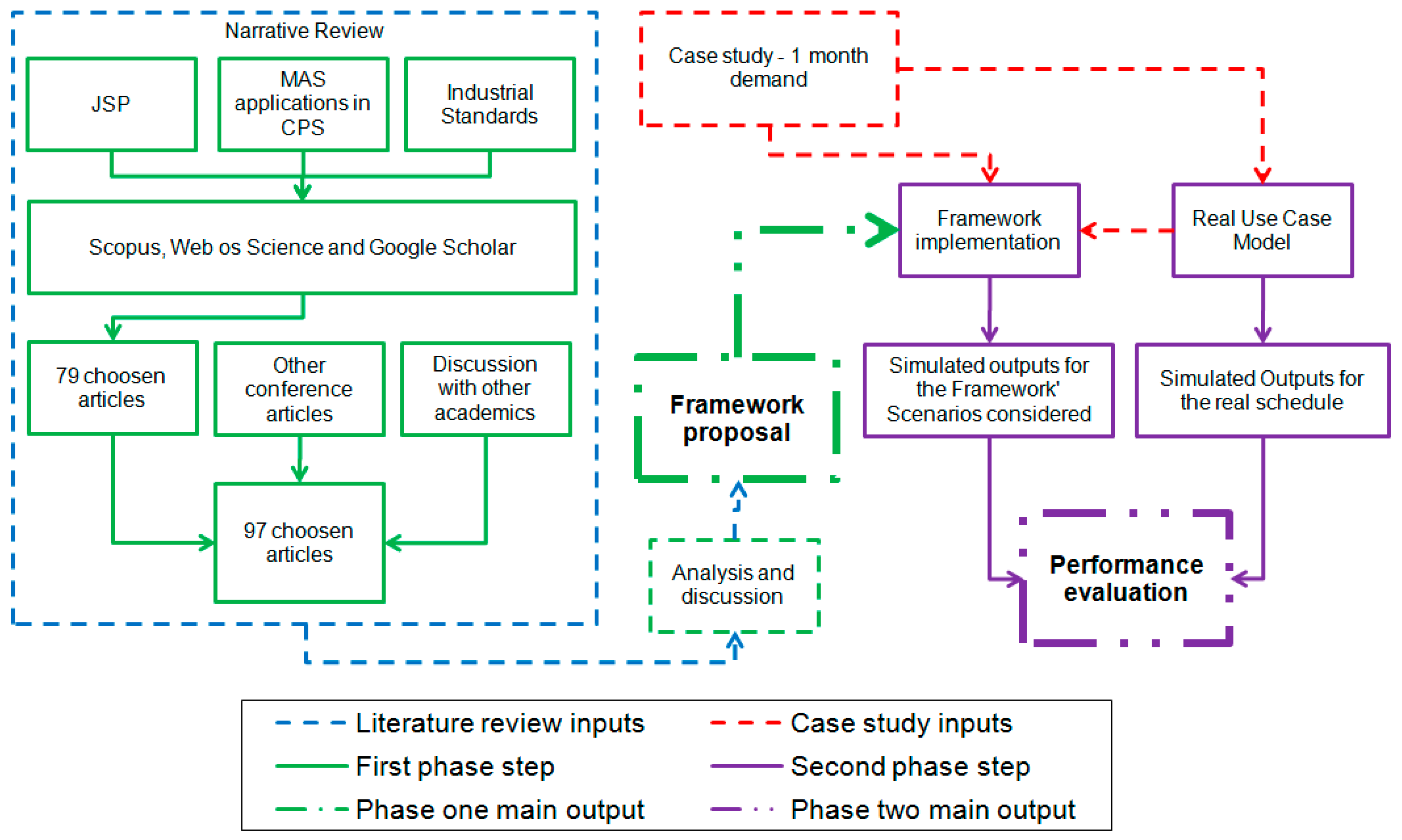

2. Materials and Methods

- JSP, in order to identify the main characteristics and methods to deal with it;

- Applications of MAS in CPS, in order to assess the best practices in the development of MAS and technologies currently applied in the implementation of such systems in the CPS domain;

- Industrial standards, in order to analyze the main standards currently used in the industry, as well as relevant characteristics to be considered for facilitating its implementation.

3. Literature Review

3.1. The Job-Shop Scheduling Problem

3.1.1. Approaches to Deal with the JSP

3.1.2. Scheduling Flexibility of the JSP

Classical Approach

Dynamic Approach

- Completely reactive scheduling: no pre-schedule is generated and scheduling is done in real-time.

- Predictive-reactive scheduling: a schedule is generated beforehand and a rescheduling is considered for responding to real-time disturbances.

- Predictive-reactive robust scheduling: a schedule is generated beforehand and a rescheduling is performed when the impact of disturbances on performance measures is significant.

- Robust pro-active scheduling: the schedule is generated beforehand anticipating the impact of disturbances in the manufacturing system.

3.2. Multi-Agent Systems

MASs Applications in Cyber-Physical Systems

3.3. Industrial Standards for Data Exchange

4. A MAS Framework to Dynamically Deal with the JSP

4.1. Framework Proposal

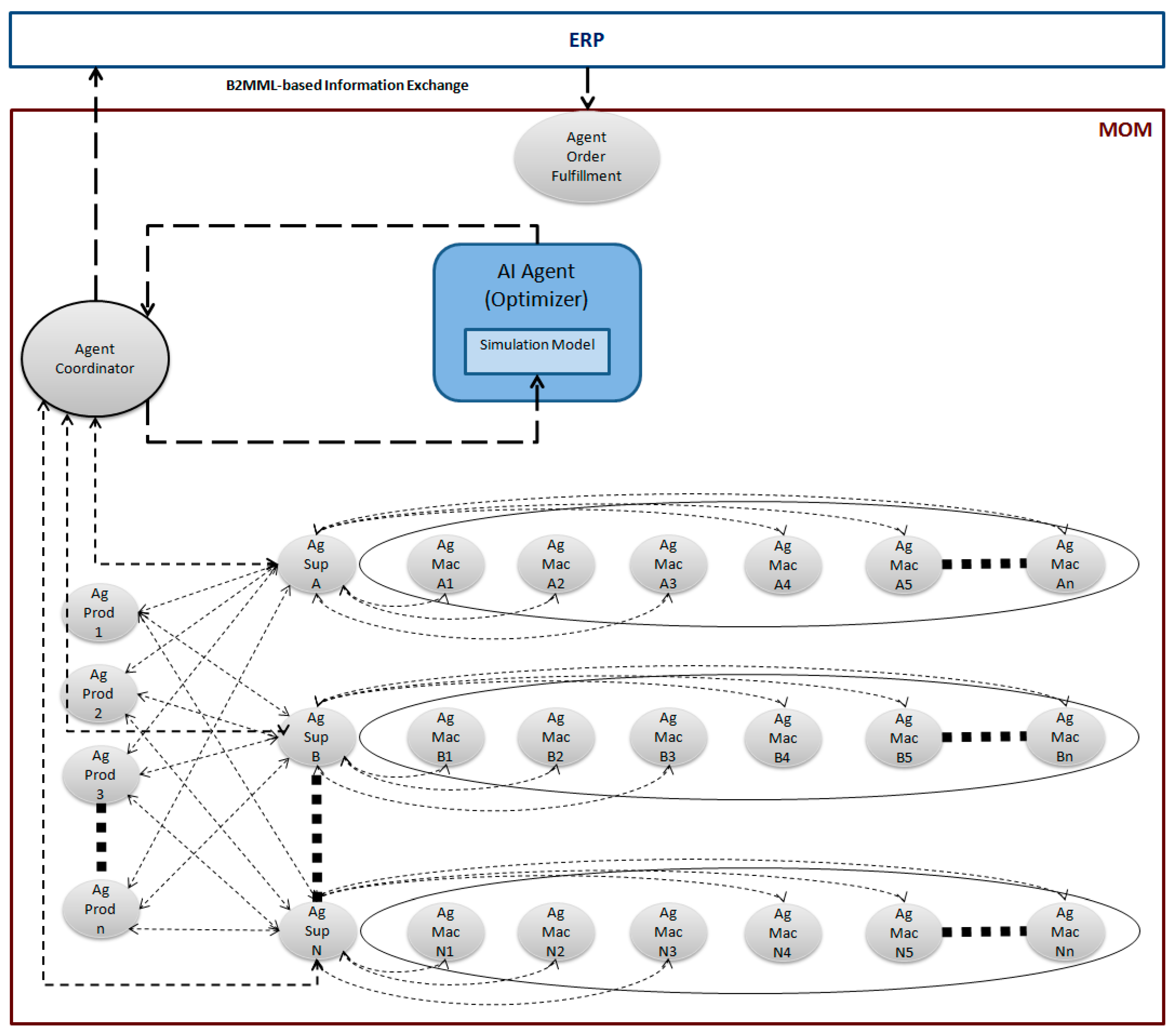

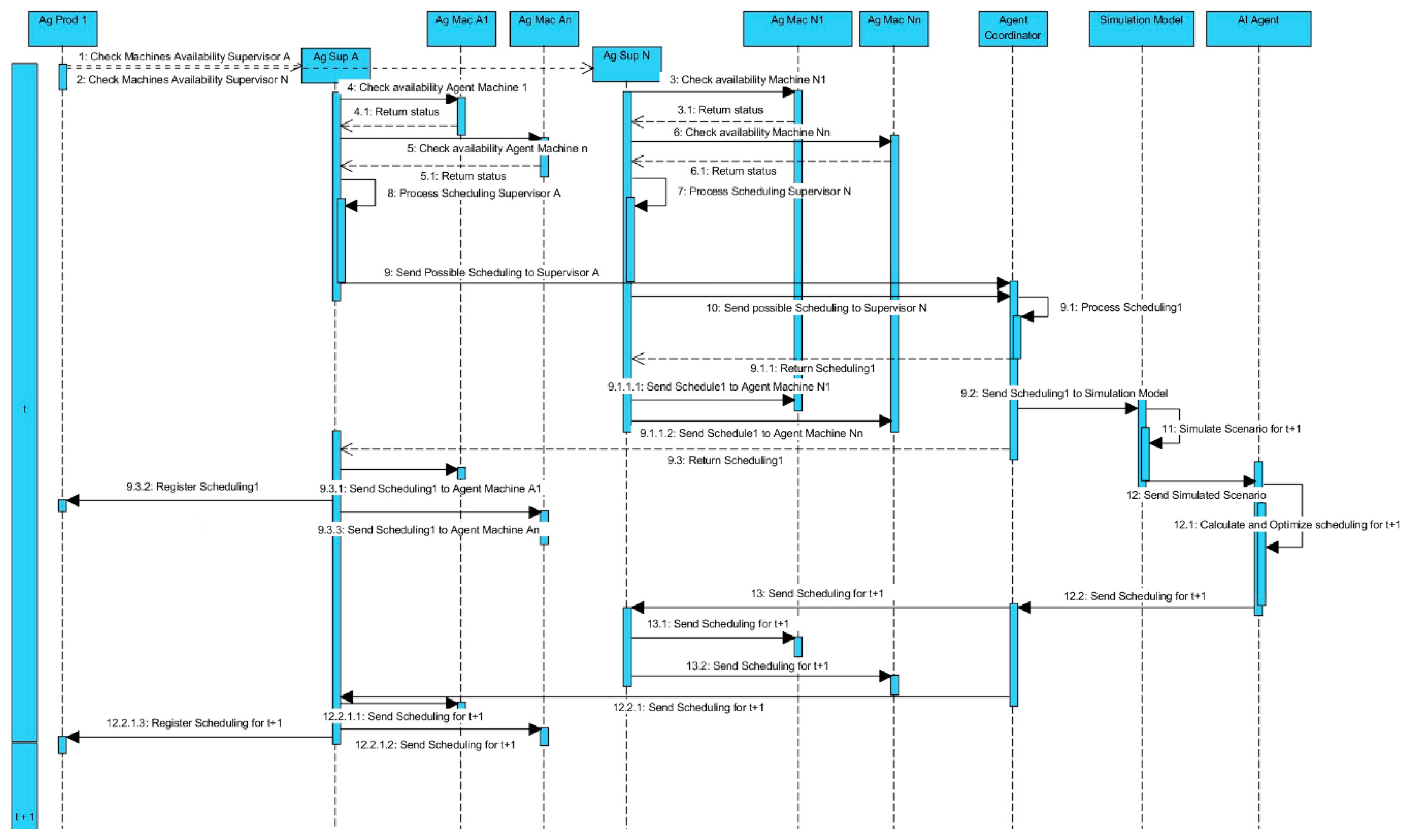

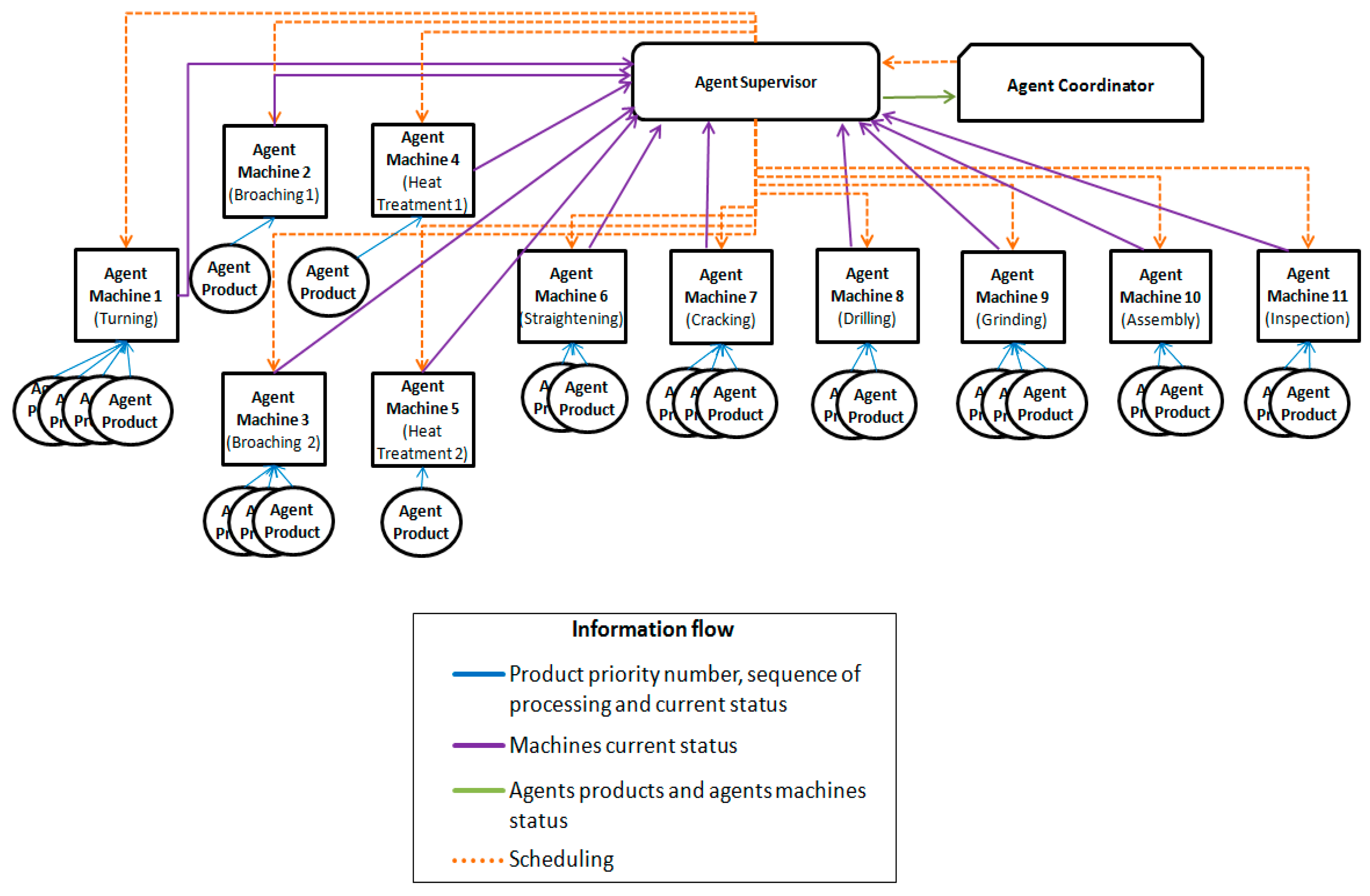

- Agent Order Fulfillment: This type of agent receives demand information from the ERP and separates them into orders, creating a new agent for each product to be manufactured (Ag Prod). For this, Agent Order Fulfillment must have data about the variety of possible products to be made, as well as the operations required for their production. This agent records priority numbers on these newly created Agents Product according to a given dispatching rule (order of arrival, priority, due time, etc.), which is used for determining their order in waiting queues;

- Agents Product (Ag Prod): Each agent of this type contains information of a given order to be made, such as due time, processes sequence, priority and so forth, according to the information provided by Agent Order Fulfillment. This agent still records on itself the operations already performed for its production;

- Agents Machine (Ag Mac): This type of agent provides data of interest on a particular machine, such as availability, queued products, production delays and so forth. It can still be used to send alerts of interest about the machine on which it is allocated, warning about breakages or possible defects, for example;

- Agents Supervisor (Ag Sup): This type of agent supervises a certain number of machines with specific characteristics, collecting information individually from each machine about availability, delays, performance and so forth. It can still have a dispatching rule to determine the best processing sequence of its supervised machines according to an objective function;

- Agent Coordinator: This agent receives the processing sequences created by each Agent Supervisor (based on these agents particular local information) and generates a new schedule based on this information considering the best global performance. Agent Coordinator can also be used for coordinating other agents exclusively using dispatching rules (and therefore does not creating a schedule per se) and for providing periodically information needed by the ERP, such as order status, machine breaks, new scheduling and so forth;

- AI Agent: This agent has an A.I. algorithm that is applied in a simulation model, which uses the schedule provided by Agent Coordinator as input, to create an optimized schedule. This agent can use optimization or A.I. approaches for exploring the search space in an effective and efficient way—as pointed out in Reference [69]—or to build and learn an understanding of possible results’ panorama while going in the direction of the solution space—hence reducing computational times.

4.2. Theoretical Implementation

- Agent Order Fulfillment: Production Resource Management and Product Definition Management;

- Agents Product: Product Definition Management, Production Tracking and Production Data Collection;

- Agents Supervisor: Production Resource Management, Production Dispatching, Production Execution, Production Tracking, Production Data Collection and Production Performance Analysis;

- Agents Machine: Production Resource Management, Production Dispatching, Production Execution, Production Tracking, Production Data Collection and Production Performance Analysis;

- Agent Coordinator: Detailed Production Scheduling, Production Dispatching, Production Data Collection and Production Performance Analysis.

- AI Agent: Detailed Production Scheduling.

5. Framework Implementation in a Real Case

5.1. Case Study

5.2. Framework Application

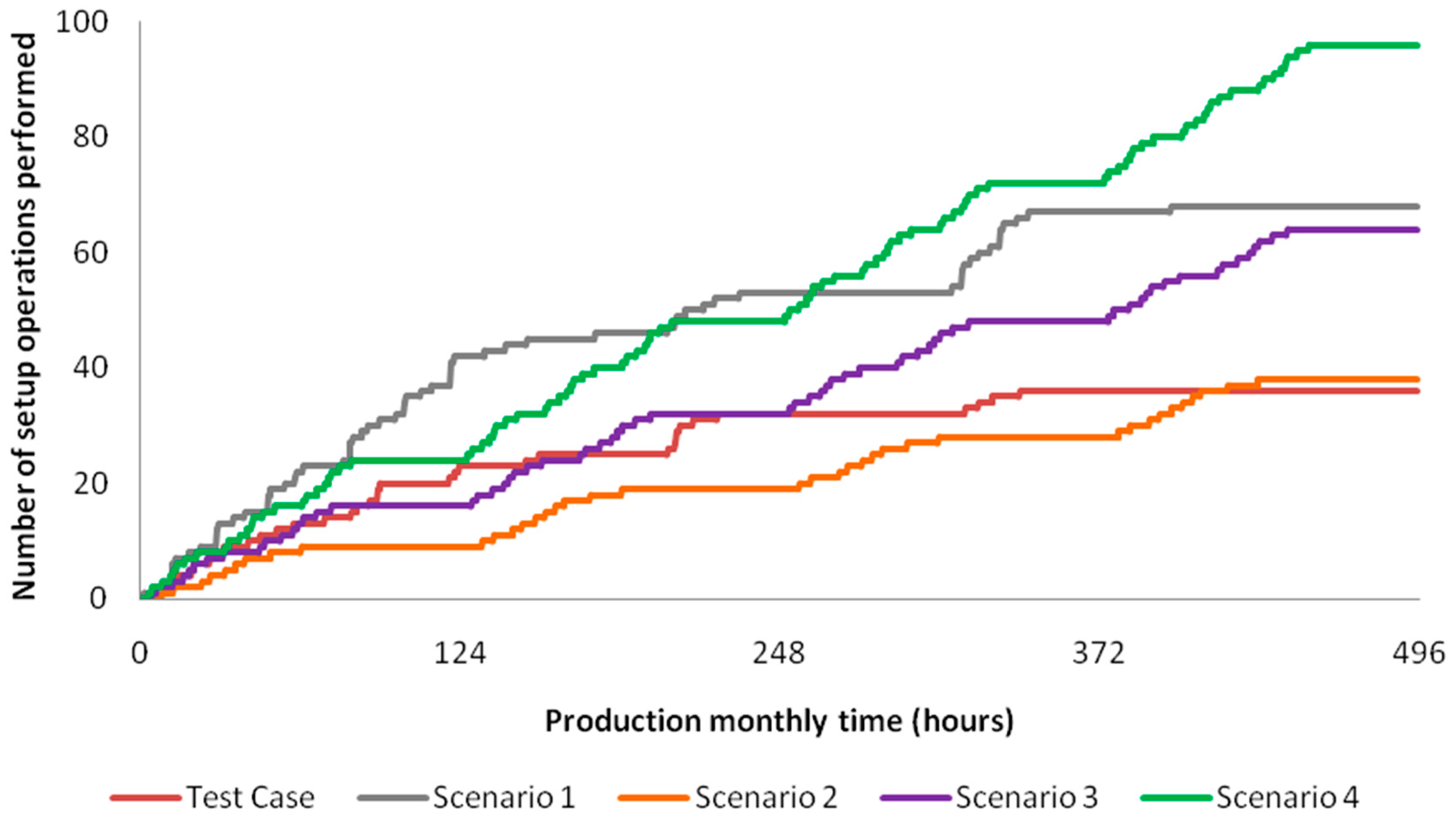

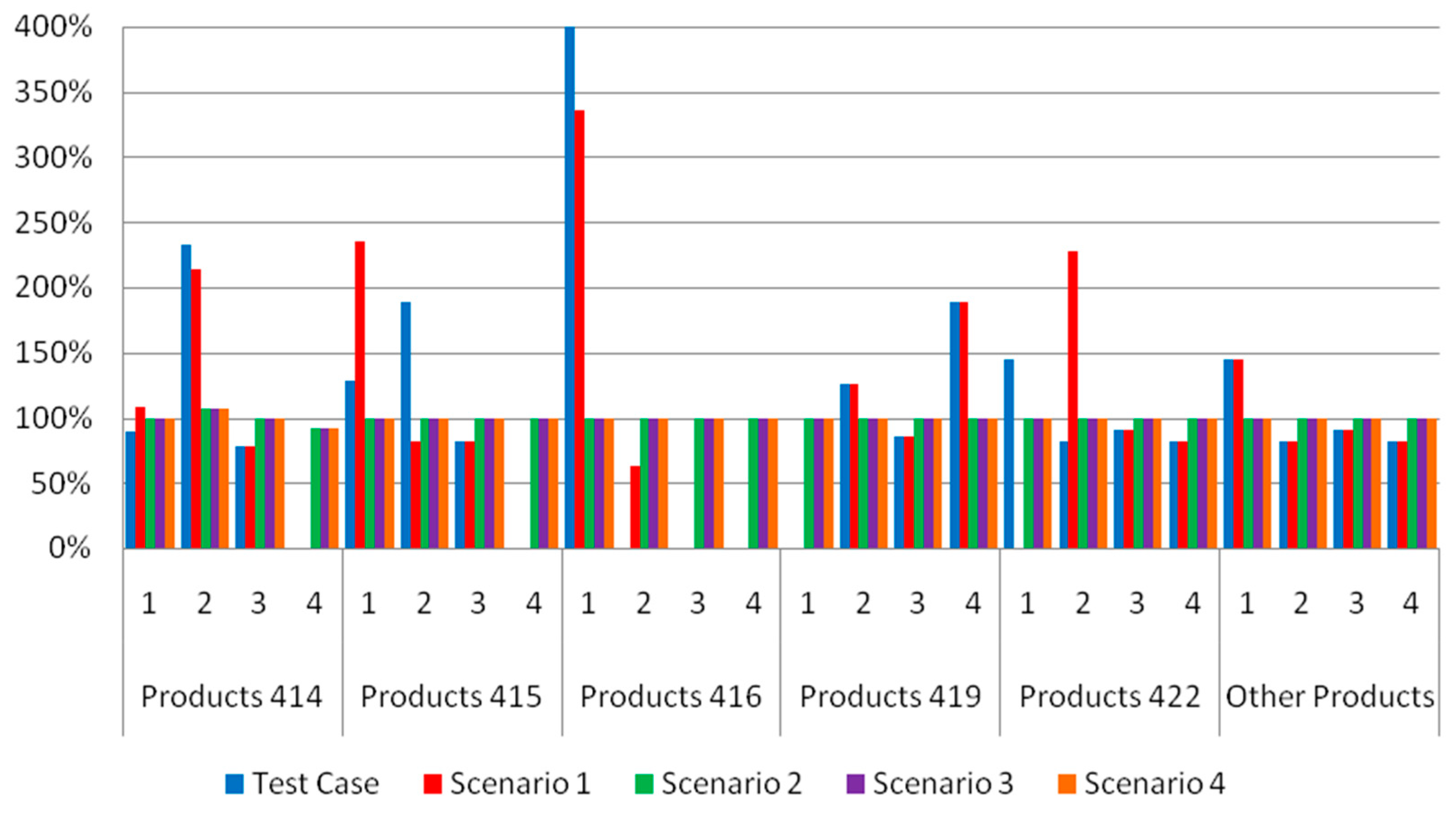

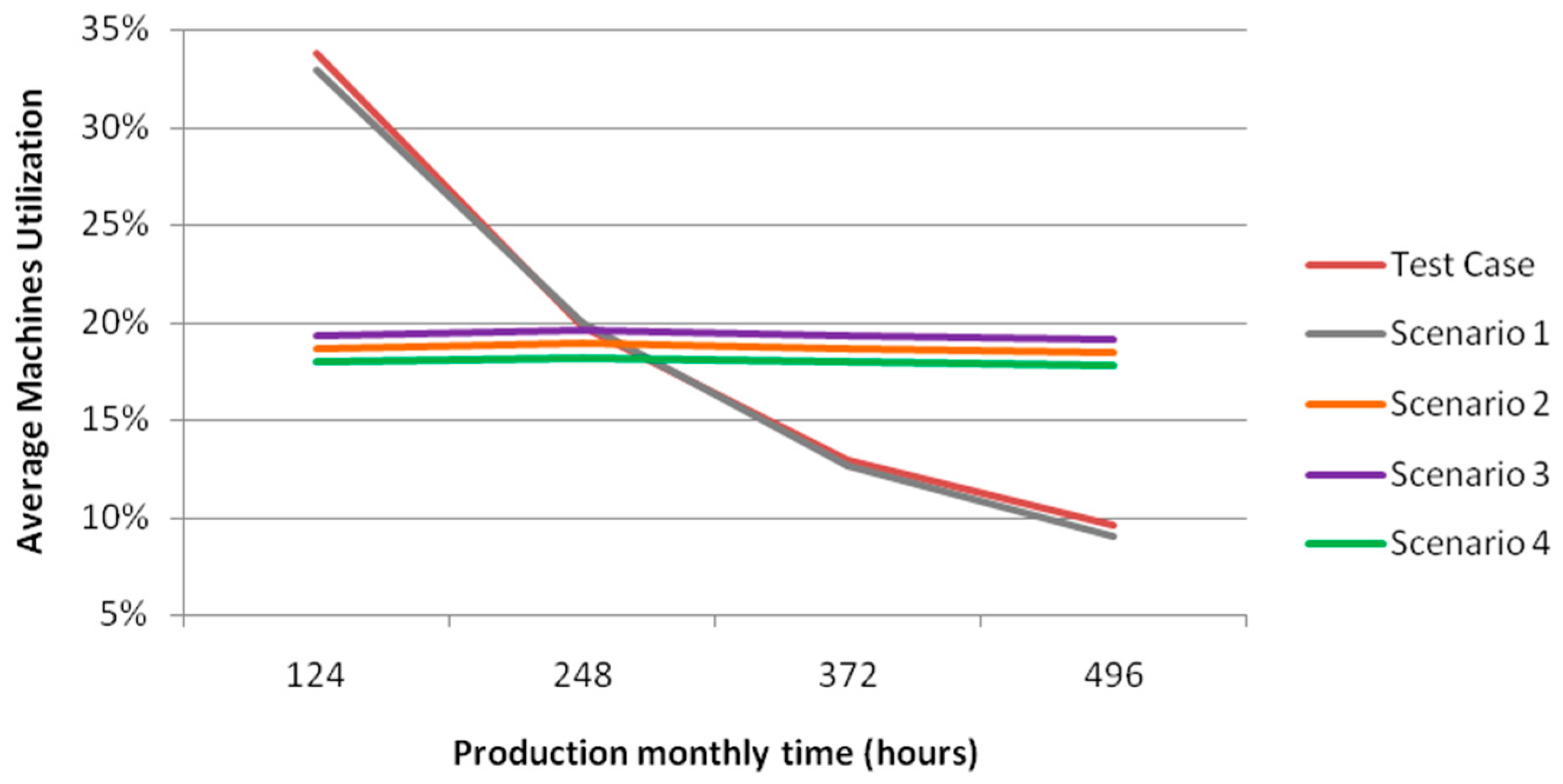

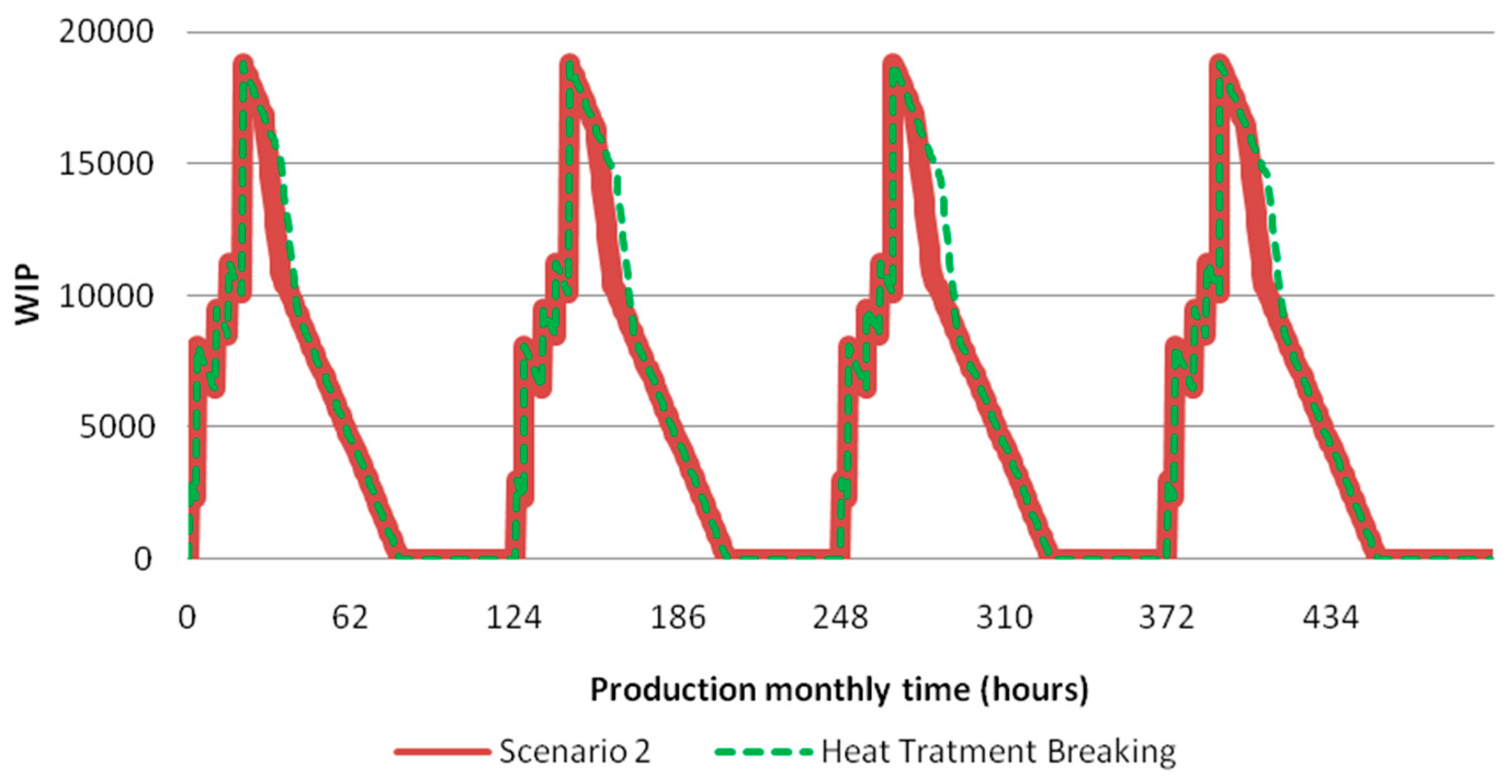

5.3. Framework Performance

5.4. Discussion and Implementation

5.4.1. Technical Details of Implementation

5.4.2. General Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Leitao, P.; Rodrigues, N.; Barbosa, J.; Turrin, C.; Pagani, A. Intelligent products: The grace experience. Control Eng. Pract. 2015, 42, 95–105. [Google Scholar] [CrossRef]

- Leitao, P.; Colombo, A.W.; Karnouskos, S. Industrial automation based on cyber-physical systems technologies: Prototype implementations and challenges. Comput. Ind. 2016, 81, 11–25. [Google Scholar] [CrossRef]

- Vogel-Heuser, B.; Lee, J.; Leitao, P. Agents enabling cyber-physical production systems. AT-Autom. 2015, 63, 777–789. [Google Scholar] [CrossRef]

- Lee, E.A.; Seshia, S.A. Introduction to Embedded Systems: A Cyber-Physical Systems Approach; MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Boulekrouche, B.; Jabeur, N.; Alimazighi, Z. Toward integrating grid and cloud-based concepts for an enhanced deployment of spatial data warehouses in cyber-physical system applications. J. Ambient Intell. Humaniz. Comput. 2016, 7, 475–487. [Google Scholar] [CrossRef]

- Toader, F.A. Production scheduling in flexible manufacturing systems: A state of the art survey. J. Electr. Eng. Electron. Control Comput. Sci. 2017, 1, 1–6. [Google Scholar]

- Xiang, W.; Lee, H.P. Ant colony intelligence in multi-agent dynamic manufacturing scheduling. Eng. Appl. Artif. Intell. 2008, 21, 73–85. [Google Scholar] [CrossRef]

- Hall, N.G.; Potts, C.N. Rescheduling for new orders. Oper. Res. 2004, 52, 440–453. [Google Scholar] [CrossRef]

- Asadzadeh, L. A local search genetic algorithm for the job shop scheduling problem with intelligent agents. Comput. Ind. Eng. 2015, 85, 376–383. [Google Scholar] [CrossRef]

- Vinod, V.; Sridharan, R. Scheduling a dynamic job shop production system with sequence-dependent setups: An experimental study. Robot Comput. Integr. Manuf. 2008, 24, 435–449. [Google Scholar] [CrossRef]

- Kundakcı, N.; Kulak, O. Hybrid genetic algorithms for minimizing makespan in dynamic job shop scheduling problem. Comput. Ind. Eng. 2016, 96, 31–51. [Google Scholar] [CrossRef]

- Wang, S.Y.; Wan, J.F.; Zhang, D.Q.; Li, D.; Zhang, C.H. Towards smart factory for industry 4.0: A self-organized multi-agent system with big data based feedback and coordination. Comput. Netw. 2016, 101, 158–168. [Google Scholar] [CrossRef]

- Leitão, P. Agent-based distributed manufacturing control: A state-of-the-art survey. Eng. Appl. Artif. Intell. 2009, 22, 979–991. [Google Scholar] [CrossRef]

- Kouider, A.; Bouzouia, B. Multi-agent job shop scheduling system based on co-operative approach of idle time minimisation. Int. J. Prod. Res. 2012, 50, 409–424. [Google Scholar] [CrossRef]

- Merdan, M.; Moser, T.; Sunindyo, W.; Biffl, S.; Vrba, P. Workflow scheduling using multi-agent systems in a dynamically changing environment. J. Simul. 2013, 7, 144–158. [Google Scholar] [CrossRef]

- Shaw, M.J. Dynamic scheduling in cellular manufacturing systems: A framework for networked decision making. J. Manuf. Syst. 1988, 7, 83–94. [Google Scholar] [CrossRef]

- Shen, W.; Hao, Q.; Yoon, H.J.; Norrie, D.H. Applications of agent-based systems in intelligent manufacturing: An updated review. Adv. Eng. Inform. 2006, 20, 415–431. [Google Scholar] [CrossRef]

- Lou, P.; Ong, S.K.; Nee, A.Y.C. Agent-based distributed scheduling for virtual job shops. Int. J. Prod. Res. 2010, 48, 3889–3910. [Google Scholar] [CrossRef]

- Shen, W. Distributed manufacturing scheduling using intelligent agents. IEEE Intell. Syst. 2002, 17, 88–94. [Google Scholar] [CrossRef]

- Leitão, P.; Mařík, V.; Vrba, P. Past, Present and future of industrial agent applications. IEEE Trans. Ind. Inform. 2013, 9, 2360–2372. [Google Scholar] [CrossRef]

- Choi, S.S.; Jung, K.; Kulvatunyou, B.; Morris, K.C. An analysis of technologies and standards for designing smart manufacturing systems. J. Res. Natl. Inst. Stand. Technol. 2016, 121, 422–433. [Google Scholar] [CrossRef]

- Frey, D.; Nimis, J.; Worn, H.; Lockemann, P. Benchmarking and robust multi-agent-based production planning and control. Eng. Appl. Artif. Intell. 2003, 16, 307–320. [Google Scholar] [CrossRef]

- Leusin, M.E.; Kück, M.; Frazzon, E.M.; Maldonado, M.U.; Freitag, M. Potential of a multi-agent system approach for production control in smart factories. In Proceedings of the 16th IFAC Symposium on Information Control Problems in Manufacturing (INCOM), Bergamo, Italy, 11–13 June 2018; pp. 1459–1464. [Google Scholar]

- Borshchev, A. The Big Book of Simulation Modeling: Multimethod Modeling with Anylogic 6; Any Logic North America: Chicago, IL, USA, 2013. [Google Scholar]

- Ennigrou, M.; Ghedira, K. New local diversification techniques for flexible job shop scheduling problem with a multi-agent approach. Auton. Agents Multi-Agent Syst. 2008, 17, 270–287. [Google Scholar] [CrossRef]

- Jain, A.S.; Meeran, S. Deterministic job-shop scheduling: Past, present and future. Eur. J. Oper. Res. 1999, 113, 390–434. [Google Scholar] [CrossRef]

- Ghedira, K.; Ennigrou, M. How to schedule a job shop problem through agent cooperation. In Artificial Intelligence: Methodology, Systems, Applications, Proceedings; Cerri, S.A., Dochev, D., Eds.; Springer: Berlin, Germany, 2000; Volume 1904, pp. 132–141. [Google Scholar]

- Kück, M.; Ehm, J.; Hildebrandt, T.; Freitag, M.; Frazzon, E.M. Potential of data-driven simulation-based optimization for adaptive scheduling and control of dynamic manufacturing systems. In Proceedings of the 2016 Winter Simulation Conference, Washington, DC, USA, 11–14 December 2016; pp. 2820–2831. [Google Scholar]

- Sellers, D.W. A survey of approaches to the job shop scheduling problem. In Proceedings of the Southeastern Symposium on System Theory, Baton Rouge, LA, USA, 31 March–2 April 1996; p. 396. [Google Scholar]

- Durasević, M.; Jakobović, D. A survey of dispatching rules for the dynamic unrelated machines environment. Expert Syst. Appl. 2018, 113, 555–569. [Google Scholar] [CrossRef]

- Ouelhadj, D.; Petrovic, S. A survey of dynamic scheduling in manufacturing systems. J. Sched. 2009, 12, 417. [Google Scholar] [CrossRef]

- Sabuncuoglu, I.; Bayız, M. Analysis of reactive scheduling problems in a job shop environment. Eur. J. Oper. Res. 2000, 126, 567–586. [Google Scholar] [CrossRef]

- Rajabinasab, A.; Mansour, S. Dynamic flexible job shop scheduling with alternative process plans: An agent-based approach. Int. J. Adv. Manuf. Technol. 2011, 54, 1091–1107. [Google Scholar] [CrossRef]

- Zhang, G.; Ye, D. A note on on-line scheduling with partial information. Comput. Math. Appl. 2002, 44, 539–543. [Google Scholar] [CrossRef]

- Li, R.-K.; Shyu, Y.-T.; Adiga, S. A heuristic rescheduling algorithm for computer-based production scheduling systems. Int. J. Prod. Res. 1993, 31, 1815–1826. [Google Scholar] [CrossRef]

- Renna, P. Job shop scheduling by pheromone approach in a dynamic environment. Int. J. Comput. Integr. Manuf. 2010, 23, 412–424. [Google Scholar] [CrossRef]

- Mehta, S.V. Predictable scheduling of a single machine subject to breakdowns. Int. J. Comput. Integr. Manuf. 1999, 12, 15–38. [Google Scholar] [CrossRef]

- Vieira, G.E.; Herrmann, J.W.; Lin, E. Analytical models to predict the performance of a single-machine system under periodic and event–driven rescheduling strategies. Int. J. Prod. Res. 2000, 38, 1899–1915. [Google Scholar] [CrossRef]

- Figueira, G.; Almada-Lobo, B. Hybrid simulation-optimization methods: A taxonomy and discussion. Simul. Model. Pract. Theor. 2014, 46, 118–134. [Google Scholar] [CrossRef]

- Owliya, M.; Saadat, M.; Jules, G.G.; Goharian, M.; Anane, R. Agent-based interaction protocols and topologies for manufacturing task allocation. IEEE Trans. Syst. Man Cybern. Syst. 2013, 43, 38–52. [Google Scholar] [CrossRef]

- Shen, W.; Wang, L.; Hao, Q. Agent-based distributed manufacturing process planning and scheduling: A state-of-the-art survey. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2006, 36, 563–577. [Google Scholar] [CrossRef]

- Barber, K.S.; Liu, T.H.; Goel, A.; Ramaswamy, S. Flexible reasoning using sensible agent-based systems: A case study in job flow scheduling. Prod. Plan. Control 1999, 10, 606–615. [Google Scholar] [CrossRef]

- Scholz-Reiter, B.; Freitag, M. Autonomous processes in assembly systems. CIRP Ann. Manuf. Technol. 2007, 56, 712–729. [Google Scholar] [CrossRef]

- Scholz-Reiter, B.; Kolditz, J.; Hildebrandt, T. Engineering autonomously controlled logistic systems. Int. J. Prod. Res. 2009, 47, 1449–1468. [Google Scholar] [CrossRef]

- Li, D.N.; Wang, Y.; Xiao, G.X.; Tang, J.F. Dynamic parts scheduling in multiple job shop cells considering intercell moves and flexible routes. Comput. Oper. Res. 2013, 40, 1207–1223. [Google Scholar] [CrossRef]

- Cicirello, V.A.; Smith, S.F. Wasp-like agents for distributed factory coordination. Auton. Agents Multi-Agent Syst. 2004, 8, 237–266. [Google Scholar] [CrossRef]

- Caridi, M.; Cavalieri, S. Multi-agent systems in production planning and control: An overview. Prod. Plan. Control 2004, 15, 106–118. [Google Scholar] [CrossRef]

- Wong, T.N.; Leung, C.W.; Mak, K.L.; Fung, R.Y.K. Dynamic shopfloor scheduling in multi-agent manufacturing systems. Expert Syst. Appl. 2006, 31, 486–494. [Google Scholar] [CrossRef]

- Wong, T.N.; Zhang, S.C.; Wang, G.; Zhang, L.P. Integrated process planning and scheduling—multi-agent system with two-stage ant colony optimisation algorithm. Int. J. Prod. Res. 2012, 50, 6188–6201. [Google Scholar] [CrossRef]

- Wong, T.N.; Leungy, C.W.; Mak, K.L.; Fung, R.Y.K. Integrated process planning and scheduling/rescheduling—An agent-based approach. Int. J. Prod. Res. 2006, 44, 3627–3655. [Google Scholar] [CrossRef]

- Scholz-Reiter, B.; De Beer, C.; Freitag, M.; Jagalski, T. Bio-inspired and pheromone-based shop-floor control. Int. J. Comput. Integr. Manuf. 2008, 21, 201–205. [Google Scholar] [CrossRef]

- Duffie, N.A. Synthesis of heterarchical manufacturing systems. Comput. Ind. 1990, 14, 167–174. [Google Scholar] [CrossRef]

- Giannakis, M.; Louis, M. A multi-agent based system with big data processing for enhanced supply chain agility. J. Enterp. Inf. Manag. 2016, 29, 706–727. [Google Scholar] [CrossRef]

- Semwal, T.; Nair, S.B. AgPi: Agents on Raspberry Pi. Electronics 2016, 5, 72. [Google Scholar] [CrossRef]

- Reaidy, P.J.; Gunasekaran, A.; Spalanzani, A. Bottom-up approach based on Internet of Things for order fulfillment in a collaborative warehousing environment. Int. J. Prod. Econ. 2015, 159, 29–40. [Google Scholar] [CrossRef]

- Cupek, R.; Ziebinski, A.; Huczala, L.; Erdogan, H. Agent-based manufacturing execution systems for short-series production scheduling. Comput. Ind. 2016, 82, 245–258. [Google Scholar] [CrossRef]

- Hellingrath, B.; Pereira, C.E.; Espíndola, D.; Frazzon, E.M.; Cordes, A.-K.; Saalmann, P.; Zuccolotto, M. On the integration of intelligent maintenance and spare parts supply chain management. IFAC-PapersOnLine 2015, 48, 983–988. [Google Scholar] [CrossRef]

- Mansour Fallah, S. Multi agent based control architectures. In Proceedings of the 26th DAAAM International Symposium, Vienna, Austria, 23–30 November 2016; pp. 1166–1170. [Google Scholar] [CrossRef]

- Hwang, G.; Lee, J.; Park, J.; Chang, T.W. Developing performance measurement system for Internet of Things and smart factory environment. Int. J. Prod. Res. 2017, 55, 2590–2602. [Google Scholar] [CrossRef]

- Cottyn, J.; Van Landeghem, H.; Stockman, K.; Derammelaere, S. A method to align a manufacturing execution system with Lean objectives. Int. J. Prod. Res. 2011, 49, 4397–4413. [Google Scholar] [CrossRef]

- Saenz de Ugarte, B.; Artiba, A.; Pellerin, R. Manufacturing execution system—A literature review. Prod. Plan. Control 2009, 20, 525–539. [Google Scholar] [CrossRef]

- Shaojun, W.; Gang, W.; Min, L.; Guoan, G. Enterprise resource planning implementation decision & optimization models. J. Syst. Eng. Electron. 2008, 19, 513–521. [Google Scholar]

- Vidoni, M.C.; Vecchietti, A.R. An intelligent agent for ERP’s data structure analysis based on ANSI/ISA-95 standard. Comput. Ind. 2015, 73, 39–50. [Google Scholar] [CrossRef]

- Lee, H.; Ryu, K.; Son, Y.J.; Cho, Y. Capturing Green Information and Mapping with IVIES Functions for Increasing Manufacturing Sustainability. Int. J. Precis. Eng. Manuf. 2014, 15, 1709–1716. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Qu, T.; Ho, O.; Huang, G.Q. Real-time work-in-progress management for smart object-enabled ubiquitous shop-floor environment. Int. J. Comput. Integr. Manuf. 2011, 24, 431–445. [Google Scholar] [CrossRef]

- Nagorny, K.; Colombo, A.W.; Schmidtmann, U. A service- and multi-agent-oriented manufacturing automation architecture an IEC 62264 level 2 compliant implementation. Comput. Ind. 2012, 63, 813–823. [Google Scholar] [CrossRef]

- Chu, Y.F.; You, F.Q. Integrated Scheduling and Dynamic Optimization by Stackelberg Game: Bilevel Model Formulation and Efficient Solution Algorithm. Ind. Eng. Chem. Res. 2014, 53, 5564–5581. [Google Scholar] [CrossRef]

- Popovics, G.; Pfeiffer, A.; Monostori, L. Generic data structure and validation methodology for simulation of manufacturing systems. Int. J. Comput. Integr. Manuf. 2016, 29, 1272–1286. [Google Scholar] [CrossRef]

- Blum, C.; Roli, A. Metaheuristics in combinatorial optimization: Overview and conceptual comparison. ACM Comput. Surv. CSUR 2003, 35, 268–308. [Google Scholar] [CrossRef]

- Pfeiffer, A.; Kádár, B.; Monostori, L. Stability-oriented evaluation of rescheduling strategies, by using simulation. Comput. Ind. 2007, 58, 630–643. [Google Scholar] [CrossRef]

- Vieira, G.E.; Herrmann, J.W.; Lin, E. Rescheduling manufacturing systems: A framework of strategies, policies, and methods. J. Sched. 2003, 6, 39–62. [Google Scholar] [CrossRef]

- Barnett, L.; Rahimifard, S.; Newman, S. Distributed scheduling to support mass customization in the shoe industry. Int. J. Comput. Integr. Manuf. 2004, 17, 623–632. [Google Scholar] [CrossRef]

- Zuravlyov, V.; Matrosov, A. Multi-agent system built using RFID technology. In Proceedings of the 6th International Conference on Electrical and Control Technologies, Kaunas, Lithuania, 5–6 May 2011; pp. 16–21. [Google Scholar]

- Baudin, M.; Rao, A. RFID Applications in Manufacturing. 2000. Available online: https://www.researchgate.net/profile/Michel_Baudin/publication/267218891_RFID_applications_in_manufacturing/links/54b86f380cf2c27adc48b475.pdf (accessed on 4 November 2018).

- Zhao, F.; Wang, J.; Wang, J.; Jonrinaldi, J. A dynamic rescheduling model with multi-agent system and its solution method. Strojniski Vestn. J. Mech. Eng. 2012, 58, 81–92. [Google Scholar] [CrossRef]

- Zattar, I.C.; Ferreira, J.C.E.; Rodrigues, J.G.G.; De Sousa, C.H.B. A multi-agent system for the integration of process planning and scheduling using operation-based time-extended negotiation protocols. Int. J. Comput. Integr. Manuf. 2010, 23, 441–452. [Google Scholar] [CrossRef]

- Asadzadeh, L.; Zamanifar, K. An agent-based parallel approach for the job shop scheduling problem with genetic algorithms. Math. Comput. Model. 2010, 52, 1957–1965. [Google Scholar] [CrossRef]

- Guo, L.; Wang, S.; Kang, L.; Cao, Y. Agent-based manufacturing service discovery method for cloud manufacturing. Int. J. Adv. Manuf. Technol. 2015, 81, 2167–2181. [Google Scholar] [CrossRef]

- Yang, L.; Sun, X.; Peng, L.; Yao, X.; Chi, T. An agent–based artificial bee colony (ABC) algorithm for hyperspectral image endmember extraction in parallel. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2015, 8, 4657–4664. [Google Scholar] [CrossRef]

| Decision Mode | Advantages | Disadvantages |

|---|---|---|

| Simulation-based |

|

|

| Artificial intelligence |

|

|

| Agent-based or Multi-Agent Systems |

|

|

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leusin, M.E.; Frazzon, E.M.; Uriona Maldonado, M.; Kück, M.; Freitag, M. Solving the Job-Shop Scheduling Problem in the Industry 4.0 Era. Technologies 2018, 6, 107. https://doi.org/10.3390/technologies6040107

Leusin ME, Frazzon EM, Uriona Maldonado M, Kück M, Freitag M. Solving the Job-Shop Scheduling Problem in the Industry 4.0 Era. Technologies. 2018; 6(4):107. https://doi.org/10.3390/technologies6040107

Chicago/Turabian StyleLeusin, Matheus E., Enzo M. Frazzon, Mauricio Uriona Maldonado, Mirko Kück, and Michael Freitag. 2018. "Solving the Job-Shop Scheduling Problem in the Industry 4.0 Era" Technologies 6, no. 4: 107. https://doi.org/10.3390/technologies6040107

APA StyleLeusin, M. E., Frazzon, E. M., Uriona Maldonado, M., Kück, M., & Freitag, M. (2018). Solving the Job-Shop Scheduling Problem in the Industry 4.0 Era. Technologies, 6(4), 107. https://doi.org/10.3390/technologies6040107