Abstract

In recent years, organic solar cells became more attractive due to their flexible power devices and the potential for low-cost manufacturing. Inkjet printing is a very potential manufacturing technique of organic solar cells because of its low material usage, flexibility, and large area formation. In this paper, we presented an overall review on the inkjet printing technology as well as advantages of inkjet-printing, comparison of inkjet printing with other printing technologies and its potential for organic solar cells (OSCs). Here we highlighted in more details about the viability of environment-friendly and cost-effective, non-halogenated indium tin oxide (ITO) free large scale roll to roll production of the OSC by inkjet printing technology. The challenges of inkjet printing like the viscosity limitations, nozzle clogging, coffee ring effect, and limitation of printability as well as dot spacing are also discussed. Lastly, some of the improvement strategies for getting the higher efficiency of the OSCs have been suggested.

1. Introduction

The increasing concern about global warming, the upsurge of oil price, and pollution of petroleum energy has led scientists to search for cost-effective energy sources, for example, photovoltaics. The sun delivers about 174 quadrillion watt-hours of energy onto the earth in every hour, which is greater than the energy demand of the entire human population in one whole year. Solar energy is the source of fresh, plentiful, harmless and environment-friendly energy [1,2].

Nowadays, the organic solar cells (OSC) is acknowledged as a very encouraging technology because of its simple fabrication method, cost effectiveness, excellent mechanical properties, thermal budget and high processing speed [3]. However, there are still some concerns that should be addressed. Although indium tin oxide (ITO) substitution has been started as a transparent electrode, these novel activities yet to be executed since these initiatives are in their nascent phase. Additionally, for the preparation of conjugated polymers in OSCs usually, poisonous and halogenated solvents are utilized, which should be substituted by more harmless solvents. For the large area production of OSCs, one of the essentials that must be considered is environmental friendliness. Furthermore, for roll to roll production of large area OSCs, it is necessary to improve the registration throughout roll to roll procedure because it is utilized to adjust the diverse layers [4].

Inkjet printing is considered to be the following emerging solar cell fabrication technology because of high material utilization rate, cost-effectiveness, and flexibility [5]. An active layer of Poly(3-hexylthiophene):[6,6] phenyl C61-butyric acid methylester (P3HT:PCBM) has been developed in polymer solar cells by using inkjet printing [6]. Inkjet-printed OSCs has a great future ahead, however, we need to address the challenges of utilizing inkjet printing technique. There are researches going on to improve the efficiency of inkjet-printed OSCs as well as to solve the coffee ring effect, viscosity limitations, film uniformity, nozzle clogging, etc.

In this paper, we presented a thorough study on the inkjet fabrication technique followed by the advantages of inkjet printing technology. In the next section, we discussed more on inkjet-printed OSCs. Then, we discussed the recent developments of inkjet-printed organic solar cells with respect to environment friendliness, cost effectiveness, and roll to roll production. So here we presented more about organic photovoltaic (OPV) cells without halogen and ITO and also the viability of roll to roll production of OSC by inkjet printing. After that, we presented and the challenges of inkjet printing such as the coffee ring effect and dot spacing, viscosity limitations and nozzle clogging. We also suggested some of the improvement strategies for getting the higher efficiency of the OSC.

2. Introduction to Inkjet Printing Technology

The scope of inkjet printing technique and the essential factors are analyzed around here, including an extensive variety of ways to manage the digitally controlled development and circumstance of little fluid drops. Inkjet printing is characterized as continuous inkjet printing (CIJ), field- or flow-induced tip streaming (FITS) and drops on demand (DoD) printing where CIJ and DoD are recognized by generation method of the drops [7].

CIJ printing is the ejection of nonstop flow of fluid through a nozzle that separates under surface tension forces. In CIJ applications this normal separation under surface tension forces can be improved by balancing the flow at a suitable frequency, regularly done by a piezoelectric transducer at the rear of the orifice. For a constant flow of ink drops to be utilized for printing, singular drops should be “controlled” to a specific arrival spot with a specific end goal to deliver a printed design. This is typically accomplished by initiating an electrical charge on a portion of the drops, which are then avoided from the primary axis of the flow as they go through an electrostatic field. Undesirable drops are gotten in a "drain" and the fluid recycled through the system. CIJ has its concentration in the high-speed graphical applications, industrial labeling, and engraving of individual data [8].

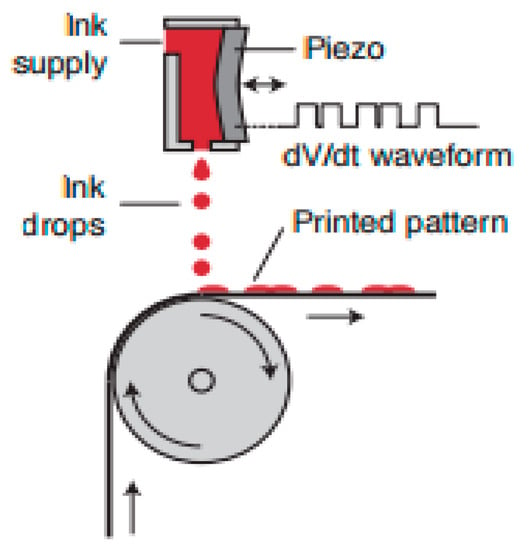

Drop-on-demand is more used and popular method because of its more modest extent and high placement correctness. Ink droplets are ejected by an acoustic pulse from a repository through an orifice. This pulse could be produced either thermally or piezoelectrically. In thermal DoD inkjet printers ink is warmed locally to frame a quickly growing vapor bubble, which discharges an ink droplet. In Thermal DoD water is typically utilized as a solvent and might be consequently imposing limitations on the quantity of polymers, which could be printed utilizing this procedure, despite the fact that non-fluid thermal inks are accessible. Piezoelectric DoD inkjet imprinting then again depends on the arrangement of a few piezoelectric material to bring about an abrupt volume change and subsequently create an acoustic pulse. Piezoelectric DoD is on a basic level, suited to an assortment of solvents [9]. In DoD inkjet printing, piezoelectrically incited transducers are used to eject droplets from the orifice. A streamlined diagram appears in Figure 1. A mechanical motivation is initiated in the piezo due to a terminating pulse in the form of a voltage waveform. This excitation proliferates a pressure pulsate through the ink enclosed in the ink compartment. When the pressure surpasses at the edge of the outlet, the droplets propelled from the orifice. Ink remains inside the ink compartment because of surface tension and static pressure that balances out the phenomenon named meniscus, which is the curved upper surface of a non-turbulent fluid, at the orifice [10]. A comparative motivation strategy is accomplished utilizing micro-electromechanical systems (MEMS) and electrostatic forces.

Figure 1.

Simplified schematics of drop-on-demand piezoelectric inkjet. Reprinted with permission from [4].

The DoD approach is usually utilized for precise deposition of inks on the definite place. This printing technology removes the requirement for post-patterning of the coated films and permits an exact printing with micrometric resolution [11].

Inkjet printing relies fundamentally on the conduct of catapulted printed drops after the streaming activity. Those streaming drops are influenced by a few components that include jetting characteristics and attributes of the encompassing [12].

3. Advantages of Inkjet Printing

Because of low material waste production along with additive deposition of materials, Inkjet printing is becoming popular in the field of scientific research. For the ease of material handling, this method is now actively being used to build an efficient solar cell with different material compositions [13]. Rather than other solution deposition methods, for example, spin-coating, screen printing, gravure printing and doctor blading, this method is a mask-less and contact-free process [12,14]. Considering the fact that large area formation and roll-to-roll (R2R) processing can be done by inkjet printing, it can be a good choice for preparing homogeneous and thin layers of active materials for constructing organic solar cell [13]. Inkjet printing permits deposition of active material solutions on definite areas of the substrate which are already beneficiary to incorporate layers onto substrates containing layers of other components, which is an important advantage for the fabrication of OSCs [15,16,17,18,19,20]. In solar cell module, adjacent solar cell blocks are electrically connected in series with each other. For this type of interconnection of an efficient solar cell module, simple designing of active layers is very important, which can be obtained by using inkjet printing technology. As an example of using inkjet printing to make this module flexible in terms of shape and easy patterning, Eggenhuisen et al. printed Christmas card having fully inkjet-printed OPV Christmas trees with an active area of 6.5 cm2 [21]. The printed Christmas trees were functional however the performance was low due to the non-optimal series resistance of inkjet-printed Ag grid.

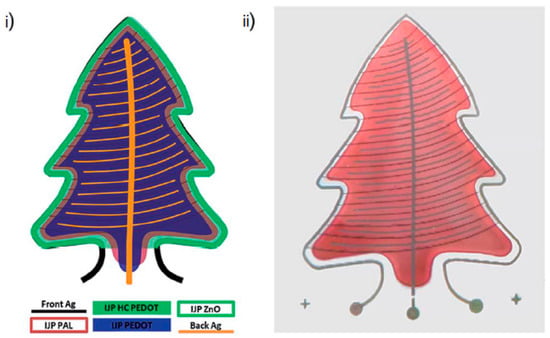

After further research in another study, Eggenhuisen et al. showed that by using inkjet printer it is possible to print different types of sizes and shapes as they printed an OPV Christmas tree on a Christmas card [22]. They again proved that freedom of design is another great advantage of inkjet printing. For designing the Christmas tree they used Poly(3,4-ethylenedioxythiophene) (PEDOT) as hole collecting layer and ZnO as electron transport layer and utilized front and back Ag electrode. In Figure 2, the Christmas tree has been shown. Figure 2. (i) Is the layout diagram of printed layers and Figure 2. (ii) Is the picture of the finished product. The active layer of the tree was 6.24 cm2 and P3HT: PCBM photoactive layer showed an open circuit voltage (VOC) of 0.46 V as well as fill factor of 28.2%.

Figure 2.

A flexible organic solar cell in the form of a Christmas tree, (i) layout diagram of printed layers; (ii) A snapshot of completely inkjet-printed organic photovoltaic (OPV) Christmas tree [22].

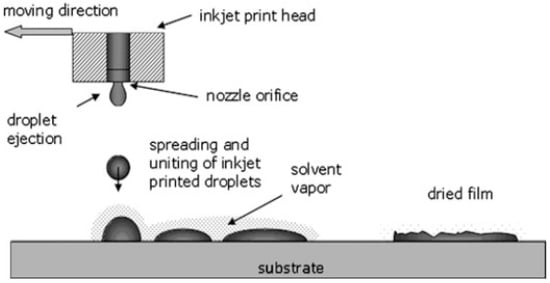

In this technology, the DoD process can print selected areas with high accuracy, which means post-patterning is not needed. Recently, Eggenhuisen et al. reported 4.1% power conversion efficiency (PCE) of the organic solar cell prepared by fully inkjet printing technology [22]. Also, by using this printing method the printing pattern can be easily changed with a printing speed as high as 1000 m2/h [6]. For organic devices, the use of inkjet printing technology is exceptionally encouraging because of the compatibility with different substrates [11]. As appeared in the in Figure 3 [14], the ink has been removed from a head to the substrate without direct contact with the surface [23].

Figure 3.

Standard film development by inkjet printing. Reprinted with permission from [14].

3.1. Advantages of Inkjet Printing over Screen Printing

Though screen printing has demonstrated its excellence in printing thick films, it exhibits drawbacks in speed because of noteworthy drying prerequisites additionally it requires huge quantity of material [24,25]. Screen printing is especially two kinds, flatbed screen printing, and rotary screen printing. Flatbed screen printing has shown excellence in printing quality but at the same time is the slowest and it cannot print continuous patterns. In flatbed screen printing ink utilization is high and it’s not possible to avoid waste because a considerable measure of ink must be on the screen to empower appropriate ink flooding over the entire screen. Overabundance ink ought not to be utilized again in production if it has been presented to air for a really long time. Despite the fact that rotary screen printing has faster speed and can have a continuous pattern, the ink utilization is somewhat higher and ink wastage is similar to the flatbed [26].

Screen printing additionally represents a couple of difficulties for building up all layers of a flexible device. These consist of the high wet thickness of the film, high viscosity ink requirements and stability of the ink formulation as well as the inks can dry out on the mask, which can degrade the design of the mask of the screen [11,27].

The most important benefit of the inkjet printing procedure is the opportunity to modify the printed design effectively on a computer, which does not need to make a physical printing structure (i.e., it is a whole digital process). It is also the main difference between inkjet printing and screen printing [28]. Screen printing needs a mask to print each layer but the inkjet printing technique does not need any mask. Inkjet printing is a single step procedure producing no wastage as well as material efficient. It also does not need the high viscosity ink.

3.2. Comparison of Inkjet Printing with Screen, Gravure and Flexographic Printing

In Table 1. Comparison of inkjet printing with screen, Gravure and Flexographic printing has been shown.

Table 1.

Comparison of inkjet printing with screen, Gravure and Flexographic printing.

4. Inkjet Printing for OSC

In recent years, Inkjet printing for the manufacturing of OSCs has been expanding considerably. The goal for printing functional layers and Poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) (PEDOT:PSS) electrodes or homogenous intermediary layers while AgNP ink has been ideally utilized as current collecting grid [40,41,42,43]. It has been identified that inkjet printing can generate active layer morphologies performing the same device performance like spin coating. It is necessary for Inkjet to have optimized ink that ought to be printable and have to be suitable for the surface on that it will be printed. For this reason most of the research file on customized solvent systems as well as systems conditions [44]. A summary of inkjet printable inks and suppliers has been shown in Table 2. Additives also have a robust influence on morphology, printability, and optoelectronic characteristic of the PEDOT:PSS and functional layer [40,45]. The robustness of inkjet printing is the advanced digital patterning of subtle line and grid structures, which could be utilized as a part of OPV devices, particularly for front grid electrodes [46,47], in addition to back electrodes [42,43].

Table 2.

Available inkjet printed materials and suppliers.

Despite the fact that inkjet printing has been utilized plenty for OPVs, up scaling in real-world yet to appear as well as for all intents and purposes no reports on R2R printed OPVs with the exception of conductive grid structures exist [51]. The intricacy of huge scale inkjet system which regularly includes recirculation systems, the necessary ink volumes and the drying conditions that affects the layer formation and lastly on the device efficiency has a tendency to be the fundamental bottleneck [52].

5. Recent Developments of Inkjet-Printed OSCs

The major concern with regard to scale up of all inkjet-printed organic photovoltaics (OPVs) are expanding power conversion efficiency of huge region applications, huge area printing, and low resistance electrodes, non-halogenated solvent utilization for printing all layers uses of several nozzles in industrialized print heads and exhibition of freedom of form and pattern [22]. In Table 3, the power conversion efficiency (PCE) of inkjet-printed OSCs with VOC, short-circuit current (JSC) and fill factor (FF) have been shown.

Table 3.

Power conversion efficiency (PCE) table of inkjet-printed organic solar cells (OSCs).

In this section, we discussed more on the impact of halogen and ITO on organic solar cells as well as how to replace them with more convenient solvent and material respectively. Large area roll to roll production of OPVs is also demonstrated.

5.1. Halogen Free Inkjet-Printed OSCs

Organic Photovoltaic Cell possesses a huge potential for the next generation renewable energy field. For commercialization OPV, two basic things should be considered. One is to elect a faster and economical production method and another is the notion that the selected method should be eco-friendly. The recently introduced production method by inkjet printing is compatible in both ways. But one concern is that, in the lab, for the solution processing of OPV using inkjet printing, still halogenated solvents are used, which will not be eco-friendly in large-scale production [55,56,57,58]. So for industrialization, an alternative deposition method is required using halogen-free solvents. Most recently Zhang et al. have presented a state of art of OSCs using non-halogenated solvents having nearly 9% efficiencies [59]. Here we highlighted more specifically inkjet-printed OSCs using non-halogenated solvents. Recently, by using the combination of several aromatic based solvents with additives, for instance, di-iodooctane, researchers get an auspicious result [60,61]. A maximum efficiency is recorded up to 2.7% for an OPV produced using a poly[9,9-dioctylfluorenyl-2,7-dyil-co-10,12-bis(thiophen-2-y)-3,6-dioxooctyl-11-thia-9,13-diaza-cyclopenta[b]triphenylene](PFDTBTP) photo-active polymer inkjet printing from non-halogenated solvents whereas using halogenated solvents the efficiency reached up to 3.5% [62]. So the efficiency of the OPV produced with halogen-free solvents is still lower. Typical devices can be made of printed PEDOT:PSS (PEDOT) as hole transport layer and poly (3 hexylthiophene):phenyl-C61-butyric acid methyl ester (P3HT:PCBM) utilizing halogen-free solvents. Researchers recently confirmed that this kind of device has overall performance identical to the devices having photo-active layer from spin-coated with ortho-dichlorobenzene [63].

Lim, Guan-Hui, et al. demonstrated a new halogen-free solvent strategy, which is capable of producing desired film macromorphology and good nanomorphology in regioregular poly (3 hexylthiophene):phenyl-C61-butyric acid methyl ester (P3HT:PCBM) model films [64]. The key to this strategy is a good volatile solvent combines with a less volatile miscible poor solvent. This technique is the total reverse of typical low high-boiling-point solvent methodology. They examined four solvent systems which are: chlorobenzene (CB), o-dichlorobenzene (DCB), 3:3:4 vol/vol (v/v) butylbenzene: mesitylene: chlorobenzene (BB:MS:CB), and 8:2 v/v butylbenzene :toluene (BB:TOL). The initial two have regularly been utilized to print P3HT:PCBM and another polymer: fullerene films. The last two solvent systems are combinations that they have created to outline their solvent procedure to print P3HT:PCBM.They got the best inkjet-printed P3HT:PCBM cells with power conversion efficiency of 2.2% versus 1.3% announced for tetralene and which is around seventy-five percent of that found in the typical spin-coated cells from CB or DCB having same photoactive layer synthesis and thickness. This demonstrates a noteworthy improvement for non-halogenated solvents, in spite of the fact that there is still extension for further refinement.

In another study Eggenhuisen et al. effectively utilize inkjet printing for depositing four layers of the OPV cell by replacing unsafe halogenated solvents with more considerate non-halogenated solvents in ink preparation [48]. They showed that inkjet-printed photoactive layer with non-halogenated solvents combinations has merely performance losses in comparison with layer spin-casted from chlorobenzene. They made cells having a four and three inkjet-printed layers individually using an active area of 1 cm2 and 2.0 mW/cm2. Also, they made a huge area module containing 92 cm2 functional region having an efficiency of 0.98%.

5.2. ITO-Free Inkjet-Printed OSCs

ITO has a transparency of 90.2% and conductivity of ρ = 7.2 × 10-4 Ω·cm [65]. Due to these extraordinary properties of ITO, it has been broadly employed as a transparent electrode for organic or polymer light emitting diode (OLED/PLED) and organic photovoltaics (OPVs) [66,67]. But it has some drawbacks also, such as applying in large devices, it is possible to have cracks or delamination and conductivity losses with bending [68]. Again paucity and expensiveness are also major shortcomings. So the objective is to find highly conductive, flexible, transparent and cost-effective material. Various endeavors to replace ITO, especially in OSCs, have been published for instance, PEDOT:PSS [poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate)] [69,70], carbon nanotubes (CNTs) [71,72], ultra thin metal layers [73], graphene [74].

Hösel, et al. show that flextrode substrate which consists of silver-grid/PEDOT:PSS/ZnO is an appealing ITO-free alternate for the quick fabrication of inverted-structure OSCs [75]. They also explained how this flextrode substrate is handled at high speed by printing some layers simultaneously utilizing inline coating and printing. The sheet resistance of the joined silver grid and PEDOT:PSS stack is nearly six times lower than commonplace adaptable ITO-coated Polyethylene terephthalate (PET) substrate. They successfully produced Completely R2R-prepared solar cells and modules with more than 1.8% PCEs on single cells, 1.6% PCE on the active layer and 60% of FFs.

Burgués-Ceballos, et al. replaced indium tin oxide (ITO) in OSCs by inkjet-printed silver grids and showed that the ITO-free solar cells indicated marginally higher performance over the ITO built reference [76]. The most noteworthy FF got in this study was 67% and JSC is nearly the same concerning the ITO-based application, which demonstrates that the grid structure has an indistinguishable current collecting ability from ITO. But still, the PCE is lower than anticipated. It is inferred that JSC is the fundamental driver of this and also great correction in open-circuit voltages (VOC) are acquired. Hence different elements other than the anode might be responsible for this, for example, active material corruption.

5.3. Roll-to-Roll Printing of OSCs

Recently, the requirement for economical and quick preparing of huge areas of thin organic cells has turned into an undeniably vital objective inside various research fields. Large area OPV cells are anticipated to add to energy harvesting when incorporated in exteriors, greenhouses, structures or in broad daylight transport. In this situation, R2R fabrication of OPV will encourage the high throughput at diminished expenses for these applications [77,78]. Recently, the fabrication of top standard conductive silver structures utilizing inkjet printing in fast R2R processing has been shown for various electronic devices [79]. These most recent improvements convey R2R inkjet printing of OPVs a step closer by demonstrating the usefulness of making these devices reliably utilizing a high-volume roll-to-roll technology.

In lab scale, inkjet printers have a limited set of nozzles, which make printers slow to print large areas. It is showed that 3.5 cm width of industrial printhead allows printing of huge areas that are compatible with the R2R production of OPVs. The capability of inkjet printing for huge area OPV was exhibited by the creation of a module with 92 cm2 active area that demonstrated an efficiency of 0.98% [48].

6. Challenges in Inkjet Printing

As a recent technology inkjet printing has some limitations in order to ink formulation as well as processing speeds. Inkjet printing technology works with dropping a small droplet of ink to the substrate layer upon layer, which is relatively complex printing technique. Ink formulation has a great effect on inkjet printing [4]. Low viscosity (4–30 cP) [3] and high surface tension (typically greater than 35 mNm−1) of the ink is required to generate a stream of droplets [3,80]. The standard of jetting is controlled by solvent composition, surface tension, vapor pressure, viscosity as well as the solid content of an ink [81].

6.1. Viscosity Limitations

To enhance the reliability of inkjet printing technique for the roll to roll fabrication of OPVs, an expansion in viscosity is required. Because of restricted polymer solvability, halogen free formulations for bulk heterojunction layers frequently have low viscosity. Still, in the room temperature solubility of generally utilized conjugated polymer/fullerene mixes confines the solute concentrations to 1–2 wt % [82]. This decreased solubility is a concern for the utilization of inkjet printing as it confines the ink viscosity.

Higher viscosities are commonly acquired by

- (i)

- Expanding the polymer concentration.

- (ii)

- Utilizing an alternate solvent system.

- (iii)

- Expanding the molecular weight of the polymer.

Additionally in dilute concentrations high molecular weight polymers have been appeared as beneficial for jetting of low viscosity inks [83]. For instance, it is exhibited that the addition of a low-viscosity 6,13-Bis(triisopropylsilylethynyl) (TIPS)-pentacene solution and the high molecular weight polystyrene would be able to enhance the reproducibility and control of the drop formation of inkjet-printed thin-film transistors [84].

Lamont et al. added polystyrene with the bulk heterojunction inks to investigate the increment of the viscosity for inkjet-printed OSC [49]. They have chosen Polystyrene in view of its dissolvability in the utilized halogen free fragrant solvent system. The execution and printing of P3HT/PCBM photoactive layer inks can be described as the components of polystyrene concentration and three diverse molecular weights. Abatement in the current density has been seen when polystyrene is added to the bulk heterojunction (BHJ) layer. With the cautious thought of both molecular weight and polystyrene concentration, viscosity gains have been advanced to a 1.7-fold increment without fundamentally ruining jetting performance as well as to the detriment of 20% decrease in the manufactured OPVs efficiency. The procedure analyzed here is connected to inks defined with halogen-free solvents that show low viscosities as well as constrained P3HT/PCBM solvability. Despite the fact that this decrease in efficiency is huge, particularly for poorly performing P3HT: PCBM bulk heterojunction their strategy gives a straightforward technique to enhance the procedure capacity of photoactive materials.

6.2. Nozzle Clogging

In inkjet printing, nozzle clogging is one of the predominant challenges, which occurs because of the evaporation of ink in the inkjet printhead. It is reported that for avoiding the coffee ring effect and nozzle clogging in the inkjet print head the inkjet inks require having a high boiling point [63,64]. It is also reported before that for inkjet-printed functional layers utilizing o-dichlorobenzene (oDCB) as a solvent, the particular temperature areas prompt to optimal solvent evaporation and in this way drying behavior of the little amounts of solution shot out line by line onto the substrate and in addition suitable solution viscosity inside the cartridge evade nozzle clogging [85].

Lange, Alexander, et al. carried out UV-VIS spectroscopy on P3HT:PCBM in solution to test the appropriateness of possible solvents for inkjet printing [53]. In this study, the chosen solvents are chlorobenzene, trichlorobenzene, and mesitylene. Chlorobenzene is chosen due to the fact that for P3HT chlorinated solvents are generally great solvents where trichlorobenzene has been picked because of its high boiling point (>200 °C) [86]. In the spectra of P3HT:PCBM which is with chloro- or trichloro-benzene, the nonappearance of aggregation bands demonstrates that the chloro-/trichlorobenzene solvent blend is helpful for inkjet-printing since it’s offering great P3HT solubility and a high boiling point.

Hermerschmidt, et al. displayed inkjet-printed organic solar cells with Si-PCPDTBT:PC70BM mixes possess 3% power conversion efficiency, where Si-PCPDTBT is poly[(4,40-bis(2-ethylhexyl) dithieno[3,2-b:20,30-d]silole)-2,6-diyl-alt-(4,7-bis(2-thienyl)-2,1,3-benzothiadiazole)-5,50-diyl] and PCDTBT:PC70BM mixes possess 4% power conversion efficiency, where PCDTBT is poly[N-90-hepta-decanyl-2,7-carbazole-alt-5,5-(40,70-di-2-thienyl-20,10,30-benzothiadiazole)] [54]. By utilizing proper solvents and mix concentrations they tried to overcome the inkjet processing issues such as line merging and nozzle clogging. On account of SiPCPDTBT:PC70BM mixes the concentration expected to at first be halved so as to print effectively, while on account of PCDTBT:PC70BM mixes the concentration continued as before, nevertheless the solvent should have been improved all together for effective printing.

6.3. Coffee Ring Effect

The challenge of coffee ring effect happened during inkjet printing of organic solar cells has been reported by several studies [6,13,20].

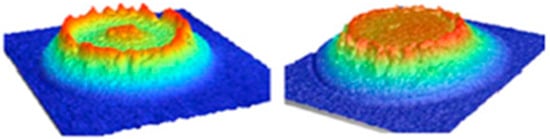

In inkjet printing technology, coffee ring effect is one of the fundamental difficulties, which is to achieve control over the resultant film homogeneity throughout the drying process. Solid spread in a drying drop will move to the edge of the drop and form a solid ring, which is named as coffee ring effect [87]. Due to induced capillary flow, an evaporating water droplet on a solid surface forms a ring likewise shape at the edge. It is reported that droplet size, solvent evaporation time and solute diffusion time are the reasons for coffee ring effect. It is also found that, if solvent evaporation time is more than the solute diffusion time, the formation of the coffee ring can be ceased. In another study, the typical prototype of deposition to a form of duct flow has been defined. Liquid evaporating from the periphery is filled up by liquid from the core, where the contact line of the drying drops is an evidence of this phenomenon [88]. In Figure 4. Coffee ring effect has been shown.

Figure 4.

Coffee ring effect. Reprinted with permission from [6].

In another effort, it was shown that if we can control the evaporation profile of drying drops and lines, where the solute is relocated to the rim, it is possible to control coffee ring effect [89]. It is possible to decrease coffee ring effect by expanding vapor pressure throughout the drying process. It has been demonstrated that an improved drying pattern can be attained by revealing the drying drop to an augmented solvent vapor [90]. It is assumed that solvent evaporation can be stimulated by the increment of substrate temperature, that decrease the diameter of the drop, the contact diameter at the substrate and the scattering of the drop as a result coffee ring effect [91,92].

Another solution of the coffee-ring effect is to print the film from a solvent blend, in which the fundamental solvent should have a high surface tension and a low boiling point from the co-solvent [93].

6.4. Limitation of Printability

The major physical points of confinement to printability of inkjet printing imposed by the properties of the fluid which is demonstrated by [9].The Ohnesorge number (Oh) is represented by the vertical axis, a dimensionless set has been found out by the surface tension, density and viscosity of the liquid, and diameter of the drop. For high estimations of Oh (greater than one), viscous forces stop the partition of a drop, while for low esteems (less than 0.1) the stream frames an extensive number of drops. The stream should also have sufficient kinetic energy to be satisfactorily ejected from the orifice. The stream should also have sufficient kinetic energy to be satisfactorily ejected from the orifice. If the speed of the drop is enough high then it might sprinkle, prompting poor control of the material position which leads to poor resolution. Long-chain polymers with low concentrations could forestall acceptable printing, whereas considerably larger concentrations of polymers having low molecular weight could be accepted [83].

6.5. Surface Texture/Feature Resolution

One of the challenges of inkjet printing is feature resolution. The resolution of a printed object is unmistakably constrained by the volume of the drop. Drop size is now estimated around 1 picoliter/diameter of ≈12 μm. It is improbable that substantially little drops will be accessible from inkjet printheads sooner rather than later due to the restricting physics of the drop production procedure [94]. Better surface texture could be accomplished through suitable designing and structuring of the substrate before printing [95,96]. The steadiness of a fluid dot is fundamentally depending on the conduct of the progressing and subsiding contact lines [97]. The investigation of fluid line soundness has been resolved for planar consistent surfaces, and it is uncertain whether they are appropriate to the stability of fluid dots restricted by surface energy hindrances [98]. New models should be formed for identifying the least feature size attainable by structuring. While modeling it ought to be considered the prior effect-driven phases of drop and substrate interaction. Such contemplations are especially vital, as the sprinkling change is a component of surface roughness [99,100].

6.6. Dot Spacing

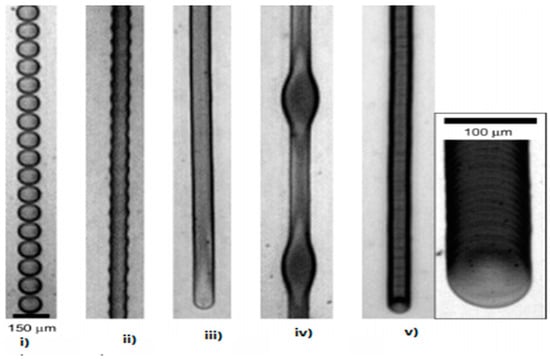

Dot spacing plays an important role to determine the quality of inkjet-printed films or lines. For very small dot spacing, bulging effects could be appeared because of excessively deposited material. This large dot spacing will form individual droplets, but only for optimized dot spacing, continuous and homogeneous lines will be formed [101].

Some examples of inkjet-printed line behaviors are shown below in the Figure 5.

Figure 5.

Samples of printed line characteristics: (i) single drops; (ii) scalloped; (iii) even; (iv) bulging; and (v) stacked coins. Reprinted with permission from [89].

There are many other parameters that have an influence on the film development, comprising a concentration of the solute, solvent and the temperature of the substrate. To reveal homogeneous features, all parameters need to be optimized for each polymer class [102].

7. Efficiency Improvement Strategies

Significant improvements of the organic solar cells in their power conversion efficiency can be controlled by their morphological properties. Polymer-fullerene blends morphology of OPVs could be considerably controlled over the selection of annealing conditions [11,103], polymer donor chemical properties, drying rate [104], and solvent [81,105].

7.1. Efficiency Improvement by Energy Conversion Layer

Bin Yeol et al., they used rubrene layer as an energy conversion layer (ECL) [106]. The proposed OPV was consisted of an Aluminum layer of 100 nm as an electrode, a poly (3,4-ethylenedioxythiophne)-poly (styrenenesulfonate) (PEDOT-PSS) layer with the thickness of 100 nm, P3HT:PCBM layer of 80 nm, a glass substrate, and Rubrene (5, 6, II, I 2-tetraphenyltetracene) layer to enhance OPV device performance. The layer was fashioned on the outer surface of the organic photovoltaic cell. To re-emits visible light and absorb Ultraviolet light, rubrene layer was used which acted as a spectral down-conversion layer. With respect to the thickness of rubrene layer, the Power Conversion Efficiency of the OPV cell has been investigated by the team and about 1.5 times increase in the efficiency was recorded, at what time the thickness of the rubrene layer 295 nm was compared to the OPV device without rubrene layer.

7.2. Efficiency Improvement by Vapor Annealing and Thermal Annealing

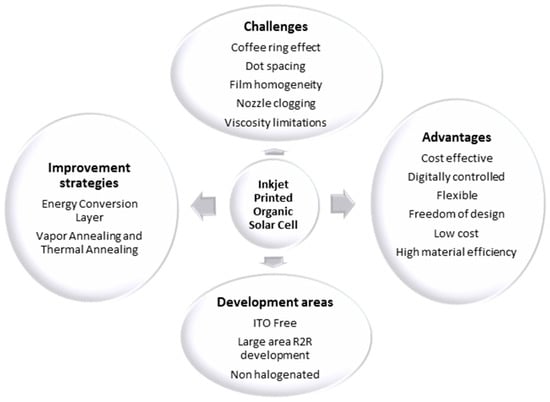

The efficiency of organic and inorganic solar cells can be improved notably by solvent vapor annealing and/or thermal annealing [103,107]. Following these annealing techniques Chen et al. observed a significant improvement in organic small molecule solar cells (OSMSCs), which consist of several layers, e.g., ITO/PEDOT:PSS/p-DTS(FBTTh2)2:PC71BM/PFN/Al, where p-DTS(FBTTh2)2 is 7,7-(4,4-bis(2-ethylhexyl)-4H-silolo[3,2-b:4,5-b]dithiophene-2,6-diyl)bis(6-fluoro-4-(5-hexyl-[2,2-bithiophen]-5-yl)benzo[c][1,2,5]thiadiazole), PC71BM is [6,6]-phenyl C71 butyric acid methyl-ester PFN is poly[(9, 9-bis(3-(N,N-dimethylamino)propyl)-2,7-fluorene)-alt-2,7-(9,9-dioctylfluorene)], Al is aluminum [103]. The overall device performance improved additionally while thermal annealing treatment is done after the solvent vapor annealing treatment. The optimized devices showed a PCE of 8.22% and the simultaneous improvement of the device parameters (with a VOC = 0.80 V, short-circuit current (JSC) = 15.2 mA cm−2, and fill factor (FF) = 67.7%). Solvent vapor annealing (SVA) can also enhance the efficiency, but, there will be a decrease in open-circuit voltage (VOC). The utilization of SVA will be able to guide to enhance the magnitude in hole mobility, that is very useful for charge collection as well as transport, but also liable for a decrease of VOC because of depleted steady carrier density. The lessening of VOC is possible to avoid successfully if the devices have been treated with a subsequent thermal annealing that was revealed to be a recommended change in charge dynamic. This is how it leads to a high overall device performance and increases VOC. As a result, the two-step annealing processes, Solvent Vapor Annealing (SVA), and thermal annealing are corresponding to each other. Those can likewise give reasonable courses to enhance the VOC, current density, fill factor and power conversion efficiency of organic small molecule solar cells. Schematic illustration of advantages, challenges, development areas and improvement strategies of the inkjet-printed OSC has been shown in Figure 6.

Figure 6.

Schematic illustration of advantages, challenges, development areas and improvement strategies of the inkjet-printed OSC [22,102,103,107].

8. Conclusions

This review has shown some examples of the possibilities of utilizing inkjet printing in large-scale production of OPV solar cells. Fabrication of OPV solar cell utilizing R2R systems unmistakably holds a guaranteeing future in the field of renewable energy. Using Inkjet printing technology for R2R production of OPV solar cell has become the researcher’s dream nowadays for its promise towards low-cost, fast and economical large-scale production. This report gives a synopsis of the potentials of inkjet printing technology as well as highlights the challenges, which have to be overcome. This review also shows some alternatives of ITO and halogen solvents for producing more cost effective and eco-friendly inkjet-printed OSCs. Furthermore, there have been suggested some strategies that might be used to improve the efficiency of OSC. Additionally, it discussed more on the major challenges of inkjet printing such as viscosity limitations, coffee ring effect, nozzle clogging and dot spacing. If a successful way of solving such problems can be achieved, then inkjet printing will be one of the most attractive alternatives for numerous designing and modeling applications.

Acknowledgments

The authors would like to thank Department of Manufacturing and Electrical Engineering of Georgia Southern University (GSU) for providing their constant support.

Author Contributions

K.K. and A.E.-S. contributed to conceiving the idea, provided theoretical guidance, edits and approved the final version. Other contributions include special conceptualization of the whole review work as well as discussion of the contents of the manuscript. S.S. reviewed the literature, conducted analysis on the topic, as well as designed and wrote the manuscript. Furthermore S.S. contributed to manuscript formation and development of the work. The authors contributed equally to this paper. All authors have read and approved the final manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bagher, A.M. Introduction to Organic Solar Cells. Sustain. Energy 2014, 2, 85–90. [Google Scholar]

- Haque, A.; Rahman, M.A.; Ahsan, Q. Building integrated photovoltaic system: Cost effectiveness. In Proceedings of the 2012 7th International Conference on Electrical and Computer Engineering, Dhaka, Bangladesh, 20–22 December 2012; pp. 904–907. [Google Scholar]

- Krebs, F.C. Fabrication and processing of polymer solar cells: A review of printing and coating techniques. Sol. Energy Mater. Sol. Cells 2009, 93, 394–412. [Google Scholar] [CrossRef]

- Søndergaard, R.R.; Hösel, M.; Krebs, F.C. Roll-to-Roll fabrication of large area functional organic materials. J. Polym. Sci. Part B Polym. Phys. 2013, 51, 16–34. [Google Scholar] [CrossRef]

- Cheyney, T. Innovalight Installs OTB Solar Silicon Ink Inkjet Printing Production Tool. 2009. Available online: https://www.pv-tech.org/news/innovalight_installs_otb_solar_silicon-ink_inkjet_printing_production_tool (accessed on 9 June 2009).

- Aernouts, T.; Aleksandrov, T.; Girotto, C.; Genoe, J.; Poortmans, J. Polymer based organic solar cells using ink-jet printed active layers. Appl. Phys. Lett. 2008, 92, 033306. [Google Scholar] [CrossRef]

- Basaran, O.A.; Gao, H.; Bhat, P.P. Nonstandard inkjets. Ann. Rev. Fluid Mech. 2013, 45, 85–113. [Google Scholar] [CrossRef]

- Daly, R.; Harrington, T.S.; Martin, G.D.; Hutchings, I.M. Inkjet printing for pharmaceutics—A review of research and manufacturing. Int. J. Pharm. 2015, 494, 554–567. [Google Scholar] [CrossRef] [PubMed]

- DeGans, B.J.; Duineveld, P.C.; Schubert, U.S. Inkjet printing of polymers: State of the art and future developments. Adv. Mater. 2004, 16, 203–213. [Google Scholar] [CrossRef]

- Derby, B. Inkjet printing of functional and structural materials: Fluid property requirements, feature stability, and resolution. Ann. Rev. Mater. Res. 2010, 40, 395–414. [Google Scholar] [CrossRef]

- Hoth, C.N.; Schilinsky, P.; Choulis, S.A.; Balasubramanian, S.; Brabec, C.J. Solution-processed organic photovoltaics. In Applications of Organic and Printed Electronics; Springer: Berlin, Germany, 2013; pp. 27–56. [Google Scholar]

- Singh, M.; Haverinen, H.M.; Dhagat, P.; Jabbour, G.E. Inkjet printing—Process and its applications. Adv. Mater. 2010, 22, 673–685. [Google Scholar] [CrossRef] [PubMed]

- Teichler, A.; Eckardt, R.; Hoeppener, S.; Friebe, C.; Perelaer, J.; Senes, A.; Morana, M.; Brabec, C.J.; Schubert, U.S. Combinatorial screening of polymer: Fullerene blends for organic solar cells by inkjet printing. Adv. Energy Mater. 2011, 1, 105–114. [Google Scholar] [CrossRef]

- Hoth, C.N.; Choulis, S.A.; Schilinsky, P.; Brabec, C.J. High photovoltaic performance of inkjet printed polymer: Fullerene blends. Adv. Mater. 2007, 19, 3973–3978. [Google Scholar] [CrossRef]

- Krebs, F.C.; Biancardo, M.; Winther-Jensen, B.; Spanggard, H.; Alstrup, J. Strategies for incorporation of polymer photovoltaics into garments and textiles. Sol. Energy Mater. Sol. Cell. 2006, 90, 1058–1067. [Google Scholar] [CrossRef]

- Shaheen, S.E.; Radspinner, R.; Peyghambarian, N.; Jabbour, G.E. Fabrication of bulk heterojunction plastic solar cells by screen printing. Appl. Phys. Lett. 2001, 79, 2996–2998. [Google Scholar] [CrossRef]

- Haque, A.; Rahman, M.A. Study of a solar PV-powered mini-grid pumped hydroelectric storage & its comparison with battery storage. In Proceedings of the 2012 7th International Conference on Electrical and Computer Engineering, Dhaka, Bangladesh, 20–22 December 2012; pp. 626–629. [Google Scholar]

- Krebs, F.C.; Alstrup, J.; Spanggaard, H.; Larsen, K.; Kold, E. Production of large-area polymer solar cells by industrial silk screen printing, lifetime considerations and lamination with polyethyleneterephthalate. Sol. Energy Mater. Sol. Cells 2004, 83, 293–300. [Google Scholar] [CrossRef]

- Mazzio, K.A.; Rice, A.H.; Durban, M.M.; Luscombe, C.K. Effect of regioregularity on charge transport and structural and excitonic coherence in poly (3-hexylthiophene) nanowires. J. Phys. Chem. C 2015, 119, 14911–14918. [Google Scholar] [CrossRef]

- Hoth, C.N.; Schilinsky, P.; Choulis, S.A.; Brabec, C.J. Printing highly efficient organic solar cells. Nano Lett. 2008, 8, 2806–2813. [Google Scholar] [CrossRef] [PubMed]

- Eggenhuisen, T.M.; Galagan, Y.; Biezemans, A.; Coenen, M.; Gilot, J.; Groen, P.; Andriessen, R. Organic photovoltaic cells with all inkjet printed layers and freedom of form. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; pp. 2842–2845. [Google Scholar]

- Eggenhuisen, T.M.; Galagan, Y.; Biezemans, A.F.K.V.; Slaats, T.M.W.L.; Voorthuijzen, W.P.; Kommeren, S.; Shanmugam, S.; Teunissen, J.P.; Hadipour, A.; Verhees, T.M.W.L.; et al. High efficiency, fully inkjet printed organic solar cells with freedom of design. J. Mater. Chem. A 2015, 3, 7255–7272. [Google Scholar] [CrossRef]

- Hoth, C.N.; Choulis, S.A.; Schilinsky, P.; Brabec, C.J. On the effect of poly (3-hexylthiophene) regioregularity on inkjet printed organic solar cells. J. Mater. Chem. 2009, 19, 5398–5404. [Google Scholar] [CrossRef]

- Krebs, F.C.; Tromholt, T.; Jørgensen, M. Upscaling of polymer solar cell fabrication using full roll-to-roll processing. Nanoscale 2010, 2, 873–886. [Google Scholar] [CrossRef] [PubMed]

- Espinosa, N.; García-Valverde, R.; Urbina, A.; Krebs, F.C. A life cycle analysis of polymer solar cell modules prepared using roll-to-roll methods under ambient conditions. Sol. Energy Mater. Sol. Cells 2011, 95, 1293–1302. [Google Scholar] [CrossRef]

- Hösel, M.; Søndergaard, R.R.; Angmo, D.; Krebs, F.C. Comparison of Fast Roll-to-Roll Flexographic, Inkjet, Flatbed, and Rotary Screen Printing of Metal Back Electrodes for Polymer Solar Cells. Adv. Eng. Mater. 2013, 15, 995–1001. [Google Scholar] [CrossRef]

- Krebs, F.C.; Jørgensen, M.; Norrman, K.; Hagemann, O.; Alstrup, J.; Nielsen, T.D.; Fyenbo, J.; Larsen, K.; Kristensen, J. A complete process for production of flexible large area polymer solar cells entirely using screen printing—First public demonstration. Sol. Energy Mater. Sol. Cells 2009, 93, 422–441. [Google Scholar] [CrossRef]

- Alamán, J.; Alicante, R.; Peña, J.I.; Sánchez-Somolinos, C. Inkjet Printing of Functional Materials for Optical and Photonic Applications. Materials 2016, 9, 910. [Google Scholar] [CrossRef] [PubMed]

- Perelaer, J.; Smith, P.J.; Mager, D.; Soltman, D.; Volkman, S.K.; Subramanian, V.; Korvink, J.G.; Schubert, U.S. Printed electronics: The challenges involved in printing devices, interconnects, and contacts based on inorganic materials. J. Mater. Chem. 2010, 20, 8446–8453. [Google Scholar] [CrossRef]

- Kang, W.; Kitamura, M.; Arakawa, Y. High performance inkjet-printed C 60 fullerene thin-film transistors: Toward a low-cost and reproducible solution process. Org. Electron. 2013, 14, 644–648. [Google Scholar] [CrossRef]

- Kang, B.J.; Lee, C.K.; Oh, J.H. All-inkjet-printed electrical components and circuit fabrication on a plastic substrate. Microelectron. Eng. 2012, 97, 251–254. [Google Scholar] [CrossRef]

- Smaal, W.; Kjellander, C.; Jeong, Y.; Tripathi, A.; van der Putten, B.; Facchetti, A.; Yan, H.; Quinn, J.; Anthony, J.; Myny, K.; et al. Complementary integrated circuits on plastic foil using inkjet printed n- and p-type organic semiconductors: Fabrication, characterization, and circuit analysis. Org. Electron. 2012, 13, 1686–1692. [Google Scholar] [CrossRef]

- Tobjörk, D.; Österbacka, R. Paper electronics. Adv. Mater. 2011, 23, 1935–1961. [Google Scholar] [CrossRef] [PubMed]

- Castrejon-Pita, J.R.; Baxter, W.R.S.; Morgan, J.; Temple, S.; Martin, G.D.; Hutchings, I.M. Future, opportunities and challenges of inkjet technologies. At. Sprays 2013, 23, 541–564. [Google Scholar] [CrossRef]

- Moonen, P.F.; Yakimets, I.; Huskens, J. Fabrication of transistors on flexible substrates: From mass-printing to high-resolution alternative lithography strategies. Adv. Mater. 2012, 24, 5526–5541. [Google Scholar] [CrossRef] [PubMed]

- Shi, C.W.P.; Shan, X.; Tarapata, G.; Jachowicz, R.; Weremczuk, J.; Hui, H.T. Fabrication of wireless sensors on flexible film using screen printing and via filling. Microsyst. Technol. 2011, 17, 661–667. [Google Scholar] [CrossRef]

- Kempa, H.; Hambsch, M.; Reuter, K.; Stanel, M.; Schmidt, G.C.; Meier, B.; Hubler, A.C. Complementary ring oscillator exclusively prepared by means of gravure and flexographic printing. IEEE Trans. Electron Devices 2011, 58, 2765–2769. [Google Scholar] [CrossRef]

- Sung, D.; de la Fuente Vornbrock, A.; Subramanian, V. Scaling and optimization of gravure-printed silver nanoparticle lines for printed electronics. IEEE Trans. Compon. Packag. Technol. 2010, 33, 105–114. [Google Scholar] [CrossRef]

- Deganello, D.; Cherry, J.A.; Gethin, D.T.; Claypole, T.C. Patterning of micro-scale conductive networks using reel-to-reel flexographic printing. Thin Solid Films 2010, 518, 6113–6116. [Google Scholar] [CrossRef]

- Eom, S.H.; Park, H.; Mujawar, S.H.; Yoon, S.C.; Kim, S.S.; Na, S.I.; Kang, S.J.; Khim, D.; Kim, D.Y.; Lee, S.H. High efficiency polymer solar cells via sequential inkjet-printing of PEDOT: PSS and P3HT: PCBM inks with additives. Org. Electron. 2010, 11, 1516–1522. [Google Scholar] [CrossRef]

- Lange, A.; Schindler, W.; Wegener, M.; Fostiropoulos, K.; Janietz, S. Inkjet printed solar cell active layers based on a novel, amorphous polymer. J. Nanosci. Nanotechnol. 2013, 13, 5209–5214. [Google Scholar] [CrossRef] [PubMed]

- Angmo, D.; Sweelssen, J.; Andriessen, R.; Galagan, Y.; Krebs, F.C. Inkjet printing of back electrodes for inverted polymer solar cells. Adv. Energy Mater. 2013, 3, 1230–1237. [Google Scholar] [CrossRef]

- Van Franeker, J.J.; Voorthuijzen, W.P.; Gorter, H.; Hendriks, K.H.; Janssen, R.A.; Hadipour, A.; Andriessen, R.; Galagan, Y. All-solution-processed organic solar cells with conventional architecture. Sol. Energy Mater. Sol. Cells 2013, 117, 267–272. [Google Scholar] [CrossRef]

- Vandevenne, G.; Marchal, W.; Verboven, I.; Drijkoningen, J.; D’Haen, J.; Van Bael, M.K.; Hardy, A.; Deferme, W. A study on the thermal sintering process of silver nanoparticle inkjet inks to achieve smooth and highly conducting silver layers. Phys. Status Solidi 2016, 213, 1403–1409. [Google Scholar] [CrossRef]

- Eom, S.H.; Senthilarasu, S.; Uthirakumar, P.; Yoon, S.C.; Lim, J.; Lee, C.; Lim, H.S.; Lee, J.; Lee, S.H. Polymer solar cells based on inkjet-printed PEDOT: PSS layer. Org. Electron. 2009, 10, 536–542. [Google Scholar] [CrossRef]

- Gotleyb, D.; Shikler, R. A new model of organic solar cells reveals open circuit conditions and size dependent power loss induced by the finite conductivity of a transparent contact. J. Appl. Phys. 2017, 121, 045502. [Google Scholar] [CrossRef]

- Huang, Y.C.; Hsu, F.H.; Cha, H.C.; Chuang, C.M.; Tsao, C.S.; Chen, C.Y. High-performance ITO-free spray-processed polymer solar cells with incorporating ink-jet printed grid. Org. Electron. 2013, 14, 2809–2817. [Google Scholar] [CrossRef]

- Eggenhuisen, T.M.; Galagan, Y.; Coenen, E.W.C.; Voorthuijzen, W.P.; Slaats, M.W.L.; Kommeren, S.A.; Shanmuganam, S.; Coenen, M.J.J.; Andriessen, R.; Groen, W.A. Digital fabrication of organic solar cells by Inkjet printing using non-halogenated solvents. Sol. Energy Mater. Sol. Cells 2015, 134, 364–372. [Google Scholar] [CrossRef]

- Lamont, C.A.; Eggenhuisen, T.M.; Coenen, M.J.; Slaats, T.W.; Andriessen, R.; Groen, P. Tuning the viscosity of halogen free bulk heterojunction inks for inkjet printed organic solar cells. Org. Electron. 2015, 17, 107–114. [Google Scholar] [CrossRef]

- Jung, S.; Sou, A.; Banger, K.; Ko, D.H.; Chow, P.C.; McNeill, C.R.; Sirringhaus, H. All-inkjet-printed, all-air-processed solar cells. Adv. Energy Mater. 2014, 4, 1–9. [Google Scholar] [CrossRef]

- Seo, K.W.; Lee, J.H.; Cho, N.G.; Kang, S.J.; Kim, H.K.; Na, S.I.; Koo, H.W.; Kim, T.W. Simple brush painted Ag nanowire network on graphene sheets for flexible organic solar cells. J. Vac. Sci. Technol. A Vac. Surfaces Films 2014, 32, 061201. [Google Scholar] [CrossRef]

- Hösel, M.; Krebs, F.C. Large-Scale Roll-to-Roll Fabrication of Organic Solar Cells for Energy Production; Department of Energy Conversion and Storage, Technical University of Denmark: Kongens Lyngby, Denmark, 2013. [Google Scholar]

- Lange, A.; Wegener, M.; Boeffel, C.; Fischer, B.; Wedel, A.; Neher, D. A new approach to the solvent system for inkjet-printed P3HT: PCBM solar cells and its use in devices with printed passive and active layers. Sol. Energy Mater. Sol. Cells 2010, 94, 1816–1821. [Google Scholar] [CrossRef]

- Hermerschmidt, F.; Papagiorgis, P.; Savva, A.; Christodoulou, C.; Itskos, G.; Choulis, S.A. Inkjet printing processing conditions for bulk-heterojunction solar cells using two high-performing conjugated polymer donors. Sol. Energy Mater. Sol. Cells 2014, 130, 474–480. [Google Scholar] [CrossRef]

- Hachmann, J.; Olivares-Amaya, R.; Atahan-Evrenk, S.; Amador-Bedolla, C.; Sánchez-Carrera, R.S.; Gold-Parker, A.; Vogt, L.; Brockway, A.M.; Aspuru-Guzik, A. The Harvard clean energy project: Large-scale computational screening and design of organic photovoltaics on the world community grid. J. Phys. Chem. Lett. 2011, 2, 2241–2251. [Google Scholar] [CrossRef]

- Perelaer, J.; Schubert, U.S. Polymer Science: A Comprehensive Reference; Elsevier: Amsterdam, The Netherlands, 2012; pp. 147–175. [Google Scholar]

- Singh, M.; Haverinen, H.M.; Yoshioka, Y.; Jabbour, G.E. Inkjet Technology for Digital Fabrication; Hutchings, I.M., Martin, G.D., Eds.; John Wiley & Sons Ltd.: London, UK, 2013. [Google Scholar]

- He, Z.; Zhong, C.; Su, S.; Xu, M.; Wu, H.; Cao, Y. Enhanced power-conversion efficiency in polymer solar cells using an inverted device structure. Nat. Photonics 2012, 6, 591–595. [Google Scholar] [CrossRef]

- Zhang, S.; Ye, L.; Zhang, H.; Hou, J. Green-solvent-processable organic solar cells. Mater. Today 2016, 19, 533–543. [Google Scholar] [CrossRef]

- Aïch, B.R.; Beaupré, S.; Leclerc, M.; Tao, Y. Highly efficient thieno [3, 4-c] pyrrole-4, 6-dione-based solar cells processed from non-chlorinated solvent. Org. Electr. 2014, 15, 543–548. [Google Scholar] [CrossRef]

- Chueh, C.C.; Yao, K.; Yip, H.L.; Chang, C.Y.; Xu, Y.X.; Chen, K.S.; Li, C.Z.; Liu, P.; Huang, F.; Chen, Y.; et al. Non-halogenated solvents for environmentally friendly processing of high-performance bulk-heterojunction polymer solar cells. Energy Environ. Sci. 2013, 6, 3241–3248. [Google Scholar] [CrossRef]

- Lange, A.; Schindler, W.; Wegener, M.; Fostiropoulos, K.; Janietz, S. Inkjet printed solar cell active layers prepared from chlorine-free solvent systems. Sol. Energy Mater. Sol. Cells 2013, 109, 104–110. [Google Scholar] [CrossRef]

- Ren, M.; Sweelssen, J.; Grossiord, N.; Gorter, H.; Eggenhuisen, T.M.; Andriessen, R. Inkjet printing technology for OPV applications. J. Image Sci. Technol. 2012, 56, 40501–40504. [Google Scholar] [CrossRef]

- Lim, G.H.; Zhuo, J.M.; Wong, L.Y.; Chua, S.J.; Chua, L.L.; Ho, P.K. A transition solvent strategy to print polymer: Fullerene films using halogen-free solvents for solar cell applications. Org. Electron. 2014, 15, 449–460. [Google Scholar] [CrossRef]

- Chen, Z.; Li, W.; Li, R.; Zhang, Y.; Xu, G.; Cheng, H. Fabrication of highly transparent and conductive indium–tin oxide thin films with a high figure of merit via solution processing. Langmuir 2013, 29, 13836–13842. [Google Scholar] [CrossRef] [PubMed]

- Sandström, A.; Dam, H.F.; Krebs, F.C.; Edman, L. Ambient fabrication of flexible and large-area organic light-emitting devices using slot-die coating. Nat. Commun. 2012, 3, 1002. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.; Yang, C.; Gong, X.; Lee, K.; Heeger, A.J. Thermally stable, efficient polymer solar cells with nanoscale control of the interpenetrating network morphology. Adv. Funct. Mater. 2005, 15, 1617–1622. [Google Scholar] [CrossRef]

- Cairns, D.R.; Witte, R.P.; Sparacin, D.K.; Sachsman, S.M.; Paine, D.C.; Crawford, G.P.; Newton, R.R. Strain-dependent electrical resistance of tin-doped indium oxide on polymer substrates. Appl. Phys. Lett. 2000, 76, 1425–1427. [Google Scholar] [CrossRef]

- Xia, Y.; Sun, K.; Ouyang, J. Solution-processed metallic conducting polymer films as transparent electrode of optoelectronic devices. Adv. Mater. 2012, 24, 2436–2440. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Cheun, H.; Choi, S.; Potscavage, W.J., Jr.; Fuentes-Hernandez, C.; Kippelen, B. Indium tin oxide-free and metal-free semitransparent organic solar cells. Appl. Phys. Lett. 2010, 97, 153304. [Google Scholar] [CrossRef]

- Stubhan, T.; Krantz, J.; Li, N.; Guo, F.; Litzov, I.; Steidl, M.; Richter, M.; Matt, G.J.; Brabec, C.J. High fill factor polymer solar cells comprising a transparent, low temperature solution processed doped metal oxide/metal nanowire composite electrode. Sol. Energy Mater. Sol. Cells 2012, 107, 248–251. [Google Scholar] [CrossRef]

- Lim, J.W.; Cho, D.Y.; Na, S.I.; Kim, H.K. Simple brush-painting of flexible and transparent Ag nanowire network electrodes as an alternative ITO anode for cost-efficient flexible organic solar cells. Sol. Energy Mater. Sol. Cells 2012, 107, 348–354. [Google Scholar] [CrossRef]

- Angmo, D.; Hösel, M.; Krebs, F.C. All solution processing of ITO-free organic solar cell modules directly on barrier foil. Sol. Energy Mater. Sol. Cells 2012, 107, 329–336. [Google Scholar] [CrossRef]

- Choi, Y.Y.; Kang, S.J.; Kim, H.K.; Choi, W.M.; Na, S.I. Multilayer graphene films as transparent electrodes for organic photovoltaic devices. Sol. Energy Mater. Sol. Cells 2012, 96, 281–285. [Google Scholar] [CrossRef]

- Hösel, M.; Søndergaard, R.R.; Jørgensen, M.; Krebs, F.C. Fast inline roll-to-roll printing for indium-tin-oxide-free polymer solar cells using automatic registration. Energy Technol. 2013, 1, 102–107. [Google Scholar] [CrossRef]

- Burgués-Ceballos, I.; Kehagias, C.M.; Sotomayor-Torres, N.; Campoy-Quiles, M.; Lacharmoise, P.D. Embedded inkjet printed silver grids for ITO-free organic solar cells with high fill factor. Sol. Energy Mater. Sol. Cells 2014, 127, 50–57. [Google Scholar] [CrossRef]

- Kaduwal, D.; Schleiermacher, H.F.; Schulz-Gericke, J.; Kroyer, T.; Zimmermann, B.; Würfel, U. ITO-free organic solar cells with roll-to-roll coated organic functional layers from non-halogenated solvents. Sol. Energy Mater. Sol. Cells 2014, 124, 92–97. [Google Scholar] [CrossRef]

- Kopola, P.; Aernouts, T.; Sliz, R.; Guillerez, S.; Ylikunnari, M.; Cheyns, D.; Välimäki, M.; Tuomikoski, M.; Hast, J.; Jabbour, G.; et al. Gravure printed flexible organic photovoltaic modules. Sol. Energy Mater. Sol. Cells 2011, 95, 1344–1347. [Google Scholar] [CrossRef]

- Abbel, R.; Teunissen, P.; Rubingh, E.; van Lammeren, T.; Cauchois, R.; Everaars, M.; Valeton, J.; van de Geijn, S.; Groen, P. Industrial-scale inkjet printed electronics manufacturing—Production up-scaling from concept tools to a roll-to-roll pilot line. Transl. Mater. Res. 2014, 1, 015002. [Google Scholar] [CrossRef] [PubMed]

- Croucher, M.D.; Hair, M.L. Design criteria and future directions in ink-jet ink technology. Ind. Eng. Chem. Res. 1989, 28, 1712–1718. [Google Scholar] [CrossRef]

- Rhaman, M.M.; Matin, M.A. Organic Solar Cells: Historical developments and challenges. In Proceedings of the 2015 International Conference on Advances in Electrical Engineering (ICAEE), Dhaka, Bangladesh, 17–19 December 2015; pp. 26–29. [Google Scholar]

- Nilsson, S.; Bernasik, A.; Budkowski, A.; Moons, E. Morphology and phase segregation of spin-casted films of polyfluorene/PCBM blends. Macromolecules 2007, 40, 8291–8301. [Google Scholar] [CrossRef]

- Hoath, S.D.; Harlen, O.G.; Hutchings, I.M. Jetting behavior of polymer solutions in drop-on-demand inkjet printing. J. Rheol. 2012, 56, 1109–1127. [Google Scholar] [CrossRef]

- Madec, M.B.; Smith, P.J.; Malandraki, A.; Wang, N.; Korvink, J.G.; Yeates, S.G. Enhanced reproducibility of inkjet printed organic thin film transistors based on solution processable polymer-small molecule blends. J. Mater. Chem. 2010, 20, 9155–9160. [Google Scholar] [CrossRef]

- Neophytou, M.; Cambarau, W.; Hermerschmidt, F.; Waldauf, C.; Christodoulou, C.; Pacios, R.; Choulis, S.A. Inkjet-printed polymer–fullerene blends for organic electronic applications. Microelectron. Eng. 2012, 95, 102–106. [Google Scholar] [CrossRef]

- Chang, J.F.; Sun, B.; Breiby, D.W.; Nielsen, M.M.; Sölling, T.I.; Giles, M.; McCulloch, I.; Sirringhaus, H. Enhanced mobility of poly (3-hexylthiophene) transistors by spin-coating from high-boiling-point solvents. Chem. Mater., 2004, 16, 4772–4776. [Google Scholar] [CrossRef]

- Kang, S.J.; Vandadi, V.; Felske, J.D.; Masoud, H. Alternative mechanism for coffee-ring deposition based on active role of free surface. Phys. Rev. E 2016, 94, 063104. [Google Scholar] [CrossRef] [PubMed]

- Deegan, R.D.; Bakajin, O.; Dupont, T.F.; Huber, G.; Nagel, S.R.; Witten, T.A. Capillary flow as the cause of ring stains from dried liquid drops. Nature 1997, 389, 827–829. [Google Scholar] [CrossRef]

- Soltman, D.; Subramanian, V. Inkjet-printed line morphologies and temperature control of the coffee ring effect. Langmuir 2008, 24, 2224–2231. [Google Scholar] [CrossRef] [PubMed]

- Kajiya, T.; Kobayashi, W.; Okuzono, T.; Doi, M. Controlling profiles of polymer dots by switching between evaporation and condensation. Langmuir 2010, 26, 10429–10432. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.X.; Fuh, J.Y.; Loh, H.T.; San Wong, Y.; Ng, Y.S.; Gray, J.J.; Chua, S.J. Characterization of drop-on-demand microdroplet printing. Int. J. Adv. Manuf. Technol. 2010, 48, 243–250. [Google Scholar] [CrossRef]

- Perelaer, J.; Smith, P.J.; Wijnen, M.M.; van den Bosch, E.; Eckardt, R.; Ketelaars, P.H.; Schubert, U.S. Droplet tailoring using evaporative inkjet printing. Macromol. Chem. Phys. 2009, 210, 387–393. [Google Scholar] [CrossRef]

- Tekin, E.; de Gans, B.J.; Schubert, U.S. Ink-jet printing of polymers-from single dots to thin film libraries. J. Mater. Chem. 2004, 14, 2627–2632. [Google Scholar] [CrossRef]

- Martin, G.D.; Hoath, S.D.; Hutchings, I.M. Inkjet printing-the physics of manipulating liquid jets and drops. J. Phys. Conf. Ser. 2008, 105, 012001. [Google Scholar] [CrossRef]

- Noh, Y.Y.; Zhao, N.; Caironi, M.; Sirringhaus, H. Downscaling of self-aligned, all-printed polymer thin-film transistors. Nat. Nanotechnol. 2007, 2, 784–789. [Google Scholar] [CrossRef] [PubMed]

- Hendriks, C.E.; Smith, P.J.; Perelaer, J.; Van den Berg, A.M.; Schubert, U.S. “Invisible” Silver Tracks Produced by Combining Hot-Embossing and Inkjet Printing. Adv. Funct. Mater. 2008, 18, 1031–1038. [Google Scholar] [CrossRef]

- Stringer, J.; Derby, B. Formation and stability of lines produced by inkjet printing. Langmuir 2010, 26, 10365–10372. [Google Scholar] [CrossRef] [PubMed]

- Duineveld, P.C. The stability of ink-jet printed lines of liquid with zero receding contact angle on a homogeneous substrate. J. Fluid Mech. 2003, 477, 175–200. [Google Scholar] [CrossRef]

- Stow, C.D.; Hadfield, M.G. An experimental investigation of fluid flow resulting from the impact of a water drop with an unyielding dry surface. Math. Phys. Eng. Sci. 1755, 373, 419–441. [Google Scholar] [CrossRef]

- Bhola, R.; Chandra, S. Parameters controlling solidification of molten wax droplets falling on a solid surface. J. Mater. Sci. 1999, 34, 4883–4894. [Google Scholar] [CrossRef]

- Oh, Y.; Kim, J.; Yoon, Y.J.; Kim, H.; Yoon, H.G.; Lee, S.N.; Kim, J. Inkjet printing of Al 2 O 3 dots, lines, and films: From uniform dots to uniform films. Curr. Appl. Phys. 2011, 11, S359–S363. [Google Scholar] [CrossRef]

- Teichler, A.; Perelaer, J.; Schubert, U.S. Inkjet printing of organic electronics-comparison of deposition techniques and state-of-the-art developments. J. Mater. Chem. C 2013, 1, 1910–1925. [Google Scholar] [CrossRef]

- Chen, H.; Miao, J.; Yan, J.; He, Z.; Wu, H. Improving Organic Solar Cells Efficiency Through a Two-Step Method Consisting of Solvent Vapor Annealing and Thermal Annealing. IEEE J. Sel. Top. Quantum Electron. 2016, 22, 66–72. [Google Scholar] [CrossRef]

- Pantho, M.J.H.; Junnat, N.A.; Alam, M.J. Design and analysis the characteristics of a cost-effective polymer based bulk heterojunction tandem solar cell. In Proceedings of the 8th International Conference on Electrical and Computer Engineering (ICECE), Dhaka, Bangladesh, 20–22 December 2014; pp. 516–519. [Google Scholar]

- Burgués-Ceballos, I.; Stella, M.; Lacharmoise, P.; Martínez-Ferrero, E. Towards industrialization of polymer solar cells: Material processing for upscaling. J. Mater. Chem. A 2014, 2, 17711–17722. [Google Scholar] [CrossRef]

- Yeo, D.B.; Heo, K.C.; Bae, G.; Chae, S.H.; Moon, C.B.; Kim, W.Y.; Jhun, C.G. High efficiency of organic photovoltaic device by the energy conversion layer. In Proceedings of the 2015 IEEE 42nd Photovoltaic Specialist Conference (PVSC), New Orleans, LA, USA, 14–19 June 2015; pp. 1–3. [Google Scholar]

- Bhaumik, A.; Haque, A.; Karnati, P.; Taufique, M.F.N.; Patel, R.; Ghosh, K. Copper oxide based nanostructures for improved solar cell efficiency. Thin Solid Films 2014, 572, 126–133. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).